DODGE RAM 2001 Service Repair Manual

Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 2321 of 2889

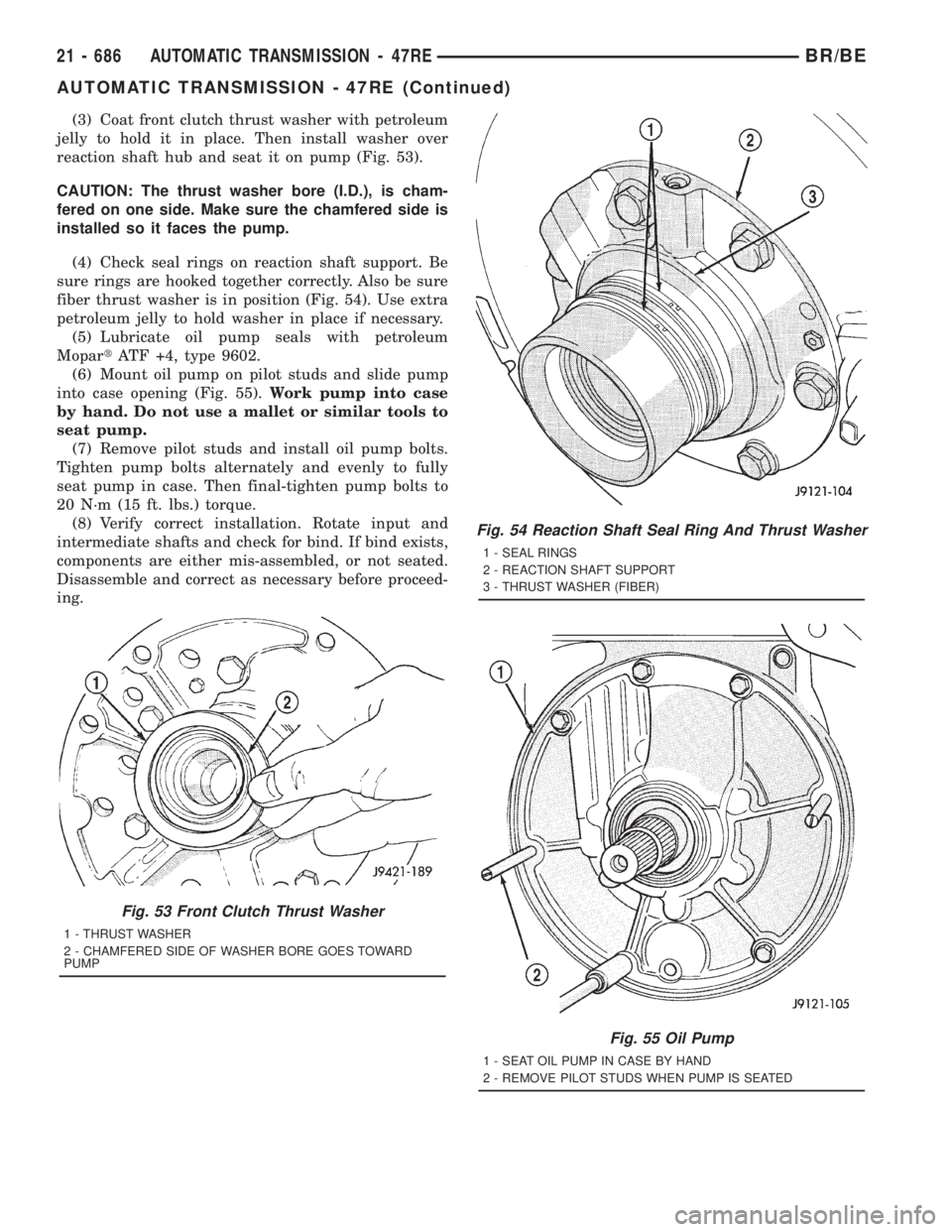

(3) Coat front clutch thrust washer with petroleum

jelly to hold it in place. Then install washer over

reaction shaft hub and seat it on pump (Fig. 53).

CAUTION: The thrust washer bore (I.D.), is cham-

fered on one side. Make sure the chamfered side is

installed so it faces the pump.

(4) Check seal rings on reaction shaft support. Be

sure rings are hooked together correctly. Also be sure

fiber thrust washer is in position (Fig. 54). Use extra

petroleum jelly to hold washer in place if necessary.

(5) Lubricate oil pump seals with petroleum

MopartATF +4, type 9602.

(6) Mount oil pump on pilot studs and slide pump

into case opening (Fig. 55).Work pump into case

by hand. Do not use a mallet or similar tools to

seat pump.

(7) Remove pilot studs and install oil pump bolts.

Tighten pump bolts alternately and evenly to fully

seat pump in case. Then final-tighten pump bolts to

20 N´m (15 ft. lbs.) torque.

(8) Verify correct installation. Rotate input and

intermediate shafts and check for bind. If bind exists,

components are either mis-assembled, or not seated.

Disassemble and correct as necessary before proceed-

ing.

Fig. 53 Front Clutch Thrust Washer

1 - THRUST WASHER

2 - CHAMFERED SIDE OF WASHER BORE GOES TOWARD

PUMP

Fig. 54 Reaction Shaft Seal Ring And Thrust Washer

1 - SEAL RINGS

2 - REACTION SHAFT SUPPORT

3 - THRUST WASHER (FIBER)

Fig. 55 Oil Pump

1 - SEAT OIL PUMP IN CASE BY HAND

2 - REMOVE PILOT STUDS WHEN PUMP IS SEATED

21 - 686 AUTOMATIC TRANSMISSION - 47REBR/BE

AUTOMATIC TRANSMISSION - 47RE (Continued)

Page 2322 of 2889

INPUT SHAFT END PLAY CHECK

NOTE: Overdrive unit must be installed in order to

correctly measure the input shaft end-play.

(1) Measure input shaft end play (Fig. 56).

NOTE: If end play is incorrect, transmission is

incorrectly assembled, or reaction shaft thrust

washer is incorrect. The reaction shaft thrust

washer is selective.

(a) Attach Adapter 8266-5 to Handle 8266-8.

(b) Attach dial indicator C-3339 to Handle

8266-8.

(c) Install the assembled tool onto the input

shaft of the transmission and tighten the retaining

screw on Adapter 8266-5 to secure it to the input

shaft.

(d) Position the dial indicator plunger against a

flat spot on the oil pump and zero the dial indica-

tor.

(e) Move input shaft in and out and record read-

ing. End play should be 0.86 - 2.13 mm (0.034 -

0.084 in.). Adjust as necessary.

ACCUMULATOR, VALVE BODY, OIL PAN, AND

TORQUE CONVERTER

(1) Install accumulator inner spring, piston and

outer spring (Fig. 57).(2) Verify that park/neutral position switch has

notbeen installed in case. Valve body can not be

installed if switch is in position.

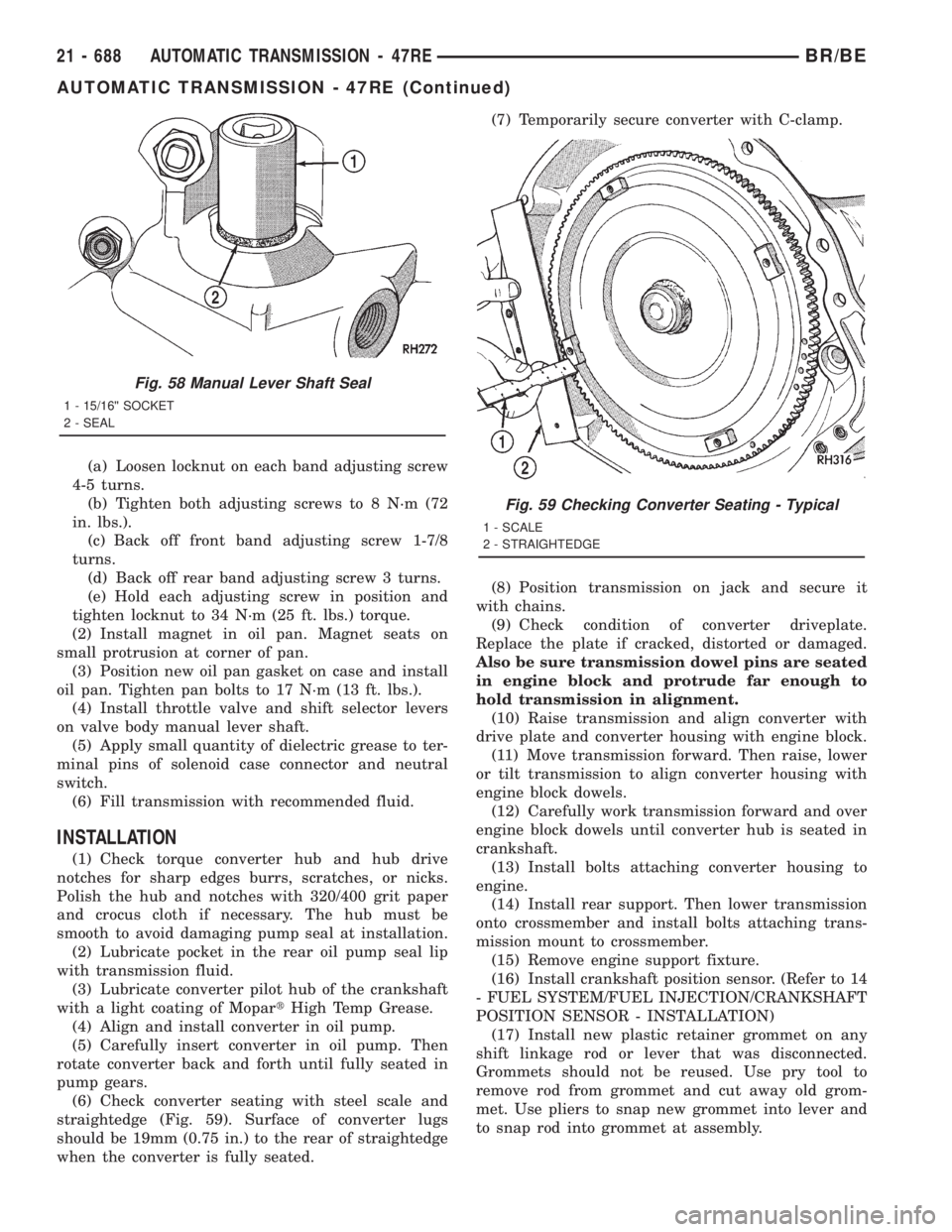

(3) Install new valve body manual shaft seal in

case (Fig. 58). Lubricate seal lip and manual shaft

with petroleum jelly. Start seal over shaft and into

case. Seat seal with 15/16 inch, deep well socket.

(4) Install valve body as follows:

(a) Start park rod into park pawl. If rod will not

slide past park pawl, pawl is engaged in park gear.

Rotate overdrive output shaft with suitable size 12

point socket; this will free pawl and allow rod to

engage.

(b) Align and seat valve body on case. Be sure

manual lever shaft and overdrive connector are

fully seated in case.

(c) Install and start all valve body attaching

bolts by hand. Then tighten bolts evenly, in a diag-

onal pattern to 12 N´m (105 in. lbs.) torque.Do

not overtighten valve body bolts. This could

result in distortion and cross leakage after

installation..

(5) Install new filter on valve body. Tighten filter

screws to 4 N´m (35 in. lbs.).

(6) Install seal on park/neutral position switch.

Then install and tighten switch to 34 N´m (25 ft.

lbs.).

CAUTION: If the condition of the transmission

before the overhaul procedure caused excessive

metallic or fiber contamination in the fluid, replace

the torque converter and reverse flush the cooler(s)

and cooler lines. Fluid contamination and transmis-

sion failure can result if not done.

(7) Install torque converter. Use C-clamp or metal

strap to hold converter in place for installation.

BAND ADJUSTMENT AND FINAL

(1) Adjust front and rear bands as follows:

Fig. 56 Checking Input Shaft End Play

1 - TOOL 8266-8

2 - TOOL 8266-5

3 - TOOL C-3339

Fig. 57 Accumulator Piston And Springs

1 - ACCUMULATOR PISTON

2 - OUTER SPRING

3 - INNER SPRING

BR/BEAUTOMATIC TRANSMISSION - 47RE 21 - 687

AUTOMATIC TRANSMISSION - 47RE (Continued)

Page 2323 of 2889

(a) Loosen locknut on each band adjusting screw

4-5 turns.

(b) Tighten both adjusting screws to 8 N´m (72

in. lbs.).

(c) Back off front band adjusting screw 1-7/8

turns.

(d) Back off rear band adjusting screw 3 turns.

(e) Hold each adjusting screw in position and

tighten locknut to 34 N´m (25 ft. lbs.) torque.

(2) Install magnet in oil pan. Magnet seats on

small protrusion at corner of pan.

(3) Position new oil pan gasket on case and install

oil pan. Tighten pan bolts to 17 N´m (13 ft. lbs.).

(4) Install throttle valve and shift selector levers

on valve body manual lever shaft.

(5) Apply small quantity of dielectric grease to ter-

minal pins of solenoid case connector and neutral

switch.

(6) Fill transmission with recommended fluid.

INSTALLATION

(1) Check torque converter hub and hub drive

notches for sharp edges burrs, scratches, or nicks.

Polish the hub and notches with 320/400 grit paper

and crocus cloth if necessary. The hub must be

smooth to avoid damaging pump seal at installation.

(2) Lubricate pocket in the rear oil pump seal lip

with transmission fluid.

(3) Lubricate converter pilot hub of the crankshaft

with a light coating of MopartHigh Temp Grease.

(4) Align and install converter in oil pump.

(5) Carefully insert converter in oil pump. Then

rotate converter back and forth until fully seated in

pump gears.

(6) Check converter seating with steel scale and

straightedge (Fig. 59). Surface of converter lugs

should be 19mm (0.75 in.) to the rear of straightedge

when the converter is fully seated.(7) Temporarily secure converter with C-clamp.

(8) Position transmission on jack and secure it

with chains.

(9) Check condition of converter driveplate.

Replace the plate if cracked, distorted or damaged.

Also be sure transmission dowel pins are seated

in engine block and protrude far enough to

hold transmission in alignment.

(10) Raise transmission and align converter with

drive plate and converter housing with engine block.

(11) Move transmission forward. Then raise, lower

or tilt transmission to align converter housing with

engine block dowels.

(12) Carefully work transmission forward and over

engine block dowels until converter hub is seated in

crankshaft.

(13) Install bolts attaching converter housing to

engine.

(14) Install rear support. Then lower transmission

onto crossmember and install bolts attaching trans-

mission mount to crossmember.

(15) Remove engine support fixture.

(16) Install crankshaft position sensor. (Refer to 14

- FUEL SYSTEM/FUEL INJECTION/CRANKSHAFT

POSITION SENSOR - INSTALLATION)

(17) Install new plastic retainer grommet on any

shift linkage rod or lever that was disconnected.

Grommets should not be reused. Use pry tool to

remove rod from grommet and cut away old grom-

met. Use pliers to snap new grommet into lever and

to snap rod into grommet at assembly.

Fig. 58 Manual Lever Shaft Seal

1 - 15/16©© SOCKET

2 - SEAL

Fig. 59 Checking Converter Seating - Typical

1 - SCALE

2 - STRAIGHTEDGE

21 - 688 AUTOMATIC TRANSMISSION - 47REBR/BE

AUTOMATIC TRANSMISSION - 47RE (Continued)

Page 2324 of 2889

(18) Connect gearshift and throttle cable to trans-

mission.

(19) Connect wires to park/neutral position switch,

transmission solenoid(s) and oxygen sensor. Be sure

transmission harnesses are properly routed.

CAUTION: It is essential that correct length bolts be

used to attach the converter to the driveplate. Bolts

that are too long will damage the clutch surface

inside the converter.

(20) Install torque converter-to-driveplate bolts.

Tighten bolts to 47 N´m (35 ft. lbs.).

(21) Install converter housing access cover.

(22) Install starter motor and cooler line bracket.

(Refer to 8 - ELECTRICAL/STARTING/STARTER

MOTOR - INSTALLATION)(23) Connect cooler lines to transmission.

(24) Install transmission fill tube. Install new seal

on tube before installation.

(25) Install exhaust components.

(26) Align and connect propeller shaft. (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - INSTALLATION)

(27) Adjust gearshift linkage and throttle valve

cable if necessary.

(28) Lower vehicle.

(29) Fill transmission with MopartATF +4, type

9602, Automatic Transmission fluid.

BR/BEAUTOMATIC TRANSMISSION - 47RE 21 - 689

AUTOMATIC TRANSMISSION - 47RE (Continued)

Page 2325 of 2889

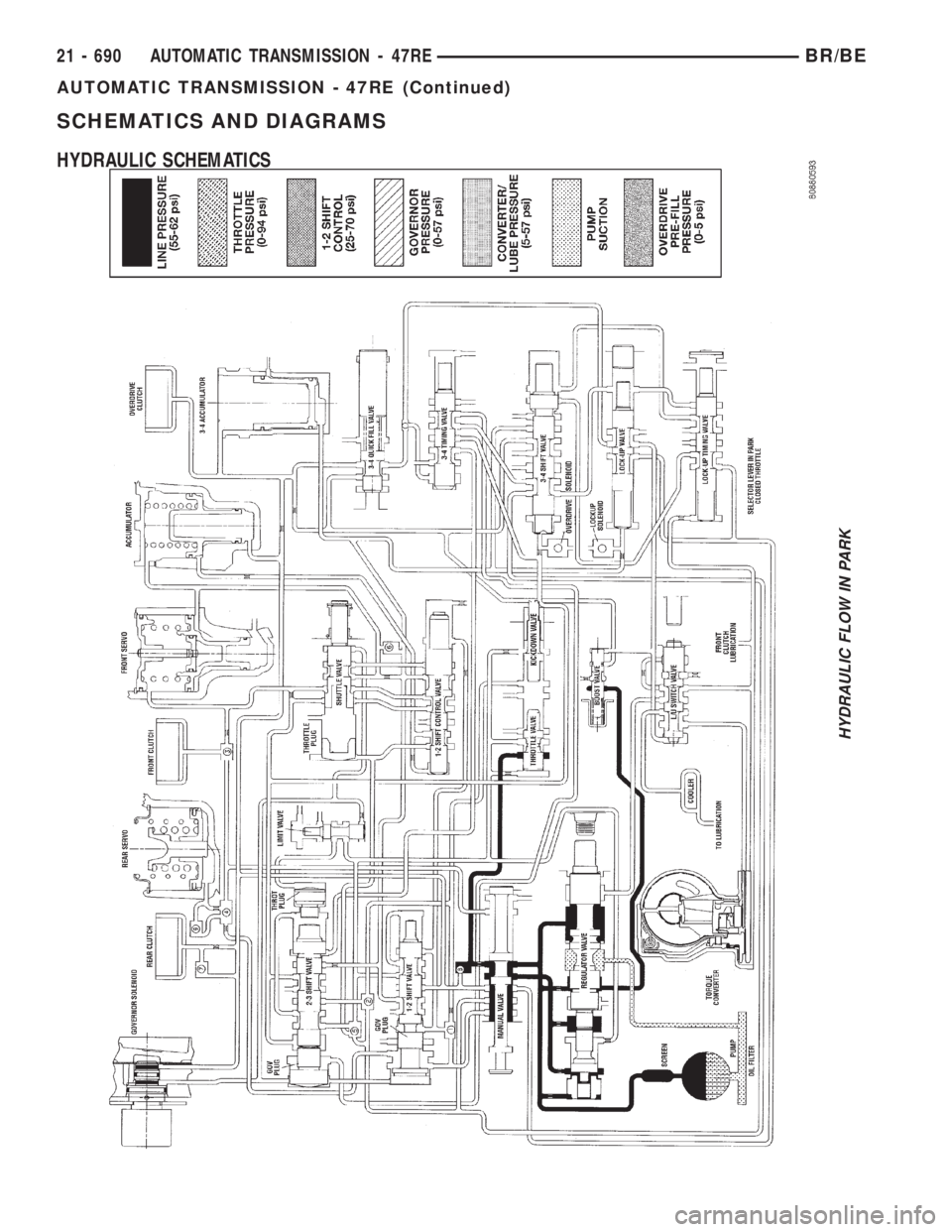

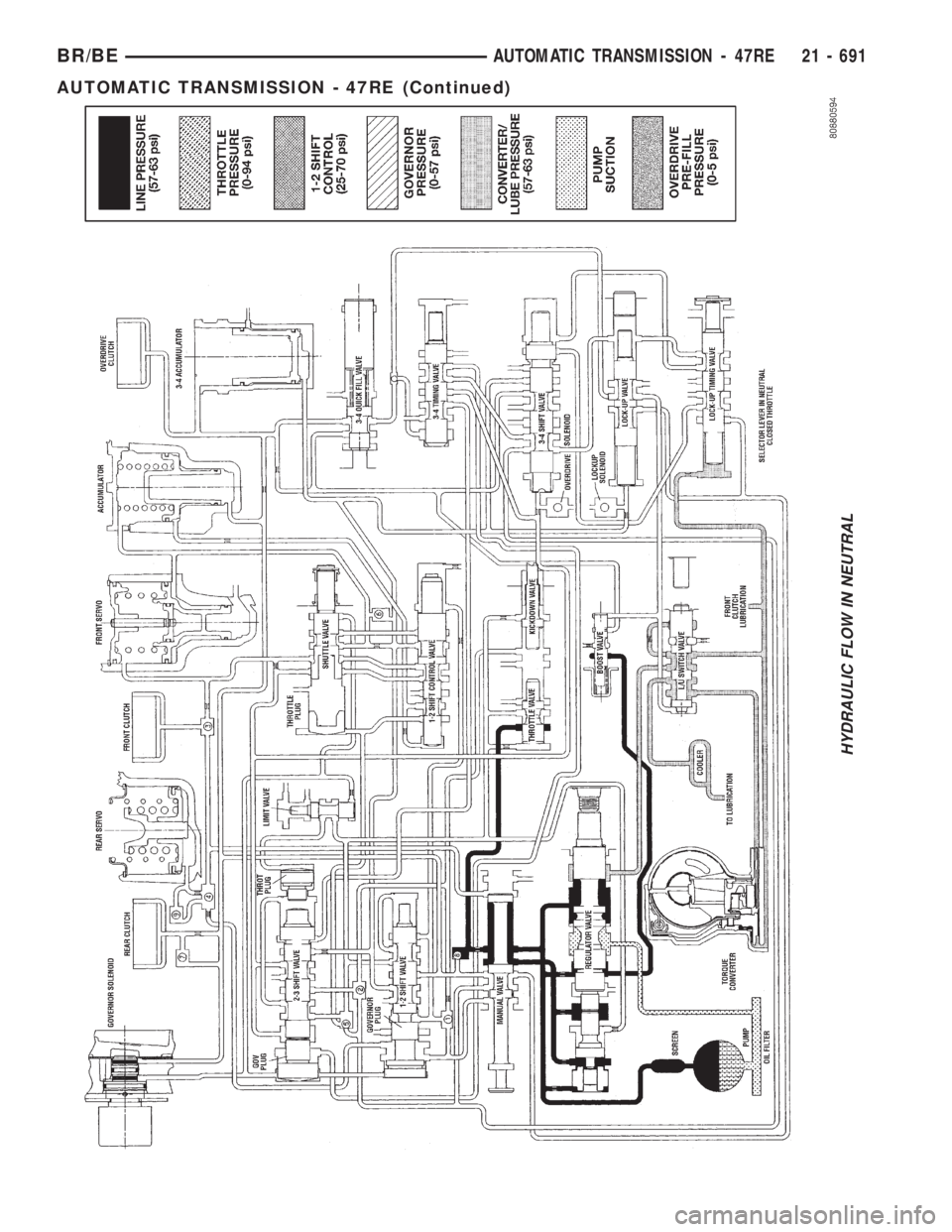

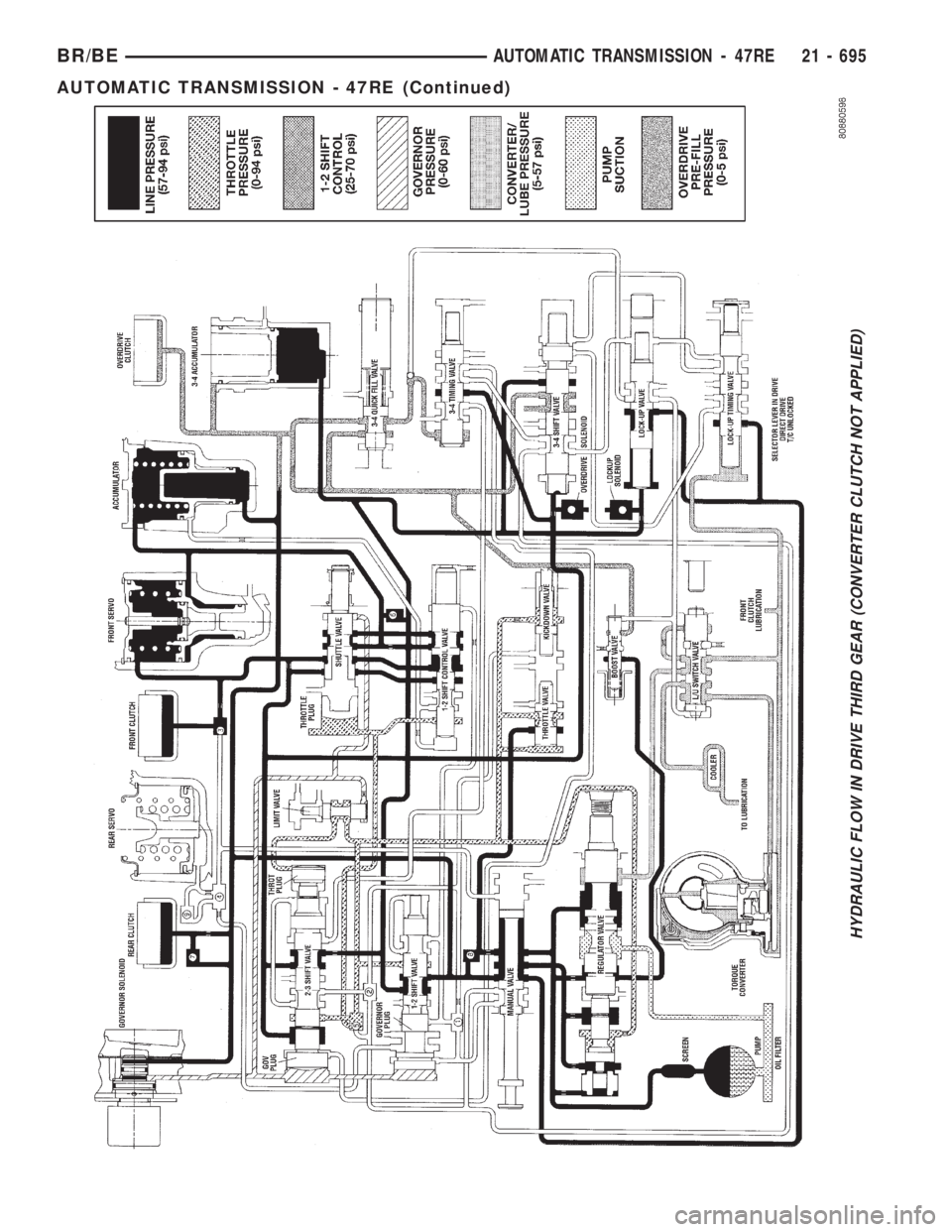

SCHEMATICS AND DIAGRAMS

HYDRAULIC SCHEMATICS

HYDRAULIC FLOW IN PARK

21 - 690 AUTOMATIC TRANSMISSION - 47REBR/BE

AUTOMATIC TRANSMISSION - 47RE (Continued)

Page 2326 of 2889

HYDRAULIC FLOW IN NEUTRAL

BR/BEAUTOMATIC TRANSMISSION - 47RE 21 - 691

AUTOMATIC TRANSMISSION - 47RE (Continued)

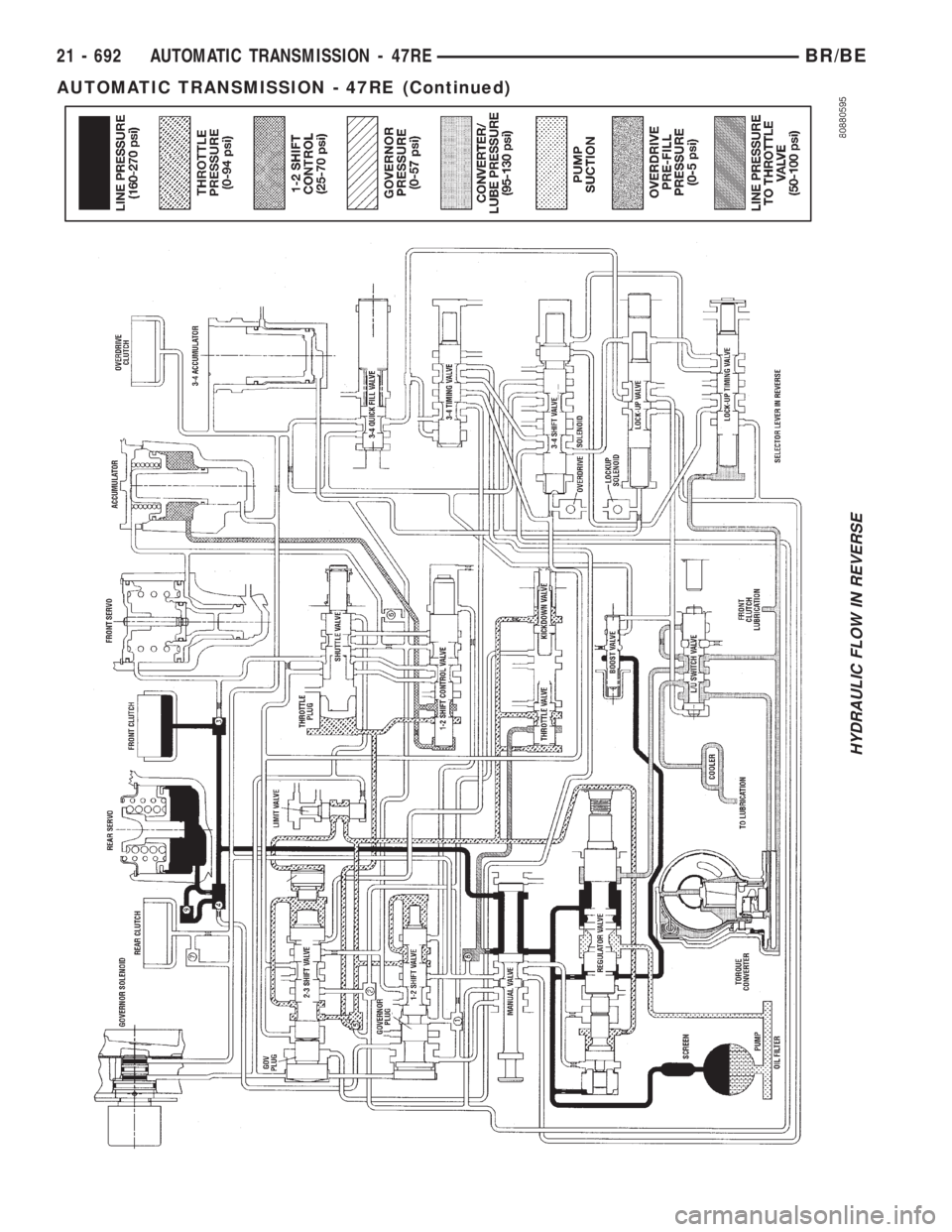

Page 2327 of 2889

HYDRAULIC FLOW IN REVERSE

21 - 692 AUTOMATIC TRANSMISSION - 47REBR/BE

AUTOMATIC TRANSMISSION - 47RE (Continued)

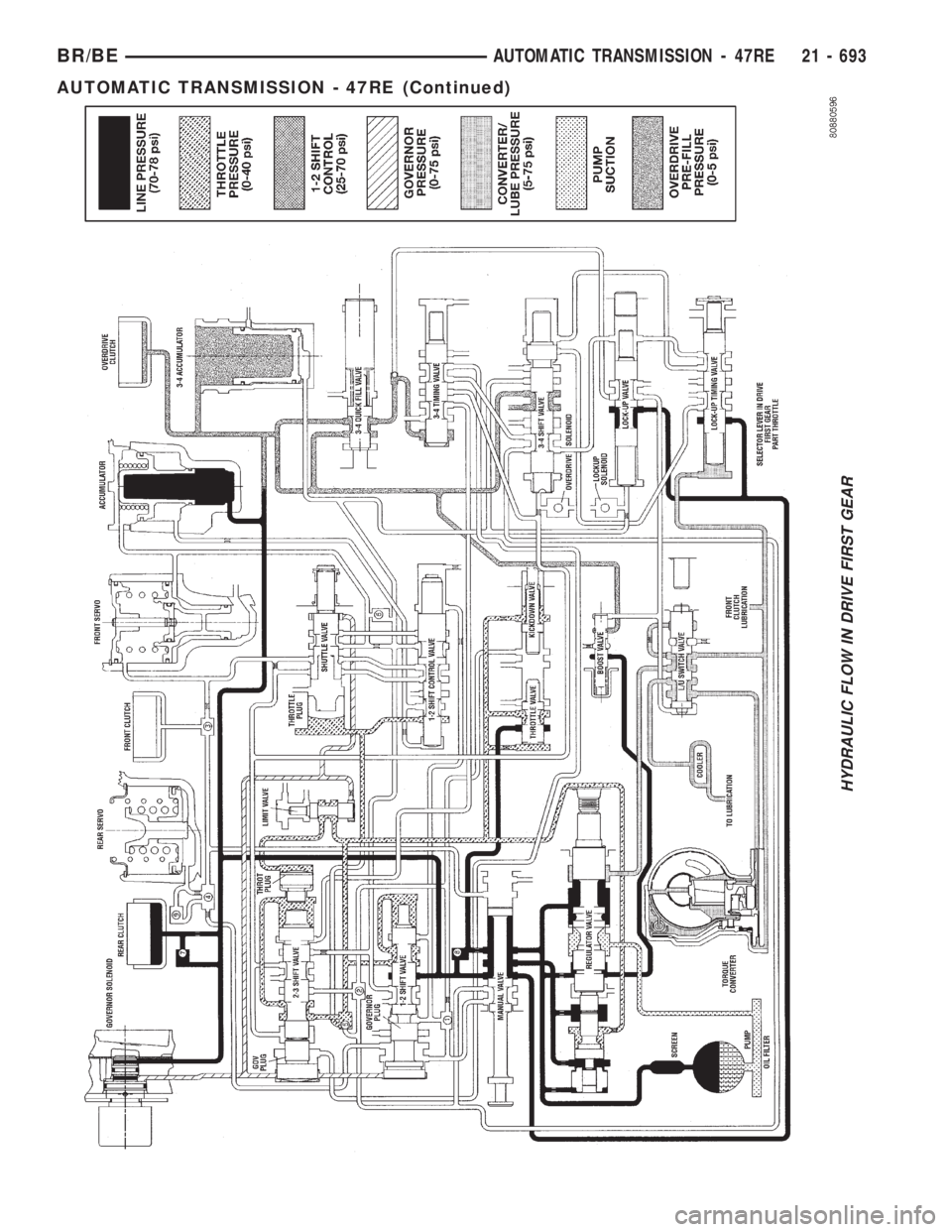

Page 2328 of 2889

HYDRAULIC FLOW IN DRIVE FIRST GEAR

BR/BEAUTOMATIC TRANSMISSION - 47RE 21 - 693

AUTOMATIC TRANSMISSION - 47RE (Continued)

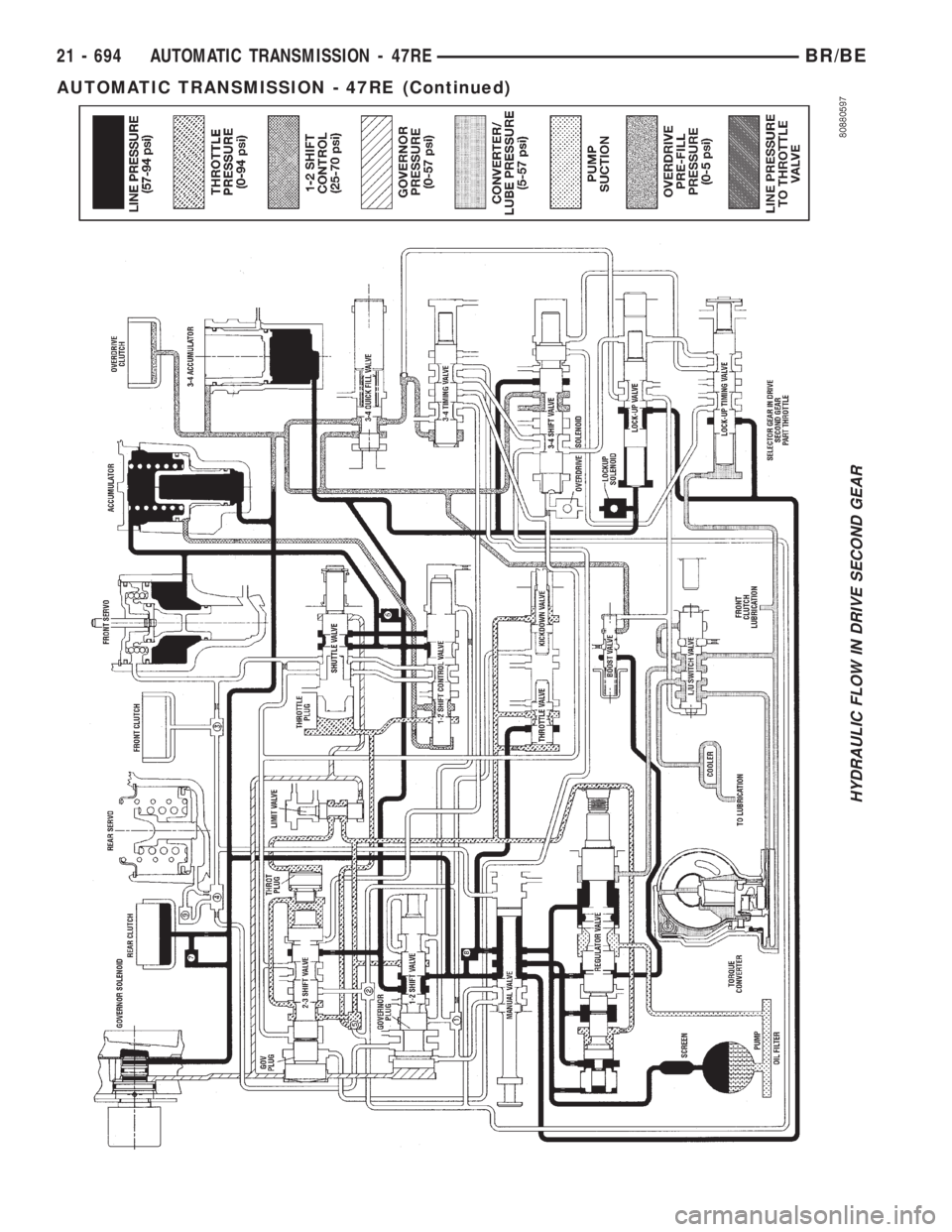

Page 2329 of 2889

HYDRAULIC FLOW IN DRIVE SECOND GEAR

21 - 694 AUTOMATIC TRANSMISSION - 47REBR/BE

AUTOMATIC TRANSMISSION - 47RE (Continued)

Page 2330 of 2889

HYDRAULIC FLOW IN DRIVE THIRD GEAR (CONVERTER CLUTCH NOT APPLIED)

BR/BEAUTOMATIC TRANSMISSION - 47RE 21 - 695

AUTOMATIC TRANSMISSION - 47RE (Continued)