lock DATSUN PICK-UP 1977 Manual Online

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 262 of 537

The

model

3N7l

B

automatic

trans

mission

is

a

fully

automatic

unit

con

sisting

primarily

of

3

element

hydrau

lic

torque

converter

and

two

planetary

gear

sets

Two

multiple

disc

clutches

a

multiple

disc

brake

a

band

brake

and

a

one

way

sprag

clutch

provide

the

friction

elements

required

to

obtain

the

desir

d

function

of

lhe

two

plane

tary

gear

sets

The

two

planetary

gear

sets

give

three

forward

ratios

and

one

reverse

Changing

of

the

gear

ratios

is

fully

automatic

in

relation

to

vehicle

speed

and

engine

torque

input

V

chide

speed

and

engine

manifold

vacuum

signals

are

constantly

fed

to

the

transmission

to

provide

the

proper

gear

ralio

for

maximum

efficiency

and

performance

at

all

throttle

openings

The

model

3N71

B

has

six

selector

1

9sition

LP

R

N

D

2

1

I

Park

position

positively

locks

the

output

shaft

to

the

transmission

case

by

means

of

a

locking

pawl

to

prevent

the

vehicle

from

rolling

in

either

direction

This

position

should

be

selected

whenever

the

driver

leaves

Ihe

vehicle

Thc

engine

may

be

slarted

in

Park

position

R

Reverse

range

enables

the

vehicle

to

be

operated

in

a

reverse

direction

N

Neutral

position

enables

the

engine

to

be

started

and

run

without

driving

the

vehicle

0

Drive

range

is

used

for

all

normal

driving

conditions

Drive

range

has

three

gear

ratios

from

the

starting

ratio

to

direct

drive

Automatic

Transmission

DESCRIPTION

2

2

range

provides

performance

for

driving

on

slippery

surfaces

2

range

can

also

be

used

for

engine

braking

2

range

can

be

selected

at

any

vehicle

speed

and

prevents

the

trans

mission

from

shifting

out

of

second

gear

I

I

range

can

be

selected

at

any

vehicle

speed

and

the

transmission

will

shift

to

second

gear

and

remain

in

second

until

v

hicle

speed

is

reduced

10

approximately

40

to

50

kmfh

25

to

30

MPH

I

range

position

prevents

the

transmission

from

shifting

out

of

low

gear

This

is

particularly

beneficial

for

maintaining

maximum

engin

braking

when

continuous

low

gear

operation

is

desirable

The

torque

converter

assembly

is

of

welded

construction

and

can

nOlbe

disassembled

for

service

FLUID

RECOMMENDATION

Use

automatic

transmission

fluid

having

DEXRON

identifications

only

in

the

3N71

B

automatic

transmis

sion

IDENTIFICATioN

NUMBER

Stamped

position

The

plate

is

attached

to

the

right

hand

side

of

transmission

case

as

shown

io

Figure

AT

I

AT

2

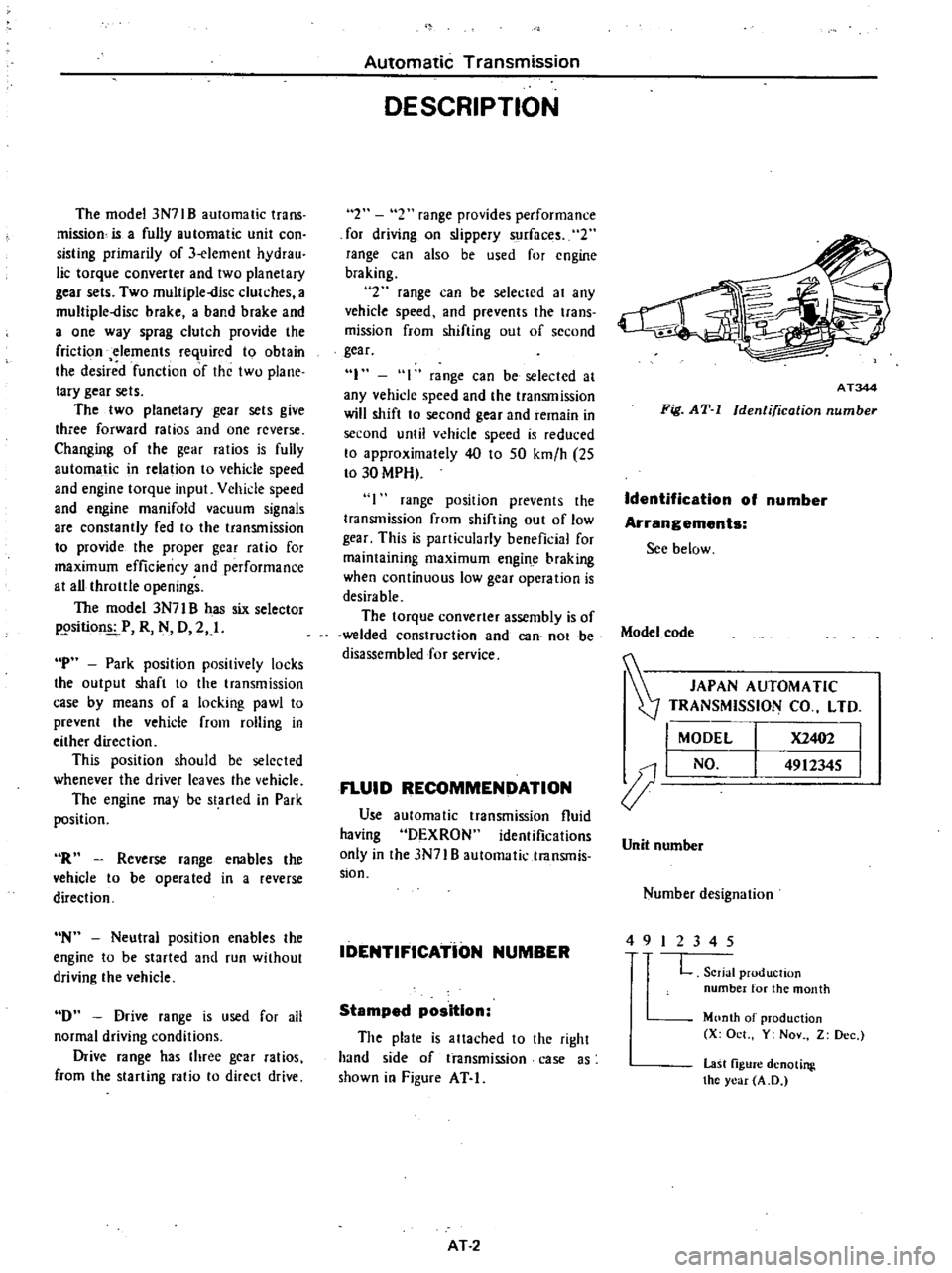

AT344

Fig

AT

I

Identification

number

Identification

of

number

Arrangements

See

below

Model

code

JAPAN

AUTOMATIC

0J

TRANSMISSION

CO

LTD

I

MODEL

X2402

I

J

I

NO

4912345

I

Unit

number

Number

designation

4

9

I

234

5

L

Serial

production

number

for

the

month

Month

of

production

X

Oct

Y

Nov

Z

Dec

last

figure

denoting

the

year

A

D

Page 265 of 537

plate

The

parking

rod

pin

operates

the

rod

at

p

range

and

operates

the

mechanical

lock

system

The

above

described

manual

shaft

is

further

equipped

with

an

inhibitor

switch

A

rotor

inside

the

inhibitor

switch

rotates

in

response

to

each

range

When

tne

range

is

selected

at

p

or

N

the

rotor

closes

the

starter

magnet

circuit

so

that

the

engine

can

be

started

When

the

range

is

selected

at

R

the

rolor

closes

the

back

up

lamp

circuit

and

the

back

up

lamp

lights

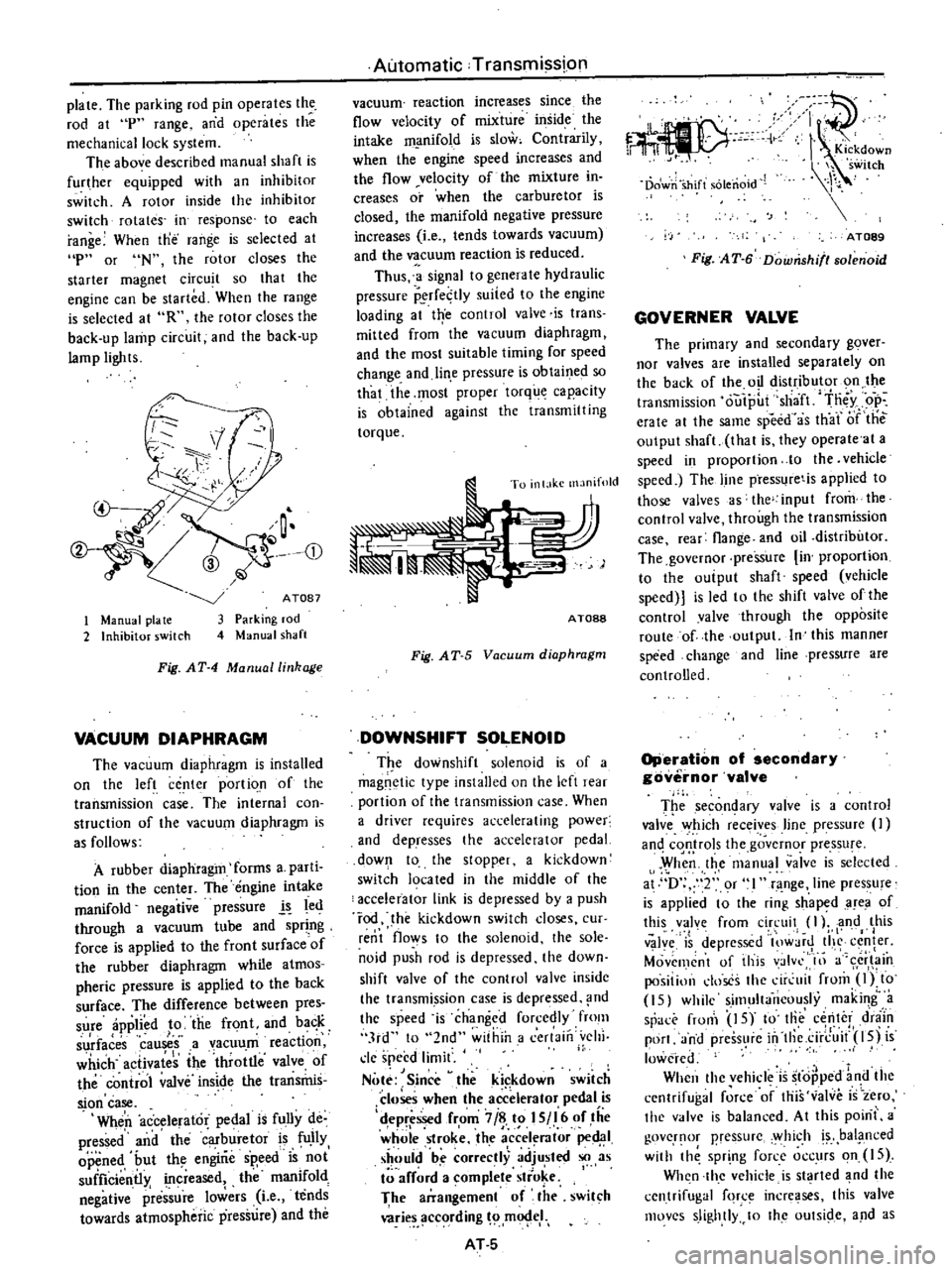

CD

1

Manual

pia

te

2

Inhibitor

switch

ATOB7

Parking

rod

Manual

shaft

Fig

AT

4

Manual

linkage

VACUUM

DIAPHRAGM

The

vacuum

diaphragm

is

installed

on

the

left

center

portio

n

of

the

transmission

case

The

internal

con

struction

of

the

vacuum

diaphragm

is

as

follows

A

rubber

diaphragm

forms

a

parti

tion

in

the

center

The

engine

intake

manifold

negative

pressure

l

led

through

a

vacuum

tube

and

spring

force

is

applied

to

the

front

surfaceof

the

rubber

diaphragm

while

atmos

pheric

pressure

is

applied

to

the

back

surface

The

difference

between

pres

sure

applied

to

the

front

and

ba

K

I

surfaces

causes

a

vacuum

reactIOn

which

activates

the

throttle

valve

of

the

control

valve

inside

the

transrhis

sion

case

Wheri

accelerator

pedal

is

fully

de

pressed

and

the

buretor

is

fU

IIy

opened

but

th

engirie

sp

eed

is

not

suificientl

increased

the

manifold

negative

plre

sure

lowers

Le

tends

towards

atmospheric

pressure

and

the

Automatic

Transmission

vacuum

reaction

increases

since

the

flow

velocity

of

mixture

inside

the

intake

m

mifold

is

slow

Contrarily

when

the

engine

speed

increases

and

the

flow

velocity

of

the

mixture

in

creases

or

when

the

carburetor

is

closed

the

manifold

negative

pressure

increases

Le

tends

towards

vacuum

and

the

vacuum

reaction

is

reduced

Thus

a

signal

to

genera

Ie

hydraulic

pressure

P

rfe

tly

suited

to

the

engine

loading

at

trye

control

valve

is

trans

mitted

from

the

vacuum

diaphragm

and

the

most

suitable

timing

for

speed

change

and

lin

e

pressure

is

obtaine

so

that

the

most

proper

torque

capacity

is

obtained

against

the

transmitting

torque

To

inl

lkc

manifold

AT088

Fig

AT

5

Vacuum

diaphragm

DOWNSHIFT

SOLENOID

T

e

downshift

solenoid

is

of

a

magnetic

type

installed

on

the

left

re

r

portion

of

the

transmission

case

When

a

driver

requires

accelerating

power

and

dePresses

the

accelerator

pedal

down

to

the

stopper

a

kickdown

switch

19ca

ted

in

the

middle

of

the

accelerator

link

is

depressed

by

a

push

rod

he

kickdown

switch

doses

cur

rent

flows

to

the

solenoid

the

sole

noid

push

rod

is

depressed

the

down

shift

valve

of

the

control

valvc

insidc

the

transmi

ssion

case

is

depressed

nd

the

speed

is

changed

forcedly

fmm

3rd

to

2nd

within

a

cerlaill

vehi

cle

speed

limit

Note

Since

theki

kdown

switch

closes

when

the

accelerator

pedal

is

d

epr

ssed

from

7

i

t

I

S

I

6

of

tiie

whole

stroke

the

a

ccel

rator

ped

1

should

be

correctly

adjusted

so

as

arf

rd

a

omplete

stro

e

I

The

arrangement

of

the

swit

h

wries

ccording

m

eI

AT

S

c

C

r

11

I

Kickdown

h

switch

Dowri

shift

solenoid

AT089

Fig

AT

6

Downshifl80lenoid

GOVERNER

VALVE

The

primary

and

secondary

gover

nor

valves

are

installed

separately

on

the

back

of

the

oil

distributor

on

the

transmission

outp

t

sha

ft

tn

y

op

erate

al

the

same

speed

as

th

ar

iJf

tile

output

shaft

thai

is

they

operate

at

a

speed

in

proportion

10

the

vehicle

speed

The

line

press

retis

applied

to

those

valves

s

the

input

from

the

control

valve

through

the

transmission

case

rear

flange

and

oil

distributor

The

governor

pressure

in

proportion

to

the

ouiput

shaft

speed

vehicle

speed

is

led

to

the

shift

valve

ofthe

control

valve

through

the

opposite

route

of

the

output

In

this

manner

speed

change

and

line

pressure

are

controlled

Operation

of

secondary

governor

valve

T

e

secon

ary

valve

is

a

contro

valve

Y

hich

receives

line

pressure

an

cqQ

rols

the

governor

pressu

e

When

the

manual

valve

is

selected

at

D

2

or

l

range

line

pressure

is

applied

t

the

ri

g

sh

aped

area

of

this

valve

from

circuit

I

l

and

this

I

v

Jy

is

depressed

lOW

jr

tI

c

fer

Movemcnt

of

this

valvl

III

a

cr

in

positillll

doses

the

dr

uit

from

Olto

15

while

simultaneously

making

a

sr

rronl

IS

to

Iii

center

d

niin

port

and

press

re

in

tllc

ci

rJ

it

l5j

is

lowered

When

thc

vehicle

is

stopped

1

d

the

cenlrifugal

force

of

this

valve

is

zero

the

v

lve

is

balanced

At

this

poini

a

govcr

lOr

pressurc

y

hich

bal

i1

nced

with

th

spr

ng

force

occurs

on

IS

Wh

n

thc

vehicle

is

st

rted

nd

the

centrifugal

fqr

incre

ses

this

valve

movcs

slightly

10

Ihc

oUlSide

and

as

Page 267 of 537

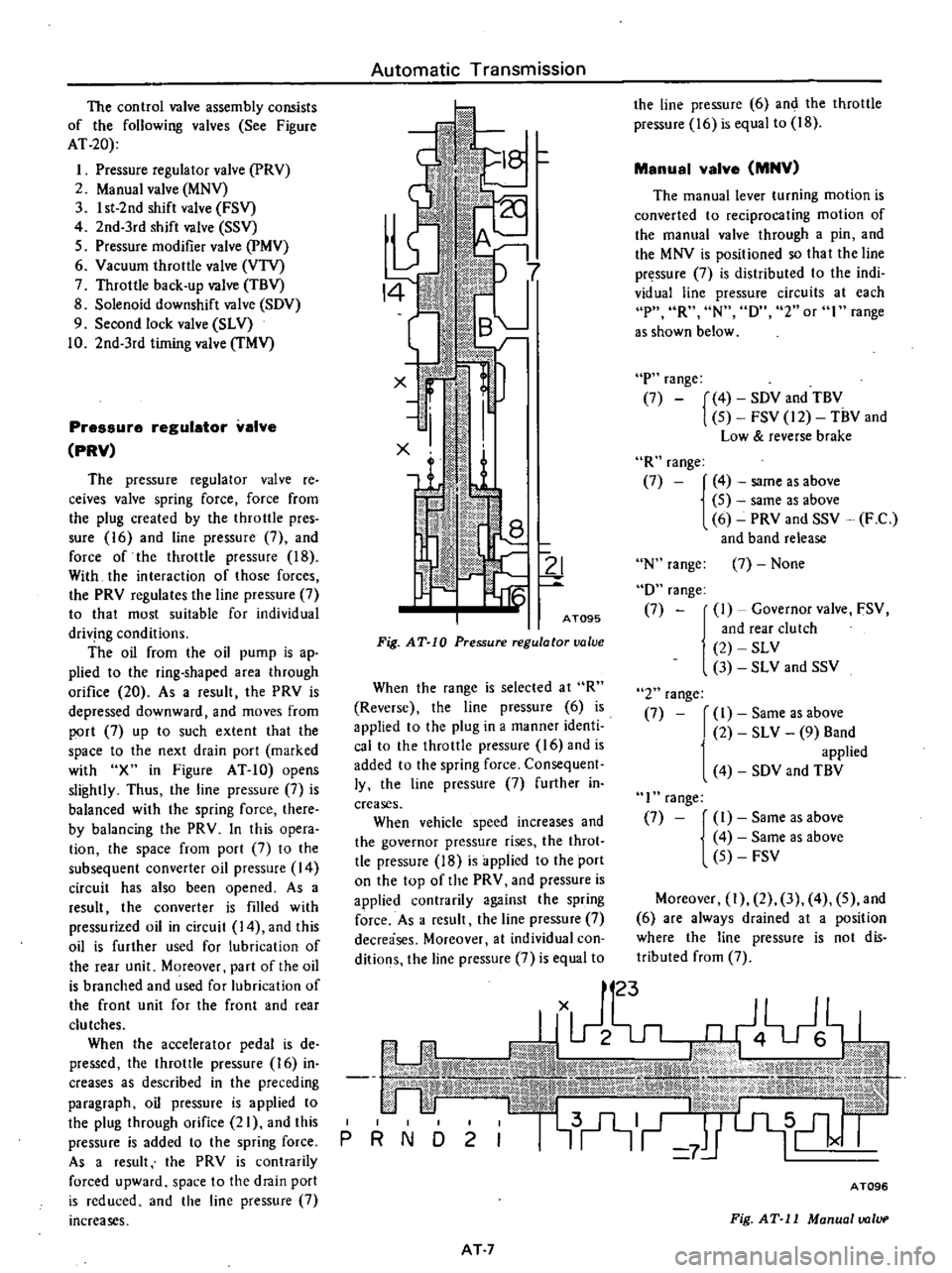

The

control

valve

assembly

consists

of

the

following

valves

See

Figure

AT

20

I

Pressure

regulator

valve

PRV

2

Manual

valve

MNV

3

I

st

2nd

shift

valve

FSV

4

2nd

3rd

shift

valve

SSV

5

Pressure

modifier

valve

PMV

6

Vacuum

throttle

valve

VTV

7

Throttle

back

up

valve

TBV

8

Solenoid

downshift

valve

SDV

9

Second

lock

valve

SL

V

10

2nd

3rd

timing

valve

TMV

Pressure

regulator

valve

PRV

The

pressure

regulator

valve

re

ceives

valve

spring

force

force

from

the

plug

created

by

the

throttle

pres

sure

16

and

line

pressure

7

and

force

of

the

throttle

pressure

18

With

the

interaction

of

those

forces

the

PRY

regulates

the

line

pressure

7

to

that

most

suitable

for

individual

driving

conditions

The

oil

from

the

oil

pump

is

ap

plied

to

the

ring

shaped

area

through

orifice

20

As

a

result

the

PRV

is

depressed

downward

and

moves

from

port

7

up

to

such

extent

that

the

space

to

the

next

drain

port

marked

with

X

in

Figure

AT

10

opens

slightly

Thus

the

line

pressure

7

is

balanced

with

the

spring

force

there

by

balancing

the

PRV

In

this

opera

tion

Ihe

space

from

port

7

to

the

subsequent

converter

oil

pressure

14

circuit

has

also

been

opened

As

a

result

the

converter

is

filled

with

pressurized

oil

in

circuit

14

and

this

oil

is

further

used

for

lubrication

of

the

rear

unit

Moreover

part

of

the

oil

is

branched

and

used

for

lubrication

of

the

front

unit

for

the

front

and

rear

clutches

When

Ihe

accelerator

pedal

is

de

presscd

the

throttle

pressure

16

in

creases

as

described

in

the

preceding

paragraph

oil

pressure

is

applied

to

the

plug

through

orifice

21

and

this

pressure

is

added

to

the

spring

force

As

a

result

the

PRV

is

contrarily

forced

upward

space

to

the

drain

port

is

reduced

and

Ihe

line

pressure

7

increases

Automatic

Transmission

11

AT095

Fig

AT

10

Pressure

regulator

ualue

When

the

range

is

selected

at

R

Reverse

the

line

pressure

6

is

applied

10

the

plug

in

a

manner

identi

caito

the

throttle

pressure

16

and

is

added

10

the

spring

force

Consequent

ly

the

line

pressure

7

further

in

creases

When

vehicle

speed

increases

and

the

governor

pressure

rises

the

theot

tle

pressure

18

is

applied

to

the

port

on

the

top

of

the

PRV

and

pressure

is

applied

contrarily

against

the

spring

force

As

a

result

the

line

pressure

7

decreases

Moreover

at

individual

con

ditions

the

line

pressure

7

is

equal

to

the

line

pressure

6

and

the

throttle

pressure

16

is

equal

to

18

Manual

valve

MNV

The

manual

lever

turning

motion

is

converted

to

reciprocating

motion

of

the

manual

valve

through

a

pin

and

the

MNV

is

positioned

so

that

the

line

pressure

7

is

distributed

to

the

indi

vidual

line

pressure

circuits

at

each

P

R

N

D

2

or

I

range

as

shown

below

P

range

7

4

SDV

and

TBV

5

FSV

12

TBV

and

Low

reverse

brake

R

range

7

4

same

as

above

5

same

as

above

6

PRY

and

SSV

F

C

and

band

release

N

range

D

range

7

7

None

I

Governor

valve

FSV

and

rear

clutch

2

SLY

3

SL

V

and

SSV

2

range

7

I

Same

as

above

2

SL

V

9

Band

applied

4

SDV

and

TBV

I

range

7

I

Same

as

above

4

Same

as

above

5

FSV

Moreover

1

2

3

4

5

and

6

are

always

drained

at

a

position

where

the

line

pressure

is

not

dis

tributed

from

7

u

JJX

g4Vhl

dIillillt

1

dlMIi

W

ld

IiIb

It

i

B

J

jd

l

tJj

fitMi

td

j

L@

x

x

j

j

P

R

N

17

l

AT7

AT096

Fig

AT

11

Manual

ualvp

Page 270 of 537

space

from

the

throttle

pressure

16

to

the

drain

17

decreases

and

the

space

from

the

line

pressure

7

to

Ihe

throttle

pressure

16

increases

Consequently

the

throttle

pressure

16

increases

and

the

valve

is

bal

anced

Contrarily

when

the

engine

torque

lowers

and

the

negative

pr

sure

in

the

intake

line

lowers

tending

toward

vacuum

the

force

of

the

rod

depressing

the

valve

decreases

and

the

throttle

pressure

16

also

decreases

When

pressure

regulated

by

the

throt

tle

back

p

valve

described

in

the

subsequent

paragraph

is

led

to

circuit

17

a

high

pressure

is

applied

through

the

space

from

the

circuit

17

to

the

throttle

pressure

16

Consequently

the

VTV

is

unbalanced

the

throttle

pressure

16

becomes

equal

to

the

back

up

pressure

17

and

the

valve

is

locked

upward

I

16

III

AT100

Fig

AT

15

Vacuum

throttle

valIN

Throttle

back

up

valve

TBY

Usually

this

valve

is

depressed

downward

by

the

spring

force

and

circuit

17

is

drained

upward

As

soon

as

the

lever

is

shifted

either

to

2

or

I

range

line

pressure

is

led

from

circuit

4

the

line

pressure

is

applied

to

the

area

difference

of

the

valve

the

valve

is

forced

upward

the

space

from

circuit

4

to

circuit

17

is

closed

and

with

the

space

from

circuit

Automatic

Transmission

17

to

Ihe

upper

drain

about

to

open

the

back

up

pressure

17

which

is

lower

than

the

line

pressure

4

by

the

pressure

loss

due

to

the

space

from

circuit

4

to

circuit

17

is

balanced

with

the

spring

force

Further

when

gear

is

shifted

from

2nd

to

Low

at

the

range

I

line

pressure

is

led

from

circuit

12

and

the

line

pressure

is

applied

pward

to

the

bottom

of

the

valve

through

the

valve

hole

Consequently

the

valve

is

forced

upward

and

locked

As

a

result

the

space

from

the

line

pressure

4

to

the

back

up

pressure

17

is

closed

completely

and

the

back

up

pressure

17

is

drained

upward

AT101

Fig

AT

16

Throttle

back

up

lJ

Jlve

Solenoid

downshift

valve

SDY

This

valve

is

a

transfer

valve

which

leads

the

line

pressure

7

to

13

and

transmits

the

same

to

the

FSV

and

SSV

when

a

kickdown

signal

is

re

ceived

from

the

downshift

solenoid

Usually

the

solenoid

push

rod

and

valve

are

locked

upward

by

the

spring

in

the

lower

end

and

the

circuit

from

line

pressure

4

to

line

pressure

13

is

opened

When

kickdown

is

performed

the

push

rod

operates

Ihe

valve

is

de

pressed

downward

and

the

circuit

from

line

pressure

7

to

line

pressure

13

opens

Line

pressure

13

opposes

the

governor

pressure

15

at

Ihe

SSV

and

FSV

thus

accomplishing

the

downshift

operation

AT

10

r

AT102

Fig

AT

17

Solenoid

dow

hift

valve

Second

lock

valve

SLY

This

valve

is

a

transfer

valve

which

assists

the

shift

valve

in

determining

the

fixed

2nd

speed

at

the

2

range

In

the

D

range

the

sum

of

the

spring

force

and

line

pressure

3

APplied

upward

xce

ds

the

linepres

sure

2

which

is

applied

to

the

valve

area

difference

as

a

downward

force

As

a

result

the

valve

is

locked

upward

and

the

circuit

from

line

pressure

8

to

line

pressure

9

is

opened

Consequently

the

FSV

becomes

the

2nd

speed

condition

and

line

pressure

is

led

to

the

band

servo

engaging

circuit

9

only

when

line

pressure

1

is

released

to

line

pressure

8

In

the

2

range

the

upward

force

is

retained

only

on

the

spring

and

the

downward

line

pressure

2

exceeds

the

upward

force

As

a

result

Ihe

valve

is

locked

downward

line

pressure

2

is

released

to

9

regardless

of

the

operating

condition

of

the

FSV

and

the

band

servo

is

engaged

J

2

8

ATl03

3

Fig

AT

18

Second

lock

lJ

Jlve

Page 271 of 537

2nd

3rd

timln

valve

TMV

This

valve

is

a

transfer

valve

which

switches

the

by

pass

circuit

of

the

orifice

22

in

the

front

clutch

pres

sure

circuit

II

in

response

to

vehicle

speed

and

throttle

condition

A

force

created

when

the

governor

pressure

IS

is

applied

to

the

bottom

of

the

TMV

constitutes

the

upward

force

and

a

force

created

when

the

spring

force

and

the

throttle

pressure

are

applied

to

the

top

of

the

TMV

consti

tutes

the

downward

force

When

the

throttle

pressure

16

is

lower

than

the

governor

pressure

IS

Automatic

Transmission

the

upward

force

exceeds

the

down

ward

force

the

valve

is

locked

upward

and

passage

from

circuit

l0

2nd

from

the

Top

to

circuit

II

is

closed

Consequently

the

line

pressure

10

is

led

to

the

front

clutch

circuit

II

through

the

orifice

22

and

the

oil

pressure

is

thus

transmitted

slowly

However

under

normal

shifting

the

throttle

pressure

16

has

a

pressure

exceeding

a

certain

level

and

the

downward

force

e

xceeds

the

upward

force

As

a

result

the

valve

is

locked

downward

the

passage

from

circuit

10

to

circuit

II

is

opened

and

the

orifice

22

is

bypassed

ATll

AT104

Fig

JlT

19

2nd

3rd

timing

valve

Page 272 of 537

Automatic

Transmission

d

n

ern

I

lLU

I

J

A1

094

1

Pressure

regulating

valve

PRV

2

Manual

val

MNV

31st

2nd

shift

val

fSV

4

2nd

3rd

shift

val

SSV

5

Pressure

modifier

valve

PMV

6

Vacuum

throttle

valve

VfV

7

Throttle

back

up

valve

TBV

8

Solenoid

down

shift

valve

SDV

9

Second

lock

valve

SL

V

10

2

3

timing

val

TMV

Fig

AT

20

Controloolve

AT

12

Page 274 of 537

Automatic

Transmission

P

RANGE

PARK

The

operation

of

clutches

and

band

are

functionally

the

same

as

in

Neu

tral

In

parking

however

when

the

parking

pawl

meshes

in

a

gear

which

is

splined

to

the

output

shaft

the

output

shaft

is

mechanically

locked

from

rotating

Free

Lock

AT086

Fig

AT

24

Parlling

mechanum

The

oil

discharged

from

the

oil

Low

Band

ervo

On

pump

is

fed

to

each

part

in

a

similar

Gw

Clutch

Parkin

Range

atia

Il

Yer5e

r

pawl

manner

to

that

of

the

N

range

The

Fron

Rear

brakt

Operation

Release

clutch

oil

having

the

line

pressure

7

which

Park

on

has

been

introduced

into

the

manual

valve

Il

reaches

the

I

st

2nd

shift

Re

er

2

132

on

on

on

valve

CID

through

the

line

pressure

circuit

5

As

the

1st

2nd

shift

Neutral

valve

s

force

to

th

right

hand

ide

PI

L

w

2

3

on

by

the

spring

the

line

pressure

5

and

Drive

P2

Second

14S3

on

on

12

actuates

the

low

and

reverse

brake

through

the

groove

Also

Ihe

03

Top

1

000

on

on

parking

pawl

engages

with

the

outer

2

Second

1

458

teeth

of

the

oil

distributor

by

means

of

the

manual

lever

mechanically

12

Second

1458

on

on

locking

the

output

shaft

II

Low

2

453

on

AT

14

Page 275 of 537

P

range

Park

Automatic

Transmission

L

A

r

k

8r

k

I

f

I

CID

VK

TIlro

V

lv

I

I

2

ID

Mocl

1

5

FrOl

ll

Clutch

Au

rr

tth

1

1

1

r

I

r

D

II

R

tOl

V

II

L

I

Torqu

Con

ter

0

I

ump

4

011

Coo

AM

Lubr

tlo

D

i

t

V

l

Front

o

v

n

Llrll

rt

Not

rk

t

to

Sol

n

BI

Cow

1ft

v

t

1

j

I

1111

II

I

I

il

1111

III

r

Orlflc

K

v

Throttl

Dr

ln

v

II

11

5

@

2nd

3

d

Timing

I

V

l

w

J

I

JQ

l

r

R

II

I

IKOnd

Lock

V

l

I

3J

I

t

rJ

I

q

I

rr

u

J2

3

n

l

l

J

r

A

J1

J

I

I

V

nu

l

V

l

P

21

Or

ln

LlMl

pr

r

100

10r

1

I

rlmarv

OoverrwJf

VIIfve

BIeOM

IV

OOll

nor

Y

M

Oo

or

It

Torqu

conv

ner

Throttl

Fig

A

T

25

Oil

pressu

circuit

diagram

P

range

Parh

AT

15

Page 276 of 537

R

RANGE

REVERSE

In

R

range

the

front

clutch

and

the

low

and

reverse

brake

are

applied

The

power

flow

is

through

the

input

shaft

front

clutch

and

connecting

shell

to

the

sun

gear

Clockwise

rota

tion

of

the

sun

gear

causes

counter

clockwise

rotation

of

the

rear

planeta

ry

gears

With

the

connecting

drum

held

stationary

by

the

low

and

reverse

brake

the

rear

planetary

gears

rotate

the

rear

internal

gear

and

drive

the

flange

counterclockwise

The

rear

drive

flange

splined

to

the

output

shaft

rotates

the

output

shaft

counterclock

wise

at

a

reduced

speed

with

an

increase

in

torque

for

reverse

gear

Automatic

Transmission

R

Fig

AT

26

Power

tranamis

ion

during

R

range

m

i

1

A

TOBS

Fig

A

T

21

Optrationof

each

mechanism

during

R

range

When

the

manual

valve

V

is

posi

Clutch

Low

Band

servo

One

tioned

at

R

range

the

oil

having

the

Gear

Partina

Ranae

re

ne

way

line

pressure

7

is

directed

to

line

ralio

Front

Rear

brake

Openlion

Relulie

clutch

plwl

pressure

circuits

5

and

6

The

pressure

in

the

circuit

5

actuates

the

Park

on

on

low

and

reverse

brake

after

being

Ruene

2

182

on

on

on

introduced

into

line

pressure

circuit

Neutral

12

through

the

I

st

2nd

shift

valve

ID

The

pressure

in

the

circuit

op

DI

Low

2

458

on

on

erates

the

release

side

of

the

band

servo

and

the

front

c1u

tch

after

being

Driowe

D2

Second

1

458

on

on

led

to

line

pressure

circuit

0

D3

Top

1

000

on

on

on

through

the

2nd

3rd

shift

valve

@

2

Second

1

458

The

throttle

pressure

I

6

and

the

line

on

on

pressure

6

which

vary

with

the

12

Second

S8

on

on

degree

of

accelerator

pedal

depression

II

Low

2

458

both

act

the

pressure

regulator

on

on

on

valve

CD

and

press

against

its

valve

CD

increasing

line

pressure

7

In

Rn

range

the

governor

pressure

is

absent

making

all

such

valves

as

the

1st

2nd

shift

valve

ID

lnd

3rd

shift

valvc

@

and

pressurc

modifier

valve

inoperative

AT16

Page 280 of 537

Automatic

Transmission

R

RANGE

REVERSE

R

In

R

range

the

front

dutch

and

the

low

and

reverse

brake

are

applied

The

power

flow

is

through

the

input

shaft

front

clutch

and

connecting

shell

to

the

sun

gear

Clockwise

rota

tion

of

the

sun

gear

causes

counter

clockwise

rotation

of

the

rear

planeta

ry

gears

With

the

connecting

drum

held

Slationary

by

the

low

and

reverse

brake

the

rear

planetary

gears

rotate

the

rear

internal

gear

and

drive

the

flange

counterclockwise

The

rear

drive

flange

splined

to

the

output

shaft

rotates

the

output

shaft

counterclock

wise

at

a

reduced

speed

with

an

increase

in

torque

for

reverse

gear

f

When

Ihe

manual

valve

CV

is

posi

tioned

at

R

range

Ihe

oil

having

Ihe

line

pressure

7

is

directed

to

line

pressure

circuits

5

and

6

The

pressure

in

the

circuit

5

actuates

the

low

and

reverse

brake

after

being

introduced

into

line

pressure

circuit

12

through

the

I

st

2nd

shift

valve

@

The

pressure

in

Ihe

circuit

op

erates

the

release

side

of

the

band

servo

and

the

front

clutch

after

being

led

to

line

pressure

circuit

10

through

the

2nd

3rd

shift

valve

@

The

throtlle

pressure

16

and

the

line

pressure

6

which

vary

with

the

degree

of

acceJerator

pedal

depression

both

act

on

the

prcssure

regulator

valve

CD

and

press

against

its

valve

CD

increasing

line

pressure

7

In

R

range

the

governor

pressure

is

absent

making

all

slldl

valves

as

the

J

SI

2nd

shift

valve

@

2nd

3rd

shift

valvc

@

and

pressure

modifier

valve

j

inoperative

C

Fig

AT

26

Power

transmi

ion

during

R

range

A

TOS5

Fig

AT

27

Operation

attach

mechanism

during

R

range

G

Clutch

Low

A

Band

servo

One

Parkin

Ran

no

wa

plwl

ratio

Front

Rear

brake

Operllioo

Rdr

ue

clutch

k

on

on

Revctte

1

181

on

on

on

Neutnl

DI

Low

1

418

on

on

Driw

D2

Second

1

458

on

on

DJ

Top

1

000

on

on

on

on

2

Second

1

458

on

on

12

Second

1

458

on

on

I

II

Low

2

458

on

on

AT

16