lock DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 1096 of 1200

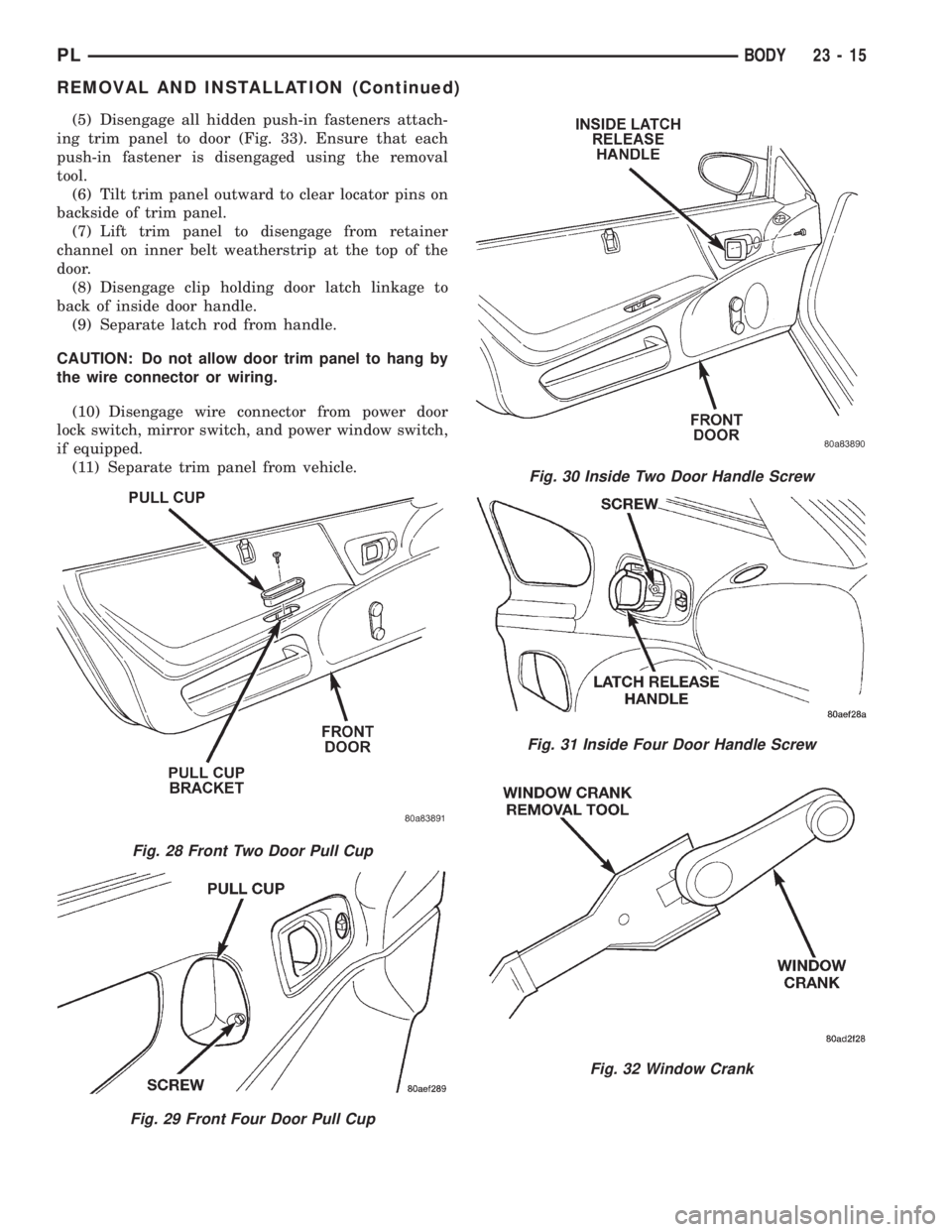

(5) Disengage all hidden push-in fasteners attach-

ing trim panel to door (Fig. 33). Ensure that each

push-in fastener is disengaged using the removal

tool.

(6) Tilt trim panel outward to clear locator pins on

backside of trim panel.

(7) Lift trim panel to disengage from retainer

channel on inner belt weatherstrip at the top of the

door.

(8) Disengage clip holding door latch linkage to

back of inside door handle.

(9) Separate latch rod from handle.

CAUTION: Do not allow door trim panel to hang by

the wire connector or wiring.

(10) Disengage wire connector from power door

lock switch, mirror switch, and power window switch,

if equipped.

(11) Separate trim panel from vehicle.

Fig. 28 Front Two Door Pull Cup

Fig. 29 Front Four Door Pull Cup

Fig. 30 Inside Two Door Handle Screw

Fig. 31 Inside Four Door Handle Screw

Fig. 32 Window Crank

PLBODY 23 - 15

REMOVAL AND INSTALLATION (Continued)

Page 1097 of 1200

INSTALLATION

(1) Replace any damaged or missing push±in fas-

teners with original equipment push-in fasteners.

(2) Place trim panel near door.

(3) Engage wire connectors to power lock switch,

mirror switch, and power window switch, if equipped.

(4) Insert latch rod into inside latch release.

(5) Engage clip holding door latch linkage to back

of inside door handle.

(6) Engage trim panel into retainer channel at top

of door and push down to seat.

(7) Locate door trim panel to inner door panel by

aligning locating pins on backside of trim panel to

mating holes in inner door panel. Gently shift panel

forward or rearward if necessary.

(8) Engage hidden push±in fasteners holding trim

panel to door from around perimeter of trim panel.

(9) With the window in the down position, orien-

tate the window regulator crank handle appropri-

ately. Install the right handle at the 10 o'clock

position and the left handle at the 2 o'clock position,

if equipped.

(10) Install screw holding trim panel to door from

behind inside latch release handle.

(11) Install screw inside pull cup holding door trim

panel to bracket.

FRONT DOOR WATER SHIELD

REMOVAL

(1) Remove door trim panel.

(2) Remove Door speaker, if equipped.

(3) Remove door trim pull cup mount bracket.

(4) Disengage clip holding lock linkage to lock but-

ton bell crank.

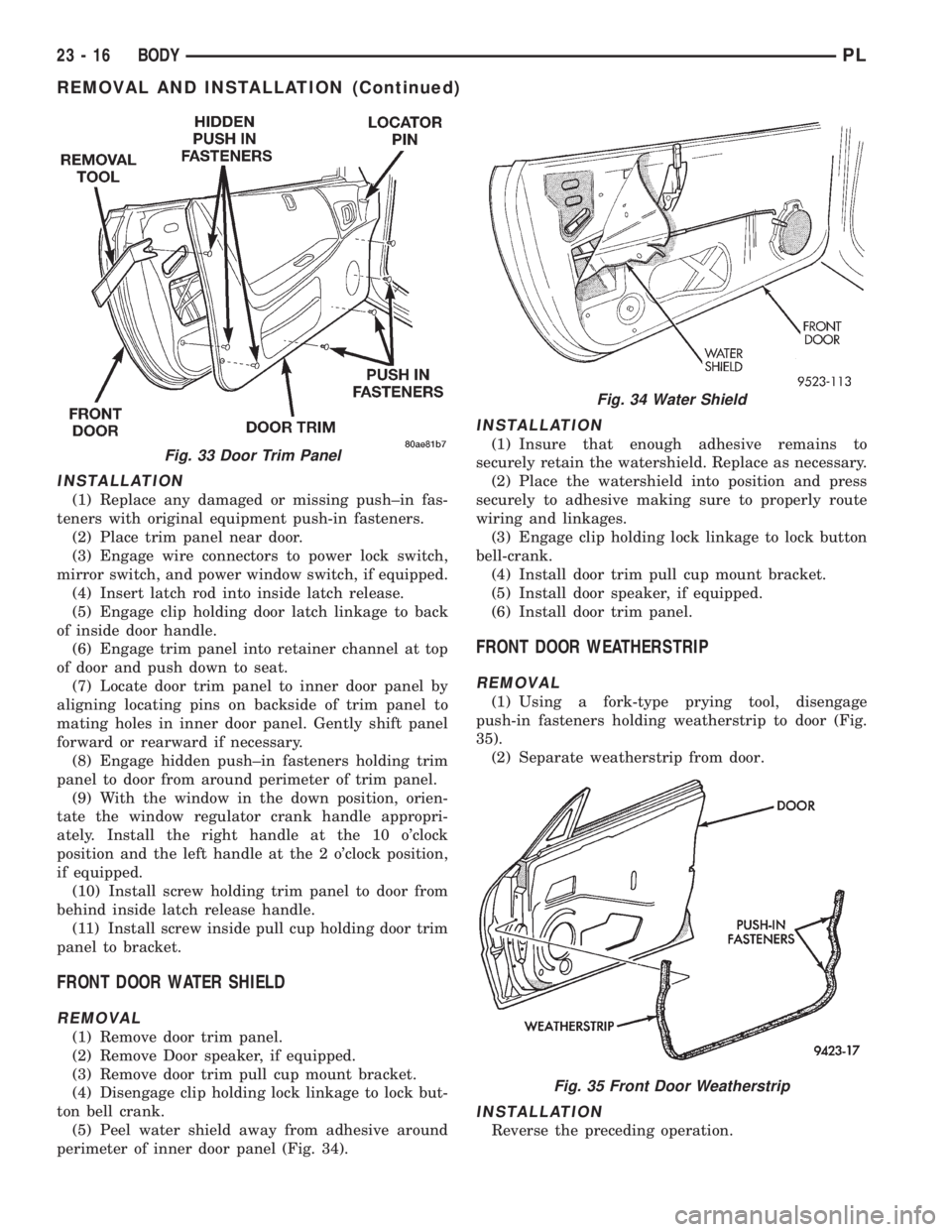

(5) Peel water shield away from adhesive around

perimeter of inner door panel (Fig. 34).

INSTALLATION

(1) Insure that enough adhesive remains to

securely retain the watershield. Replace as necessary.

(2) Place the watershield into position and press

securely to adhesive making sure to properly route

wiring and linkages.

(3) Engage clip holding lock linkage to lock button

bell-crank.

(4) Install door trim pull cup mount bracket.

(5) Install door speaker, if equipped.

(6) Install door trim panel.

FRONT DOOR WEATHERSTRIP

REMOVAL

(1) Using a fork-type prying tool, disengage

push-in fasteners holding weatherstrip to door (Fig.

35).

(2) Separate weatherstrip from door.

INSTALLATION

Reverse the preceding operation.

Fig. 33 Door Trim Panel

Fig. 34 Water Shield

Fig. 35 Front Door Weatherstrip

23 - 16 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1098 of 1200

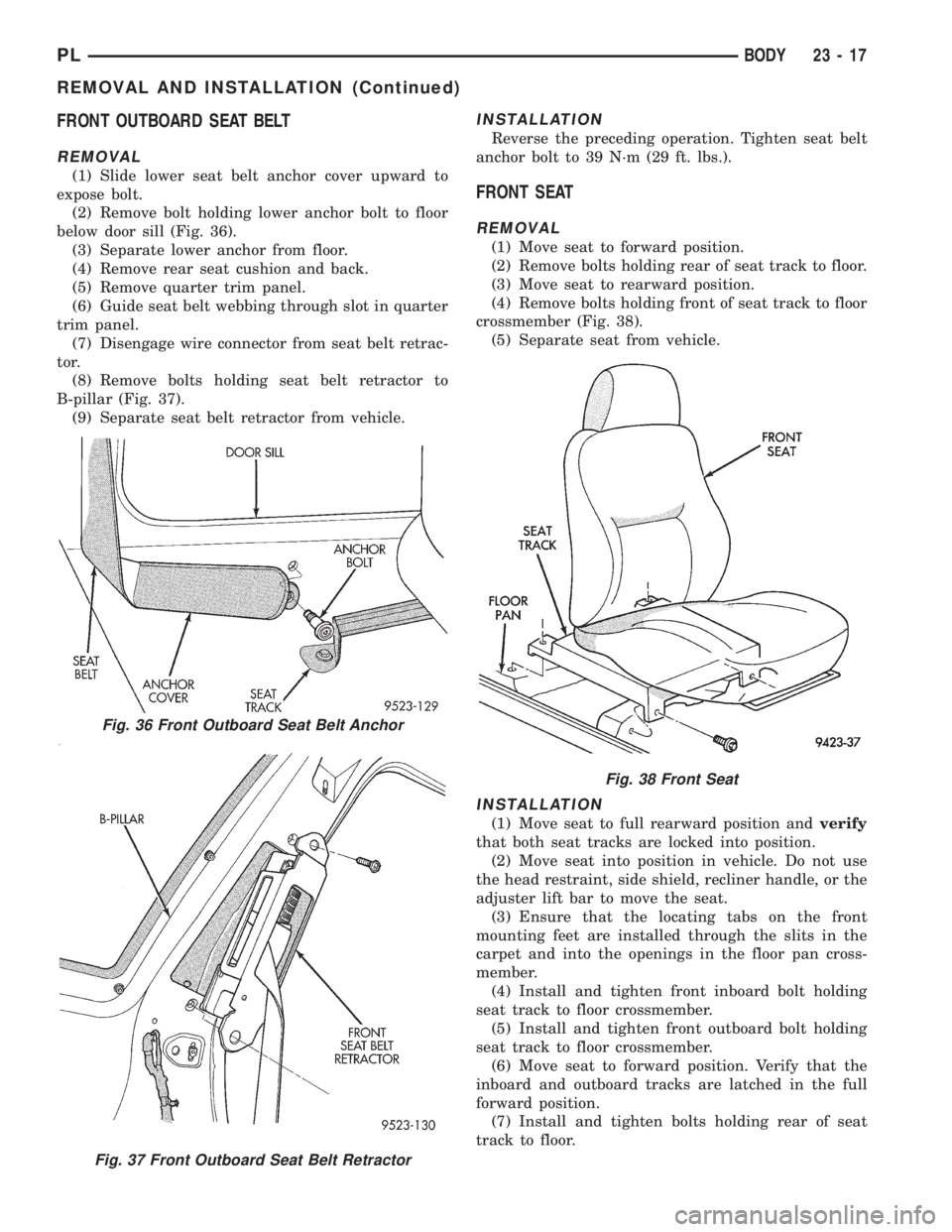

FRONT OUTBOARD SEAT BELT

REMOVAL

(1) Slide lower seat belt anchor cover upward to

expose bolt.

(2) Remove bolt holding lower anchor bolt to floor

below door sill (Fig. 36).

(3) Separate lower anchor from floor.

(4) Remove rear seat cushion and back.

(5) Remove quarter trim panel.

(6) Guide seat belt webbing through slot in quarter

trim panel.

(7) Disengage wire connector from seat belt retrac-

tor.

(8) Remove bolts holding seat belt retractor to

B-pillar (Fig. 37).

(9) Separate seat belt retractor from vehicle.

INSTALLATION

Reverse the preceding operation. Tighten seat belt

anchor bolt to 39 N´m (29 ft. lbs.).

FRONT SEAT

REMOVAL

(1) Move seat to forward position.

(2) Remove bolts holding rear of seat track to floor.

(3) Move seat to rearward position.

(4) Remove bolts holding front of seat track to floor

crossmember (Fig. 38).

(5) Separate seat from vehicle.

INSTALLATION

(1) Move seat to full rearward position andverify

that both seat tracks are locked into position.

(2) Move seat into position in vehicle. Do not use

the head restraint, side shield, recliner handle, or the

adjuster lift bar to move the seat.

(3) Ensure that the locating tabs on the front

mounting feet are installed through the slits in the

carpet and into the openings in the floor pan cross-

member.

(4) Install and tighten front inboard bolt holding

seat track to floor crossmember.

(5) Install and tighten front outboard bolt holding

seat track to floor crossmember.

(6) Move seat to forward position. Verify that the

inboard and outboard tracks are latched in the full

forward position.

(7) Install and tighten bolts holding rear of seat

track to floor.

Fig. 36 Front Outboard Seat Belt Anchor

Fig. 37 Front Outboard Seat Belt Retractor

Fig. 38 Front Seat

PLBODY 23 - 17

REMOVAL AND INSTALLATION (Continued)

Page 1102 of 1200

(4) Remove bolts holding hood hinge to front

fender flange and separate hinge from vehicle. If nec-

essary, paint new hinge before installation.

INSTALLATION

(1) If necessary, paint new hinge before installa-

tion.

(2) Place hinge in position on vehicle.

(3) Install bolts to hold hood hinge to front fender

flange.

(4) Install bolts to hold hood to hinge.

(5) Align all marks and secure bolts. The hood

should be aligned to 4 mm (0.160 in.) gap to the front

fenders and flush across the top surfaces along fend-

ers. Shims can be added or removed under hood

hinge to achieve proper hood height.

(6) Remove support from under hood and verify

hood operation.

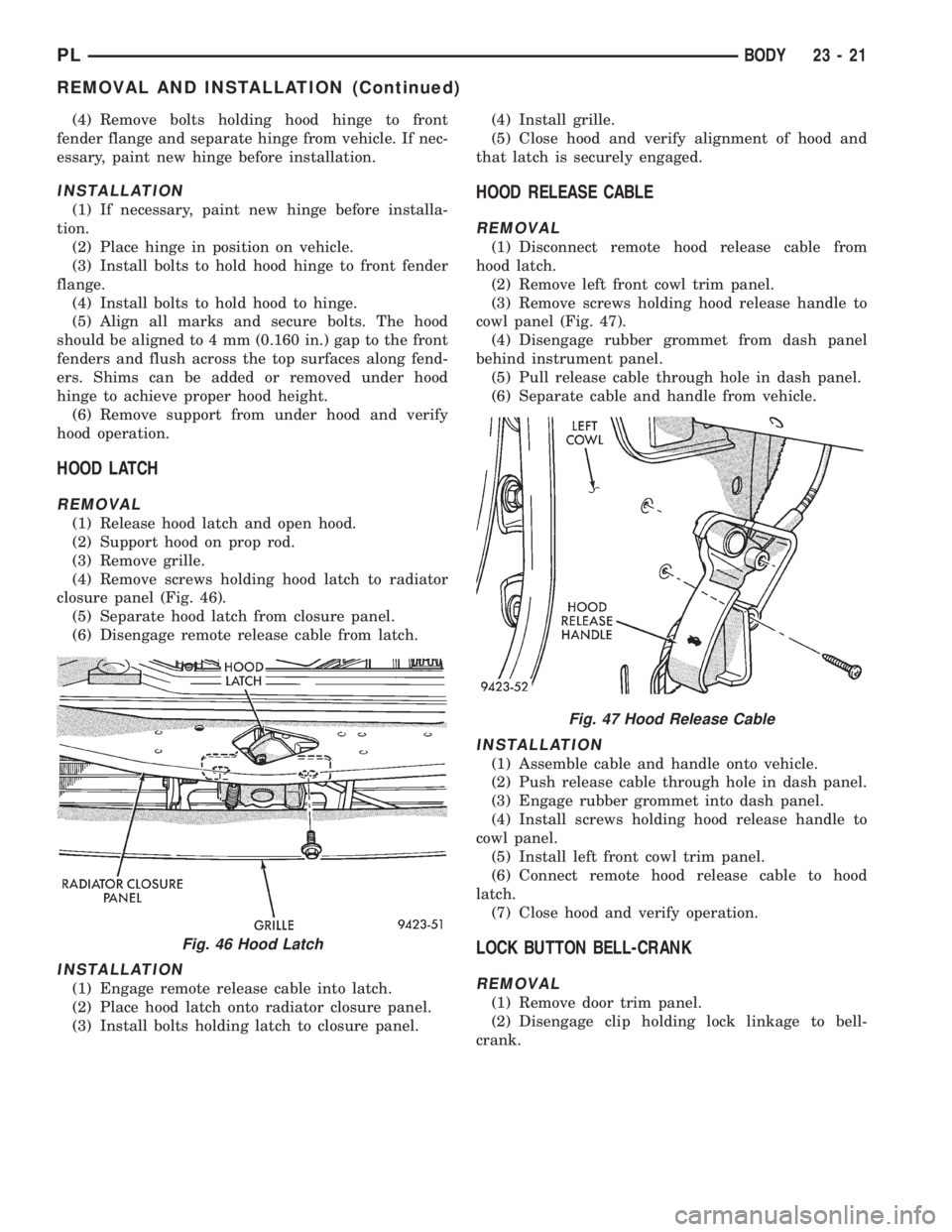

HOOD LATCH

REMOVAL

(1) Release hood latch and open hood.

(2) Support hood on prop rod.

(3) Remove grille.

(4) Remove screws holding hood latch to radiator

closure panel (Fig. 46).

(5) Separate hood latch from closure panel.

(6) Disengage remote release cable from latch.

INSTALLATION

(1) Engage remote release cable into latch.

(2) Place hood latch onto radiator closure panel.

(3) Install bolts holding latch to closure panel.(4) Install grille.

(5) Close hood and verify alignment of hood and

that latch is securely engaged.

HOOD RELEASE CABLE

REMOVAL

(1) Disconnect remote hood release cable from

hood latch.

(2) Remove left front cowl trim panel.

(3) Remove screws holding hood release handle to

cowl panel (Fig. 47).

(4) Disengage rubber grommet from dash panel

behind instrument panel.

(5) Pull release cable through hole in dash panel.

(6) Separate cable and handle from vehicle.

INSTALLATION

(1) Assemble cable and handle onto vehicle.

(2) Push release cable through hole in dash panel.

(3) Engage rubber grommet into dash panel.

(4) Install screws holding hood release handle to

cowl panel.

(5) Install left front cowl trim panel.

(6) Connect remote hood release cable to hood

latch.

(7) Close hood and verify operation.

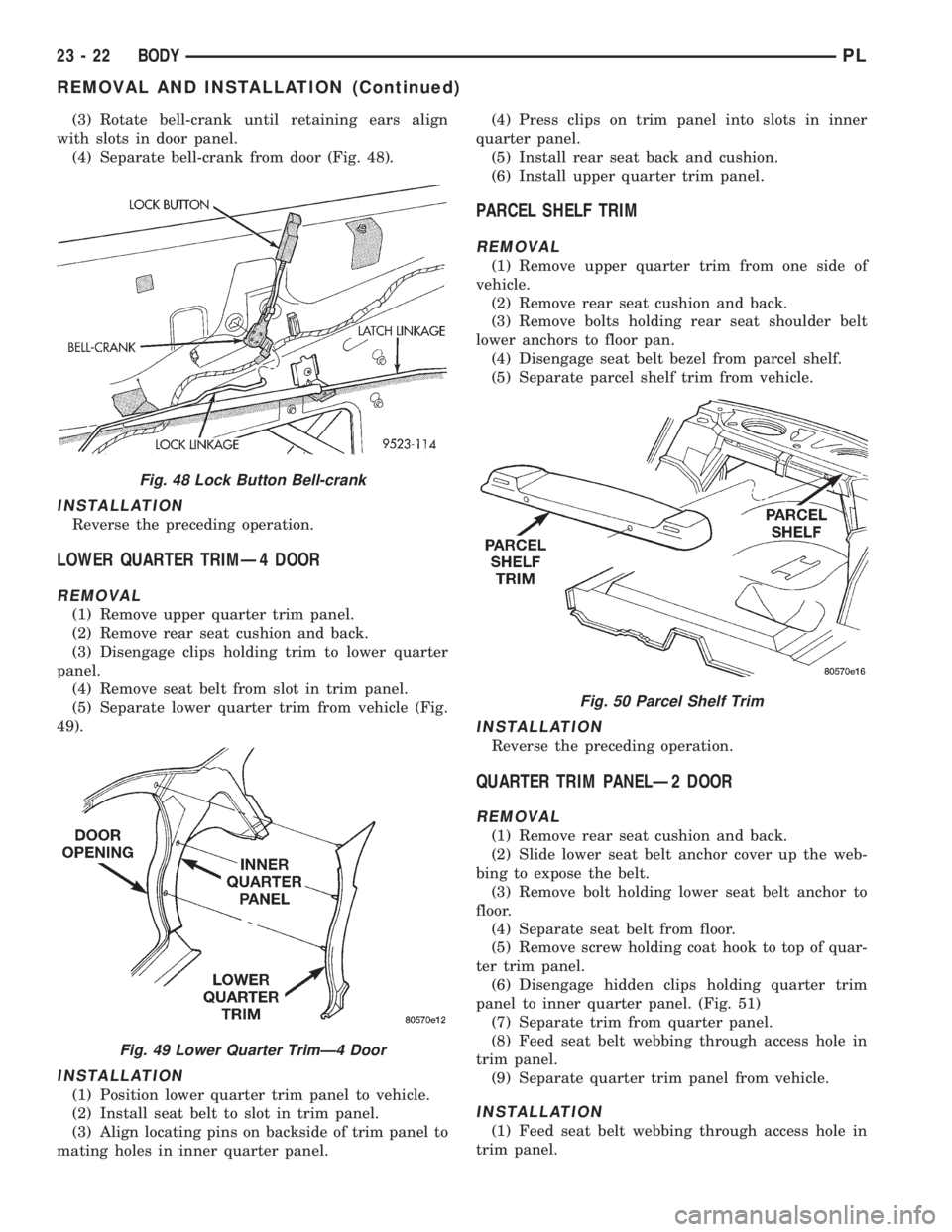

LOCK BUTTON BELL-CRANK

REMOVAL

(1) Remove door trim panel.

(2) Disengage clip holding lock linkage to bell-

crank.

Fig. 46 Hood Latch

Fig. 47 Hood Release Cable

PLBODY 23 - 21

REMOVAL AND INSTALLATION (Continued)

Page 1103 of 1200

(3) Rotate bell-crank until retaining ears align

with slots in door panel.

(4) Separate bell-crank from door (Fig. 48).

INSTALLATION

Reverse the preceding operation.

LOWER QUARTER TRIMÐ4 DOOR

REMOVAL

(1) Remove upper quarter trim panel.

(2) Remove rear seat cushion and back.

(3) Disengage clips holding trim to lower quarter

panel.

(4) Remove seat belt from slot in trim panel.

(5) Separate lower quarter trim from vehicle (Fig.

49).

INSTALLATION

(1) Position lower quarter trim panel to vehicle.

(2) Install seat belt to slot in trim panel.

(3) Align locating pins on backside of trim panel to

mating holes in inner quarter panel.(4) Press clips on trim panel into slots in inner

quarter panel.

(5) Install rear seat back and cushion.

(6) Install upper quarter trim panel.

PARCEL SHELF TRIM

REMOVAL

(1) Remove upper quarter trim from one side of

vehicle.

(2) Remove rear seat cushion and back.

(3) Remove bolts holding rear seat shoulder belt

lower anchors to floor pan.

(4) Disengage seat belt bezel from parcel shelf.

(5) Separate parcel shelf trim from vehicle.

INSTALLATION

Reverse the preceding operation.

QUARTER TRIM PANELÐ2 DOOR

REMOVAL

(1) Remove rear seat cushion and back.

(2) Slide lower seat belt anchor cover up the web-

bing to expose the belt.

(3) Remove bolt holding lower seat belt anchor to

floor.

(4) Separate seat belt from floor.

(5) Remove screw holding coat hook to top of quar-

ter trim panel.

(6) Disengage hidden clips holding quarter trim

panel to inner quarter panel. (Fig. 51)

(7) Separate trim from quarter panel.

(8) Feed seat belt webbing through access hole in

trim panel.

(9) Separate quarter trim panel from vehicle.

INSTALLATION

(1) Feed seat belt webbing through access hole in

trim panel.

Fig. 48 Lock Button Bell-crank

Fig. 49 Lower Quarter TrimÐ4 Door

Fig. 50 Parcel Shelf Trim

23 - 22 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1105 of 1200

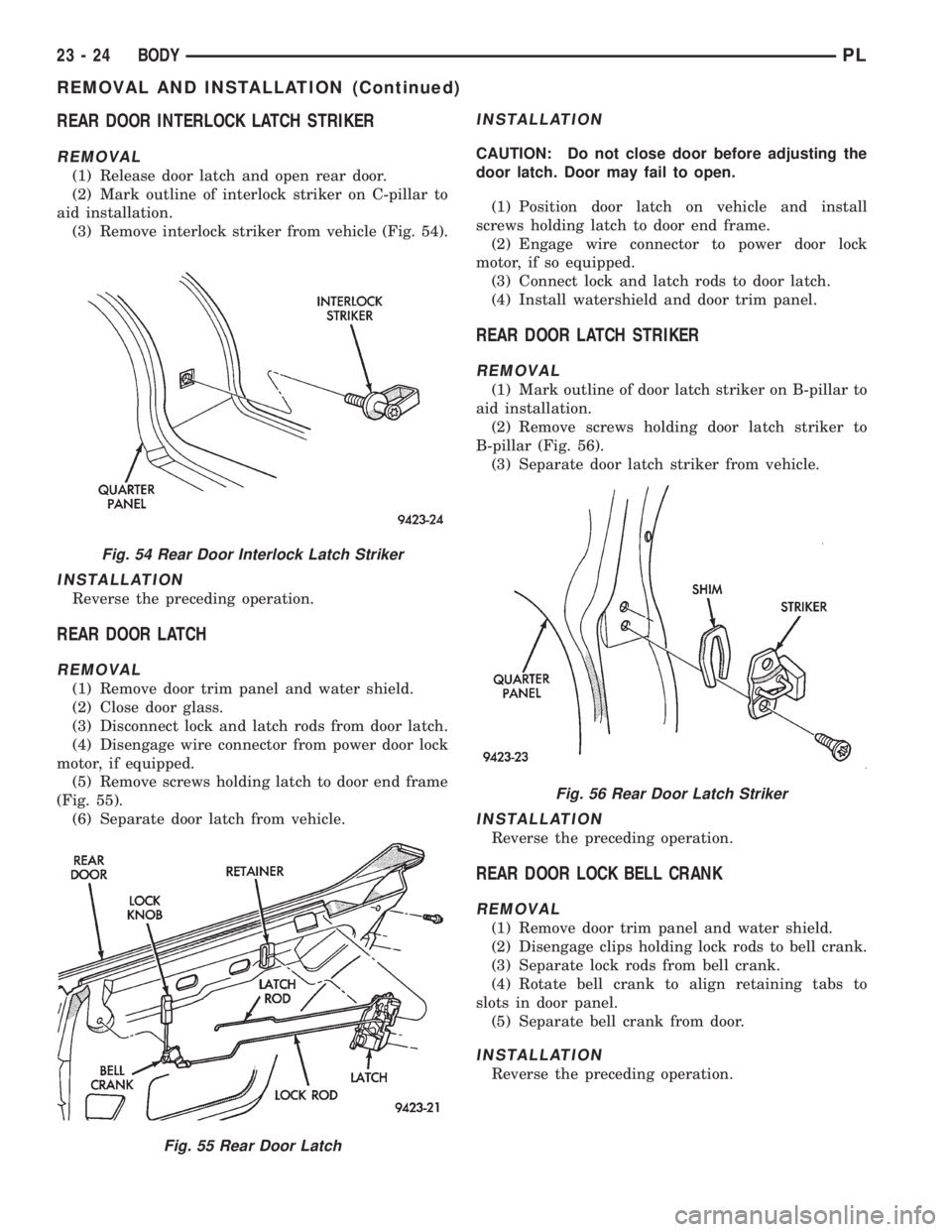

REAR DOOR INTERLOCK LATCH STRIKER

REMOVAL

(1) Release door latch and open rear door.

(2) Mark outline of interlock striker on C-pillar to

aid installation.

(3) Remove interlock striker from vehicle (Fig. 54).

INSTALLATION

Reverse the preceding operation.

REAR DOOR LATCH

REMOVAL

(1) Remove door trim panel and water shield.

(2) Close door glass.

(3) Disconnect lock and latch rods from door latch.

(4) Disengage wire connector from power door lock

motor, if equipped.

(5) Remove screws holding latch to door end frame

(Fig. 55).

(6) Separate door latch from vehicle.

INSTALLATION

CAUTION: Do not close door before adjusting the

door latch. Door may fail to open.

(1) Position door latch on vehicle and install

screws holding latch to door end frame.

(2) Engage wire connector to power door lock

motor, if so equipped.

(3) Connect lock and latch rods to door latch.

(4) Install watershield and door trim panel.

REAR DOOR LATCH STRIKER

REMOVAL

(1) Mark outline of door latch striker on B-pillar to

aid installation.

(2) Remove screws holding door latch striker to

B-pillar (Fig. 56).

(3) Separate door latch striker from vehicle.

INSTALLATION

Reverse the preceding operation.

REAR DOOR LOCK BELL CRANK

REMOVAL

(1) Remove door trim panel and water shield.

(2) Disengage clips holding lock rods to bell crank.

(3) Separate lock rods from bell crank.

(4) Rotate bell crank to align retaining tabs to

slots in door panel.

(5) Separate bell crank from door.

INSTALLATION

Reverse the preceding operation.

Fig. 54 Rear Door Interlock Latch Striker

Fig. 55 Rear Door Latch

Fig. 56 Rear Door Latch Striker

23 - 24 BODYPL

REMOVAL AND INSTALLATION (Continued)

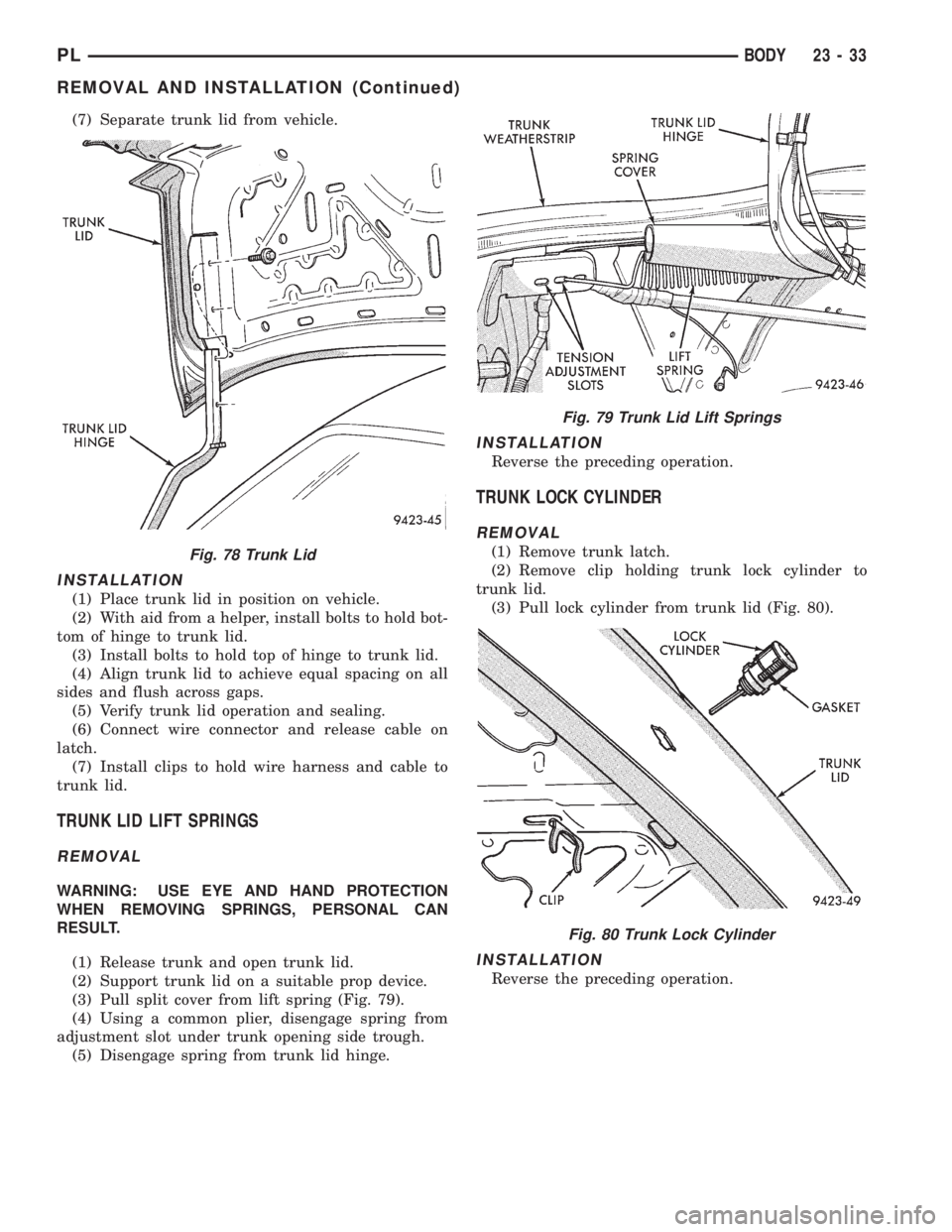

Page 1114 of 1200

(7) Separate trunk lid from vehicle.

INSTALLATION

(1) Place trunk lid in position on vehicle.

(2) With aid from a helper, install bolts to hold bot-

tom of hinge to trunk lid.

(3) Install bolts to hold top of hinge to trunk lid.

(4) Align trunk lid to achieve equal spacing on all

sides and flush across gaps.

(5) Verify trunk lid operation and sealing.

(6) Connect wire connector and release cable on

latch.

(7) Install clips to hold wire harness and cable to

trunk lid.

TRUNK LID LIFT SPRINGS

REMOVAL

WARNING: USE EYE AND HAND PROTECTION

WHEN REMOVING SPRINGS, PERSONAL CAN

RESULT.

(1) Release trunk and open trunk lid.

(2) Support trunk lid on a suitable prop device.

(3) Pull split cover from lift spring (Fig. 79).

(4) Using a common plier, disengage spring from

adjustment slot under trunk opening side trough.

(5) Disengage spring from trunk lid hinge.

INSTALLATION

Reverse the preceding operation.

TRUNK LOCK CYLINDER

REMOVAL

(1) Remove trunk latch.

(2) Remove clip holding trunk lock cylinder to

trunk lid.

(3) Pull lock cylinder from trunk lid (Fig. 80).

INSTALLATION

Reverse the preceding operation.

Fig. 78 Trunk Lid

Fig. 79 Trunk Lid Lift Springs

Fig. 80 Trunk Lock Cylinder

PLBODY 23 - 33

REMOVAL AND INSTALLATION (Continued)

Page 1120 of 1200

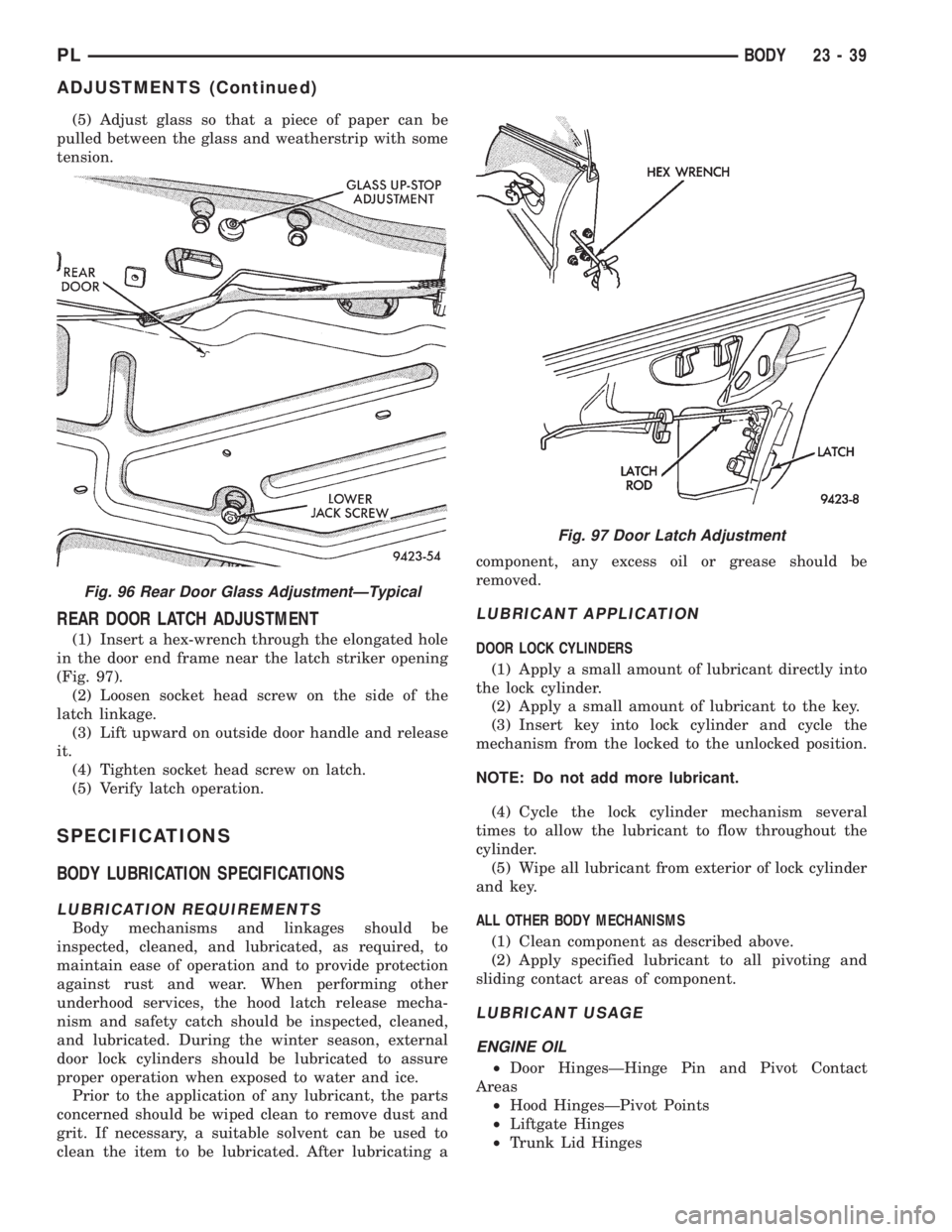

(5) Adjust glass so that a piece of paper can be

pulled between the glass and weatherstrip with some

tension.

REAR DOOR LATCH ADJUSTMENT

(1) Insert a hex-wrench through the elongated hole

in the door end frame near the latch striker opening

(Fig. 97).

(2) Loosen socket head screw on the side of the

latch linkage.

(3) Lift upward on outside door handle and release

it.

(4) Tighten socket head screw on latch.

(5) Verify latch operation.

SPECIFICATIONS

BODY LUBRICATION SPECIFICATIONS

LUBRICATION REQUIREMENTS

Body mechanisms and linkages should be

inspected, cleaned, and lubricated, as required, to

maintain ease of operation and to provide protection

against rust and wear. When performing other

underhood services, the hood latch release mecha-

nism and safety catch should be inspected, cleaned,

and lubricated. During the winter season, external

door lock cylinders should be lubricated to assure

proper operation when exposed to water and ice.

Prior to the application of any lubricant, the parts

concerned should be wiped clean to remove dust and

grit. If necessary, a suitable solvent can be used to

clean the item to be lubricated. After lubricating acomponent, any excess oil or grease should be

removed.

LUBRICANT APPLICATION

DOOR LOCK CYLINDERS

(1) Apply a small amount of lubricant directly into

the lock cylinder.

(2) Apply a small amount of lubricant to the key.

(3) Insert key into lock cylinder and cycle the

mechanism from the locked to the unlocked position.

NOTE: Do not add more lubricant.

(4) Cycle the lock cylinder mechanism several

times to allow the lubricant to flow throughout the

cylinder.

(5) Wipe all lubricant from exterior of lock cylinder

and key.

ALL OTHER BODY MECHANISMS

(1) Clean component as described above.

(2) Apply specified lubricant to all pivoting and

sliding contact areas of component.

LUBRICANT USAGE

ENGINE OIL

²Door HingesÐHinge Pin and Pivot Contact

Areas

²Hood HingesÐPivot Points

²Liftgate Hinges

²Trunk Lid Hinges

Fig. 96 Rear Door Glass AdjustmentÐTypical

Fig. 97 Door Latch Adjustment

PLBODY 23 - 39

ADJUSTMENTS (Continued)

Page 1121 of 1200

MOPARTSPRAY WHITE LUBE OR EQUIVALENT

²Door Check Straps

²Liftgate Latches

²Liftgate Prop Pivots

²Ash Receiver

²Fuel Filler Door Remote Control Latch Mecha-

nism

²Parking Brake Mechanism

²Sliding Seat Tracks

²Trunk Latch

MOPARTMULTI±PURPOSE GREASE OR

EQUIVALENT

²All Other Hood Mechanisms

MOPARTLOCK CYLINDER LUBRICANT OR

EQUIVALENT

²Door Lock Cylinders

²Trunk Lock Cylinder

SPECIAL TOOLS

BODY

STICK, TRIM C 4755

23 - 40 BODYPL

SPECIFICATIONS (Continued)

Page 1125 of 1200

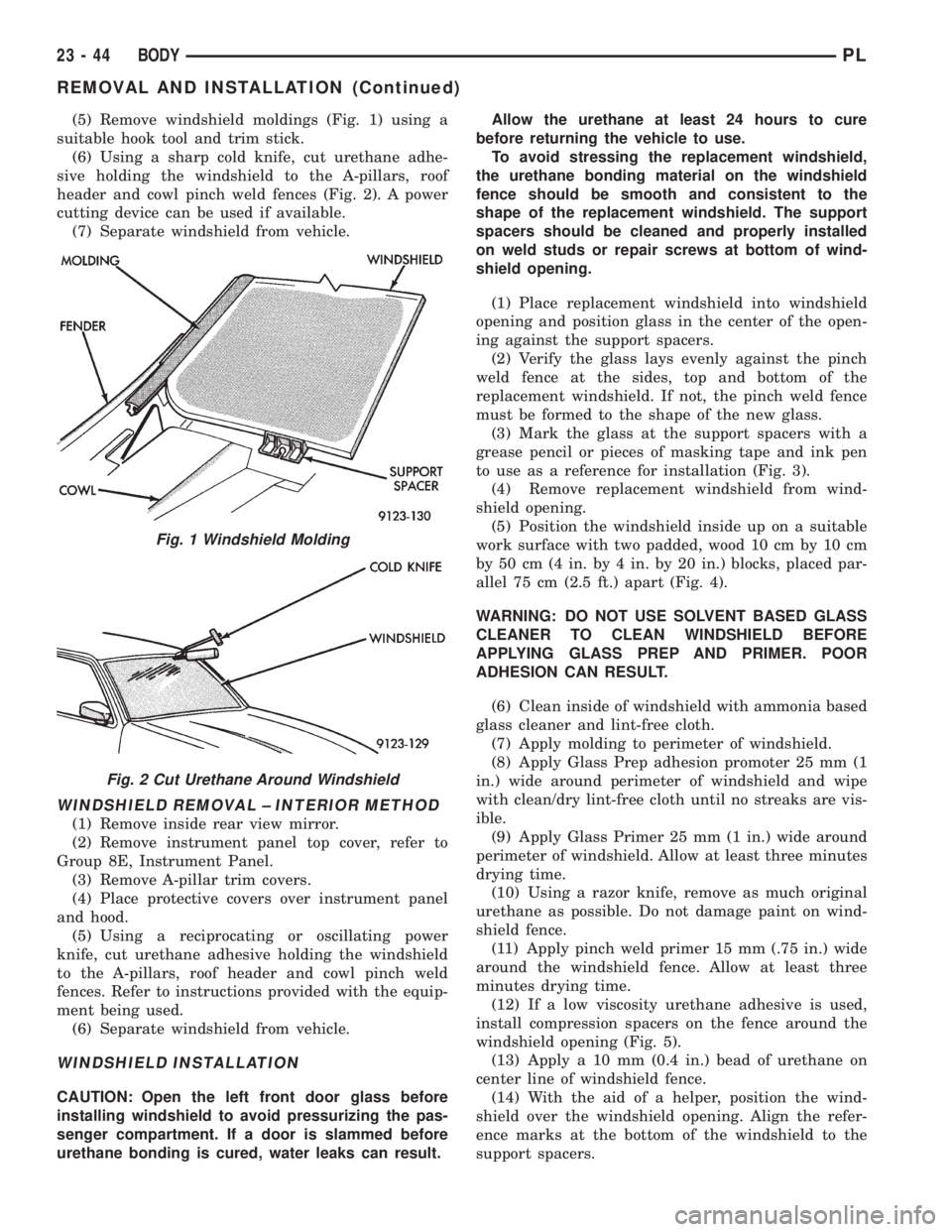

(5) Remove windshield moldings (Fig. 1) using a

suitable hook tool and trim stick.

(6) Using a sharp cold knife, cut urethane adhe-

sive holding the windshield to the A-pillars, roof

header and cowl pinch weld fences (Fig. 2). A power

cutting device can be used if available.

(7) Separate windshield from vehicle.

WINDSHIELD REMOVAL ± INTERIOR METHOD

(1) Remove inside rear view mirror.

(2) Remove instrument panel top cover, refer to

Group 8E, Instrument Panel.

(3) Remove A-pillar trim covers.

(4) Place protective covers over instrument panel

and hood.

(5) Using a reciprocating or oscillating power

knife, cut urethane adhesive holding the windshield

to the A-pillars, roof header and cowl pinch weld

fences. Refer to instructions provided with the equip-

ment being used.

(6) Separate windshield from vehicle.

WINDSHIELD INSTALLATION

CAUTION: Open the left front door glass before

installing windshield to avoid pressurizing the pas-

senger compartment. If a door is slammed before

urethane bonding is cured, water leaks can result.Allow the urethane at least 24 hours to cure

before returning the vehicle to use.

To avoid stressing the replacement windshield,

the urethane bonding material on the windshield

fence should be smooth and consistent to the

shape of the replacement windshield. The support

spacers should be cleaned and properly installed

on weld studs or repair screws at bottom of wind-

shield opening.

(1) Place replacement windshield into windshield

opening and position glass in the center of the open-

ing against the support spacers.

(2) Verify the glass lays evenly against the pinch

weld fence at the sides, top and bottom of the

replacement windshield. If not, the pinch weld fence

must be formed to the shape of the new glass.

(3) Mark the glass at the support spacers with a

grease pencil or pieces of masking tape and ink pen

to use as a reference for installation (Fig. 3).

(4) Remove replacement windshield from wind-

shield opening.

(5) Position the windshield inside up on a suitable

work surface with two padded, wood 10 cm by 10 cm

by 50 cm (4 in. by 4 in. by 20 in.) blocks, placed par-

allel 75 cm (2.5 ft.) apart (Fig. 4).

WARNING: DO NOT USE SOLVENT BASED GLASS

CLEANER TO CLEAN WINDSHIELD BEFORE

APPLYING GLASS PREP AND PRIMER. POOR

ADHESION CAN RESULT.

(6) Clean inside of windshield with ammonia based

glass cleaner and lint-free cloth.

(7) Apply molding to perimeter of windshield.

(8) Apply Glass Prep adhesion promoter 25 mm (1

in.) wide around perimeter of windshield and wipe

with clean/dry lint-free cloth until no streaks are vis-

ible.

(9) Apply Glass Primer 25 mm (1 in.) wide around

perimeter of windshield. Allow at least three minutes

drying time.

(10) Using a razor knife, remove as much original

urethane as possible. Do not damage paint on wind-

shield fence.

(11) Apply pinch weld primer 15 mm (.75 in.) wide

around the windshield fence. Allow at least three

minutes drying time.

(12) If a low viscosity urethane adhesive is used,

install compression spacers on the fence around the

windshield opening (Fig. 5).

(13) Apply a 10 mm (0.4 in.) bead of urethane on

center line of windshield fence.

(14) With the aid of a helper, position the wind-

shield over the windshield opening. Align the refer-

ence marks at the bottom of the windshield to the

support spacers.

Fig. 1 Windshield Molding

Fig. 2 Cut Urethane Around Windshield

23 - 44 BODYPL

REMOVAL AND INSTALLATION (Continued)