DODGE RAM 2001 Service Repair Manual

Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1471 of 2889

CAUTION: The turbocharger is only serviced as an

assembly. Do not attempt to repair the turbocharger

as turbocharger and/or engine damage can result.

CLEANING

Clean the turbocharger and exhaust manifold

mounting surfaces with a suitable scraper.

INSPECTION

Visually inspect the turbocharger and exhaust

manifold gasket surfaces. Replace stripped or eroded

mounting studs.

(1) Visually inspect the turbocharger for cracks.

The following cracks are NOT acceptable:

²Cracks in the turbine and compressor housing

that go completely through.

²Cracks in the mounting flange that are longer

than 15 mm (0.6 in.).

²Cracks in the mounting flange that intersect

bolt through-holes.

²Two (2) Cracks in the mounting flange that are

closer than 6.4 mm (0.25 in.) together.

(2) Visually inspect the impeller and compressor

wheel fins for nicks, cracks, or chips. Note: Some

impellers may have a factory placed paint mark

which, after normal operation, appears to be a crack.Remove this mark with a suitable solvent to verify

that it is not a crack.

(3) Visually inspect the turbocharger compressor

housing for an impeller rubbing condition (Fig. 25).

Replace the turbocharger if the condition exists.

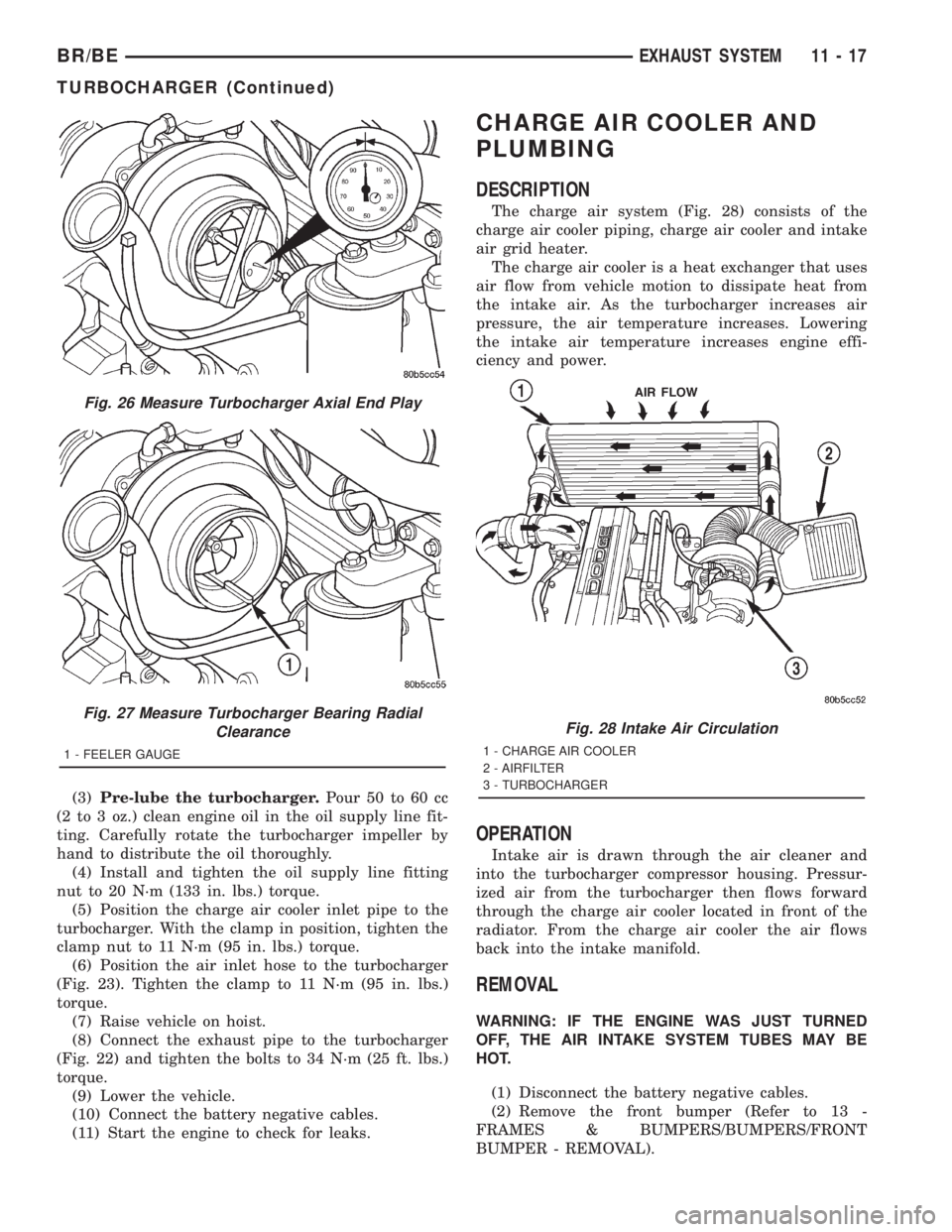

(4) Measure the turbocharger axial end play:

(a) Install a dial indicator as shown in (Fig. 26).

Zero the indicator at one end of travel.

(b) Move the impeller shaft fore and aft and

record the measurement. Allowable end play is

0.038 mm (0.0015 in.) MIN. and 0.089 mm (0.0035

in.) MAX. If the recorded measurement falls out-

side these parameters, replace the turbocharger

assembly.

(5) Measure the turbocharger bearing radial clear-

ance:

(a) Insert a narrow blade or wire style feeler

gauge between the compressor wheel and the hous-

ing (Fig. 27).

(b) Gently push the compresser wheel toward

the housing and record the clearance.

(c) With the feeler gauge in the same location,

gently push the compressor wheel away from the

housing and again record the clearance.

(d) Subtract the smaller clearance from the

larger clearance. This is the radial bearing clear-

ance.

(e) Allowable radial bearing clearance is 0.326

mm (0.0128 in.) MIN. and 0.496 mm (0.0195 in.)

MAX. If the recorded measurement falls outside

these specifications, replace the turbocharger assy.

INSTALLATION

(1) Install the turbocharger. Apply anti-seize to the

studs and then tighten the turbocharger mounting

nuts to 32 N´m (24 ft. lbs.) torque.

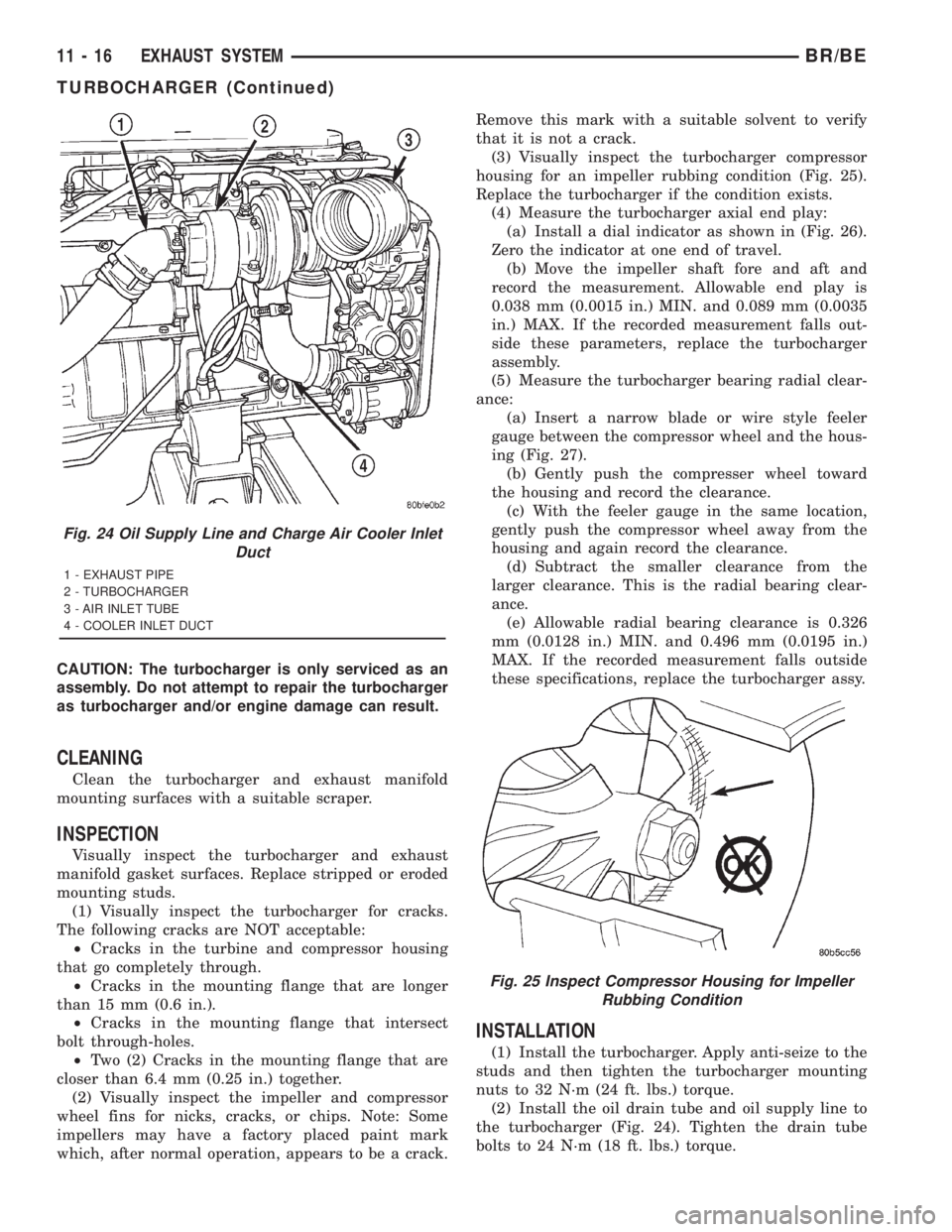

(2) Install the oil drain tube and oil supply line to

the turbocharger (Fig. 24). Tighten the drain tube

bolts to 24 N´m (18 ft. lbs.) torque.

Fig. 24 Oil Supply Line and Charge Air Cooler Inlet

Duct

1 - EXHAUST PIPE

2 - TURBOCHARGER

3 - AIR INLET TUBE

4 - COOLER INLET DUCT

Fig. 25 Inspect Compressor Housing for Impeller

Rubbing Condition

11 - 16 EXHAUST SYSTEMBR/BE

TURBOCHARGER (Continued)

Page 1472 of 2889

(3)Pre-lube the turbocharger.Pour 50 to 60 cc

(2 to 3 oz.) clean engine oil in the oil supply line fit-

ting. Carefully rotate the turbocharger impeller by

hand to distribute the oil thoroughly.

(4) Install and tighten the oil supply line fitting

nut to 20 N´m (133 in. lbs.) torque.

(5) Position the charge air cooler inlet pipe to the

turbocharger. With the clamp in position, tighten the

clamp nut to 11 N´m (95 in. lbs.) torque.

(6) Position the air inlet hose to the turbocharger

(Fig. 23). Tighten the clamp to 11 N´m (95 in. lbs.)

torque.

(7) Raise vehicle on hoist.

(8) Connect the exhaust pipe to the turbocharger

(Fig. 22) and tighten the bolts to 34 N´m (25 ft. lbs.)

torque.

(9) Lower the vehicle.

(10) Connect the battery negative cables.

(11) Start the engine to check for leaks.

CHARGE AIR COOLER AND

PLUMBING

DESCRIPTION

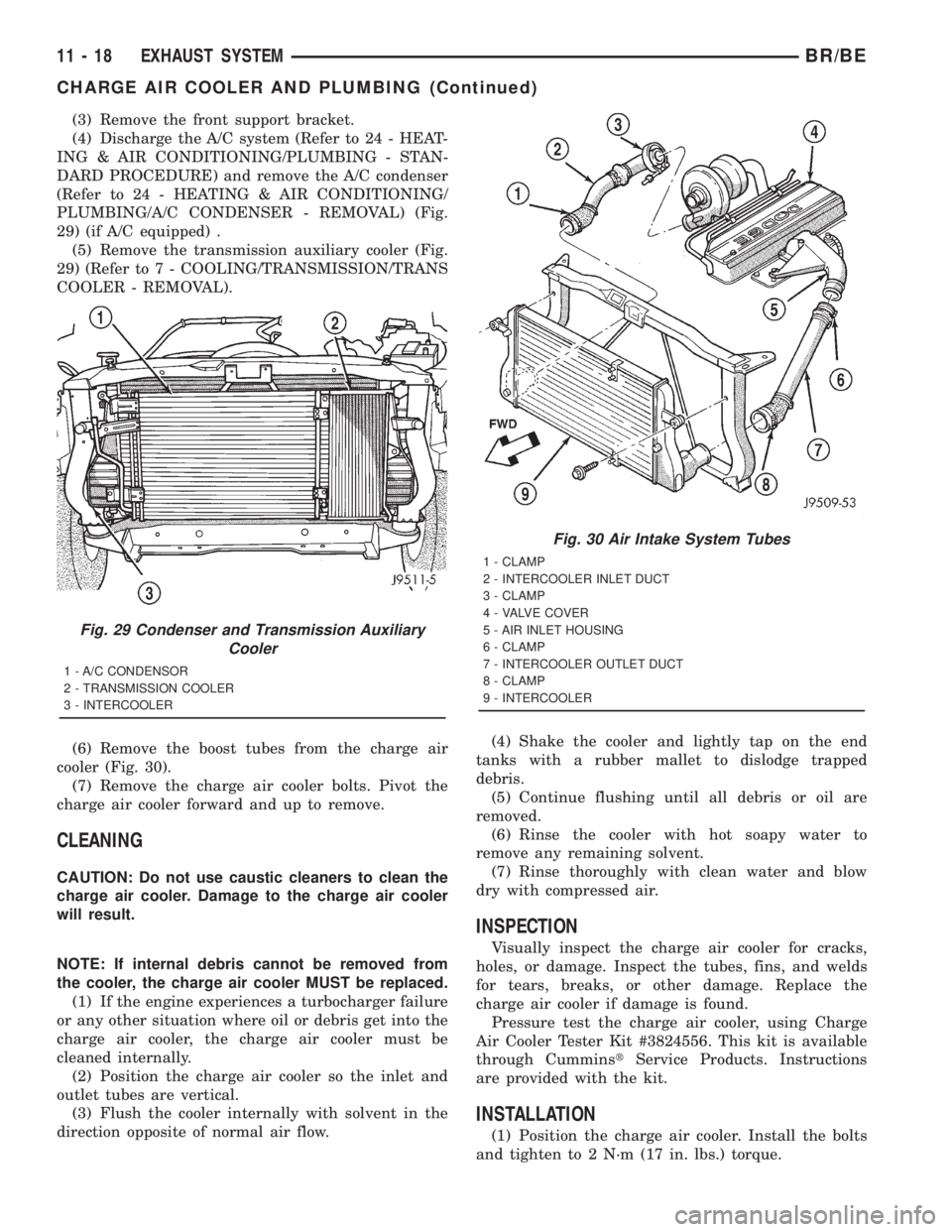

The charge air system (Fig. 28) consists of the

charge air cooler piping, charge air cooler and intake

air grid heater.

The charge air cooler is a heat exchanger that uses

air flow from vehicle motion to dissipate heat from

the intake air. As the turbocharger increases air

pressure, the air temperature increases. Lowering

the intake air temperature increases engine effi-

ciency and power.

OPERATION

Intake air is drawn through the air cleaner and

into the turbocharger compressor housing. Pressur-

ized air from the turbocharger then flows forward

through the charge air cooler located in front of the

radiator. From the charge air cooler the air flows

back into the intake manifold.

REMOVAL

WARNING: IF THE ENGINE WAS JUST TURNED

OFF, THE AIR INTAKE SYSTEM TUBES MAY BE

HOT.

(1) Disconnect the battery negative cables.

(2) Remove the front bumper (Refer to 13 -

FRAMES & BUMPERS/BUMPERS/FRONT

BUMPER - REMOVAL).

Fig. 26 Measure Turbocharger Axial End Play

Fig. 27 Measure Turbocharger Bearing Radial

Clearance

1 - FEELER GAUGE

Fig. 28 Intake Air Circulation

1 - CHARGE AIR COOLER

2 - AIRFILTER

3 - TURBOCHARGER

BR/BEEXHAUST SYSTEM 11 - 17

TURBOCHARGER (Continued)

Page 1473 of 2889

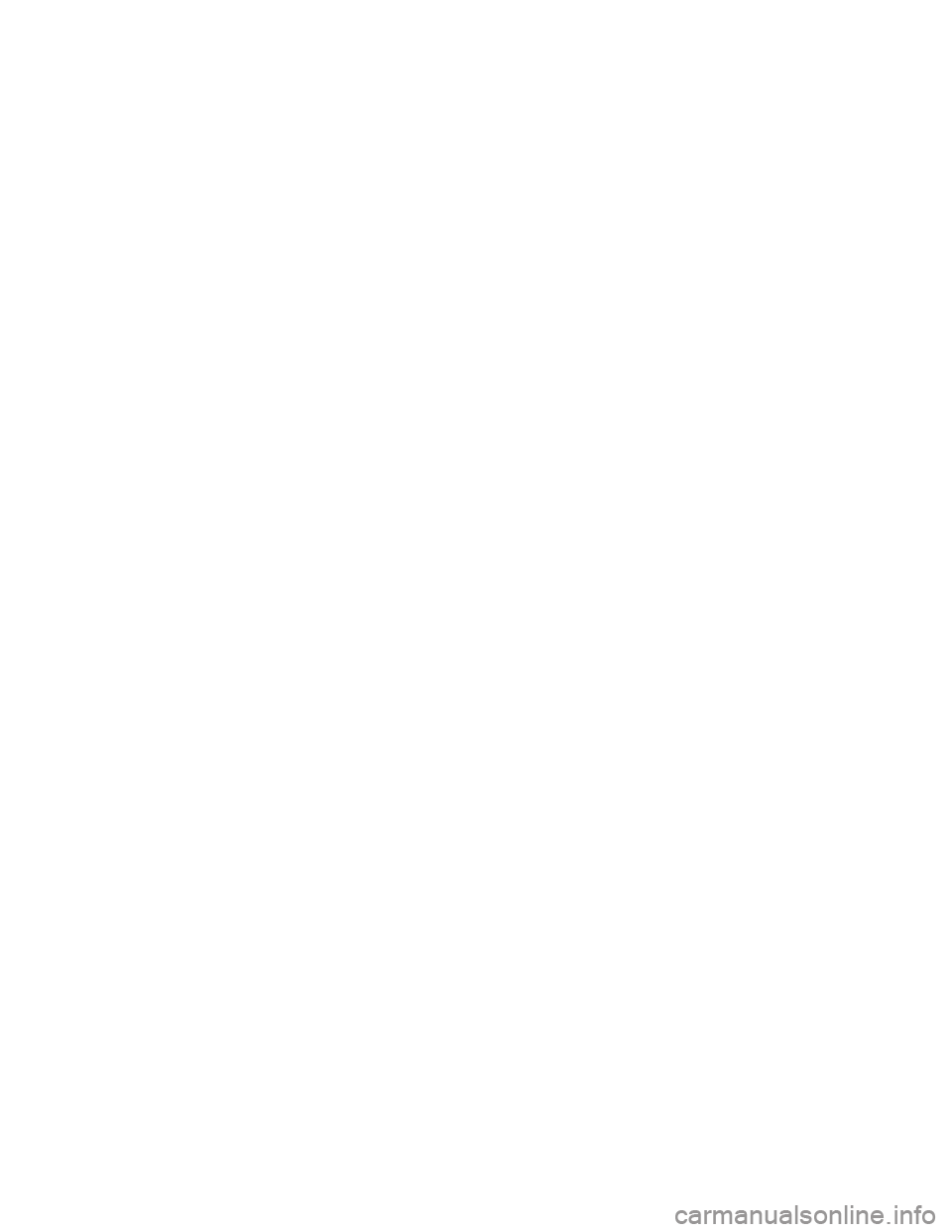

(3) Remove the front support bracket.

(4) Discharge the A/C system (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE) and remove the A/C condenser

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/A/C CONDENSER - REMOVAL) (Fig.

29) (if A/C equipped) .

(5) Remove the transmission auxiliary cooler (Fig.

29) (Refer to 7 - COOLING/TRANSMISSION/TRANS

COOLER - REMOVAL).

(6) Remove the boost tubes from the charge air

cooler (Fig. 30).

(7) Remove the charge air cooler bolts. Pivot the

charge air cooler forward and up to remove.

CLEANING

CAUTION: Do not use caustic cleaners to clean the

charge air cooler. Damage to the charge air cooler

will result.

NOTE: If internal debris cannot be removed from

the cooler, the charge air cooler MUST be replaced.

(1) If the engine experiences a turbocharger failure

or any other situation where oil or debris get into the

charge air cooler, the charge air cooler must be

cleaned internally.

(2) Position the charge air cooler so the inlet and

outlet tubes are vertical.

(3) Flush the cooler internally with solvent in the

direction opposite of normal air flow.(4) Shake the cooler and lightly tap on the end

tanks with a rubber mallet to dislodge trapped

debris.

(5) Continue flushing until all debris or oil are

removed.

(6) Rinse the cooler with hot soapy water to

remove any remaining solvent.

(7) Rinse thoroughly with clean water and blow

dry with compressed air.

INSPECTION

Visually inspect the charge air cooler for cracks,

holes, or damage. Inspect the tubes, fins, and welds

for tears, breaks, or other damage. Replace the

charge air cooler if damage is found.

Pressure test the charge air cooler, using Charge

Air Cooler Tester Kit #3824556. This kit is available

through CumminstService Products. Instructions

are provided with the kit.

INSTALLATION

(1) Position the charge air cooler. Install the bolts

and tighten to 2 N´m (17 in. lbs.) torque.

Fig. 29 Condenser and Transmission Auxiliary

Cooler

1 - A/C CONDENSOR

2 - TRANSMISSION COOLER

3 - INTERCOOLER

Fig. 30 Air Intake System Tubes

1 - CLAMP

2 - INTERCOOLER INLET DUCT

3 - CLAMP

4 - VALVE COVER

5 - AIR INLET HOUSING

6 - CLAMP

7 - INTERCOOLER OUTLET DUCT

8 - CLAMP

9 - INTERCOOLER

11 - 18 EXHAUST SYSTEMBR/BE

CHARGE AIR COOLER AND PLUMBING (Continued)

Page 1474 of 2889

(2) Install the air intake system tubes to the

charge air cooler . With the clamps in position,

tighten the clamps to 11 N´m (95 in. lbs.) torque.

(3) Install the transmission auxiliary cooler (if

equipped) (Refer to 7 - COOLING/TRANSMISSION/

TRANS COOLER - INSTALLATION).

(4) Install the A/C condenser (if A/C equipped)

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/A/C CONDENSER - INSTALLATION).

Recharge A/C system (Refer to 24 - HEATING & AIRCONDITIONING/PLUMBING - STANDARD PRO-

CEDURE).

(5) Install the front support bracket. Install and

tighten the bolts.

(6) Install the front bumper (Refer to 13 -

FRAMES & BUMPERS/BUMPERS/FRONT

BUMPER - INSTALLATION).

(7) Connect the battery negative cables.

(8) Start engine and check for boost system leaks.

BR/BEEXHAUST SYSTEM 11 - 19

CHARGE AIR COOLER AND PLUMBING (Continued)

Page 1475 of 2889

Page 1476 of 2889

FRAME & BUMPERS

TABLE OF CONTENTS

page page

BUMPERS

DESCRIPTION............................1

FRONT AIR DAM

REMOVAL...............................1

INSTALLATION............................2

FRONT FASCIA

REMOVAL...............................2

INSTALLATION............................2

ADJUSTMENT............................2

FRONT LOWER FASCIA

REMOVAL...............................3

INSTALLATION............................3

FRONT FASCIAÐSPORT

REMOVAL...............................3

INSTALLATION............................3

FRONT BUMPER

REMOVAL...............................3

INSTALLATION............................4

FRONT BUMPERÐSPORT

REMOVAL...............................4

INSTALLATION............................4REAR BUMPER

REMOVAL...............................5

INSTALLATION............................5

FRAME

DESCRIPTION............................6

SPECIFICATIONS.........................7

CAB CHASSIS ADAPTER BRACKET

REMOVAL...............................9

INSTALLATION............................9

FRONT TOW HOOK

REMOVAL...............................9

INSTALLATION...........................10

SPARE TIRE WINCH

REMOVAL..............................10

INSTALLATION...........................10

TRAILER HITCH

REMOVAL..............................10

INSTALLATION...........................10

TRANSFER CASE SKID PLATE

REMOVAL..............................11

INSTALLATION...........................11

BUMPERS

DESCRIPTION

Bumpers are used at the front and rear of the

vehicle. Bumpers may be chrome or painted.

Bumpers are designed to protect the exterior sheet-

metal in low impact situations. The bumpers are

attached to the frame and provide mounting points

for some optional accessories such as fog lights and

tow hooks.

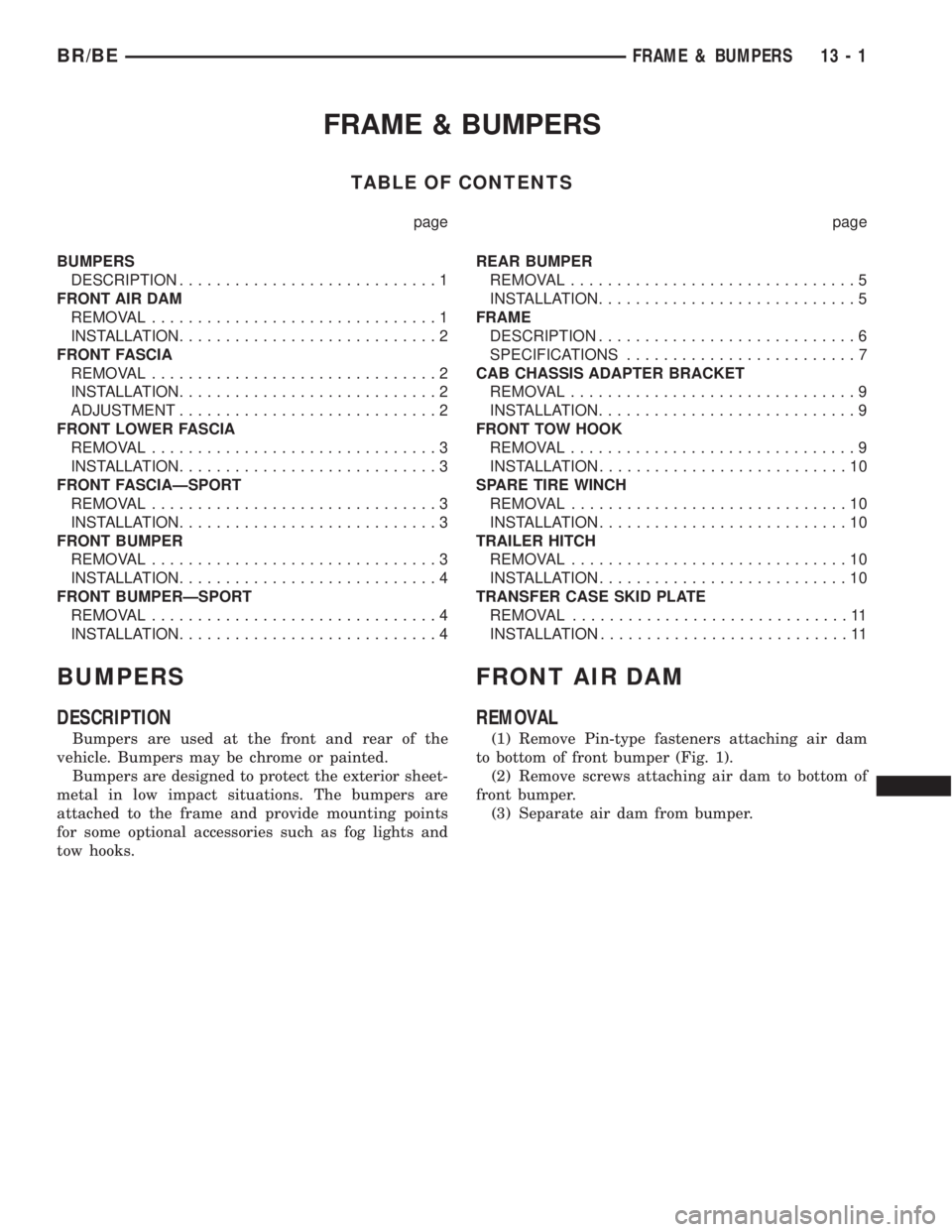

FRONT AIR DAM

REMOVAL

(1) Remove Pin-type fasteners attaching air dam

to bottom of front bumper (Fig. 1).

(2) Remove screws attaching air dam to bottom of

front bumper.

(3) Separate air dam from bumper.

BR/BEFRAME & BUMPERS 13 - 1

Page 1477 of 2889

INSTALLATION

(1) Position air dam on bumper.

(2) Install screws attaching air dam to bottom of

front bumper.

(3) Install Pin-type fasteners attaching air dam to

bottom of front bumper.

FRONT FASCIA

REMOVAL

(1) Open hood.

(2) Remove fasteners at fender side openings.

(3) Separate fascia from bumper.

INSTALLATION

(1) Position fascia on bumper.

(2) Install front fascia. See fascia adjustment pro-

cedure in this section.

(3) Install fasteners at fender side openings.

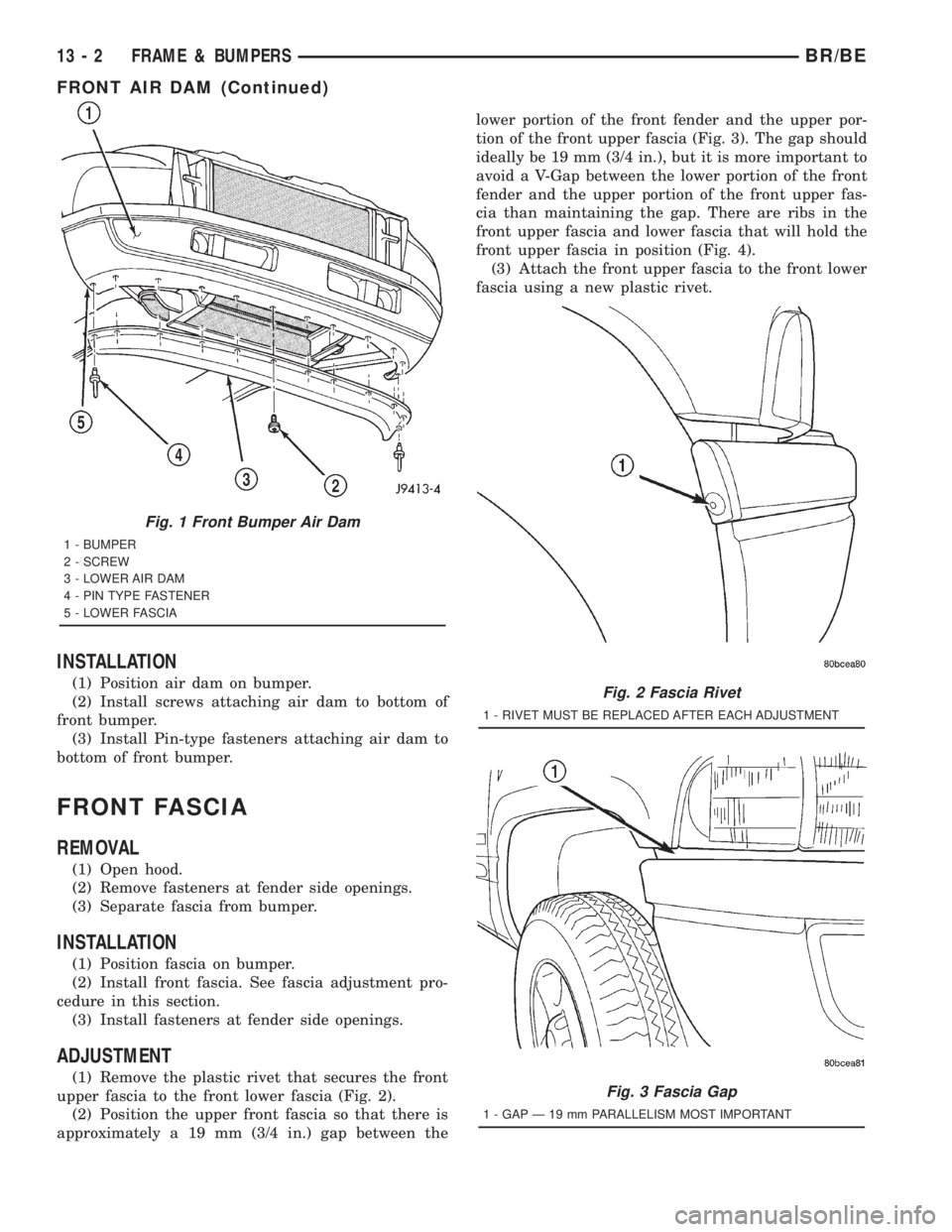

ADJUSTMENT

(1) Remove the plastic rivet that secures the front

upper fascia to the front lower fascia (Fig. 2).

(2) Position the upper front fascia so that there is

approximately a 19 mm (3/4 in.) gap between thelower portion of the front fender and the upper por-

tion of the front upper fascia (Fig. 3). The gap should

ideally be 19 mm (3/4 in.), but it is more important to

avoid a V-Gap between the lower portion of the front

fender and the upper portion of the front upper fas-

cia than maintaining the gap. There are ribs in the

front upper fascia and lower fascia that will hold the

front upper fascia in position (Fig. 4).

(3) Attach the front upper fascia to the front lower

fascia using a new plastic rivet.

Fig. 1 Front Bumper Air Dam

1 - BUMPER

2 - SCREW

3 - LOWER AIR DAM

4 - PIN TYPE FASTENER

5 - LOWER FASCIA

Fig. 2 Fascia Rivet

1 - RIVET MUST BE REPLACED AFTER EACH ADJUSTMENT

Fig. 3 Fascia Gap

1 - GAP Ð 19 mm PARALLELISM MOST IMPORTANT

13 - 2 FRAME & BUMPERSBR/BE

FRONT AIR DAM (Continued)

Page 1478 of 2889

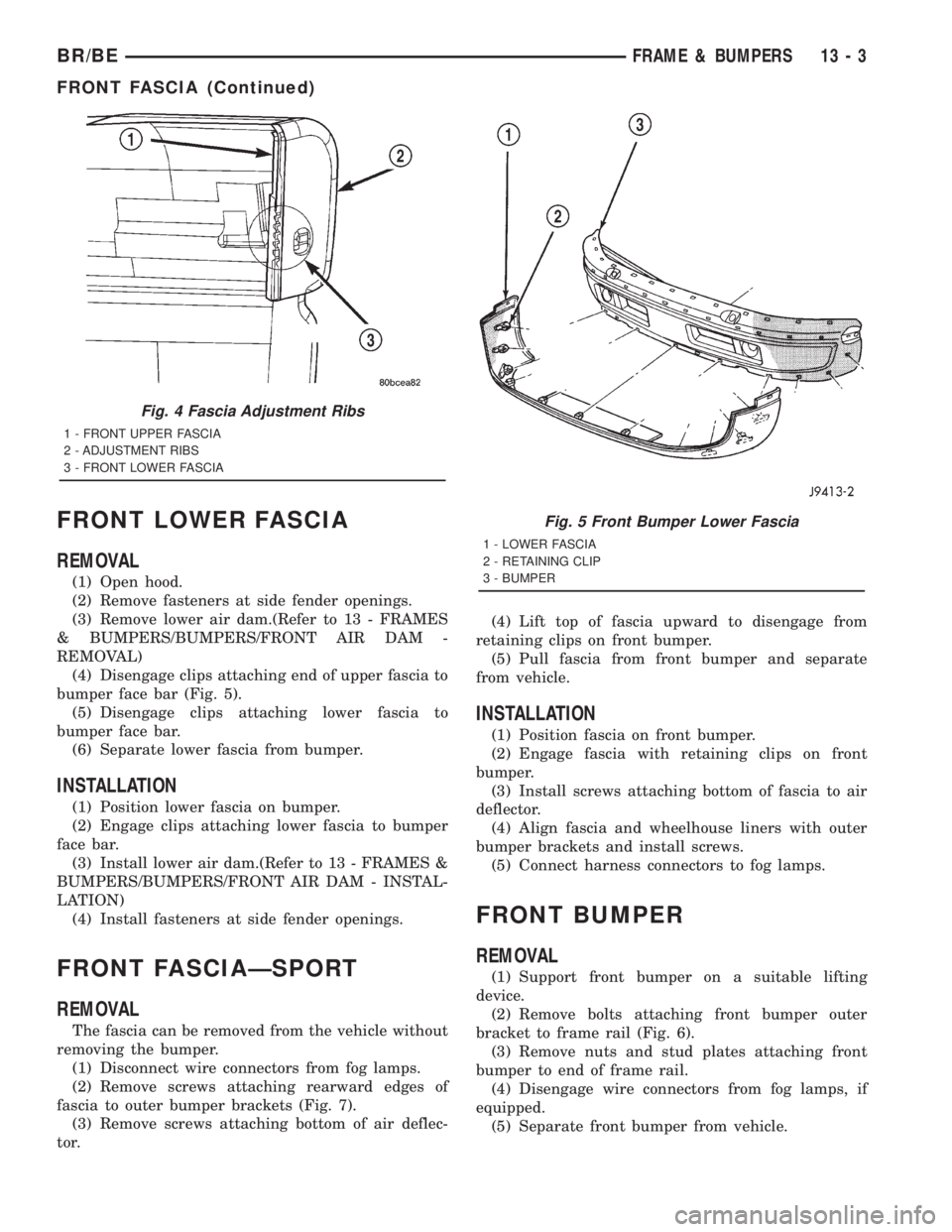

FRONT LOWER FASCIA

REMOVAL

(1) Open hood.

(2) Remove fasteners at side fender openings.

(3) Remove lower air dam.(Refer to 13 - FRAMES

& BUMPERS/BUMPERS/FRONT AIR DAM -

REMOVAL)

(4) Disengage clips attaching end of upper fascia to

bumper face bar (Fig. 5).

(5) Disengage clips attaching lower fascia to

bumper face bar.

(6) Separate lower fascia from bumper.

INSTALLATION

(1) Position lower fascia on bumper.

(2) Engage clips attaching lower fascia to bumper

face bar.

(3) Install lower air dam.(Refer to 13 - FRAMES &

BUMPERS/BUMPERS/FRONT AIR DAM - INSTAL-

LATION)

(4) Install fasteners at side fender openings.

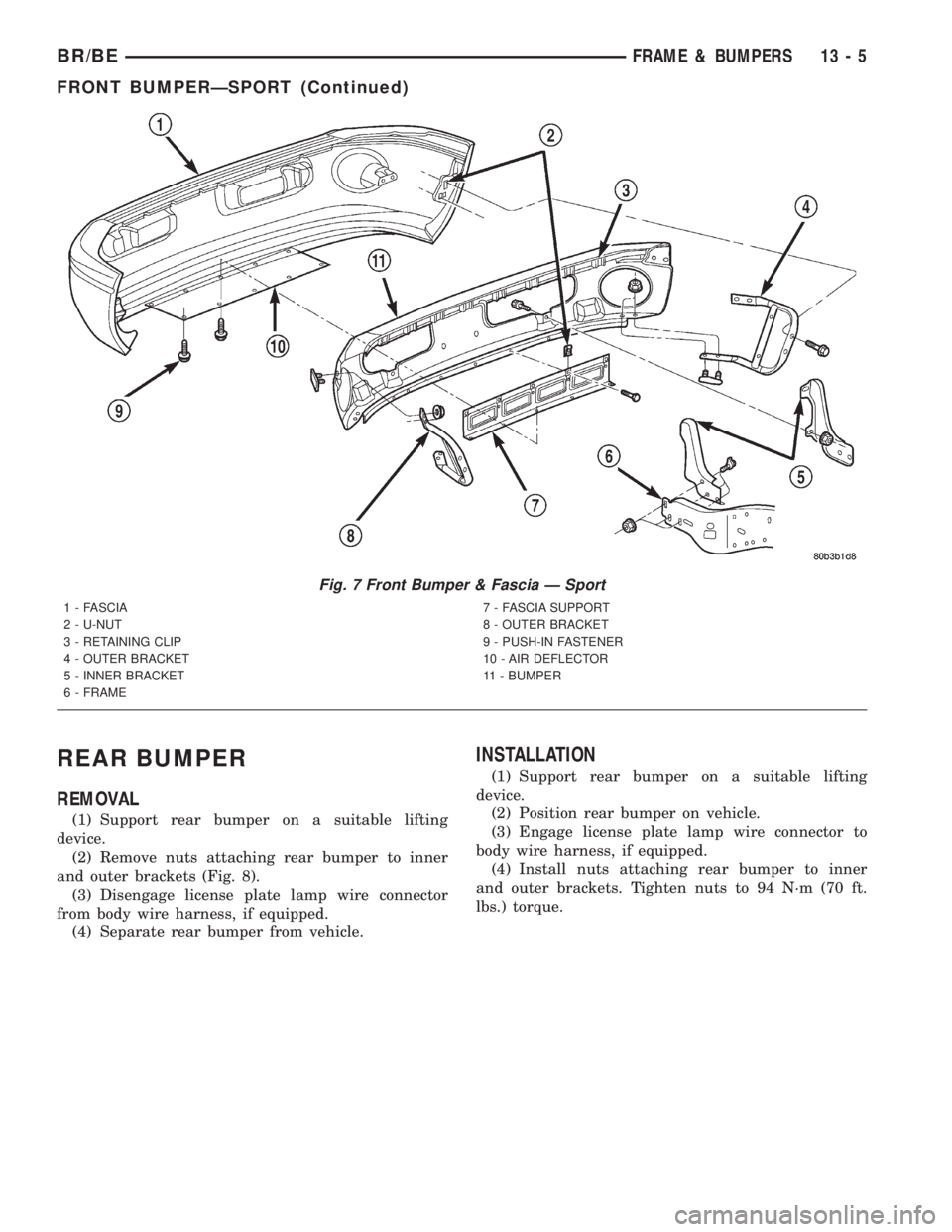

FRONT FASCIAÐSPORT

REMOVAL

The fascia can be removed from the vehicle without

removing the bumper.

(1) Disconnect wire connectors from fog lamps.

(2) Remove screws attaching rearward edges of

fascia to outer bumper brackets (Fig. 7).

(3) Remove screws attaching bottom of air deflec-

tor.(4) Lift top of fascia upward to disengage from

retaining clips on front bumper.

(5) Pull fascia from front bumper and separate

from vehicle.

INSTALLATION

(1) Position fascia on front bumper.

(2) Engage fascia with retaining clips on front

bumper.

(3) Install screws attaching bottom of fascia to air

deflector.

(4) Align fascia and wheelhouse liners with outer

bumper brackets and install screws.

(5) Connect harness connectors to fog lamps.

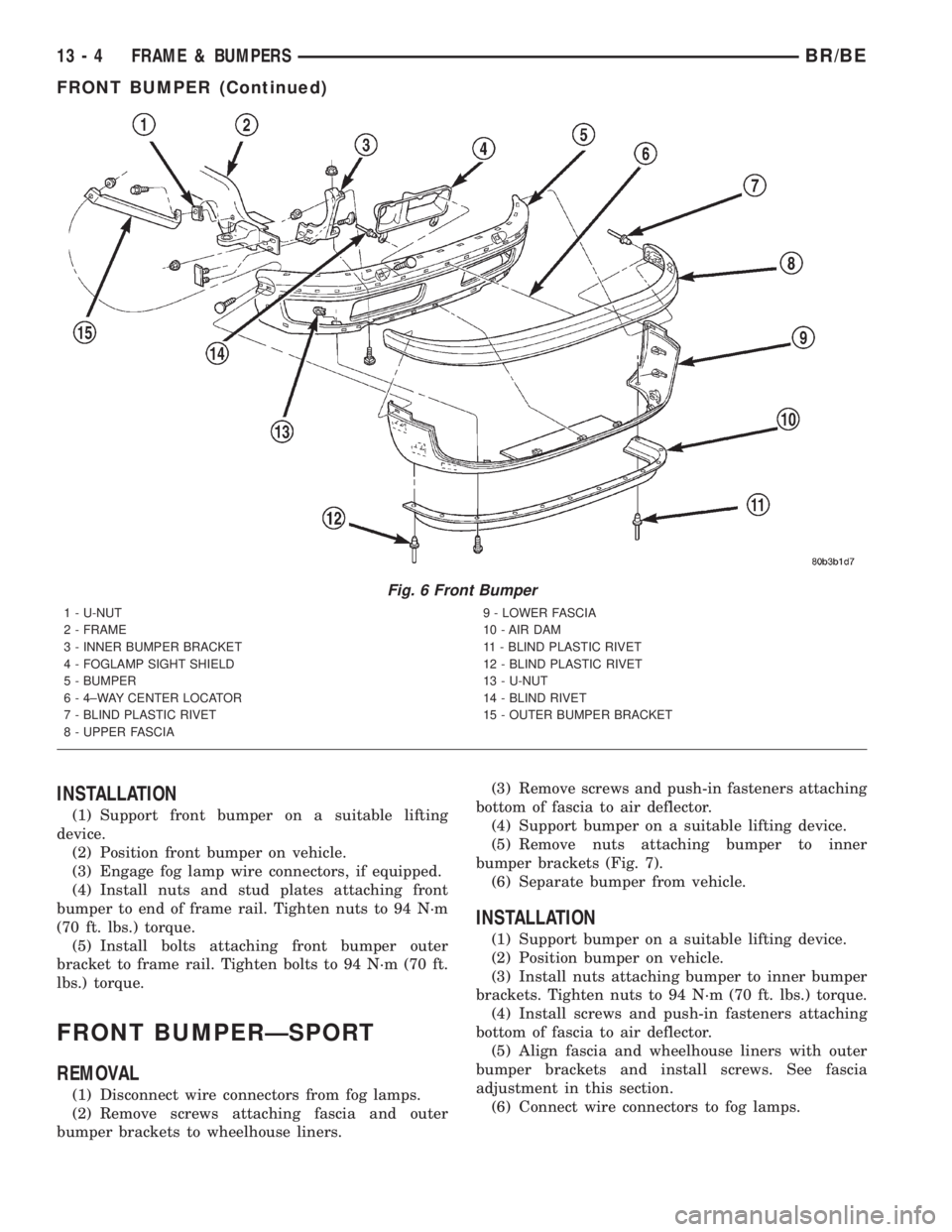

FRONT BUMPER

REMOVAL

(1) Support front bumper on a suitable lifting

device.

(2) Remove bolts attaching front bumper outer

bracket to frame rail (Fig. 6).

(3) Remove nuts and stud plates attaching front

bumper to end of frame rail.

(4) Disengage wire connectors from fog lamps, if

equipped.

(5) Separate front bumper from vehicle.

Fig. 4 Fascia Adjustment Ribs

1 - FRONT UPPER FASCIA

2 - ADJUSTMENT RIBS

3 - FRONT LOWER FASCIA

Fig. 5 Front Bumper Lower Fascia

1 - LOWER FASCIA

2 - RETAINING CLIP

3 - BUMPER

BR/BEFRAME & BUMPERS 13 - 3

FRONT FASCIA (Continued)

Page 1479 of 2889

INSTALLATION

(1) Support front bumper on a suitable lifting

device.

(2) Position front bumper on vehicle.

(3) Engage fog lamp wire connectors, if equipped.

(4) Install nuts and stud plates attaching front

bumper to end of frame rail. Tighten nuts to 94 N´m

(70 ft. lbs.) torque.

(5) Install bolts attaching front bumper outer

bracket to frame rail. Tighten bolts to 94 N´m (70 ft.

lbs.) torque.

FRONT BUMPERÐSPORT

REMOVAL

(1) Disconnect wire connectors from fog lamps.

(2) Remove screws attaching fascia and outer

bumper brackets to wheelhouse liners.(3) Remove screws and push-in fasteners attaching

bottom of fascia to air deflector.

(4) Support bumper on a suitable lifting device.

(5) Remove nuts attaching bumper to inner

bumper brackets (Fig. 7).

(6) Separate bumper from vehicle.

INSTALLATION

(1) Support bumper on a suitable lifting device.

(2) Position bumper on vehicle.

(3) Install nuts attaching bumper to inner bumper

brackets. Tighten nuts to 94 N´m (70 ft. lbs.) torque.

(4) Install screws and push-in fasteners attaching

bottom of fascia to air deflector.

(5) Align fascia and wheelhouse liners with outer

bumper brackets and install screws. See fascia

adjustment in this section.

(6) Connect wire connectors to fog lamps.

Fig. 6 Front Bumper

1 - U-NUT

2 - FRAME

3 - INNER BUMPER BRACKET

4 - FOGLAMP SIGHT SHIELD

5 - BUMPER

6 - 4±WAY CENTER LOCATOR

7 - BLIND PLASTIC RIVET

8 - UPPER FASCIA9 - LOWER FASCIA

10 - AIR DAM

11 - BLIND PLASTIC RIVET

12 - BLIND PLASTIC RIVET

13 - U-NUT

14 - BLIND RIVET

15 - OUTER BUMPER BRACKET

13 - 4 FRAME & BUMPERSBR/BE

FRONT BUMPER (Continued)

Page 1480 of 2889

REAR BUMPER

REMOVAL

(1) Support rear bumper on a suitable lifting

device.

(2) Remove nuts attaching rear bumper to inner

and outer brackets (Fig. 8).

(3) Disengage license plate lamp wire connector

from body wire harness, if equipped.

(4) Separate rear bumper from vehicle.

INSTALLATION

(1) Support rear bumper on a suitable lifting

device.

(2) Position rear bumper on vehicle.

(3) Engage license plate lamp wire connector to

body wire harness, if equipped.

(4) Install nuts attaching rear bumper to inner

and outer brackets. Tighten nuts to 94 N´m (70 ft.

lbs.) torque.

Fig. 7 Front Bumper & Fascia Ð Sport

1 - FASCIA

2 - U-NUT

3 - RETAINING CLIP

4 - OUTER BRACKET

5 - INNER BRACKET

6 - FRAME7 - FASCIA SUPPORT

8 - OUTER BRACKET

9 - PUSH-IN FASTENER

10 - AIR DEFLECTOR

11 - BUMPER

BR/BEFRAME & BUMPERS 13 - 5

FRONT BUMPERÐSPORT (Continued)