ESP DODGE RAM 2002 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 366 of 2255

ELECTRONIC CONTROL MODULES

TABLE OF CONTENTS

page page

CENTRAL TIMER MODULE

DESCRIPTION..........................1

OPERATION............................3

DIAGNOSIS AND TESTING - CENTRAL TIMER

MODULE.............................4

REMOVAL.............................5

INSTALLATION..........................6

COMMUNICATION

DESCRIPTION - CCD DATA BUS............6

OPERATION - CCD DATA BUS..............7

DIAGNOSIS AND TESTING - CCD DATA BUS . . 11

CONTROLLER ANTILOCK BRAKE

DESCRIPTION.........................11

OPERATION...........................11

REMOVAL.............................11

INSTALLATION.........................12

DATA LINK CONNECTOR

DESCRIPTION - DATA LINK CONNECTOR....12

OPERATION - DATA LINK CONNECTOR......12

ENGINE CONTROL MODULE

DESCRIPTION - ECM....................13

OPERATION - ECM.....................13

REMOVAL.............................14

INSTALLATION.........................14POWERTRAIN CONTROL MODULE

DESCRIPTION

DESCRIPTION - PCM..................15

DESCRIPTION - MODES OF OPERATION . . . 15

DESCRIPTION - 5 VOLT SUPPLIES.......17

DESCRIPTION - IGNITION CIRCUIT SENSE . 17

DESCRIPTION - POWER GROUNDS......17

DESCRIPTION - SENSOR RETURN.......17

DESCRIPTION - SIGNAL GROUND........17

OPERATION

OPERATION - PCM - GAS ENGINES.......18

OPERATION - DIESEL..................18

OPERATION - 5 VOLT SUPPLIES.........19

OPERATION - IGNITION CIRCUIT SENSE . . . 19

REMOVAL.............................19

INSTALLATION.........................20

HEATED SEAT MODULE

DESCRIPTION.........................20

OPERATION...........................20

DIAGNOSIS AND TESTING - HEATED SEAT

MODULE............................21

REMOVAL.............................23

INSTALLATION.........................23

CENTRAL TIMER MODULE

DESCRIPTION

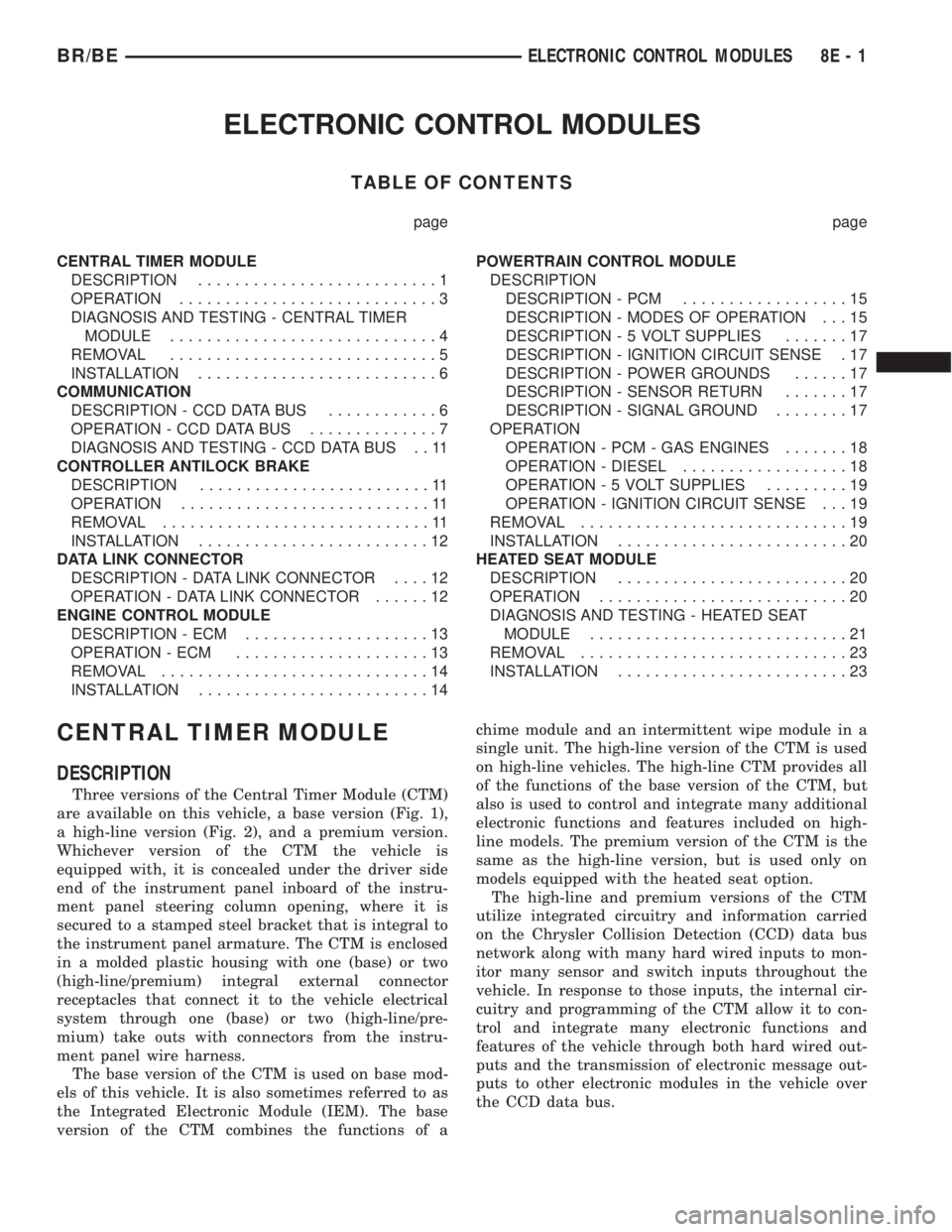

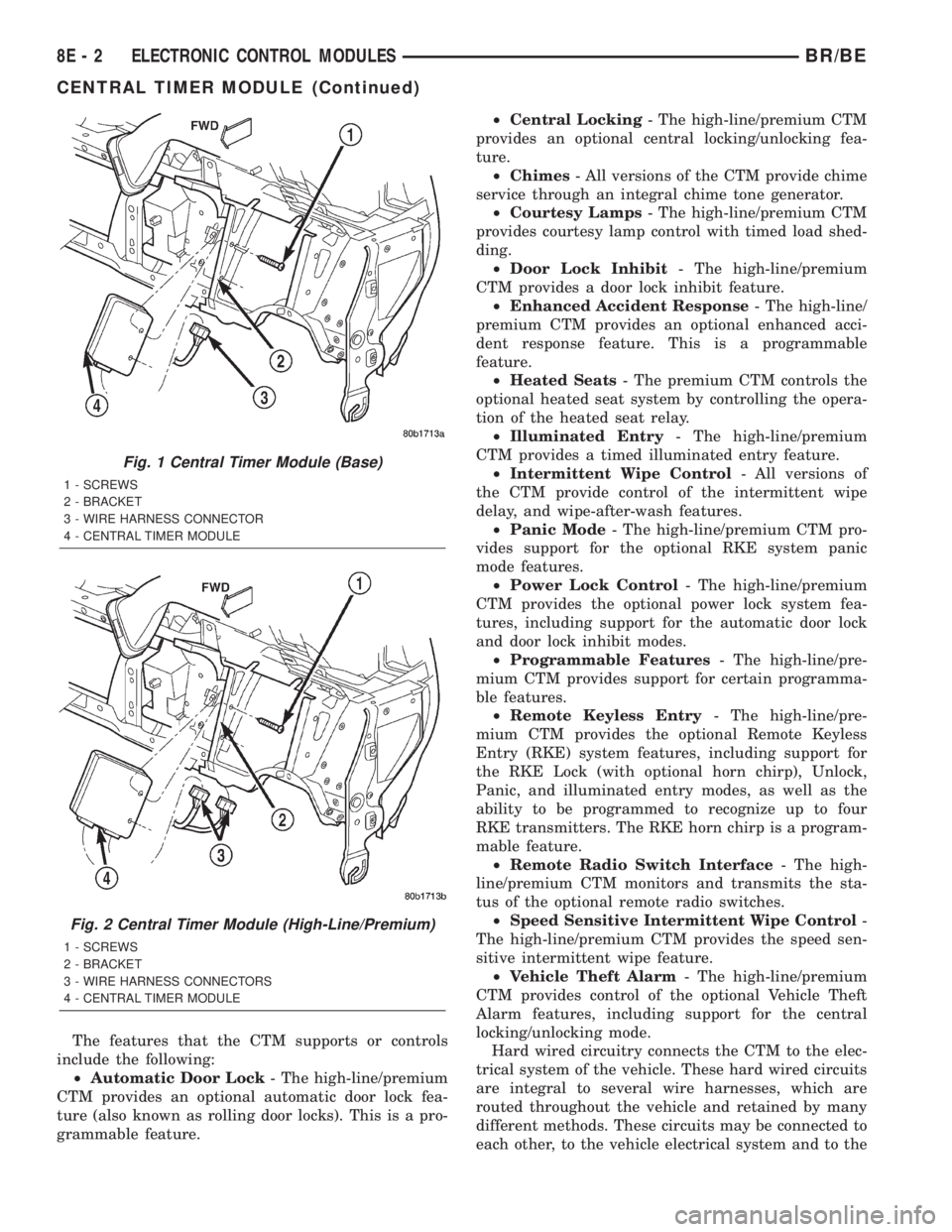

Three versions of the Central Timer Module (CTM)

are available on this vehicle, a base version (Fig. 1),

a high-line version (Fig. 2), and a premium version.

Whichever version of the CTM the vehicle is

equipped with, it is concealed under the driver side

end of the instrument panel inboard of the instru-

ment panel steering column opening, where it is

secured to a stamped steel bracket that is integral to

the instrument panel armature. The CTM is enclosed

in a molded plastic housing with one (base) or two

(high-line/premium) integral external connector

receptacles that connect it to the vehicle electrical

system through one (base) or two (high-line/pre-

mium) take outs with connectors from the instru-

ment panel wire harness.

The base version of the CTM is used on base mod-

els of this vehicle. It is also sometimes referred to as

the Integrated Electronic Module (IEM). The base

version of the CTM combines the functions of achime module and an intermittent wipe module in a

single unit. The high-line version of the CTM is used

on high-line vehicles. The high-line CTM provides all

of the functions of the base version of the CTM, but

also is used to control and integrate many additional

electronic functions and features included on high-

line models. The premium version of the CTM is the

same as the high-line version, but is used only on

models equipped with the heated seat option.

The high-line and premium versions of the CTM

utilize integrated circuitry and information carried

on the Chrysler Collision Detection (CCD) data bus

network along with many hard wired inputs to mon-

itor many sensor and switch inputs throughout the

vehicle. In response to those inputs, the internal cir-

cuitry and programming of the CTM allow it to con-

trol and integrate many electronic functions and

features of the vehicle through both hard wired out-

puts and the transmission of electronic message out-

puts to other electronic modules in the vehicle over

the CCD data bus.

BR/BEELECTRONIC CONTROL MODULES 8E - 1

Page 367 of 2255

The features that the CTM supports or controls

include the following:

²Automatic Door Lock- The high-line/premium

CTM provides an optional automatic door lock fea-

ture (also known as rolling door locks). This is a pro-

grammable feature.²Central Locking- The high-line/premium CTM

provides an optional central locking/unlocking fea-

ture.

²Chimes- All versions of the CTM provide chime

service through an integral chime tone generator.

²Courtesy Lamps- The high-line/premium CTM

provides courtesy lamp control with timed load shed-

ding.

²Door Lock Inhibit- The high-line/premium

CTM provides a door lock inhibit feature.

²Enhanced Accident Response- The high-line/

premium CTM provides an optional enhanced acci-

dent response feature. This is a programmable

feature.

²Heated Seats- The premium CTM controls the

optional heated seat system by controlling the opera-

tion of the heated seat relay.

²Illuminated Entry- The high-line/premium

CTM provides a timed illuminated entry feature.

²Intermittent Wipe Control- All versions of

the CTM provide control of the intermittent wipe

delay, and wipe-after-wash features.

²Panic Mode- The high-line/premium CTM pro-

vides support for the optional RKE system panic

mode features.

²Power Lock Control- The high-line/premium

CTM provides the optional power lock system fea-

tures, including support for the automatic door lock

and door lock inhibit modes.

²Programmable Features- The high-line/pre-

mium CTM provides support for certain programma-

ble features.

²Remote Keyless Entry- The high-line/pre-

mium CTM provides the optional Remote Keyless

Entry (RKE) system features, including support for

the RKE Lock (with optional horn chirp), Unlock,

Panic, and illuminated entry modes, as well as the

ability to be programmed to recognize up to four

RKE transmitters. The RKE horn chirp is a program-

mable feature.

²Remote Radio Switch Interface- The high-

line/premium CTM monitors and transmits the sta-

tus of the optional remote radio switches.

²Speed Sensitive Intermittent Wipe Control-

The high-line/premium CTM provides the speed sen-

sitive intermittent wipe feature.

²Vehicle Theft Alarm- The high-line/premium

CTM provides control of the optional Vehicle Theft

Alarm features, including support for the central

locking/unlocking mode.

Hard wired circuitry connects the CTM to the elec-

trical system of the vehicle. These hard wired circuits

are integral to several wire harnesses, which are

routed throughout the vehicle and retained by many

different methods. These circuits may be connected to

each other, to the vehicle electrical system and to the

Fig. 1 Central Timer Module (Base)

1 - SCREWS

2 - BRACKET

3 - WIRE HARNESS CONNECTOR

4 - CENTRAL TIMER MODULE

Fig. 2 Central Timer Module (High-Line/Premium)

1 - SCREWS

2 - BRACKET

3 - WIRE HARNESS CONNECTORS

4 - CENTRAL TIMER MODULE

8E - 2 ELECTRONIC CONTROL MODULESBR/BE

CENTRAL TIMER MODULE (Continued)

Page 368 of 2255

CTM through the use of a combination of soldered

splices, splice block connectors, and many different

types of wire harness terminal connectors and insu-

lators. Refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, further

details on wire harness routing and retention, as well

as pin-out and location views for the various wire

harness connectors, splices and grounds.

All versions of the CTM for this model are serviced

only as a complete unit. Many of the electronic fea-

tures in the vehicle controlled or supported by the

high-line or premium versions of the CTM are pro-

grammable using the DRBIIItscan tool.However, if

any of the CTM hardware components are damaged

or faulty, the entire CTM unit must be replaced. The

base version of the CTM and the hard wired inputs

or outputs of all CTM versions can be diagnosed

using conventional diagnostic tools and methods;

however, for diagnosis of the high-line or premium

versions of the CTM or the CCD data bus, the use of

a DRBIIItscan tool is required. Refer to the appro-

priate diagnostic information.

OPERATION

The Central Timer Module (CTM) is designed to

control and integrate many of the electronic features

and functions of the vehicle. The base version of the

CTM monitors only hard wired inputs and responds

with the proper hard wired outputs. The microproces-

sor-based high-line/premium version of the CTM

monitors many hard wired switch and sensor inputs

as well as those resources it shares with other elec-

tronic modules in the vehicle through its communica-

tion over the Chrysler Collision Detection (CCD) data

bus network. The internal programming and all of

these inputs allow the high-line/premium CTM

microprocessor to determine the tasks it needs to

perform and their priorities, as well as both the stan-

dard and optional features that it should provide.

The high-line/premium CTM programming then per-

forms those tasks and provides those features

through both CCD data bus communication with

other electronic modules and through hard wired out-

puts to a number of circuits, relays, and actuators.

These outputs allow the high-line/premium CTM the

ability to control numerous accessory systems in the

vehicle.

All versions of the CTM operate on battery current

received through fuses in the Junction Block (JB) on

a non-switched fused B(+) circuit, a fused ignition

switch output (st-run) circuit (base version only), and

a fused ignition switch output (run-acc) circuit (high-

line/premium version only). This arrangement allows

the CTM to provide some features regardless of the

ignition switch position, while other features willoperate only with the ignition switch in the Acces-

sory, On, and/or Start positions. All versions of the

CTM are grounded through their connector and take

out of the instrument panel wire harness. The high-

line/premium CTM has another ground received

through a second connector and take out of the

instrument panel wire harness. The first ground cir-

cuit receives ground through a take out with an eye-

let terminal connector of the instrument panel wire

harness that is secured by a nut to a ground stud

located on the left instrument panel end bracket,

while the second ground circuit (high-line/premium

version only) receives ground through a take out with

an eyelet terminal connector of the instrument panel

wire harness that is secured by a nut to a ground

stud located on the back of the instrument panel

armature above the inboard side of the instrument

panel steering column opening.

The high-line/premium CTM monitors its own

internal circuitry as well as many of its input and

output circuits, and will store a Diagnostic Trouble

Code (DTC) in electronic memory for any failure it

detects. These DTCs can be retrieved and diagnosed

using a DRBIIItscan tool. Refer to the appropriate

diagnostic information.

HARD WIRED INPUTS

The hard wired inputs to the CTM include the fol-

lowing:

²CCD bus± - high-line/premium version only

²CCD bus+ - high-line/premium version only

²Cylinder lock switch mux - high-line premium

version only

²Driver door ajar switch sense

²Fused B(+)

²Fused ignition switch output (run-acc) - high-

line/premium version only

²Fused ignition switch output (st-run) - base ver-

sion only

²Ground (one circuit - base version, two circuits -

high-line/premium version)

²Key-in ignition switch sense

²Passenger door ajar switch sense - high-line/pre-

mium version only

²Power door lock motor B(+) lock - high-line/pre-

mium version only

²Power door lock motor B(+) unlock - high-line/

premium version only

²Radio control mux - high-line/premium version

only

²Tone request signal

²Washer switch sense

²Wiper park switch sense

²Wiper switch mode sense

²Wiper switch mode signal

BR/BEELECTRONIC CONTROL MODULES 8E - 3

CENTRAL TIMER MODULE (Continued)

Page 369 of 2255

HARD WIRED OUTPUTS

The hard wired outputs of the CTM include the fol-

lowing:

²CCD bus± - high-line/premium version only

²CCD bus+ - high-line/premium version only

²Courtesy lamp switch output - high-line/pre-

mium version only

²Door lock driver - high-line/premium version

only

²Door unlock driver - high-line/premium version

only

²Headlamp relay control - high-line/premium ver-

sion only

²Heated seat relay control - premium version

only

²Horn relay control - high-line/premium version

only

²VTSS indicator driver - high-line/premium ver-

sion only

²Wiper motor relay control

MESSAGING

The high-line/premium CTM uses the following

messages received from other electronic modules over

the CCD data bus:

²Airbag Deploy (ACM)

²Charging System Failure (PCM)

²Engine RPM (PCM)

²System Voltage (PCM)

²Vehicle Speed (PCM)

²Voltage Fault (PCM)

The high-line/premium CTM provides the following

messages to other electronic modules over the CCD

data bus:

²Engine Enable (PCM)

²Radio Seek Up (Radio)

²Radio Seek Down (Radio)

²Radio Volume Up (Radio)

²Radio Volume Down (Radio)

²Preset Scan (Radio)

DIAGNOSIS AND TESTING - CENTRAL TIMER

MODULE

The hard wired inputs to and outputs from the

Central Timer Module (CTM) may be diagnosed and

tested using conventional diagnostic tools and meth-

ods. Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds.

However, conventional diagnostic methods may not

prove conclusive in the diagnosis of the high-line/pre-

mium CTM. In order to obtain conclusive testing of

the high-line/premium CTM, the Chrysler CollisionDetection (CCD) data bus network and all of the elec-

tronic modules that provide inputs to or receive out-

puts from the CTM must also be checked. The most

reliable, efficient, and accurate means to diagnose

the high-line/premium CTM, the CCD data bus net-

work, and the electronic modules that provide inputs

to or receive outputs from the high-line/premium

CTM requires the use of a DRBIIItscan tool and the

appropriate diagnostic information. The DRBIIIt

scan tool can provide confirmation that the CCD data

bus network is functional, that all of the electronic

modules are sending and receiving the proper mes-

sages over the CCD data bus, and that the CTM is

receiving the proper hard wired inputs and respond-

ing with the proper hard wired outputs needed to

perform its many functions.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: The following tests may not prove conclu-

sive in the diagnosis of the high-line or premium

versions of the Central Timer Module (CTM). The

most reliable, efficient, and accurate means to diag-

nose the high-line or premium CTM requires the

use of a DRBIIITscan tool and the appropriate diag-

nostic information.

(1) Check the fused B(+) fuse (Fuse 13 - 10

ampere) in the Junction Block (JB). If OK, go to Step

2. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

(Fuse 13 - 10 ampere) in the JB. If OK, go to Step 3.

If not OK, repair the open fused B(+) circuit between

the JB and the Power Distribution Center (PDC) as

required.

(3) For a base version CTM, check the fused igni-

tion switch output (st-run) fuse (Fuse 11 - 10 ampere)

in the JB. For a high-line/premium version CTM,

check the fused ignition switch output (run-acc) fuse

(Fuse6-25ampere) in the JB. If OK, go to Step 4. If

not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

8E - 4 ELECTRONIC CONTROL MODULESBR/BE

CENTRAL TIMER MODULE (Continued)

Page 373 of 2255

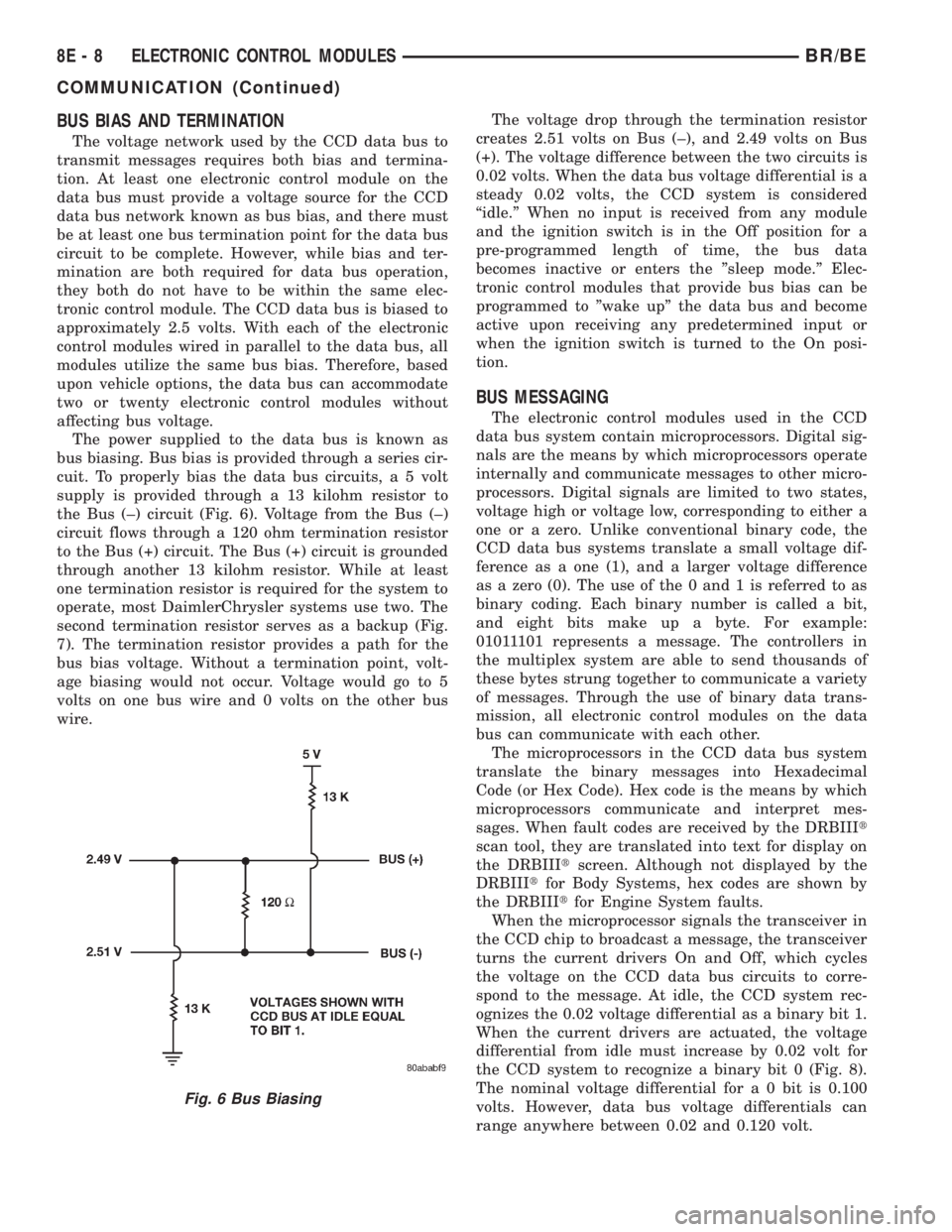

BUS BIAS AND TERMINATION

The voltage network used by the CCD data bus to

transmit messages requires both bias and termina-

tion. At least one electronic control module on the

data bus must provide a voltage source for the CCD

data bus network known as bus bias, and there must

be at least one bus termination point for the data bus

circuit to be complete. However, while bias and ter-

mination are both required for data bus operation,

they both do not have to be within the same elec-

tronic control module. The CCD data bus is biased to

approximately 2.5 volts. With each of the electronic

control modules wired in parallel to the data bus, all

modules utilize the same bus bias. Therefore, based

upon vehicle options, the data bus can accommodate

two or twenty electronic control modules without

affecting bus voltage.

The power supplied to the data bus is known as

bus biasing. Bus bias is provided through a series cir-

cuit. To properly bias the data bus circuits, a 5 volt

supply is provided through a 13 kilohm resistor to

the Bus (±) circuit (Fig. 6). Voltage from the Bus (±)

circuit flows through a 120 ohm termination resistor

to the Bus (+) circuit. The Bus (+) circuit is grounded

through another 13 kilohm resistor. While at least

one termination resistor is required for the system to

operate, most DaimlerChrysler systems use two. The

second termination resistor serves as a backup (Fig.

7). The termination resistor provides a path for the

bus bias voltage. Without a termination point, volt-

age biasing would not occur. Voltage would go to 5

volts on one bus wire and 0 volts on the other bus

wire.The voltage drop through the termination resistor

creates 2.51 volts on Bus (±), and 2.49 volts on Bus

(+). The voltage difference between the two circuits is

0.02 volts. When the data bus voltage differential is a

steady 0.02 volts, the CCD system is considered

ªidle.º When no input is received from any module

and the ignition switch is in the Off position for a

pre-programmed length of time, the bus data

becomes inactive or enters the ºsleep mode.º Elec-

tronic control modules that provide bus bias can be

programmed to ºwake upº the data bus and become

active upon receiving any predetermined input or

when the ignition switch is turned to the On posi-

tion.

BUS MESSAGING

The electronic control modules used in the CCD

data bus system contain microprocessors. Digital sig-

nals are the means by which microprocessors operate

internally and communicate messages to other micro-

processors. Digital signals are limited to two states,

voltage high or voltage low, corresponding to either a

one or a zero. Unlike conventional binary code, the

CCD data bus systems translate a small voltage dif-

ference as a one (1), and a larger voltage difference

as a zero (0). The use of the 0 and 1 is referred to as

binary coding. Each binary number is called a bit,

and eight bits make up a byte. For example:

01011101 represents a message. The controllers in

the multiplex system are able to send thousands of

these bytes strung together to communicate a variety

of messages. Through the use of binary data trans-

mission, all electronic control modules on the data

bus can communicate with each other.

The microprocessors in the CCD data bus system

translate the binary messages into Hexadecimal

Code (or Hex Code). Hex code is the means by which

microprocessors communicate and interpret mes-

sages. When fault codes are received by the DRBIIIt

scan tool, they are translated into text for display on

the DRBIIItscreen. Although not displayed by the

DRBIIItfor Body Systems, hex codes are shown by

the DRBIIItfor Engine System faults.

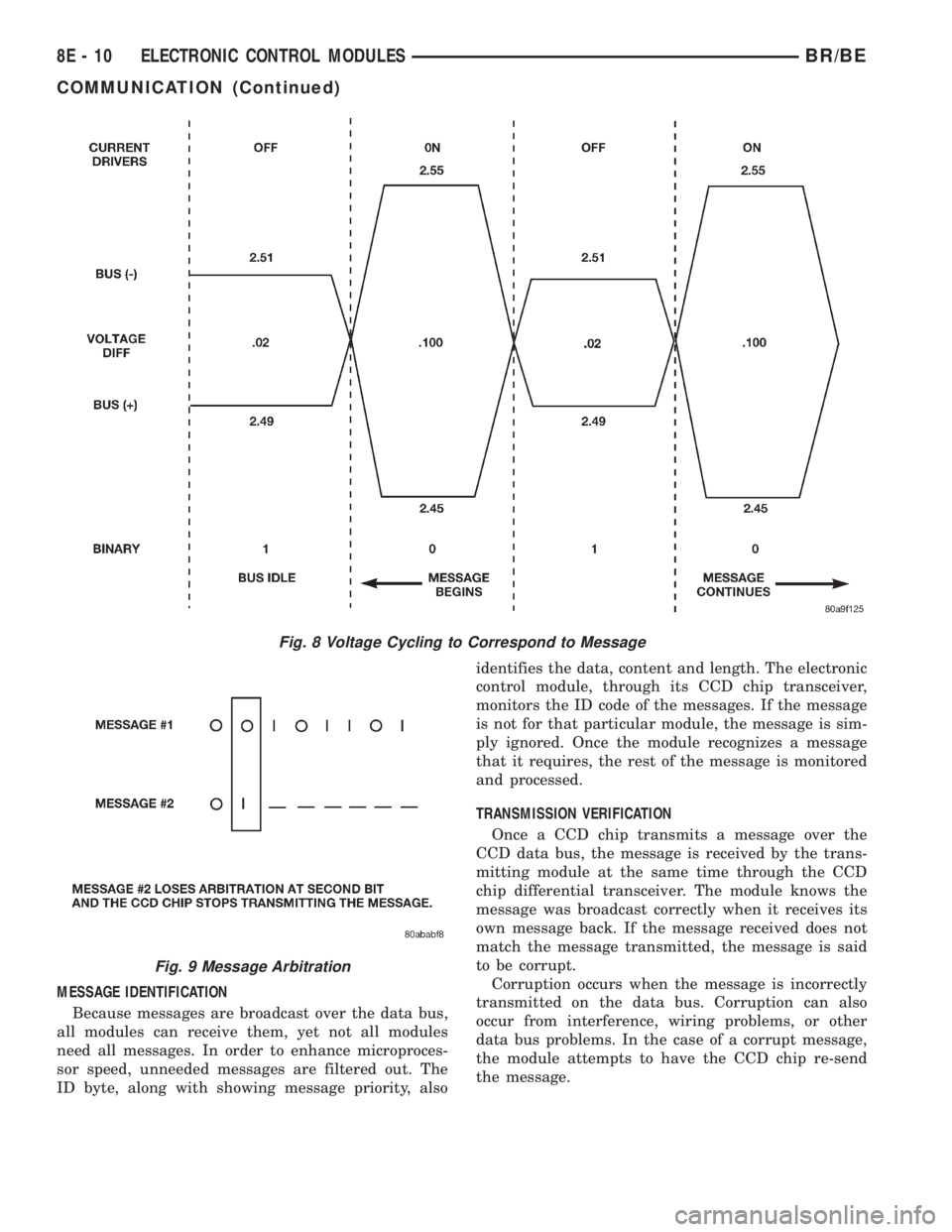

When the microprocessor signals the transceiver in

the CCD chip to broadcast a message, the transceiver

turns the current drivers On and Off, which cycles

the voltage on the CCD data bus circuits to corre-

spond to the message. At idle, the CCD system rec-

ognizes the 0.02 voltage differential as a binary bit 1.

When the current drivers are actuated, the voltage

differential from idle must increase by 0.02 volt for

the CCD system to recognize a binary bit 0 (Fig. 8).

The nominal voltage differential for a 0 bit is 0.100

volts. However, data bus voltage differentials can

range anywhere between 0.02 and 0.120 volt.

Fig. 6 Bus Biasing

8E - 8 ELECTRONIC CONTROL MODULESBR/BE

COMMUNICATION (Continued)

Page 375 of 2255

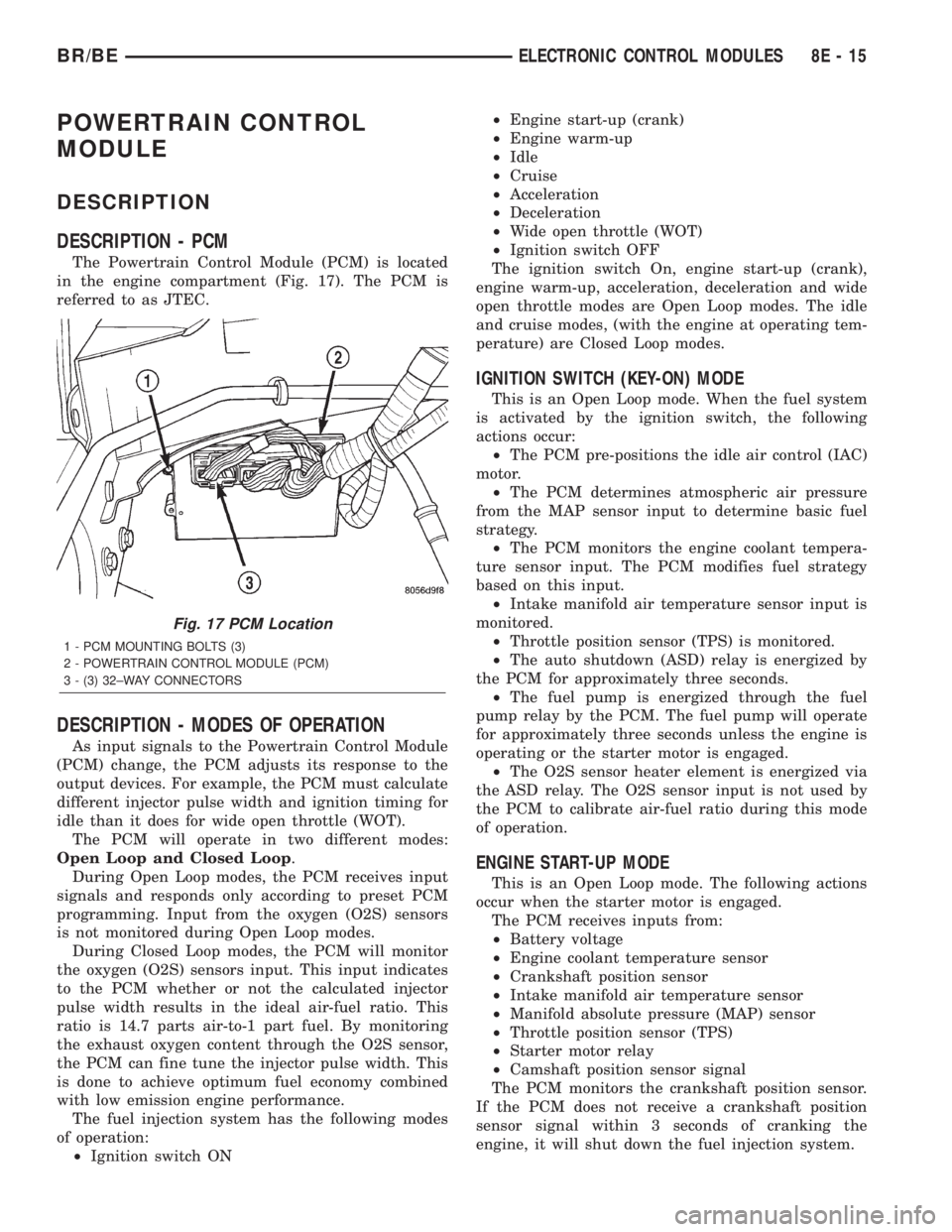

MESSAGE IDENTIFICATION

Because messages are broadcast over the data bus,

all modules can receive them, yet not all modules

need all messages. In order to enhance microproces-

sor speed, unneeded messages are filtered out. The

ID byte, along with showing message priority, alsoidentifies the data, content and length. The electronic

control module, through its CCD chip transceiver,

monitors the ID code of the messages. If the message

is not for that particular module, the message is sim-

ply ignored. Once the module recognizes a message

that it requires, the rest of the message is monitored

and processed.

TRANSMISSION VERIFICATION

Once a CCD chip transmits a message over the

CCD data bus, the message is received by the trans-

mitting module at the same time through the CCD

chip differential transceiver. The module knows the

message was broadcast correctly when it receives its

own message back. If the message received does not

match the message transmitted, the message is said

to be corrupt.

Corruption occurs when the message is incorrectly

transmitted on the data bus. Corruption can also

occur from interference, wiring problems, or other

data bus problems. In the case of a corrupt message,

the module attempts to have the CCD chip re-send

the message.

Fig. 8 Voltage Cycling to Correspond to Message

Fig. 9 Message Arbitration

8E - 10 ELECTRONIC CONTROL MODULESBR/BE

COMMUNICATION (Continued)

Page 380 of 2255

POWERTRAIN CONTROL

MODULE

DESCRIPTION

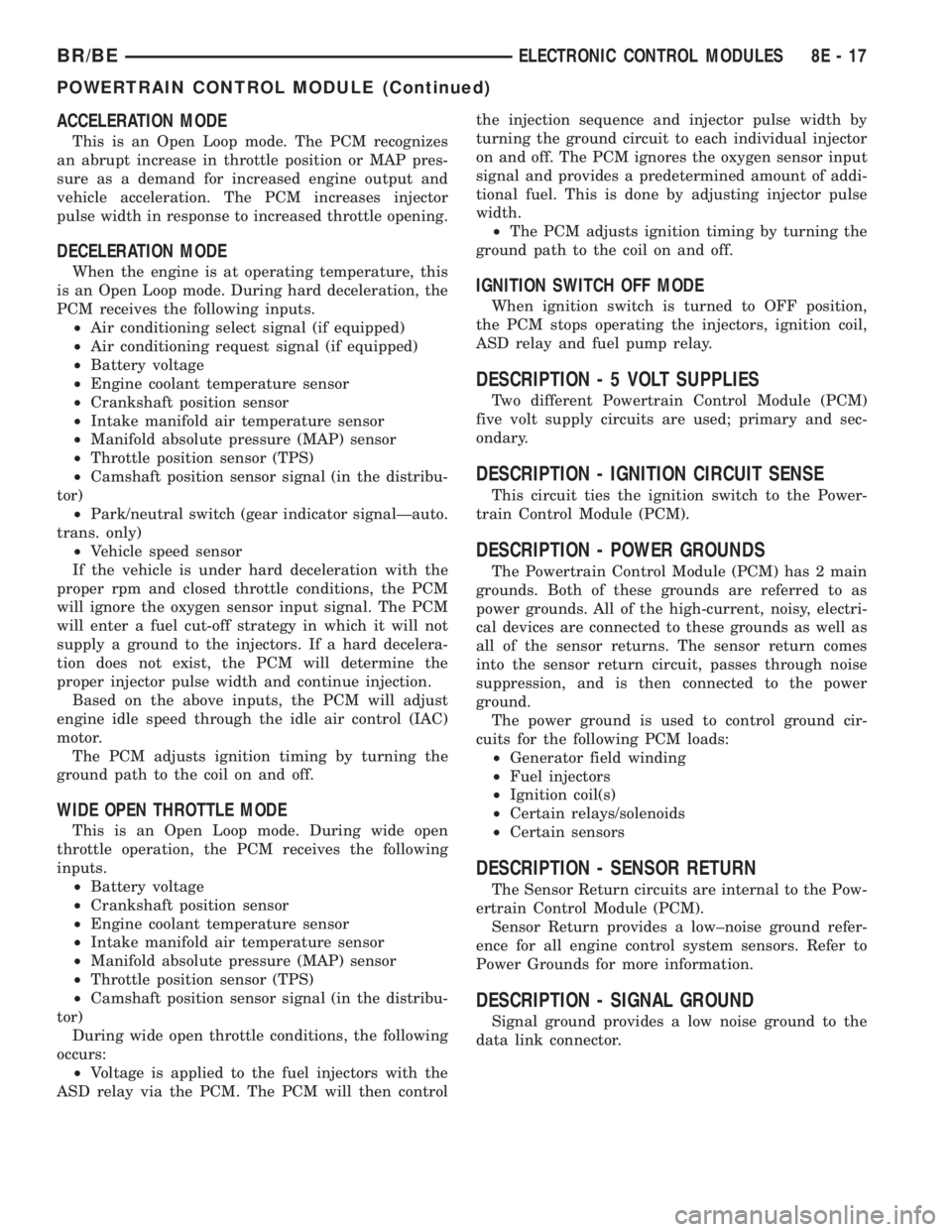

DESCRIPTION - PCM

The Powertrain Control Module (PCM) is located

in the engine compartment (Fig. 17). The PCM is

referred to as JTEC.

DESCRIPTION - MODES OF OPERATION

As input signals to the Powertrain Control Module

(PCM) change, the PCM adjusts its response to the

output devices. For example, the PCM must calculate

different injector pulse width and ignition timing for

idle than it does for wide open throttle (WOT).

The PCM will operate in two different modes:

Open Loop and Closed Loop.

During Open Loop modes, the PCM receives input

signals and responds only according to preset PCM

programming. Input from the oxygen (O2S) sensors

is not monitored during Open Loop modes.

During Closed Loop modes, the PCM will monitor

the oxygen (O2S) sensors input. This input indicates

to the PCM whether or not the calculated injector

pulse width results in the ideal air-fuel ratio. This

ratio is 14.7 parts air-to-1 part fuel. By monitoring

the exhaust oxygen content through the O2S sensor,

the PCM can fine tune the injector pulse width. This

is done to achieve optimum fuel economy combined

with low emission engine performance.

The fuel injection system has the following modes

of operation:

²Ignition switch ON²Engine start-up (crank)

²Engine warm-up

²Idle

²Cruise

²Acceleration

²Deceleration

²Wide open throttle (WOT)

²Ignition switch OFF

The ignition switch On, engine start-up (crank),

engine warm-up, acceleration, deceleration and wide

open throttle modes are Open Loop modes. The idle

and cruise modes, (with the engine at operating tem-

perature) are Closed Loop modes.

IGNITION SWITCH (KEY-ON) MODE

This is an Open Loop mode. When the fuel system

is activated by the ignition switch, the following

actions occur:

²The PCM pre-positions the idle air control (IAC)

motor.

²The PCM determines atmospheric air pressure

from the MAP sensor input to determine basic fuel

strategy.

²The PCM monitors the engine coolant tempera-

ture sensor input. The PCM modifies fuel strategy

based on this input.

²Intake manifold air temperature sensor input is

monitored.

²Throttle position sensor (TPS) is monitored.

²The auto shutdown (ASD) relay is energized by

the PCM for approximately three seconds.

²The fuel pump is energized through the fuel

pump relay by the PCM. The fuel pump will operate

for approximately three seconds unless the engine is

operating or the starter motor is engaged.

²The O2S sensor heater element is energized via

the ASD relay. The O2S sensor input is not used by

the PCM to calibrate air-fuel ratio during this mode

of operation.

ENGINE START-UP MODE

This is an Open Loop mode. The following actions

occur when the starter motor is engaged.

The PCM receives inputs from:

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Starter motor relay

²Camshaft position sensor signal

The PCM monitors the crankshaft position sensor.

If the PCM does not receive a crankshaft position

sensor signal within 3 seconds of cranking the

engine, it will shut down the fuel injection system.

Fig. 17 PCM Location

1 - PCM MOUNTING BOLTS (3)

2 - POWERTRAIN CONTROL MODULE (PCM)

3 - (3) 32±WAY CONNECTORS

BR/BEELECTRONIC CONTROL MODULES 8E - 15

Page 382 of 2255

ACCELERATION MODE

This is an Open Loop mode. The PCM recognizes

an abrupt increase in throttle position or MAP pres-

sure as a demand for increased engine output and

vehicle acceleration. The PCM increases injector

pulse width in response to increased throttle opening.

DECELERATION MODE

When the engine is at operating temperature, this

is an Open Loop mode. During hard deceleration, the

PCM receives the following inputs.

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal (in the distribu-

tor)

²Park/neutral switch (gear indicator signalÐauto.

trans. only)

²Vehicle speed sensor

If the vehicle is under hard deceleration with the

proper rpm and closed throttle conditions, the PCM

will ignore the oxygen sensor input signal. The PCM

will enter a fuel cut-off strategy in which it will not

supply a ground to the injectors. If a hard decelera-

tion does not exist, the PCM will determine the

proper injector pulse width and continue injection.

Based on the above inputs, the PCM will adjust

engine idle speed through the idle air control (IAC)

motor.

The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

WIDE OPEN THROTTLE MODE

This is an Open Loop mode. During wide open

throttle operation, the PCM receives the following

inputs.

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal (in the distribu-

tor)

During wide open throttle conditions, the following

occurs:

²Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then controlthe injection sequence and injector pulse width by

turning the ground circuit to each individual injector

on and off. The PCM ignores the oxygen sensor input

signal and provides a predetermined amount of addi-

tional fuel. This is done by adjusting injector pulse

width.

²The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

IGNITION SWITCH OFF MODE

When ignition switch is turned to OFF position,

the PCM stops operating the injectors, ignition coil,

ASD relay and fuel pump relay.

DESCRIPTION - 5 VOLT SUPPLIES

Two different Powertrain Control Module (PCM)

five volt supply circuits are used; primary and sec-

ondary.

DESCRIPTION - IGNITION CIRCUIT SENSE

This circuit ties the ignition switch to the Power-

train Control Module (PCM).

DESCRIPTION - POWER GROUNDS

The Powertrain Control Module (PCM) has 2 main

grounds. Both of these grounds are referred to as

power grounds. All of the high-current, noisy, electri-

cal devices are connected to these grounds as well as

all of the sensor returns. The sensor return comes

into the sensor return circuit, passes through noise

suppression, and is then connected to the power

ground.

The power ground is used to control ground cir-

cuits for the following PCM loads:

²Generator field winding

²Fuel injectors

²Ignition coil(s)

²Certain relays/solenoids

²Certain sensors

DESCRIPTION - SENSOR RETURN

The Sensor Return circuits are internal to the Pow-

ertrain Control Module (PCM).

Sensor Return provides a low±noise ground refer-

ence for all engine control system sensors. Refer to

Power Grounds for more information.

DESCRIPTION - SIGNAL GROUND

Signal ground provides a low noise ground to the

data link connector.

BR/BEELECTRONIC CONTROL MODULES 8E - 17

POWERTRAIN CONTROL MODULE (Continued)

Page 386 of 2255

of the vehicle. Inputs to the module include a resistor

multiplexed heated seat switch request circuit for

each of the two heated seat switches and the heated

seat sensor inputs from the seat cushions of each

front seat. In response to those inputs the heated

seat module controls battery current feeds to the

heated seat elements and sensors, and controls the

ground for the heated seat switch indicator lamps.

NOTE: The vehicle's engine must be running in

order for the heated seat system to function. This

eliminates the possibility of draining the vehicles

battery voltage while operating the heated seat sys-

tem.

When a heated seat switch (Driver or Passenger) is

depressed a signal is received by the heated seat

module, the module energizes the proper indicator

LED (Low or High) in the switch by grounding the

indicator lamp circuit to indicate that the heated seat

system is operating. At the same time, the heated

seat module energizes the selected heated seat sensor

circuit and the sensor provides the module with an

input indicating the surface temperature of the

selected seat cushion.

The Low heat set point is about 36É C (96.8É F),

and the High heat set point is about 42É C (107.6É F).

If the seat cushion surface temperature input is

below the temperature set point for the selected tem-

perature setting, the heated seat module energizes

an N-channel Field Effect Transistor (N-FET) within

the module which energizes the heated seat elements

in the selected seat cushion and back. When the sen-

sor input to the module indicates the correct temper-

ature set point has been achieved, the module

de-energizes the N-FET which de-energizes the

heated seat elements. The heated seat module will

continue to cycle the N-FET as needed to maintain

the selected temperature set point.

If the heated seat module detects a heated seat

sensor value input that is out of range or a shorted

or open heated seat element circuit, it will notify the

vehicle operator or the repair technician of this con-

dition by flashing the High and/or Low indicator

lamps in the affected heated seat switch. Refer to

Diagnosis and Testing Heated Seat Systemin

Heated Systems for flashing LED diagnosis and test-

ing procedures. Refer toDiagnosis and Testing

Heated Seat Modulein this section for heated seat

module diagnosis and testing procedures. Also refer

to the Body Diagnostic Manual for additional diagno-

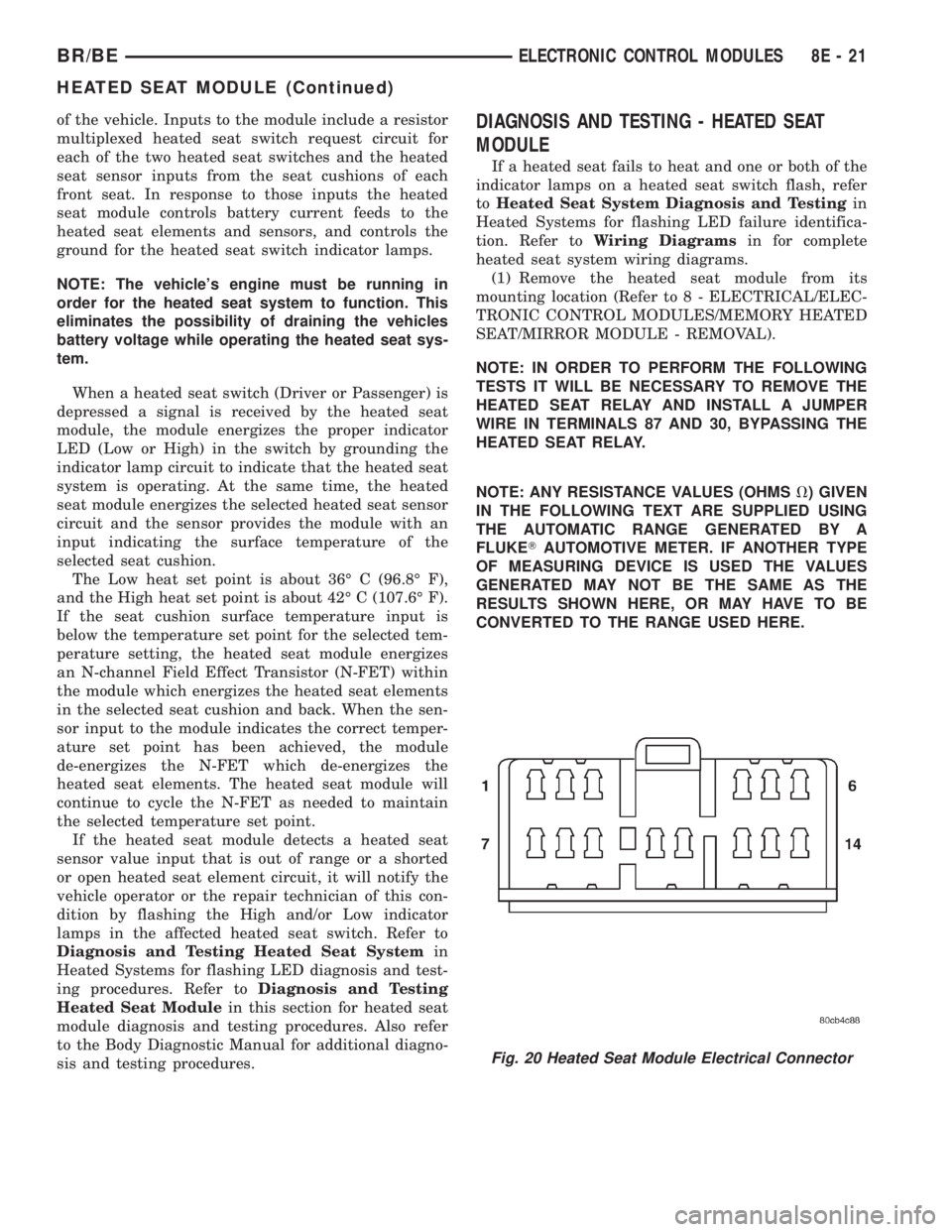

sis and testing procedures.DIAGNOSIS AND TESTING - HEATED SEAT

MODULE

If a heated seat fails to heat and one or both of the

indicator lamps on a heated seat switch flash, refer

toHeated Seat System Diagnosis and Testingin

Heated Systems for flashing LED failure identifica-

tion. Refer toWiring Diagramsin for complete

heated seat system wiring diagrams.

(1) Remove the heated seat module from its

mounting location (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/MEMORY HEATED

SEAT/MIRROR MODULE - REMOVAL).

NOTE: IN ORDER TO PERFORM THE FOLLOWING

TESTS IT WILL BE NECESSARY TO REMOVE THE

HEATED SEAT RELAY AND INSTALL A JUMPER

WIRE IN TERMINALS 87 AND 30, BYPASSING THE

HEATED SEAT RELAY.

NOTE: ANY RESISTANCE VALUES (OHMSV) GIVEN

IN THE FOLLOWING TEXT ARE SUPPLIED USING

THE AUTOMATIC RANGE GENERATED BY A

FLUKETAUTOMOTIVE METER. IF ANOTHER TYPE

OF MEASURING DEVICE IS USED THE VALUES

GENERATED MAY NOT BE THE SAME AS THE

RESULTS SHOWN HERE, OR MAY HAVE TO BE

CONVERTED TO THE RANGE USED HERE.

Fig. 20 Heated Seat Module Electrical Connector

BR/BEELECTRONIC CONTROL MODULES 8E - 21

HEATED SEAT MODULE (Continued)

Page 396 of 2255

SPECIAL TOOLS

BATTERY

DESCRIPTION

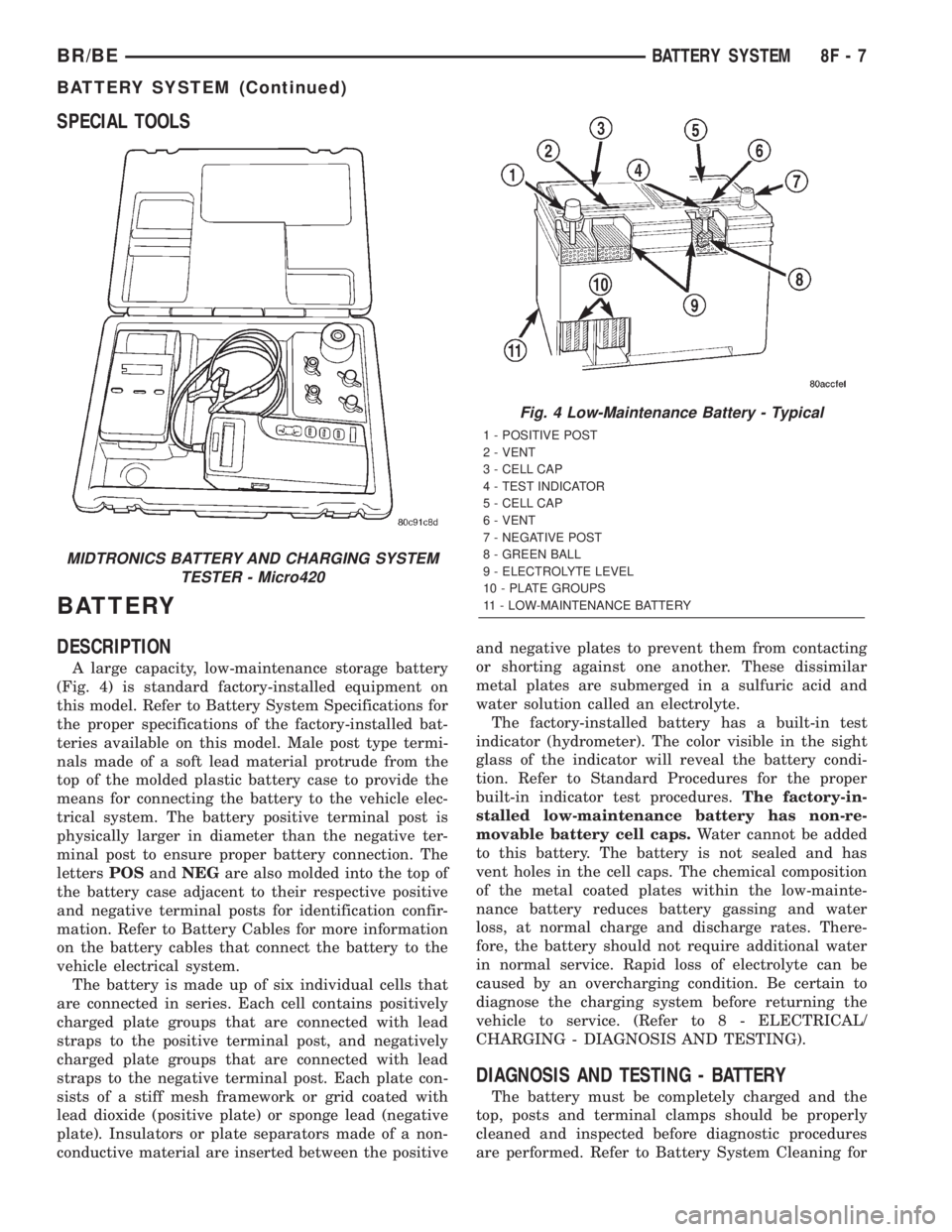

A large capacity, low-maintenance storage battery

(Fig. 4) is standard factory-installed equipment on

this model. Refer to Battery System Specifications for

the proper specifications of the factory-installed bat-

teries available on this model. Male post type termi-

nals made of a soft lead material protrude from the

top of the molded plastic battery case to provide the

means for connecting the battery to the vehicle elec-

trical system. The battery positive terminal post is

physically larger in diameter than the negative ter-

minal post to ensure proper battery connection. The

lettersPOSandNEGare also molded into the top of

the battery case adjacent to their respective positive

and negative terminal posts for identification confir-

mation. Refer to Battery Cables for more information

on the battery cables that connect the battery to the

vehicle electrical system.

The battery is made up of six individual cells that

are connected in series. Each cell contains positively

charged plate groups that are connected with lead

straps to the positive terminal post, and negatively

charged plate groups that are connected with lead

straps to the negative terminal post. Each plate con-

sists of a stiff mesh framework or grid coated with

lead dioxide (positive plate) or sponge lead (negative

plate). Insulators or plate separators made of a non-

conductive material are inserted between the positiveand negative plates to prevent them from contacting

or shorting against one another. These dissimilar

metal plates are submerged in a sulfuric acid and

water solution called an electrolyte.

The factory-installed battery has a built-in test

indicator (hydrometer). The color visible in the sight

glass of the indicator will reveal the battery condi-

tion. Refer to Standard Procedures for the proper

built-in indicator test procedures.The factory-in-

stalled low-maintenance battery has non-re-

movable battery cell caps.Water cannot be added

to this battery. The battery is not sealed and has

vent holes in the cell caps. The chemical composition

of the metal coated plates within the low-mainte-

nance battery reduces battery gassing and water

loss, at normal charge and discharge rates. There-

fore, the battery should not require additional water

in normal service. Rapid loss of electrolyte can be

caused by an overcharging condition. Be certain to

diagnose the charging system before returning the

vehicle to service. (Refer to 8 - ELECTRICAL/

CHARGING - DIAGNOSIS AND TESTING).

DIAGNOSIS AND TESTING - BATTERY

The battery must be completely charged and the

top, posts and terminal clamps should be properly

cleaned and inspected before diagnostic procedures

are performed. Refer to Battery System Cleaning for

MIDTRONICS BATTERY AND CHARGING SYSTEM

TESTER - Micro420

Fig. 4 Low-Maintenance Battery - Typical

1 - POSITIVE POST

2 - VENT

3 - CELL CAP

4 - TEST INDICATOR

5 - CELL CAP

6 - VENT

7 - NEGATIVE POST

8 - GREEN BALL

9 - ELECTROLYTE LEVEL

10 - PLATE GROUPS

11 - LOW-MAINTENANCE BATTERY

BR/BEBATTERY SYSTEM 8F - 7

BATTERY SYSTEM (Continued)