lock DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 1069 of 1200

RADIAL-PLY TIRES

Radial-ply tires improve handling, tread life and

ride quality, and decrease rolling resistance.

Radial-ply tires must always be used in sets of

four. Under no circumstances should they be used on

the front only. They may be mixed with temporary

spare tires when necessary. A maximum speed of 50

MPH is recommended while a temporary spare is in

use.

Radial-ply tires have the same load-carrying capac-

ity as other types of tires of the same size. They also

use the same recommended inflation pressures.

The use of oversized tires, either in the front or

rear of the vehicle, can cause vehicle drive train fail-

ure. This could also cause inaccurate wheel speed

signals when the vehicle is equipped with Anti-Lock

Brakes.

The use of tires from different manufactures on the

same vehicle is NOT recommended. The proper tire

pressure should be maintained on all four tires. For

proper tire pressure refer to the Tire Inflation Pres-

sure Chart provided with the vehicle.

SPARE TIRE±TEMPORARY

The temporary spare tire is designed for emer-

gency use only. The original tire should be repaired

or replaced at the first opportunity and reinstall. Donot exceed speeds of 50 MPH. Refer to Owner's Man-

ual for complete details.

TIRE INFLATION PRESSURES

Under inflation causes rapid shoulder wear, tire

flexing, and can result in tire failure (Fig. 2).

Over inflation causes rapid center wear and loss of

the tire's ability to cushion shocks (Fig. 3).

Improper inflation can cause:

²Uneven wear patterns

²Reduced tread life

²Reduced fuel economy

²Unsatisfactory ride

²The vehicle to drift.

For proper tire pressure specification refer to the

Tire Inflation Pressure Chart Placard provided with

the vehicle.

Tire pressures have been chosen to provide safe

operation, vehicle stability, and a smooth ride. Tire

pressure should be checked cold once per month.

Check tire pressure more frequently when the

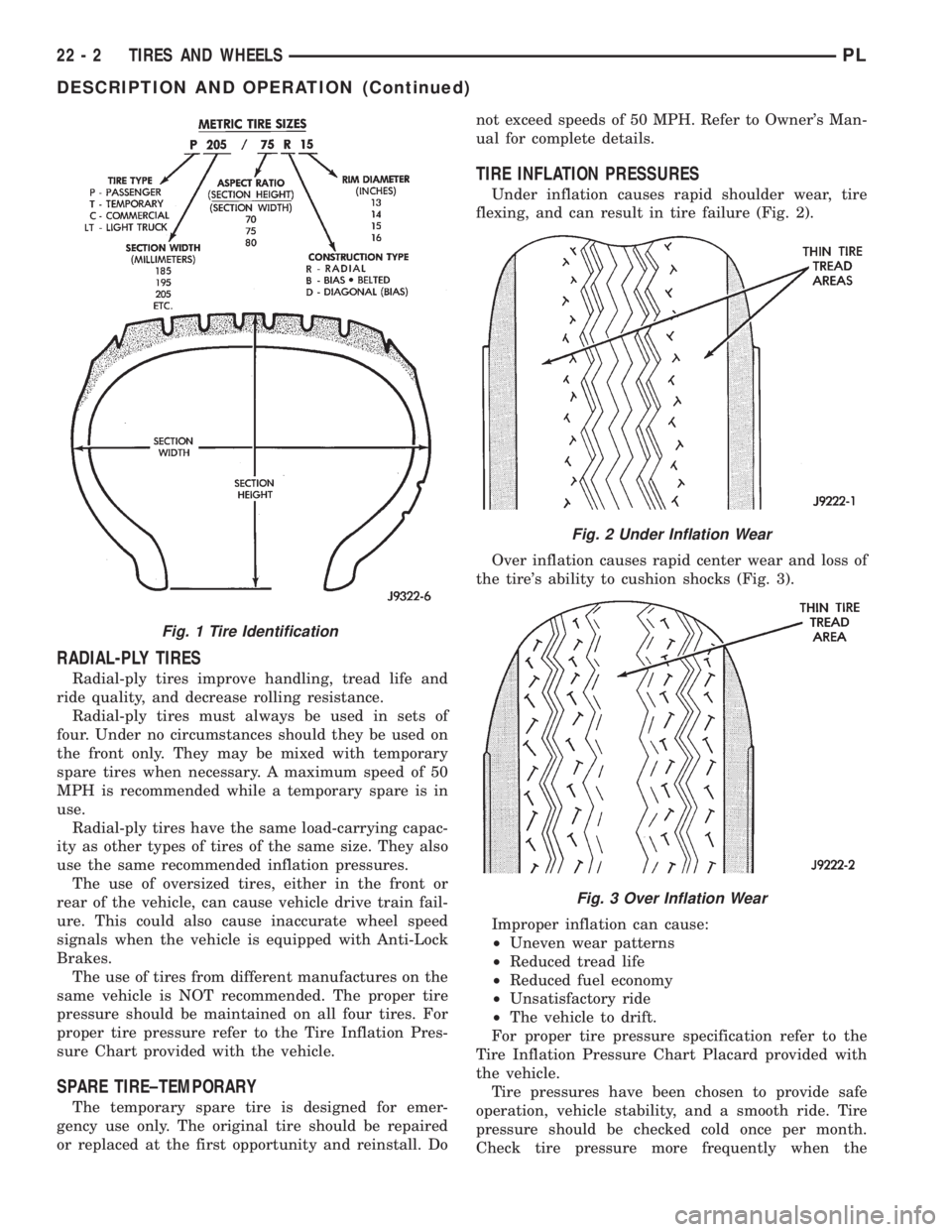

Fig. 1 Tire Identification

Fig. 2 Under Inflation Wear

Fig. 3 Over Inflation Wear

22 - 2 TIRES AND WHEELSPL

DESCRIPTION AND OPERATION (Continued)

Page 1075 of 1200

WHEELS

INDEX

page page

DESCRIPTION AND OPERATION

WHEEL COVER (LOCK-ON)................. 8

WHEEL INFORMATION.................... 8

DIAGNOSIS AND TESTING

TIRE AND WHEEL RUNOUT................ 9

WHEEL INSPECTION...................... 9

SERVICE PROCEDURES

TIRE AND WHEEL BALANCE............... 10REMOVAL AND INSTALLATION

WHEEL AND TIRE....................... 12

WHEEL COVER (LOCK-ON)................ 12

WHEEL COVER RETAINING NUT........... 13

SPECIFICATIONS

WHEEL SPECIFICATIONS................. 14

DESCRIPTION AND OPERATION

WHEEL INFORMATION

Original equipment wheels are designed for proper

operation at all loads up to the specified maximum

vehicle capacity.

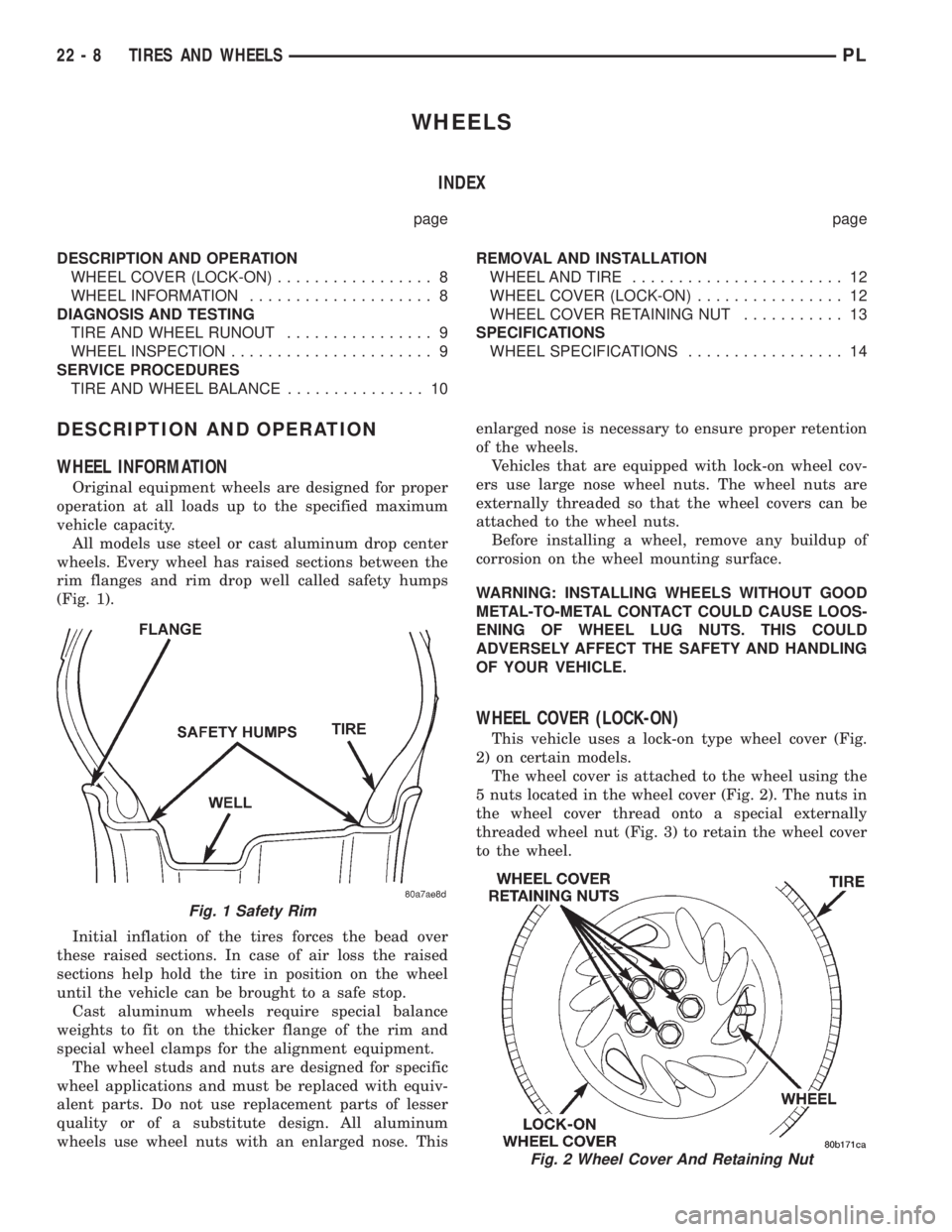

All models use steel or cast aluminum drop center

wheels. Every wheel has raised sections between the

rim flanges and rim drop well called safety humps

(Fig. 1).

Initial inflation of the tires forces the bead over

these raised sections. In case of air loss the raised

sections help hold the tire in position on the wheel

until the vehicle can be brought to a safe stop.

Cast aluminum wheels require special balance

weights to fit on the thicker flange of the rim and

special wheel clamps for the alignment equipment.

The wheel studs and nuts are designed for specific

wheel applications and must be replaced with equiv-

alent parts. Do not use replacement parts of lesser

quality or of a substitute design. All aluminum

wheels use wheel nuts with an enlarged nose. Thisenlarged nose is necessary to ensure proper retention

of the wheels.

Vehicles that are equipped with lock-on wheel cov-

ers use large nose wheel nuts. The wheel nuts are

externally threaded so that the wheel covers can be

attached to the wheel nuts.

Before installing a wheel, remove any buildup of

corrosion on the wheel mounting surface.

WARNING: INSTALLING WHEELS WITHOUT GOOD

METAL-TO-METAL CONTACT COULD CAUSE LOOS-

ENING OF WHEEL LUG NUTS. THIS COULD

ADVERSELY AFFECT THE SAFETY AND HANDLING

OF YOUR VEHICLE.

WHEEL COVER (LOCK-ON)

This vehicle uses a lock-on type wheel cover (Fig.

2) on certain models.

The wheel cover is attached to the wheel using the

5 nuts located in the wheel cover (Fig. 2). The nuts in

the wheel cover thread onto a special externally

threaded wheel nut (Fig. 3) to retain the wheel cover

to the wheel.

Fig. 1 Safety Rim

Fig. 2 Wheel Cover And Retaining Nut

22 - 8 TIRES AND WHEELSPL

Page 1076 of 1200

The wheel cover retaining nut (Fig. 2) is retained

in the wheel cover and will stay on the wheel cover

when un-threaded from the wheel nut. If required,

the retaining nut can be removed from the wheel

cover and replaced as a separate part of the wheel

cover.

The lock-on wheel cover can not be removed from

the wheel until all 5 wheel cover retaining nuts are

un-threaded from the wheel nuts. Then the lock-on

wheel cover can be removed by hand from the wheel.

DIAGNOSIS AND TESTING

WHEEL INSPECTION

Inspect wheels for:

²Excessive run out

²Dents or cracks

²Damaged wheel lug nut holes

²Air Leaks from any area or surface of the rim

NOTE: Do not attempt to repair a wheel by ham-

mering, heating or welding.

If a wheel is damaged an original equipment

replacement wheel should be used. When obtaining

replacement wheels, they should be equivalent in

load carrying capacity. The diameter, width, offset,

pilot hole and bolt circle of the wheel should be the

same as the original wheel.

WARNING: FAILURE TO USE EQUIVALENT

REPLACEMENT WHEELS MAY ADVERSELY AFFECT

THE SAFETY AND HANDLING OF THE VEHICLE.

USED WHEELS ARE NOT RECOMMENDED. THE

SERVICE HISTORY OF THE WHEEL MAY HAVE

INCLUDED SEVERE TREATMENT OR VERY HIGH

MILEAGE. THE RIM COULD FAIL WITHOUT WARN-

ING.

TIRE AND WHEEL RUNOUT

NOTE: Runout should always be measured off the

vehicle and on a suitable balance machine.Radial run out is the difference between the high

and low points on the outer edge of the tire or wheel.

Lateral run out is the total side±to±side wobble of

the tire or wheel.

Radial run out of more than 1.5 mm (.060 inch)

measured at the center line of the tread may cause

the vehicle to shake.

Lateral run out of more than 2.0 mm (.080 inch)

measured at the side of the tire as close to the tread

as possible may cause the vehicle to shake.

Sometimes radial run out can be reduced by relo-

cating the wheel and tire on the wheel studs (See

Method 1). If this does not reduce run out to an

acceptable level, the tire can be rotated on the wheel.

(See Method 2).

METHOD 1 (RELOCATE WHEEL ON HUB)

Check accuracy of the wheel mounting surface;

adjust wheel bearings.

Drive vehicle a short distance to eliminate tire flat

spotting from a parked position.

Verify all wheel nuts are tightened and properly

torqued in the correct sequence (Fig. 4).

Use run out gauge D-128-TR to determine run out

(Fig. 5).

Fig. 3 Wheel Nut And Wheel Cover Retaining Nut

Fig. 4 Tightening Wheel Nuts

Fig. 5 Run Out Gauge

PLTIRES AND WHEELS 22 - 9

DESCRIPTION AND OPERATION (Continued)

Page 1079 of 1200

REMOVAL AND INSTALLATION

WHEEL COVER (LOCK-ON)

REMOVE

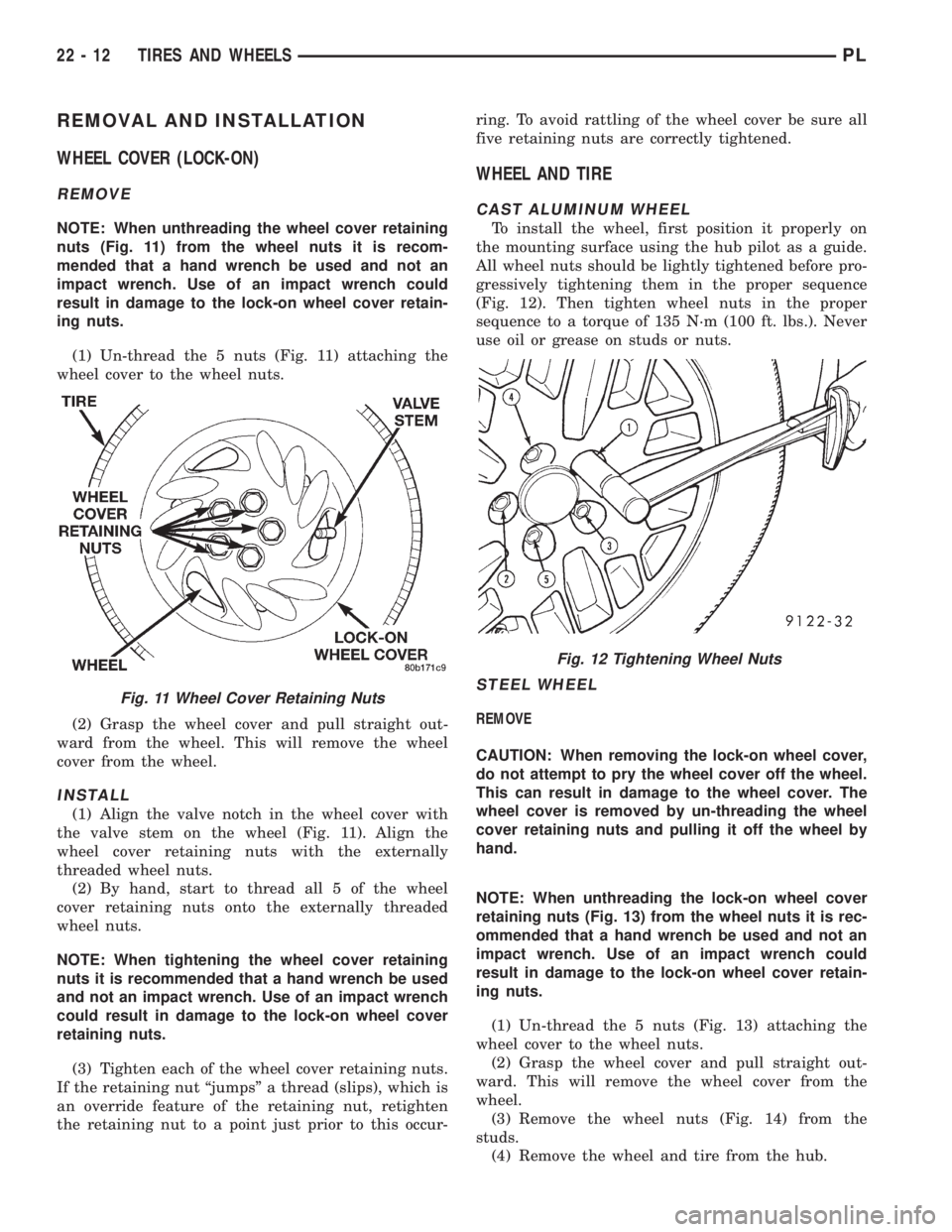

NOTE: When unthreading the wheel cover retaining

nuts (Fig. 11) from the wheel nuts it is recom-

mended that a hand wrench be used and not an

impact wrench. Use of an impact wrench could

result in damage to the lock-on wheel cover retain-

ing nuts.

(1) Un-thread the 5 nuts (Fig. 11) attaching the

wheel cover to the wheel nuts.

(2) Grasp the wheel cover and pull straight out-

ward from the wheel. This will remove the wheel

cover from the wheel.

INSTALL

(1) Align the valve notch in the wheel cover with

the valve stem on the wheel (Fig. 11). Align the

wheel cover retaining nuts with the externally

threaded wheel nuts.

(2) By hand, start to thread all 5 of the wheel

cover retaining nuts onto the externally threaded

wheel nuts.

NOTE: When tightening the wheel cover retaining

nuts it is recommended that a hand wrench be used

and not an impact wrench. Use of an impact wrench

could result in damage to the lock-on wheel cover

retaining nuts.

(3) Tighten each of the wheel cover retaining nuts.

If the retaining nut ªjumpsº a thread (slips), which is

an override feature of the retaining nut, retighten

the retaining nut to a point just prior to this occur-ring. To avoid rattling of the wheel cover be sure all

five retaining nuts are correctly tightened.

WHEEL AND TIRE

CAST ALUMINUM WHEEL

To install the wheel, first position it properly on

the mounting surface using the hub pilot as a guide.

All wheel nuts should be lightly tightened before pro-

gressively tightening them in the proper sequence

(Fig. 12). Then tighten wheel nuts in the proper

sequence to a torque of 135 N´m (100 ft. lbs.). Never

use oil or grease on studs or nuts.

STEEL WHEEL

REMOVE

CAUTION: When removing the lock-on wheel cover,

do not attempt to pry the wheel cover off the wheel.

This can result in damage to the wheel cover. The

wheel cover is removed by un-threading the wheel

cover retaining nuts and pulling it off the wheel by

hand.

NOTE: When unthreading the lock-on wheel cover

retaining nuts (Fig. 13) from the wheel nuts it is rec-

ommended that a hand wrench be used and not an

impact wrench. Use of an impact wrench could

result in damage to the lock-on wheel cover retain-

ing nuts.

(1) Un-thread the 5 nuts (Fig. 13) attaching the

wheel cover to the wheel nuts.

(2) Grasp the wheel cover and pull straight out-

ward. This will remove the wheel cover from the

wheel.

(3) Remove the wheel nuts (Fig. 14) from the

studs.

(4) Remove the wheel and tire from the hub.

Fig. 11 Wheel Cover Retaining Nuts

Fig. 12 Tightening Wheel Nuts

22 - 12 TIRES AND WHEELSPL

Page 1080 of 1200

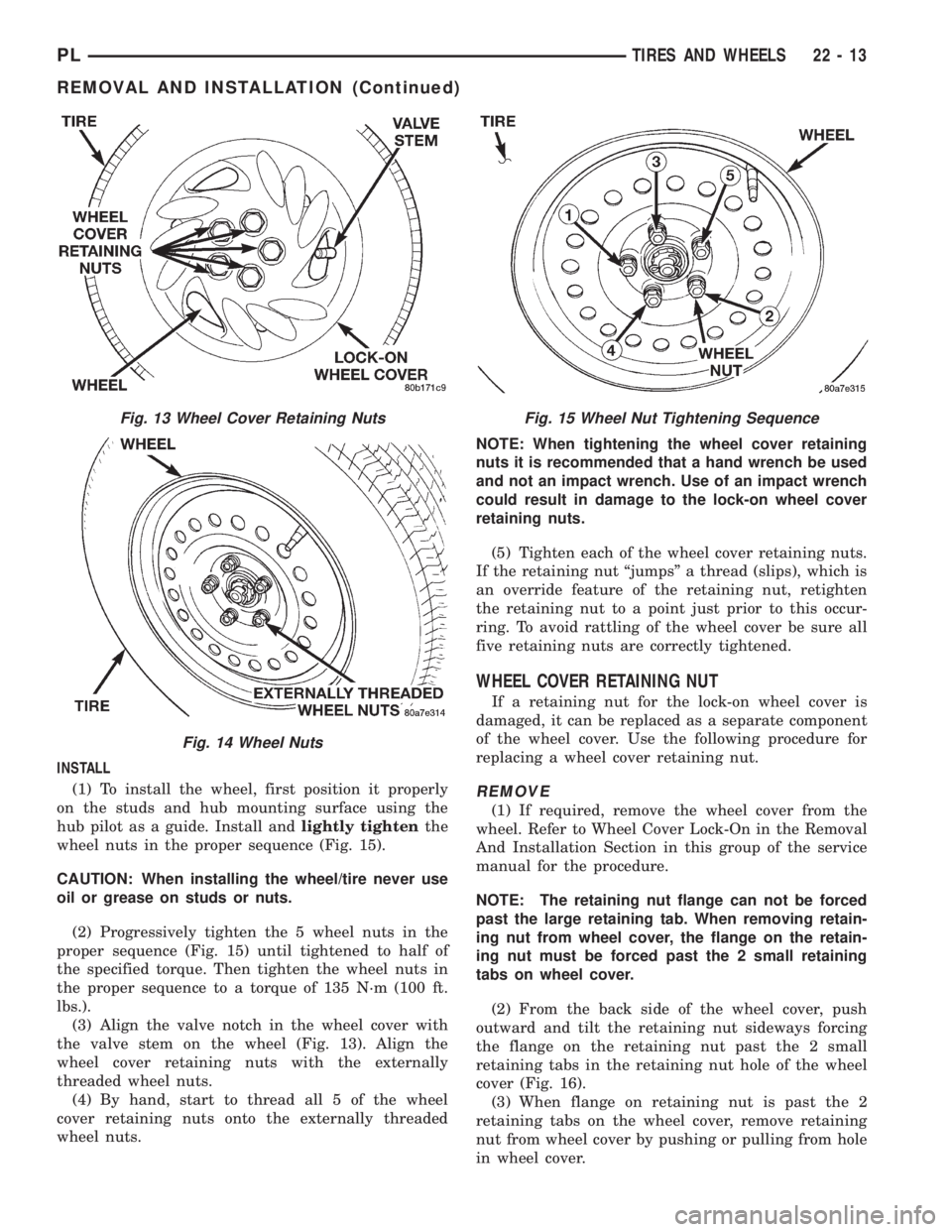

INSTALL

(1) To install the wheel, first position it properly

on the studs and hub mounting surface using the

hub pilot as a guide. Install andlightly tightenthe

wheel nuts in the proper sequence (Fig. 15).

CAUTION: When installing the wheel/tire never use

oil or grease on studs or nuts.

(2) Progressively tighten the 5 wheel nuts in the

proper sequence (Fig. 15) until tightened to half of

the specified torque. Then tighten the wheel nuts in

the proper sequence to a torque of 135 N´m (100 ft.

lbs.).

(3) Align the valve notch in the wheel cover with

the valve stem on the wheel (Fig. 13). Align the

wheel cover retaining nuts with the externally

threaded wheel nuts.

(4) By hand, start to thread all 5 of the wheel

cover retaining nuts onto the externally threaded

wheel nuts.NOTE: When tightening the wheel cover retaining

nuts it is recommended that a hand wrench be used

and not an impact wrench. Use of an impact wrench

could result in damage to the lock-on wheel cover

retaining nuts.

(5) Tighten each of the wheel cover retaining nuts.

If the retaining nut ªjumpsº a thread (slips), which is

an override feature of the retaining nut, retighten

the retaining nut to a point just prior to this occur-

ring. To avoid rattling of the wheel cover be sure all

five retaining nuts are correctly tightened.

WHEEL COVER RETAINING NUT

If a retaining nut for the lock-on wheel cover is

damaged, it can be replaced as a separate component

of the wheel cover. Use the following procedure for

replacing a wheel cover retaining nut.

REMOVE

(1) If required, remove the wheel cover from the

wheel. Refer to Wheel Cover Lock-On in the Removal

And Installation Section in this group of the service

manual for the procedure.

NOTE: The retaining nut flange can not be forced

past the large retaining tab. When removing retain-

ing nut from wheel cover, the flange on the retain-

ing nut must be forced past the 2 small retaining

tabs on wheel cover.

(2) From the back side of the wheel cover, push

outward and tilt the retaining nut sideways forcing

the flange on the retaining nut past the 2 small

retaining tabs in the retaining nut hole of the wheel

cover (Fig. 16).

(3) When flange on retaining nut is past the 2

retaining tabs on the wheel cover, remove retaining

nut from wheel cover by pushing or pulling from hole

in wheel cover.

Fig. 13 Wheel Cover Retaining Nuts

Fig. 14 Wheel Nuts

Fig. 15 Wheel Nut Tightening Sequence

PLTIRES AND WHEELS 22 - 13

REMOVAL AND INSTALLATION (Continued)

Page 1083 of 1200

BODY COMPONENTS

INDEX

page page

DIAGNOSIS AND TESTING

WATER LEAKS.......................... 3

WIND NOISE............................ 4

SERVICE PROCEDURES

HEAT STAKING.......................... 4

REMOVAL AND INSTALLATION

WINDOW REGULATORÐ4 DOOR........... 36

A-PILLAR TRIM.......................... 4

B-PILLAR APPLIQUEÐ2 DOOR.............. 5

B-PILLAR APPLIQUEÐ4 DOOR.............. 5

B-PILLAR TRIMÐ4 DOOR.................. 6

B-PILLAR WEATHERSTRIP CHANNEL......... 6

BODY VENT............................. 6

CARPET............................... 7

CHILD RESTRAINT SEAT BACK............. 8

CHILD SEAT MODULE..................... 8

COWL COVER........................... 7

DOOR HINGE........................... 9

DOOR LOCK CYLINDER.................. 10

DOOR OPENING TRIM WELT.............. 10

DOOR SILL TRIM........................ 10

DOOR................................. 9

FLOOR CONSOLE LATCH................. 11

FLOOR CONSOLE....................... 11

FRONT DOOR CHECK STOP............... 11

FRONT DOOR GLASSÐ2 DOOR............ 12

FRONT DOOR GLASSÐ4 DOOR............ 13

FRONT DOOR INNER BELT WEATHERSTRIP . . 13

FRONT DOOR LATCH STRIKER............ 14

FRONT DOOR LATCH.................... 13

FRONT DOOR OUTER BELT WEATHERSTRIP . 14

FRONT DOOR OUTSIDE HANDLE........... 14

FRONT DOOR TRIM PANEL................ 14

FRONT DOOR WATER SHIELD............. 16

FRONT DOOR WEATHERSTRIP............ 16

FRONT OUTBOARD SEAT BELT............ 17

FRONT SEAT BELT BUCKLE............... 18

FRONT SEAT BELT RETRACTOR........... 18

FRONT SEAT........................... 17

FRONT SHOULDER BELT ADJUSTER........ 18

FRONT VERTICAL GUIDE BAR............. 18

GRILLE............................... 19

HEADLINING........................... 19

HOOD HINGE.......................... 20

HOOD LATCH.......................... 21

HOOD RELEASE CABLE.................. 21

HOOD................................ 20

LOCK BUTTON BELL-CRANK.............. 21

LOWER QUARTER TRIMÐ4 DOOR.......... 22PARCEL SHELF TRIM.................... 22

QUARTER TRIM PANELÐ2 DOOR........... 22

REAR DOOR GLASS..................... 23

REAR DOOR INNER BELT WEATHERSTRIP . . . 23

REAR DOOR INTERLOCK LATCH STRIKER . . . 24

REAR DOOR LATCH STRIKER............. 24

REAR DOOR LATCH..................... 24

REAR DOOR LOCK BELL CRANK........... 24

REAR DOOR OUTER BELT WEATHERSTRIP . . 25

REAR DOOR TRIM....................... 25

REAR DOOR WINDOW REGULATOR........ 25

REAR SEAT BACK....................... 26

REAR SEAT BELT BUCKLE................ 26

REAR SEAT BELT RETRACTOR............ 26

REAR SEAT CUSHION.................... 26

REAR SPOILER......................... 27

REAR VERTICAL GUIDE BAR.............. 27

ROOF APERTURE (RAP) MOLDING.......... 28

ROOF RACK CROSS RAILS............... 28

ROOF RACK........................... 28

ROOF RAIL WEATHER-STRIP FOUR DOOR . . . 29

ROOF RAIL WEATHER-STRIP ± TWO DOOR . . . 29

SIDE COWL TRIM....................... 30

SIDE VIEW MIRROR STANCHION........... 31

SIDE VIEW MIRROR TRIM COVER.......... 31

SIDE VIEW MIRROR..................... 30

SUN VISOR SUPPORT................... 31

SUN VISOR............................ 31

TRUNK CARPET........................ 31

TRUNK LATCH STRIKER.................. 32

TRUNK LATCH.......................... 32

TRUNK LID LIFT SPRINGS................ 33

TRUNK LID............................ 32

TRUNK LOCK CYLINDER................. 33

TRUNK TRIM PANEL..................... 34

TRUNK WEATHERSTRIP.................. 34

UPPER QUARTER TRIMÐ4 DOOR.......... 34

WINDOW INNERBELT STABILIZER.......... 34

WINDOW REGULATORÐ2 DOOR........... 35

ADJUSTMENTS

FRONT DOOR GLASS ADJUSTMENT........ 37

FRONT DOOR LATCH ADJUSTMENT........ 38

REAR DOOR GLASS ADJUSTMENT......... 38

REAR DOOR LATCH ADJUSTMENT.......... 39

SPECIFICATIONS

BODY LUBRICATION SPECIFICATIONS....... 39

SPECIAL TOOLS

BODY................................. 40

23 - 2 BODYPL

Page 1084 of 1200

DIAGNOSIS AND TESTING

WATER LEAKS

Water leaks can be caused by poor sealing,

improper body component alignment, body seam

porosity, missing plugs, or blocked drain holes. Cen-

trifugal and gravitational force can cause water to

drip from a location away from the actual leak point,

making leak detection difficult. All body sealing

points should be water tight in normal wet-driving

conditions. Water flowing downward from the front of

the vehicle should not enter the passenger or luggage

compartment. Moving sealing surfaces will not

always seal water tight under all conditions. At

times, side glass or door seals will allow water to

enter the passenger compartment during high pres-

sure washing or hard driving rain (severe) condi-

tions. Overcompensating on door or glass

adjustments to stop a water leak that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After completing

a repair, water-test vehicle to verify leak has stopped

before returning vehicle to use.

VISUAL INSPECTION BEFORE WATER LEAK

TESTS

Verify that floor and body plugs are in place, body

drains are clear, and body components are properly

aligned and sealed. If component alignment or seal-

ing is necessary, refer to the appropriate section of

this group for proper procedures.

WATER LEAK TESTS

WARNING: DO NOT USE ELECTRIC SHOP LIGHTS

OR TOOLS IN WATER TEST AREA. PERSONAL

INJURY CAN RESULT.

When the conditions causing a water leak have

been determined, simulate the conditions as closely

as possible.

²If a leak occurs with the vehicle parked in a

steady light rain, flood the leak area with an open-

ended garden hose.

²If a leak occurs while driving at highway speeds

in a steady rain, test the leak area with a reasonable

velocity stream or fan spray of water. Direct the

spray in a direction comparable to actual conditions.

²If a leak occurs when the vehicle is parked on an

incline, hoist the end or side of the vehicle to simu-

late this condition. This method can be used when

the leak occurs when the vehicle accelerates, stops or

turns. If the leak occurs on acceleration, hoist the

front of the vehicle. If the leak occurs when braking,

hoist the back of the vehicle. If the leak occurs on left

turns, hoist the left side of the vehicle. If the leak

occurs on right turns, hoist the right side of the vehi-cle. For hoisting recommendations refer to Group 0,

Lubrication and Maintenance, General Information

section.

WATER LEAK DETECTION

To detect a water leak point-of-entry, do a water

test and watch for water tracks or droplets forming

on the inside of the vehicle. If necessary, remove inte-

rior trim covers or panels to gain visual access to the

leak area. If the hose cannot be positioned without

being held, have someone help do the water test.

Some water leaks must be tested for a considerable

length of time to become apparent. When a leak

appears, find the highest point of the water track or

drop. The highest point usually will show the point of

entry. After leak point has been found, repair the

leak and water test to verify that the leak has

stopped.

Locating the entry point of water that is leaking

into a cavity between panels can be difficult. The

trapped water may splash or run from the cavity,

often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on an incline.

MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use

a suitable mirror to gain visual access. A mirror can

also be used to deflect light to a limited-access area

to assist in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can

be detected without water testing. Position the vehi-

cle in a brightly lit area. From inside the darkened

luggage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop light

over the suspected leak areas around the luggage

compartment. If light is visible through a normally

sealed location, water could enter through the open-

ing.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compart-

ment cannot be detected by water testing, pressurize

the passenger compartment and soap test exterior of

the vehicle. To pressurize the passenger compart-

ment, close all doors and windows, start engine, and

set heater control to high blower in HEAT position. If

engine can not be started, connect a charger to the

battery to ensure adequate voltage to the blower.

With interior pressurized, apply dish detergent solu-

tion to suspected leak area on the exterior of the

vehicle. Apply detergent solution with spray device or

soft bristle brush. If soap bubbles occur at a body

seam, joint, seal or gasket, the leak entry point could

be at that location.

PLBODY 23 - 3

Page 1091 of 1200

(3) Loosely install bolts holding hinge to lower

A±pillar.

(4) Loosely install bolts holding hinge to door end

frame.

(5) Align hinge to marks made previously and

tighten all bolts.

(6) Install bolts holding door check strap to lower

A±pillar, if removed previously.

(7) Verify door fit and operation. Adjust door hinge

for proper door alignment, if necessary.

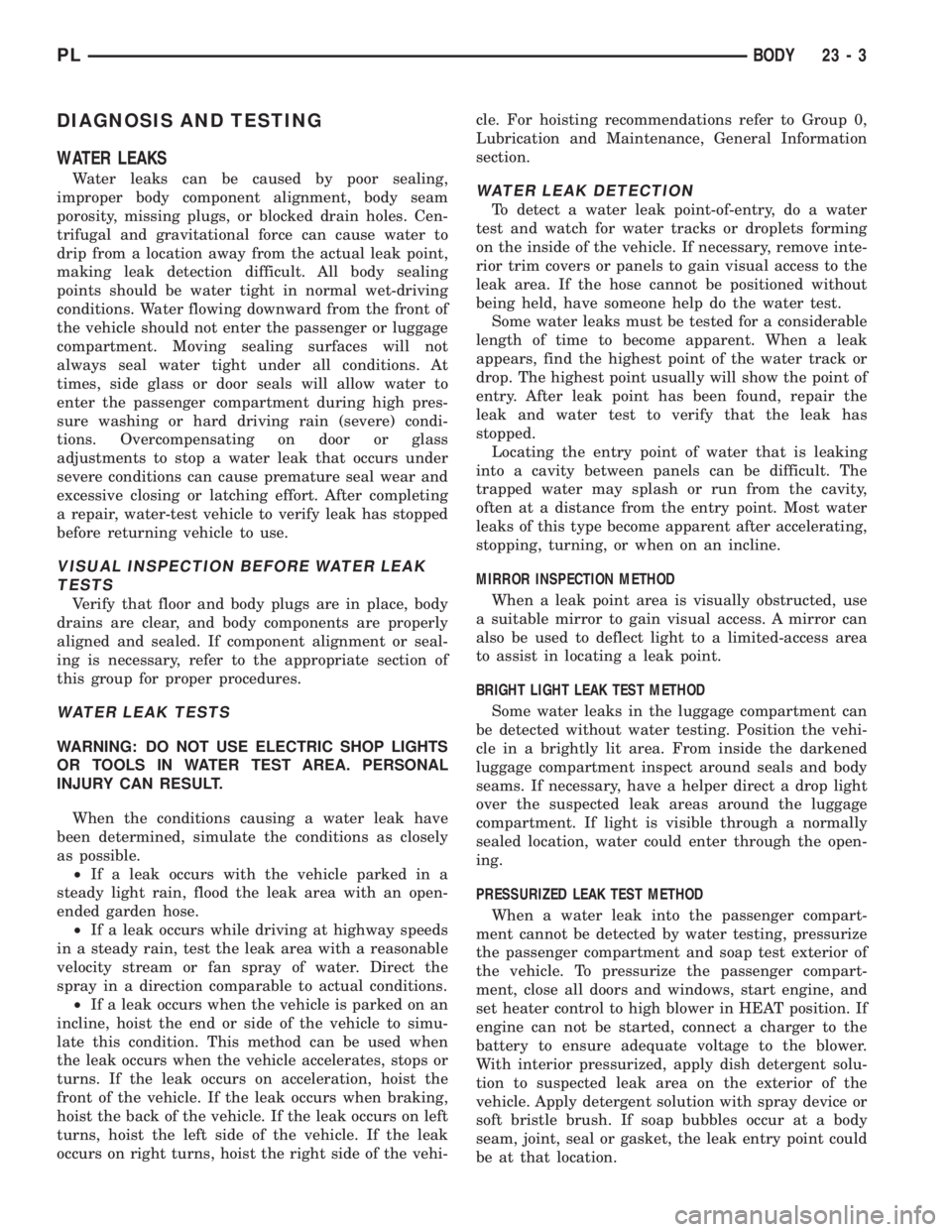

DOOR LOCK CYLINDER

REMOVAL

(1) Remove door trim panel and water shield.

(2) Close door glass.

(3) Disconnect door lock rod from latch.

(4) Remove clip holding lock cylinder to door han-

dle.

(5) Pull lock cylinder from door handle (Fig. 13).

INSTALLATION

(1) Push lock cylinder into door handle.

(2) Install clip holding lock cylinder to door han-

dle.

(3) Connect door lock rod from latch.

(4) Install door trim panel and water shield.

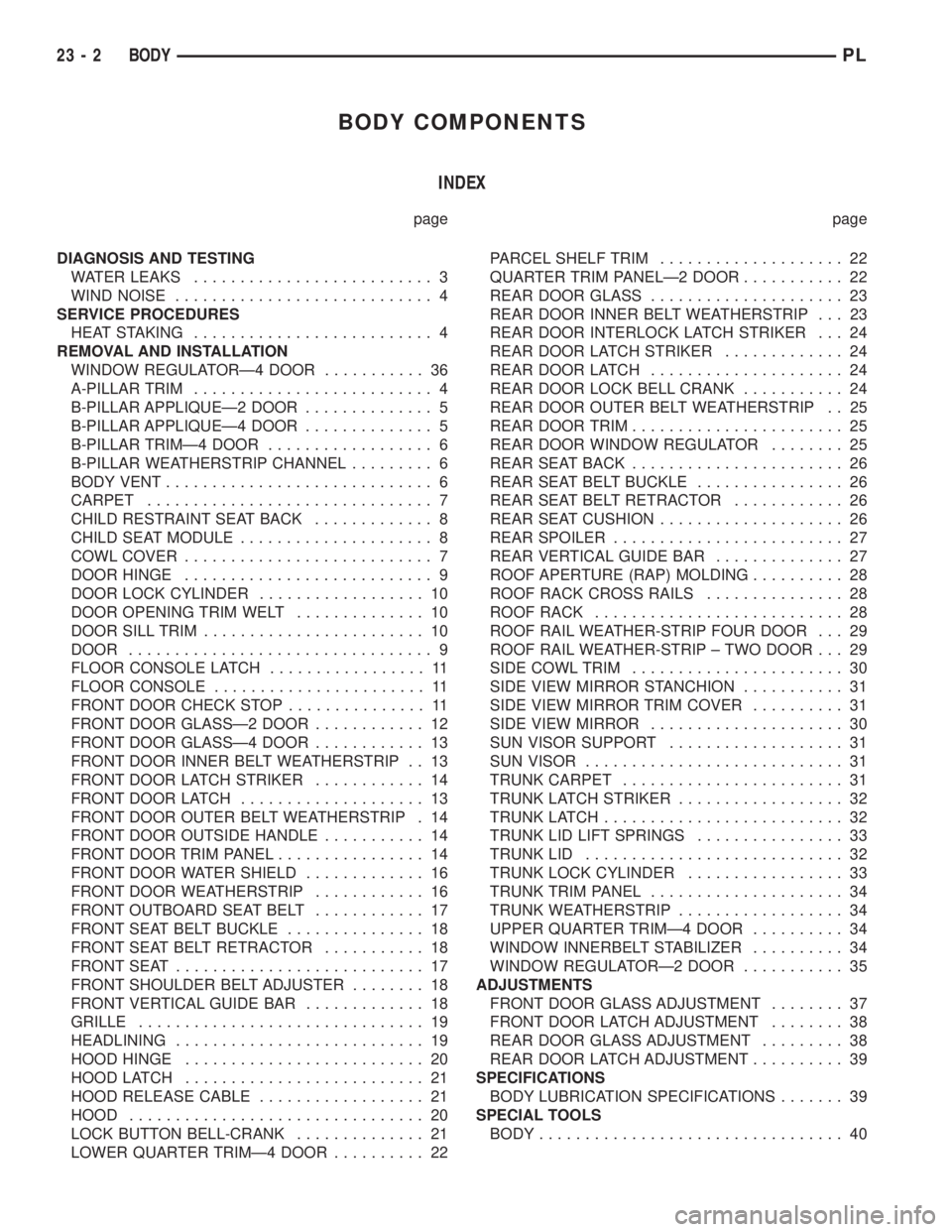

DOOR OPENING TRIM WELT

REMOVAL

(1) Open door to gain access to trim welt.

(2) Remove door sill trim panel.

(3) Pull trim welt from door opening flange (Fig.

14).

INSTALLATION

(1) Locate paint dot on backside of trim welt.

(2) Position trim welt to vehicle with paint dot in

the appropriate position.(3) Press trim welt onto door opening flange start-

ing at the paint dot position.

(4) Install door sill trim panel

DOOR SILL TRIM

REMOVAL

(1) Open door to gain access to sill trim.

(2) Disengage clips holding sill trim to door sill

and door opening flange.

(3) Separate door sill trim from vehicle (Fig. 15).

INSTALLATION

(1) Position door sill trim on door sill.

(2) Align locating pins on backside of trim panel to

holes in door sill.

(3) Engage clips on trim panel into slots in door

sill.

(4) Engage clips on trim panel onto door opening

flange.

(5) Press downward on trim panel to fully engage

all clips.

Fig. 13 Door Lock Cylinder

Fig. 14 Door Opening Trim Welt

Fig. 15 Door Sill Trim

23 - 10 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1094 of 1200

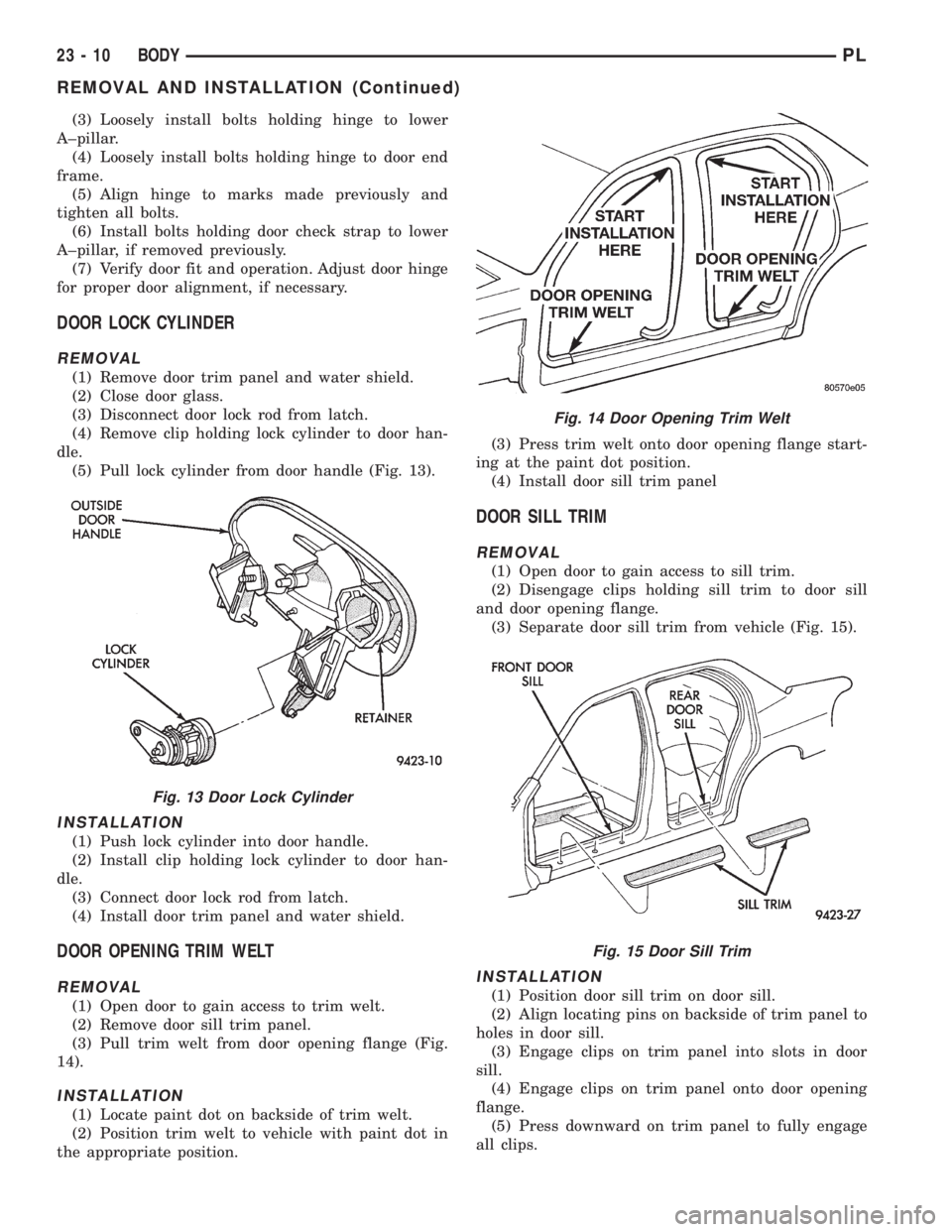

FRONT DOOR GLASSÐ4 DOOR

REMOVAL

(1) Remove door trim panel and water shield.

(2) Remove inner door belt weatherstrip.

(3) Loosen window inner belt stabilizer.

(4) Lower door glass to bottom of door to gain

access to attaching bolts.

(5) Remove bolts holding door glass to window reg-

ulator lift plates (Fig. 22).

(6) Disengage door glass from regulator.

(7) Lift door glass upward out of the opening at

the top of door.

INSTALLATION

(1) Carefully lower door glass through opening in

top of door.

(2) Position door glass into window regulator lift

plates.

(3) Install bolts securing door glass to lift plates.

(4) Tighten window inner belt stabilizer.

(5) Install inner door belt weatherstrip.

(6) Install door trim panel and water shield.

FRONT DOOR INNER BELT WEATHERSTRIP

REMOVAL

(1) Remove door trim panel.

(2) Separate weatherstrip from door.

INSTALLATION

(1) Push down on weatherstrip to engage channel

to door panel.

(2) Install door trim panel.

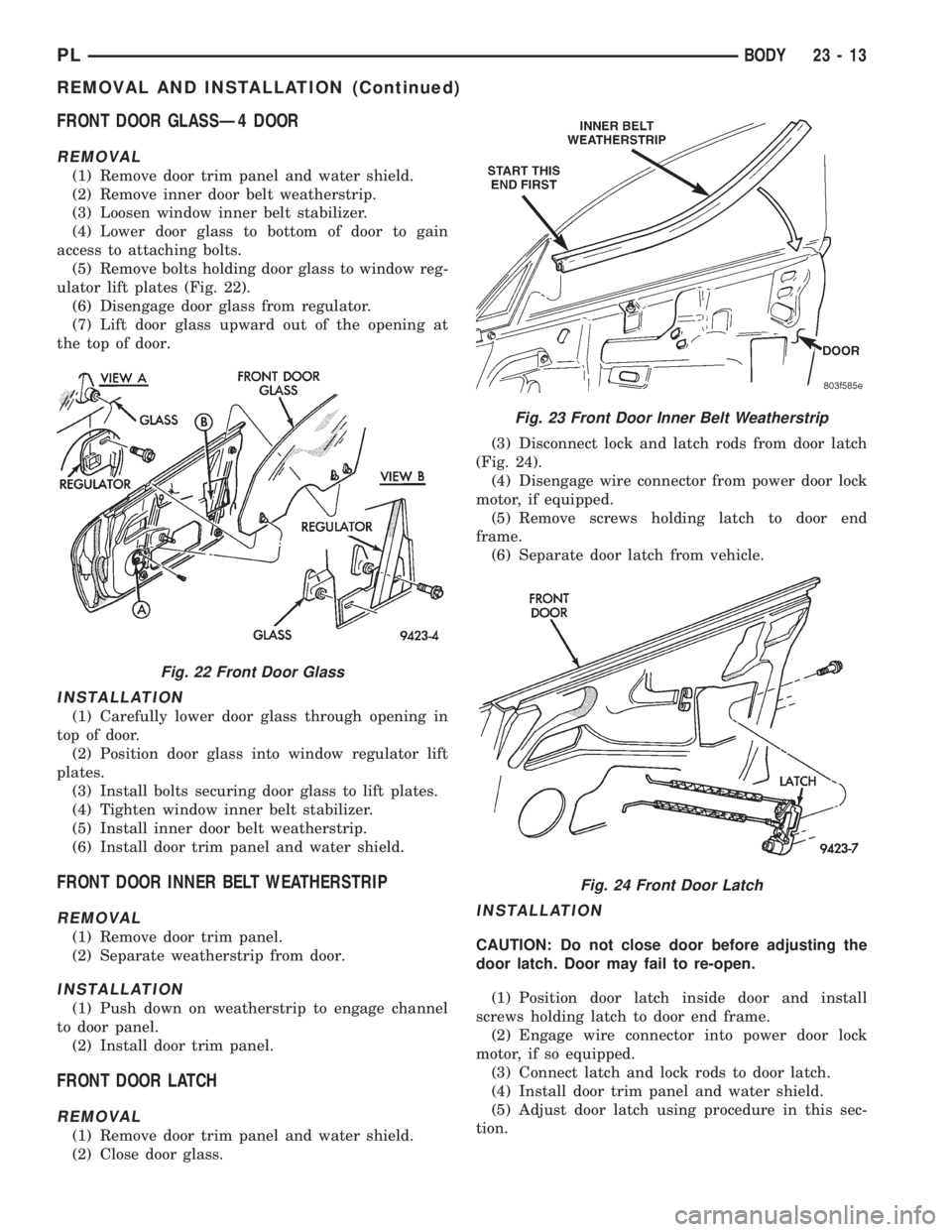

FRONT DOOR LATCH

REMOVAL

(1) Remove door trim panel and water shield.

(2) Close door glass.(3) Disconnect lock and latch rods from door latch

(Fig. 24).

(4) Disengage wire connector from power door lock

motor, if equipped.

(5) Remove screws holding latch to door end

frame.

(6) Separate door latch from vehicle.

INSTALLATION

CAUTION: Do not close door before adjusting the

door latch. Door may fail to re-open.

(1) Position door latch inside door and install

screws holding latch to door end frame.

(2) Engage wire connector into power door lock

motor, if so equipped.

(3) Connect latch and lock rods to door latch.

(4) Install door trim panel and water shield.

(5) Adjust door latch using procedure in this sec-

tion.

Fig. 22 Front Door Glass

Fig. 23 Front Door Inner Belt Weatherstrip

Fig. 24 Front Door Latch

PLBODY 23 - 13

REMOVAL AND INSTALLATION (Continued)

Page 1095 of 1200

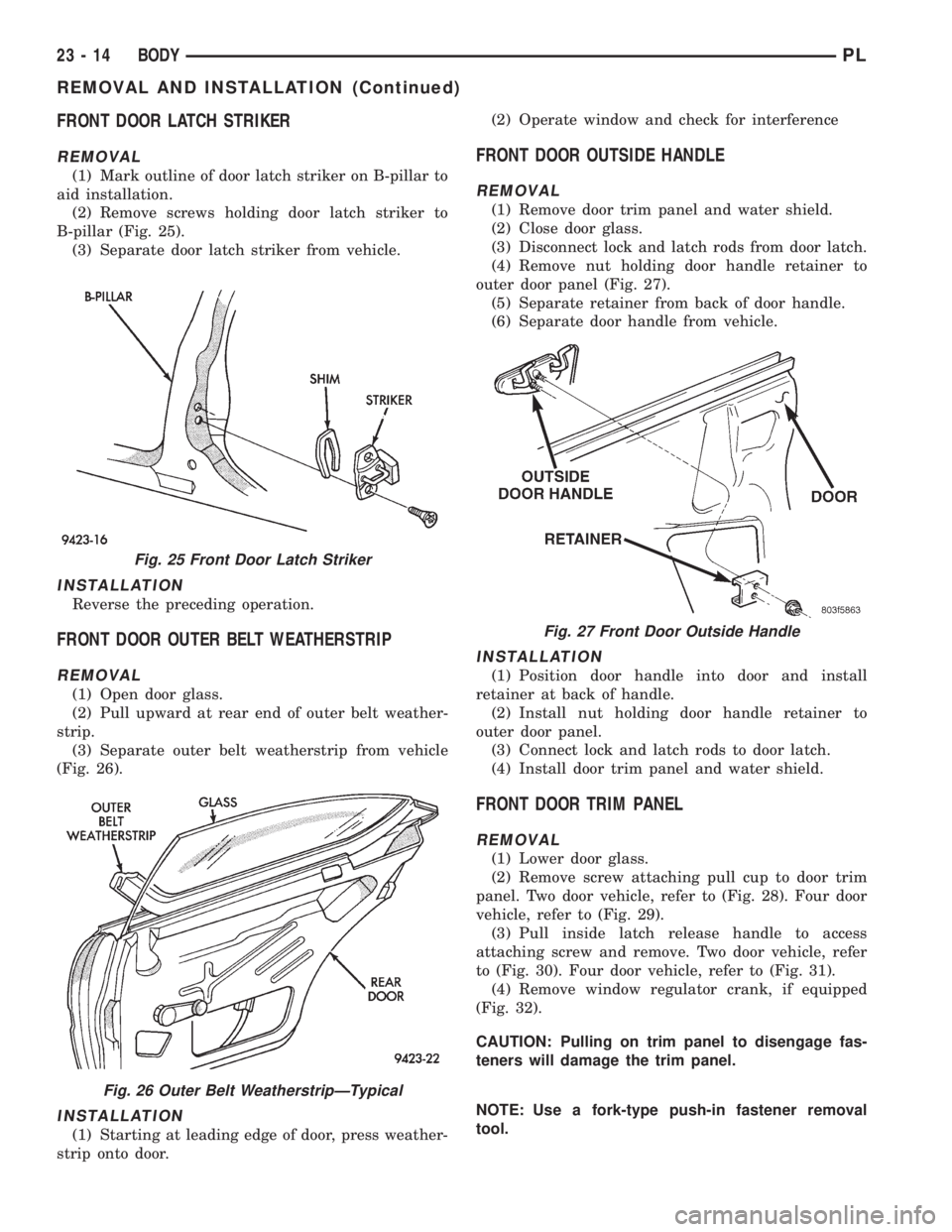

FRONT DOOR LATCH STRIKER

REMOVAL

(1) Mark outline of door latch striker on B-pillar to

aid installation.

(2) Remove screws holding door latch striker to

B-pillar (Fig. 25).

(3) Separate door latch striker from vehicle.

INSTALLATION

Reverse the preceding operation.

FRONT DOOR OUTER BELT WEATHERSTRIP

REMOVAL

(1) Open door glass.

(2) Pull upward at rear end of outer belt weather-

strip.

(3) Separate outer belt weatherstrip from vehicle

(Fig. 26).

INSTALLATION

(1) Starting at leading edge of door, press weather-

strip onto door.(2) Operate window and check for interference

FRONT DOOR OUTSIDE HANDLE

REMOVAL

(1) Remove door trim panel and water shield.

(2) Close door glass.

(3) Disconnect lock and latch rods from door latch.

(4) Remove nut holding door handle retainer to

outer door panel (Fig. 27).

(5) Separate retainer from back of door handle.

(6) Separate door handle from vehicle.

INSTALLATION

(1) Position door handle into door and install

retainer at back of handle.

(2) Install nut holding door handle retainer to

outer door panel.

(3) Connect lock and latch rods to door latch.

(4) Install door trim panel and water shield.

FRONT DOOR TRIM PANEL

REMOVAL

(1) Lower door glass.

(2) Remove screw attaching pull cup to door trim

panel. Two door vehicle, refer to (Fig. 28). Four door

vehicle, refer to (Fig. 29).

(3) Pull inside latch release handle to access

attaching screw and remove. Two door vehicle, refer

to (Fig. 30). Four door vehicle, refer to (Fig. 31).

(4) Remove window regulator crank, if equipped

(Fig. 32).

CAUTION: Pulling on trim panel to disengage fas-

teners will damage the trim panel.

NOTE: Use a fork-type push-in fastener removal

tool.

Fig. 25 Front Door Latch Striker

Fig. 26 Outer Belt WeatherstripÐTypical

Fig. 27 Front Door Outside Handle

23 - 14 BODYPL

REMOVAL AND INSTALLATION (Continued)