DODGE RAM 2001 Service Repair Manual

Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 291 of 2889

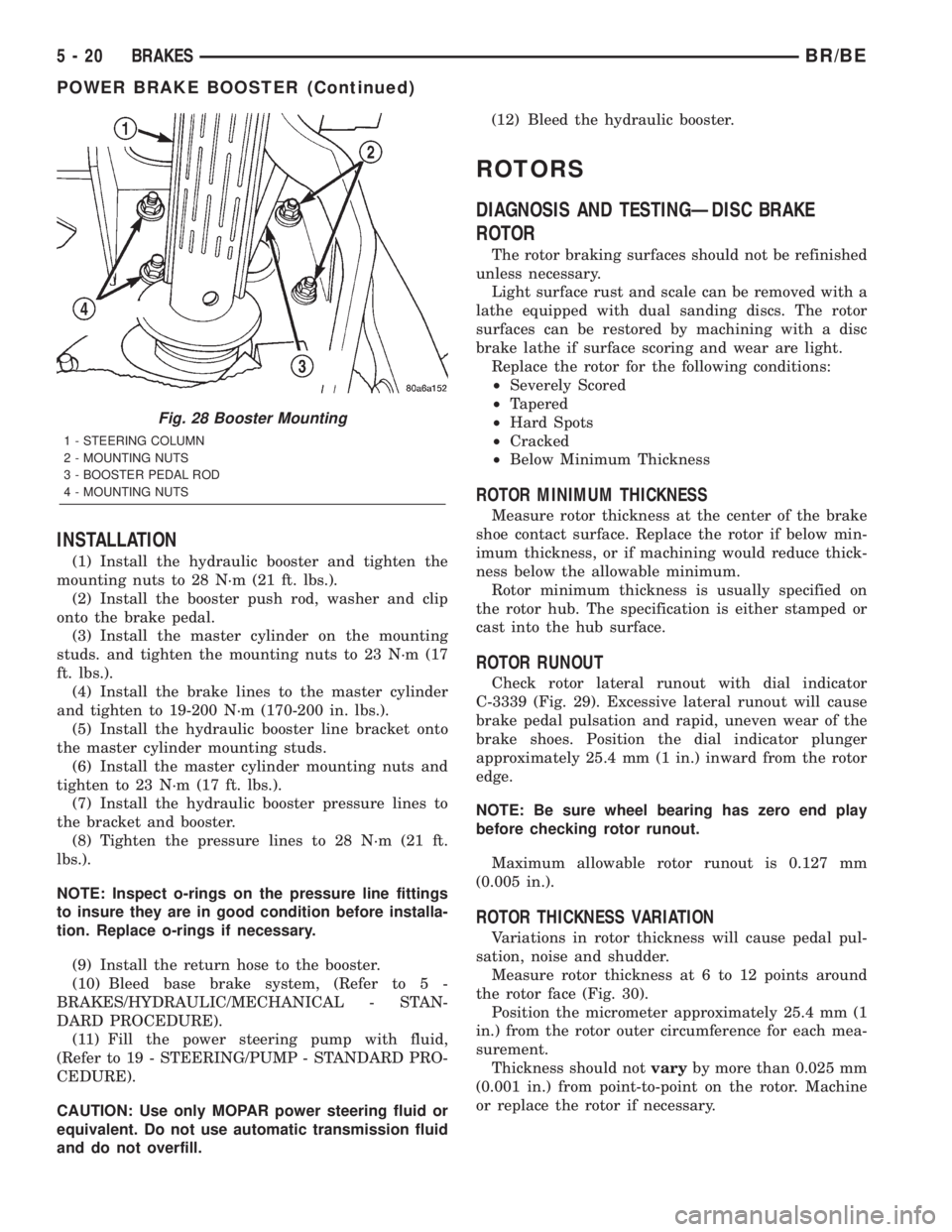

INSTALLATION

(1) Install the hydraulic booster and tighten the

mounting nuts to 28 N´m (21 ft. lbs.).

(2) Install the booster push rod, washer and clip

onto the brake pedal.

(3) Install the master cylinder on the mounting

studs. and tighten the mounting nuts to 23 N´m (17

ft. lbs.).

(4) Install the brake lines to the master cylinder

and tighten to 19-200 N´m (170-200 in. lbs.).

(5) Install the hydraulic booster line bracket onto

the master cylinder mounting studs.

(6) Install the master cylinder mounting nuts and

tighten to 23 N´m (17 ft. lbs.).

(7) Install the hydraulic booster pressure lines to

the bracket and booster.

(8) Tighten the pressure lines to 28 N´m (21 ft.

lbs.).

NOTE: Inspect o-rings on the pressure line fittings

to insure they are in good condition before installa-

tion. Replace o-rings if necessary.

(9) Install the return hose to the booster.

(10) Bleed base brake system, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL - STAN-

DARD PROCEDURE).

(11) Fill the power steering pump with fluid,

(Refer to 19 - STEERING/PUMP - STANDARD PRO-

CEDURE).

CAUTION: Use only MOPAR power steering fluid or

equivalent. Do not use automatic transmission fluid

and do not overfill.(12) Bleed the hydraulic booster.

ROTORS

DIAGNOSIS AND TESTINGÐDISC BRAKE

ROTOR

The rotor braking surfaces should not be refinished

unless necessary.

Light surface rust and scale can be removed with a

lathe equipped with dual sanding discs. The rotor

surfaces can be restored by machining with a disc

brake lathe if surface scoring and wear are light.

Replace the rotor for the following conditions:

²Severely Scored

²Tapered

²Hard Spots

²Cracked

²Below Minimum Thickness

ROTOR MINIMUM THICKNESS

Measure rotor thickness at the center of the brake

shoe contact surface. Replace the rotor if below min-

imum thickness, or if machining would reduce thick-

ness below the allowable minimum.

Rotor minimum thickness is usually specified on

the rotor hub. The specification is either stamped or

cast into the hub surface.

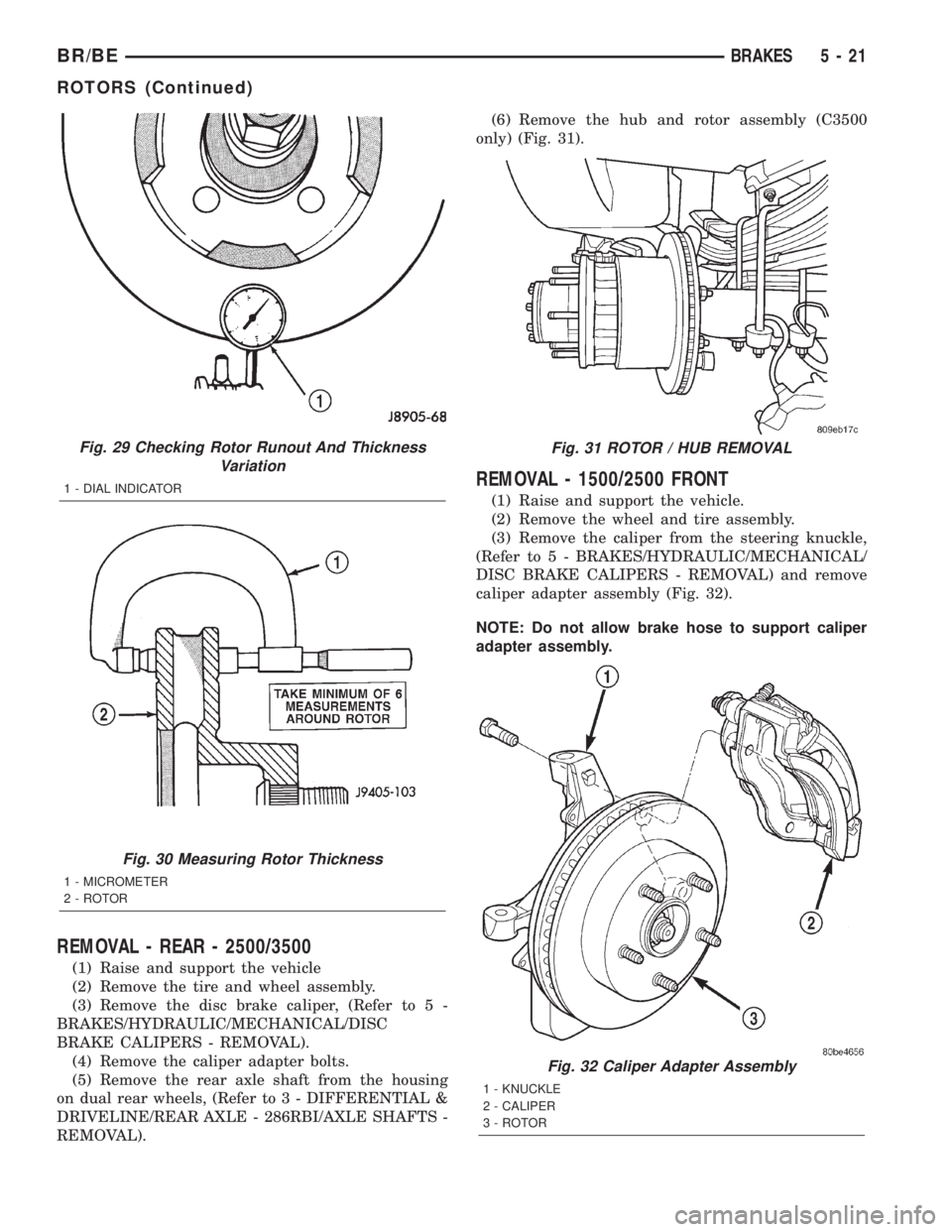

ROTOR RUNOUT

Check rotor lateral runout with dial indicator

C-3339 (Fig. 29). Excessive lateral runout will cause

brake pedal pulsation and rapid, uneven wear of the

brake shoes. Position the dial indicator plunger

approximately 25.4 mm (1 in.) inward from the rotor

edge.

NOTE: Be sure wheel bearing has zero end play

before checking rotor runout.

Maximum allowable rotor runout is 0.127 mm

(0.005 in.).

ROTOR THICKNESS VARIATION

Variations in rotor thickness will cause pedal pul-

sation, noise and shudder.

Measure rotor thickness at 6 to 12 points around

the rotor face (Fig. 30).

Position the micrometer approximately 25.4 mm (1

in.) from the rotor outer circumference for each mea-

surement.

Thickness should notvaryby more than 0.025 mm

(0.001 in.) from point-to-point on the rotor. Machine

or replace the rotor if necessary.

Fig. 28 Booster Mounting

1 - STEERING COLUMN

2 - MOUNTING NUTS

3 - BOOSTER PEDAL ROD

4 - MOUNTING NUTS

5 - 20 BRAKESBR/BE

POWER BRAKE BOOSTER (Continued)

Page 292 of 2889

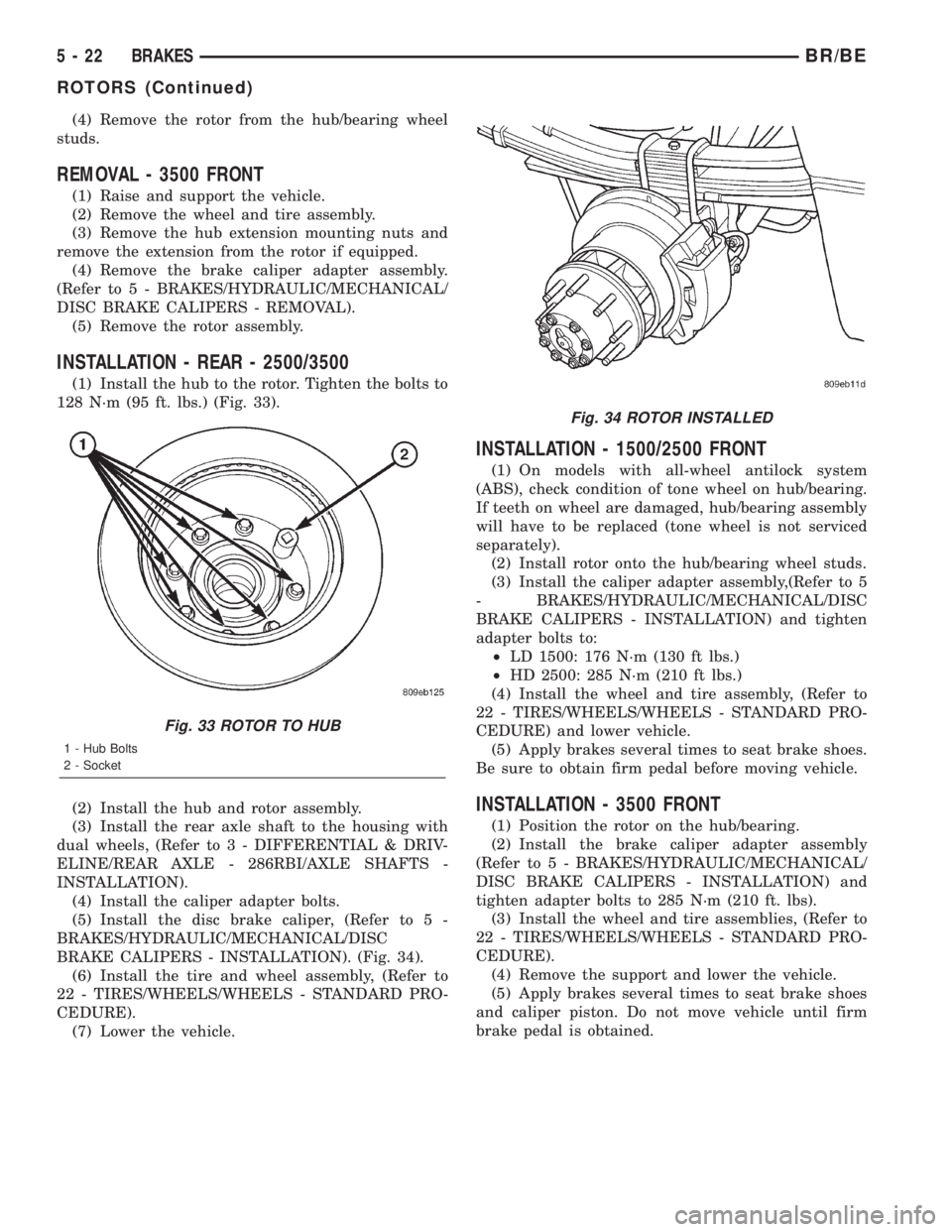

REMOVAL - REAR - 2500/3500

(1) Raise and support the vehicle

(2) Remove the tire and wheel assembly.

(3) Remove the disc brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(4) Remove the caliper adapter bolts.

(5) Remove the rear axle shaft from the housing

on dual rear wheels, (Refer to 3 - DIFFERENTIAL &

DRIVELINE/REAR AXLE - 286RBI/AXLE SHAFTS -

REMOVAL).(6) Remove the hub and rotor assembly (C3500

only) (Fig. 31).

REMOVAL - 1500/2500 FRONT

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assembly.

(3) Remove the caliper from the steering knuckle,

(Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/

DISC BRAKE CALIPERS - REMOVAL) and remove

caliper adapter assembly (Fig. 32).

NOTE: Do not allow brake hose to support caliper

adapter assembly.

Fig. 29 Checking Rotor Runout And Thickness

Variation

1 - DIAL INDICATOR

Fig. 30 Measuring Rotor Thickness

1 - MICROMETER

2 - ROTOR

Fig. 31 ROTOR / HUB REMOVAL

Fig. 32 Caliper Adapter Assembly

1 - KNUCKLE

2 - CALIPER

3 - ROTOR

BR/BEBRAKES 5 - 21

ROTORS (Continued)

Page 293 of 2889

(4) Remove the rotor from the hub/bearing wheel

studs.

REMOVAL - 3500 FRONT

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assembly.

(3) Remove the hub extension mounting nuts and

remove the extension from the rotor if equipped.

(4) Remove the brake caliper adapter assembly.

(Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/

DISC BRAKE CALIPERS - REMOVAL).

(5) Remove the rotor assembly.

INSTALLATION - REAR - 2500/3500

(1) Install the hub to the rotor. Tighten the bolts to

128 N´m (95 ft. lbs.) (Fig. 33).

(2) Install the hub and rotor assembly.

(3) Install the rear axle shaft to the housing with

dual wheels, (Refer to 3 - DIFFERENTIAL & DRIV-

ELINE/REAR AXLE - 286RBI/AXLE SHAFTS -

INSTALLATION).

(4) Install the caliper adapter bolts.

(5) Install the disc brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION). (Fig. 34).

(6) Install the tire and wheel assembly, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

(7) Lower the vehicle.

INSTALLATION - 1500/2500 FRONT

(1) On models with all-wheel antilock system

(ABS), check condition of tone wheel on hub/bearing.

If teeth on wheel are damaged, hub/bearing assembly

will have to be replaced (tone wheel is not serviced

separately).

(2) Install rotor onto the hub/bearing wheel studs.

(3) Install the caliper adapter assembly,(Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION) and tighten

adapter bolts to:

²LD 1500: 176 N´m (130 ft lbs.)

²HD 2500: 285 N´m (210 ft lbs.)

(4) Install the wheel and tire assembly, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE) and lower vehicle.

(5) Apply brakes several times to seat brake shoes.

Be sure to obtain firm pedal before moving vehicle.

INSTALLATION - 3500 FRONT

(1) Position the rotor on the hub/bearing.

(2) Install the brake caliper adapter assembly

(Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/

DISC BRAKE CALIPERS - INSTALLATION) and

tighten adapter bolts to 285 N´m (210 ft. lbs).

(3) Install the wheel and tire assemblies, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

(4) Remove the support and lower the vehicle.

(5) Apply brakes several times to seat brake shoes

and caliper piston. Do not move vehicle until firm

brake pedal is obtained.

Fig. 33 ROTOR TO HUB

1 - Hub Bolts

2 - Socket

Fig. 34 ROTOR INSTALLED

5 - 22 BRAKESBR/BE

ROTORS (Continued)

Page 294 of 2889

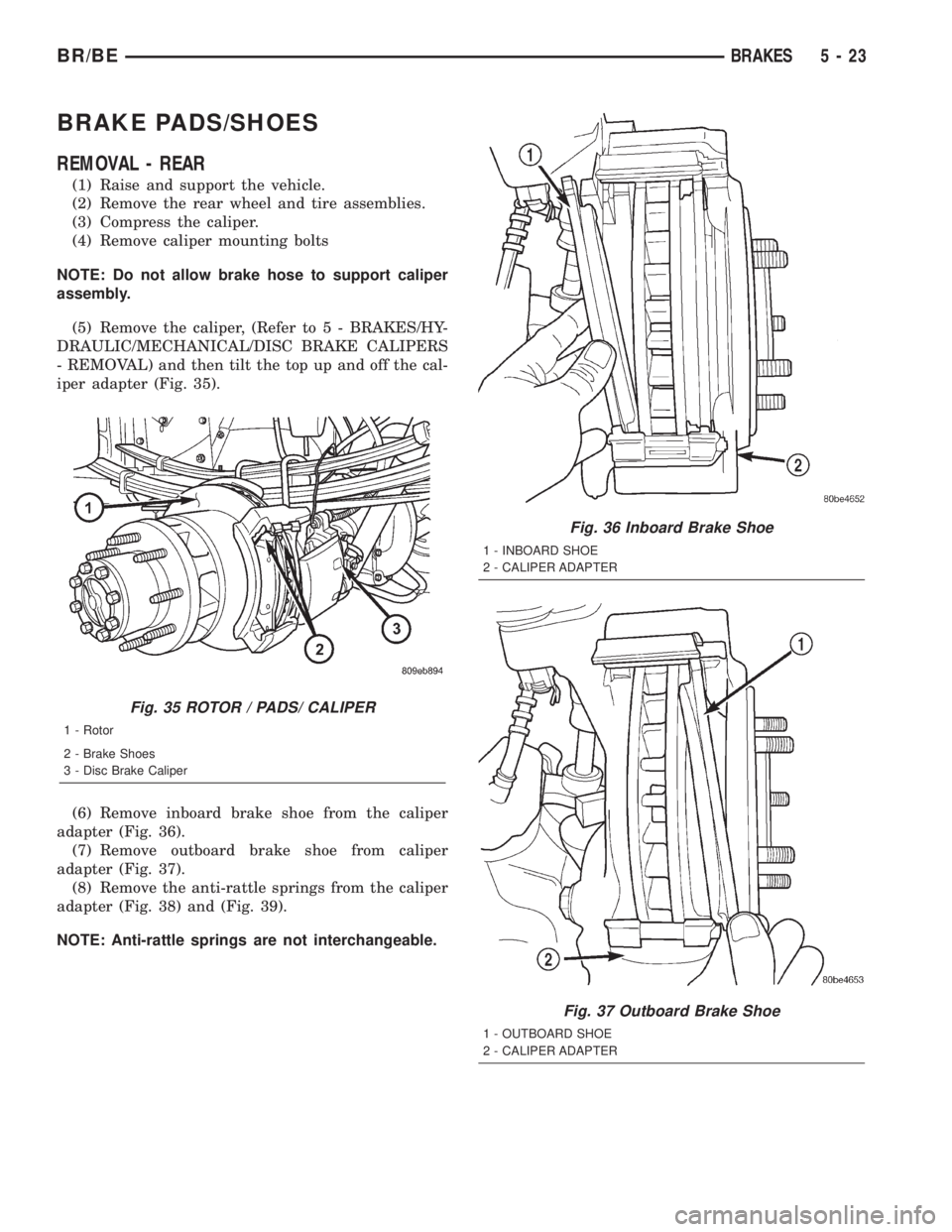

BRAKE PADS/SHOES

REMOVAL - REAR

(1) Raise and support the vehicle.

(2) Remove the rear wheel and tire assemblies.

(3) Compress the caliper.

(4) Remove caliper mounting bolts

NOTE: Do not allow brake hose to support caliper

assembly.

(5) Remove the caliper, (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/DISC BRAKE CALIPERS

- REMOVAL) and then tilt the top up and off the cal-

iper adapter (Fig. 35).

(6) Remove inboard brake shoe from the caliper

adapter (Fig. 36).

(7) Remove outboard brake shoe from caliper

adapter (Fig. 37).

(8) Remove the anti-rattle springs from the caliper

adapter (Fig. 38) and (Fig. 39).

NOTE: Anti-rattle springs are not interchangeable.

Fig. 35 ROTOR / PADS/ CALIPER

1 - Rotor

2 - Brake Shoes

3 - Disc Brake Caliper

Fig. 36 Inboard Brake Shoe

1 - INBOARD SHOE

2 - CALIPER ADAPTER

Fig. 37 Outboard Brake Shoe

1 - OUTBOARD SHOE

2 - CALIPER ADAPTER

BR/BEBRAKES 5 - 23

Page 295 of 2889

REMOVAL - FRONT

(1) Raise and support vehicle.

(2) Remove front wheel and tire assemblies.

(3) Compress caliper.

(4) Remove caliper, (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/DISC BRAKE CALIPERS

- REMOVAL).

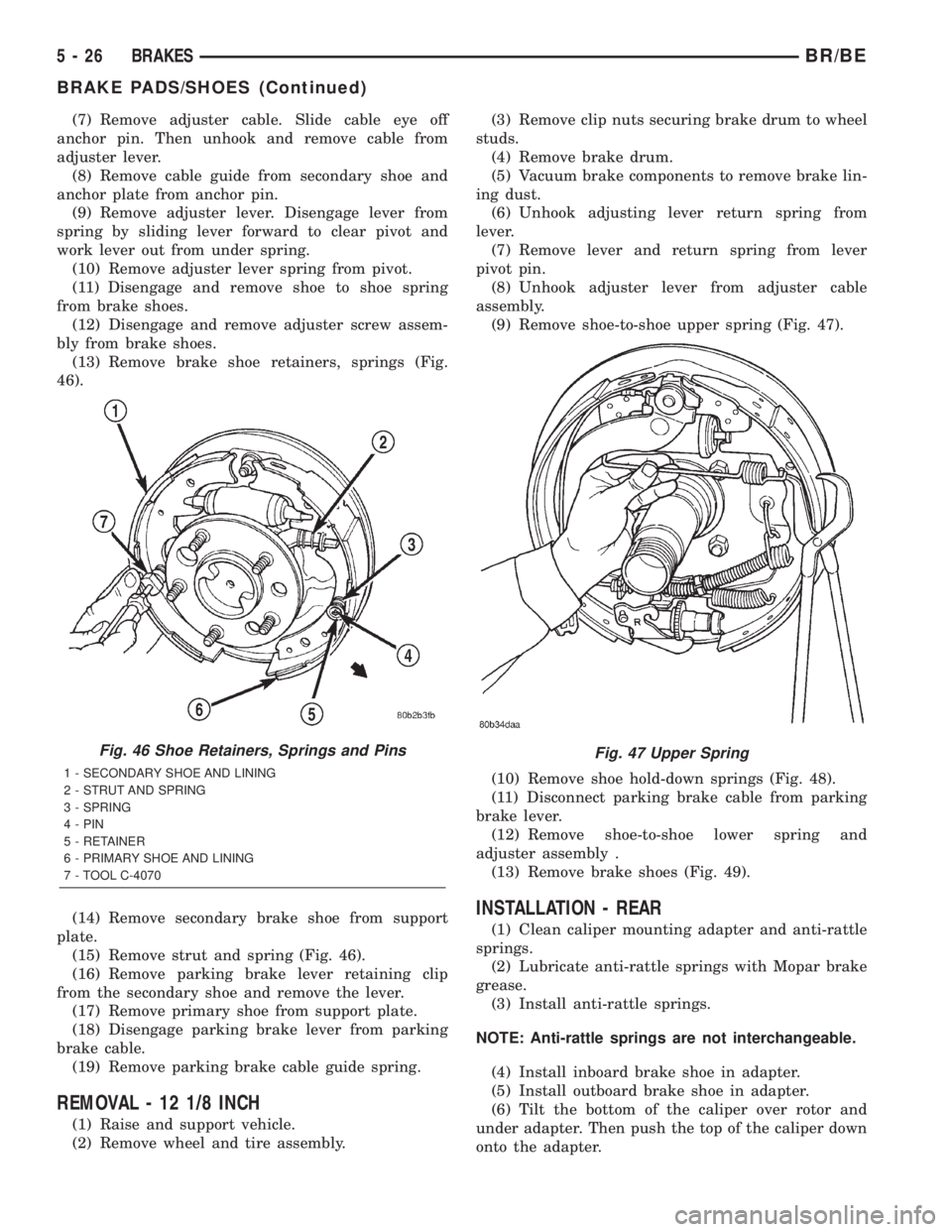

(5) Remove caliper by tilting the top up and off the

caliper adapter (Fig. 40).

NOTE: Do not allow brake hose to support caliper

assembly.

(6) Remove inboard brake shoe from the caliper

adapter (Fig. 41).(7) Remove outboard brake shoe from caliper

adapter (Fig. 42).

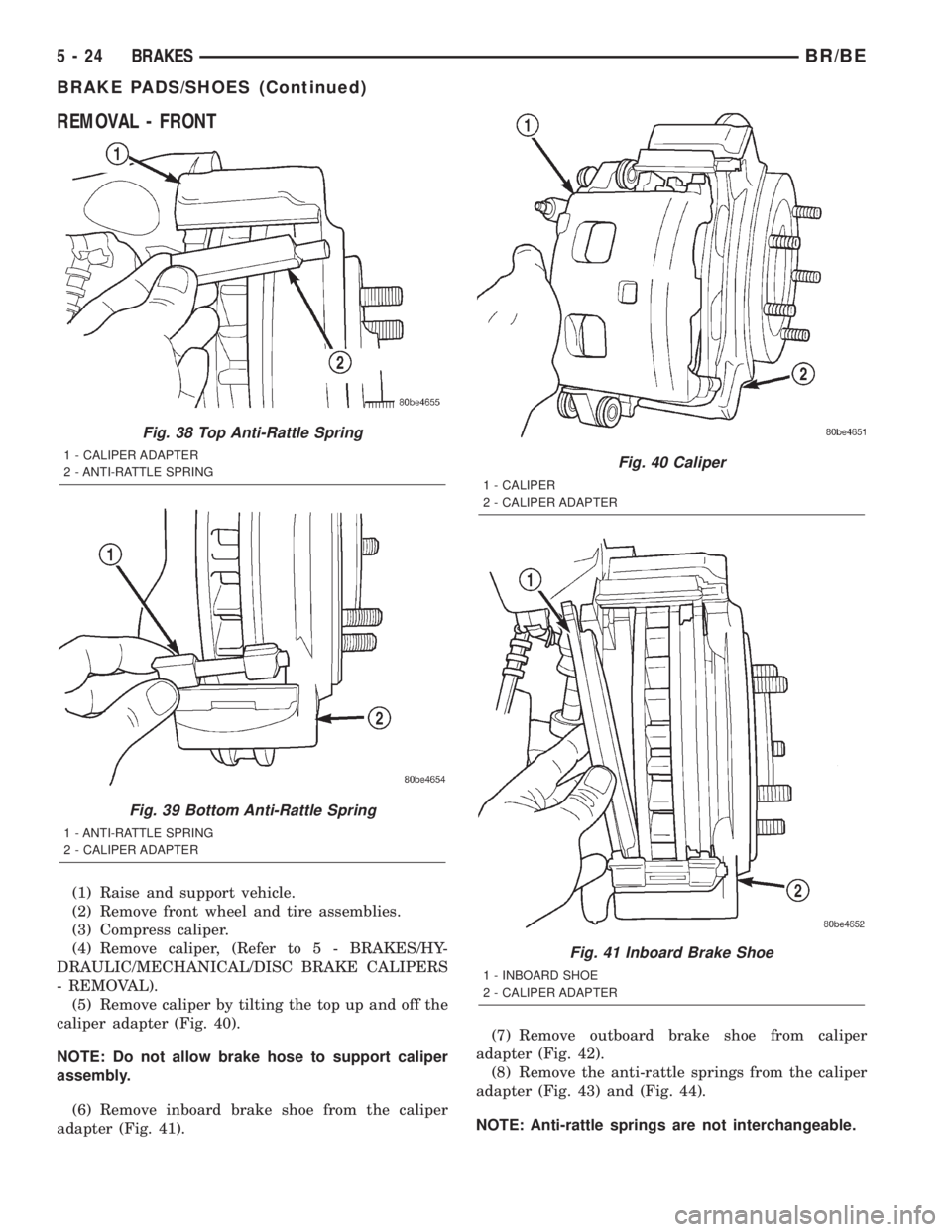

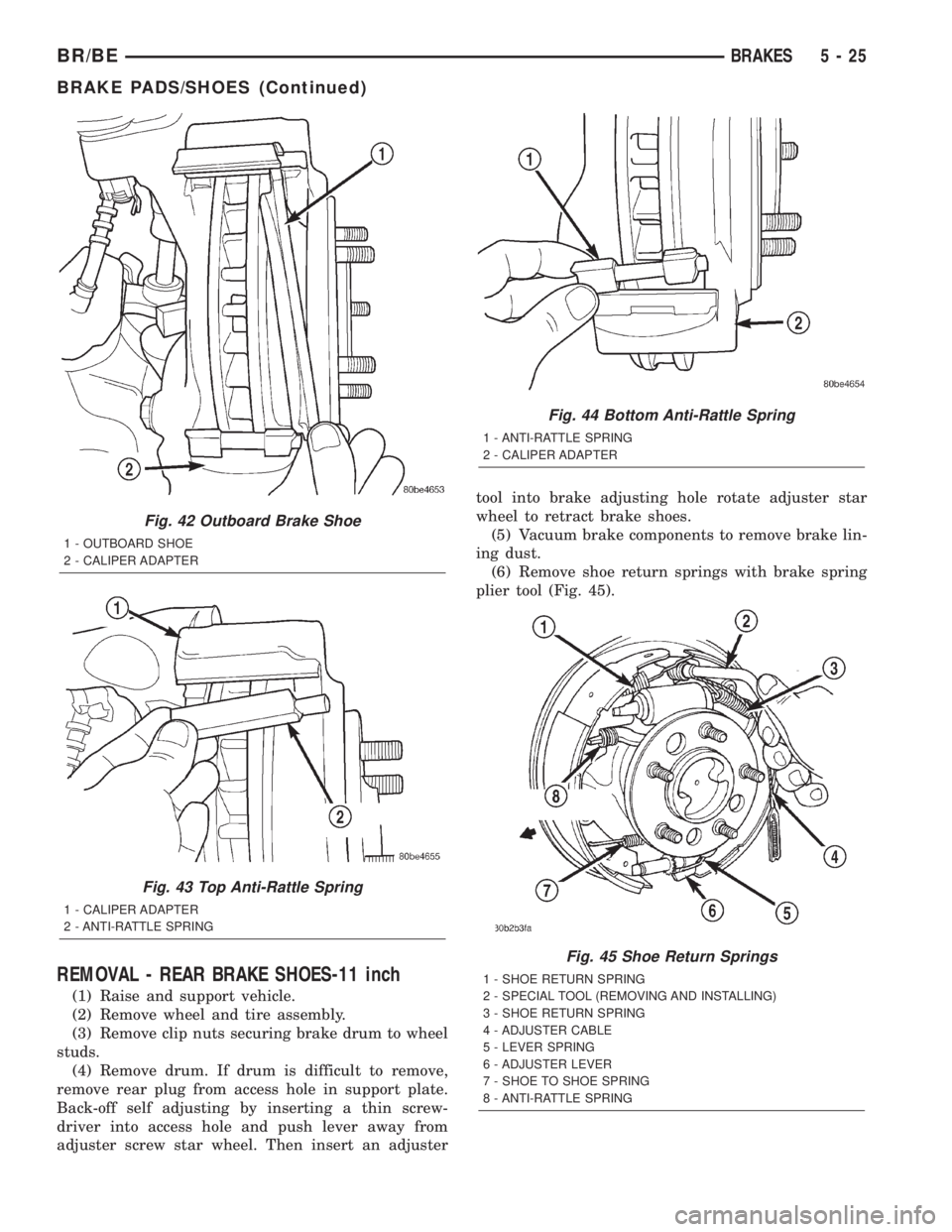

(8) Remove the anti-rattle springs from the caliper

adapter (Fig. 43) and (Fig. 44).

NOTE: Anti-rattle springs are not interchangeable.

Fig. 38 Top Anti-Rattle Spring

1 - CALIPER ADAPTER

2 - ANTI-RATTLE SPRING

Fig. 39 Bottom Anti-Rattle Spring

1 - ANTI-RATTLE SPRING

2 - CALIPER ADAPTER

Fig. 40 Caliper

1 - CALIPER

2 - CALIPER ADAPTER

Fig. 41 Inboard Brake Shoe

1 - INBOARD SHOE

2 - CALIPER ADAPTER

5 - 24 BRAKESBR/BE

BRAKE PADS/SHOES (Continued)

Page 296 of 2889

REMOVAL - REAR BRAKE SHOES-11 inch

(1) Raise and support vehicle.

(2) Remove wheel and tire assembly.

(3) Remove clip nuts securing brake drum to wheel

studs.

(4) Remove drum. If drum is difficult to remove,

remove rear plug from access hole in support plate.

Back-off self adjusting by inserting a thin screw-

driver into access hole and push lever away from

adjuster screw star wheel. Then insert an adjustertool into brake adjusting hole rotate adjuster star

wheel to retract brake shoes.

(5) Vacuum brake components to remove brake lin-

ing dust.

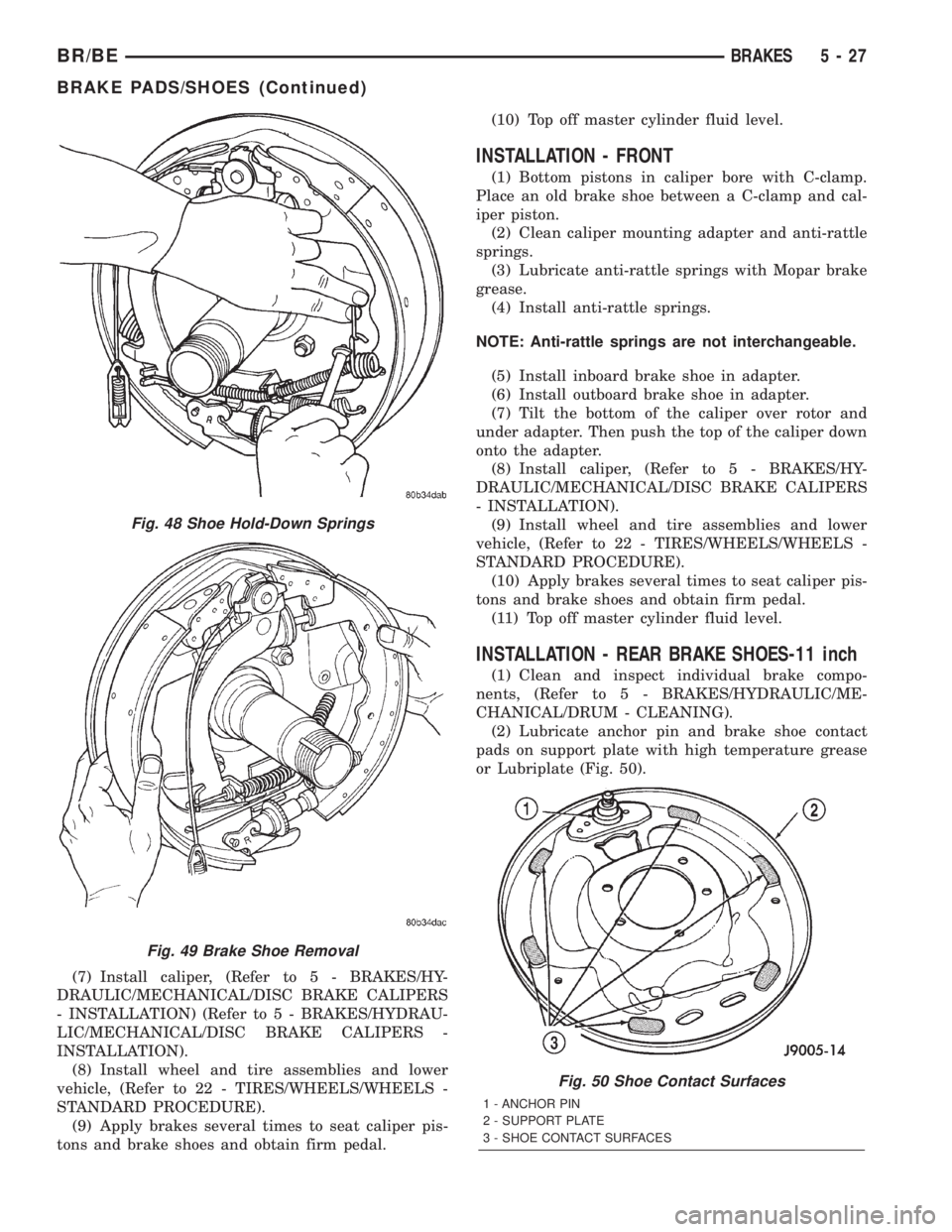

(6) Remove shoe return springs with brake spring

plier tool (Fig. 45).

Fig. 42 Outboard Brake Shoe

1 - OUTBOARD SHOE

2 - CALIPER ADAPTER

Fig. 43 Top Anti-Rattle Spring

1 - CALIPER ADAPTER

2 - ANTI-RATTLE SPRING

Fig. 44 Bottom Anti-Rattle Spring

1 - ANTI-RATTLE SPRING

2 - CALIPER ADAPTER

Fig. 45 Shoe Return Springs

1 - SHOE RETURN SPRING

2 - SPECIAL TOOL (REMOVING AND INSTALLING)

3 - SHOE RETURN SPRING

4 - ADJUSTER CABLE

5 - LEVER SPRING

6 - ADJUSTER LEVER

7 - SHOE TO SHOE SPRING

8 - ANTI-RATTLE SPRING

BR/BEBRAKES 5 - 25

BRAKE PADS/SHOES (Continued)

Page 297 of 2889

(7) Remove adjuster cable. Slide cable eye off

anchor pin. Then unhook and remove cable from

adjuster lever.

(8) Remove cable guide from secondary shoe and

anchor plate from anchor pin.

(9) Remove adjuster lever. Disengage lever from

spring by sliding lever forward to clear pivot and

work lever out from under spring.

(10) Remove adjuster lever spring from pivot.

(11) Disengage and remove shoe to shoe spring

from brake shoes.

(12) Disengage and remove adjuster screw assem-

bly from brake shoes.

(13) Remove brake shoe retainers, springs (Fig.

46).

(14) Remove secondary brake shoe from support

plate.

(15) Remove strut and spring (Fig. 46).

(16) Remove parking brake lever retaining clip

from the secondary shoe and remove the lever.

(17) Remove primary shoe from support plate.

(18) Disengage parking brake lever from parking

brake cable.

(19) Remove parking brake cable guide spring.

REMOVAL - 12 1/8 INCH

(1) Raise and support vehicle.

(2) Remove wheel and tire assembly.(3) Remove clip nuts securing brake drum to wheel

studs.

(4) Remove brake drum.

(5) Vacuum brake components to remove brake lin-

ing dust.

(6) Unhook adjusting lever return spring from

lever.

(7) Remove lever and return spring from lever

pivot pin.

(8) Unhook adjuster lever from adjuster cable

assembly.

(9) Remove shoe-to-shoe upper spring (Fig. 47).

(10) Remove shoe hold-down springs (Fig. 48).

(11) Disconnect parking brake cable from parking

brake lever.

(12) Remove shoe-to-shoe lower spring and

adjuster assembly .

(13) Remove brake shoes (Fig. 49).

INSTALLATION - REAR

(1) Clean caliper mounting adapter and anti-rattle

springs.

(2) Lubricate anti-rattle springs with Mopar brake

grease.

(3) Install anti-rattle springs.

NOTE: Anti-rattle springs are not interchangeable.

(4) Install inboard brake shoe in adapter.

(5) Install outboard brake shoe in adapter.

(6) Tilt the bottom of the caliper over rotor and

under adapter. Then push the top of the caliper down

onto the adapter.

Fig. 46 Shoe Retainers, Springs and Pins

1 - SECONDARY SHOE AND LINING

2 - STRUT AND SPRING

3 - SPRING

4 - PIN

5 - RETAINER

6 - PRIMARY SHOE AND LINING

7 - TOOL C-4070

Fig. 47 Upper Spring

5 - 26 BRAKESBR/BE

BRAKE PADS/SHOES (Continued)

Page 298 of 2889

(7) Install caliper, (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/DISC BRAKE CALIPERS

- INSTALLATION) (Refer to 5 - BRAKES/HYDRAU-

LIC/MECHANICAL/DISC BRAKE CALIPERS -

INSTALLATION).

(8) Install wheel and tire assemblies and lower

vehicle, (Refer to 22 - TIRES/WHEELS/WHEELS -

STANDARD PROCEDURE).

(9) Apply brakes several times to seat caliper pis-

tons and brake shoes and obtain firm pedal.(10) Top off master cylinder fluid level.

INSTALLATION - FRONT

(1) Bottom pistons in caliper bore with C-clamp.

Place an old brake shoe between a C-clamp and cal-

iper piston.

(2) Clean caliper mounting adapter and anti-rattle

springs.

(3) Lubricate anti-rattle springs with Mopar brake

grease.

(4) Install anti-rattle springs.

NOTE: Anti-rattle springs are not interchangeable.

(5) Install inboard brake shoe in adapter.

(6) Install outboard brake shoe in adapter.

(7) Tilt the bottom of the caliper over rotor and

under adapter. Then push the top of the caliper down

onto the adapter.

(8) Install caliper, (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/DISC BRAKE CALIPERS

- INSTALLATION).

(9) Install wheel and tire assemblies and lower

vehicle, (Refer to 22 - TIRES/WHEELS/WHEELS -

STANDARD PROCEDURE).

(10) Apply brakes several times to seat caliper pis-

tons and brake shoes and obtain firm pedal.

(11) Top off master cylinder fluid level.

INSTALLATION - REAR BRAKE SHOES-11 inch

(1) Clean and inspect individual brake compo-

nents, (Refer to 5 - BRAKES/HYDRAULIC/ME-

CHANICAL/DRUM - CLEANING).

(2) Lubricate anchor pin and brake shoe contact

pads on support plate with high temperature grease

or Lubriplate (Fig. 50).

Fig. 48 Shoe Hold-Down Springs

Fig. 49 Brake Shoe Removal

Fig. 50 Shoe Contact Surfaces

1 - ANCHOR PIN

2 - SUPPORT PLATE

3 - SHOE CONTACT SURFACES

BR/BEBRAKES 5 - 27

BRAKE PADS/SHOES (Continued)

Page 299 of 2889

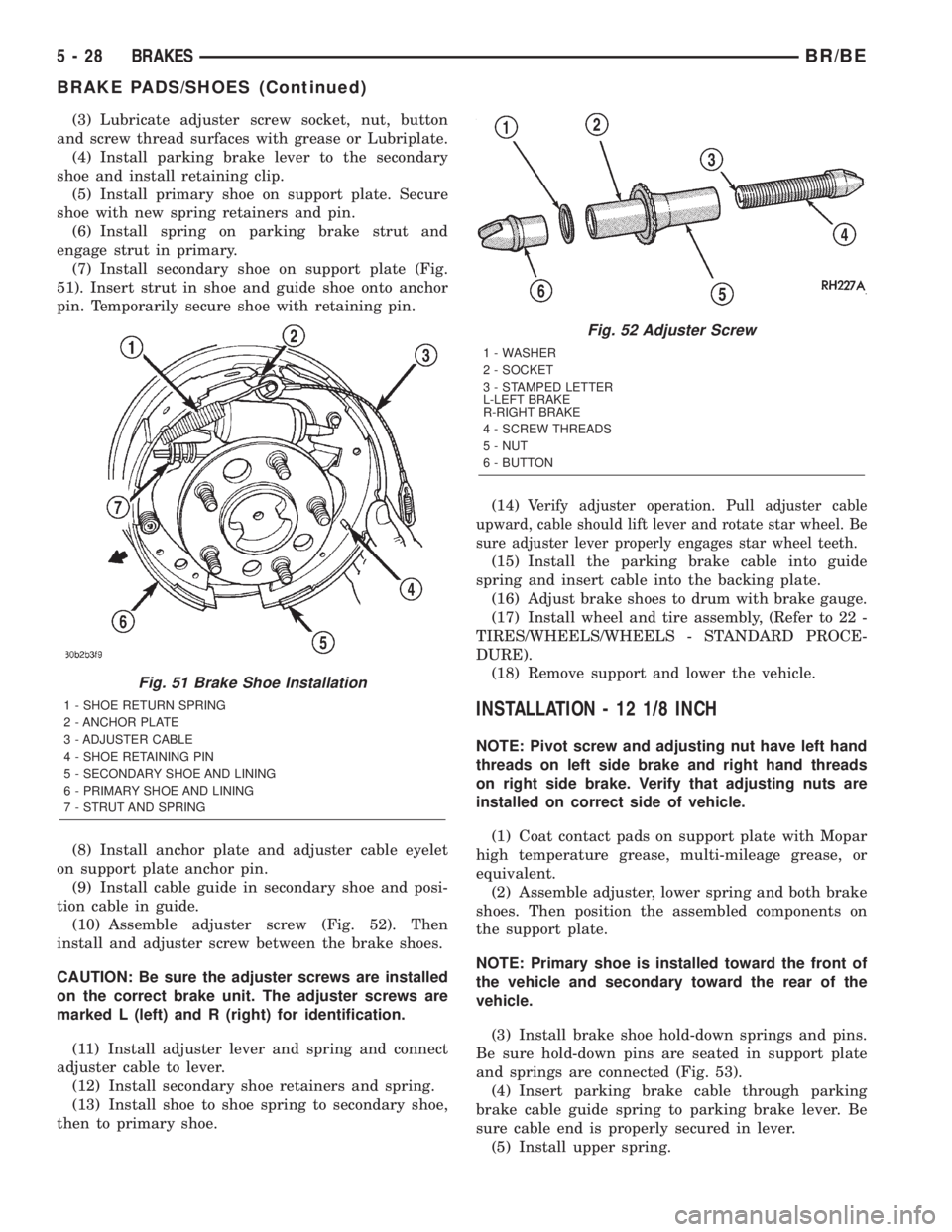

(3) Lubricate adjuster screw socket, nut, button

and screw thread surfaces with grease or Lubriplate.

(4) Install parking brake lever to the secondary

shoe and install retaining clip.

(5) Install primary shoe on support plate. Secure

shoe with new spring retainers and pin.

(6) Install spring on parking brake strut and

engage strut in primary.

(7) Install secondary shoe on support plate (Fig.

51). Insert strut in shoe and guide shoe onto anchor

pin. Temporarily secure shoe with retaining pin.

(8) Install anchor plate and adjuster cable eyelet

on support plate anchor pin.

(9) Install cable guide in secondary shoe and posi-

tion cable in guide.

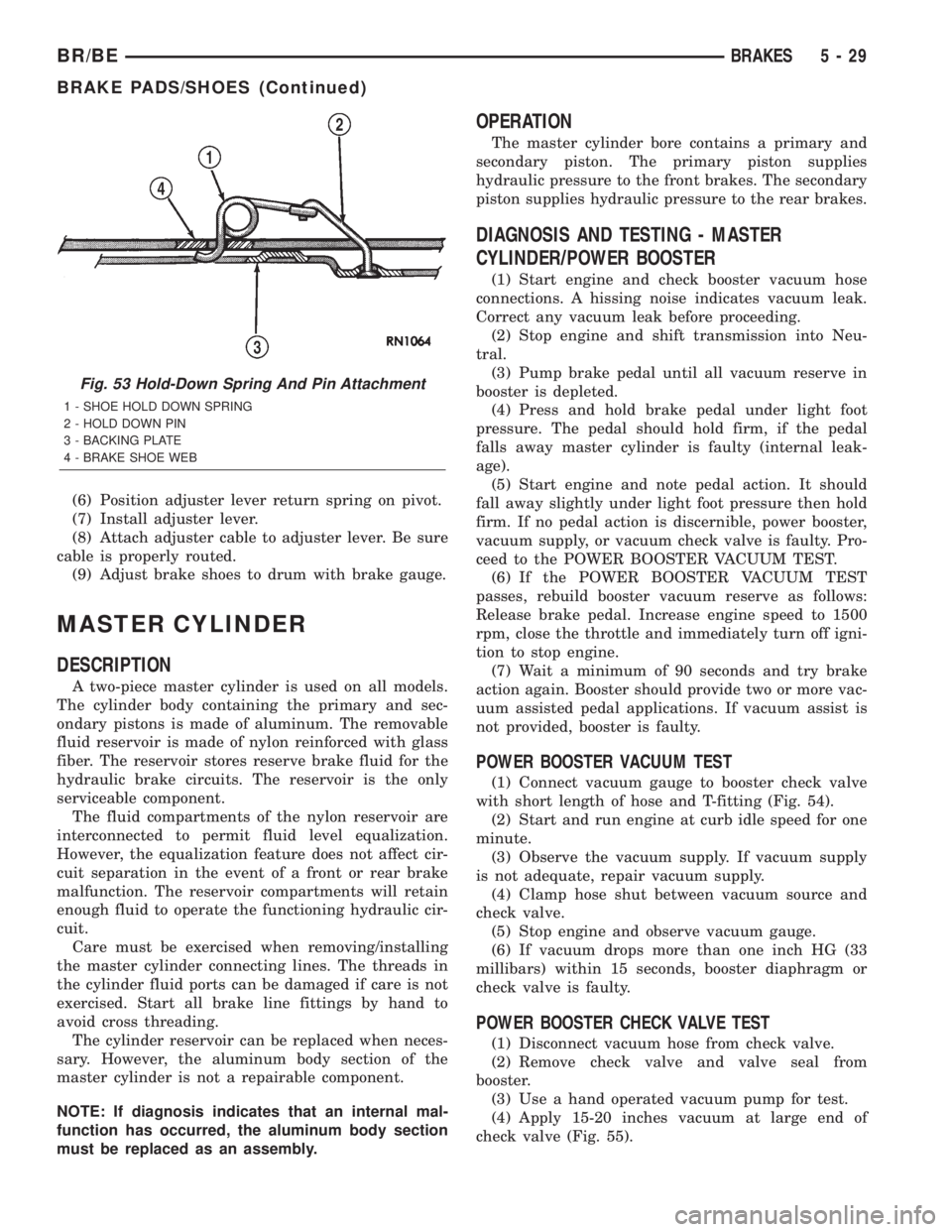

(10) Assemble adjuster screw (Fig. 52). Then

install and adjuster screw between the brake shoes.

CAUTION: Be sure the adjuster screws are installed

on the correct brake unit. The adjuster screws are

marked L (left) and R (right) for identification.

(11) Install adjuster lever and spring and connect

adjuster cable to lever.

(12) Install secondary shoe retainers and spring.

(13) Install shoe to shoe spring to secondary shoe,

then to primary shoe.(14)

Verify adjuster operation. Pull adjuster cable

upward, cable should lift lever and rotate star wheel. Be

sure adjuster lever properly engages star wheel teeth.

(15) Install the parking brake cable into guide

spring and insert cable into the backing plate.

(16) Adjust brake shoes to drum with brake gauge.

(17) Install wheel and tire assembly, (Refer to 22 -

TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(18) Remove support and lower the vehicle.

INSTALLATION - 12 1/8 INCH

NOTE: Pivot screw and adjusting nut have left hand

threads on left side brake and right hand threads

on right side brake. Verify that adjusting nuts are

installed on correct side of vehicle.

(1) Coat contact pads on support plate with Mopar

high temperature grease, multi-mileage grease, or

equivalent.

(2) Assemble adjuster, lower spring and both brake

shoes. Then position the assembled components on

the support plate.

NOTE: Primary shoe is installed toward the front of

the vehicle and secondary toward the rear of the

vehicle.

(3) Install brake shoe hold-down springs and pins.

Be sure hold-down pins are seated in support plate

and springs are connected (Fig. 53).

(4) Insert parking brake cable through parking

brake cable guide spring to parking brake lever. Be

sure cable end is properly secured in lever.

(5) Install upper spring.

Fig. 51 Brake Shoe Installation

1 - SHOE RETURN SPRING

2 - ANCHOR PLATE

3 - ADJUSTER CABLE

4 - SHOE RETAINING PIN

5 - SECONDARY SHOE AND LINING

6 - PRIMARY SHOE AND LINING

7 - STRUT AND SPRING

Fig. 52 Adjuster Screw

1 - WASHER

2 - SOCKET

3 - STAMPED LETTER

L-LEFT BRAKE

R-RIGHT BRAKE

4 - SCREW THREADS

5 - NUT

6 - BUTTON

5 - 28 BRAKESBR/BE

BRAKE PADS/SHOES (Continued)

Page 300 of 2889

(6) Position adjuster lever return spring on pivot.

(7) Install adjuster lever.

(8) Attach adjuster cable to adjuster lever. Be sure

cable is properly routed.

(9) Adjust brake shoes to drum with brake gauge.

MASTER CYLINDER

DESCRIPTION

A two-piece master cylinder is used on all models.

The cylinder body containing the primary and sec-

ondary pistons is made of aluminum. The removable

fluid reservoir is made of nylon reinforced with glass

fiber. The reservoir stores reserve brake fluid for the

hydraulic brake circuits. The reservoir is the only

serviceable component.

The fluid compartments of the nylon reservoir are

interconnected to permit fluid level equalization.

However, the equalization feature does not affect cir-

cuit separation in the event of a front or rear brake

malfunction. The reservoir compartments will retain

enough fluid to operate the functioning hydraulic cir-

cuit.

Care must be exercised when removing/installing

the master cylinder connecting lines. The threads in

the cylinder fluid ports can be damaged if care is not

exercised. Start all brake line fittings by hand to

avoid cross threading.

The cylinder reservoir can be replaced when neces-

sary. However, the aluminum body section of the

master cylinder is not a repairable component.

NOTE: If diagnosis indicates that an internal mal-

function has occurred, the aluminum body section

must be replaced as an assembly.

OPERATION

The master cylinder bore contains a primary and

secondary piston. The primary piston supplies

hydraulic pressure to the front brakes. The secondary

piston supplies hydraulic pressure to the rear brakes.

DIAGNOSIS AND TESTING - MASTER

CYLINDER/POWER BOOSTER

(1) Start engine and check booster vacuum hose

connections. A hissing noise indicates vacuum leak.

Correct any vacuum leak before proceeding.

(2) Stop engine and shift transmission into Neu-

tral.

(3) Pump brake pedal until all vacuum reserve in

booster is depleted.

(4) Press and hold brake pedal under light foot

pressure. The pedal should hold firm, if the pedal

falls away master cylinder is faulty (internal leak-

age).

(5) Start engine and note pedal action. It should

fall away slightly under light foot pressure then hold

firm. If no pedal action is discernible, power booster,

vacuum supply, or vacuum check valve is faulty. Pro-

ceed to the POWER BOOSTER VACUUM TEST.

(6) If the POWER BOOSTER VACUUM TEST

passes, rebuild booster vacuum reserve as follows:

Release brake pedal. Increase engine speed to 1500

rpm, close the throttle and immediately turn off igni-

tion to stop engine.

(7) Wait a minimum of 90 seconds and try brake

action again. Booster should provide two or more vac-

uum assisted pedal applications. If vacuum assist is

not provided, booster is faulty.

POWER BOOSTER VACUUM TEST

(1) Connect vacuum gauge to booster check valve

with short length of hose and T-fitting (Fig. 54).

(2) Start and run engine at curb idle speed for one

minute.

(3) Observe the vacuum supply. If vacuum supply

is not adequate, repair vacuum supply.

(4) Clamp hose shut between vacuum source and

check valve.

(5) Stop engine and observe vacuum gauge.

(6) If vacuum drops more than one inch HG (33

millibars) within 15 seconds, booster diaphragm or

check valve is faulty.

POWER BOOSTER CHECK VALVE TEST

(1) Disconnect vacuum hose from check valve.

(2) Remove check valve and valve seal from

booster.

(3) Use a hand operated vacuum pump for test.

(4) Apply 15-20 inches vacuum at large end of

check valve (Fig. 55).

Fig. 53 Hold-Down Spring And Pin Attachment

1 - SHOE HOLD DOWN SPRING

2 - HOLD DOWN PIN

3 - BACKING PLATE

4 - BRAKE SHOE WEB

BR/BEBRAKES 5 - 29

BRAKE PADS/SHOES (Continued)