differential DODGE NEON 1999 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 76 of 1200

CAUTION: Seal must not be dimpled, stretched, or

out±of±shape in any way. If seal is NOT shaped cor-

rectly, equalize pressure in seal and shape it by

hand.

(8) Position sealing boot into the tripod housing

retaining groove. Install seal boot retaining clamp

evenly on sealing boot.

CAUTION: The following positioning procedure

determines the correct air pressure inside the inner

tripod joint assembly prior to clamping the sealing

boot to inner tripod joint housing. If this procedure

is not done prior to clamping sealing boot to tripod

joint housing, boot durability can be adversely

affected.

CAUTION: When venting the inner tripod joint

assembly, use care so inner tripod sealing boot

does not get punctured or, in any other way, dam-

aged. If sealing boot is punctured or damaged while

being vented, the sealing boot can not be used.

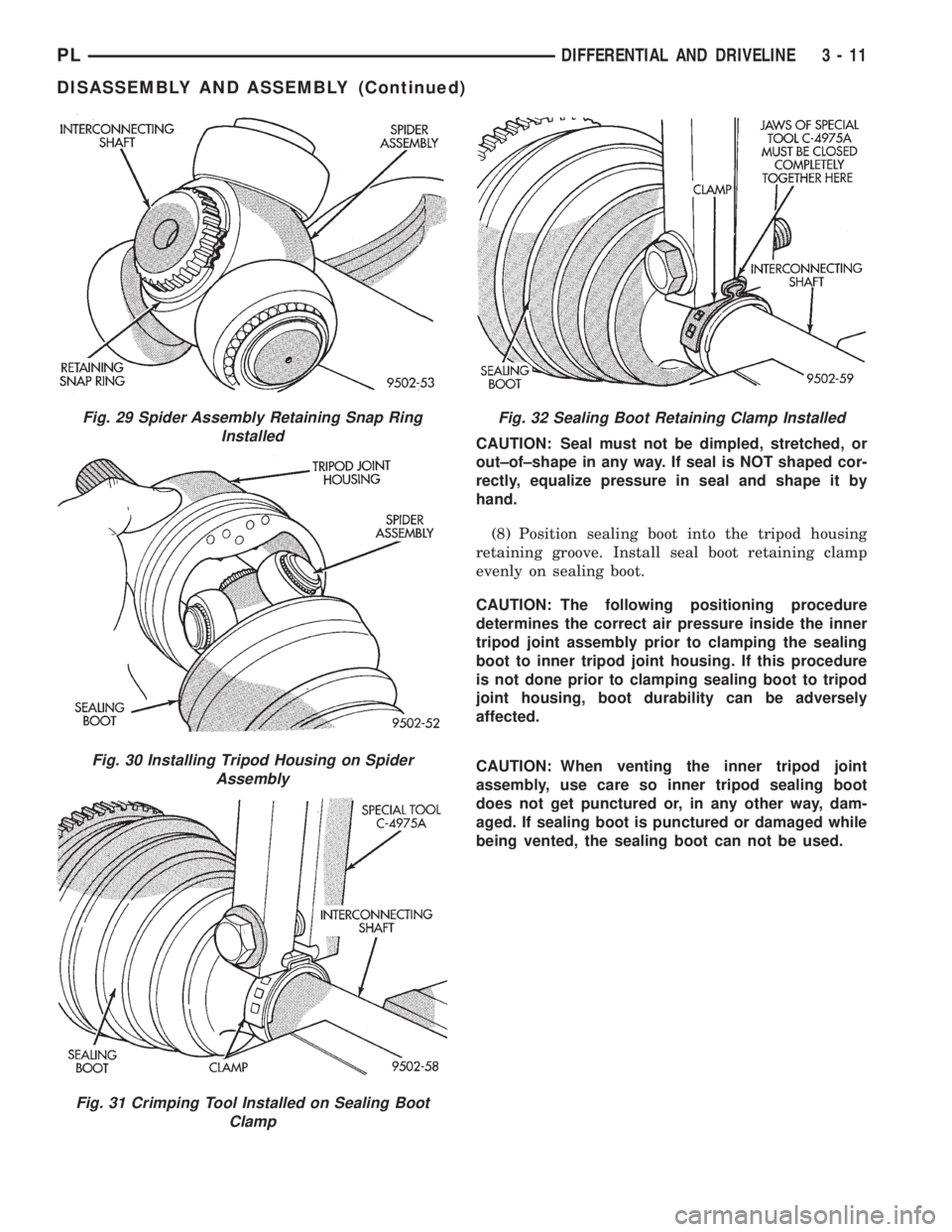

Fig. 29 Spider Assembly Retaining Snap Ring

Installed

Fig. 30 Installing Tripod Housing on Spider

Assembly

Fig. 31 Crimping Tool Installed on Sealing Boot

Clamp

Fig. 32 Sealing Boot Retaining Clamp Installed

PLDIFFERENTIAL AND DRIVELINE 3 - 11

DISASSEMBLY AND ASSEMBLY (Continued)

Page 77 of 1200

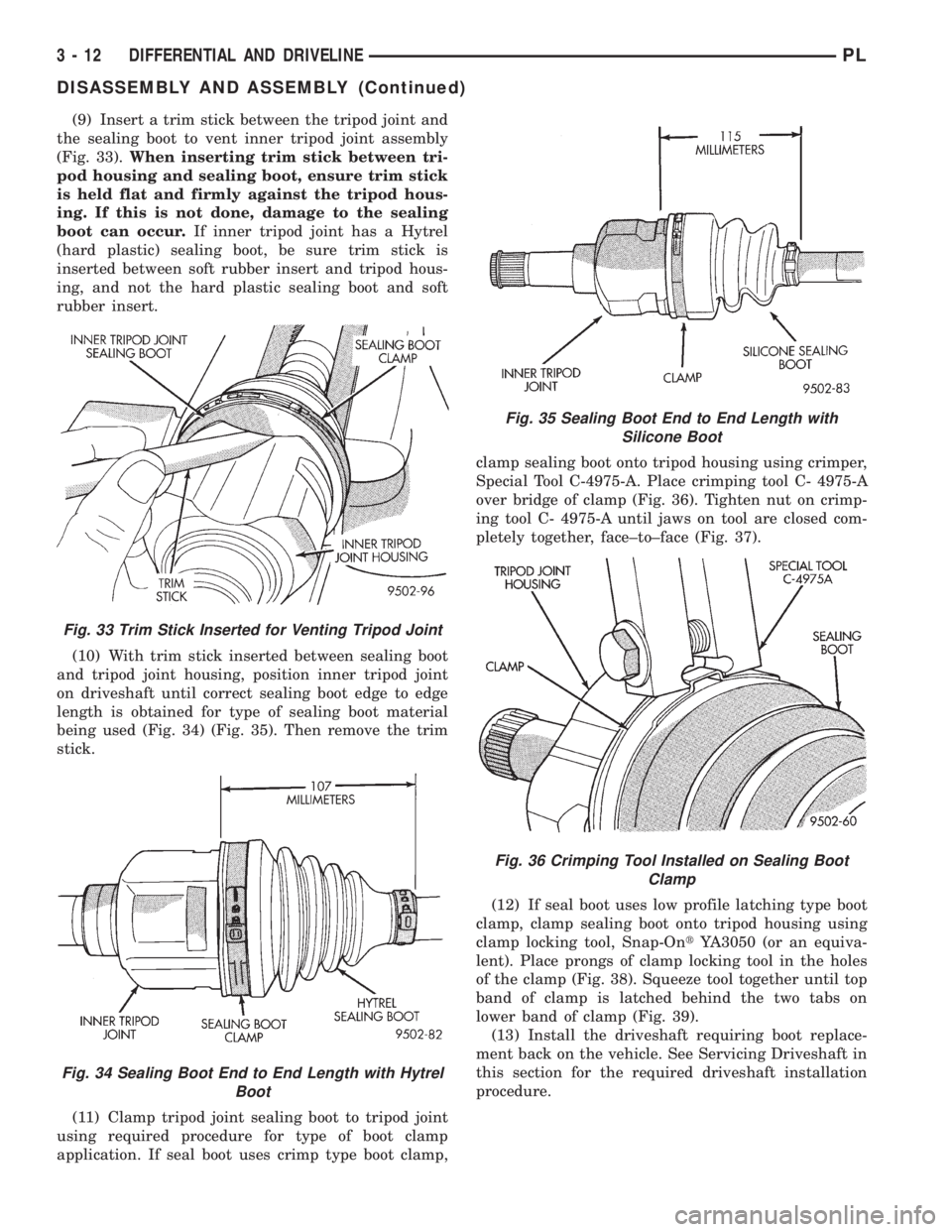

(9) Insert a trim stick between the tripod joint and

the sealing boot to vent inner tripod joint assembly

(Fig. 33).When inserting trim stick between tri-

pod housing and sealing boot, ensure trim stick

is held flat and firmly against the tripod hous-

ing. If this is not done, damage to the sealing

boot can occur.If inner tripod joint has a Hytrel

(hard plastic) sealing boot, be sure trim stick is

inserted between soft rubber insert and tripod hous-

ing, and not the hard plastic sealing boot and soft

rubber insert.

(10) With trim stick inserted between sealing boot

and tripod joint housing, position inner tripod joint

on driveshaft until correct sealing boot edge to edge

length is obtained for type of sealing boot material

being used (Fig. 34) (Fig. 35). Then remove the trim

stick.

(11) Clamp tripod joint sealing boot to tripod joint

using required procedure for type of boot clamp

application. If seal boot uses crimp type boot clamp,clamp sealing boot onto tripod housing using crimper,

Special Tool C-4975-A. Place crimping tool C- 4975-A

over bridge of clamp (Fig. 36). Tighten nut on crimp-

ing tool C- 4975-A until jaws on tool are closed com-

pletely together, face±to±face (Fig. 37).

(12) If seal boot uses low profile latching type boot

clamp, clamp sealing boot onto tripod housing using

clamp locking tool, Snap-OntYA3050 (or an equiva-

lent). Place prongs of clamp locking tool in the holes

of the clamp (Fig. 38). Squeeze tool together until top

band of clamp is latched behind the two tabs on

lower band of clamp (Fig. 39).

(13) Install the driveshaft requiring boot replace-

ment back on the vehicle. See Servicing Driveshaft in

this section for the required driveshaft installation

procedure.

Fig. 33 Trim Stick Inserted for Venting Tripod Joint

Fig. 34 Sealing Boot End to End Length with Hytrel

Boot

Fig. 35 Sealing Boot End to End Length with

Silicone Boot

Fig. 36 Crimping Tool Installed on Sealing Boot

Clamp

3 - 12 DIFFERENTIAL AND DRIVELINEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 78 of 1200

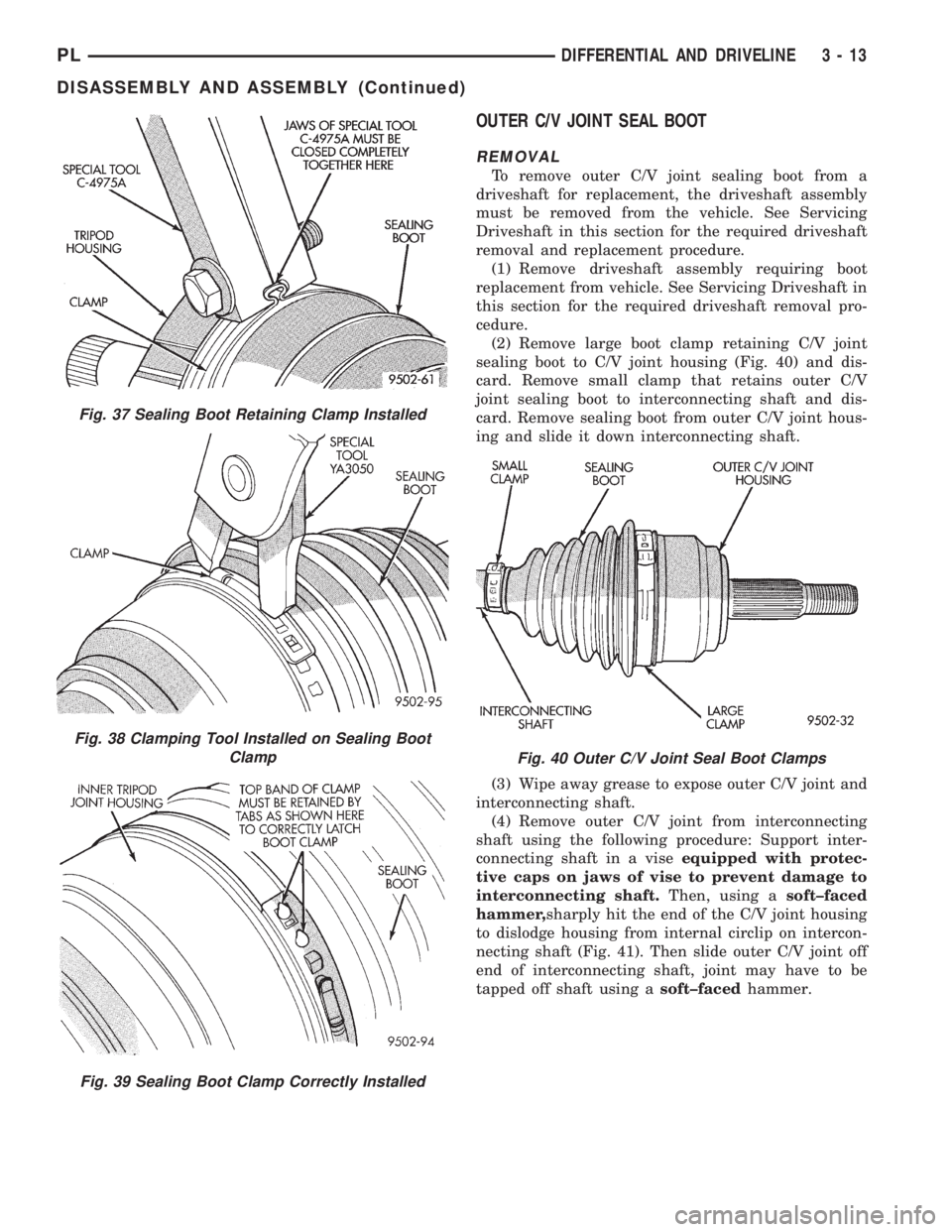

OUTER C/V JOINT SEAL BOOT

REMOVAL

To remove outer C/V joint sealing boot from a

driveshaft for replacement, the driveshaft assembly

must be removed from the vehicle. See Servicing

Driveshaft in this section for the required driveshaft

removal and replacement procedure.

(1) Remove driveshaft assembly requiring boot

replacement from vehicle. See Servicing Driveshaft in

this section for the required driveshaft removal pro-

cedure.

(2) Remove large boot clamp retaining C/V joint

sealing boot to C/V joint housing (Fig. 40) and dis-

card. Remove small clamp that retains outer C/V

joint sealing boot to interconnecting shaft and dis-

card. Remove sealing boot from outer C/V joint hous-

ing and slide it down interconnecting shaft.

(3) Wipe away grease to expose outer C/V joint and

interconnecting shaft.

(4) Remove outer C/V joint from interconnecting

shaft using the following procedure: Support inter-

connecting shaft in a viseequipped with protec-

tive caps on jaws of vise to prevent damage to

interconnecting shaft.Then, using asoft±faced

hammer,sharply hit the end of the C/V joint housing

to dislodge housing from internal circlip on intercon-

necting shaft (Fig. 41). Then slide outer C/V joint off

end of interconnecting shaft, joint may have to be

tapped off shaft using asoft±facedhammer.

Fig. 37 Sealing Boot Retaining Clamp Installed

Fig. 38 Clamping Tool Installed on Sealing Boot

Clamp

Fig. 39 Sealing Boot Clamp Correctly Installed

Fig. 40 Outer C/V Joint Seal Boot Clamps

PLDIFFERENTIAL AND DRIVELINE 3 - 13

DISASSEMBLY AND ASSEMBLY (Continued)

Page 79 of 1200

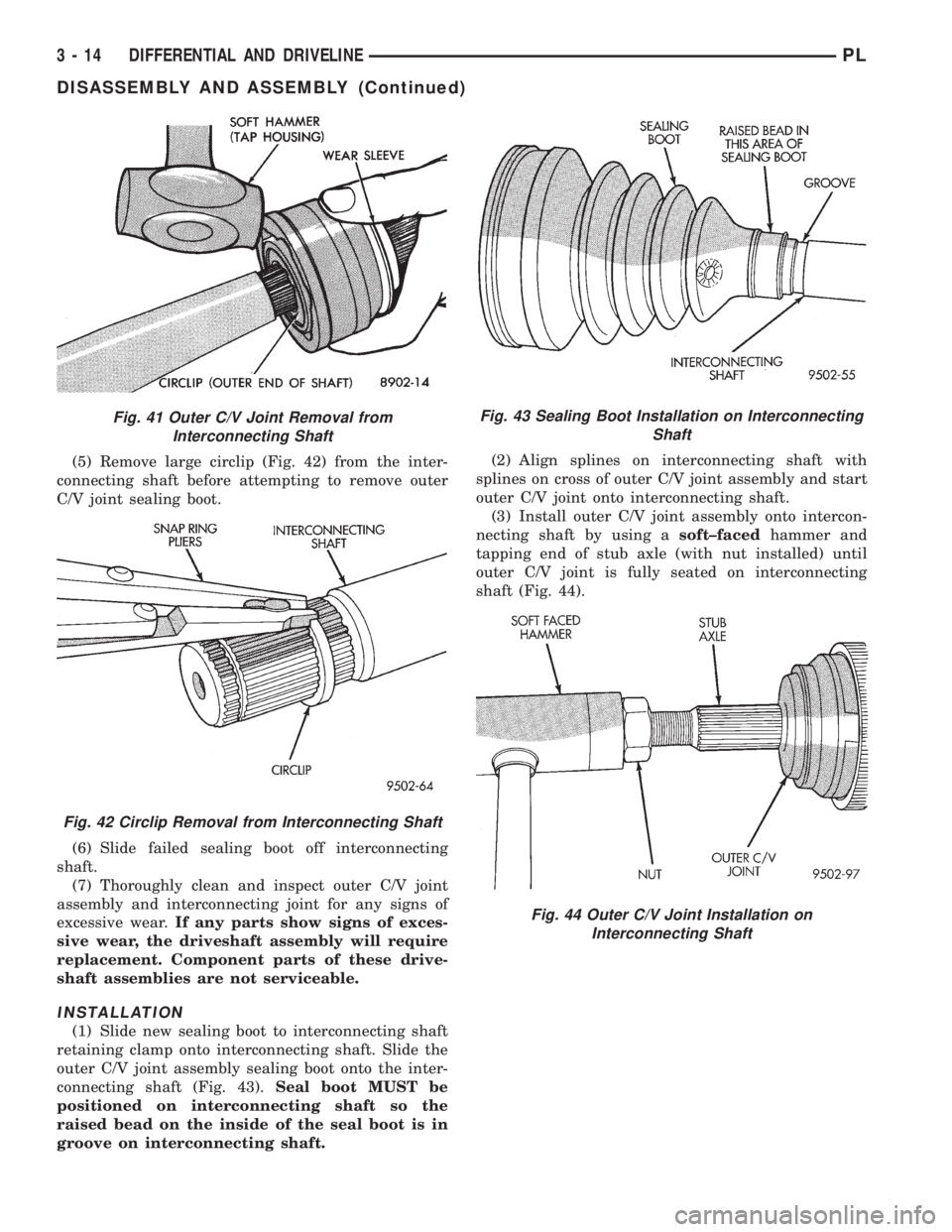

(5) Remove large circlip (Fig. 42) from the inter-

connecting shaft before attempting to remove outer

C/V joint sealing boot.

(6) Slide failed sealing boot off interconnecting

shaft.

(7) Thoroughly clean and inspect outer C/V joint

assembly and interconnecting joint for any signs of

excessive wear.If any parts show signs of exces-

sive wear, the driveshaft assembly will require

replacement. Component parts of these drive-

shaft assemblies are not serviceable.

INSTALLATION

(1) Slide new sealing boot to interconnecting shaft

retaining clamp onto interconnecting shaft. Slide the

outer C/V joint assembly sealing boot onto the inter-

connecting shaft (Fig. 43).Seal boot MUST be

positioned on interconnecting shaft so the

raised bead on the inside of the seal boot is in

groove on interconnecting shaft.(2) Align splines on interconnecting shaft with

splines on cross of outer C/V joint assembly and start

outer C/V joint onto interconnecting shaft.

(3) Install outer C/V joint assembly onto intercon-

necting shaft by using asoft±facedhammer and

tapping end of stub axle (with nut installed) until

outer C/V joint is fully seated on interconnecting

shaft (Fig. 44).

Fig. 41 Outer C/V Joint Removal from

Interconnecting Shaft

Fig. 42 Circlip Removal from Interconnecting Shaft

Fig. 43 Sealing Boot Installation on Interconnecting

Shaft

Fig. 44 Outer C/V Joint Installation on

Interconnecting Shaft

3 - 14 DIFFERENTIAL AND DRIVELINEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 80 of 1200

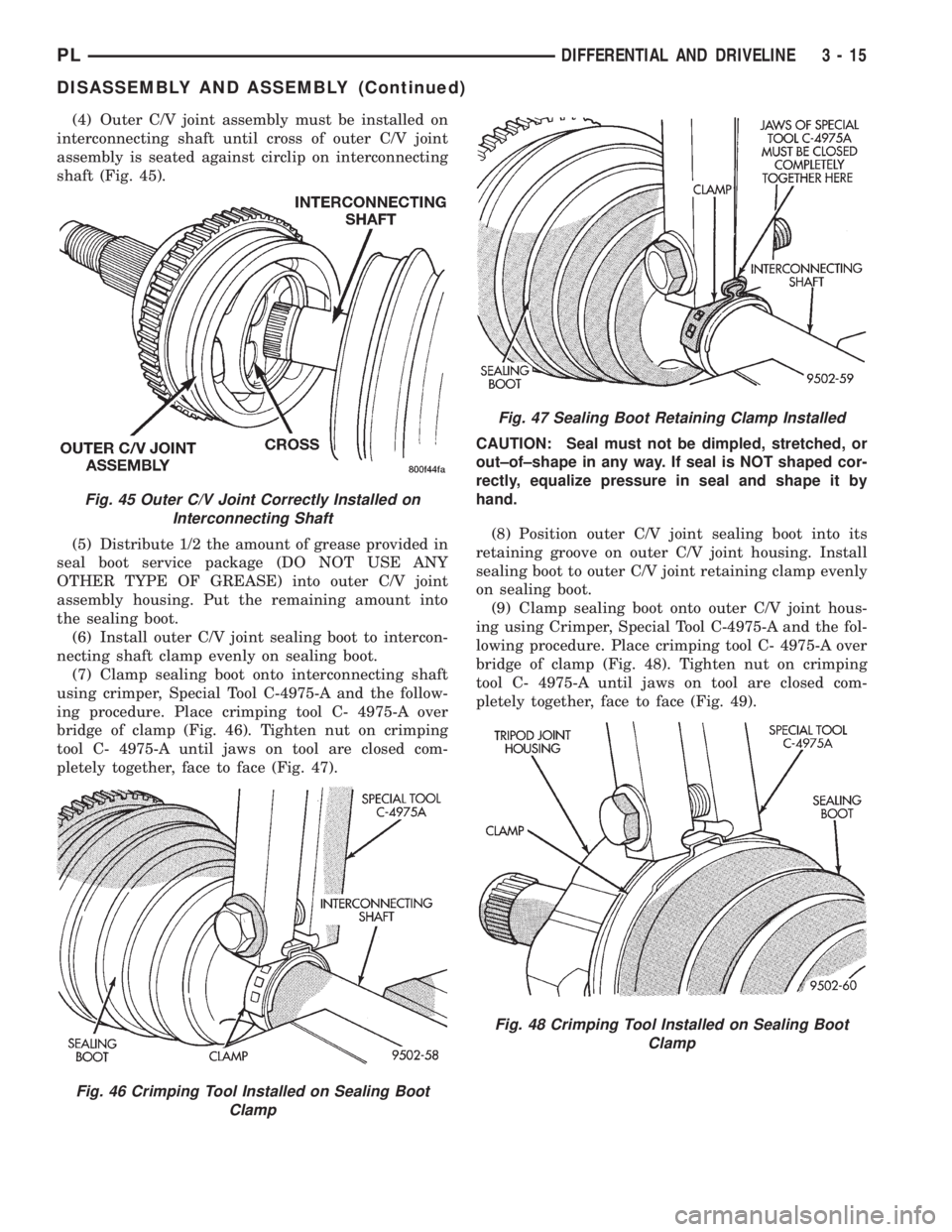

(4) Outer C/V joint assembly must be installed on

interconnecting shaft until cross of outer C/V joint

assembly is seated against circlip on interconnecting

shaft (Fig. 45).

(5) Distribute 1/2 the amount of grease provided in

seal boot service package (DO NOT USE ANY

OTHER TYPE OF GREASE) into outer C/V joint

assembly housing. Put the remaining amount into

the sealing boot.

(6) Install outer C/V joint sealing boot to intercon-

necting shaft clamp evenly on sealing boot.

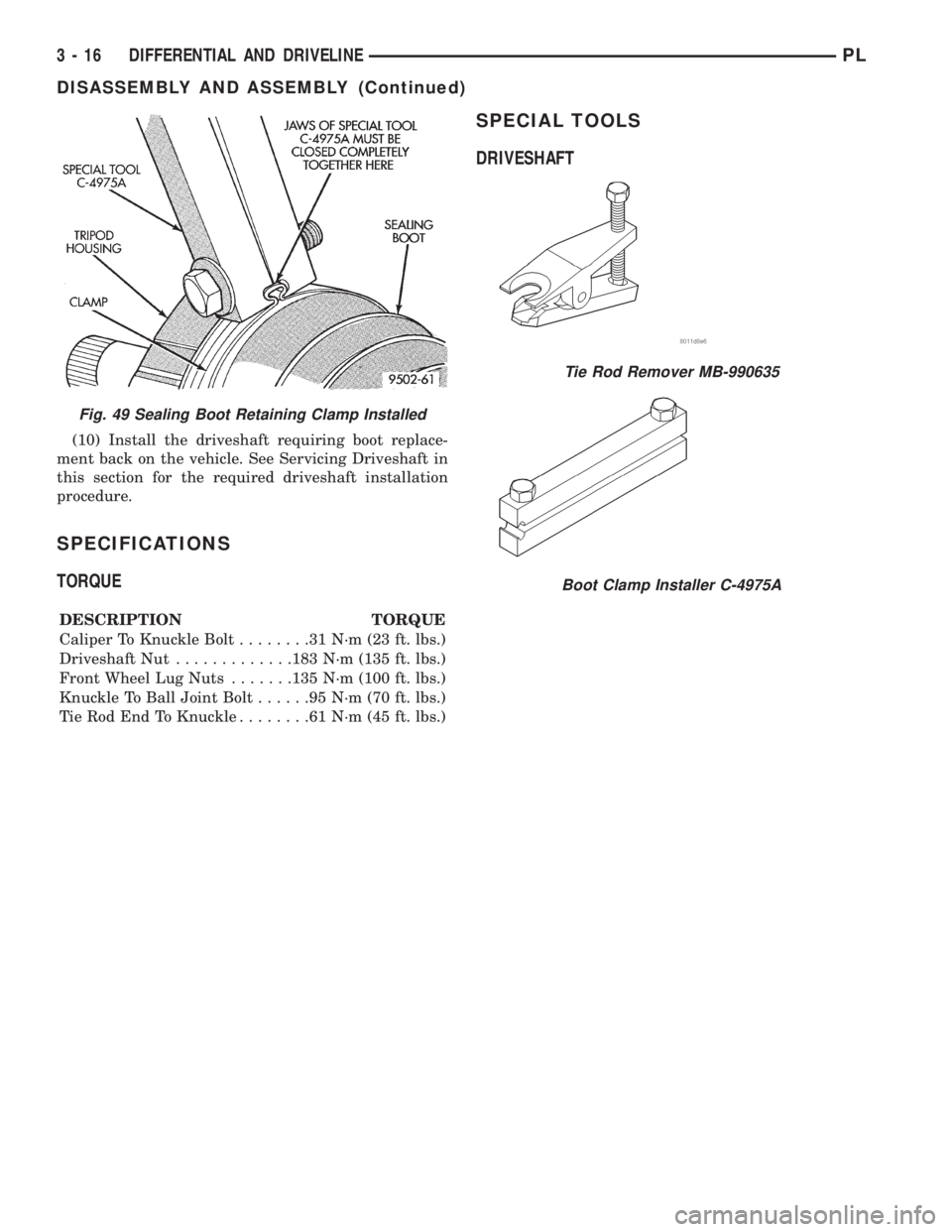

(7) Clamp sealing boot onto interconnecting shaft

using crimper, Special Tool C-4975-A and the follow-

ing procedure. Place crimping tool C- 4975-A over

bridge of clamp (Fig. 46). Tighten nut on crimping

tool C- 4975-A until jaws on tool are closed com-

pletely together, face to face (Fig. 47).CAUTION: Seal must not be dimpled, stretched, or

out±of±shape in any way. If seal is NOT shaped cor-

rectly, equalize pressure in seal and shape it by

hand.

(8) Position outer C/V joint sealing boot into its

retaining groove on outer C/V joint housing. Install

sealing boot to outer C/V joint retaining clamp evenly

on sealing boot.

(9) Clamp sealing boot onto outer C/V joint hous-

ing using Crimper, Special Tool C-4975-A and the fol-

lowing procedure. Place crimping tool C- 4975-A over

bridge of clamp (Fig. 48). Tighten nut on crimping

tool C- 4975-A until jaws on tool are closed com-

pletely together, face to face (Fig. 49).

Fig. 45 Outer C/V Joint Correctly Installed on

Interconnecting Shaft

Fig. 46 Crimping Tool Installed on Sealing Boot

Clamp

Fig. 47 Sealing Boot Retaining Clamp Installed

Fig. 48 Crimping Tool Installed on Sealing Boot

Clamp

PLDIFFERENTIAL AND DRIVELINE 3 - 15

DISASSEMBLY AND ASSEMBLY (Continued)

Page 81 of 1200

(10) Install the driveshaft requiring boot replace-

ment back on the vehicle. See Servicing Driveshaft in

this section for the required driveshaft installation

procedure.

SPECIFICATIONS

TORQUE

DESCRIPTION TORQUE

Caliper To Knuckle Bolt........31N´m(23ft.lbs.)

Driveshaft Nut.............183 N´m (135 ft. lbs.)

Front Wheel Lug Nuts.......135 N´m (100 ft. lbs.)

Knuckle To Ball Joint Bolt......95N´m(70ft.lbs.)

Tie Rod End To Knuckle........61N´m(45ft.lbs.)

SPECIAL TOOLS

DRIVESHAFT

Fig. 49 Sealing Boot Retaining Clamp Installed

Tie Rod Remover MB-990635

Boot Clamp Installer C-4975A

3 - 16 DIFFERENTIAL AND DRIVELINEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 944 of 1200

TRANSAXLE

CONTENTS

page page

31TH AUTOMATIC TRANSAXLE............. 40 NVT350 (A-578) MANUAL TRANSAXLE....... 1

NV T350 (A-578) MANUAL TRANSAXLE

INDEX

page page

GENERAL INFORMATION

GEAR RATIOS........................... 2

GEARSHIFT PATTERN..................... 2

NV T350 MANUAL TRANSAXLE.............. 1

SEALANTS.............................. 2

SELECTION OF LUBRICANT................ 2

SPECIAL ADDITIVES...................... 2

TRANSAXLE IDENTIFICATION INFORMATION . . . 2

DESCRIPTION AND OPERATION

AXLE SEALS............................ 3

SHIFT LEVERS.......................... 3

DIAGNOSIS AND TESTING

CLUTCH PROBLEMS...................... 3

COMMON PROBLEM CAUSES.............. 3

HARD SHIFTING......................... 3

LOW LUBRICANT LEVEL................... 3

NOISY OPERATION....................... 3

SLIPS OUT OF GEAR..................... 3

SERVICE PROCEDURES

FLUID DRAIN AND FILL.................... 3

REMOVAL AND INSTALLATION

AXLE SEALS............................ 8

BACK-UP LAMP SWITCH................... 7

CROSSOVER LEVER...................... 7

GEARSHIFT BOOT....................... 4

GEARSHIFT CABLES...................... 4GEARSHIFT KNOB....................... 4

GEARSHIFT MECHANISM REPLACEMENT..... 6

SELECTOR LEVER....................... 8

SHIFT SHAFT SEALS...................... 8

TRANSAXLE............................ 8

VEHICLE SPEED SENSOR DRIVE GEAR...... 7

DISASSEMBLY AND ASSEMBLY

DIFFERENTIAL......................... 24

INPUT SHAFT.......................... 20

OUTPUT SHAFT........................ 24

SHIFT RAILS OVERHAUL................. 29

SYNCHRONIZER........................ 29

TRANSAXLE CASE OVERHAUL............. 30

TRANSAXLE........................... 10

CLEANING AND INSPECTION

SYNCHRONIZER........................ 35

TRANSAXLE........................... 35

ADJUSTMENTS

BEARING ADJUSTMENT PROCEDURE....... 35

DIFFERENTIAL BEARING PRELOAD

ADJUSTMENT......................... 36

GEARSHIFT CROSSOVER CABLE........... 35

SPECIFICATIONS

NV T350 (A-578) SPECIFICATIONS.......... 37

SPECIAL TOOLS

NV T350 (A-578) MANUAL TRANSAXLE....... 37

GENERAL INFORMATION

NV T350 MANUAL TRANSAXLE

NOTE: Safety goggles should be worn at all times

when working on these transaxles.

This five speed is a constant-mesh manual tran-

saxle. All gear ranges, except reverse, are synchro-

nized. The reverse gear utilizes a brake and blockingring for shifting ease. The reverse idler gear is sup-

ported on a sliding spindle idler shaft. The transaxle

case is aluminum with a steel end±plate bearing

cover. It is housed in a die-cast aluminum case fea-

turing a two±piece, middle split design.

The NV T350 (A-578) transaxle internal compo-

nents can be serviced only by separating the gear

case from the bellhousing case.

PLTRANSAXLE 21 - 1

Page 945 of 1200

CAUTION: The transaxle output shaft is serviced as

a unit. No disassembly and reassembly is possible.

Damage to the transaxle may result.

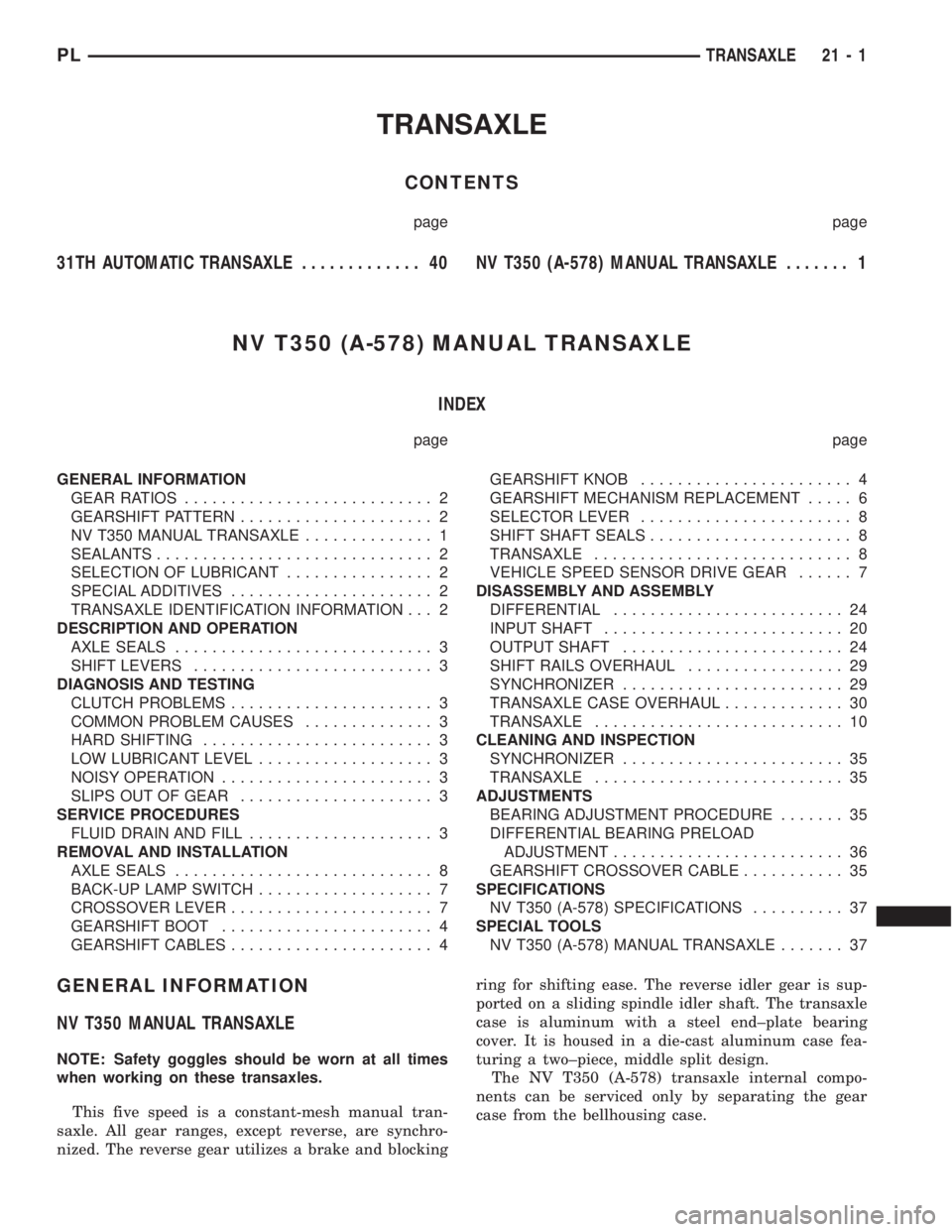

TRANSAXLE IDENTIFICATION INFORMATION

The transaxle model, assembly number, and build

date are on a metal I.D. tag that is attached to the

end cover of the transaxle (Fig. 1). This information

is also shown on a bar code label that is attached to

the front of the transaxle.

NOTE: Transaxles use various final drive gear

ratios in different vehicle applications. Therefore, it

is necessary that the correct transaxle assembly

number is used when ordering service parts.

The last eight digits of the Vehicle Identification

Number (V.I.N.) are stamped on the case, below the

back±up lamp switch.

NOTE: There are four different versions of this

transaxle. There are no external differences

between the models. Refer to the identification tag

on the transaxle to determine which transaxle the

vehicle is equipped with.

SELECTION OF LUBRICANT

NV T350 (A-578) transaxles use MopartType M.S.

9417 Manual Transaxle Fluid.Hypoid gear lube,

engine oil, and/or automatic transmission fluid

should not be used in this transaxle.Hard shift-

ing effort, bearing, gear, and/or synchronizer failure

may occur if incorrect fluid is used.

SPECIAL ADDITIVES

The addition of any fluids to the transaxle, other

than the fluid listed above, is not recommended. An

exception to this policy is the use of special dyes toaid in detecting fluid leaks. The use of transmission

sealers should be avoided, since they may adversely

affect seals.

SEALANTS

The sealant used to seal the transaxle case halves

and input bearing is MopartGasket Maker, Loctitet

518, or equivalent. The sealant used for the bearing

end plate cover is MopartRTV.

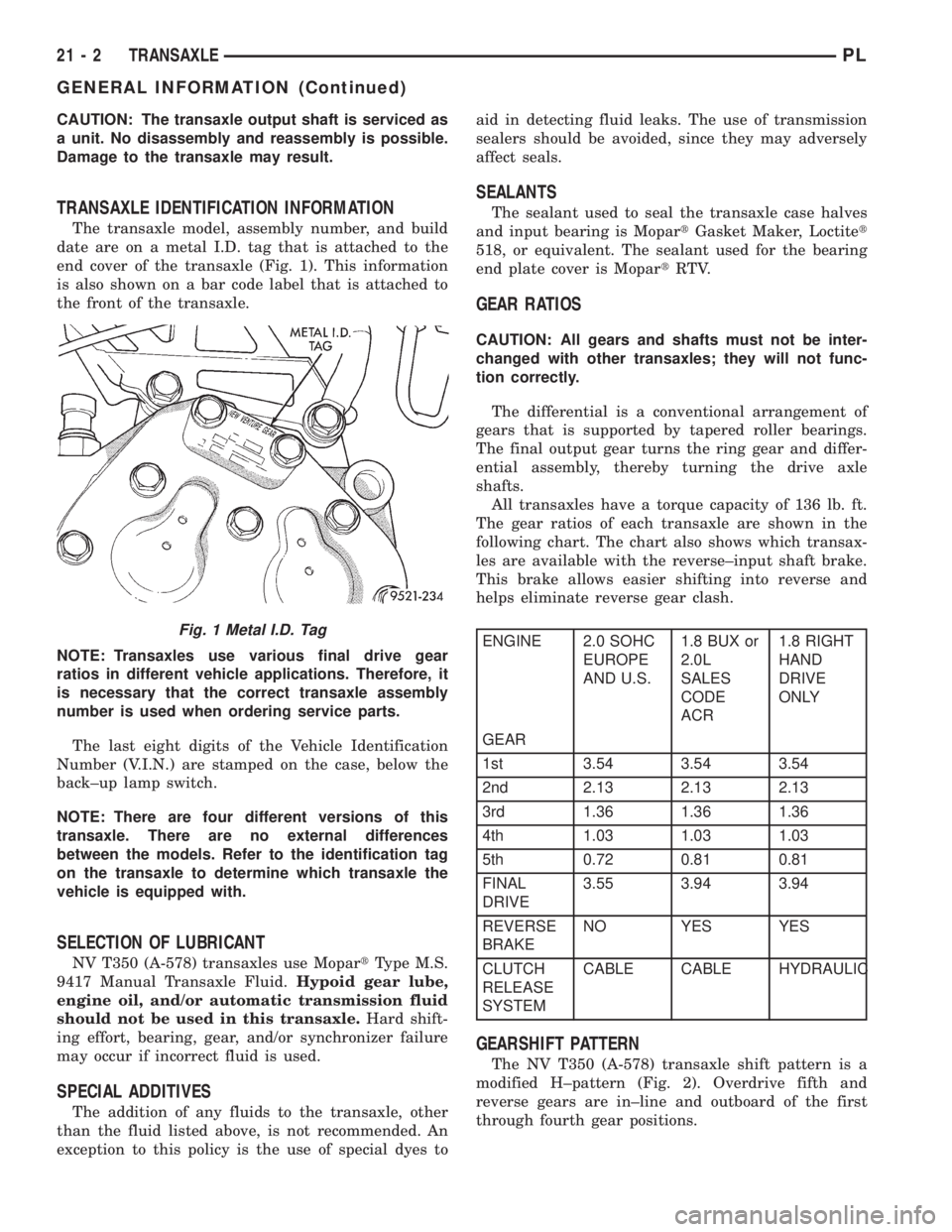

GEAR RATIOS

CAUTION: All gears and shafts must not be inter-

changed with other transaxles; they will not func-

tion correctly.

The differential is a conventional arrangement of

gears that is supported by tapered roller bearings.

The final output gear turns the ring gear and differ-

ential assembly, thereby turning the drive axle

shafts.

All transaxles have a torque capacity of 136 lb. ft.

The gear ratios of each transaxle are shown in the

following chart. The chart also shows which transax-

les are available with the reverse±input shaft brake.

This brake allows easier shifting into reverse and

helps eliminate reverse gear clash.

ENGINE 2.0 SOHC

EUROPE

AND U.S.1.8 BUX or

2.0L

SALES

CODE

ACR1.8 RIGHT

HAND

DRIVE

ONLY

GEAR

1st 3.54 3.54 3.54

2nd 2.13 2.13 2.13

3rd 1.36 1.36 1.36

4th 1.03 1.03 1.03

5th 0.72 0.81 0.81

FINAL

DRIVE3.55 3.94 3.94

REVERSE

BRAKENO YES YES

CLUTCH

RELEASE

SYSTEMCABLE CABLE HYDRAULIC

GEARSHIFT PATTERN

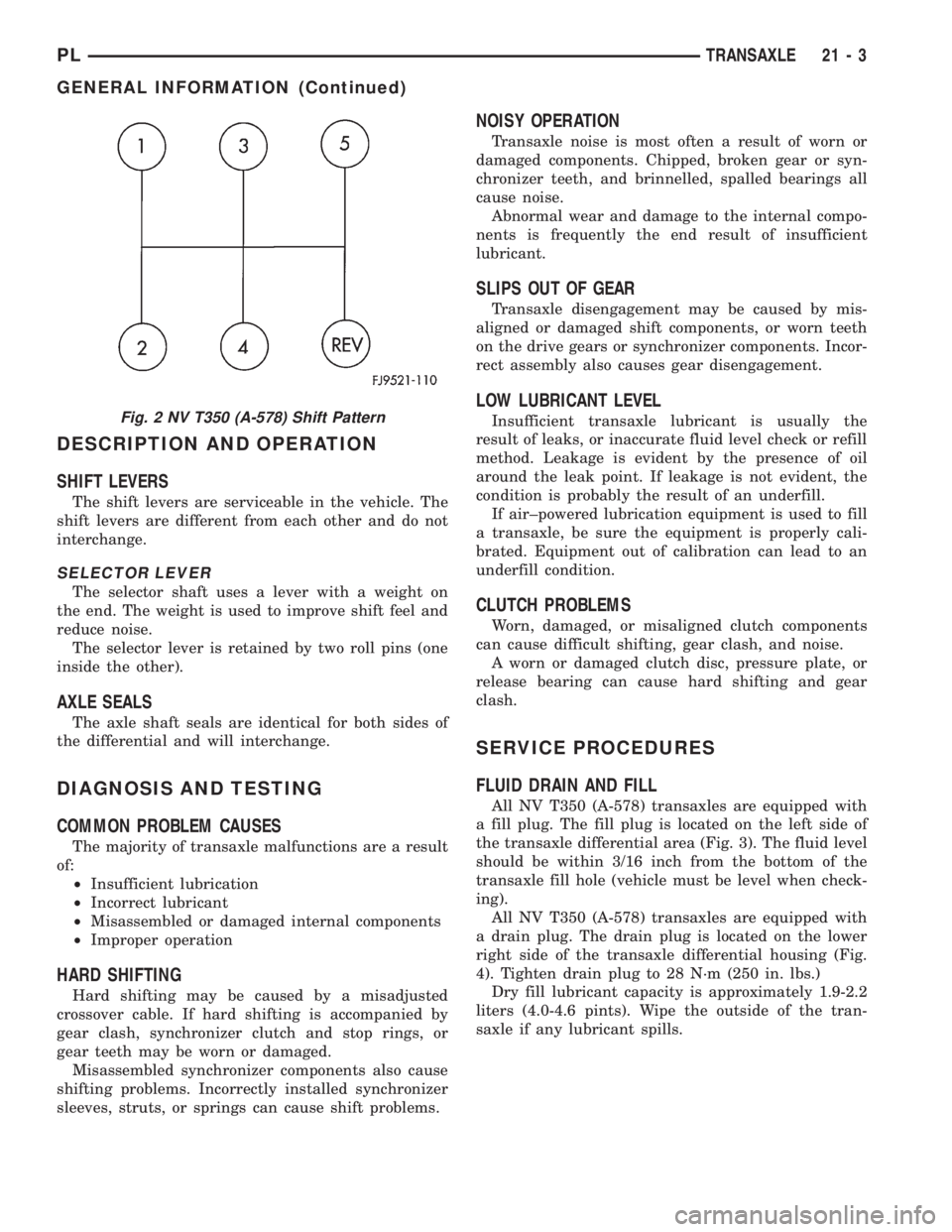

The NV T350 (A-578) transaxle shift pattern is a

modified H±pattern (Fig. 2). Overdrive fifth and

reverse gears are in±line and outboard of the first

through fourth gear positions.

Fig. 1 Metal I.D. Tag

21 - 2 TRANSAXLEPL

GENERAL INFORMATION (Continued)

Page 946 of 1200

DESCRIPTION AND OPERATION

SHIFT LEVERS

The shift levers are serviceable in the vehicle. The

shift levers are different from each other and do not

interchange.

SELECTOR LEVER

The selector shaft uses a lever with a weight on

the end. The weight is used to improve shift feel and

reduce noise.

The selector lever is retained by two roll pins (one

inside the other).

AXLE SEALS

The axle shaft seals are identical for both sides of

the differential and will interchange.

DIAGNOSIS AND TESTING

COMMON PROBLEM CAUSES

The majority of transaxle malfunctions are a result

of:

²Insufficient lubrication

²Incorrect lubricant

²Misassembled or damaged internal components

²Improper operation

HARD SHIFTING

Hard shifting may be caused by a misadjusted

crossover cable. If hard shifting is accompanied by

gear clash, synchronizer clutch and stop rings, or

gear teeth may be worn or damaged.

Misassembled synchronizer components also cause

shifting problems. Incorrectly installed synchronizer

sleeves, struts, or springs can cause shift problems.

NOISY OPERATION

Transaxle noise is most often a result of worn or

damaged components. Chipped, broken gear or syn-

chronizer teeth, and brinnelled, spalled bearings all

cause noise.

Abnormal wear and damage to the internal compo-

nents is frequently the end result of insufficient

lubricant.

SLIPS OUT OF GEAR

Transaxle disengagement may be caused by mis-

aligned or damaged shift components, or worn teeth

on the drive gears or synchronizer components. Incor-

rect assembly also causes gear disengagement.

LOW LUBRICANT LEVEL

Insufficient transaxle lubricant is usually the

result of leaks, or inaccurate fluid level check or refill

method. Leakage is evident by the presence of oil

around the leak point. If leakage is not evident, the

condition is probably the result of an underfill.

If air±powered lubrication equipment is used to fill

a transaxle, be sure the equipment is properly cali-

brated. Equipment out of calibration can lead to an

underfill condition.

CLUTCH PROBLEMS

Worn, damaged, or misaligned clutch components

can cause difficult shifting, gear clash, and noise.

A worn or damaged clutch disc, pressure plate, or

release bearing can cause hard shifting and gear

clash.

SERVICE PROCEDURES

FLUID DRAIN AND FILL

All NV T350 (A-578) transaxles are equipped with

a fill plug. The fill plug is located on the left side of

the transaxle differential area (Fig. 3). The fluid level

should be within 3/16 inch from the bottom of the

transaxle fill hole (vehicle must be level when check-

ing).

All NV T350 (A-578) transaxles are equipped with

a drain plug. The drain plug is located on the lower

right side of the transaxle differential housing (Fig.

4). Tighten drain plug to 28 N´m (250 in. lbs.)

Dry fill lubricant capacity is approximately 1.9-2.2

liters (4.0-4.6 pints). Wipe the outside of the tran-

saxle if any lubricant spills.

Fig. 2 NV T350 (A-578) Shift Pattern

PLTRANSAXLE 21 - 3

GENERAL INFORMATION (Continued)

Page 951 of 1200

SELECTOR LEVER

The selector shaft uses a lever with a weight on

the end. The weight is used to improve shift±feel and

reduce noise.

The selector lever is retained by two roll pins (one

inside the other).

REMOVAL

(1) Remove the selector cable. Refer to Gearshift

Cable removal.

(2) Using a pin punch, remove both roll pins from

the lever.

(3) Pull up and remove the selector lever from the

transaxle selector shaft

INSTALLATION

(1) For installation, reverse removal procedure.

Replace the roll pins that were removed with new

ones. The correct orientation for the roll pins is

shown in (Fig. 18).

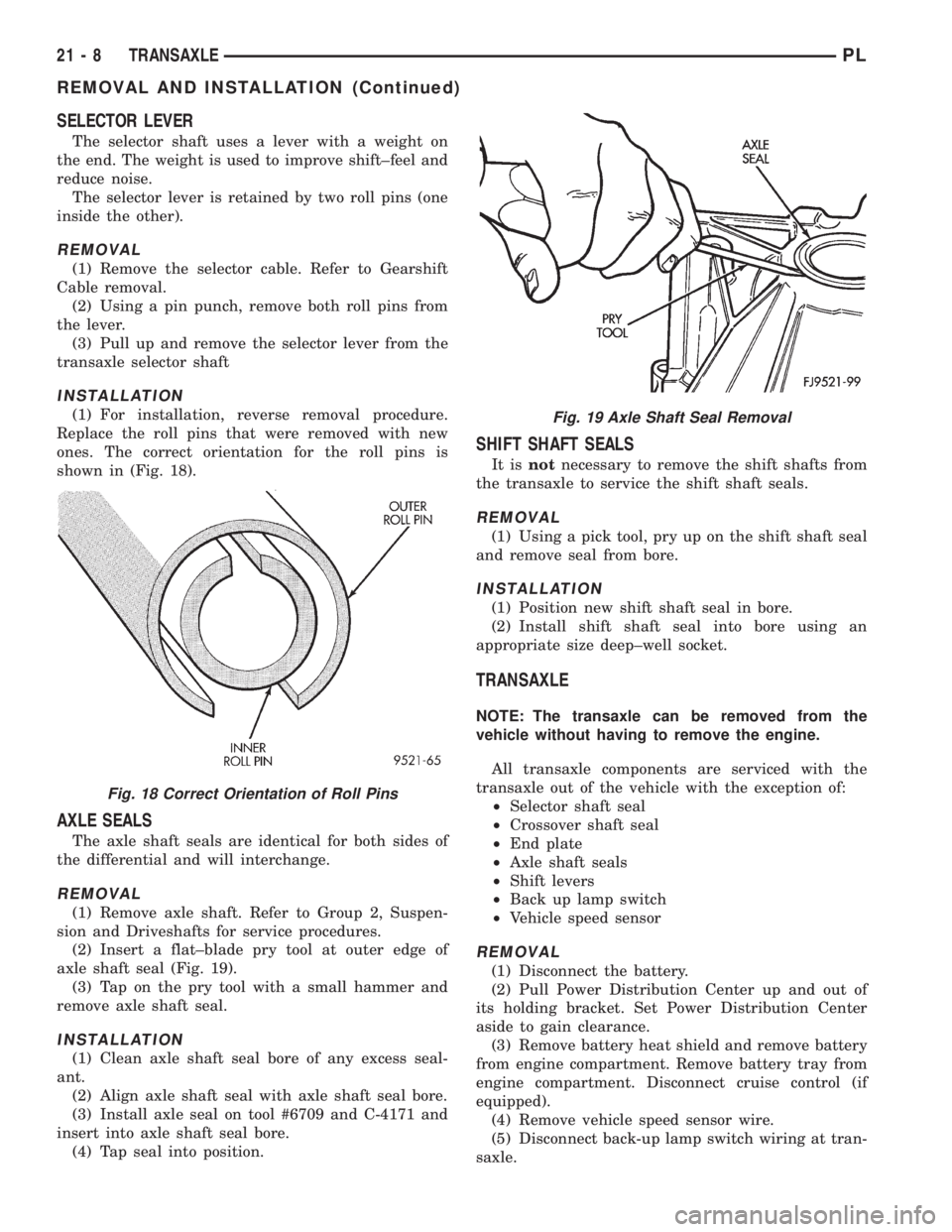

AXLE SEALS

The axle shaft seals are identical for both sides of

the differential and will interchange.

REMOVAL

(1) Remove axle shaft. Refer to Group 2, Suspen-

sion and Driveshafts for service procedures.

(2) Insert a flat±blade pry tool at outer edge of

axle shaft seal (Fig. 19).

(3) Tap on the pry tool with a small hammer and

remove axle shaft seal.

INSTALLATION

(1) Clean axle shaft seal bore of any excess seal-

ant.

(2) Align axle shaft seal with axle shaft seal bore.

(3) Install axle seal on tool #6709 and C-4171 and

insert into axle shaft seal bore.

(4) Tap seal into position.

SHIFT SHAFT SEALS

It isnotnecessary to remove the shift shafts from

the transaxle to service the shift shaft seals.

REMOVAL

(1) Using a pick tool, pry up on the shift shaft seal

and remove seal from bore.

INSTALLATION

(1) Position new shift shaft seal in bore.

(2) Install shift shaft seal into bore using an

appropriate size deep±well socket.

TRANSAXLE

NOTE: The transaxle can be removed from the

vehicle without having to remove the engine.

All transaxle components are serviced with the

transaxle out of the vehicle with the exception of:

²Selector shaft seal

²Crossover shaft seal

²End plate

²Axle shaft seals

²Shift levers

²Back up lamp switch

²Vehicle speed sensor

REMOVAL

(1) Disconnect the battery.

(2) Pull Power Distribution Center up and out of

its holding bracket. Set Power Distribution Center

aside to gain clearance.

(3) Remove battery heat shield and remove battery

from engine compartment. Remove battery tray from

engine compartment. Disconnect cruise control (if

equipped).

(4) Remove vehicle speed sensor wire.

(5) Disconnect back-up lamp switch wiring at tran-

saxle.

Fig. 18 Correct Orientation of Roll Pins

Fig. 19 Axle Shaft Seal Removal

21 - 8 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)