DODGE RAM 2001 Service Repair Manual

Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 331 of 2889

OPERATION

The pilot bearing supports the transmission input

shaft, maintains proper clutch assembly alignment

and allows the transmission input shaft to rotate at a

different speed (RPM) than the engine mounted

crankshaft.

When the clutch pedal is depressed (with vehicle in

drive mode) the clutch disc slows and stops therefore,

the transmission input shaft slows and stops as well.

The pilot bearing allows the engine crankshaft to

continue to rotate even though the transmission

input shaft is stationary.

REMOVAL

(1) Remove transmission, transfer case, if

equipped, and clutch housing. Refer to Group 21,

Transmission and Transfer Case, for proper proce-

dures.

(2) Remove clutch cover and disc.

(3) Using a suitable blind hole puller, remove pilot

bearing.

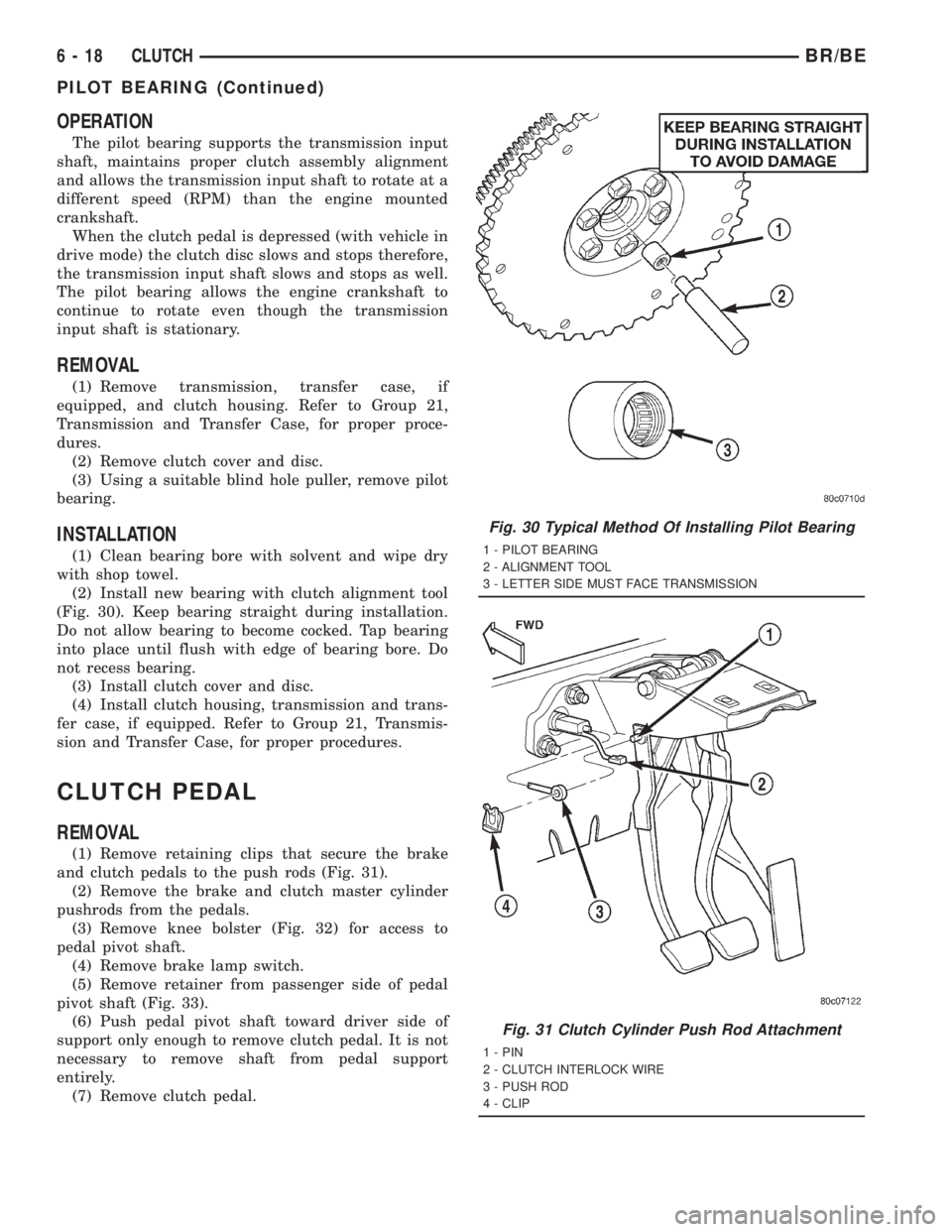

INSTALLATION

(1) Clean bearing bore with solvent and wipe dry

with shop towel.

(2) Install new bearing with clutch alignment tool

(Fig. 30). Keep bearing straight during installation.

Do not allow bearing to become cocked. Tap bearing

into place until flush with edge of bearing bore. Do

not recess bearing.

(3) Install clutch cover and disc.

(4) Install clutch housing, transmission and trans-

fer case, if equipped. Refer to Group 21, Transmis-

sion and Transfer Case, for proper procedures.

CLUTCH PEDAL

REMOVAL

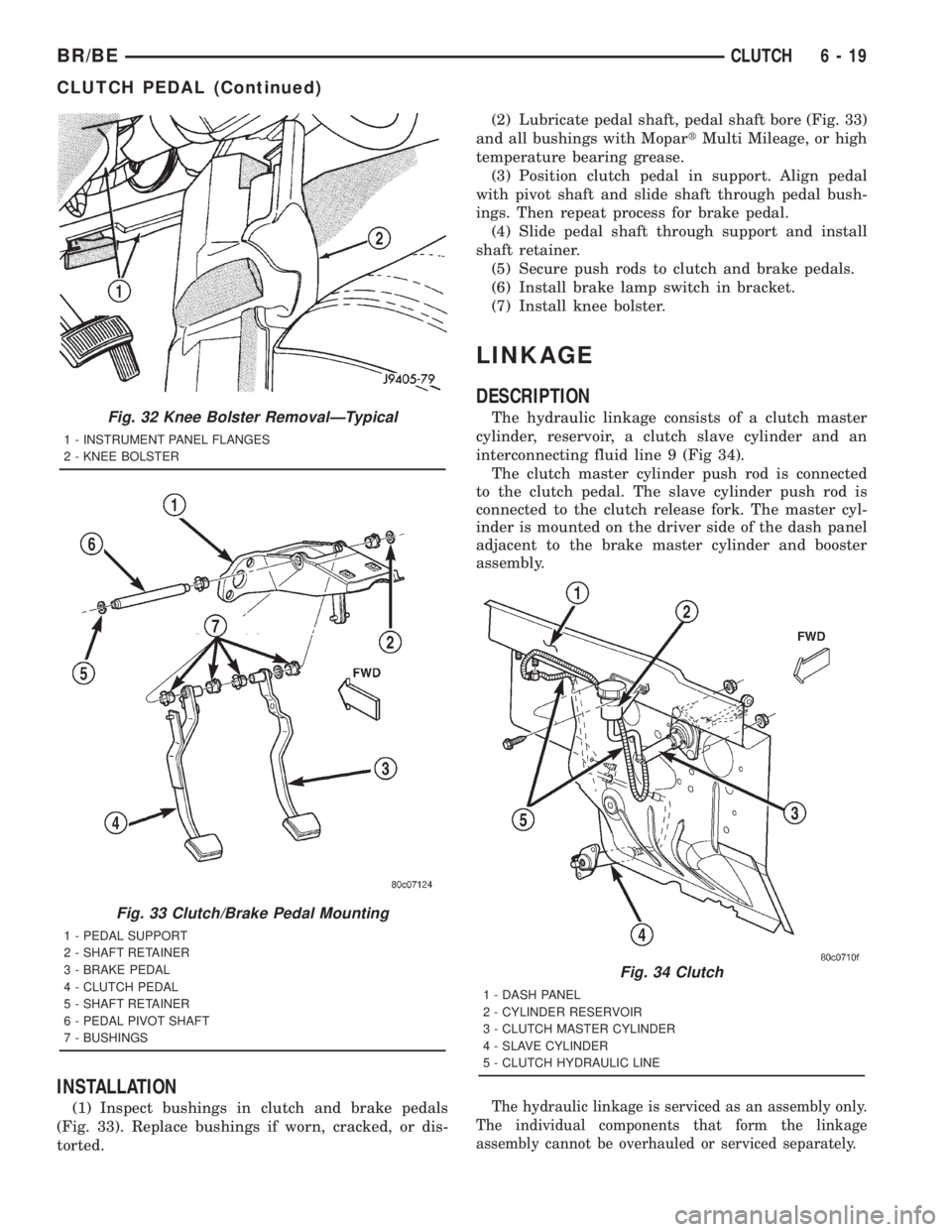

(1) Remove retaining clips that secure the brake

and clutch pedals to the push rods (Fig. 31).

(2) Remove the brake and clutch master cylinder

pushrods from the pedals.

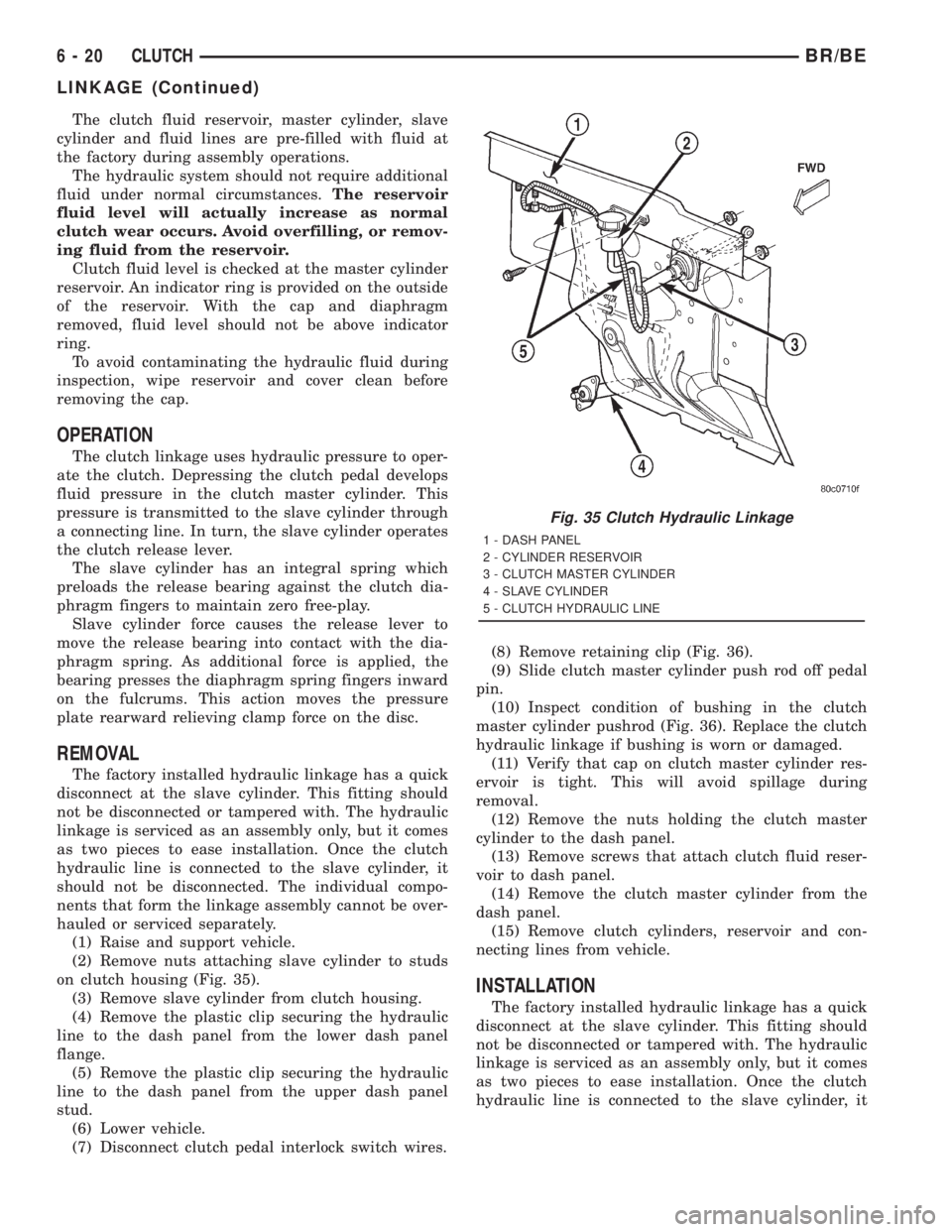

(3) Remove knee bolster (Fig. 32) for access to

pedal pivot shaft.

(4) Remove brake lamp switch.

(5) Remove retainer from passenger side of pedal

pivot shaft (Fig. 33).

(6) Push pedal pivot shaft toward driver side of

support only enough to remove clutch pedal. It is not

necessary to remove shaft from pedal support

entirely.

(7) Remove clutch pedal.

Fig. 30 Typical Method Of Installing Pilot Bearing

1 - PILOT BEARING

2 - ALIGNMENT TOOL

3 - LETTER SIDE MUST FACE TRANSMISSION

Fig. 31 Clutch Cylinder Push Rod Attachment

1 - PIN

2 - CLUTCH INTERLOCK WIRE

3 - PUSH ROD

4 - CLIP

6 - 18 CLUTCHBR/BE

PILOT BEARING (Continued)

Page 332 of 2889

INSTALLATION

(1) Inspect bushings in clutch and brake pedals

(Fig. 33). Replace bushings if worn, cracked, or dis-

torted.(2) Lubricate pedal shaft, pedal shaft bore (Fig. 33)

and all bushings with MopartMulti Mileage, or high

temperature bearing grease.

(3) Position clutch pedal in support. Align pedal

with pivot shaft and slide shaft through pedal bush-

ings. Then repeat process for brake pedal.

(4) Slide pedal shaft through support and install

shaft retainer.

(5) Secure push rods to clutch and brake pedals.

(6) Install brake lamp switch in bracket.

(7) Install knee bolster.

LINKAGE

DESCRIPTION

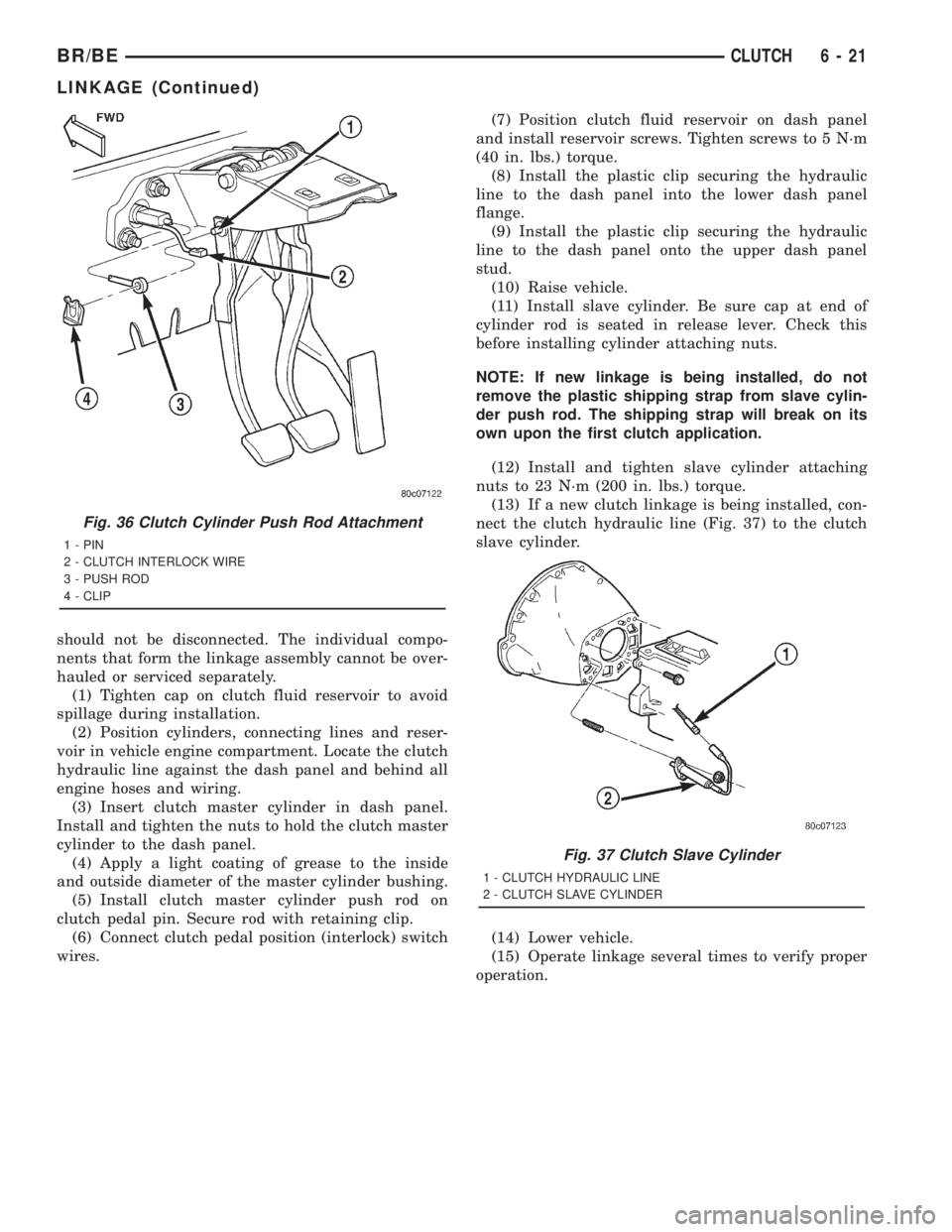

The hydraulic linkage consists of a clutch master

cylinder, reservoir, a clutch slave cylinder and an

interconnecting fluid line 9 (Fig 34).

The clutch master cylinder push rod is connected

to the clutch pedal. The slave cylinder push rod is

connected to the clutch release fork. The master cyl-

inder is mounted on the driver side of the dash panel

adjacent to the brake master cylinder and booster

assembly.

The hydraulic linkage is serviced as an assembly only.

The individual components that form the linkage

assembly cannot be overhauled or serviced separately.

Fig. 32 Knee Bolster RemovalÐTypical

1 - INSTRUMENT PANEL FLANGES

2 - KNEE BOLSTER

Fig. 33 Clutch/Brake Pedal Mounting

1 - PEDAL SUPPORT

2 - SHAFT RETAINER

3 - BRAKE PEDAL

4 - CLUTCH PEDAL

5 - SHAFT RETAINER

6 - PEDAL PIVOT SHAFT

7 - BUSHINGS

Fig. 34 Clutch

1 - DASH PANEL

2 - CYLINDER RESERVOIR

3 - CLUTCH MASTER CYLINDER

4 - SLAVE CYLINDER

5 - CLUTCH HYDRAULIC LINE

BR/BECLUTCH 6 - 19

CLUTCH PEDAL (Continued)

Page 333 of 2889

The clutch fluid reservoir, master cylinder, slave

cylinder and fluid lines are pre-filled with fluid at

the factory during assembly operations.

The hydraulic system should not require additional

fluid under normal circumstances.The reservoir

fluid level will actually increase as normal

clutch wear occurs. Avoid overfilling, or remov-

ing fluid from the reservoir.

Clutch fluid level is checked at the master cylinder

reservoir. An indicator ring is provided on the outside

of the reservoir. With the cap and diaphragm

removed, fluid level should not be above indicator

ring.

To avoid contaminating the hydraulic fluid during

inspection, wipe reservoir and cover clean before

removing the cap.

OPERATION

The clutch linkage uses hydraulic pressure to oper-

ate the clutch. Depressing the clutch pedal develops

fluid pressure in the clutch master cylinder. This

pressure is transmitted to the slave cylinder through

a connecting line. In turn, the slave cylinder operates

the clutch release lever.

The slave cylinder has an integral spring which

preloads the release bearing against the clutch dia-

phragm fingers to maintain zero free-play.

Slave cylinder force causes the release lever to

move the release bearing into contact with the dia-

phragm spring. As additional force is applied, the

bearing presses the diaphragm spring fingers inward

on the fulcrums. This action moves the pressure

plate rearward relieving clamp force on the disc.

REMOVAL

The factory installed hydraulic linkage has a quick

disconnect at the slave cylinder. This fitting should

not be disconnected or tampered with. The hydraulic

linkage is serviced as an assembly only, but it comes

as two pieces to ease installation. Once the clutch

hydraulic line is connected to the slave cylinder, it

should not be disconnected. The individual compo-

nents that form the linkage assembly cannot be over-

hauled or serviced separately.

(1) Raise and support vehicle.

(2) Remove nuts attaching slave cylinder to studs

on clutch housing (Fig. 35).

(3) Remove slave cylinder from clutch housing.

(4) Remove the plastic clip securing the hydraulic

line to the dash panel from the lower dash panel

flange.

(5) Remove the plastic clip securing the hydraulic

line to the dash panel from the upper dash panel

stud.

(6) Lower vehicle.

(7) Disconnect clutch pedal interlock switch wires.(8) Remove retaining clip (Fig. 36).

(9) Slide clutch master cylinder push rod off pedal

pin.

(10) Inspect condition of bushing in the clutch

master cylinder pushrod (Fig. 36). Replace the clutch

hydraulic linkage if bushing is worn or damaged.

(11) Verify that cap on clutch master cylinder res-

ervoir is tight. This will avoid spillage during

removal.

(12) Remove the nuts holding the clutch master

cylinder to the dash panel.

(13) Remove screws that attach clutch fluid reser-

voir to dash panel.

(14) Remove the clutch master cylinder from the

dash panel.

(15) Remove clutch cylinders, reservoir and con-

necting lines from vehicle.

INSTALLATION

The factory installed hydraulic linkage has a quick

disconnect at the slave cylinder. This fitting should

not be disconnected or tampered with. The hydraulic

linkage is serviced as an assembly only, but it comes

as two pieces to ease installation. Once the clutch

hydraulic line is connected to the slave cylinder, it

Fig. 35 Clutch Hydraulic Linkage

1 - DASH PANEL

2 - CYLINDER RESERVOIR

3 - CLUTCH MASTER CYLINDER

4 - SLAVE CYLINDER

5 - CLUTCH HYDRAULIC LINE

6 - 20 CLUTCHBR/BE

LINKAGE (Continued)

Page 334 of 2889

should not be disconnected. The individual compo-

nents that form the linkage assembly cannot be over-

hauled or serviced separately.

(1) Tighten cap on clutch fluid reservoir to avoid

spillage during installation.

(2) Position cylinders, connecting lines and reser-

voir in vehicle engine compartment. Locate the clutch

hydraulic line against the dash panel and behind all

engine hoses and wiring.

(3) Insert clutch master cylinder in dash panel.

Install and tighten the nuts to hold the clutch master

cylinder to the dash panel.

(4) Apply a light coating of grease to the inside

and outside diameter of the master cylinder bushing.

(5) Install clutch master cylinder push rod on

clutch pedal pin. Secure rod with retaining clip.

(6) Connect clutch pedal position (interlock) switch

wires.(7) Position clutch fluid reservoir on dash panel

and install reservoir screws. Tighten screws to 5 N´m

(40 in. lbs.) torque.

(8) Install the plastic clip securing the hydraulic

line to the dash panel into the lower dash panel

flange.

(9) Install the plastic clip securing the hydraulic

line to the dash panel onto the upper dash panel

stud.

(10) Raise vehicle.

(11) Install slave cylinder. Be sure cap at end of

cylinder rod is seated in release lever. Check this

before installing cylinder attaching nuts.

NOTE: If new linkage is being installed, do not

remove the plastic shipping strap from slave cylin-

der push rod. The shipping strap will break on its

own upon the first clutch application.

(12) Install and tighten slave cylinder attaching

nuts to 23 N´m (200 in. lbs.) torque.

(13) If a new clutch linkage is being installed, con-

nect the clutch hydraulic line (Fig. 37) to the clutch

slave cylinder.

(14) Lower vehicle.

(15) Operate linkage several times to verify proper

operation.

Fig. 36 Clutch Cylinder Push Rod Attachment

1 - PIN

2 - CLUTCH INTERLOCK WIRE

3 - PUSH ROD

4 - CLIP

Fig. 37 Clutch Slave Cylinder

1 - CLUTCH HYDRAULIC LINE

2 - CLUTCH SLAVE CYLINDER

BR/BECLUTCH 6 - 21

LINKAGE (Continued)

Page 335 of 2889

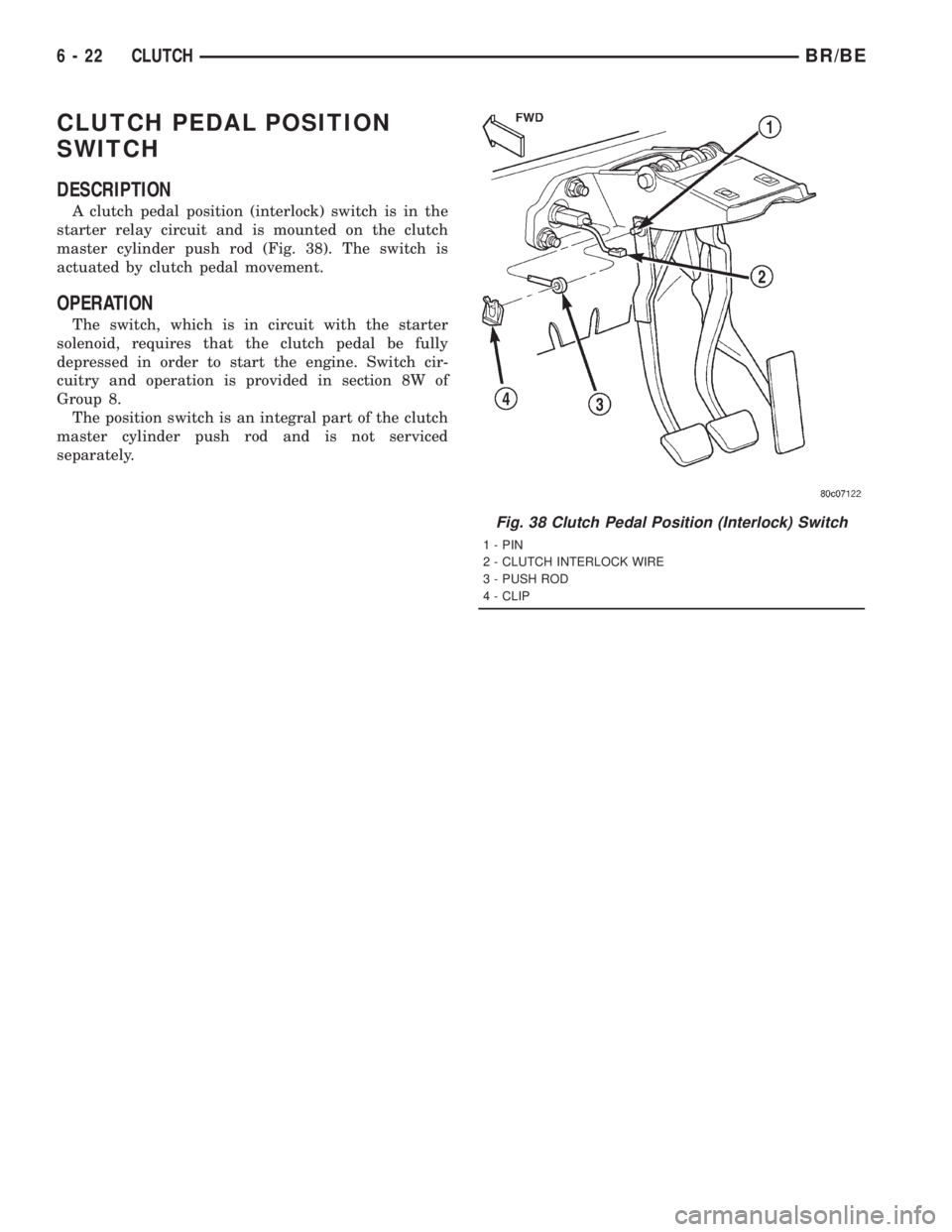

CLUTCH PEDAL POSITION

SWITCH

DESCRIPTION

A clutch pedal position (interlock) switch is in the

starter relay circuit and is mounted on the clutch

master cylinder push rod (Fig. 38). The switch is

actuated by clutch pedal movement.

OPERATION

The switch, which is in circuit with the starter

solenoid, requires that the clutch pedal be fully

depressed in order to start the engine. Switch cir-

cuitry and operation is provided in section 8W of

Group 8.

The position switch is an integral part of the clutch

master cylinder push rod and is not serviced

separately.

Fig. 38 Clutch Pedal Position (Interlock) Switch

1 - PIN

2 - CLUTCH INTERLOCK WIRE

3 - PUSH ROD

4 - CLIP

6 - 22 CLUTCHBR/BE

Page 336 of 2889

COOLING

TABLE OF CONTENTS

page page

COOLING

DESCRIPTION............................1

OPERATION.............................2

DIAGNOSIS AND TESTING..................4

PRELIMINARY CHECKS...................4

ON-BOARD DIAGNOSTICS (OBD)...........4

COOLING SYSTEM LEAKS................5

COOLING SYSTEM GAS ENGINE...........7

COOLING SYSTEM DIESEL ENGINE........12

STANDARD PROCEDURE..................15

DRAINING COOLING SYSTEM - 3.9L/5.2L/

5.9L/8.0L ENGINES......................15

DRAINING COOLING SYSTEM - 5.9L

DIESEL ENGINE........................15REFILLING COOLING SYSTEM - 3.9L/5.2L/

5.9L/8.0L ENGINES......................15

REFILLING COOLING SYSTEM - 5.9L

DIESEL ENGINE........................15

ADDING ADDITIONAL COOLANT...........16

COOLANT LEVEL CHECK................16

COOLING SYSTEM CLEANING/REVERSE

FLUSHING............................16

COOLANT SELECTION-ADDITIVES.........17

SPECIFICATIONS........................17

SPECIAL TOOLS.........................18

ACCESSORY DRIVE......................19

ENGINE................................39

TRANSMISSION.........................79

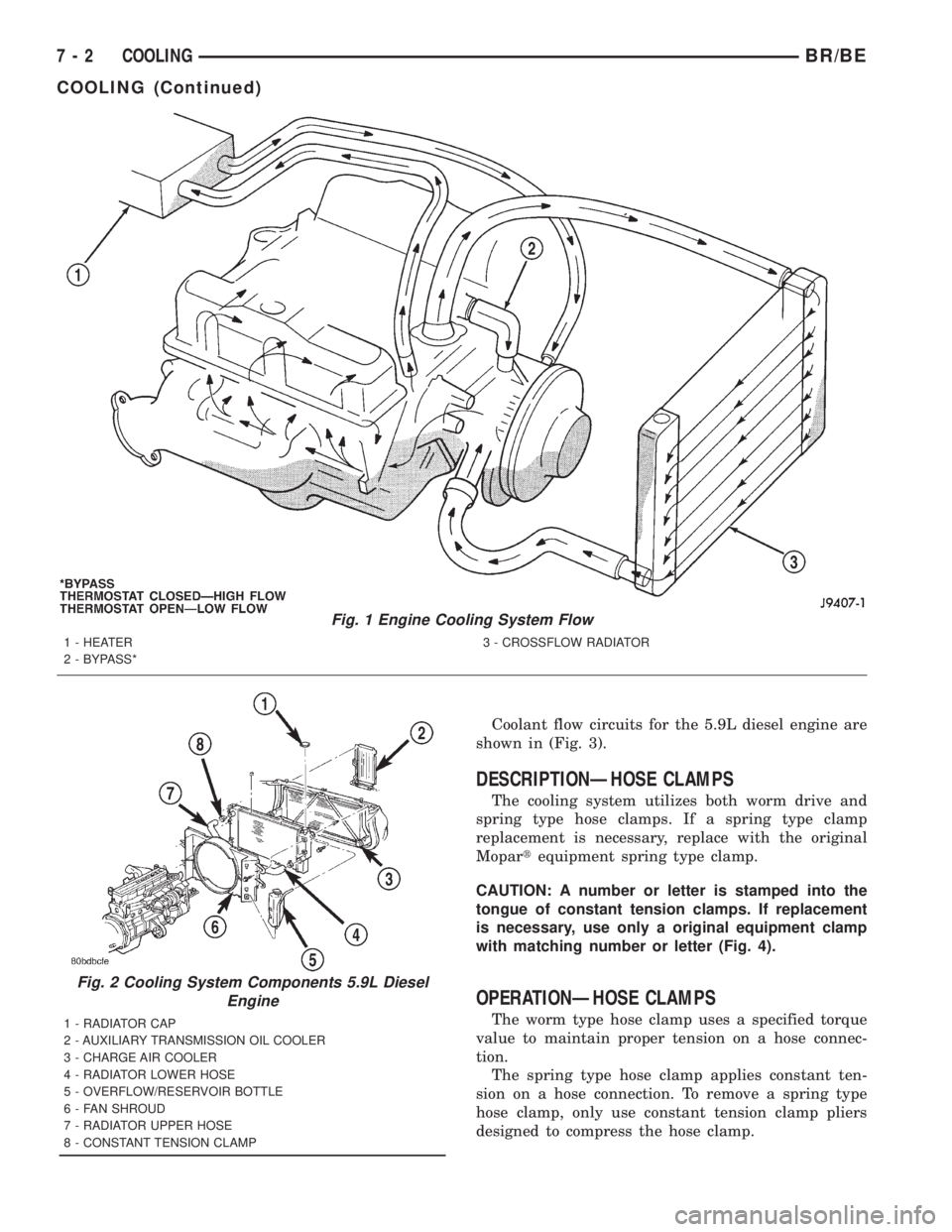

COOLING

DESCRIPTIONÐCOOLING SYSTEM FLOW -

3.9L/5.2L/5.9L ENGINE

The cooling system regulates engine operating tem-

perature. It allows the engine to reach normal oper-

ating temperature as quickly as possible. It also

maintains normal operating temperature and pre-

vents overheating.

The cooling system also provides a means of heat-

ing the passenger compartment and cooling the auto-

matic transmission fluid (if equipped). The cooling

system is pressurized and uses a centrifugal water

pump to circulate coolant throughout the system.

An optional factory installed maximum duty cool-

ing package is available on most models. This pack-

age will provide additional cooling capacity forvehicles used under extreme conditions such as

trailer towing in high ambient temperatures (Fig. 1).

DESCRIPTIONÐCOOLING SYSTEM FLOW -

5.9L DIESEL

The diesel engine cooling system consists of (Fig.

2):

²Cross-flow radiator

²Belt driven water pump

²Belt driven mechanical cooling fan

²Thermal viscous fan drive

²Fan shroud

²Radiator pressure cap

²Vertically mounted thermostat

²Coolant reserve/recovery system

²Transmission oil cooler

²Coolant

BR/BECOOLING 7 - 1

Page 337 of 2889

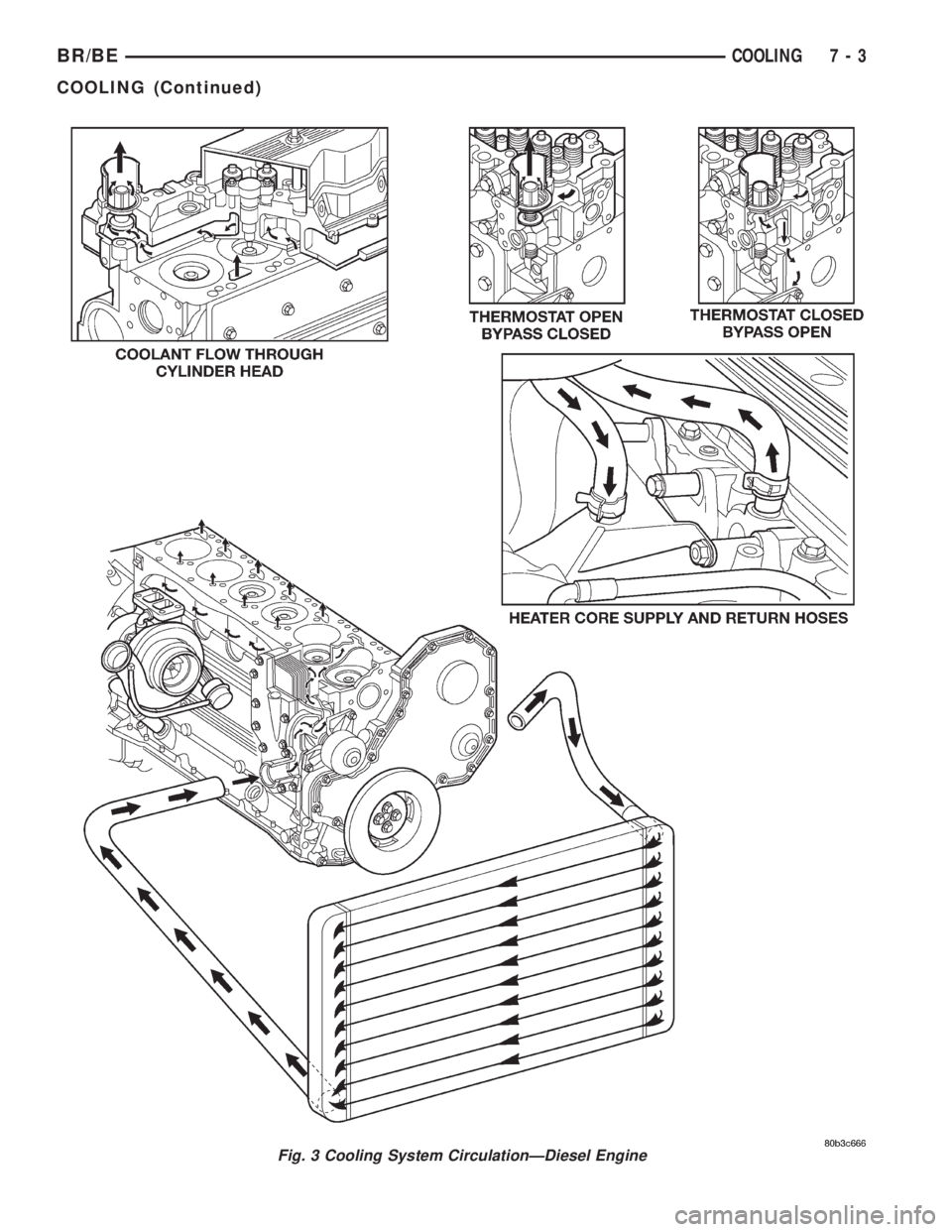

Coolant flow circuits for the 5.9L diesel engine are

shown in (Fig. 3).

DESCRIPTIONÐHOSE CLAMPS

The cooling system utilizes both worm drive and

spring type hose clamps. If a spring type clamp

replacement is necessary, replace with the original

Mopartequipment spring type clamp.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only a original equipment clamp

with matching number or letter (Fig. 4).

OPERATIONÐHOSE CLAMPS

The worm type hose clamp uses a specified torque

value to maintain proper tension on a hose connec-

tion.

The spring type hose clamp applies constant ten-

sion on a hose connection. To remove a spring type

hose clamp, only use constant tension clamp pliers

designed to compress the hose clamp.

Fig. 1 Engine Cooling System Flow

1 - HEATER

2 - BYPASS*3 - CROSSFLOW RADIATOR

Fig. 2 Cooling System Components 5.9L Diesel

Engine

1 - RADIATOR CAP

2 - AUXILIARY TRANSMISSION OIL COOLER

3 - CHARGE AIR COOLER

4 - RADIATOR LOWER HOSE

5 - OVERFLOW/RESERVOIR BOTTLE

6 - FAN SHROUD

7 - RADIATOR UPPER HOSE

8 - CONSTANT TENSION CLAMP

7 - 2 COOLINGBR/BE

COOLING (Continued)

Page 338 of 2889

Fig. 3 Cooling System CirculationÐDiesel Engine

BR/BECOOLING 7 - 3

COOLING (Continued)

Page 339 of 2889

OPERATIONÐCOOLING SYSTEM

The cooling system regulates engine operating tem-

perature. It allows the engine to reach normal oper-

ating temperature as quickly as possible. It also

maintains normal operating temperature and pre-

vents overheating.

The cooling system also provides a means of heat-

ing the passenger compartment and cooling the auto-

matic transmission fluid (if equipped). The cooling

system is pressurized and uses a centrifugal water

pump to circulate coolant throughout the system.

An optional factory installed maximum duty cool-

ing package is available on most models. This pack-

age will provide additional cooling capacity for

vehicles used under extreme conditions such as

trailer towing in high ambient temperatures.

DIAGNOSIS AND TESTING - PRELIMINARY

CHECKS

ENGINE COOLING SYSTEM OVERHEATING

Establish what driving conditions caused the com-

plaint. Abnormal loads on the cooling system such as

the following may be the cause:

²PROLONGED IDLE

²VERY HIGH AMBIENT TEMPERATURE

²SLIGHT TAIL WIND AT IDLE

²SLOW TRAFFIC

²TRAFFIC JAMS

²HIGH SPEED OR STEEP GRADES

Driving techniques that avoid overheating are:

²Idle with A/C off when temperature gauge is at

end of normal range.²Increasing engine speed for more air flow is rec-

ommended.

TRAILER TOWING:

Consult Trailer Towing section of owners manual.

Do not exceed limits.

AIR CONDITIONING; ADD-ON OR AFTER MARKET:

A maximum cooling package should have been

ordered with vehicle if add-on or after market A/C is

installed. If not, maximum cooling system compo-

nents should be installed for model involved per

manufacturer's specifications.

RECENT SERVICE OR ACCIDENT REPAIR:

Determine if any recent service has been per-

formed on vehicle that may effect cooling system.

This may be:

²Engine adjustments (incorrect timing)

²Slipping engine accessory drive belt(s)

²Brakes (possibly dragging)

²Changed parts. Incorrect water pump or pump

rotating in wrong direction due to belt not correctly

routed

²Reconditioned radiator or cooling system refill-

ing (possibly under filled or air trapped in system).

NOTE: If investigation reveals none of the previous

items as a cause for an engine overheating com-

plaint, (Refer to 7 - COOLING - DIAGNOSIS AND

TESTING)

DIAGNOSIS AND TESTINGÐON-BOARD

DIAGNOSTICS (OBD)

COOLING SYSTEM RELATED DIAGNOSTICS

The powertrain control module (PCM) has been

programmed to monitor certain cooling system com-

ponents:

²If the engine has remained cool for too long a

period, such as with a stuck open thermostat, a Diag-

nostic Trouble Code (DTC) can be set.

²If an open or shorted condition has developed in

the relay circuit controlling the electric radiator fan,

a Diagnostic Trouble Code (DTC) can be set.

If the problem is sensed in a monitored circuit

often enough to indicated an actual problem, a DTC

is stored. The DTC will be stored in the PCM mem-

ory for eventual display to the service technician.

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

Fig. 4 Spring Clamp Size Location

1 - SPRING CLAMP SIZE LOCATION

7 - 4 COOLINGBR/BE

COOLING (Continued)

Page 340 of 2889

ACCESSING DIAGNOSTIC TROUBLE CODES

To read DTC's and to obtain cooling system data,

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

ERASING TROUBLE CODES

After the problem has been repaired, use the DRB

scan tool to erase a DTC. Refer to the appropriate

Powertrain Diagnostic Procedures service informa-

tion for operation of the DRB scan tool.

DIAGNOSIS AND TESTINGÐCOOLING SYSTEM

LEAKS

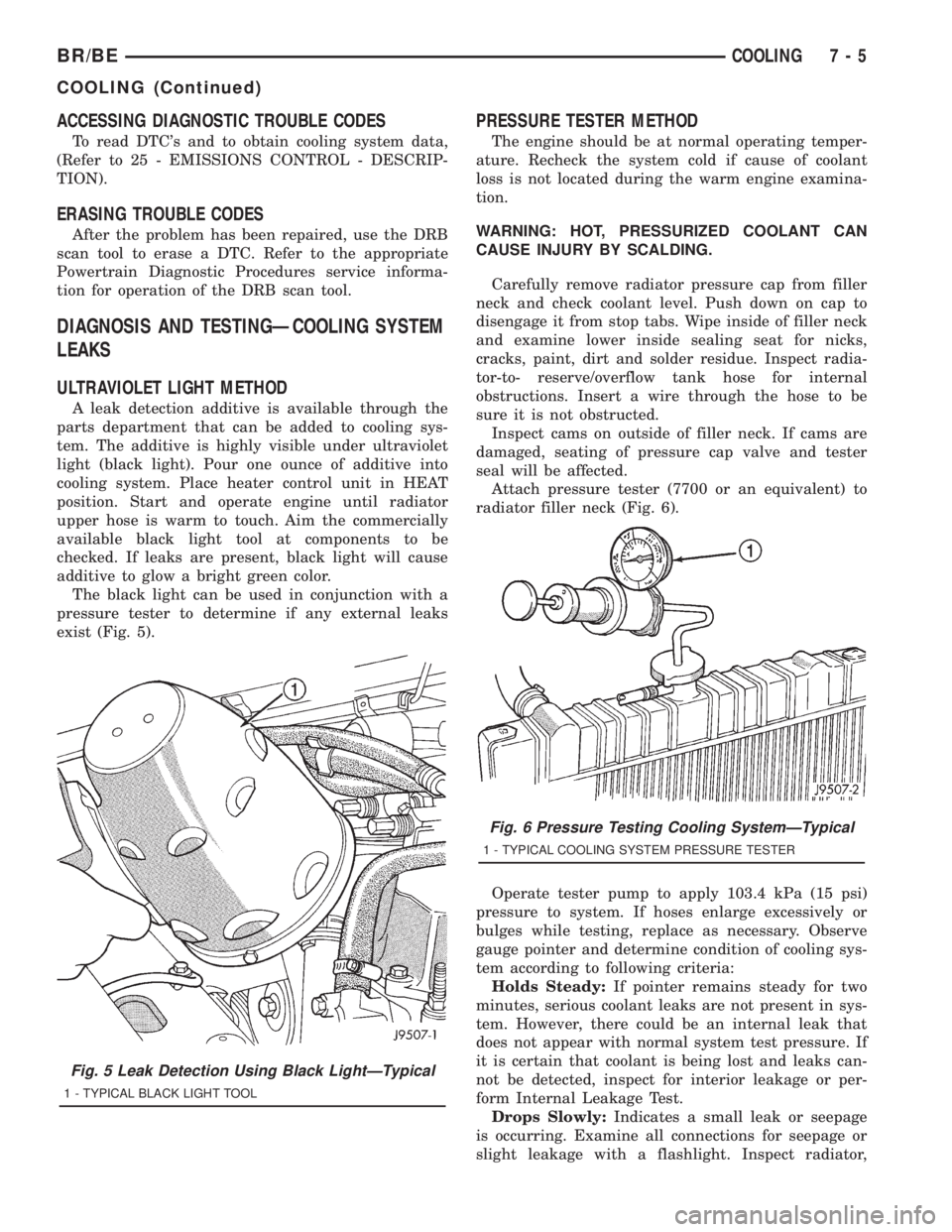

ULTRAVIOLET LIGHT METHOD

A leak detection additive is available through the

parts department that can be added to cooling sys-

tem. The additive is highly visible under ultraviolet

light (black light). Pour one ounce of additive into

cooling system. Place heater control unit in HEAT

position. Start and operate engine until radiator

upper hose is warm to touch. Aim the commercially

available black light tool at components to be

checked. If leaks are present, black light will cause

additive to glow a bright green color.

The black light can be used in conjunction with a

pressure tester to determine if any external leaks

exist (Fig. 5).

PRESSURE TESTER METHOD

The engine should be at normal operating temper-

ature. Recheck the system cold if cause of coolant

loss is not located during the warm engine examina-

tion.

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING.

Carefully remove radiator pressure cap from filler

neck and check coolant level. Push down on cap to

disengage it from stop tabs. Wipe inside of filler neck

and examine lower inside sealing seat for nicks,

cracks, paint, dirt and solder residue. Inspect radia-

tor-to- reserve/overflow tank hose for internal

obstructions. Insert a wire through the hose to be

sure it is not obstructed.

Inspect cams on outside of filler neck. If cams are

damaged, seating of pressure cap valve and tester

seal will be affected.

Attach pressure tester (7700 or an equivalent) to

radiator filler neck (Fig. 6).

Operate tester pump to apply 103.4 kPa (15 psi)

pressure to system. If hoses enlarge excessively or

bulges while testing, replace as necessary. Observe

gauge pointer and determine condition of cooling sys-

tem according to following criteria:

Holds Steady:If pointer remains steady for two

minutes, serious coolant leaks are not present in sys-

tem. However, there could be an internal leak that

does not appear with normal system test pressure. If

it is certain that coolant is being lost and leaks can-

not be detected, inspect for interior leakage or per-

form Internal Leakage Test.

Drops Slowly:Indicates a small leak or seepage

is occurring. Examine all connections for seepage or

slight leakage with a flashlight. Inspect radiator,

Fig. 5 Leak Detection Using Black LightÐTypical

1 - TYPICAL BLACK LIGHT TOOL

Fig. 6 Pressure Testing Cooling SystemÐTypical

1 - TYPICAL COOLING SYSTEM PRESSURE TESTER

BR/BECOOLING 7 - 5

COOLING (Continued)