lock DATSUN PICK-UP 1977 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 67 of 537

5

Install

rocker

arms

by

pressing

valve

springs

down

with

a

screwdriver

6

Install

valve

rocker

springs

7

After

assembling

cylinder

head

turn

camshaft

until

No

I

piston

is

at

T

D

C

on

its

compression

stroke

EM1S5

Fig

EM

83

A

embling

cylinder

head

PISTON

AND

CONNECTINGROD

1

Assemble

pistons

piston

pins

and

connecting

rods

on

the

de

ignated

cylinder

STl3030001

EM156

Fig

EM

84

Installing

piston

pin

EM157

Fig

EM

85

Assembling

piston

and

connecting

rod

Notes

a

Piston

is

pressed

into

connecting

rod

with

fitting

force

of

0

5

to

5

tons

aid

of

Piston

Pin

Press

Stand

STl303000

I

is

necessary

When

pressing

piston

pin

into

con

necting

rod

apply

engine

oil

to

pin

and

small

end

of

connecting

rod

Engine

Mechanical

b

Arrange

so

that

oil

jet

of

connect

ing

rod

big

end

is

directed

toward

right

side

of

eylinder

block

c

Be

sure

to

install

piston

in

cylinders

with

notch

mark

of

piston

head

toward

front

of

engine

2

Install

piston

rings

InstalI

top

and

second

rings

in

right

position

with

marked

side

up

Notes

a

Top

ring

is

chromium

plated

on

liner

contacting

face

b

Second

ring

has

larger

taper

surface

than

top

ring

c

In

the

combined

oil

ring

upper

rail

is

the

same

as

lower

one

j

c6J

EM158

Fig

EM

86

lalling

pidon

rings

3

Fix

bearings

on

connecting

rod

and

connecting

rod

cap

Note

Clean

back

side

of

bearing

care

fully

ENGINE

ASSEMBLY

The

first

step

in

engine

assembly

is

to

bolt

Engine

Attachment

ST0526000

I

to

right

hand

ide

of

cylinder

block

Next

install

block

on

another

Engine

Stand

ST0501S000

with

engine

bottom

up

2

Set

main

bearings

at

the

proper

portion

of

cylinder

block

Rear

Front

III

III

m

It

IlL

D

D

D

D

D

1

5

1

4

1

3

1

2

1

1

EM159

Fig

EM

87

Main

bearings

EM

22

3

Install

baffle

plate

including

cyl

inder

block

net

Notes

a

Only

center

bearing

No

3

is

a

flanged

type

b

All

inter

bearings

No

2

and

No

4

are

the

same

type

c

Front

bearing

No

I

is

also

the

same

type

as

rear

bearing

No

5

The

difference

is

that

an

oil

hole

is

provided

in

the

front

bearing

d

All

upper

and

lower

bearings

are

interchangeable

4

Apply

engine

oil

to

main

bearing

surfaces

on

both

sides

of

cylinder

block

and

cap

and

then

install

crank

shaft

5

Install

main

bearing

cap

and

tight

en

bolts

to

specified

torque

Tightening

torque

4

5

to

5

5

kg

m

33

to

40

ft

lb

Notes

a

Apply

sealant

to

each

side

of

rear

main

bearing

cap

and

each

comer

of

eylinder

block

as

shown

in

Figure

EM

79

b

Arrange

parts

so

arrow

mark

on

bearing

cap

faces

toward

front

of

engine

c

Prior

to

tightening

bearing

cap

bolts

place

bearing

cap

in

proper

position

by

shifting

crankshaft

in

the

axial

direction

d

Tighten

bearing

cap

bolts

gradually

in

two

to

three

stages

outwardly

from

center

bearing

in

the

sequence

as

shown

in

Figure

EM

88

e

After

securing

bearing

cap

bolts

ascertain

that

aankshaft

turns

smoothly

@

i

d

l

j

1

@EM543

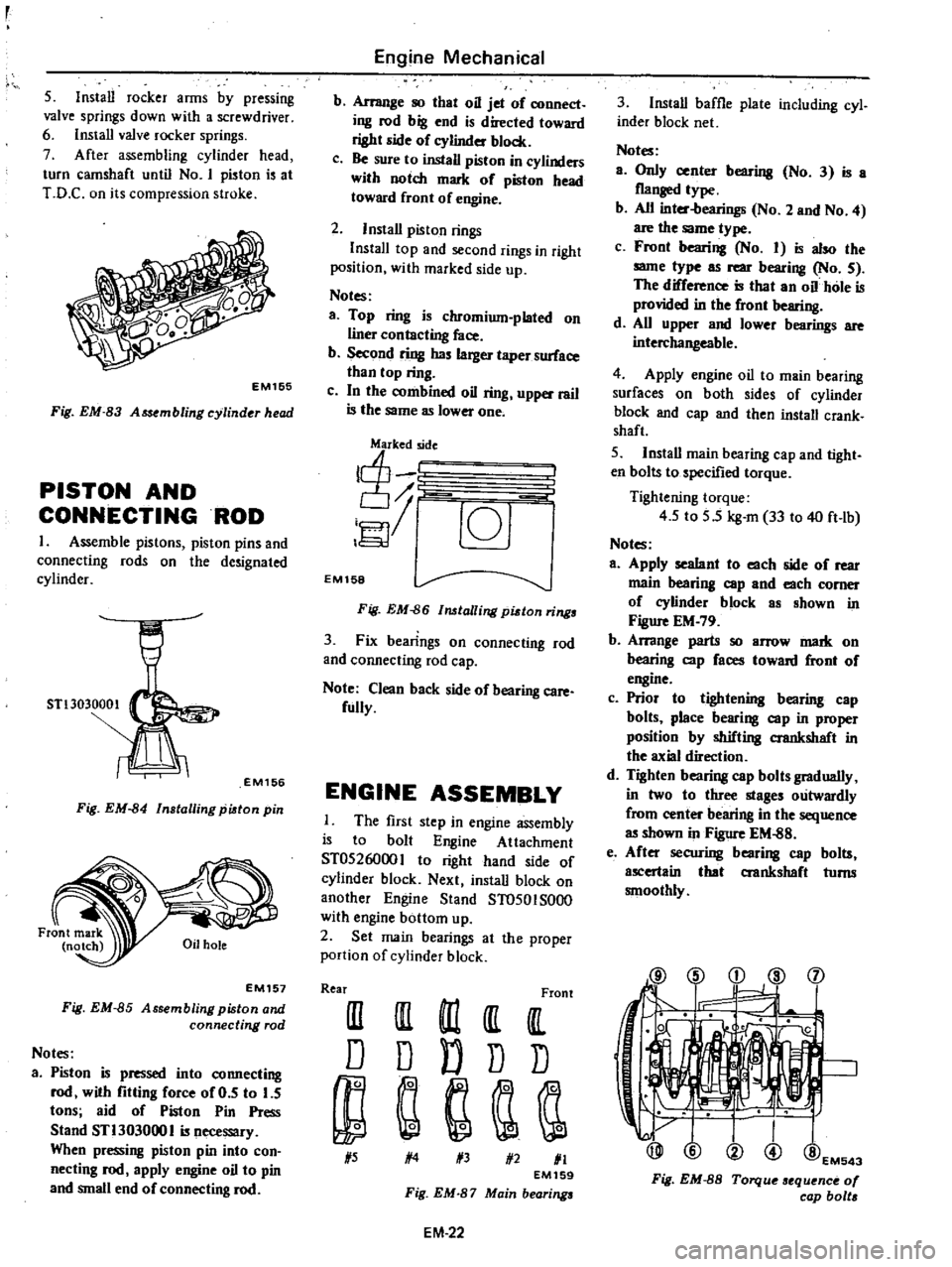

Fig

EM

8S

Torque

sequence

0

cap

bolt

Page 68 of 537

6

Make

sure

that

crankshaft

has

proper

end

play

Crankshaft

end

play

0

05

to

0

18

mm

0

0020

to

0

0071

in

Fig

EM

89

Checking

crankshaft

end

play

7

Install

side

oil

seals

into

rear

main

bearing

cap

Prior

to

installing

apply

sealant

to

seals

Fig

EM

90

Driving

side

oil

seal

8

Install

rear

oil

seal

using

Crank

shaft

Rear

Oil

Seal

Drift

STI5310000

r

STl5310000

r

EM163

Fig

EM

91

Installing

rear

oi

seal

Engine

Mechanical

Note

When

installing

oil

seal

give

coating

of

engine

oil

to

mating

shaft

to

prevent

scratches

and

fold

ed

lip

Also

give

coating

of

oil

to

periphery

of

oil

seal

9

Install

rear

end

plate

10

Install

flywheel

securely

and

tighten

bolts

to

specified

torque

Tightening

torque

14

to

16

kg

m

101

to

116

ft

lb

I

I

Insert

pistons

in

corresponding

cylinder

using

Piston

Ring

Compressor

EM03470000

EM03410000

I

EM544

Fig

EM

92

Installing

pi8ton

rod

a

Sembly

Notes

a

Apply

engine

oil

to

sliding

parts

b

Arrange

80

that

notch

mark

on

piston

head

faces

to

front

of

en

gine

c

Install

piston

rings

at

1800

to

each

other

avoiding

their

fit

in

the

thrust

and

piston

pin

directions

6

Top

ring

I

iilring

Piston

pin

ireClioJ

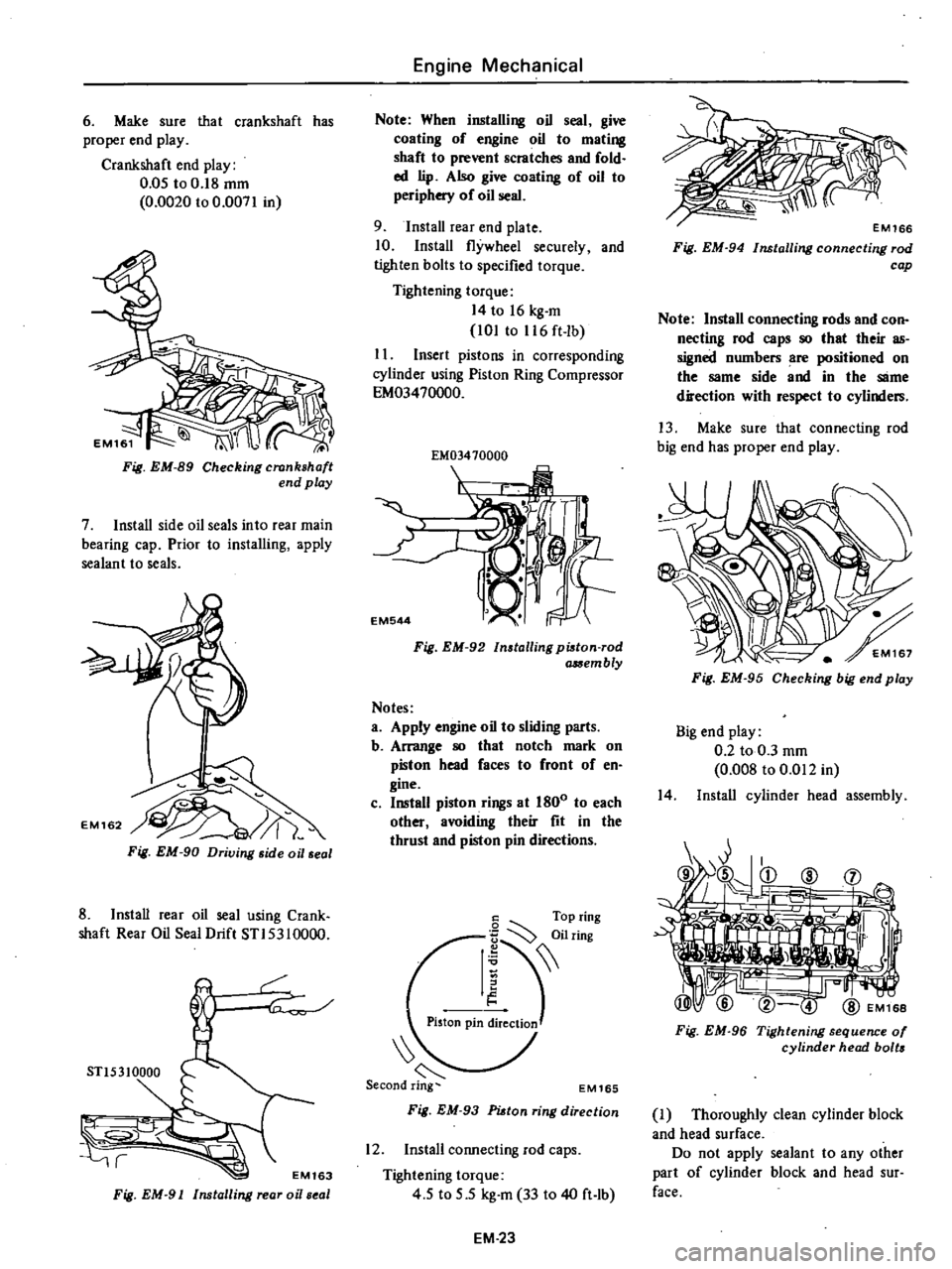

EM165

Fig

EM

93

PUtan

ring

direction

12

Install

connecting

rod

caps

Tightening

torque

4

5

to

5

5

kg

m

33

to

40

ft

lb

EM

23

Fig

EM

94

Installing

connecting

rod

cap

Note

Install

connecting

rods

and

con

necting

rod

caps

80

that

their

as

signed

numbers

are

positioned

on

the

same

side

and

in

the

SlIme

direction

with

respect

to

cylinders

13

Make

sure

that

connecting

rod

big

end

has

proper

end

play

Fig

EM

95

Checking

big

end

play

Big

end

play

0

2

to

0

3

mm

0

008

to

0

Ql2

in

14

Install

cylinder

head

assembly

Fig

EM

96

Tightening

sequence

01

cylinder

head

bolts

J

Thoroughly

clean

cylinder

block

and

head

surface

Do

not

apply

sealant

to

any

other

part

of

cylinder

block

and

head

sur

face

Page 69 of 537

2

Turn

crankshaft

until

No

I

pis

ton

is

at

T

D

C

on

its

compression

stroke

3

Make

sure

thai

camshaft

sprock

et

location

notch

and

plate

oblong

groove

are

aligned

at

their

correct

positions

4

When

installing

cylinder

head

make

sure

that

all

valves

are

apart

from

heads

of

pistons

5

Do

not

rotate

crankshaft

and

camshaft

separately

or

valves

will

hit

heads

of

pistons

6

Temporarily

tighten

two

bolts

CD

V

sJiown

in

Fig

re

EM

96

Tightening

torque

2

kg

m

14

ft

b

15

Install

crankshaft

sprocket

and

oil

pump

drive

gear

and

fit

oil

thrower

Note

Make

sure

lhat

maling

marks

of

crankshaft

sprocket

face

10

Cront

16

Install

timing

chain

Noles

a

Make

sure

that

crankshaft

and

cam

shaft

keys

point

upwards

Fuel

pump

drive

earn

2

Chain

guide

3

Chain

tensioner

4

Crank

sprocket

5

earn

sprocket

6

Chai

guide

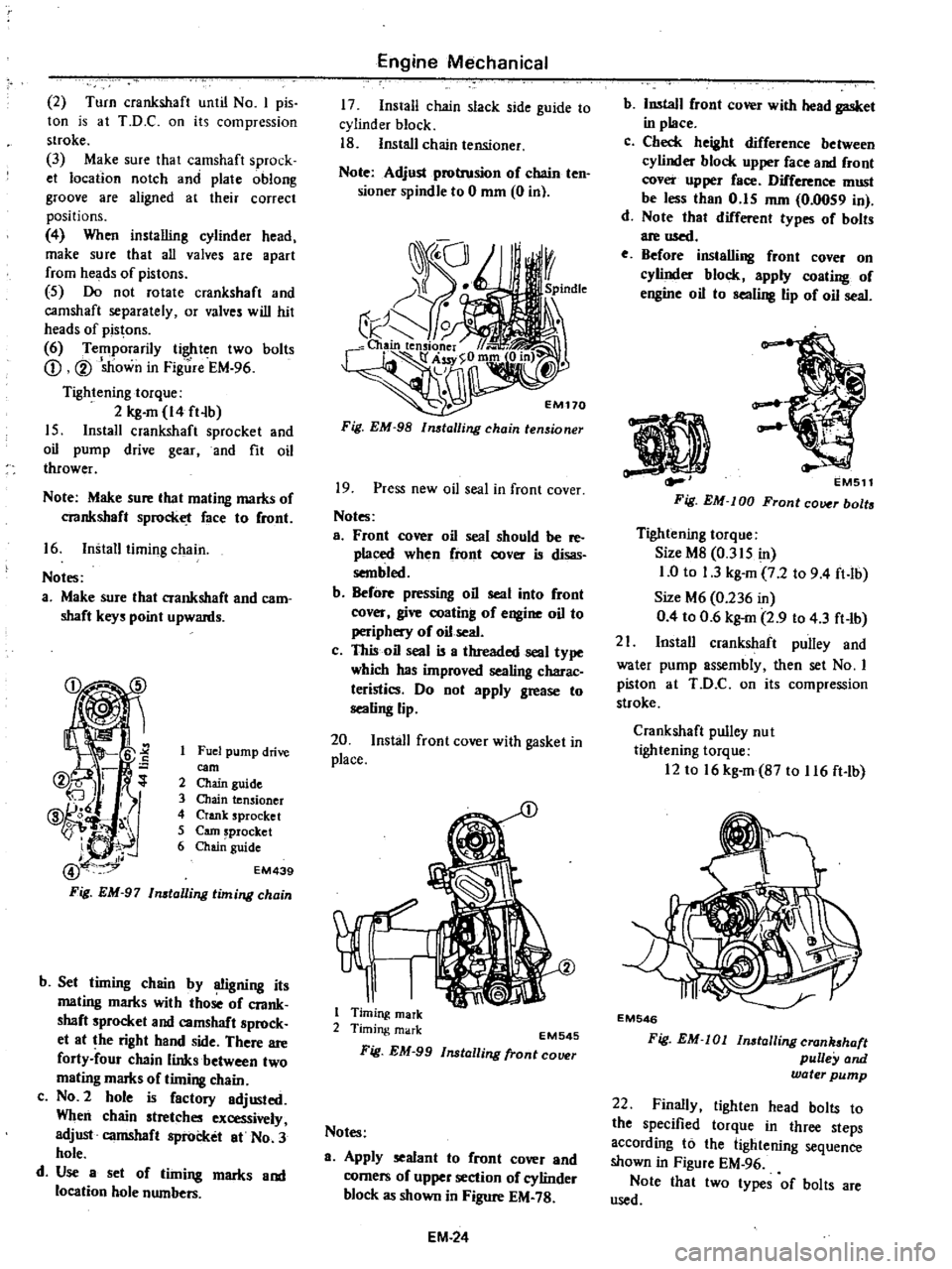

EM439

b

Set

timing

chain

by

OOgning

its

mating

marks

with

those

oC

crank

shaft

sprocket

and

camshaft

sprock

et

at

the

right

hand

side

There

are

forty

four

chain

links

between

two

mating

marks

of

timing

chain

c

NO

2

hole

is

Cactory

adjusted

When

chain

stretches

excessively

adjust

camshaft

sprocket

at

No

3

hole

d

Use

a

set

of

timing

marks

and

location

hole

numbers

Engine

Mechanical

17

Install

chain

slack

side

guide

to

cylinder

block

18

Install

chain

tensioner

Note

Adjust

protrusion

oC

chain

ten

sioner

spindle

to

0

mm

0

in

Fig

EM

98

lmtalling

chain

tensioner

19

Press

new

oil

seal

in

front

cover

Notes

a

Front

cover

oil

seal

should

be

reo

placed

when

Cront

cover

is

disas

sembled

b

BeCore

pressing

oil

seal

into

Cront

cover

give

coating

of

engine

oil

to

periphery

of

oil

seal

c

This

oil

seal

is

a

threaded

seal

type

which

has

improved

sealing

charac

teristics

Do

not

apply

grease

to

sealing

lip

20

Install

front

cover

with

gasket

in

place

1

Timing

mark

2

Timing

mark

EM545

Fig

EM

99

Installing

fronl

COlHlr

Notes

a

Apply

sealant

to

Cront

cover

and

corners

oC

upper

section

of

cylinder

block

as

shown

in

Figure

EM

78

EM

24

b

Install

Cront

cover

with

head

gasket

in

place

c

Check

height

diCCerence

between

cylinder

block

upper

Cace

and

Cront

cover

upper

Cace

DifCerence

must

be

less

than

0

15

mm

0

0059

in

d

Note

that

difCerent

types

oC

bolts

are

used

e

Before

installing

front

cover

on

cylinder

block

apply

coating

oC

engine

oil

10

sealing

lip

of

oil

seal

EMS11

Fig

EM

lOD

Front

cover

bolts

Tightening

torque

Size

M8

0

315

in

1

0

to

1

3

kg

m

7

2

to

9

4

ft

lb

Size

M6

0

236

in

0

4

to

0

6

kg

m

2

9

to

4

3

ft

lb

21

Install

crankshaft

pulley

and

water

pump

assembly

then

set

No

I

piston

at

ToO

C

on

its

compression

stloke

Crankshaft

pulley

nu

I

tightening

torque

12

to

16

kg

m

B7

to

116

ft

lb

EM546

Fig

EM

Ol

lnstallingcran

haft

pulley

and

water

pump

22

Finally

tighten

head

bolts

to

the

specified

torque

in

three

steps

according

to

the

lightening

sequence

shown

in

Figure

EM

96

Note

thai

Iwo

types

of

bolts

are

used

Page 70 of 537

Speci

ol

Cylinder

Head

Bolt

Wren

h

8110120000

Tightening

torque

1st

turn

4

0

kg

m

29

ft

lb

2nd

turn

6

0

kg

m

43

ft

lb

3rd

turn

6

5

to

8

5

kg

m

47

to

61

ft

lb

B

O

A

A

B

A

A

B

O

B

O

R

O

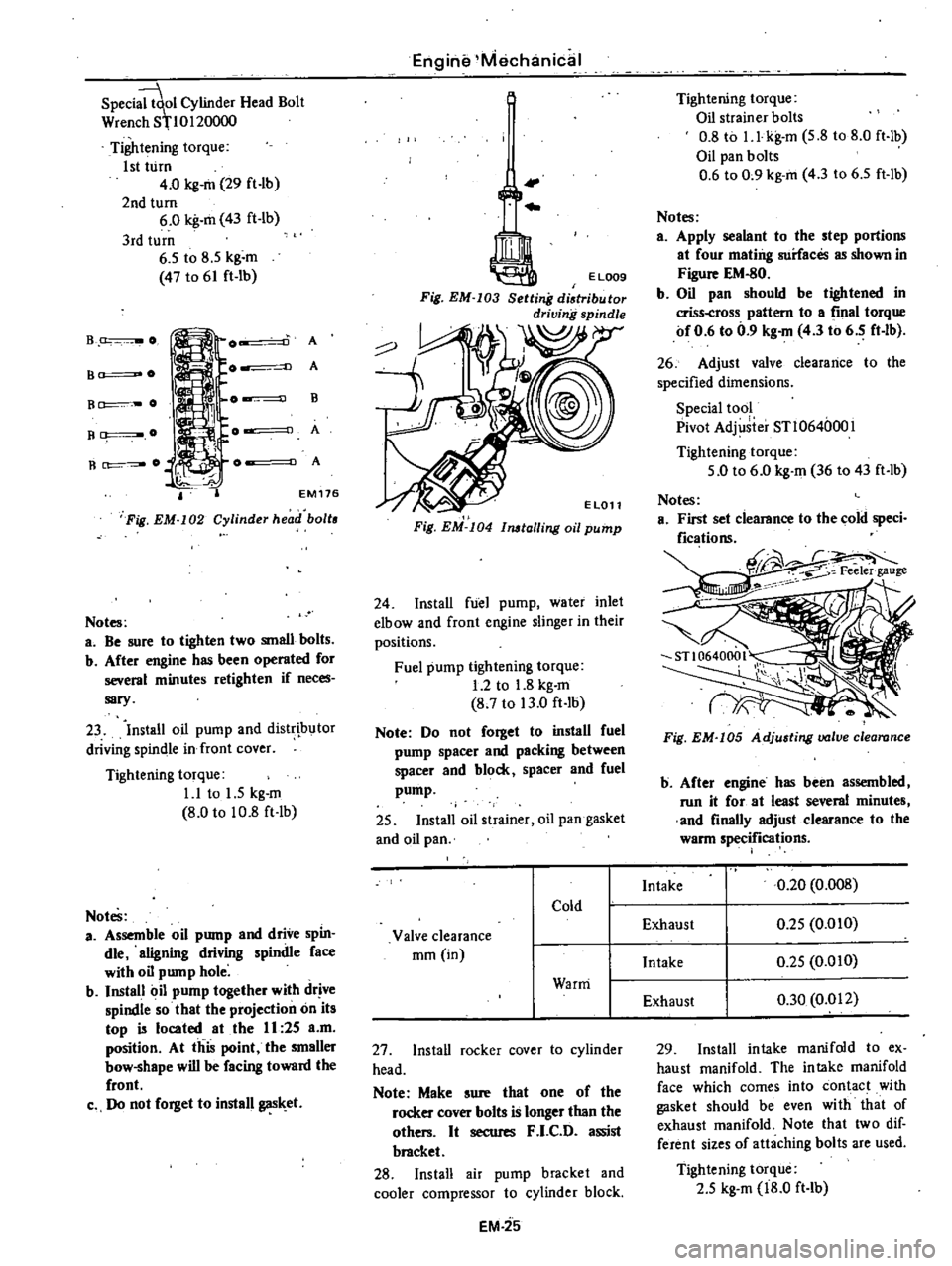

EM

176

Fig

EM

I02

Cylinder

head

boll

Notes

a

Be

sure

to

tighten

two

small

bolts

b

After

engine

has

been

operated

for

several

minutes

retighten

if

neces

sary

23

Install

oil

pump

and

distr

butor

driving

spindle

in

front

cover

Tightening

torque

1

1

to

1

5

kg

m

8

0

to

10

8

ft

lb

Notes

a

Assemble

oil

pump

and

drive

spin

die

aligning

driving

spindle

face

with

oil

pump

hole

b

Install

oil

pump

together

with

drive

spindle

so

that

the

projection

on

its

top

is

located

at

the

II

25

a

m

position

At

this

point

the

smaller

bow

shape

will

be

facing

toward

the

front

c

Do

not

forget

to

install

gas

et

Engine

Mechanical

I

Fig

EM

I04

11l6lalling

oil

pump

24

Install

fuel

pump

water

inlet

elbow

and

front

engine

slinger

in

their

positions

Fuel

pump

tightening

torque

1

2

to

1

8

kg

m

8

7

to

13

0

ft

lb

Note

Do

not

forget

to

install

fuel

pump

spacer

and

packing

between

spacer

and

block

spacer

and

fuel

pump

25

Install

oil

strainer

oil

pan

gasket

and

oil

pan

27

Install

rocker

cover

to

cylinder

head

Note

Make

sure

that

one

of

the

rocker

cover

bolts

is

longer

than

the

others

It

secures

F

I

C

D

assist

bracket

28

Install

air

pump

bracket

and

cooler

compressor

to

cylinder

block

EM

25

Tightening

torque

Oil

strainer

bolts

0

8

to

I

l

kg

m

5

8

to

8

0

ft

lb

Oil

pan

bolts

0

6

to

0

9

kg

m

4

3

to

6

5

ft

lb

Notes

a

Apply

sealant

to

the

step

portions

at

four

mating

surfaces

as

shown

in

Figure

EM

80

b

Oil

pan

should

be

tigh

tened

in

criss

cross

pattern

to

a

final

torque

of

0

6

to

0

9

kg

m

4

3

to

6

5

ft

lb

26

Adjust

valve

clearance

to

the

specified

dimensions

Special

tool

Pivot

Adj

iier

STl064000l

Tightening

torque

5

0

to

6

0

kg

m

36

to

43

ft

lb

Fig

EM

I05

Adjusting

valve

clearance

b

After

engine

has

been

assembled

run

it

for

at

least

several

minutes

and

finally

adjust

clearance

to

the

warm

specifications

29

Install

intake

manifold

to

ex

haust

manifold

The

intake

manifold

face

which

comes

into

contact

with

gasket

should

be

even

with

that

of

exhaust

manifold

Note

that

two

dif

ferent

sizes

of

attaching

bolts

are

used

Tightening

torque

2

5

kg

m

18

0

ft

lb

Page 71 of 537

30

Install

heatshieid

plate

on

mani

fold

assembly

31

Install

air

gallery

pipe

on

ex

haust

manifold

32

Install

manifold

gasket

and

manifold

assembly

on

cylinder

head

Tightening

torque

1

2to

1

6kg

m

8

7

to

11

6

ft

lb

33

Install

blow

by

gas

pipe

on

cyl

inder

block

and

tighten

with

rear

engine

slinger

34

Install

thermostat

housing

gas

ket

thermostat

housing

and

thermo

stat

35

Install

thermal

vacuum

valve

on

thermostat

housing

Before

installing

apply

a

liquid

packing

slightly

to

the

threads

36

Install

FJ

C

D

bracket

on

cylin

der

head

37

Install

E

G

R

passage

and

E

G

R

valve

on

intake

manifold

38

Connect

E

G

R

tube

to

E

G

R

tube

and

exhaust

manifold

39

Install

check

valve

on

air

gallery

pipe

40

Install

air

cleaner

bracket

on

intake

manifold

41

Install

air

control

valve

on

air

cleaner

bracket

California

models

42

Install

vacuum

and

fuel

tubes

combined

on

cylinder

head

43

Install

distributor

assembly

44

Install

heatshield

plate

joint

seat

and

carburetor

Carbure10r

tightening

torque

0

5

to

1

0

kg

m

3

6

to

7

2

ft

lb

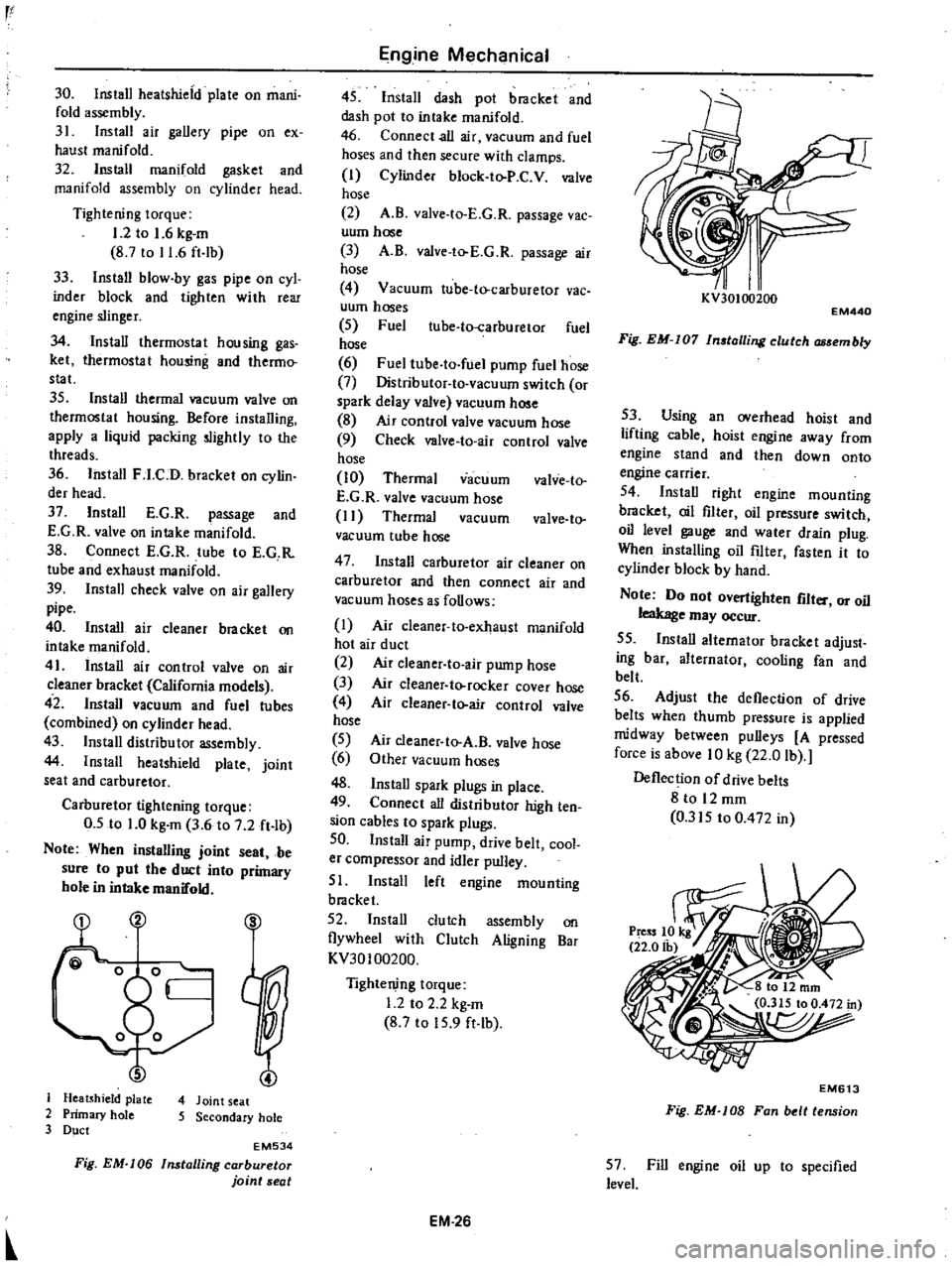

Note

When

instalUng

joint

seat

be

sure

to

put

the

duct

into

primary

hole

in

intake

manifold

S

J

Heatshield

plate

4

Joint

seat

2

Primary

hole

5

Secondary

hole

3

Duct

EM534

Fig

EM

I06

Installing

carburetor

joint

seat

Engine

Mechanical

45

Install

dash

pot

bracket

and

dash

pot

to

intake

manifold

46

Connect

all

air

vacuum

and

fuel

hoses

and

then

secure

with

clamps

I

Cylinder

block

to

P

C

V

valve

hose

2

A

B

valve

to

E

G

R

passage

vac

uum

hose

3

A

B

valve

to

E

G

R

passage

air

hose

4

Vacuum

tube

to

carburetor

vac

uum

hoses

5

Fuel

ube

to

carburetor

fuel

hose

6

Fuel

tube

to

fuel

pump

fuelhose

7

Distributor

to

vacuum

switch

or

spark

delay

valve

vacuum

hose

8

Air

control

valve

vacuum

hose

9

Check

valve

to

air

control

valve

hose

10

Thermal

vacuum

valve

to

E

G

R

valve

vacuum

hose

I

I

Thermal

vacuum

valve

to

vacuum

tube

hose

47

Install

carburetor

air

cleaner

on

carburetor

and

then

connect

air

and

vacuum

hoses

as

follows

I

Air

cleaner

to

exhaust

manifold

hot

air

duct

2

Air

c1eaner

to

air

pump

hose

3

Air

cleaner

to

rocker

cover

hose

4

Air

cleaner

to

air

control

valve

hose

5

6

48

Install

spark

plugs

in

place

49

Connect

all

distributor

high

ten

sion

cables

to

spark

plugs

50

Install

air

pump

drive

belt

cool

er

compressor

and

idler

pulley

51

Install

left

engine

mounting

bracket

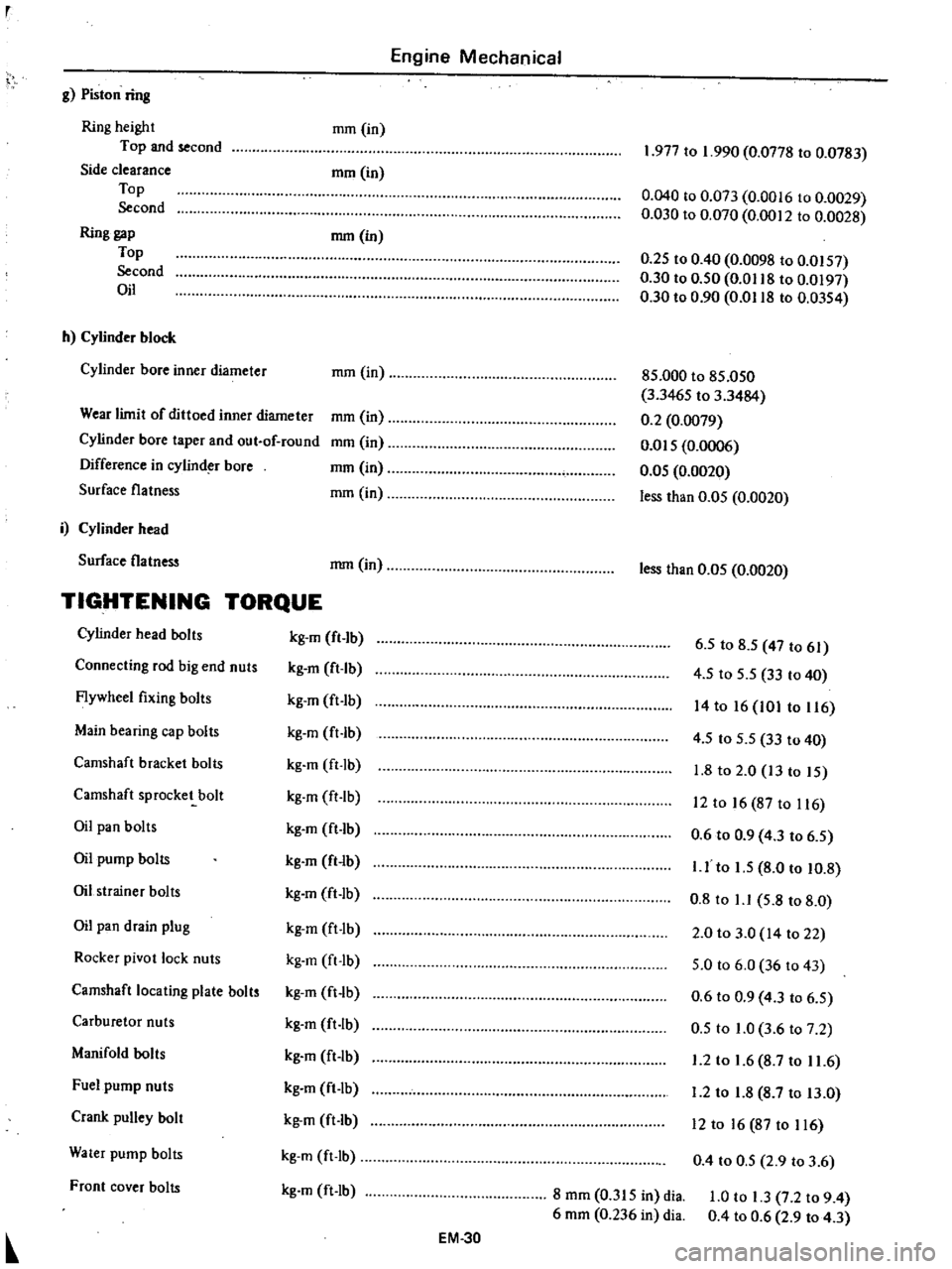

52

Install

clutch

assembly

on

flywheel

with

Clutch

Aligning

Bar

KV30100200

Air

cleaner

to

A

B

valve

hose

Other

vacuum

hoses

Tightening

torque

1

2

to

2

2

kg

m

8

7

to

15

9

ft

lb

EM

26

I

I

KV30100200

EM440

Fig

EM

I07

In

talling

clutch

embly

53

Using

an

overhead

hoist

and

lifting

cable

hoist

engine

away

from

engine

stand

and

then

down

onto

engine

carrier

54

Install

right

engine

mounting

bracket

oil

filter

oil

pressure

switch

oil

level

gauge

and

water

drain

plug

When

installing

oil

filter

fasten

it

to

cylinder

block

by

hand

Note

Do

not

overtighten

flit

or

oil

leakage

may

occur

55

Install

alternator

bracket

adjust

ing

bar

alternator

cooling

fan

and

belt

56

Adjust

the

deflection

of

drive

belts

when

thumb

pressure

is

applied

midway

between

pulleys

A

pressed

force

is

above

10

kg

22

0

lb

Deflection

of

drive

belts

8

to

12

mm

0

315

to

0

472

in

EM613

Fig

EM

lOB

Fan

belt

tension

57

Fill

engine

oil

up

to

specified

level

Page 75 of 537

Engine

Mechanical

g

Piston

ring

Ring

height

Top

and

second

Side

clearance

Top

Second

Ring

gap

Top

Second

Oil

mm

in

mrn

in

mm

in

h

Cylinder

block

Cylinder

bore

inner

diameter

mm

in

Wear

limit

of

dittoed

inner

diameter

Cylinder

bore

taper

and

out

of

round

Difference

in

cylind

bore

Surface

flatness

mm

in

mm

in

mm

in

mm

in

i

Cylinder

head

Surface

flatness

mm

in

TIGHTENING

TORQUE

Cylinder

head

bolts

kg

m

fl

lb

Connecting

rod

big

end

nuts

kg

m

ft

Ib

Flywheel

fixing

bolts

kg

m

ft

Ib

Main

bearing

cap

bolts

kg

m

ft

lb

Camshaft

bracket

bolts

kg

m

ft

lb

Camshaft

sprocket

bolt

kg

m

ft

lb

Oil

pan

bolts

kg

m

ft

1b

Oil

pump

bolts

kg

m

ft

lb

Oil

strainer

bolts

kg

m

ft

lb

Oil

pan

drain

plug

kg

m

ft

lb

Rocker

pivot

lock

nuts

kg

m

ft

Ib

Camshaft

locating

plate

bolts

kg

m

ft

lb

Carburetor

nuts

kg

m

ft

lb

Manifold

bolts

kg

m

ft

lb

Fuel

pump

nuts

kg

m

ft

lb

Crank

pulley

bolt

kg

m

ft

lb

Water

pump

bolts

kg

m

ft

Ib

Front

cover

bolts

kg

m

ft

lb

EM

30

1

977

to

1

990

0

0778

to

0

0783

0

040

to

0

073

0

0016

to

0

0029

0

030

to

0

070

0

0012

to

0

0028

0

25

to

0

40

0

0098

to

0

0157

0

30

to

0

50

0

0118

to

0

0197

0

30

to

0

90

0

0118

to

0

0354

85

000

to

85

050

3

3465

to

3

3484

0

2

0

0079

om

5

0

0006

0

05

0

0020

less

than

0

05

0

0020

less

than

0

05

0

0020

6

5

to

8

5

47

to

61

4

5

to

5

5

33

to

40

14

to

16

101

to

116

4

5

to

5

5

33

to

40

1

8

to

2

0

13

to

15

12

to

16

87

to

116

0

6

to

0

9

4

3

to

6

5

I

J

to

1

5

8

0

to

10

8

0

8

to

1

1

5

8

to

8

0

2

0

to

3

0

14

to

22

5

0

to

6

0

36

to

43

0

6

to

0

9

4

3

to

6

5

0

5

to

1

0

3

6

to

7

2

1

2

to

1

6

8

7

to

11

6

1

2

to

1

8

8

7

to

13

0

12

to

16

87

to

116

0

4

to

0

5

2

9

to

3

6

8

mm

0

315

in

dia

6

mm

0

236

in

dia

1

0

to

1

3

7

2

to

9

4

0

4

to

0

6

2

9

to

4

3

Page 80 of 537

Engine

Mechanical

SPECIAL

SERVICE

TOOL

No

Tool

number

tool

name

Description

Unit

mm

in

Engine

stand

assembly

This

engine

stand

assembly

is

used

for

disassembling

or

assembling

engine

block

or

differential

carrier

throughout

3600

in

all

directions

ST050lS000

ST050

11000

Engine

stand

ST050

12000

Base

For

use

on

Reference

page

or

Figure

No

All

Fig

EM

II

models

SE184

2

ST0526oo0l

This

engine

attachment

is

installed

to

engine

stand

Ll6

Fig

EM

II

ST0501S000

in

disassembling

or

assembling

engine

Ll8

Engine

attachment

L20B

Q

li

SE185

3

STl

0120000

Special

hollow

set

bolts

are

used

in

tightening

cylinder

heads

All

Fig

EM

18

in

L

series

engines

This

wrench

is

used

to

torque

cylinder

L

series

Cylinder

head

bolt

head

bolts

and

its

head

can

be

inserted

into

the

torque

1

rench

wrench

10

0

39

SE186

4

STl

064000

I

This

tool

is

used

togetller

with

a

torque

wrench

in

tightening

pivot

lock

nut

for

valve

clearance

adjustment

Pivot

adjuster

SE187

EM

33

All

Fig

EM

105

L

series

Page 87 of 537

ENGINE

LUBRI

CATION

SYSTEM

Note

Pump

rotors

and

body

are

not

serviced

separately

If

pump

rotors

or

body

are

damaged

or

worn

replacement

of

the

entire

oil

pump

assembly

is

necessary

Tightening

torque

Oil

pump

mounting

bolts

Oil

pump

cover

bolts

Regulator

valve

cap

nut

Specifications

Oil

pressure

at

idling

Regulator

valve

spring

Free

length

Pressured

length

Regulator

valve

opening

pressure

OIL

FILTER

The

oil

filter

is

a

cartridge

type

The

oil

filter

element

should

be

reo

placed

periodically

with

the

use

of

Oil

Filter

Wrench

ST19320000

When

installing

an

oil

filter

fasten

it

to

cylinder

block

by

hand

Note

Do

not

overtighten

filter

or

oil

leakage

may

occur

OIL

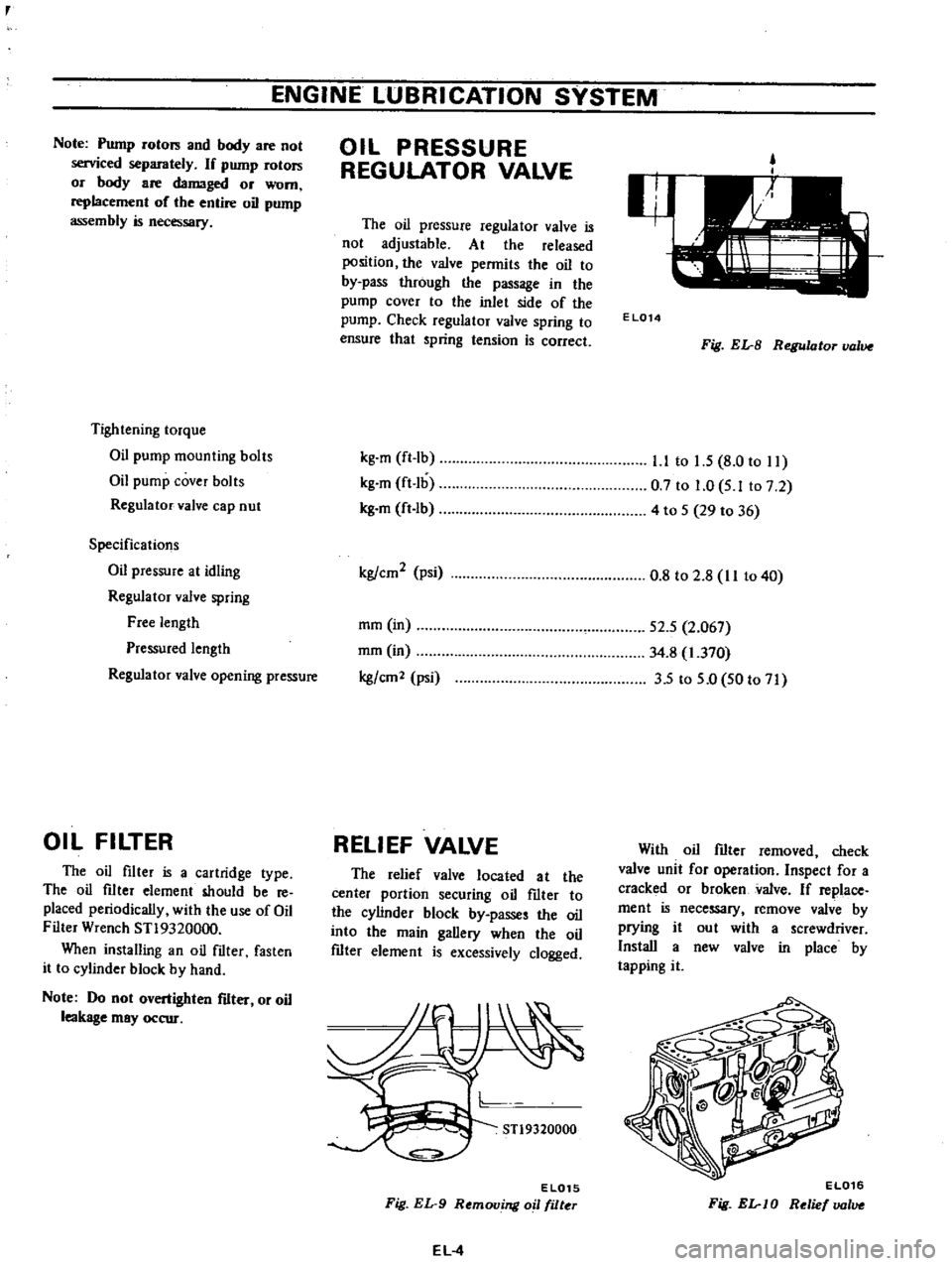

PRESSURE

REGULATOR

VALVE

The

oil

pressure

regulator

valve

is

not

adjustable

At

the

released

position

the

valve

permits

the

oil

to

by

pass

through

the

passage

in

the

pump

cover

to

the

inlet

side

of

the

pump

Check

regulator

valve

spring

to

ensure

that

spring

tension

is

correct

kg

m

ft

Ib

kg

m

ft

lb

kg

m

ft

lb

kg

cm2

psi

mm

in

mm

in

kg

em

2

psi

RELIEF

VALVE

The

relief

valve

located

at

the

center

portion

securing

oil

fIlter

to

the

cylinder

block

by

passes

the

oil

into

the

main

gallery

when

the

oil

fIlter

element

is

excessively

clogged

STl9320000

EL015

Fig

EL

9

Removing

oil

filter

EL

4

EL014

Fig

EL

B

Regulator

value

l

l

to

1

5

8

0

to

11

0

7

to

1

0

5

Ito

7

2

4

to

5

29

to

36

0

8

to

2

8

II

to

40

52

5

2

067

34

8

1

370

35

to

5

0

50

to

71

With

oil

fIlter

removed

check

valve

unit

for

operation

Inspect

for

a

cracked

or

broken

valve

If

replace

ment

is

necessary

remove

valve

by

prying

it

out

with

a

screwdriver

Install

a

new

valve

in

place

by

tapping

it

EL016

Fig

EL

JO

Relief

lJOlue

Page 91 of 537

DESCRIPTION

COOLANT

LEVEL

DRAINING

AND

FLUSHING

THE

COOLING

SYSTEM

WATER

PUMP

REMOVAL

AND

INSTALLATION

DISASSEMBLY

INSPECTION

AND

ADJUSTMENT

TORQUE

COUPLING

REMOVAL

AND

INSTALLATION

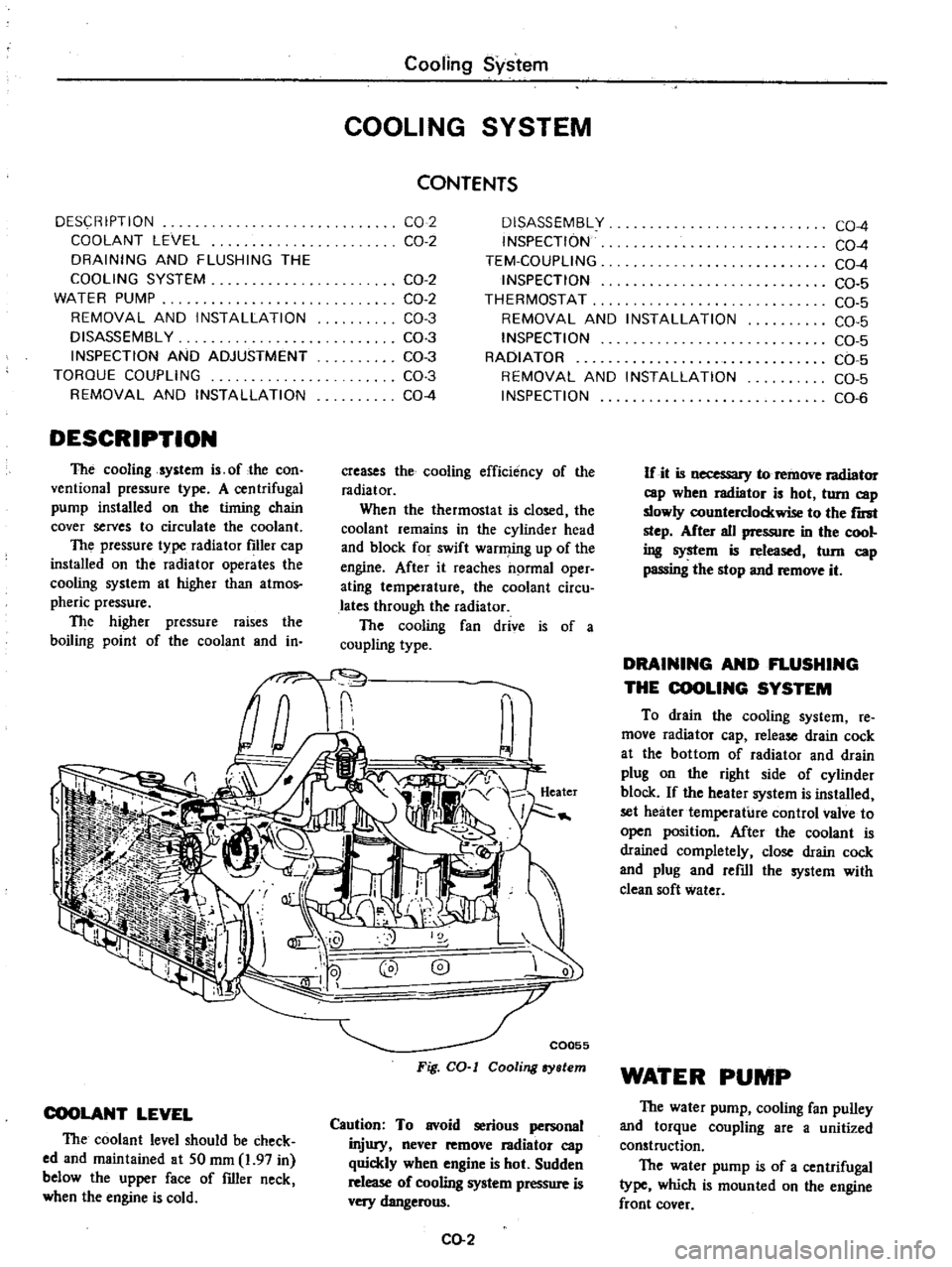

DESCRIPTION

The

cooling

system

is

of

the

con

ventional

pressure

type

A

centrifugal

pump

installed

on

the

timing

chain

cover

serves

to

circulate

the

coolant

The

pressure

type

radiator

filler

cap

installed

on

the

radiator

operates

the

cooling

system

at

higher

than

atmos

pheric

pressure

The

higher

pressure

raises

the

boiling

point

of

the

coolant

and

in

Cooling

System

COOLING

SYSTEM

CONTENTS

CO

2

CO

2

OISASSEMBL

Y

INSPECTION

TEM

COUPLlNG

INSPECTION

THERMOSTAT

REMOVAL

AND

INSTALLATION

INSPECTION

RADIATOR

REMOVAL

AND

INSTALLATION

INSPECTION

CO

2

CO

2

CO

3

CO

3

CO

3

CO

3

CO

4

creases

the

cooling

efficiency

of

the

radiator

When

the

thermostat

is

closed

the

coolant

remains

in

the

cylinder

head

and

block

for

swift

warming

up

of

the

engine

After

it

reaches

normal

oper

ating

temperature

the

coolant

circu

lates

through

the

radiator

The

cooling

fan

drive

is

of

a

coupling

type

COOLANT

LEVEL

The

coolant

level

should

be

check

ed

and

maintained

at

SO

mm

1

97

in

below

the

upper

face

of

filler

neck

when

the

engine

is

cold

C0055

Fig

CO

I

Cooling

ry

lem

Caution

To

avoid

serious

personal

injury

never

remove

I3diator

cap

quickly

when

engine

is

hot

Sudden

release

of

cooling

system

pressure

is

very

dangerous

CO

2

CO

4

CO

4

CO

4

CO

5

CO

5

CO

5

CO

5

CO

5

CO

5

CO

6

If

it

is

necessary

to

remove

radiator

cap

wben

radiator

is

hot

turn

cap

slowly

counterclockwise

to

the

r

step

After

all

pressure

in

the

cool

ing

system

is

released

tom

cap

passing

the

stop

and

remove

it

DRAINING

AND

FLUSHING

THE

COOLING

SYSTEM

To

drain

the

cooling

system

re

move

radiator

cap

release

drain

cock

at

the

bottom

of

radiator

and

drain

plug

on

the

right

side

of

cylinder

block

If

the

heater

system

is

installed

set

heater

temperature

control

valve

to

open

position

After

the

coolant

is

drained

completely

close

drain

cock

and

plug

and

refill

the

system

with

clean

soft

water

WATER

PUMP

The

water

pump

cooling

fan

pulley

and

torque

coupling

are

a

unitized

construction

The

water

pump

is

of

a

centrifugal

type

which

is

mounted

on

the

engine

front

cover

Page 96 of 537

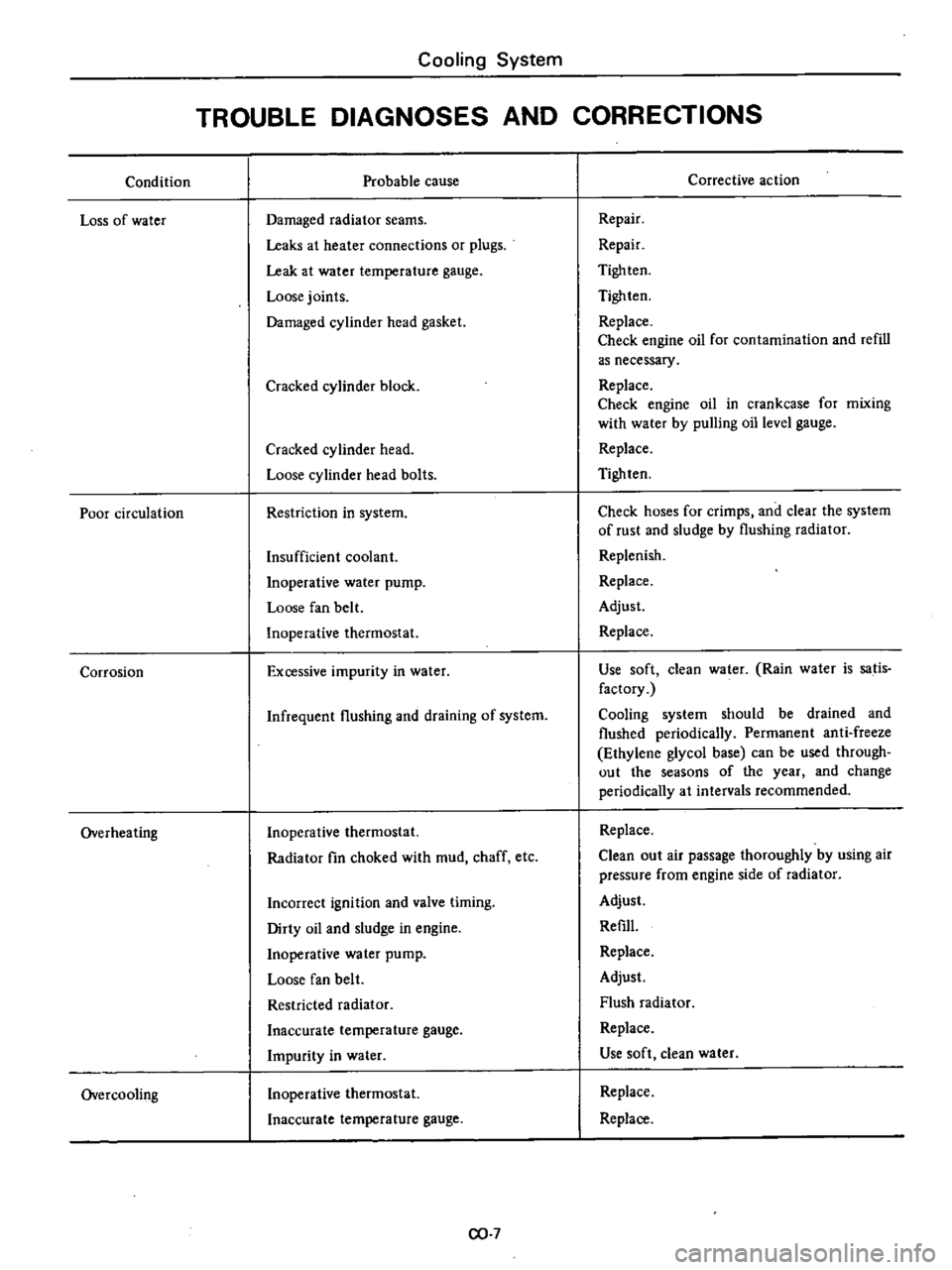

Condition

Loss

of

water

Poor

circulation

Corrosion

Overheating

Overcooling

Cooling

System

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Probable

cause

Damaged

radiator

seams

Leaks

at

heater

connections

or

plugs

Leak

at

water

temperature

gauge

Loose

joints

Damaged

cylinder

head

gasket

Cracked

cylinder

block

Cracked

cylinder

head

Loose

cylinder

head

bolts

Restriction

in

system

Insufficient

coolant

Inoperative

water

pump

Loose

fan

belt

Inoperative

thermostat

Excessive

impurity

in

water

Infrequent

flushing

and

draining

of

system

Inoperative

thermostat

Radiator

fin

choked

with

mud

chaff

etc

Incorrect

ignition

and

valve

timing

Dirty

oil

and

sludge

in

engine

Inoperative

water

pump

Loose

fan

belt

Restricted

radiator

Inaccurate

temperature

gauge

Impurity

in

water

Inoperative

thermostat

Inaccurate

temperature

gauge

CO

7

Corrective

action

Repair

Repair

Tigh

ten

Tighten

Replace

Check

engine

oil

for

contamination

and

refill

as

necessary

Replace

Check

engine

oil

in

crankcase

for

mixing

with

water

by

pulling

oil

level

gauge

Replace

Tighten

Check

hoses

for

crimps

and

clear

the

system

of

rust

and

sludge

by

flushing

radiator

Replenish

Replace

Adjust

Replace

Use

soft

clean

water

Rain

water

is

satis

factory

Cooling

system

should

be

drained

and

flushed

periodically

Permanent

anti

freeze

Ethylene

glycol

base

can

be

used

through

out

the

seasons

of

the

year

and

change

periodically

at

intervals

recommended

Replace

Clean

out

air

passage

thoroughly

by

using

air

pressure

from

engine

side

of

radiator

Adjust

Refill

Replace

Adjust

Flush

radiator

Replace

Use

soft

clean

water

Replace

Replace