lock DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 1131 of 1200

INSTALLATION

(1) With the aid of a helper, hold the sunroof glass

panel in the closed position and engage the drive

motor (10) into the sunroof drive cables.

(2) Install screws holding drive motor to bracket.

(3) Connect wire harness to drive motor.

(4) Install headlining.

SUNROOF GLASS PANEL

REMOVAL

(1) Position sunroof sunshade (4) in full rearward

position.

(2) Remove six glass attachment screws.

(3) Push glass panel upward from underside until

glass panel clears the roof panel.

(4) Lift glass panel from vehicle.

INSTALLATION

(1) Position glass panel (4) in opening in vehicle

roof.

(2) Install, but do not tighten, glass attachment

screws.

(3) With the aid of a helper, hold the glass panel in

position and tighten glass attachment screws.

(4) Verify the correct glass height. Refer to Glass

Height Adjustment procedure in this section.

SUNROOF GUIDE AND MECHANISM ASSEMBLY

REMOVAL

(1) Remove sunroof glass panel (4). Refer to proce-

dure in this section.

(2) Remove front locator (7 or 8).

(3) Disengage cable from mechanism (9).

(4) Remove screws holding sunroof guide (5) and

mechanism (9) assembly to sunroof module.

(5) Lift assembly from module.

(6) Rotate assembly to disengage wind deflector

(13) from assembly.

INSTALLATION

(1) Engage wind deflector (13) into guide (5) and

mechanism (9) assembly.

(2) Position assembly onto module and install

screws holding assembly to sunroof module.

(3) Engage drive cable to mechanism.

(4) Install front locator (7 or 8 ). It may ease

installation to move sunroof mechanism slightly rear-

ward.

(5) Install sunroof glass panel. Refer to procedure

found in this section.

SUNROOF MODULE

REMOVAL

(1) Remove headlining.

(2) Remove fasteners attaching sunroof module to

vehicle roof and support braces.

(3) With the aid of a helper, separate sunroof mod-

ule from roof.

(4) Remove sunroof module from vehicle.

INSTALLATION

(1) With the aid of a helper, position sunroof mod-

ule in vehicle.

(2) Install fasteners holding sunroof module to

vehicle roof.

(3) Tighten all fasteners, starting from the front

and working rearward and then the motor bracket.

(4) Adjust glass panel for flushness to roof. Refer

to glass adjustment procedure in this section.

(5) Install headlining.

(6) Verify correct operation.

SUNROOF SUNSHADE

REMOVAL

(1) Remove sunroof glass panel (4). Refer to proce-

dure found in this section.

(2) Slide sunshade (11) to full forward position.

(3) Disengage slide blocks on one side of sunshade

from sunshade guide (6).

(4) Lift and pull sunshade out of opposite sun-

shade guide.

INSTALLATION

(1) Place sunshade with cloth side down and

install one side's slide blocks into the track on the

sunshade guide (6).

(2) Slide the other side's slide blocks to fully

inward position and insert them into the sunshade

guide (6).

(3) Verify that all four slide blocks are fully

engaged in the sunshade guide (6).

(4) Slide sunshade (11) fully rearward.

(5) Install sunroof glass panel (4). Refer to proce-

dure found in this section.

SUNROOF WIND DEFLECTOR

REMOVAL

(1) Open sunroof to full open position.

(2) Pull one end of wind deflector flap out of the

wind deflector beam (13).

(3) Release corner piece locking tab and separate

corner piece from wind deflector beam.

(4) Rotate corner piece outboard to release tab

from roof flange.

23 - 50 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1136 of 1200

DESCRIPTION AND OPERATION

A/C REFRIGERANT LINES

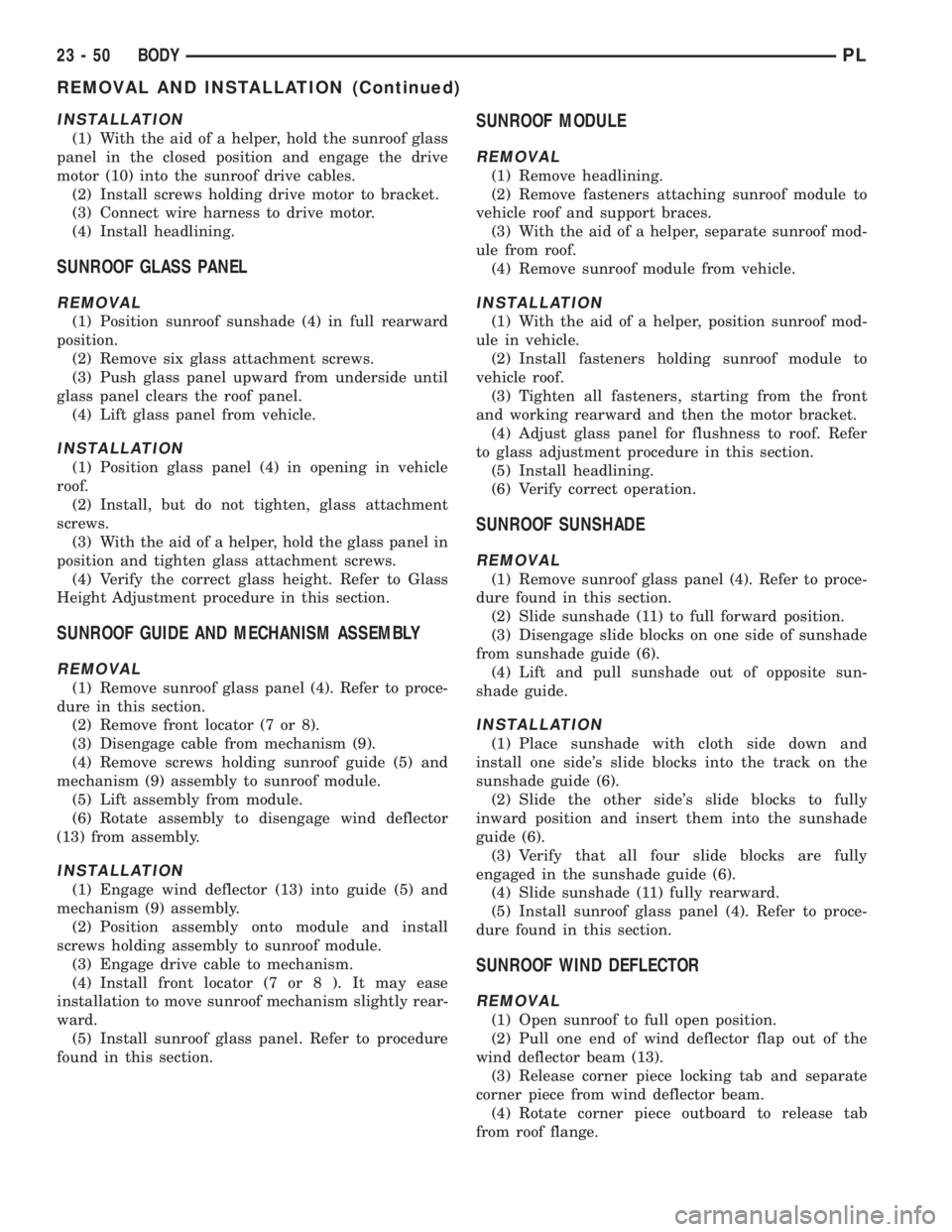

DISCHARGE LINE

The discharge line is the line that goes from the

compressor to the condenser (Fig. 3). It has no ser-

viceable parts except the rubber O- rings. If the line

is found to be leaking or is damaged it must be

replaced as an assembly.

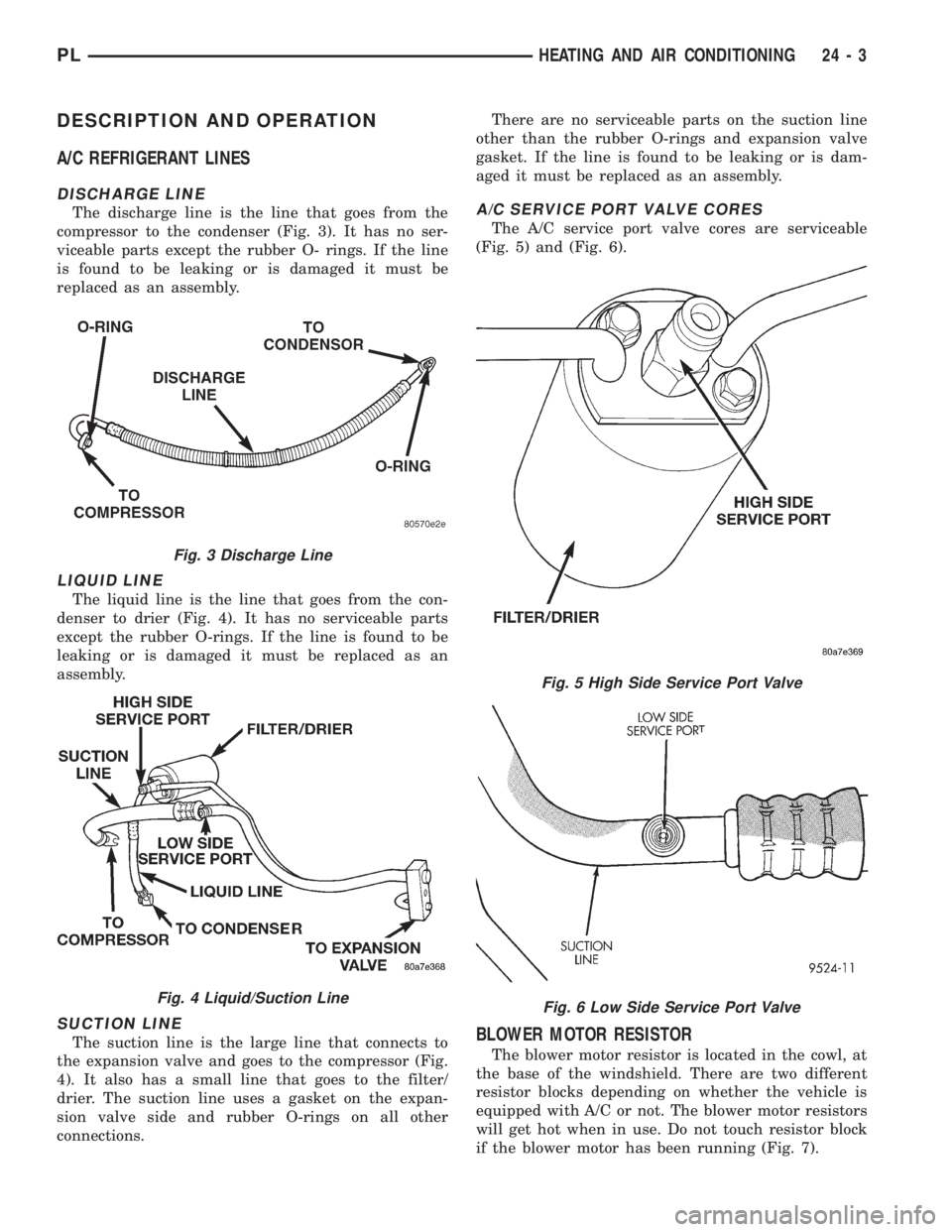

LIQUID LINE

The liquid line is the line that goes from the con-

denser to drier (Fig. 4). It has no serviceable parts

except the rubber O-rings. If the line is found to be

leaking or is damaged it must be replaced as an

assembly.

SUCTION LINE

The suction line is the large line that connects to

the expansion valve and goes to the compressor (Fig.

4). It also has a small line that goes to the filter/

drier. The suction line uses a gasket on the expan-

sion valve side and rubber O-rings on all other

connections.There are no serviceable parts on the suction line

other than the rubber O-rings and expansion valve

gasket. If the line is found to be leaking or is dam-

aged it must be replaced as an assembly.

A/C SERVICE PORT VALVE CORES

The A/C service port valve cores are serviceable

(Fig. 5) and (Fig. 6).

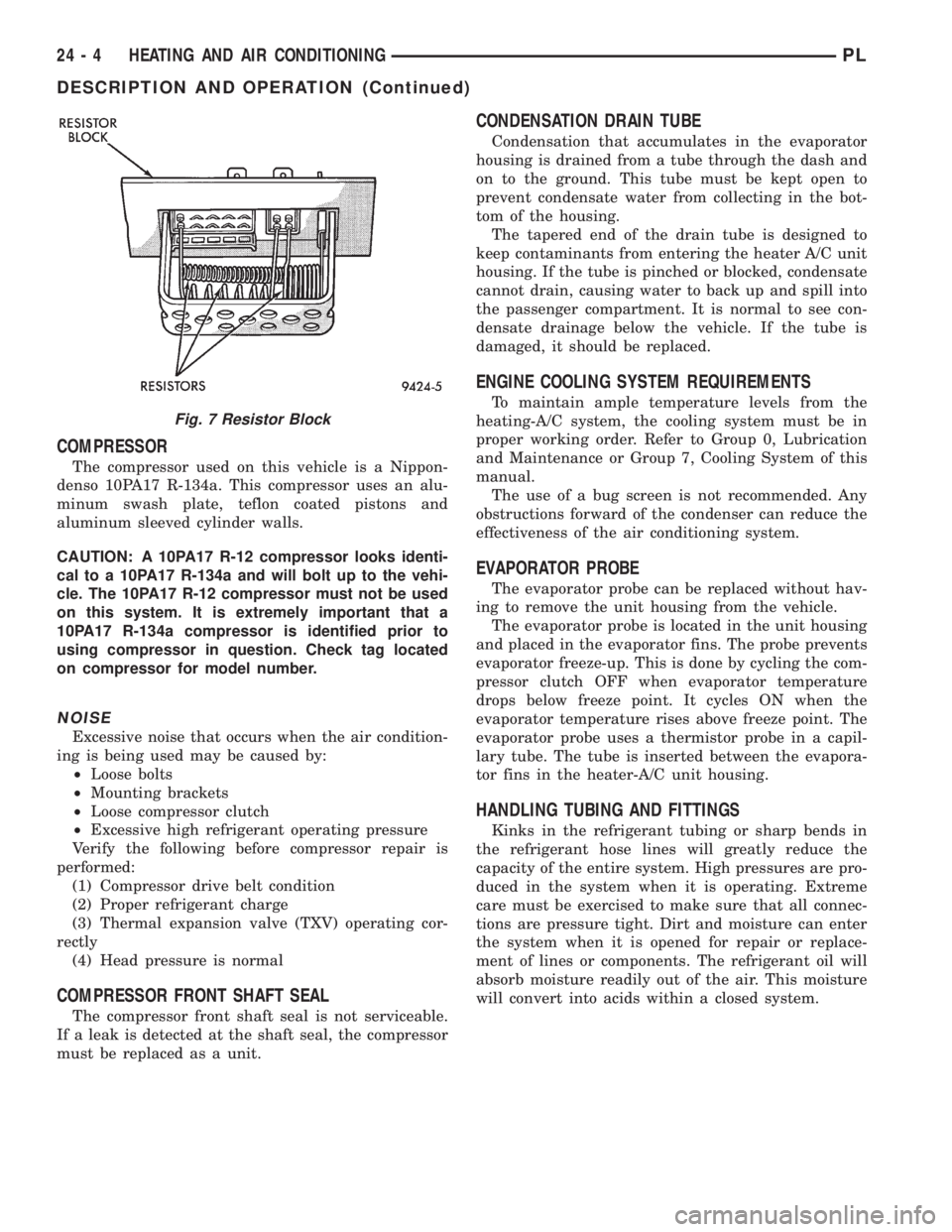

BLOWER MOTOR RESISTOR

The blower motor resistor is located in the cowl, at

the base of the windshield. There are two different

resistor blocks depending on whether the vehicle is

equipped with A/C or not. The blower motor resistors

will get hot when in use. Do not touch resistor block

if the blower motor has been running (Fig. 7).

Fig. 3 Discharge Line

Fig. 4 Liquid/Suction Line

Fig. 5 High Side Service Port Valve

Fig. 6 Low Side Service Port Valve

PLHEATING AND AIR CONDITIONING 24 - 3

Page 1137 of 1200

COMPRESSOR

The compressor used on this vehicle is a Nippon-

denso 10PA17 R-134a. This compressor uses an alu-

minum swash plate, teflon coated pistons and

aluminum sleeved cylinder walls.

CAUTION: A 10PA17 R-12 compressor looks identi-

cal to a 10PA17 R-134a and will bolt up to the vehi-

cle. The 10PA17 R-12 compressor must not be used

on this system. It is extremely important that a

10PA17 R-134a compressor is identified prior to

using compressor in question. Check tag located

on compressor for model number.

NOISE

Excessive noise that occurs when the air condition-

ing is being used may be caused by:

²Loose bolts

²Mounting brackets

²Loose compressor clutch

²Excessive high refrigerant operating pressure

Verify the following before compressor repair is

performed:

(1) Compressor drive belt condition

(2) Proper refrigerant charge

(3) Thermal expansion valve (TXV) operating cor-

rectly

(4) Head pressure is normal

COMPRESSOR FRONT SHAFT SEAL

The compressor front shaft seal is not serviceable.

If a leak is detected at the shaft seal, the compressor

must be replaced as a unit.

CONDENSATION DRAIN TUBE

Condensation that accumulates in the evaporator

housing is drained from a tube through the dash and

on to the ground. This tube must be kept open to

prevent condensate water from collecting in the bot-

tom of the housing.

The tapered end of the drain tube is designed to

keep contaminants from entering the heater A/C unit

housing. If the tube is pinched or blocked, condensate

cannot drain, causing water to back up and spill into

the passenger compartment. It is normal to see con-

densate drainage below the vehicle. If the tube is

damaged, it should be replaced.

ENGINE COOLING SYSTEM REQUIREMENTS

To maintain ample temperature levels from the

heating-A/C system, the cooling system must be in

proper working order. Refer to Group 0, Lubrication

and Maintenance or Group 7, Cooling System of this

manual.

The use of a bug screen is not recommended. Any

obstructions forward of the condenser can reduce the

effectiveness of the air conditioning system.

EVAPORATOR PROBE

The evaporator probe can be replaced without hav-

ing to remove the unit housing from the vehicle.

The evaporator probe is located in the unit housing

and placed in the evaporator fins. The probe prevents

evaporator freeze-up. This is done by cycling the com-

pressor clutch OFF when evaporator temperature

drops below freeze point. It cycles ON when the

evaporator temperature rises above freeze point. The

evaporator probe uses a thermistor probe in a capil-

lary tube. The tube is inserted between the evapora-

tor fins in the heater-A/C unit housing.

HANDLING TUBING AND FITTINGS

Kinks in the refrigerant tubing or sharp bends in

the refrigerant hose lines will greatly reduce the

capacity of the entire system. High pressures are pro-

duced in the system when it is operating. Extreme

care must be exercised to make sure that all connec-

tions are pressure tight. Dirt and moisture can enter

the system when it is opened for repair or replace-

ment of lines or components. The refrigerant oil will

absorb moisture readily out of the air. This moisture

will convert into acids within a closed system.

Fig. 7 Resistor Block

24 - 4 HEATING AND AIR CONDITIONINGPL

DESCRIPTION AND OPERATION (Continued)

Page 1139 of 1200

outlets in various combinations using the mode selec-

tor. There are 17 different mode selections possible.

Air flow velocity can be adjusted with the blower

speed selector switch on the instrument panel.

On A/C equipped vehicles the ambient air intake

can be controlled by opening and closing the recircu-

lating air door. When placed in RECIRC, air that is

inside vehicle is removed continuously and recircu-

lated through unit housing. Ambient air cannot be

controlled on vehicles without A/C. The system uses

outside air at all times.

The air conditioning compressor can be engaged by

turning the fan switch counterclockwise from the off

position. It can also be engaged by placing the mode

control in the defrost position. This will remove heat

and humidity from the air before it is directed

through or around the heater core.

SYSTEM OIL LEVEL

It is important to have the correct amount of oil in

the A/C system to ensure proper lubrication of the

compressor. Too little oil will result in damage to the

compressor. Too much oil will reduce the cooling

capacity of the system and consequently result in

higher discharge air temperatures.

NOTE: The oil used in the compressor is ND8 PAG

R-134a refrigerant oil. Only refrigerant oil of the

same type should be used to service the system.

Do not use any other oil. The oil container should

be kept tightly capped until it is ready for use.

Tightly cap afterwards to prevent contamination

from dirt and moisture. Refrigerant oil will quickly

absorb any moisture it comes in contact with. Spe-

cial effort must be used to keep all R-134a system

components moisture-free. Moisture in the oil is

very difficult to remove and will cause a reliability

problem with the compressor.

It will not be necessary to check oil level in the

compressor or to add oil unless there has been an oil

loss. Oil loss at a leak point will be evident by the

presence of a wet, shiny surface around the leak.

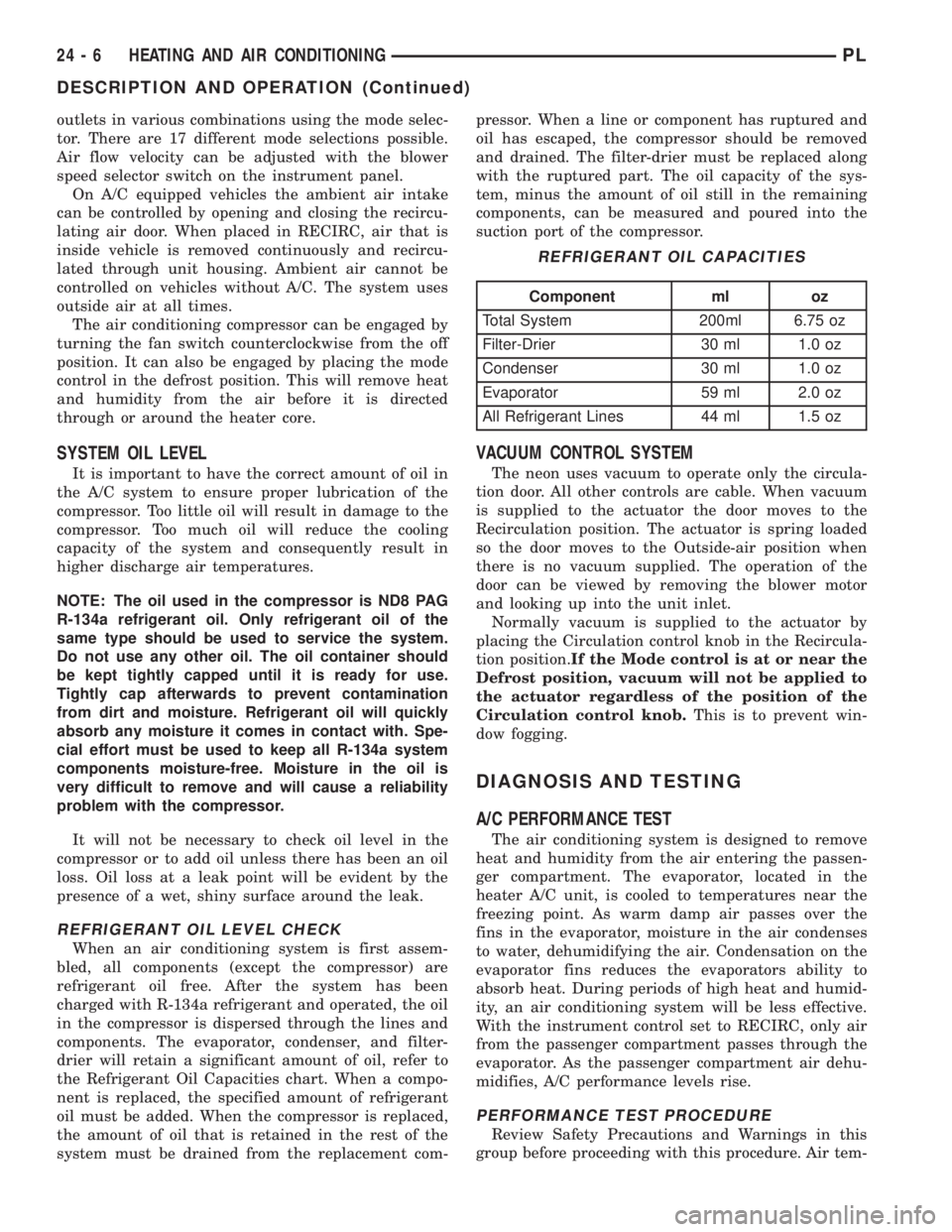

REFRIGERANT OIL LEVEL CHECK

When an air conditioning system is first assem-

bled, all components (except the compressor) are

refrigerant oil free. After the system has been

charged with R-134a refrigerant and operated, the oil

in the compressor is dispersed through the lines and

components. The evaporator, condenser, and filter-

drier will retain a significant amount of oil, refer to

the Refrigerant Oil Capacities chart. When a compo-

nent is replaced, the specified amount of refrigerant

oil must be added. When the compressor is replaced,

the amount of oil that is retained in the rest of the

system must be drained from the replacement com-pressor. When a line or component has ruptured and

oil has escaped, the compressor should be removed

and drained. The filter-drier must be replaced along

with the ruptured part. The oil capacity of the sys-

tem, minus the amount of oil still in the remaining

components, can be measured and poured into the

suction port of the compressor.

VACUUM CONTROL SYSTEM

The neon uses vacuum to operate only the circula-

tion door. All other controls are cable. When vacuum

is supplied to the actuator the door moves to the

Recirculation position. The actuator is spring loaded

so the door moves to the Outside-air position when

there is no vacuum supplied. The operation of the

door can be viewed by removing the blower motor

and looking up into the unit inlet.

Normally vacuum is supplied to the actuator by

placing the Circulation control knob in the Recircula-

tion position.If the Mode control is at or near the

Defrost position, vacuum will not be applied to

the actuator regardless of the position of the

Circulation control knob.This is to prevent win-

dow fogging.

DIAGNOSIS AND TESTING

A/C PERFORMANCE TEST

The air conditioning system is designed to remove

heat and humidity from the air entering the passen-

ger compartment. The evaporator, located in the

heater A/C unit, is cooled to temperatures near the

freezing point. As warm damp air passes over the

fins in the evaporator, moisture in the air condenses

to water, dehumidifying the air. Condensation on the

evaporator fins reduces the evaporators ability to

absorb heat. During periods of high heat and humid-

ity, an air conditioning system will be less effective.

With the instrument control set to RECIRC, only air

from the passenger compartment passes through the

evaporator. As the passenger compartment air dehu-

midifies, A/C performance levels rise.

PERFORMANCE TEST PROCEDURE

Review Safety Precautions and Warnings in this

group before proceeding with this procedure. Air tem-

REFRIGERANT OIL CAPACITIES

Component ml oz

Total System 200ml 6.75 oz

Filter-Drier 30 ml 1.0 oz

Condenser 30 ml 1.0 oz

Evaporator 59 ml 2.0 oz

All Refrigerant Lines 44 ml 1.5 oz

24 - 6 HEATING AND AIR CONDITIONINGPL

DESCRIPTION AND OPERATION (Continued)

Page 1140 of 1200

perature in test room and on vehicle must be 21É C

(70ÉF) minimum for this test.

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

(1) Connect a tachometer and manifold gauge set.

(2) Set control to A/C, RECIRC, and PANEL, tem-

perature lever on full cool and blower on high.

(3) Start engine and hold at 1000 rpm with A/C

clutch engaged.

(4) Engine should be warmed up with doors and

windows closed.

(5) Insert a thermometer in the left center A/C

outlet and operate the engine for five minutes. The

A/C clutch may cycle depending on ambient condi-

tions.

(6) With the A/C clutch engaged, compare the dis-

charge air temperature to the A/C Performance Tem-

peratures Table.

(7) If the discharge air temperature fails to meet

the specifications in the performance temperature

chart. Refer to the Refrigerant Service Procedures for

further diagnosis.

COMPRESSOR NOISE DIAGNOSIS

Excessive noise while the A/C is being used, can be

caused by loose mounts, loose clutch, or high operat-

ing pressure. Verify compressor drive belt condition,

proper refrigerant charge and head pressure before

compressor repair is performed.

If the A/C drive belt slips at initial start-up, it does

not necessarily mean the compressor has failed.

With the close tolerances of a compressor it is pos-

sible to experience a temporary lockup. The longer

the A/C system is inactive, the more likely the condi-

tion to occur.

This condition is the result of normal refrigerant

movement within the A/C system caused by temper-

ature changes. The refrigerant movement may wash

the oil out of the compressor.

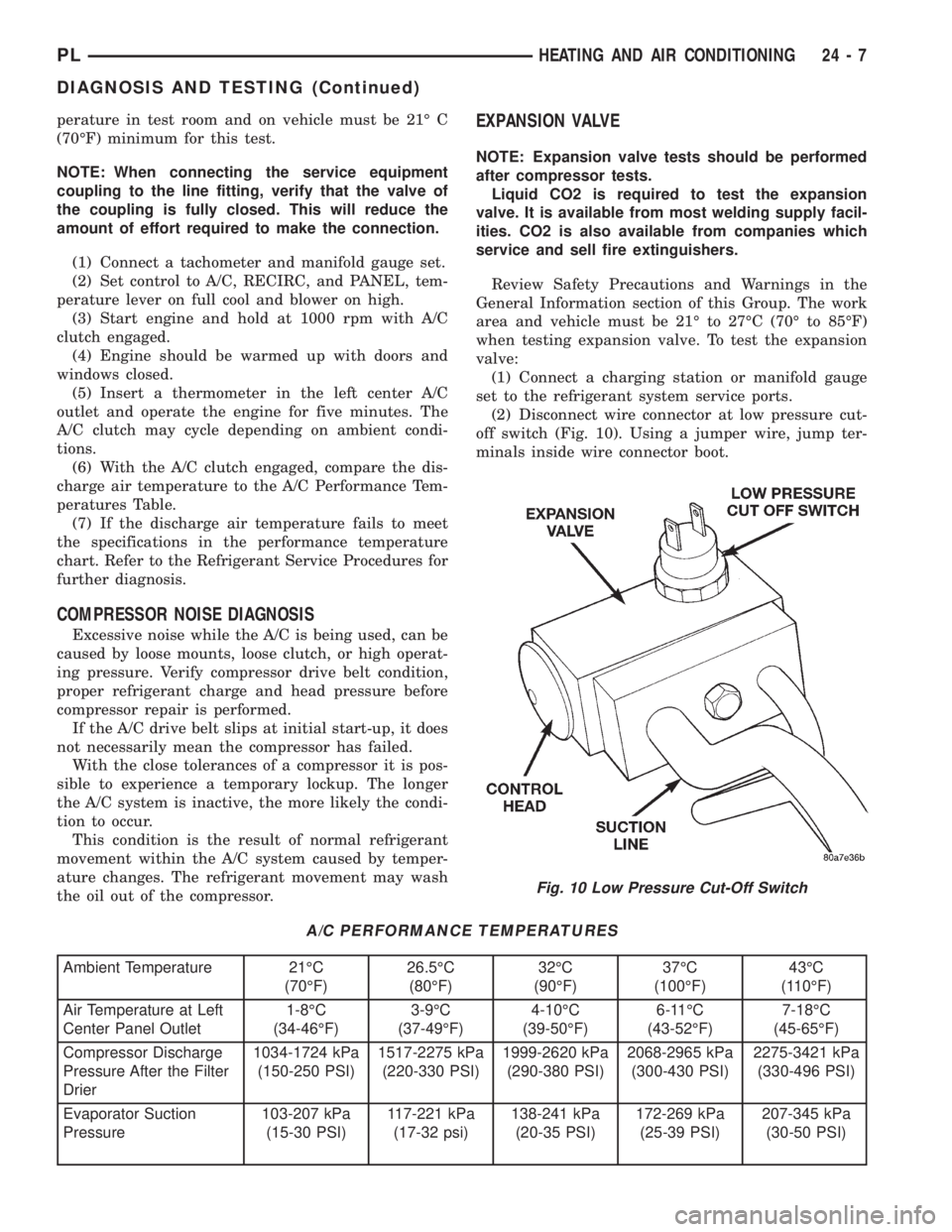

EXPANSION VALVE

NOTE: Expansion valve tests should be performed

after compressor tests.

Liquid CO2 is required to test the expansion

valve. It is available from most welding supply facil-

ities. CO2 is also available from companies which

service and sell fire extinguishers.

Review Safety Precautions and Warnings in the

General Information section of this Group. The work

area and vehicle must be 21É to 27ÉC (70É to 85ÉF)

when testing expansion valve. To test the expansion

valve:

(1) Connect a charging station or manifold gauge

set to the refrigerant system service ports.

(2) Disconnect wire connector at low pressure cut-

off switch (Fig. 10). Using a jumper wire, jump ter-

minals inside wire connector boot.

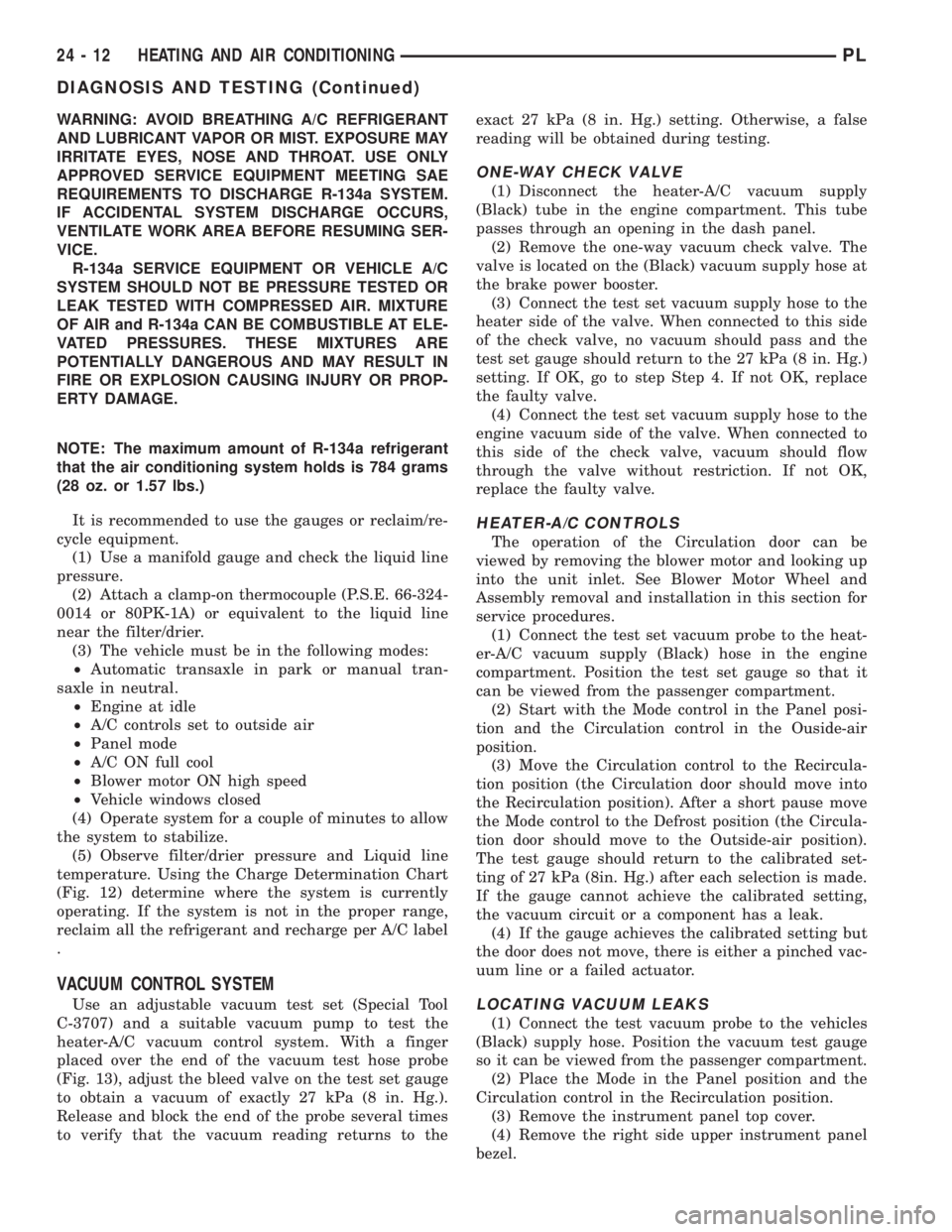

A/C PERFORMANCE TEMPERATURES

Ambient Temperature 21ÉC

(70ÉF)26.5ÉC

(80ÉF)32ÉC

(90ÉF)37ÉC

(100ÉF)43ÉC

(110ÉF)

Air Temperature at Left

Center Panel Outlet1-8ÉC

(34-46ÉF)3-9ÉC

(37-49ÉF)4-10ÉC

(39-50ÉF)6-11ÉC

(43-52ÉF)7-18ÉC

(45-65ÉF)

Compressor Discharge

Pressure After the Filter

Drier1034-1724 kPa

(150-250 PSI)1517-2275 kPa

(220-330 PSI)1999-2620 kPa

(290-380 PSI)2068-2965 kPa

(300-430 PSI)2275-3421 kPa

(330-496 PSI)

Evaporator Suction

Pressure103-207 kPa

(15-30 PSI)117-221 kPa

(17-32 psi)138-241 kPa

(20-35 PSI)172-269 kPa

(25-39 PSI)207-345 kPa

(30-50 PSI)

Fig. 10 Low Pressure Cut-Off Switch

PLHEATING AND AIR CONDITIONING 24 - 7

DIAGNOSIS AND TESTING (Continued)

Page 1141 of 1200

(3) Close all doors, windows and vents to the pas-

senger compartment.

(4) Set Heater-A/C control to A/C, full heat, floor,

RECIRC. and high blower.

(5) Start the engine and hold the idle speed (1000

rpm). After the engine has reached running temper-

ature, allow the passenger compartment to heat up.

This will create the need for maximum refrigerant

flow into the evaporator.

(6) If the refrigerant charge is sufficient, discharge

(high pressure) gauge should read 965 to 2620 kPa

(140 to 380 psi). Suction (low pressure) gauge should

read 103 to 2417 kPa (15 to 35 psi). If system cannot

achieve proper pressure readings, replace the expan-

sion valve. If pressure is correct, proceed with test.

WARNING: PROTECT SKIN AND EYES FROM CON-

TACTING CO2 PERSONAL INJURY CAN RESULT.

(7) If suction side low pressure is within specified

range, freeze the expansion valve control head (Fig.

10) for 30 seconds. Use a super cold substance (liquid

CO2).Do not spray refrigerant on the expansion

valve for this test.Suction side low pressure should

drop to 34.5 kPa (5 psi) If not, replace expansion

valve.

(8) Allow expansion valve to thaw. The low pres-

sure gauge reading should stabilize at 103 to 241

kPa (15 to 35 psi). If not, replace expansion valve.

(9) When expansion valve test is complete, test

A/C overall performance. Refer to the Heater and A/C

Performance Test in this section. Remove all test

equipment before returning vehicle to use.

BLOWER MOTOR ELECTRICAL DIAGNOSIS

Refer to the Blower Motor Electrical System Diag-

nosis chart in this section. Also refer to Group 8W,

Wiring Diagrams for more information.

BLOWER MOTOR VIBRATION AND/OR NOISE

DIAGNOSIS

The resistor block supplies the blower motor with

varied voltage (low and middle speeds) or battery

voltage (high speed).

CAUTION: Stay clear of the blower motor and resis-

tor block (Hot). Do not operate the blower motor

with the resistor block removed from the heater-A/C

housing.

Refer to the Blower Motor Vibration/Noise chart

for diagnosis.

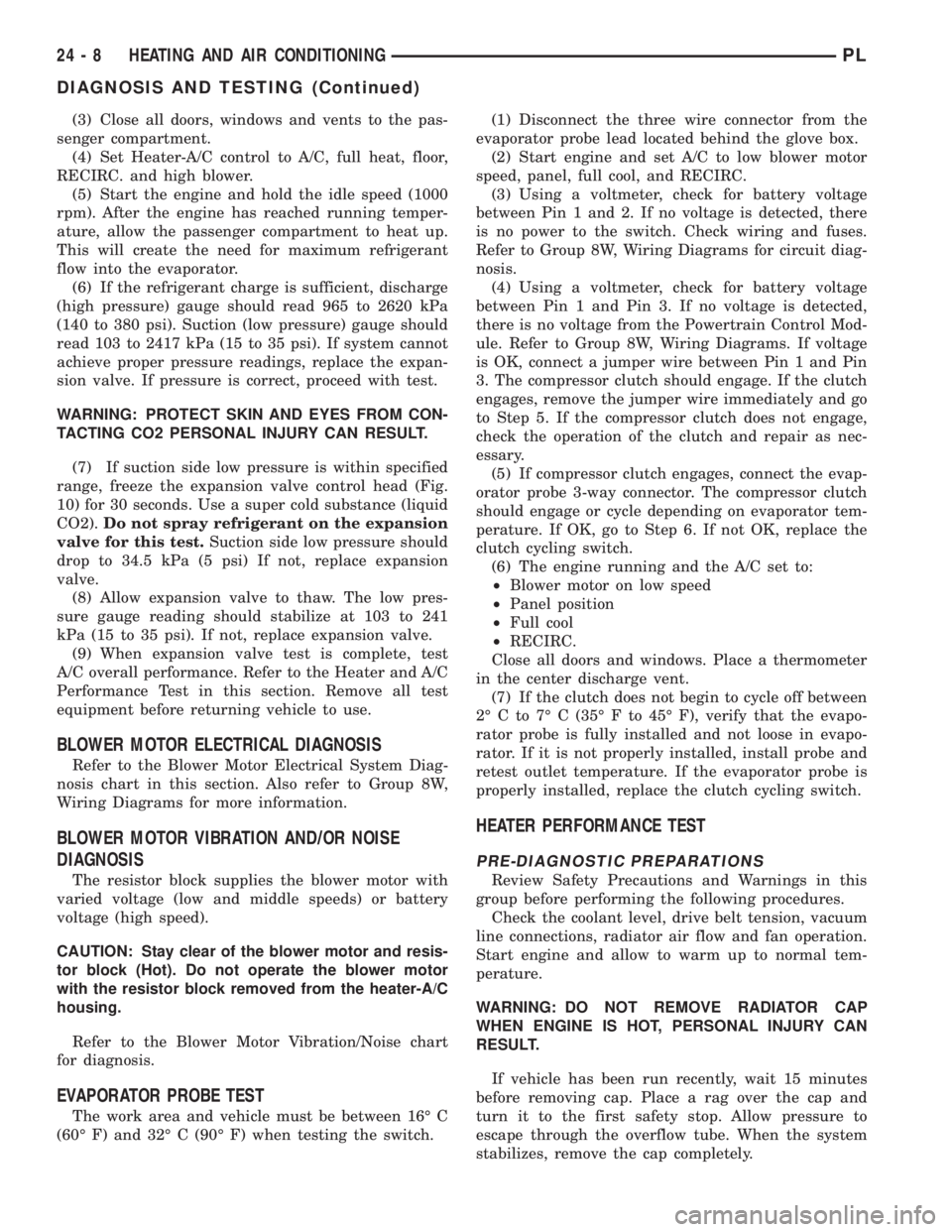

EVAPORATOR PROBE TEST

The work area and vehicle must be between 16É C

(60É F) and 32É C (90É F) when testing the switch.(1) Disconnect the three wire connector from the

evaporator probe lead located behind the glove box.

(2) Start engine and set A/C to low blower motor

speed, panel, full cool, and RECIRC.

(3) Using a voltmeter, check for battery voltage

between Pin 1 and 2. If no voltage is detected, there

is no power to the switch. Check wiring and fuses.

Refer to Group 8W, Wiring Diagrams for circuit diag-

nosis.

(4) Using a voltmeter, check for battery voltage

between Pin 1 and Pin 3. If no voltage is detected,

there is no voltage from the Powertrain Control Mod-

ule. Refer to Group 8W, Wiring Diagrams. If voltage

is OK, connect a jumper wire between Pin 1 and Pin

3. The compressor clutch should engage. If the clutch

engages, remove the jumper wire immediately and go

to Step 5. If the compressor clutch does not engage,

check the operation of the clutch and repair as nec-

essary.

(5) If compressor clutch engages, connect the evap-

orator probe 3-way connector. The compressor clutch

should engage or cycle depending on evaporator tem-

perature. If OK, go to Step 6. If not OK, replace the

clutch cycling switch.

(6) The engine running and the A/C set to:

²Blower motor on low speed

²Panel position

²Full cool

²RECIRC.

Close all doors and windows. Place a thermometer

in the center discharge vent.

(7) If the clutch does not begin to cycle off between

2É C to 7É C (35É F to 45É F), verify that the evapo-

rator probe is fully installed and not loose in evapo-

rator. If it is not properly installed, install probe and

retest outlet temperature. If the evaporator probe is

properly installed, replace the clutch cycling switch.

HEATER PERFORMANCE TEST

PRE-DIAGNOSTIC PREPARATIONS

Review Safety Precautions and Warnings in this

group before performing the following procedures.

Check the coolant level, drive belt tension, vacuum

line connections, radiator air flow and fan operation.

Start engine and allow to warm up to normal tem-

perature.

WARNING: DO NOT REMOVE RADIATOR CAP

WHEN ENGINE IS HOT, PERSONAL INJURY CAN

RESULT.

If vehicle has been run recently, wait 15 minutes

before removing cap. Place a rag over the cap and

turn it to the first safety stop. Allow pressure to

escape through the overflow tube. When the system

stabilizes, remove the cap completely.

24 - 8 HEATING AND AIR CONDITIONINGPL

DIAGNOSIS AND TESTING (Continued)

Page 1144 of 1200

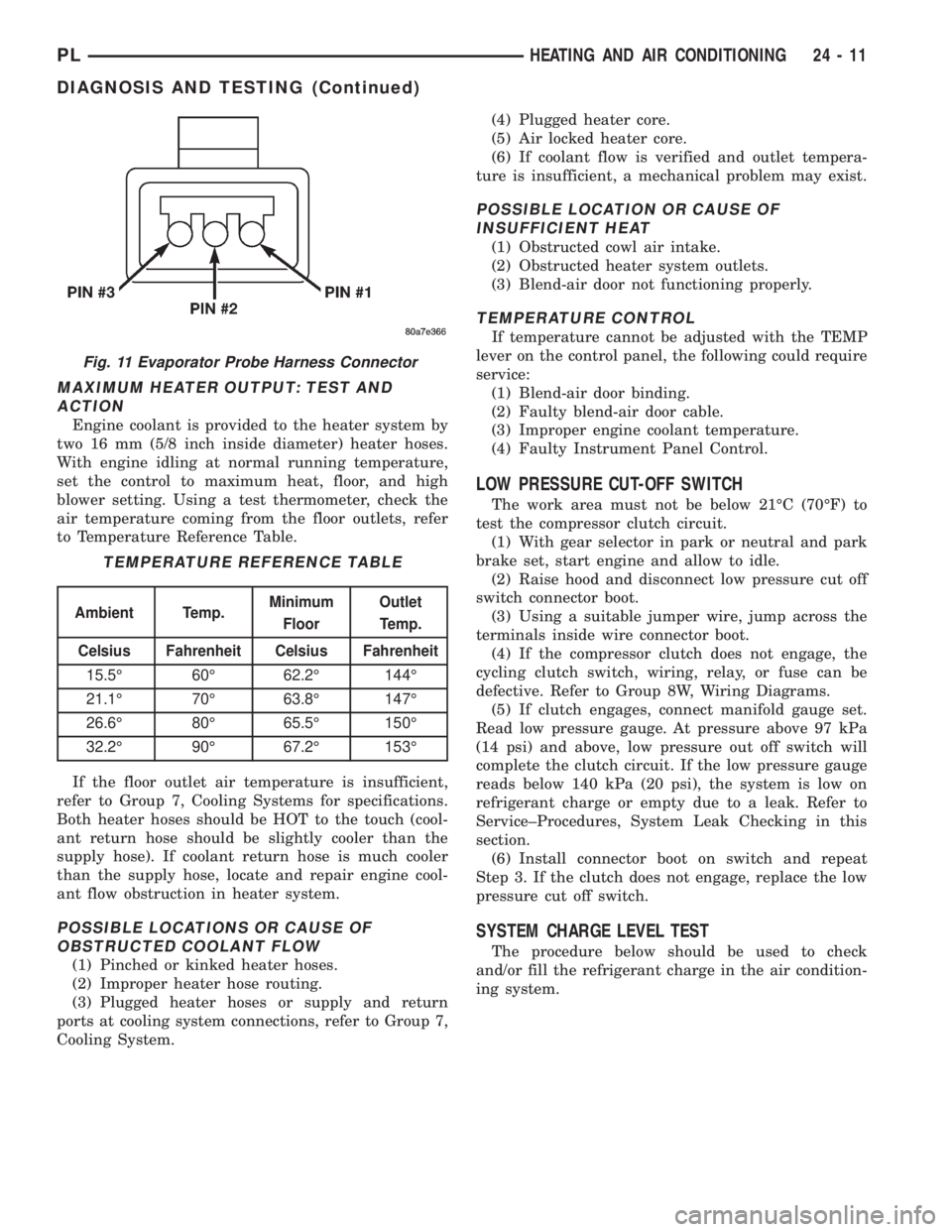

MAXIMUM HEATER OUTPUT: TEST AND

ACTION

Engine coolant is provided to the heater system by

two 16 mm (5/8 inch inside diameter) heater hoses.

With engine idling at normal running temperature,

set the control to maximum heat, floor, and high

blower setting. Using a test thermometer, check the

air temperature coming from the floor outlets, refer

to Temperature Reference Table.

If the floor outlet air temperature is insufficient,

refer to Group 7, Cooling Systems for specifications.

Both heater hoses should be HOT to the touch (cool-

ant return hose should be slightly cooler than the

supply hose). If coolant return hose is much cooler

than the supply hose, locate and repair engine cool-

ant flow obstruction in heater system.

POSSIBLE LOCATIONS OR CAUSE OF

OBSTRUCTED COOLANT FLOW

(1) Pinched or kinked heater hoses.

(2) Improper heater hose routing.

(3) Plugged heater hoses or supply and return

ports at cooling system connections, refer to Group 7,

Cooling System.(4) Plugged heater core.

(5) Air locked heater core.

(6) If coolant flow is verified and outlet tempera-

ture is insufficient, a mechanical problem may exist.

POSSIBLE LOCATION OR CAUSE OF

INSUFFICIENT HEAT

(1) Obstructed cowl air intake.

(2) Obstructed heater system outlets.

(3) Blend-air door not functioning properly.

TEMPERATURE CONTROL

If temperature cannot be adjusted with the TEMP

lever on the control panel, the following could require

service:

(1) Blend-air door binding.

(2) Faulty blend-air door cable.

(3) Improper engine coolant temperature.

(4) Faulty Instrument Panel Control.

LOW PRESSURE CUT-OFF SWITCH

The work area must not be below 21ÉC (70ÉF) to

test the compressor clutch circuit.

(1) With gear selector in park or neutral and park

brake set, start engine and allow to idle.

(2) Raise hood and disconnect low pressure cut off

switch connector boot.

(3) Using a suitable jumper wire, jump across the

terminals inside wire connector boot.

(4) If the compressor clutch does not engage, the

cycling clutch switch, wiring, relay, or fuse can be

defective. Refer to Group 8W, Wiring Diagrams.

(5) If clutch engages, connect manifold gauge set.

Read low pressure gauge. At pressure above 97 kPa

(14 psi) and above, low pressure out off switch will

complete the clutch circuit. If the low pressure gauge

reads below 140 kPa (20 psi), the system is low on

refrigerant charge or empty due to a leak. Refer to

Service±Procedures, System Leak Checking in this

section.

(6) Install connector boot on switch and repeat

Step 3. If the clutch does not engage, replace the low

pressure cut off switch.

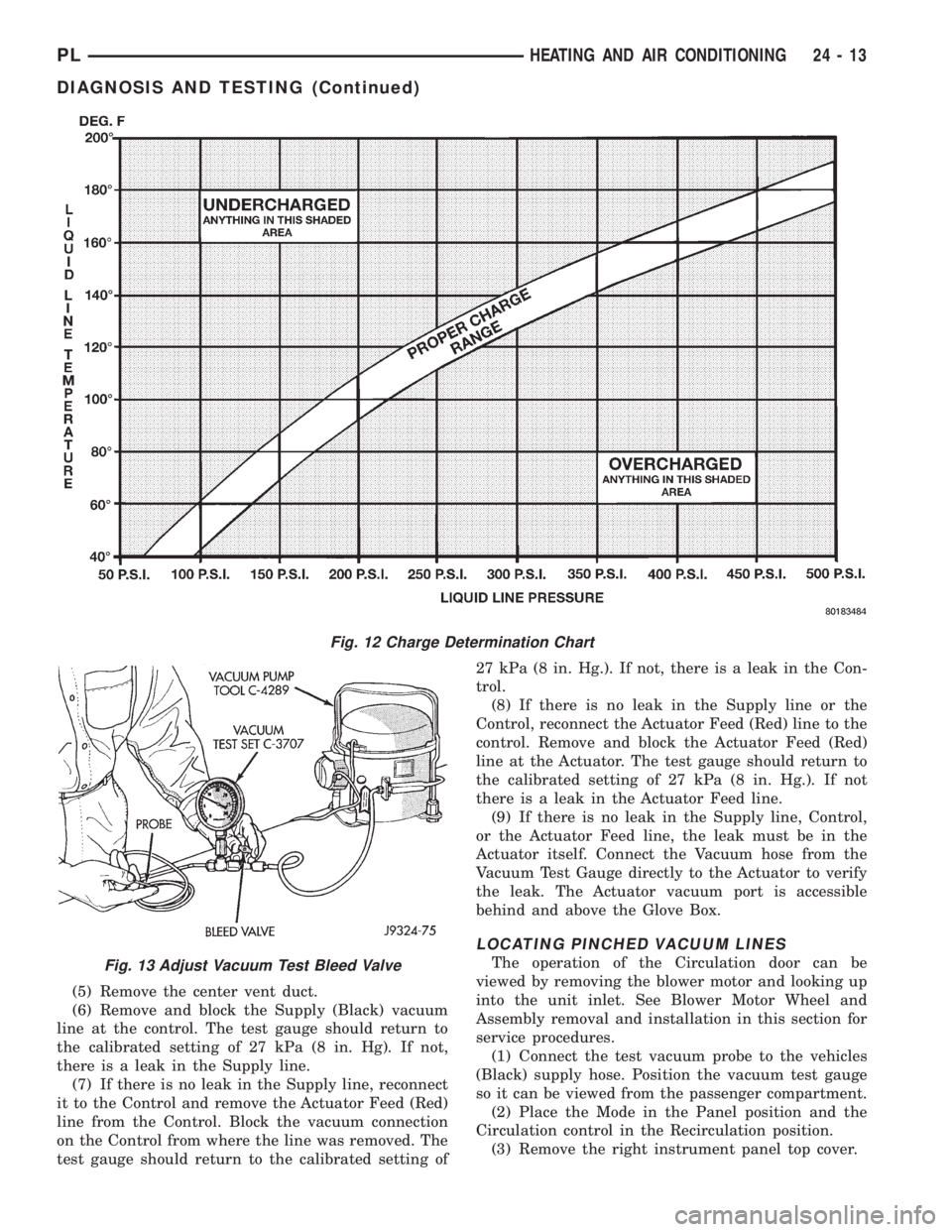

SYSTEM CHARGE LEVEL TEST

The procedure below should be used to check

and/or fill the refrigerant charge in the air condition-

ing system.

Fig. 11 Evaporator Probe Harness Connector

TEMPERATURE REFERENCE TABLE

Ambient Temp.Minimum

FloorOutlet

Temp.

Celsius Fahrenheit Celsius Fahrenheit

15.5É 60É 62.2É 144É

21.1É 70É 63.8É 147É

26.6É 80É 65.5É 150É

32.2É 90É 67.2É 153É

PLHEATING AND AIR CONDITIONING 24 - 11

DIAGNOSIS AND TESTING (Continued)

Page 1145 of 1200

WARNING: AVOID BREATHING A/C REFRIGERANT

AND LUBRICANT VAPOR OR MIST. EXPOSURE MAY

IRRITATE EYES, NOSE AND THROAT. USE ONLY

APPROVED SERVICE EQUIPMENT MEETING SAE

REQUIREMENTS TO DISCHARGE R-134a SYSTEM.

IF ACCIDENTAL SYSTEM DISCHARGE OCCURS,

VENTILATE WORK AREA BEFORE RESUMING SER-

VICE.

R-134a SERVICE EQUIPMENT OR VEHICLE A/C

SYSTEM SHOULD NOT BE PRESSURE TESTED OR

LEAK TESTED WITH COMPRESSED AIR. MIXTURE

OF AIR and R-134a CAN BE COMBUSTIBLE AT ELE-

VATED PRESSURES. THESE MIXTURES ARE

POTENTIALLY DANGEROUS AND MAY RESULT IN

FIRE OR EXPLOSION CAUSING INJURY OR PROP-

ERTY DAMAGE.

NOTE: The maximum amount of R-134a refrigerant

that the air conditioning system holds is 784 grams

(28 oz. or 1.57 lbs.)

It is recommended to use the gauges or reclaim/re-

cycle equipment.

(1) Use a manifold gauge and check the liquid line

pressure.

(2) Attach a clamp-on thermocouple (P.S.E. 66-324-

0014 or 80PK-1A) or equivalent to the liquid line

near the filter/drier.

(3) The vehicle must be in the following modes:

²Automatic transaxle in park or manual tran-

saxle in neutral.

²Engine at idle

²A/C controls set to outside air

²Panel mode

²A/C ON full cool

²Blower motor ON high speed

²Vehicle windows closed

(4) Operate system for a couple of minutes to allow

the system to stabilize.

(5) Observe filter/drier pressure and Liquid line

temperature. Using the Charge Determination Chart

(Fig. 12) determine where the system is currently

operating. If the system is not in the proper range,

reclaim all the refrigerant and recharge per A/C label

.

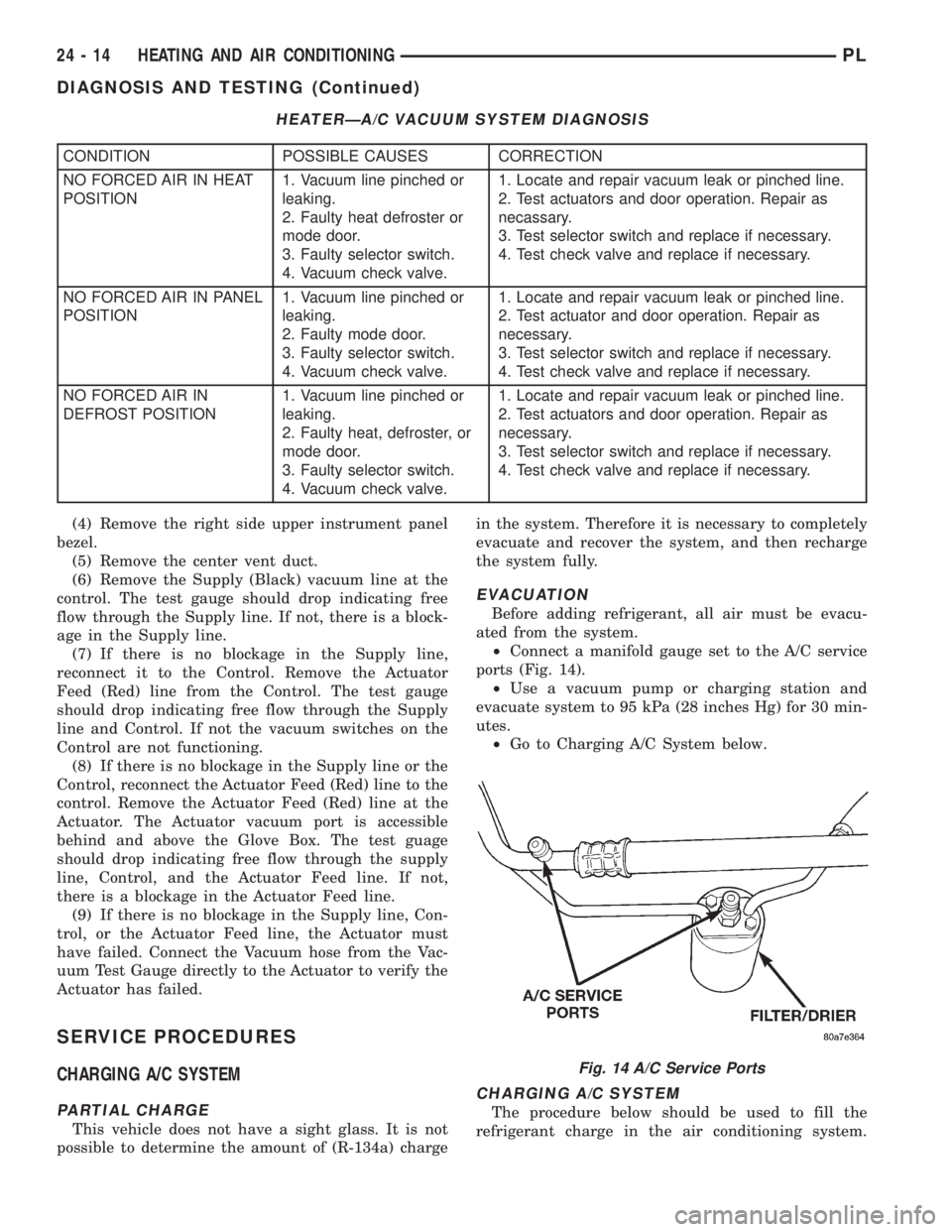

VACUUM CONTROL SYSTEM

Use an adjustable vacuum test set (Special Tool

C-3707) and a suitable vacuum pump to test the

heater-A/C vacuum control system. With a finger

placed over the end of the vacuum test hose probe

(Fig. 13), adjust the bleed valve on the test set gauge

to obtain a vacuum of exactly 27 kPa (8 in. Hg.).

Release and block the end of the probe several times

to verify that the vacuum reading returns to theexact 27 kPa (8 in. Hg.) setting. Otherwise, a false

reading will be obtained during testing.

ONE-WAY CHECK VALVE

(1) Disconnect the heater-A/C vacuum supply

(Black) tube in the engine compartment. This tube

passes through an opening in the dash panel.

(2) Remove the one-way vacuum check valve. The

valve is located on the (Black) vacuum supply hose at

the brake power booster.

(3) Connect the test set vacuum supply hose to the

heater side of the valve. When connected to this side

of the check valve, no vacuum should pass and the

test set gauge should return to the 27 kPa (8 in. Hg.)

setting. If OK, go to step Step 4. If not OK, replace

the faulty valve.

(4) Connect the test set vacuum supply hose to the

engine vacuum side of the valve. When connected to

this side of the check valve, vacuum should flow

through the valve without restriction. If not OK,

replace the faulty valve.

HEATER-A/C CONTROLS

The operation of the Circulation door can be

viewed by removing the blower motor and looking up

into the unit inlet. See Blower Motor Wheel and

Assembly removal and installation in this section for

service procedures.

(1) Connect the test set vacuum probe to the heat-

er-A/C vacuum supply (Black) hose in the engine

compartment. Position the test set gauge so that it

can be viewed from the passenger compartment.

(2) Start with the Mode control in the Panel posi-

tion and the Circulation control in the Ouside-air

position.

(3) Move the Circulation control to the Recircula-

tion position (the Circulation door should move into

the Recirculation position). After a short pause move

the Mode control to the Defrost position (the Circula-

tion door should move to the Outside-air position).

The test gauge should return to the calibrated set-

ting of 27 kPa (8in. Hg.) after each selection is made.

If the gauge cannot achieve the calibrated setting,

the vacuum circuit or a component has a leak.

(4) If the gauge achieves the calibrated setting but

the door does not move, there is either a pinched vac-

uum line or a failed actuator.

LOCATING VACUUM LEAKS

(1) Connect the test vacuum probe to the vehicles

(Black) supply hose. Position the vacuum test gauge

so it can be viewed from the passenger compartment.

(2) Place the Mode in the Panel position and the

Circulation control in the Recirculation position.

(3) Remove the instrument panel top cover.

(4) Remove the right side upper instrument panel

bezel.

24 - 12 HEATING AND AIR CONDITIONINGPL

DIAGNOSIS AND TESTING (Continued)

Page 1146 of 1200

(5) Remove the center vent duct.

(6) Remove and block the Supply (Black) vacuum

line at the control. The test gauge should return to

the calibrated setting of 27 kPa (8 in. Hg). If not,

there is a leak in the Supply line.

(7) If there is no leak in the Supply line, reconnect

it to the Control and remove the Actuator Feed (Red)

line from the Control. Block the vacuum connection

on the Control from where the line was removed. The

test gauge should return to the calibrated setting of27 kPa (8 in. Hg.). If not, there is a leak in the Con-

trol.

(8) If there is no leak in the Supply line or the

Control, reconnect the Actuator Feed (Red) line to the

control. Remove and block the Actuator Feed (Red)

line at the Actuator. The test gauge should return to

the calibrated setting of 27 kPa (8 in. Hg.). If not

there is a leak in the Actuator Feed line.

(9) If there is no leak in the Supply line, Control,

or the Actuator Feed line, the leak must be in the

Actuator itself. Connect the Vacuum hose from the

Vacuum Test Gauge directly to the Actuator to verify

the leak. The Actuator vacuum port is accessible

behind and above the Glove Box.

LOCATING PINCHED VACUUM LINES

The operation of the Circulation door can be

viewed by removing the blower motor and looking up

into the unit inlet. See Blower Motor Wheel and

Assembly removal and installation in this section for

service procedures.

(1) Connect the test vacuum probe to the vehicles

(Black) supply hose. Position the vacuum test gauge

so it can be viewed from the passenger compartment.

(2) Place the Mode in the Panel position and the

Circulation control in the Recirculation position.

(3) Remove the right instrument panel top cover.

Fig. 12 Charge Determination Chart

Fig. 13 Adjust Vacuum Test Bleed Valve

PLHEATING AND AIR CONDITIONING 24 - 13

DIAGNOSIS AND TESTING (Continued)

Page 1147 of 1200

(4) Remove the right side upper instrument panel

bezel.

(5) Remove the center vent duct.

(6) Remove the Supply (Black) vacuum line at the

control. The test gauge should drop indicating free

flow through the Supply line. If not, there is a block-

age in the Supply line.

(7) If there is no blockage in the Supply line,

reconnect it to the Control. Remove the Actuator

Feed (Red) line from the Control. The test gauge

should drop indicating free flow through the Supply

line and Control. If not the vacuum switches on the

Control are not functioning.

(8) If there is no blockage in the Supply line or the

Control, reconnect the Actuator Feed (Red) line to the

control. Remove the Actuator Feed (Red) line at the

Actuator. The Actuator vacuum port is accessible

behind and above the Glove Box. The test guage

should drop indicating free flow through the supply

line, Control, and the Actuator Feed line. If not,

there is a blockage in the Actuator Feed line.

(9) If there is no blockage in the Supply line, Con-

trol, or the Actuator Feed line, the Actuator must

have failed. Connect the Vacuum hose from the Vac-

uum Test Gauge directly to the Actuator to verify the

Actuator has failed.

SERVICE PROCEDURES

CHARGING A/C SYSTEM

PARTIAL CHARGE

This vehicle does not have a sight glass. It is not

possible to determine the amount of (R-134a) chargein the system. Therefore it is necessary to completely

evacuate and recover the system, and then recharge

the system fully.

EVACUATION

Before adding refrigerant, all air must be evacu-

ated from the system.

²Connect a manifold gauge set to the A/C service

ports (Fig. 14).

²Use a vacuum pump or charging station and

evacuate system to 95 kPa (28 inches Hg) for 30 min-

utes.

²Go to Charging A/C System below.

CHARGING A/C SYSTEM

The procedure below should be used to fill the

refrigerant charge in the air conditioning system.

HEATERÐA/C VACUUM SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO FORCED AIR IN HEAT

POSITION1. Vacuum line pinched or

leaking.

2. Faulty heat defroster or

mode door.

3. Faulty selector switch.

4. Vacuum check valve.1. Locate and repair vacuum leak or pinched line.

2. Test actuators and door operation. Repair as

necassary.

3. Test selector switch and replace if necessary.

4. Test check valve and replace if necessary.

NO FORCED AIR IN PANEL

POSITION1. Vacuum line pinched or

leaking.

2. Faulty mode door.

3. Faulty selector switch.

4. Vacuum check valve.1. Locate and repair vacuum leak or pinched line.

2. Test actuator and door operation. Repair as

necessary.

3. Test selector switch and replace if necessary.

4. Test check valve and replace if necessary.

NO FORCED AIR IN

DEFROST POSITION1. Vacuum line pinched or

leaking.

2. Faulty heat, defroster, or

mode door.

3. Faulty selector switch.

4. Vacuum check valve.1. Locate and repair vacuum leak or pinched line.

2. Test actuators and door operation. Repair as

necessary.

3. Test selector switch and replace if necessary.

4. Test check valve and replace if necessary.

Fig. 14 A/C Service Ports

24 - 14 HEATING AND AIR CONDITIONINGPL

DIAGNOSIS AND TESTING (Continued)