lock DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 996 of 1200

(5) Line pressure should read 52 to 58 psi with

throttle lever clockwise. Pressure should gradually

increase to 80 to 88 psi.as lever is moved counter-

clockwise.

(6) Low/reverse pressure should read the same as

line pressure, within 3 psi.

(7) This tests pump output, pressure regulation,

and condition of rear clutch and rear servo hydraulic

circuits.

TEST TWO (SELECTOR IN 2)

(1) Attach one gauge to line pressure port, and tee

another gauge into lower cooler line fitting. This will

allow lubrication pressure readings to be taken..

(2) Operate engine at 1000 rpm for test.

(3) Move selector lever on transaxle one detent for-

ward from full rearward position. This is selector 2

position.

(4) Read pressures on both gauges as throttle lever

on transaxle is moved from full clockwise position to

full counterclockwise position.

(5) Line pressure should read 52 to 58 psi with

throttle lever clockwise. Pressure should gradually

increase to 80 to 88 psi. as lever is moved counter-

clockwise.

(6) Lubrication pressure should be 10 to 25 psi

with lever clockwise and 10 to 35 psi with lever at

full counterclockwise.

(7) This tests pump output, pressure regulation,

and condition of rear clutch and lubrication hydraulic

circuits.

TEST THREE (SELECTOR IN D)

(1) Attach gauges to line and kickdown release

ports.

(2) Operate engine at 1600 rpm for test.

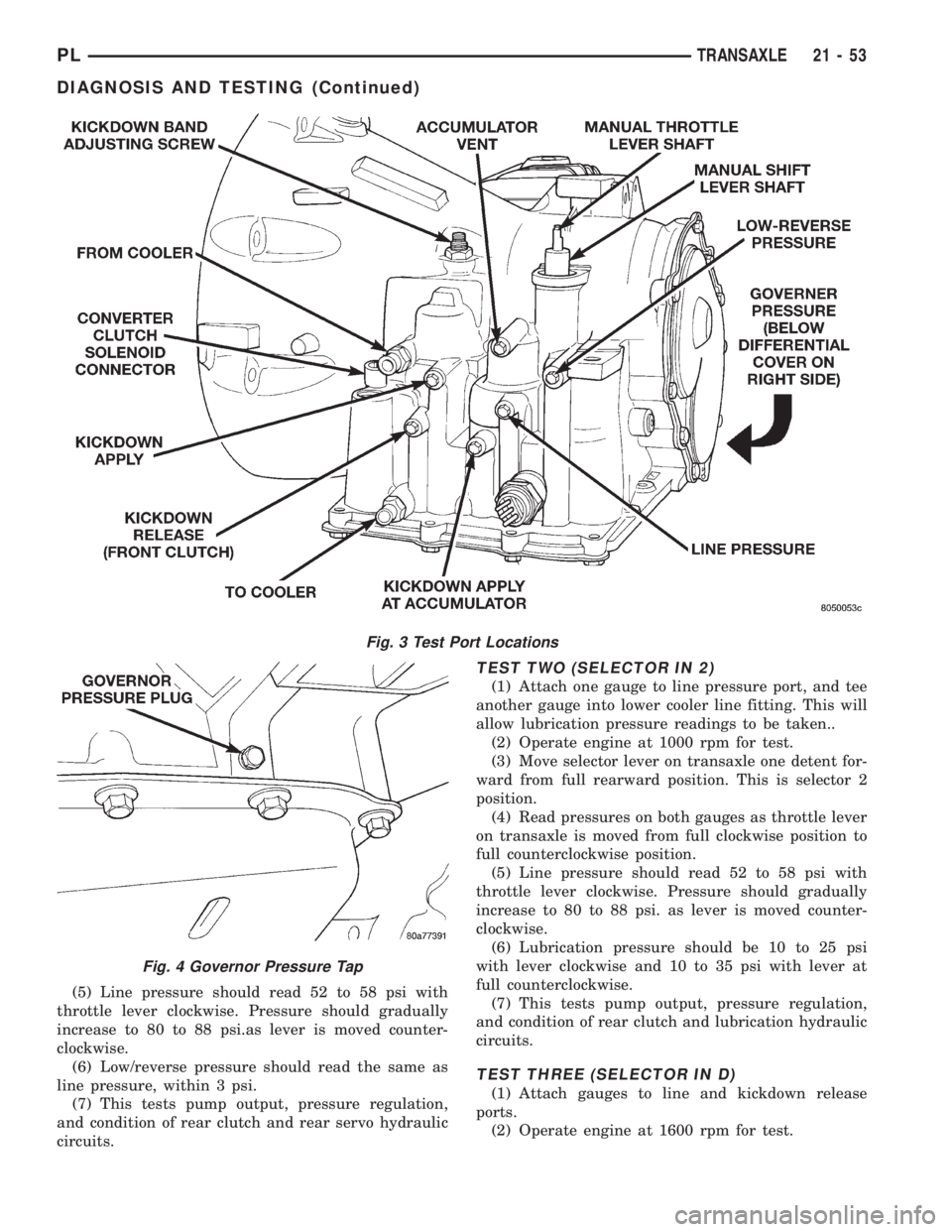

Fig. 3 Test Port Locations

Fig. 4 Governor Pressure Tap

PLTRANSAXLE 21 - 53

DIAGNOSIS AND TESTING (Continued)

Page 997 of 1200

(3) Move selector lever on transaxle two detents

forward from full rearward position. This is selector

D position.

(4) Read pressures on both gauges as throttle lever

on transaxle is moved from full clockwise to the full

counterclockwise position.

(5) Line pressure should read 52 to 58 psi with

throttle lever clockwise. Pressure should gradually

increase to 80 to 88 psi. as lever is moved counter-

clockwise.

(6) Kickdown release is pressurized only in direct

drive and should be same as line pressure within 3

psi, up to kickdown point.

(7) This tests pump output, pressure regulation,

and condition of rear clutch, front clutch, and

hydraulic circuits.

TEST FOUR (SELECTOR IN REVERSE)

(1) Attach 300 psi gauge to low-reverse port.

(2) Operate engine at 1600 rpm for test.

(3) Move selector lever on transaxle four detents

forward from full rearward position. This is selector

R position.

(4) Low/reverse pressure should read 180 to 220

psi with throttle lever clockwise. Pressure should

gradually increase to 260 to 300 psi. as lever is

moved counterclockwise.

(5) This tests pump output, pressure regulation,

and condition of front clutch and rear servo hydraulic

circuits.

(6) Move selector lever on transaxle to D position

to check that low/reverse pressure drops to zero.

(7) This tests for leakage into rear servo, due to

case porosity, which can cause reverse band burn out.

TEST RESULT INDICATIONS

(1) If proper line pressure, minimum to maximum,

is found in any one test, the pump and pressure reg-

ulator are working properly.

(2) Low pressure in D, 1, and 2 but correct pres-

sure in R, indicates rear clutch circuit leakage.

(3) Low pressure in D and R, but correct pressure

in 1 indicates front clutch circuit leakage.

(4) Low pressure in R and 1, but correct pressure

in 2 indicates rear servo circuit leakage.

(5) Low line pressure in all positions indicates a

defective pump, a clogged filter, or a stuck pressure

regulator valve.

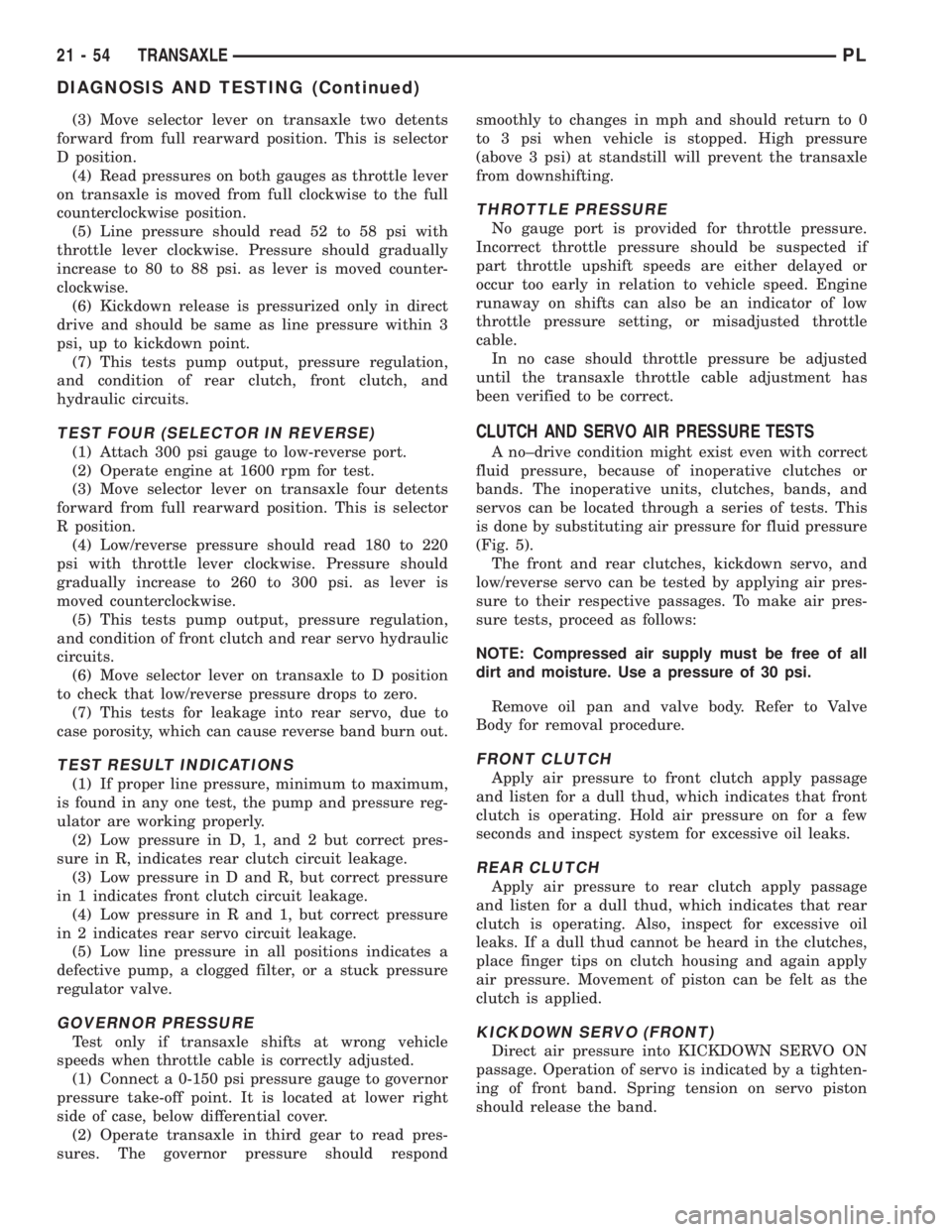

GOVERNOR PRESSURE

Test only if transaxle shifts at wrong vehicle

speeds when throttle cable is correctly adjusted.

(1) Connect a 0-150 psi pressure gauge to governor

pressure take-off point. It is located at lower right

side of case, below differential cover.

(2) Operate transaxle in third gear to read pres-

sures. The governor pressure should respondsmoothly to changes in mph and should return to 0

to 3 psi when vehicle is stopped. High pressure

(above 3 psi) at standstill will prevent the transaxle

from downshifting.

THROTTLE PRESSURE

No gauge port is provided for throttle pressure.

Incorrect throttle pressure should be suspected if

part throttle upshift speeds are either delayed or

occur too early in relation to vehicle speed. Engine

runaway on shifts can also be an indicator of low

throttle pressure setting, or misadjusted throttle

cable.

In no case should throttle pressure be adjusted

until the transaxle throttle cable adjustment has

been verified to be correct.

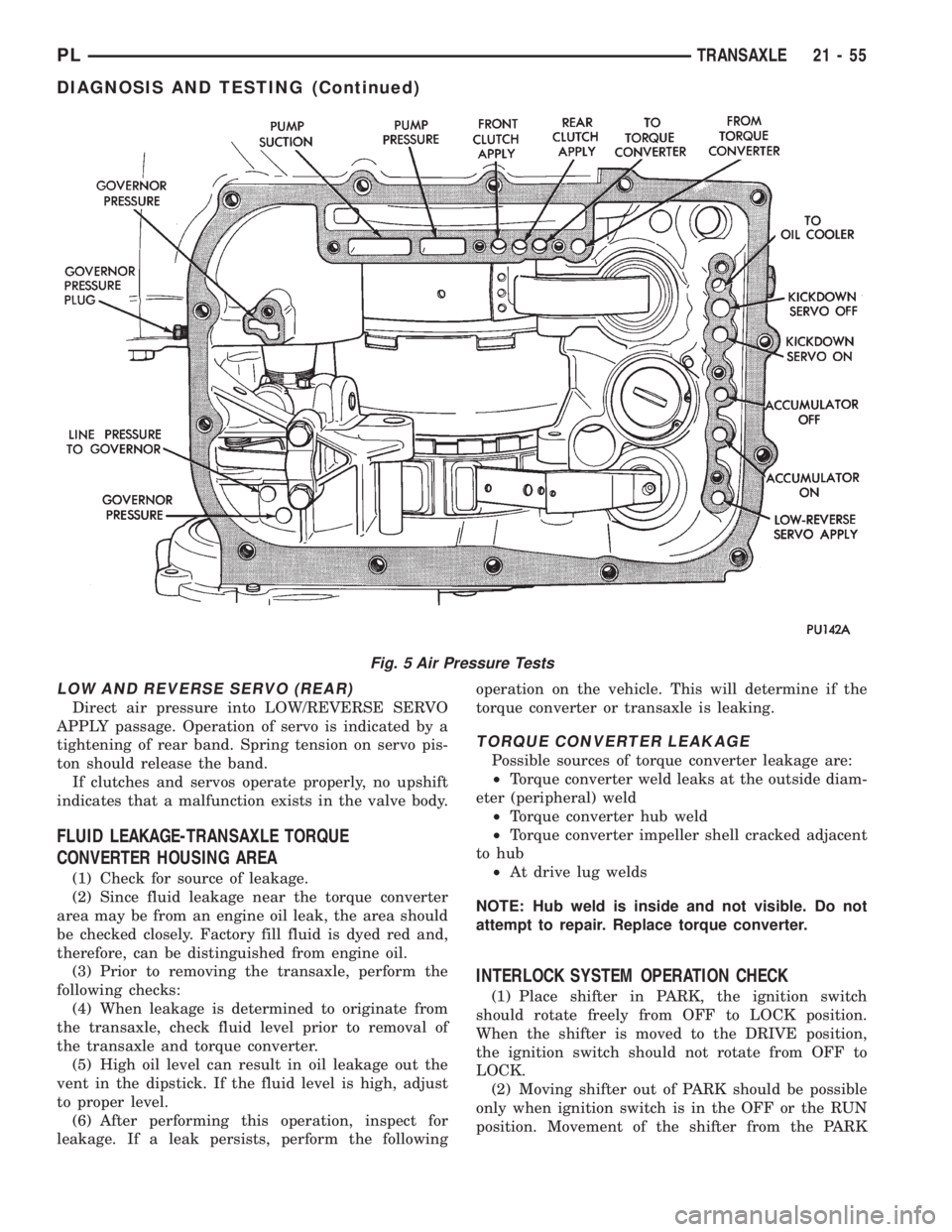

CLUTCH AND SERVO AIR PRESSURE TESTS

A no±drive condition might exist even with correct

fluid pressure, because of inoperative clutches or

bands. The inoperative units, clutches, bands, and

servos can be located through a series of tests. This

is done by substituting air pressure for fluid pressure

(Fig. 5).

The front and rear clutches, kickdown servo, and

low/reverse servo can be tested by applying air pres-

sure to their respective passages. To make air pres-

sure tests, proceed as follows:

NOTE: Compressed air supply must be free of all

dirt and moisture. Use a pressure of 30 psi.

Remove oil pan and valve body. Refer to Valve

Body for removal procedure.

FRONT CLUTCH

Apply air pressure to front clutch apply passage

and listen for a dull thud, which indicates that front

clutch is operating. Hold air pressure on for a few

seconds and inspect system for excessive oil leaks.

REAR CLUTCH

Apply air pressure to rear clutch apply passage

and listen for a dull thud, which indicates that rear

clutch is operating. Also, inspect for excessive oil

leaks. If a dull thud cannot be heard in the clutches,

place finger tips on clutch housing and again apply

air pressure. Movement of piston can be felt as the

clutch is applied.

KICKDOWN SERVO (FRONT)

Direct air pressure into KICKDOWN SERVO ON

passage. Operation of servo is indicated by a tighten-

ing of front band. Spring tension on servo piston

should release the band.

21 - 54 TRANSAXLEPL

DIAGNOSIS AND TESTING (Continued)

Page 998 of 1200

LOW AND REVERSE SERVO (REAR)

Direct air pressure into LOW/REVERSE SERVO

APPLY passage. Operation of servo is indicated by a

tightening of rear band. Spring tension on servo pis-

ton should release the band.

If clutches and servos operate properly, no upshift

indicates that a malfunction exists in the valve body.

FLUID LEAKAGE-TRANSAXLE TORQUE

CONVERTER HOUSING AREA

(1) Check for source of leakage.

(2) Since fluid leakage near the torque converter

area may be from an engine oil leak, the area should

be checked closely. Factory fill fluid is dyed red and,

therefore, can be distinguished from engine oil.

(3) Prior to removing the transaxle, perform the

following checks:

(4) When leakage is determined to originate from

the transaxle, check fluid level prior to removal of

the transaxle and torque converter.

(5) High oil level can result in oil leakage out the

vent in the dipstick. If the fluid level is high, adjust

to proper level.

(6) After performing this operation, inspect for

leakage. If a leak persists, perform the followingoperation on the vehicle. This will determine if the

torque converter or transaxle is leaking.

TORQUE CONVERTER LEAKAGE

Possible sources of torque converter leakage are:

²Torque converter weld leaks at the outside diam-

eter (peripheral) weld

²Torque converter hub weld

²Torque converter impeller shell cracked adjacent

to hub

²At drive lug welds

NOTE: Hub weld is inside and not visible. Do not

attempt to repair. Replace torque converter.

INTERLOCK SYSTEM OPERATION CHECK

(1) Place shifter in PARK, the ignition switch

should rotate freely from OFF to LOCK position.

When the shifter is moved to the DRIVE position,

the ignition switch should not rotate from OFF to

LOCK.

(2) Moving shifter out of PARK should be possible

only when ignition switch is in the OFF or the RUN

position. Movement of the shifter from the PARK

Fig. 5 Air Pressure Tests

PLTRANSAXLE 21 - 55

DIAGNOSIS AND TESTING (Continued)

Page 999 of 1200

position should not be possible when the ignition

switch is in the LOCK or the ACCESSORY position.

(3) If the interlock system, operates in any way

other than as described above, repair of the interlock

system is required. See Adjustment and Repair pro-

cedures in this section for the required procedures.

SERVICE PROCEDURES

FLUID AND FILTER CHANGE

When the factory fill fluid is changed, only fluids

labeled MOPARtATF PLUS 3 (Automatic Transmis-

sion fluid) Type 7176 should be used.

If the transaxle is disassembled for any reason, the

fluid and filter should be changed.

30,000 MILE TRANSAXLE OIL CHANGE

When a vehicle attains 30,000 miles on its odome-

ter it is recommended that the transaxle oil be

changed. To change the oil, use the procedure that

follows:

It is recommended that a transaxle fluid exchanger

(ATF 2000+ or equivalent) be used to replace the

used fluid in the transaxle. If a fluid exchanger is not

available use a fluid suction pump (Vaculayor equiv-

alent) to draw the fluid out of the dipstick tube. If a

fluid suction pump is not available remove the oil

pan and drain the fluid.

CAUTION: Chrysler Corporation does not recom-

mend using any fluid exchanger that introduces

additives into the transaxle.

TRANSAXLE FLUID EXCHANGER METHOD

(1) To perform the transaxle fluid exchange, the

transaxle must be at operating temperature. Drive

the vehicle till it reaches full operating temperature.

(2) Verify that the fill tank on the transaxle fluid

exchanger (ATF 2000+ or equivalent) is clean and

dry.

(3) Fill the tank to the recommended fill capacity

with Mopar ATF Plus 3 Type 7176.

(4) Hookup the vehicle to the machine following

the manufacturers instructions. Perform the

exchange procedure following the instructions pro-

vided with the machine.

(5) Once machine has completed the fluid

exchange. Check the fluid level and condition and fill

to proper level with Mopar ATF Plus 3 Type 7176.

NOTE: Verify that the transaxle cooler lines are

tightened to proper specifications. Cooler line

torque specification is 2 N²m (18 in. lbs.).DIPSTICK TUBE FLUID SUCTION METHOD

(1) When performing the fluid suction method,

make sure the transaxle is at full operating temper-

ature.

(2) To perform the dipstick tube fluid suction

method, use a suitable fluid suction device (Vaculay

or equivalent).

(3) Insert the fluid suction line into the dipstick

tube.

NOTE: Verify that the suction line is inserted to the

lowest point of the transaxle oil pan. This will

ensure complete evacuation of the fluid in the pan.

(4) Follow the manufacturers recommended proce-

dure and evacuate the fluid from the transaxle.

(5) Remove the suction line from the dipstick tube.

(6) Add 4 Quarts of Mopar ATF Plus 3 Type 7176

transaxle fluid.

(7) Start the engine and allow it to idle for a min-

imum of one minute. With the parking brake applied,

press your foot on the service brake and cycle the

transaxle from park to all gear positions ending in

neutral or park.

(8) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the ADD mark on the dip-

stick.

(9) Recheck the fluid level after the transaxle is at

normal operating temperature. The level should be in

the HOT range.

TRANSAXLE OIL PAN DROP METHOD

This procedure involves removing the transaxle oil

pan to drain the transaxle fluid.

(1) Bring the vehicle up to normal operating tem-

perature. Drive the vehicle a minimum of 10 miles.

(2) Raise the vehicle on the hoist.

(3) Loosen the transaxle oil pan and drain the

fluid into a suitable container.

(4) Remove the pan and clean all sealant from the

pan and transaxle mating surfaces. Clean the mag-

net and the inside of the pan.

(5) Apply a 1/8 inch bead of Mopar RTV Sealant to

the mounting flange of the transaxle oil pan. Apply

RTV Sealant to the underside of the attaching bolts.

Attach the oil pan to the transaxle. Tighten the bolts

to 19 N²m (165 in. lbs.).

(6) Lower the vehicle and add 4 Quarts of Mopar

ATF Plus 3 Type 7176 transaxle fluid.

(7) Start the engine and allow it to idle for a min-

imum of one minute. With the parking brake applied,

press your foot on the service brake and cycle the

transaxle from park to all gear positions ending in

neutral or park.

(8) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

21 - 56 TRANSAXLEPL

DIAGNOSIS AND TESTING (Continued)

Page 1003 of 1200

(18) Carefully remove the cable from the under-

body by unfolding the cable retainer clip as you go

along.

INSTALLATION

(1) To install gearshift cable, reverse removal pro-

cedure.

(2) Adjust gearshift cable using the adjustment

procedure in this Group.

GEARSHIFT MECHANISM

REMOVAL

(1) Disconnect battery negative cable and isolate.

(2) Remove console assembly. Refer to Group 23,

Body.

(3) Remove the gearshift knob set screw and knob.

(4) Remove the screws retaining the gearshift indi-

cator bezel and remove bezel and indicator lamp.

(5) Using a flat±blade pry tool, remove the shifter

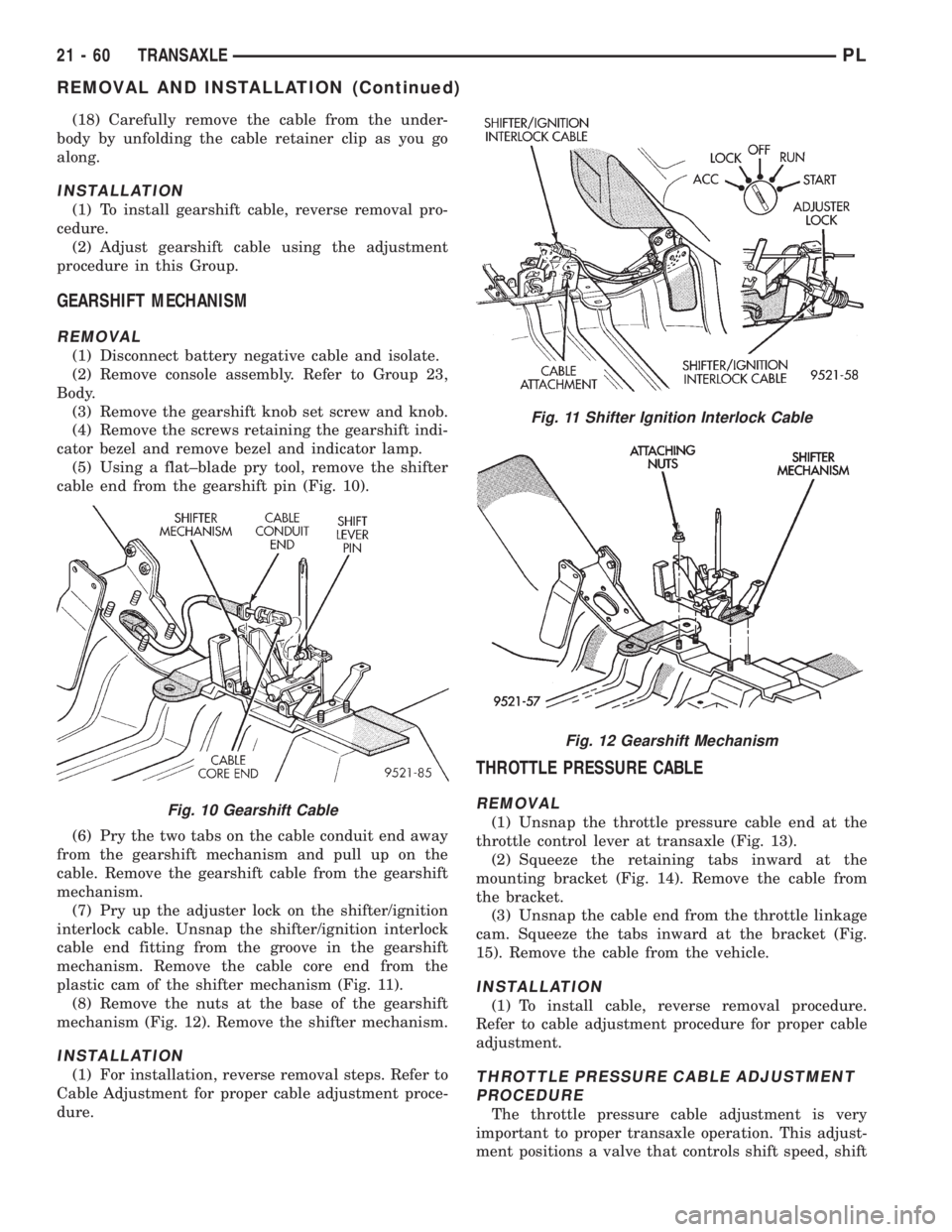

cable end from the gearshift pin (Fig. 10).

(6) Pry the two tabs on the cable conduit end away

from the gearshift mechanism and pull up on the

cable. Remove the gearshift cable from the gearshift

mechanism.

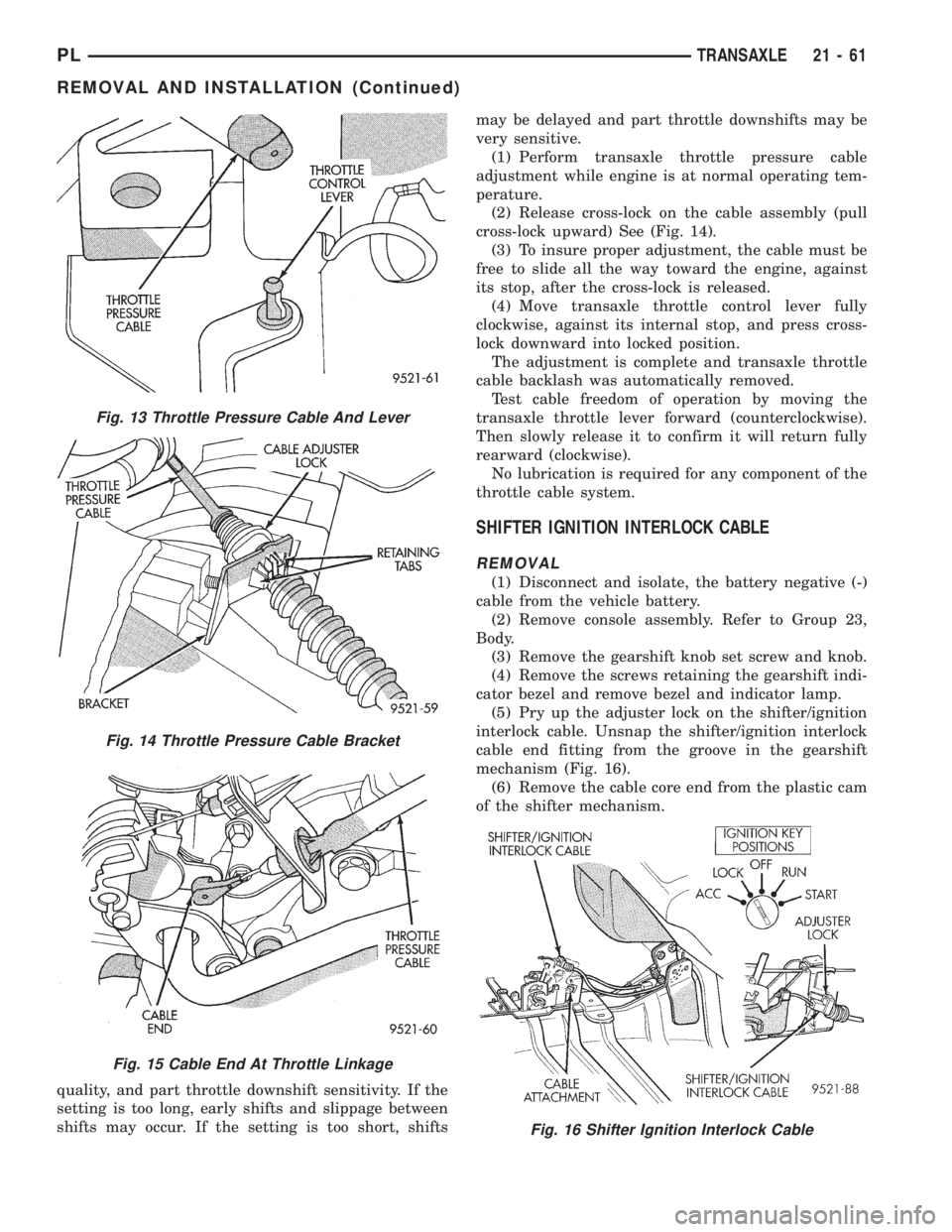

(7) Pry up the adjuster lock on the shifter/ignition

interlock cable. Unsnap the shifter/ignition interlock

cable end fitting from the groove in the gearshift

mechanism. Remove the cable core end from the

plastic cam of the shifter mechanism (Fig. 11).

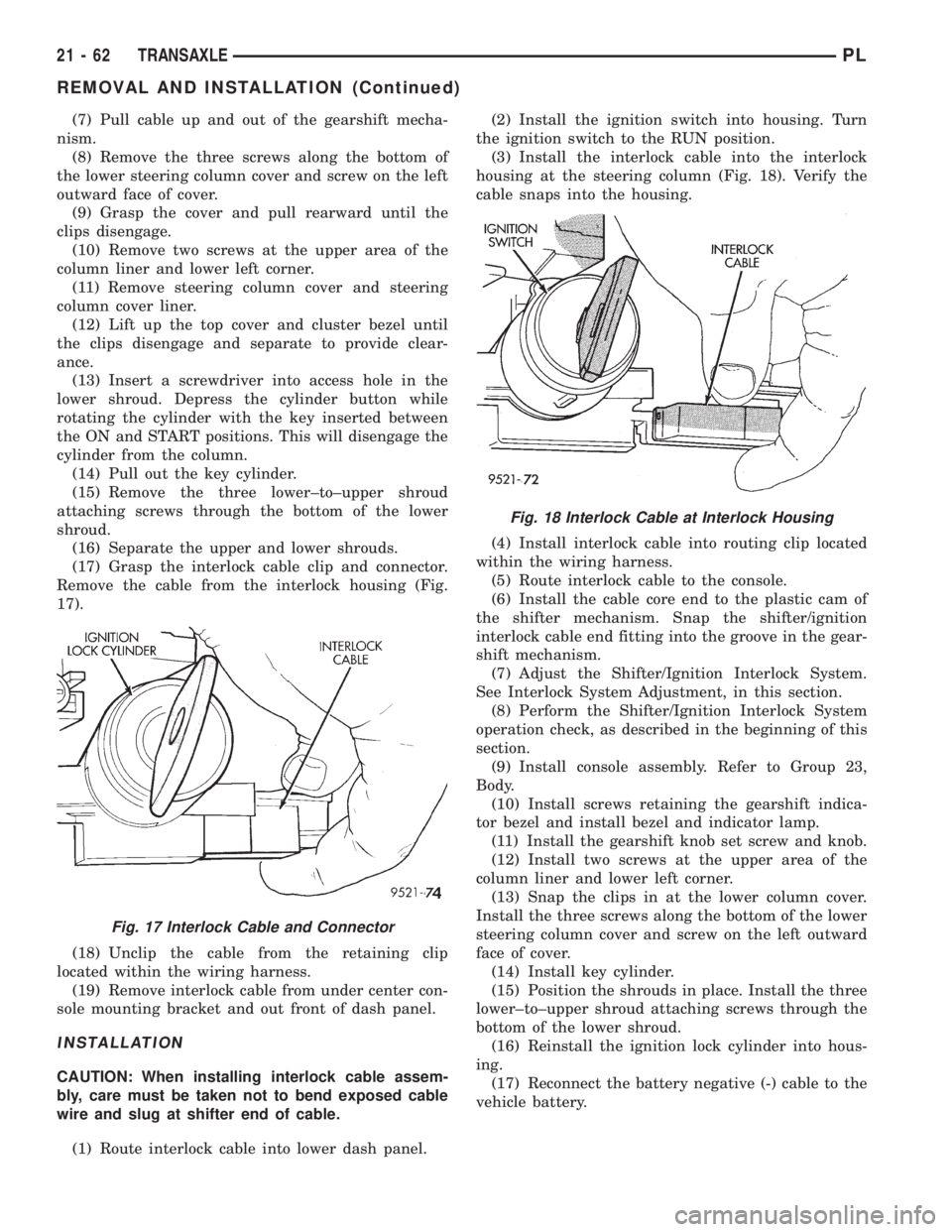

(8) Remove the nuts at the base of the gearshift

mechanism (Fig. 12). Remove the shifter mechanism.

INSTALLATION

(1) For installation, reverse removal steps. Refer to

Cable Adjustment for proper cable adjustment proce-

dure.

THROTTLE PRESSURE CABLE

REMOVAL

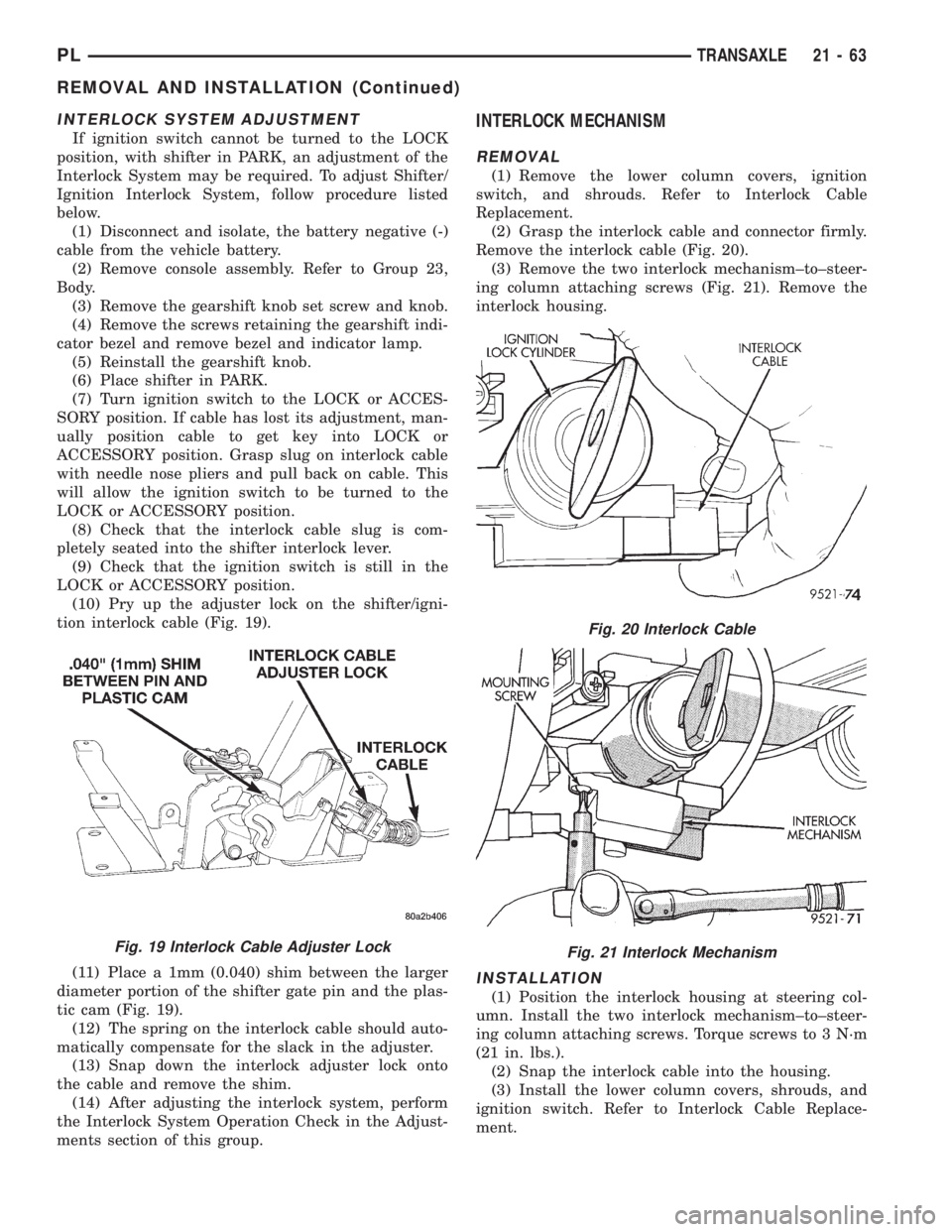

(1) Unsnap the throttle pressure cable end at the

throttle control lever at transaxle (Fig. 13).

(2) Squeeze the retaining tabs inward at the

mounting bracket (Fig. 14). Remove the cable from

the bracket.

(3) Unsnap the cable end from the throttle linkage

cam. Squeeze the tabs inward at the bracket (Fig.

15). Remove the cable from the vehicle.

INSTALLATION

(1) To install cable, reverse removal procedure.

Refer to cable adjustment procedure for proper cable

adjustment.

THROTTLE PRESSURE CABLE ADJUSTMENT

PROCEDURE

The throttle pressure cable adjustment is very

important to proper transaxle operation. This adjust-

ment positions a valve that controls shift speed, shift

Fig. 10 Gearshift Cable

Fig. 11 Shifter Ignition Interlock Cable

Fig. 12 Gearshift Mechanism

21 - 60 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 1004 of 1200

quality, and part throttle downshift sensitivity. If the

setting is too long, early shifts and slippage between

shifts may occur. If the setting is too short, shiftsmay be delayed and part throttle downshifts may be

very sensitive.

(1) Perform transaxle throttle pressure cable

adjustment while engine is at normal operating tem-

perature.

(2) Release cross-lock on the cable assembly (pull

cross-lock upward) See (Fig. 14).

(3) To insure proper adjustment, the cable must be

free to slide all the way toward the engine, against

its stop, after the cross-lock is released.

(4) Move transaxle throttle control lever fully

clockwise, against its internal stop, and press cross-

lock downward into locked position.

The adjustment is complete and transaxle throttle

cable backlash was automatically removed.

Test cable freedom of operation by moving the

transaxle throttle lever forward (counterclockwise).

Then slowly release it to confirm it will return fully

rearward (clockwise).

No lubrication is required for any component of the

throttle cable system.

SHIFTER IGNITION INTERLOCK CABLE

REMOVAL

(1) Disconnect and isolate, the battery negative (-)

cable from the vehicle battery.

(2) Remove console assembly. Refer to Group 23,

Body.

(3) Remove the gearshift knob set screw and knob.

(4) Remove the screws retaining the gearshift indi-

cator bezel and remove bezel and indicator lamp.

(5) Pry up the adjuster lock on the shifter/ignition

interlock cable. Unsnap the shifter/ignition interlock

cable end fitting from the groove in the gearshift

mechanism (Fig. 16).

(6) Remove the cable core end from the plastic cam

of the shifter mechanism.

Fig. 13 Throttle Pressure Cable And Lever

Fig. 14 Throttle Pressure Cable Bracket

Fig. 15 Cable End At Throttle Linkage

Fig. 16 Shifter Ignition Interlock Cable

PLTRANSAXLE 21 - 61

REMOVAL AND INSTALLATION (Continued)

Page 1005 of 1200

(7) Pull cable up and out of the gearshift mecha-

nism.

(8) Remove the three screws along the bottom of

the lower steering column cover and screw on the left

outward face of cover.

(9) Grasp the cover and pull rearward until the

clips disengage.

(10) Remove two screws at the upper area of the

column liner and lower left corner.

(11) Remove steering column cover and steering

column cover liner.

(12) Lift up the top cover and cluster bezel until

the clips disengage and separate to provide clear-

ance.

(13) Insert a screwdriver into access hole in the

lower shroud. Depress the cylinder button while

rotating the cylinder with the key inserted between

the ON and START positions. This will disengage the

cylinder from the column.

(14) Pull out the key cylinder.

(15) Remove the three lower±to±upper shroud

attaching screws through the bottom of the lower

shroud.

(16) Separate the upper and lower shrouds.

(17) Grasp the interlock cable clip and connector.

Remove the cable from the interlock housing (Fig.

17).

(18) Unclip the cable from the retaining clip

located within the wiring harness.

(19) Remove interlock cable from under center con-

sole mounting bracket and out front of dash panel.

INSTALLATION

CAUTION: When installing interlock cable assem-

bly, care must be taken not to bend exposed cable

wire and slug at shifter end of cable.

(1) Route interlock cable into lower dash panel.(2) Install the ignition switch into housing. Turn

the ignition switch to the RUN position.

(3) Install the interlock cable into the interlock

housing at the steering column (Fig. 18). Verify the

cable snaps into the housing.

(4) Install interlock cable into routing clip located

within the wiring harness.

(5) Route interlock cable to the console.

(6) Install the cable core end to the plastic cam of

the shifter mechanism. Snap the shifter/ignition

interlock cable end fitting into the groove in the gear-

shift mechanism.

(7) Adjust the Shifter/Ignition Interlock System.

See Interlock System Adjustment, in this section.

(8) Perform the Shifter/Ignition Interlock System

operation check, as described in the beginning of this

section.

(9) Install console assembly. Refer to Group 23,

Body.

(10) Install screws retaining the gearshift indica-

tor bezel and install bezel and indicator lamp.

(11) Install the gearshift knob set screw and knob.

(12) Install two screws at the upper area of the

column liner and lower left corner.

(13) Snap the clips in at the lower column cover.

Install the three screws along the bottom of the lower

steering column cover and screw on the left outward

face of cover.

(14) Install key cylinder.

(15) Position the shrouds in place. Install the three

lower±to±upper shroud attaching screws through the

bottom of the lower shroud.

(16) Reinstall the ignition lock cylinder into hous-

ing.

(17) Reconnect the battery negative (-) cable to the

vehicle battery.

Fig. 17 Interlock Cable and Connector

Fig. 18 Interlock Cable at Interlock Housing

21 - 62 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 1006 of 1200

INTERLOCK SYSTEM ADJUSTMENT

If ignition switch cannot be turned to the LOCK

position, with shifter in PARK, an adjustment of the

Interlock System may be required. To adjust Shifter/

Ignition Interlock System, follow procedure listed

below.

(1) Disconnect and isolate, the battery negative (-)

cable from the vehicle battery.

(2) Remove console assembly. Refer to Group 23,

Body.

(3) Remove the gearshift knob set screw and knob.

(4) Remove the screws retaining the gearshift indi-

cator bezel and remove bezel and indicator lamp.

(5) Reinstall the gearshift knob.

(6) Place shifter in PARK.

(7) Turn ignition switch to the LOCK or ACCES-

SORY position. If cable has lost its adjustment, man-

ually position cable to get key into LOCK or

ACCESSORY position. Grasp slug on interlock cable

with needle nose pliers and pull back on cable. This

will allow the ignition switch to be turned to the

LOCK or ACCESSORY position.

(8) Check that the interlock cable slug is com-

pletely seated into the shifter interlock lever.

(9) Check that the ignition switch is still in the

LOCK or ACCESSORY position.

(10) Pry up the adjuster lock on the shifter/igni-

tion interlock cable (Fig. 19).

(11) Place a 1mm (0.040) shim between the larger

diameter portion of the shifter gate pin and the plas-

tic cam (Fig. 19).

(12) The spring on the interlock cable should auto-

matically compensate for the slack in the adjuster.

(13) Snap down the interlock adjuster lock onto

the cable and remove the shim.

(14) After adjusting the interlock system, perform

the Interlock System Operation Check in the Adjust-

ments section of this group.

INTERLOCK MECHANISM

REMOVAL

(1) Remove the lower column covers, ignition

switch, and shrouds. Refer to Interlock Cable

Replacement.

(2) Grasp the interlock cable and connector firmly.

Remove the interlock cable (Fig. 20).

(3) Remove the two interlock mechanism±to±steer-

ing column attaching screws (Fig. 21). Remove the

interlock housing.

INSTALLATION

(1) Position the interlock housing at steering col-

umn. Install the two interlock mechanism±to±steer-

ing column attaching screws. Torque screws to 3 N´m

(21 in. lbs.).

(2) Snap the interlock cable into the housing.

(3) Install the lower column covers, shrouds, and

ignition switch. Refer to Interlock Cable Replace-

ment.

Fig. 19 Interlock Cable Adjuster Lock

Fig. 20 Interlock Cable

Fig. 21 Interlock Mechanism

PLTRANSAXLE 21 - 63

REMOVAL AND INSTALLATION (Continued)

Page 1009 of 1200

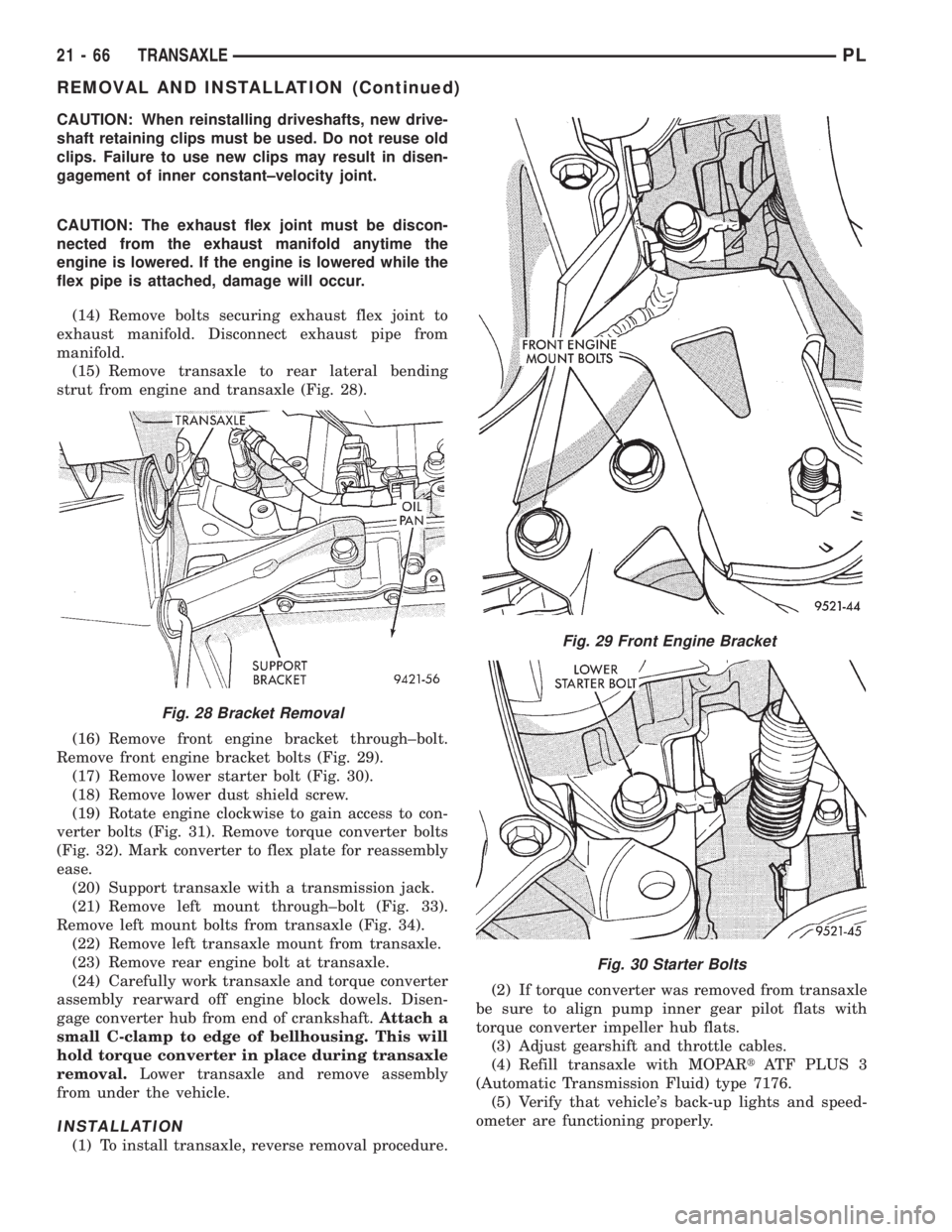

CAUTION: When reinstalling driveshafts, new drive-

shaft retaining clips must be used. Do not reuse old

clips. Failure to use new clips may result in disen-

gagement of inner constant±velocity joint.

CAUTION: The exhaust flex joint must be discon-

nected from the exhaust manifold anytime the

engine is lowered. If the engine is lowered while the

flex pipe is attached, damage will occur.

(14) Remove bolts securing exhaust flex joint to

exhaust manifold. Disconnect exhaust pipe from

manifold.

(15) Remove transaxle to rear lateral bending

strut from engine and transaxle (Fig. 28).

(16) Remove front engine bracket through±bolt.

Remove front engine bracket bolts (Fig. 29).

(17) Remove lower starter bolt (Fig. 30).

(18) Remove lower dust shield screw.

(19) Rotate engine clockwise to gain access to con-

verter bolts (Fig. 31). Remove torque converter bolts

(Fig. 32). Mark converter to flex plate for reassembly

ease.

(20) Support transaxle with a transmission jack.

(21) Remove left mount through±bolt (Fig. 33).

Remove left mount bolts from transaxle (Fig. 34).

(22) Remove left transaxle mount from transaxle.

(23) Remove rear engine bolt at transaxle.

(24) Carefully work transaxle and torque converter

assembly rearward off engine block dowels. Disen-

gage converter hub from end of crankshaft.Attach a

small C-clamp to edge of bellhousing. This will

hold torque converter in place during transaxle

removal.Lower transaxle and remove assembly

from under the vehicle.

INSTALLATION

(1) To install transaxle, reverse removal procedure.(2) If torque converter was removed from transaxle

be sure to align pump inner gear pilot flats with

torque converter impeller hub flats.

(3) Adjust gearshift and throttle cables.

(4) Refill transaxle with MOPARtATF PLUS 3

(Automatic Transmission Fluid) type 7176.

(5) Verify that vehicle's back-up lights and speed-

ometer are functioning properly.

Fig. 28 Bracket Removal

Fig. 29 Front Engine Bracket

Fig. 30 Starter Bolts

21 - 66 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 1012 of 1200

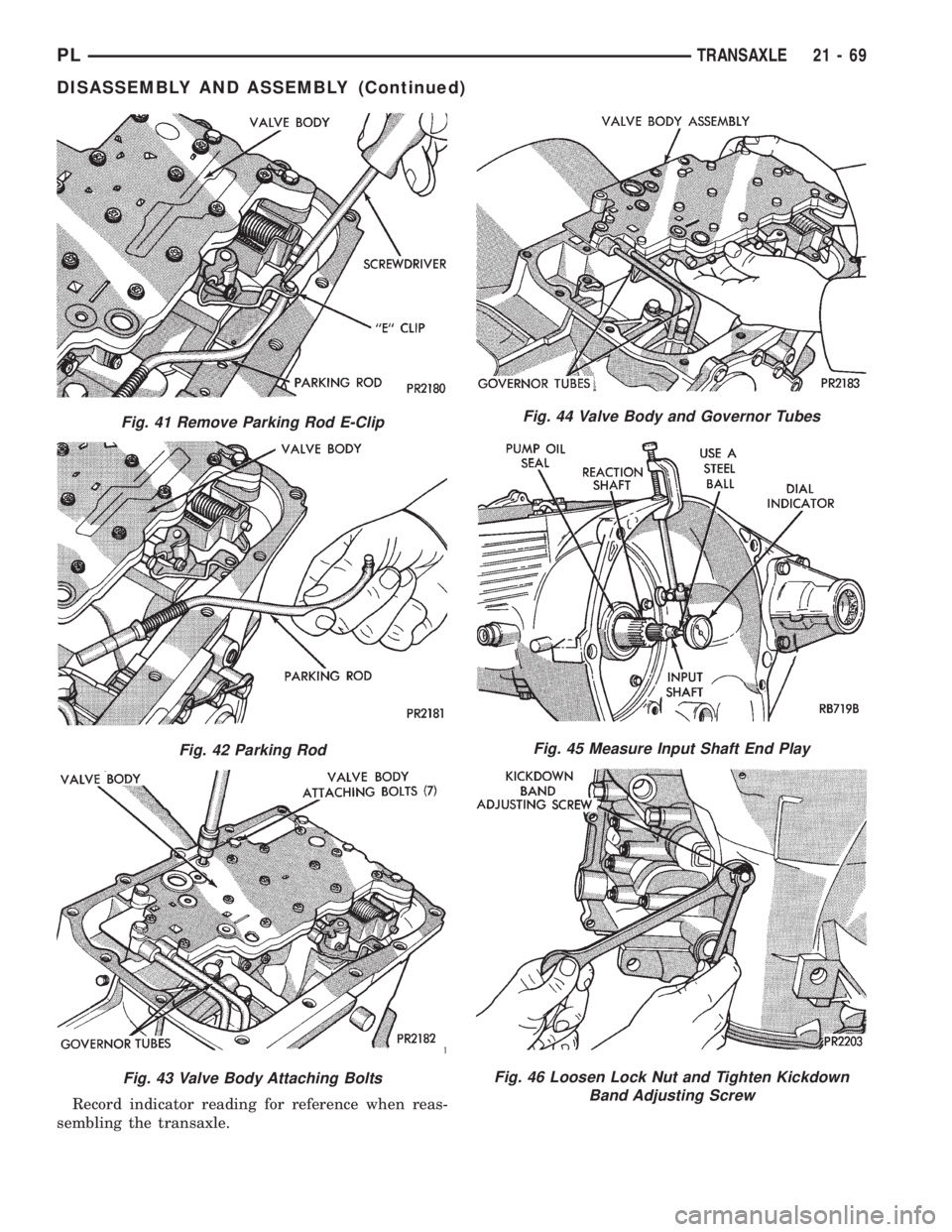

Record indicator reading for reference when reas-

sembling the transaxle.

Fig. 41 Remove Parking Rod E-Clip

Fig. 42 Parking Rod

Fig. 43 Valve Body Attaching Bolts

Fig. 44 Valve Body and Governor Tubes

Fig. 45 Measure Input Shaft End Play

Fig. 46 Loosen Lock Nut and Tighten Kickdown

Band Adjusting Screw

PLTRANSAXLE 21 - 69

DISASSEMBLY AND ASSEMBLY (Continued)