lock DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 1031 of 1200

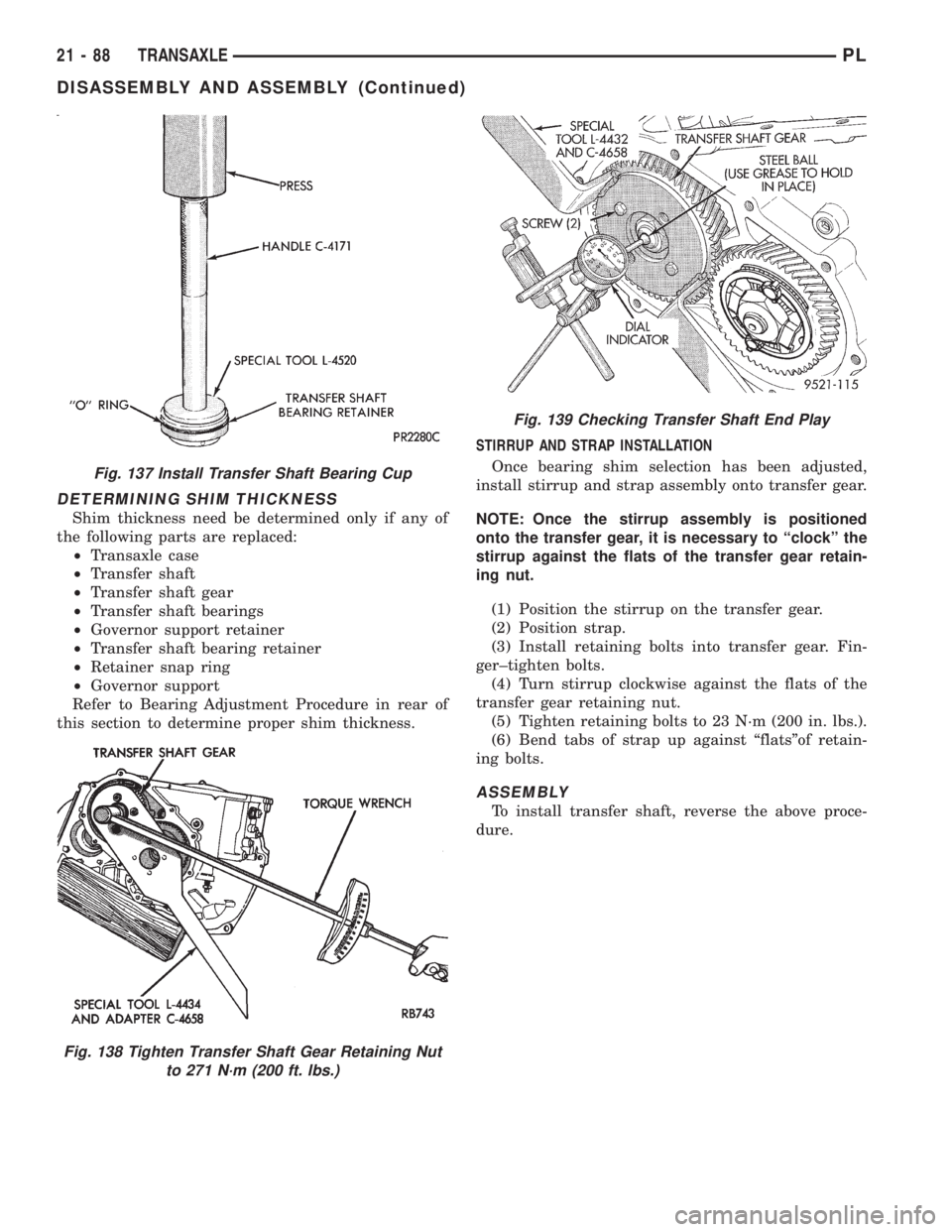

DETERMINING SHIM THICKNESS

Shim thickness need be determined only if any of

the following parts are replaced:

²Transaxle case

²Transfer shaft

²Transfer shaft gear

²Transfer shaft bearings

²Governor support retainer

²Transfer shaft bearing retainer

²Retainer snap ring

²Governor support

Refer to Bearing Adjustment Procedure in rear of

this section to determine proper shim thickness.STIRRUP AND STRAP INSTALLATION

Once bearing shim selection has been adjusted,

install stirrup and strap assembly onto transfer gear.

NOTE: Once the stirrup assembly is positioned

onto the transfer gear, it is necessary to ªclockº the

stirrup against the flats of the transfer gear retain-

ing nut.

(1) Position the stirrup on the transfer gear.

(2) Position strap.

(3) Install retaining bolts into transfer gear. Fin-

ger±tighten bolts.

(4) Turn stirrup clockwise against the flats of the

transfer gear retaining nut.

(5) Tighten retaining bolts to 23 N´m (200 in. lbs.).

(6) Bend tabs of strap up against ªflatsºof retain-

ing bolts.

ASSEMBLY

To install transfer shaft, reverse the above proce-

dure.

Fig. 137 Install Transfer Shaft Bearing Cup

Fig. 138 Tighten Transfer Shaft Gear Retaining Nut

to 271 N´m (200 ft. lbs.)

Fig. 139 Checking Transfer Shaft End Play

21 - 88 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1037 of 1200

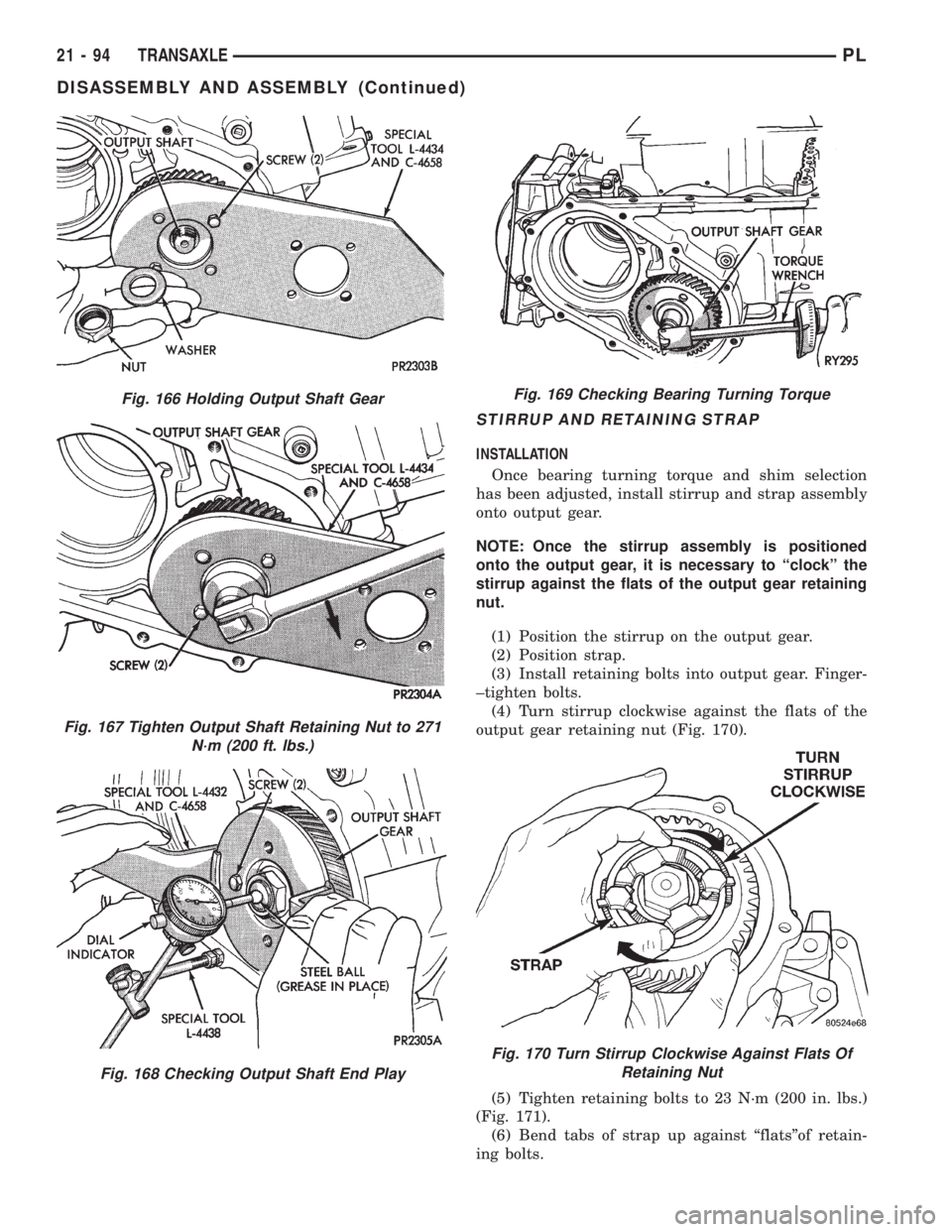

STIRRUP AND RETAINING STRAP

INSTALLATION

Once bearing turning torque and shim selection

has been adjusted, install stirrup and strap assembly

onto output gear.

NOTE: Once the stirrup assembly is positioned

onto the output gear, it is necessary to ªclockº the

stirrup against the flats of the output gear retaining

nut.

(1) Position the stirrup on the output gear.

(2) Position strap.

(3) Install retaining bolts into output gear. Finger-

±tighten bolts.

(4) Turn stirrup clockwise against the flats of the

output gear retaining nut (Fig. 170).

(5) Tighten retaining bolts to 23 N´m (200 in. lbs.)

(Fig. 171).

(6) Bend tabs of strap up against ªflatsºof retain-

ing bolts.

Fig. 166 Holding Output Shaft Gear

Fig. 167 Tighten Output Shaft Retaining Nut to 271

N´m (200 ft. lbs.)

Fig. 168 Checking Output Shaft End Play

Fig. 169 Checking Bearing Turning Torque

Fig. 170 Turn Stirrup Clockwise Against Flats Of

Retaining Nut

21 - 94 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1043 of 1200

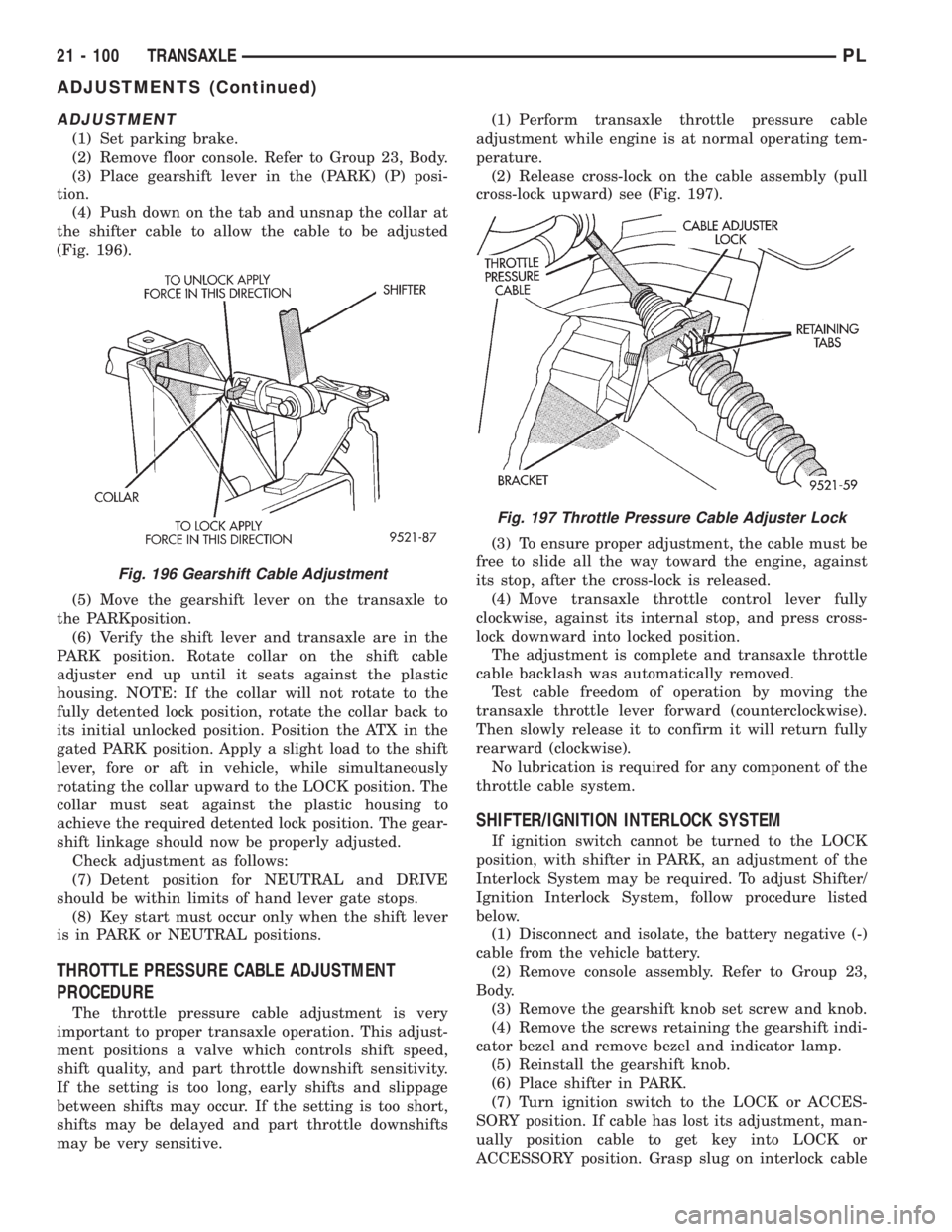

ADJUSTMENT

(1) Set parking brake.

(2) Remove floor console. Refer to Group 23, Body.

(3) Place gearshift lever in the (PARK) (P) posi-

tion.

(4) Push down on the tab and unsnap the collar at

the shifter cable to allow the cable to be adjusted

(Fig. 196).

(5) Move the gearshift lever on the transaxle to

the PARKposition.

(6) Verify the shift lever and transaxle are in the

PARK position. Rotate collar on the shift cable

adjuster end up until it seats against the plastic

housing. NOTE: If the collar will not rotate to the

fully detented lock position, rotate the collar back to

its initial unlocked position. Position the ATX in the

gated PARK position. Apply a slight load to the shift

lever, fore or aft in vehicle, while simultaneously

rotating the collar upward to the LOCK position. The

collar must seat against the plastic housing to

achieve the required detented lock position. The gear-

shift linkage should now be properly adjusted.

Check adjustment as follows:

(7) Detent position for NEUTRAL and DRIVE

should be within limits of hand lever gate stops.

(8) Key start must occur only when the shift lever

is in PARK or NEUTRAL positions.

THROTTLE PRESSURE CABLE ADJUSTMENT

PROCEDURE

The throttle pressure cable adjustment is very

important to proper transaxle operation. This adjust-

ment positions a valve which controls shift speed,

shift quality, and part throttle downshift sensitivity.

If the setting is too long, early shifts and slippage

between shifts may occur. If the setting is too short,

shifts may be delayed and part throttle downshifts

may be very sensitive.(1) Perform transaxle throttle pressure cable

adjustment while engine is at normal operating tem-

perature.

(2) Release cross-lock on the cable assembly (pull

cross-lock upward) see (Fig. 197).

(3) To ensure proper adjustment, the cable must be

free to slide all the way toward the engine, against

its stop, after the cross-lock is released.

(4) Move transaxle throttle control lever fully

clockwise, against its internal stop, and press cross-

lock downward into locked position.

The adjustment is complete and transaxle throttle

cable backlash was automatically removed.

Test cable freedom of operation by moving the

transaxle throttle lever forward (counterclockwise).

Then slowly release it to confirm it will return fully

rearward (clockwise).

No lubrication is required for any component of the

throttle cable system.

SHIFTER/IGNITION INTERLOCK SYSTEM

If ignition switch cannot be turned to the LOCK

position, with shifter in PARK, an adjustment of the

Interlock System may be required. To adjust Shifter/

Ignition Interlock System, follow procedure listed

below.

(1) Disconnect and isolate, the battery negative (-)

cable from the vehicle battery.

(2) Remove console assembly. Refer to Group 23,

Body.

(3) Remove the gearshift knob set screw and knob.

(4) Remove the screws retaining the gearshift indi-

cator bezel and remove bezel and indicator lamp.

(5) Reinstall the gearshift knob.

(6) Place shifter in PARK.

(7) Turn ignition switch to the LOCK or ACCES-

SORY position. If cable has lost its adjustment, man-

ually position cable to get key into LOCK or

ACCESSORY position. Grasp slug on interlock cable

Fig. 196 Gearshift Cable Adjustment

Fig. 197 Throttle Pressure Cable Adjuster Lock

21 - 100 TRANSAXLEPL

ADJUSTMENTS (Continued)

Page 1044 of 1200

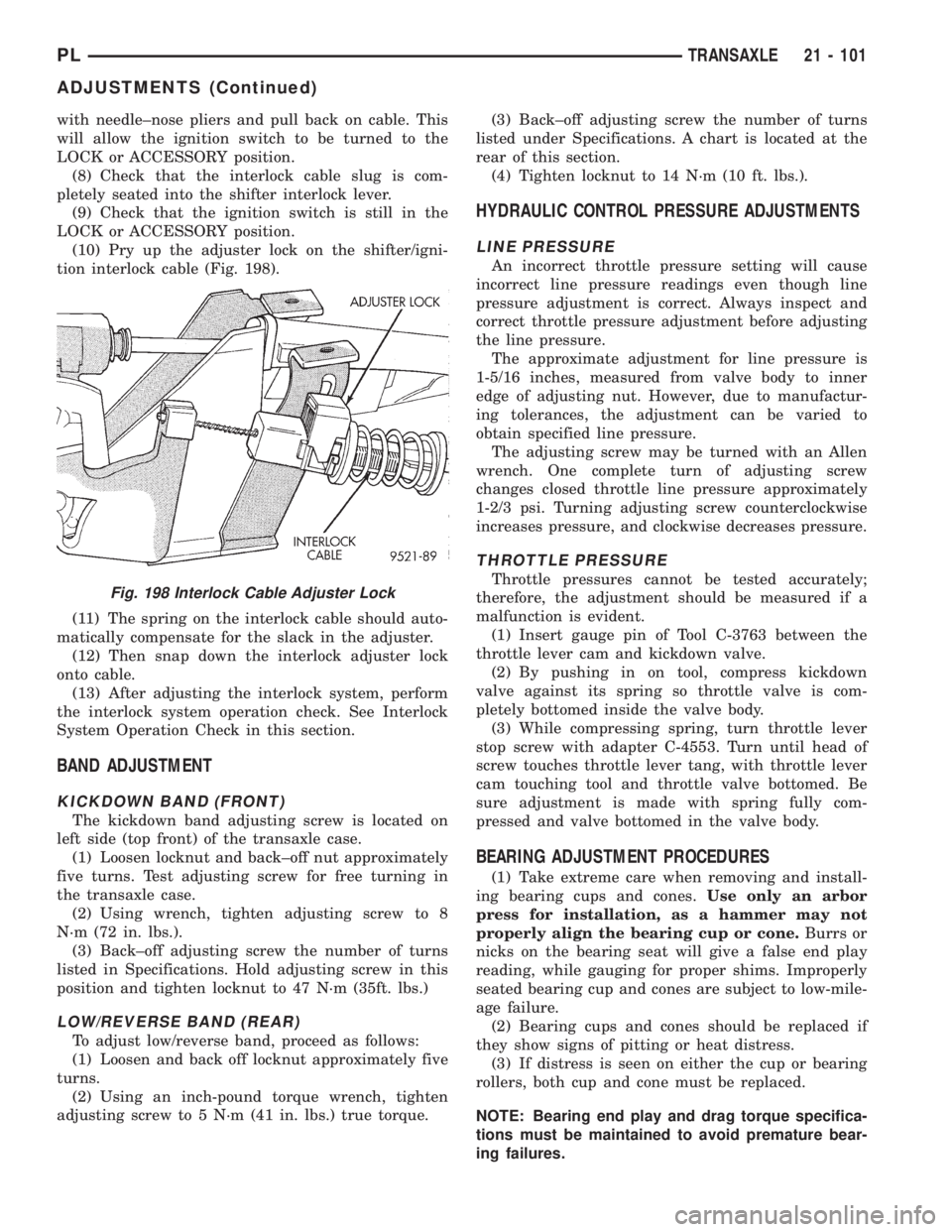

with needle±nose pliers and pull back on cable. This

will allow the ignition switch to be turned to the

LOCK or ACCESSORY position.

(8) Check that the interlock cable slug is com-

pletely seated into the shifter interlock lever.

(9) Check that the ignition switch is still in the

LOCK or ACCESSORY position.

(10) Pry up the adjuster lock on the shifter/igni-

tion interlock cable (Fig. 198).

(11) The spring on the interlock cable should auto-

matically compensate for the slack in the adjuster.

(12) Then snap down the interlock adjuster lock

onto cable.

(13) After adjusting the interlock system, perform

the interlock system operation check. See Interlock

System Operation Check in this section.

BAND ADJUSTMENT

KICKDOWN BAND (FRONT)

The kickdown band adjusting screw is located on

left side (top front) of the transaxle case.

(1) Loosen locknut and back±off nut approximately

five turns. Test adjusting screw for free turning in

the transaxle case.

(2) Using wrench, tighten adjusting screw to 8

N´m (72 in. lbs.).

(3) Back±off adjusting screw the number of turns

listed in Specifications. Hold adjusting screw in this

position and tighten locknut to 47 N´m (35ft. lbs.)

LOW/REVERSE BAND (REAR)

To adjust low/reverse band, proceed as follows:

(1) Loosen and back off locknut approximately five

turns.

(2) Using an inch-pound torque wrench, tighten

adjusting screw to 5 N´m (41 in. lbs.) true torque.(3) Back±off adjusting screw the number of turns

listed under Specifications. A chart is located at the

rear of this section.

(4) Tighten locknut to 14 N´m (10 ft. lbs.).

HYDRAULIC CONTROL PRESSURE ADJUSTMENTS

LINE PRESSURE

An incorrect throttle pressure setting will cause

incorrect line pressure readings even though line

pressure adjustment is correct. Always inspect and

correct throttle pressure adjustment before adjusting

the line pressure.

The approximate adjustment for line pressure is

1-5/16 inches, measured from valve body to inner

edge of adjusting nut. However, due to manufactur-

ing tolerances, the adjustment can be varied to

obtain specified line pressure.

The adjusting screw may be turned with an Allen

wrench. One complete turn of adjusting screw

changes closed throttle line pressure approximately

1-2/3 psi. Turning adjusting screw counterclockwise

increases pressure, and clockwise decreases pressure.

THROTTLE PRESSURE

Throttle pressures cannot be tested accurately;

therefore, the adjustment should be measured if a

malfunction is evident.

(1) Insert gauge pin of Tool C-3763 between the

throttle lever cam and kickdown valve.

(2) By pushing in on tool, compress kickdown

valve against its spring so throttle valve is com-

pletely bottomed inside the valve body.

(3) While compressing spring, turn throttle lever

stop screw with adapter C-4553. Turn until head of

screw touches throttle lever tang, with throttle lever

cam touching tool and throttle valve bottomed. Be

sure adjustment is made with spring fully com-

pressed and valve bottomed in the valve body.

BEARING ADJUSTMENT PROCEDURES

(1) Take extreme care when removing and install-

ing bearing cups and cones.Use only an arbor

press for installation, as a hammer may not

properly align the bearing cup or cone.Burrs or

nicks on the bearing seat will give a false end play

reading, while gauging for proper shims. Improperly

seated bearing cup and cones are subject to low-mile-

age failure.

(2) Bearing cups and cones should be replaced if

they show signs of pitting or heat distress.

(3) If distress is seen on either the cup or bearing

rollers, both cup and cone must be replaced.

NOTE: Bearing end play and drag torque specifica-

tions must be maintained to avoid premature bear-

ing failures.

Fig. 198 Interlock Cable Adjuster Lock

PLTRANSAXLE 21 - 101

ADJUSTMENTS (Continued)

Page 1056 of 1200

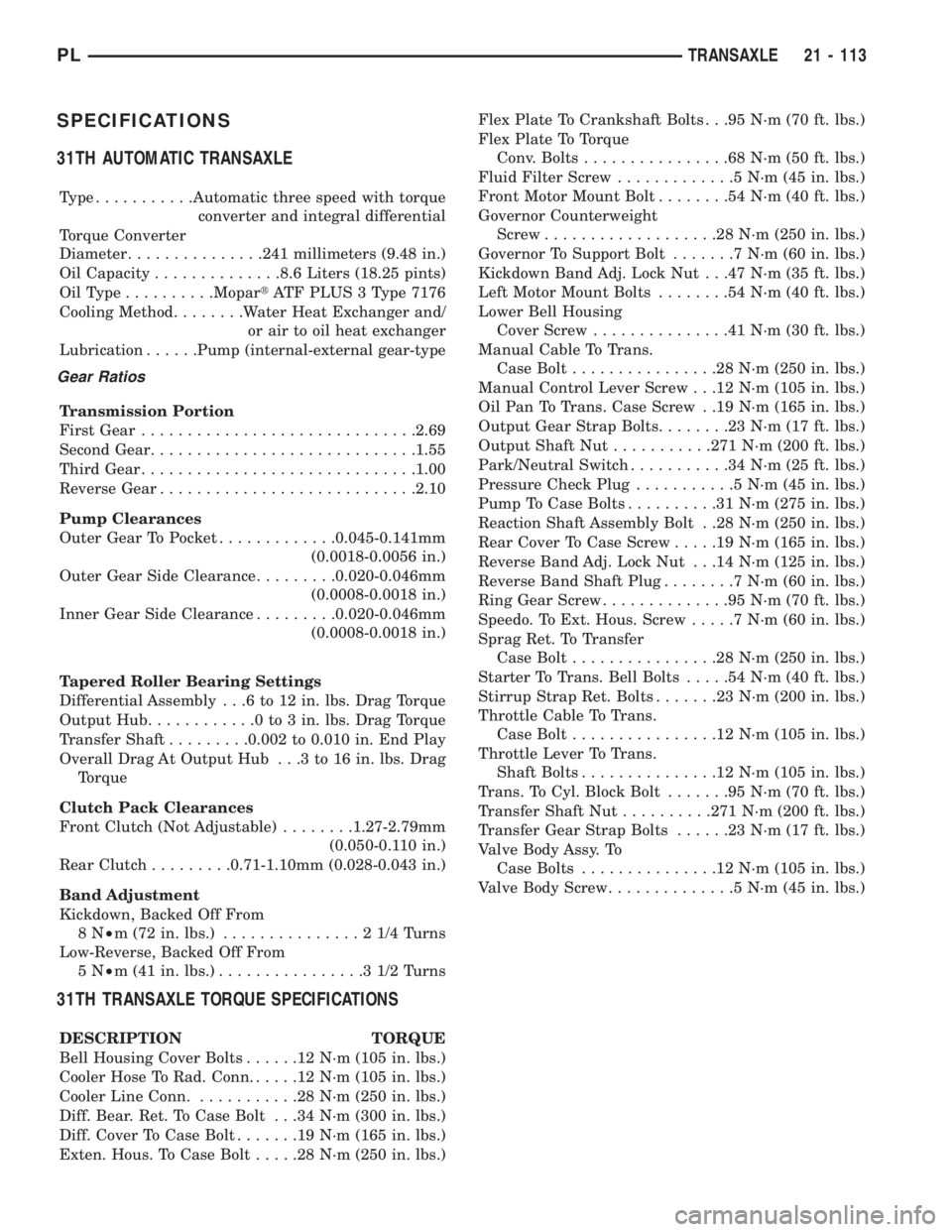

SPECIFICATIONS

31TH AUTOMATIC TRANSAXLE

Type...........Automatic three speed with torque

converter and integral differential

Torque Converter

Diameter...............241 millimeters (9.48 in.)

Oil Capacity..............8.6 Liters (18.25 pints)

OilType..........MopartATF PLUS 3 Type 7176

Cooling Method........Water Heat Exchanger and/

or air to oil heat exchanger

Lubrication......Pump (internal-external gear-type

Gear Ratios

Transmission Portion

First Gear..............................2.69

Second Gear.............................1.55

Third Gear..............................1.00

Reverse Gear............................2.10

Pump Clearances

Outer Gear To Pocket.............0.045-0.141mm

(0.0018-0.0056 in.)

Outer Gear Side Clearance.........0.020-0.046mm

(0.0008-0.0018 in.)

Inner Gear Side Clearance.........0.020-0.046mm

(0.0008-0.0018 in.)

Tapered Roller Bearing Settings

Differential Assembly . . .6 to 12 in. lbs. Drag Torque

Output Hub............0to3in.lbs. Drag Torque

Transfer Shaft.........0.002 to 0.010 in. End Play

Overall Drag At Output Hub . . .3 to 16 in. lbs. Drag

Torque

Clutch Pack Clearances

Front Clutch (Not Adjustable)........1.27-2.79mm

(0.050-0.110 in.)

Rear Clutch.........0.71-1.10mm (0.028-0.043 in.)

Band Adjustment

Kickdown, Backed Off From

8N²m (72 in. lbs.)...............21/4Turns

Low-Reverse, Backed Off From

5N²m (41 in. lbs.)................31/2Turns

31TH TRANSAXLE TORQUE SPECIFICATIONS

DESCRIPTION TORQUE

Bell Housing Cover Bolts......12N´m(105 in. lbs.)

Cooler Hose To Rad. Conn......12N´m(105 in. lbs.)

Cooler Line Conn............28N´m(250 in. lbs.)

Diff. Bear. Ret. To Case Bolt . . .34 N´m (300 in. lbs.)

Diff. Cover To Case Bolt.......19N´m(165 in. lbs.)

Exten. Hous. To Case Bolt.....28N´m(250 in. lbs.)Flex Plate To Crankshaft Bolts . . .95 N´m (70 ft. lbs.)

Flex Plate To Torque

Conv. Bolts................68N´m(50ft.lbs.)

Fluid Filter Screw.............5N´m(45in.lbs.)

Front Motor Mount Bolt........54N´m(40ft.lbs.)

Governor Counterweight

Screw...................28N´m(250 in. lbs.)

Governor To Support Bolt.......7N´m(60in.lbs.)

Kickdown Band Adj. Lock Nut . . .47 N´m (35 ft. lbs.)

Left Motor Mount Bolts........54N´m(40ft.lbs.)

Lower Bell Housing

Cover Screw...............41N´m(30ft.lbs.)

Manual Cable To Trans.

Case Bolt................28N´m(250 in. lbs.)

Manual Control Lever Screw . . .12 N´m (105 in. lbs.)

Oil Pan To Trans. Case Screw . .19 N´m (165 in. lbs.)

Output Gear Strap Bolts........23N´m(17ft.lbs.)

Output Shaft Nut...........271 N´m (200 ft. lbs.)

Park/Neutral Switch...........34N´m(25ft.lbs.)

Pressure Check Plug...........5N´m(45in.lbs.)

Pump To Case Bolts..........31N´m(275 in. lbs.)

Reaction Shaft Assembly Bolt . .28 N´m (250 in. lbs.)

Rear Cover To Case Screw.....19N´m(165 in. lbs.)

Reverse Band Adj. Lock Nut . . .14 N´m (125 in. lbs.)

Reverse Band Shaft Plug........7N´m(60in.lbs.)

Ring Gear Screw..............95N´m(70ft.lbs.)

Speedo. To Ext. Hous. Screw.....7N´m(60in.lbs.)

Sprag Ret. To Transfer

Case Bolt................28N´m(250 in. lbs.)

Starter To Trans. Bell Bolts.....54N´m(40ft.lbs.)

Stirrup Strap Ret. Bolts.......23N´m(200 in. lbs.)

Throttle Cable To Trans.

Case Bolt................12N´m(105 in. lbs.)

Throttle Lever To Trans.

Shaft Bolts...............12N´m(105 in. lbs.)

Trans. To Cyl. Block Bolt.......95N´m(70ft.lbs.)

Transfer Shaft Nut..........271 N´m (200 ft. lbs.)

Transfer Gear Strap Bolts......23N´m(17ft.lbs.)

Valve Body Assy. To

Case Bolts...............12N´m(105 in. lbs.)

Valve Body Screw..............5N´m(45in.lbs.)

PLTRANSAXLE 21 - 113

Page 1057 of 1200

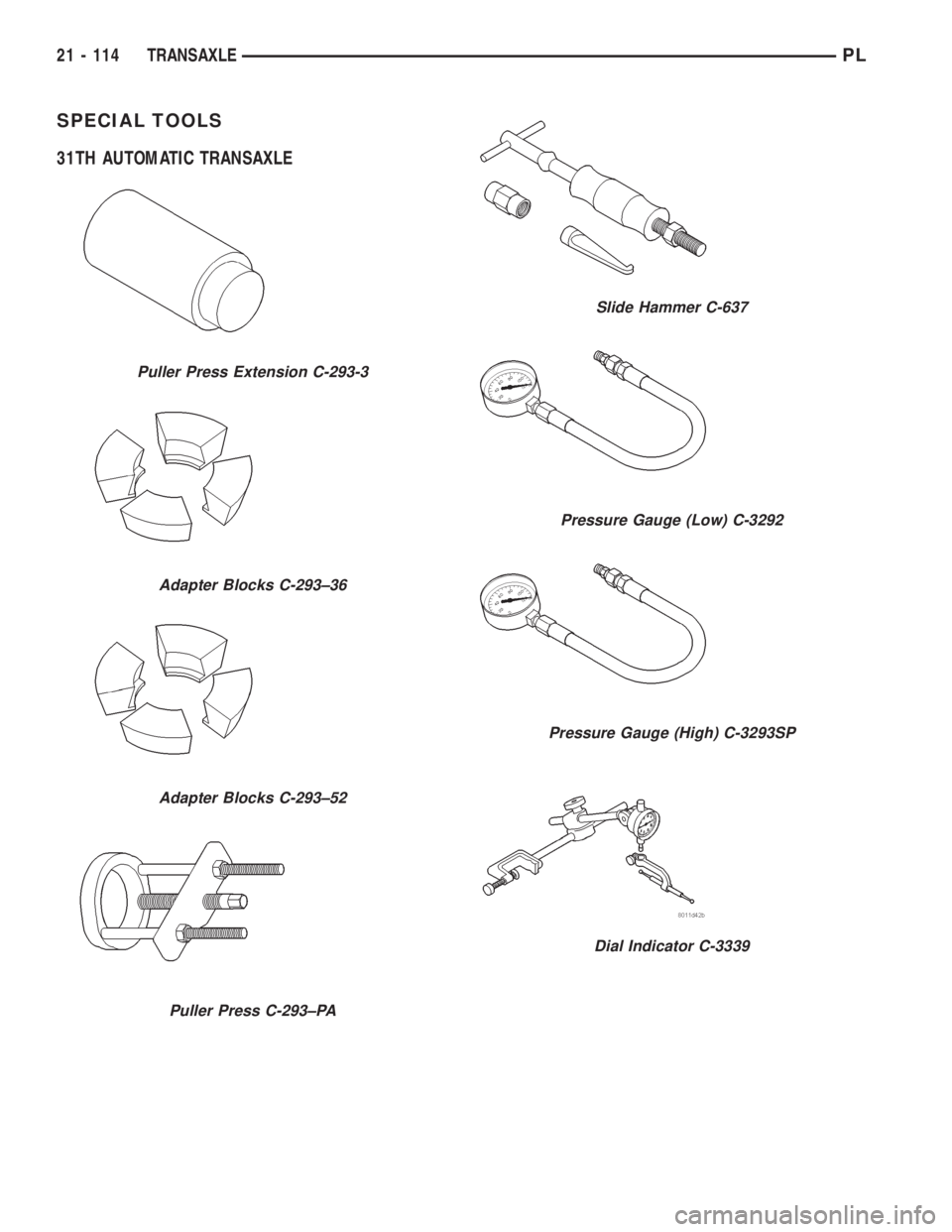

SPECIAL TOOLS

31TH AUTOMATIC TRANSAXLE

Puller Press Extension C-293-3

Adapter Blocks C-293±36

Adapter Blocks C-293±52

Puller Press C-293±PA

Slide Hammer C-637

Pressure Gauge (Low) C-3292

Pressure Gauge (High) C-3293SP

Dial Indicator C-3339

21 - 114 TRANSAXLEPL

Page 1064 of 1200

TRANSAXLE

CONTENTS

page page

DESCRIPTION AND OPERATION

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) SYSTEM........................ 1

DIAGNOSIS AND TESTING

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) SYSTEM........................ 1REMOVAL AND INSTALLATION

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) CABLE ASSEMBLY................ 2

ADJUSTMENTS

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) SYSTEM ADJUSTMENT............ 4

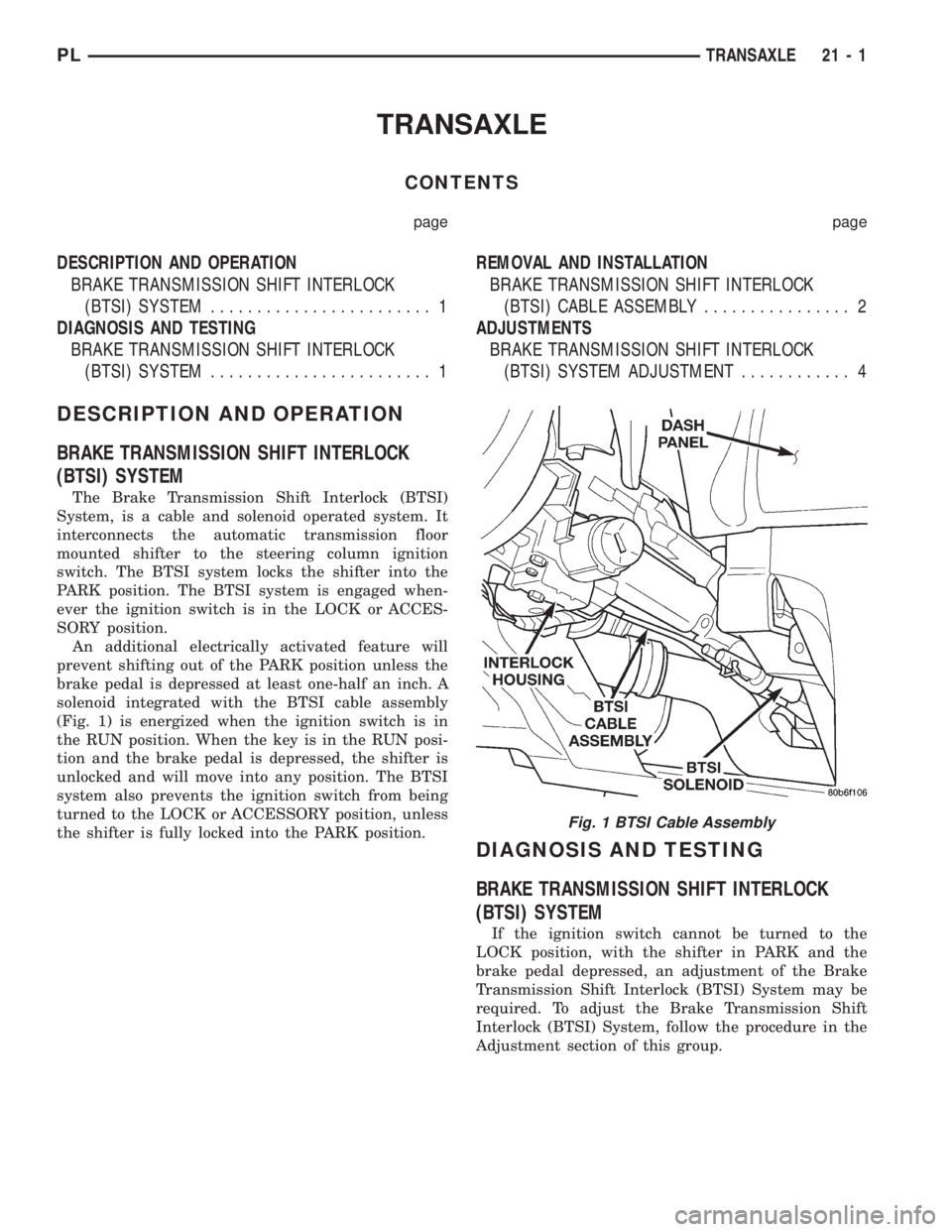

DESCRIPTION AND OPERATION

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) SYSTEM

The Brake Transmission Shift Interlock (BTSI)

System, is a cable and solenoid operated system. It

interconnects the automatic transmission floor

mounted shifter to the steering column ignition

switch. The BTSI system locks the shifter into the

PARK position. The BTSI system is engaged when-

ever the ignition switch is in the LOCK or ACCES-

SORY position.

An additional electrically activated feature will

prevent shifting out of the PARK position unless the

brake pedal is depressed at least one-half an inch. A

solenoid integrated with the BTSI cable assembly

(Fig. 1) is energized when the ignition switch is in

the RUN position. When the key is in the RUN posi-

tion and the brake pedal is depressed, the shifter is

unlocked and will move into any position. The BTSI

system also prevents the ignition switch from being

turned to the LOCK or ACCESSORY position, unless

the shifter is fully locked into the PARK position.

DIAGNOSIS AND TESTING

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) SYSTEM

If the ignition switch cannot be turned to the

LOCK position, with the shifter in PARK and the

brake pedal depressed, an adjustment of the Brake

Transmission Shift Interlock (BTSI) System may be

required. To adjust the Brake Transmission Shift

Interlock (BTSI) System, follow the procedure in the

Adjustment section of this group.

Fig. 1 BTSI Cable Assembly

PLTRANSAXLE 21 - 1

Page 1065 of 1200

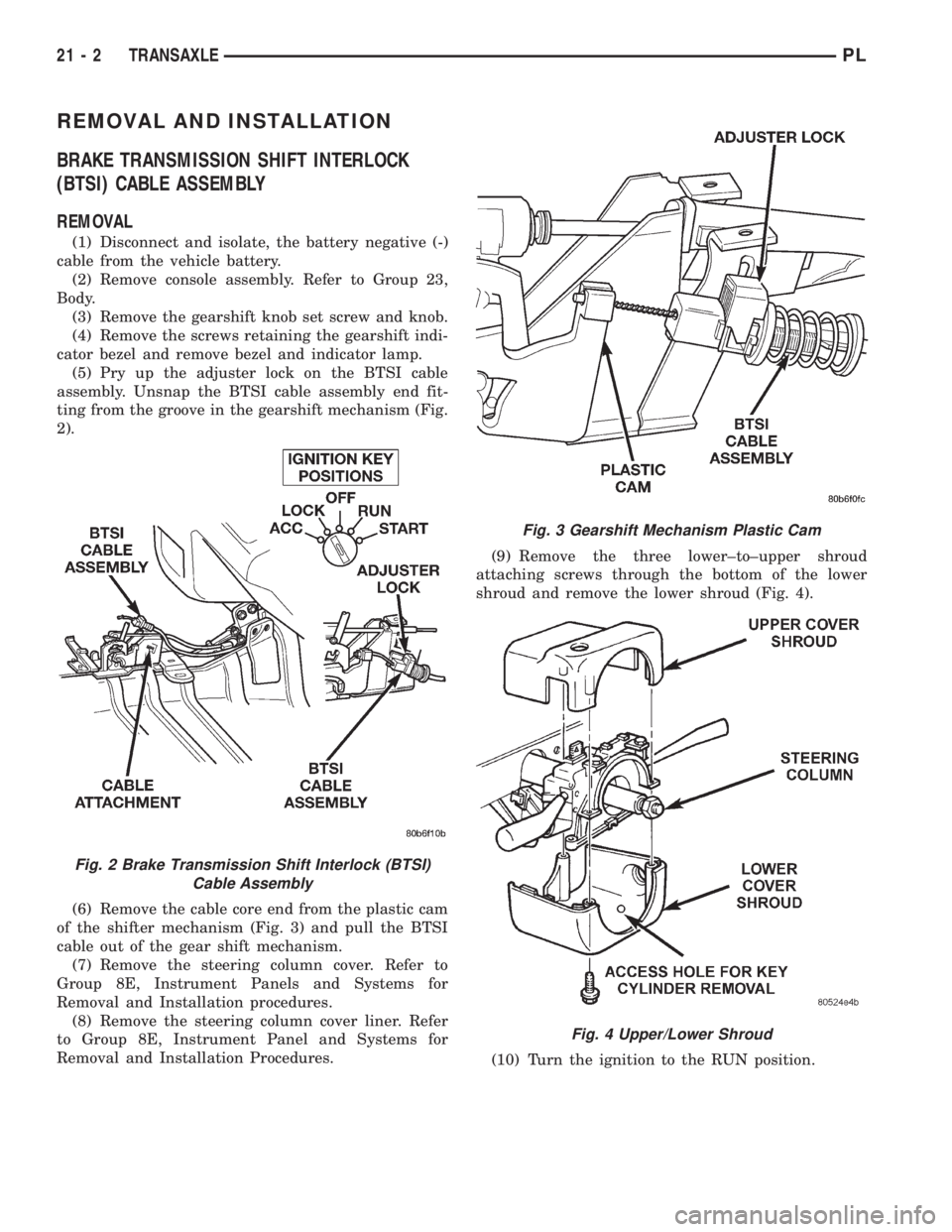

REMOVAL AND INSTALLATION

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) CABLE ASSEMBLY

REMOVAL

(1) Disconnect and isolate, the battery negative (-)

cable from the vehicle battery.

(2) Remove console assembly. Refer to Group 23,

Body.

(3) Remove the gearshift knob set screw and knob.

(4) Remove the screws retaining the gearshift indi-

cator bezel and remove bezel and indicator lamp.

(5) Pry up the adjuster lock on the BTSI cable

assembly. Unsnap the BTSI cable assembly end fit-

ting from the groove in the gearshift mechanism (Fig.

2).

(6) Remove the cable core end from the plastic cam

of the shifter mechanism (Fig. 3) and pull the BTSI

cable out of the gear shift mechanism.

(7) Remove the steering column cover. Refer to

Group 8E, Instrument Panels and Systems for

Removal and Installation procedures.

(8) Remove the steering column cover liner. Refer

to Group 8E, Instrument Panel and Systems for

Removal and Installation Procedures.(9) Remove the three lower±to±upper shroud

attaching screws through the bottom of the lower

shroud and remove the lower shroud (Fig. 4).

(10) Turn the ignition to the RUN position.

Fig. 2 Brake Transmission Shift Interlock (BTSI)

Cable Assembly

Fig. 3 Gearshift Mechanism Plastic Cam

Fig. 4 Upper/Lower Shroud

21 - 2 TRANSAXLEPL

Page 1066 of 1200

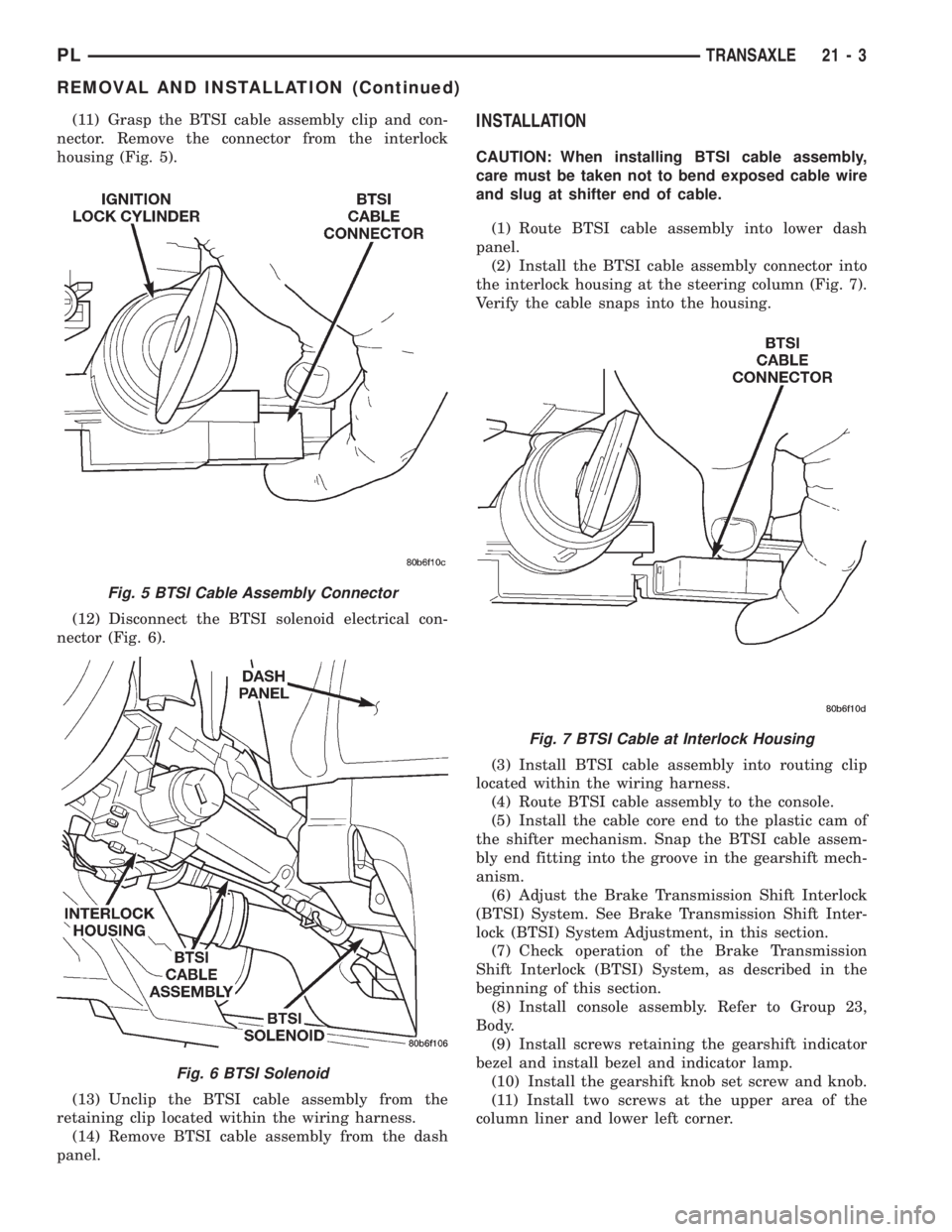

(11) Grasp the BTSI cable assembly clip and con-

nector. Remove the connector from the interlock

housing (Fig. 5).

(12) Disconnect the BTSI solenoid electrical con-

nector (Fig. 6).

(13) Unclip the BTSI cable assembly from the

retaining clip located within the wiring harness.

(14) Remove BTSI cable assembly from the dash

panel.INSTALLATION

CAUTION: When installing BTSI cable assembly,

care must be taken not to bend exposed cable wire

and slug at shifter end of cable.

(1) Route BTSI cable assembly into lower dash

panel.

(2) Install the BTSI cable assembly connector into

the interlock housing at the steering column (Fig. 7).

Verify the cable snaps into the housing.

(3) Install BTSI cable assembly into routing clip

located within the wiring harness.

(4) Route BTSI cable assembly to the console.

(5) Install the cable core end to the plastic cam of

the shifter mechanism. Snap the BTSI cable assem-

bly end fitting into the groove in the gearshift mech-

anism.

(6) Adjust the Brake Transmission Shift Interlock

(BTSI) System. See Brake Transmission Shift Inter-

lock (BTSI) System Adjustment, in this section.

(7) Check operation of the Brake Transmission

Shift Interlock (BTSI) System, as described in the

beginning of this section.

(8) Install console assembly. Refer to Group 23,

Body.

(9) Install screws retaining the gearshift indicator

bezel and install bezel and indicator lamp.

(10) Install the gearshift knob set screw and knob.

(11) Install two screws at the upper area of the

column liner and lower left corner.

Fig. 5 BTSI Cable Assembly Connector

Fig. 6 BTSI Solenoid

Fig. 7 BTSI Cable at Interlock Housing

PLTRANSAXLE 21 - 3

REMOVAL AND INSTALLATION (Continued)

Page 1067 of 1200

(12) Position the lower shroud in place. Install the

three lower±to±upper shroud attaching screws

through the bottom of the lower shroud (Fig. 8).

(13) Reconnect the battery negative (-) cable to the

vehicle battery.

ADJUSTMENTS

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) SYSTEM ADJUSTMENT

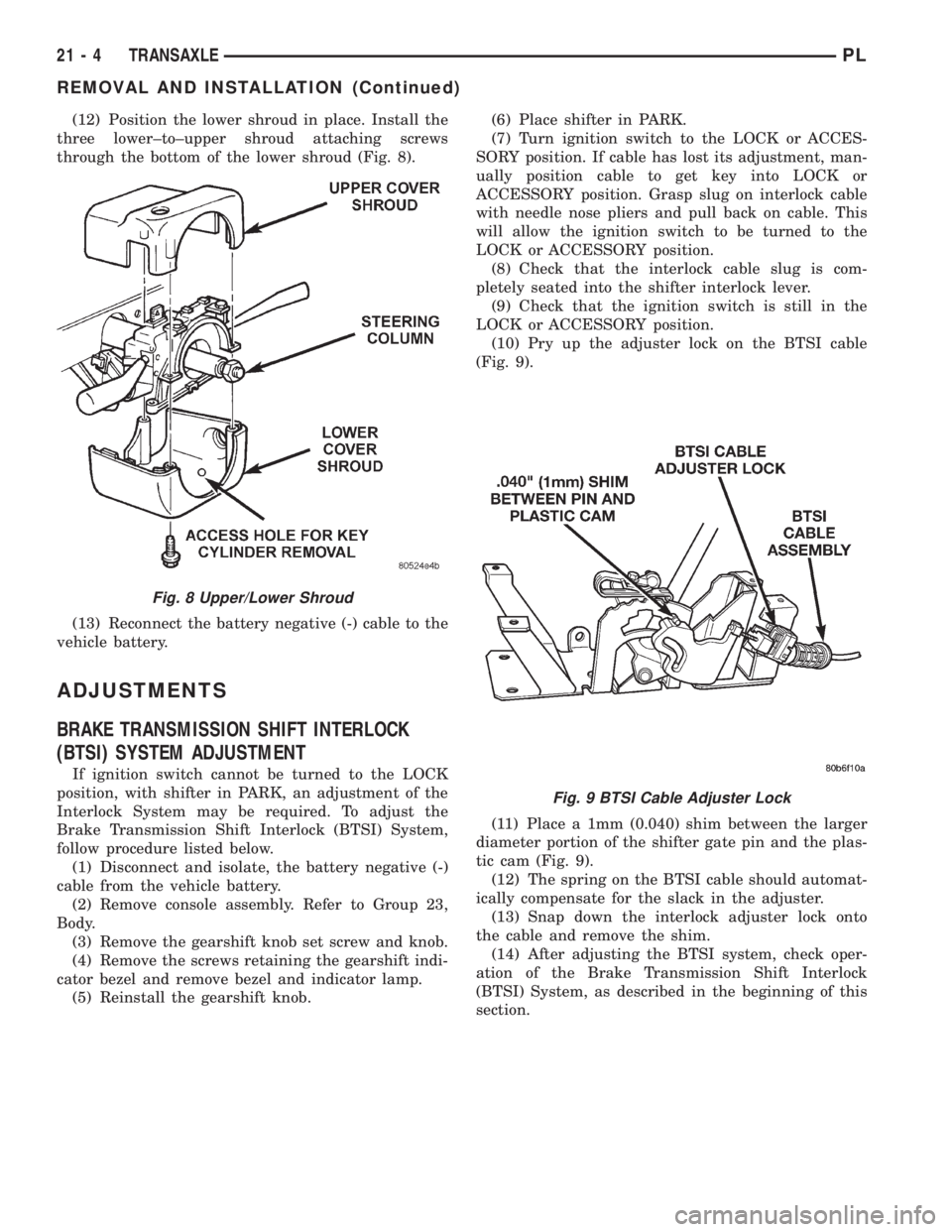

If ignition switch cannot be turned to the LOCK

position, with shifter in PARK, an adjustment of the

Interlock System may be required. To adjust the

Brake Transmission Shift Interlock (BTSI) System,

follow procedure listed below.

(1) Disconnect and isolate, the battery negative (-)

cable from the vehicle battery.

(2) Remove console assembly. Refer to Group 23,

Body.

(3) Remove the gearshift knob set screw and knob.

(4) Remove the screws retaining the gearshift indi-

cator bezel and remove bezel and indicator lamp.

(5) Reinstall the gearshift knob.(6) Place shifter in PARK.

(7) Turn ignition switch to the LOCK or ACCES-

SORY position. If cable has lost its adjustment, man-

ually position cable to get key into LOCK or

ACCESSORY position. Grasp slug on interlock cable

with needle nose pliers and pull back on cable. This

will allow the ignition switch to be turned to the

LOCK or ACCESSORY position.

(8) Check that the interlock cable slug is com-

pletely seated into the shifter interlock lever.

(9) Check that the ignition switch is still in the

LOCK or ACCESSORY position.

(10) Pry up the adjuster lock on the BTSI cable

(Fig. 9).

(11) Place a 1mm (0.040) shim between the larger

diameter portion of the shifter gate pin and the plas-

tic cam (Fig. 9).

(12) The spring on the BTSI cable should automat-

ically compensate for the slack in the adjuster.

(13) Snap down the interlock adjuster lock onto

the cable and remove the shim.

(14) After adjusting the BTSI system, check oper-

ation of the Brake Transmission Shift Interlock

(BTSI) System, as described in the beginning of this

section.

Fig. 8 Upper/Lower Shroud

Fig. 9 BTSI Cable Adjuster Lock

21 - 4 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)