ECU DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3909 of 5267

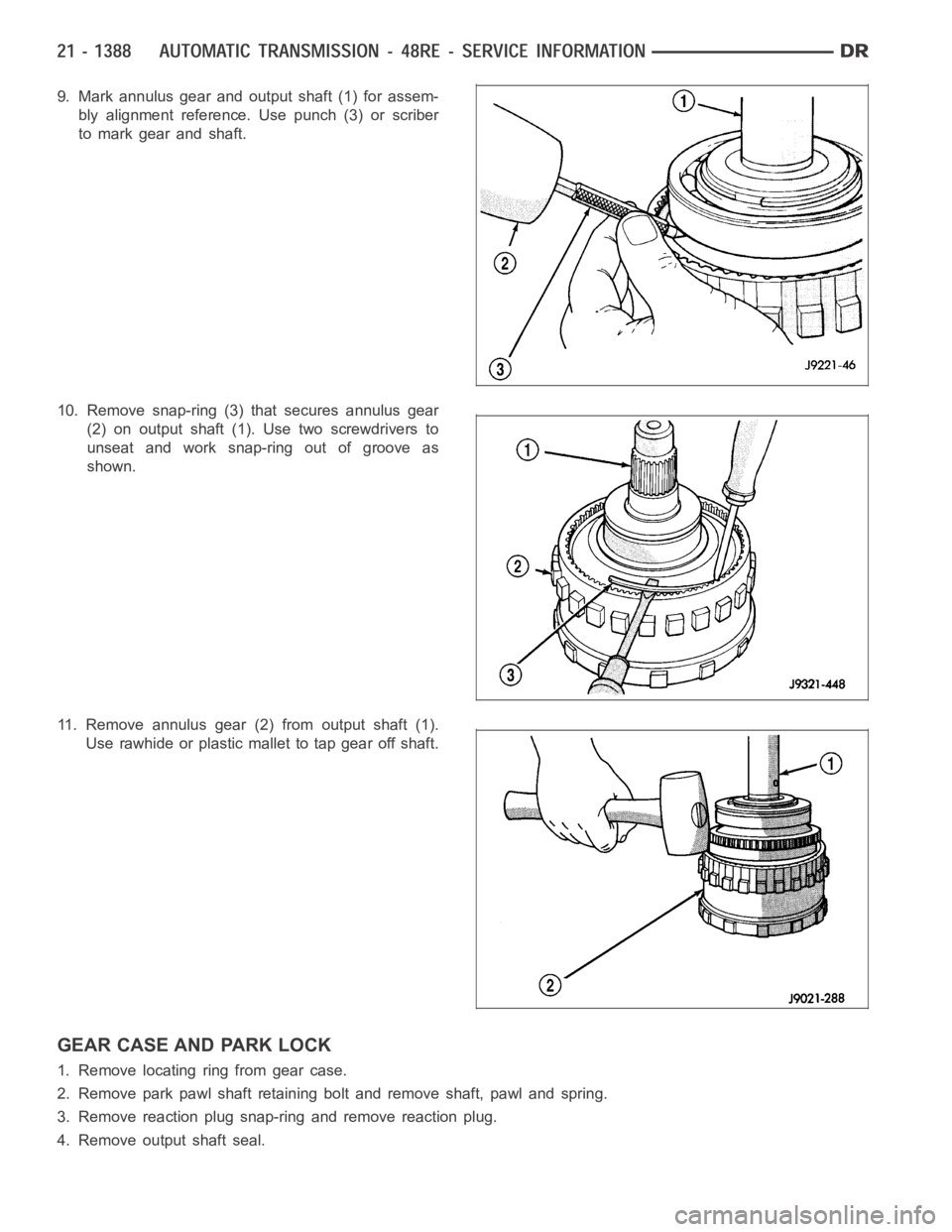

9. Mark annulus gear and output shaft (1) for assem-

bly alignment reference. Use punch (3) or scriber

to mark gear and shaft.

10. Remove snap-ring (3) that secures annulus gear

(2) on output shaft (1). Use two screwdrivers to

unseat and work snap-ring out of groove as

shown.

11. Remove annulus gear (2) from output shaft (1).

Use rawhide or plastic mallet to tap gear off shaft.

GEAR CASE AND PARK LOCK

1. Remove locating ring from gear case.

2. Remove park pawl shaft retaining bolt and remove shaft, pawl and spring.

3. Remove reaction plug snap-ring and remove reaction plug.

4. Remove output shaft seal.

Page 3910 of 5267

CLEANING

Clean the geartrain and case components with solvent. Dry all parts exceptthebearingswithcompressedair.Allow

bearings to air dry.

Do not use shop towels for wiping parts dry unless the towels are made from a lint-free material. A sufficient quan-

tity of lint (from shop towels, cloths, rags, etc.) could plug the transmission filter and fluid passages.

Discard the old case gasket and seals.Do not attempt to salvage these parts. They are not reusable. Replace any

of the overdrive unit snap-rings if distorted or damaged.

Minor nicks or scratches on components can be smoothed with crocus cloth. However, do not attempt to reduce

severescoringonanycomponentswithabrasive materials. Replace severely scored components; do not try to

salvage them.

INSPECTION

Check condition of the park lock components and the overdrive case.

Check the bushings in the overdrive case. Replace the bushings if severelyscored or worn. Also replace the case

seal if loose, distorted, or damaged.

Examine the overdrive and direct clutch discs and plates. Replace the discs if the facing is worn, severely scored,

or burned and flaking off. Replace the clutch plates if worn, heavily scored, or cracked. Check the lugs on the clutch

plates for wear. The plates should slide freely in the drum. Replace the plates or drum if binding occurs.

Check condition of the annulus gear, direct clutch hub, clutch drum and clutch spring. Replace the gear, hub and

drum if worn or damaged. Replace the spring if collapsed, distorted, or cracked.

Be sure the splines and lugs on the gear, drum and hub are in good condition. The clutch plates and discs should

slide freely in these components.

Inspect the thrust bearings and spring plate. Replace the plate if worn or scored. Replace the bearings if rough,

noisy, brinnelled, or worn.

Inspect the planetary gear assembly and the sun gear and bushings. If either the sun gear or the bushings are

damaged, replace the gear and bushings as an assembly. The gear and bushings are not serviced separately.

The planetary carrier and pinions must be in good condition. Also be sure the pinion pins are secure and in good

condition. Replace the carrier if worn or damaged.

Inspect the overrunning clutch and race. The race surface should be smoothand free of scores. Replace the over-

running clutch assembly or the race if either assembly is worn or damaged inany way.

Replace the shaft pilot bushing and inner bushing if damaged. Replace either shaft bearing if rough or noisy.

Replace the bearing snap-rings if distorted or cracked.

Check the machined surfaces on the output shaft. These surfaces should clean and smooth. Very minor nicks or

scratches can be smoothed with crocus cloth. Replace the shaft if worn, scored or damaged in any way.

Inspect the output shaft bushings. The small bushing is the intermediate shaft pilot bushing. The large bushing is the

overrunning clutch hub bushing. Replace either bushing if scored, pitted, cracked, or worn.

Page 3918 of 5267

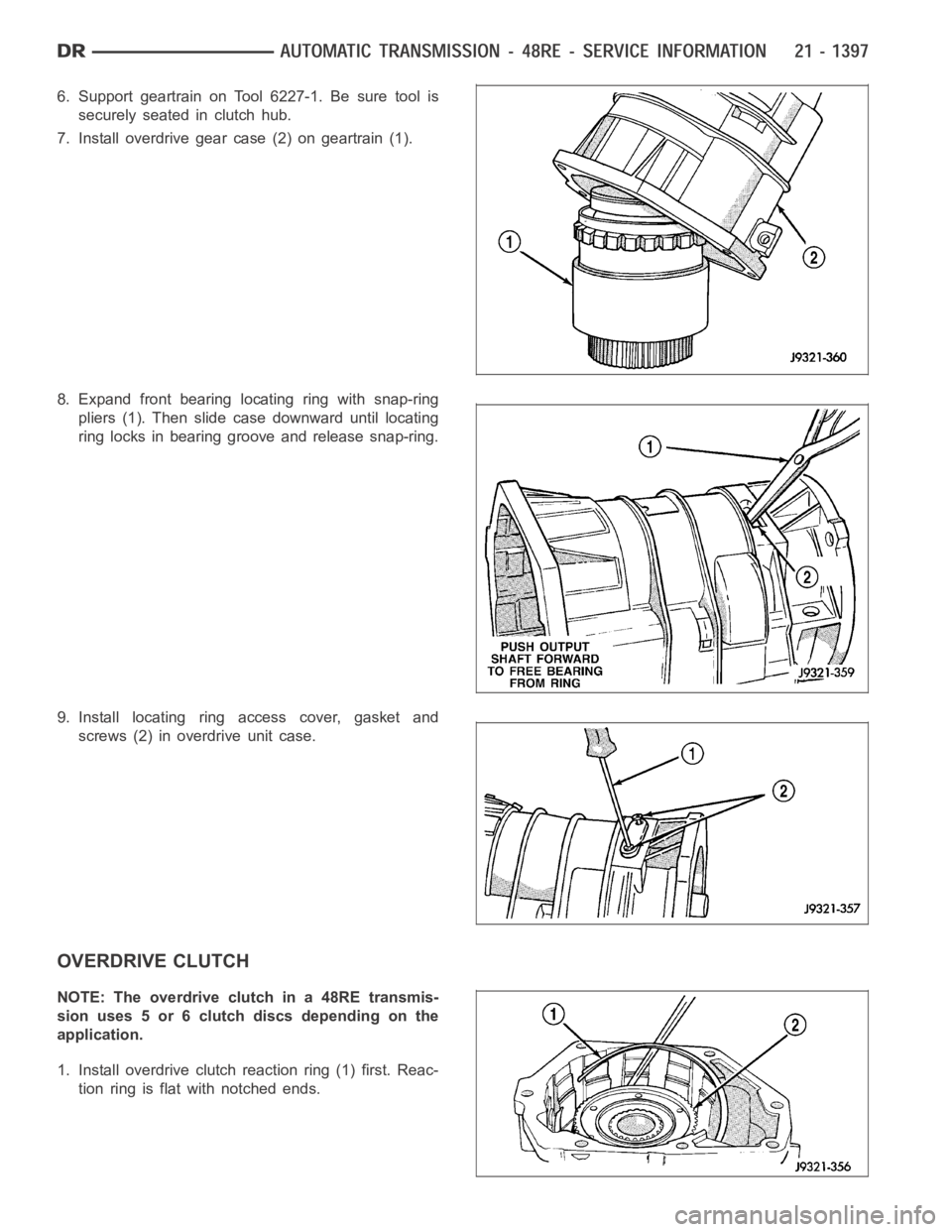

6. Support geartrain on Tool 6227-1. Be sure tool is

securely seated in clutch hub.

7. Install overdrive gear case (2) on geartrain (1).

8. Expand front bearing locating ring with snap-ring

pliers (1). Then slide case downward until locating

ring locks in bearing groove and release snap-ring.

9. Install locating ring access cover, gasket and

screws (2) in overdrive unit case.

OVERDRIVE CLUTCH

NOTE: The overdrive clutch in a 48RE transmis-

sion uses 5 or 6 clutch discs depending on the

application.

1. Install overdrive clutch reaction ring (1) first. Reac-

tion ring is flat with notched ends.

Page 3919 of 5267

2. For 5 disc overdrive clutch versions, install wave

spring (1) on top of reaction ring. Reaction ring and

waveringbothfitinsameringgroove.Usescrew-

driver to seat each ring securely in groove. Also

ensure that the ends of the two rings are offset

from each other.

3. Assemble overdrive clutch pack.

4. Install overdrive clutch reaction plate first.

5. Install first clutch disc followed by first clutch plate.

Then install remaining clutch discs and plates in

same order.

6. Install clutch pack pressure plate.

7. Install clutch pack wire-type retaining ring (1).

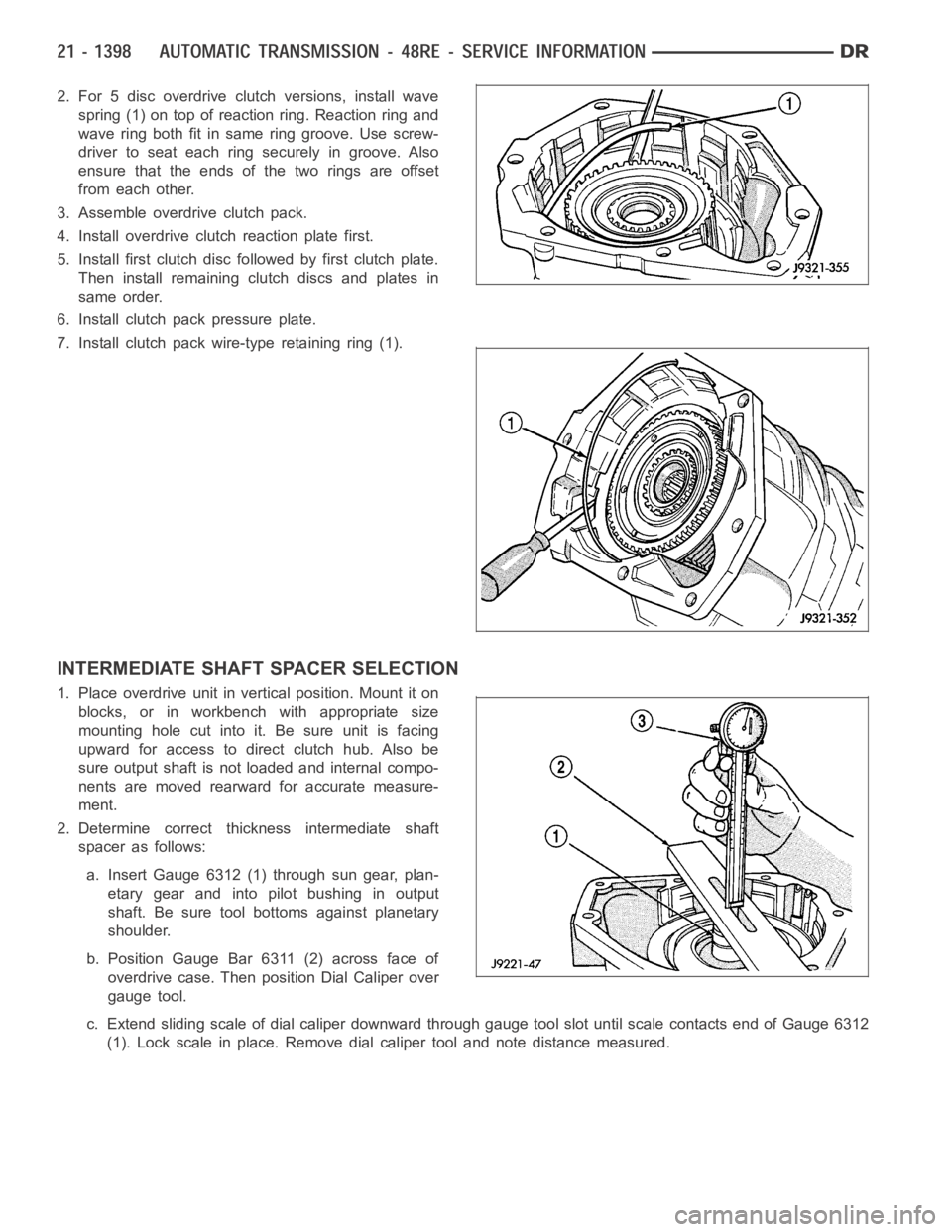

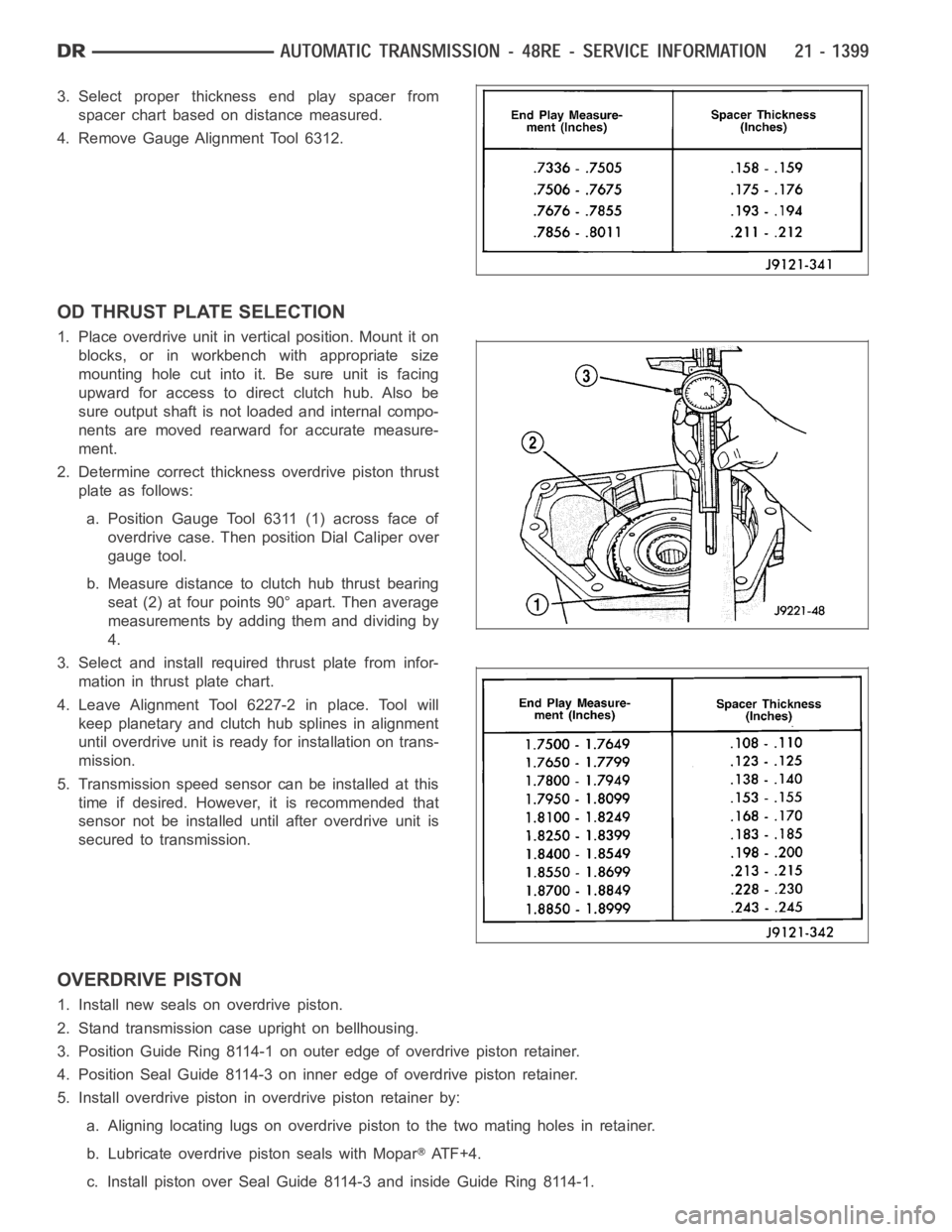

INTERMEDIATE SHAFT SPACER SELECTION

1. Place overdrive unit in vertical position. Mount it on

blocks, or in workbench with appropriate size

mounting hole cut into it. Be sure unit is facing

upward for access to direct clutch hub. Also be

sure output shaft is not loaded and internal compo-

nents are moved rearward for accurate measure-

ment.

2. Determine correct thickness intermediate shaft

spacer as follows:

a. Insert Gauge 6312 (1) through sun gear, plan-

etary gear and into pilot bushing in output

shaft. Be sure tool bottoms against planetary

shoulder.

b. Position Gauge Bar 6311 (2) across face of

overdrive case. Then position Dial Caliper over

gauge tool.

c. Extend sliding scale of dial caliper downward through gauge tool slot until scale contacts end of Gauge 6312

(1). Lock scale in place. Remove dial caliper tool and note distance measured.

Page 3920 of 5267

3. Select proper thickness end play spacer from

spacer chart based on distance measured.

4. Remove Gauge Alignment Tool 6312.

OD THRUST PLATE SELECTION

1. Place overdrive unit in vertical position. Mount it on

blocks, or in workbench with appropriate size

mounting hole cut into it. Be sure unit is facing

upward for access to direct clutch hub. Also be

sure output shaft is not loaded and internal compo-

nents are moved rearward for accurate measure-

ment.

2. Determine correct thickness overdrive piston thrust

plate as follows:

a. Position Gauge Tool 6311 (1) across face of

overdrive case. Then position Dial Caliper over

gauge tool.

b. Measure distance to clutch hub thrust bearing

seat (2) at four points 90° apart. Then average

measurements by adding them and dividing by

4.

3. Select and install required thrust plate from infor-

mation in thrust plate chart.

4. Leave Alignment Tool 6227-2 in place. Tool will

keep planetary and clutch hub splines in alignment

until overdrive unit is ready for installation on trans-

mission.

5. Transmission speed sensor can be installed at this

time if desired. However, it is recommended that

sensor not be installed until after overdrive unit is

secured to transmission.

OVERDRIVE PISTON

1. Install new seals on overdrive piston.

2. Stand transmission case upright on bellhousing.

3. Position Guide Ring 8114-1 on outer edge of overdrive piston retainer.

4. Position Seal Guide 8114-3 on inner edge of overdrive piston retainer.

5. Install overdrive piston in overdrive piston retainer by:

a. Aligning locating lugs on overdrive piston to the two mating holes in retainer.

b. Lubricate overdrive piston seals with Mopar

ATF+4.

c. Install piston over Seal Guide 8114-3 and inside Guide Ring 8114-1.

Page 3921 of 5267

d. Push overdrive piston into position in retainer.

e. Verify that the locating lugs entered the lug bores in the retainer.

6. Install intermediate shaft spacer on intermediate shaft.

7. Install overdrive piston thrust plate on overdrive piston.

8. Install overdrive piston thrust bearing on overdrive piston.

9. Install transmission speed sensorand o-ring seal in overdrive case.

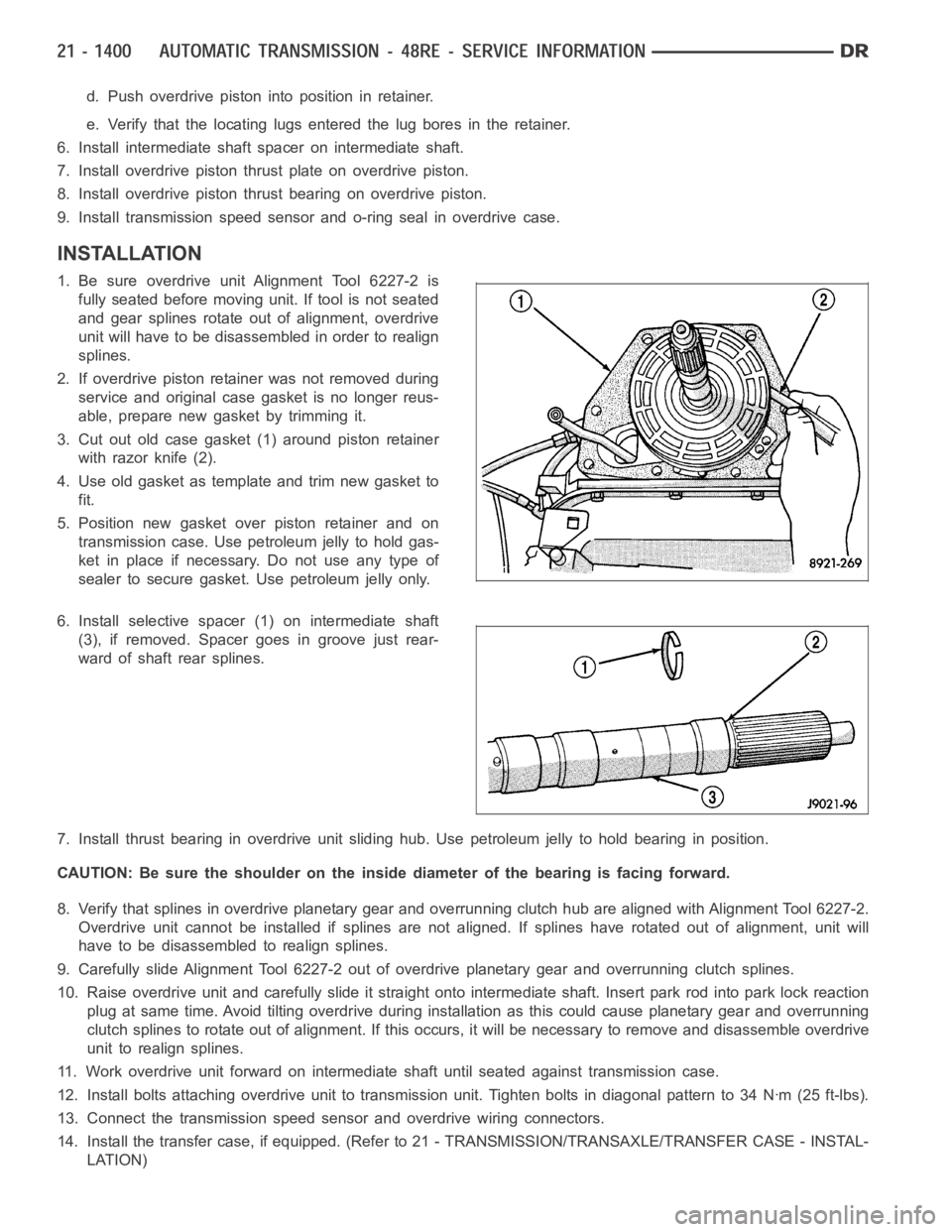

INSTALLATION

1. Be sure overdrive unit Alignment Tool 6227-2 is

fully seated before moving unit. If tool is not seated

and gear splines rotate out of alignment, overdrive

unit will have to be disassembled in order to realign

splines.

2. If overdrive piston retainer was not removed during

service and original case gasket is no longer reus-

able, prepare new gasket by trimming it.

3. Cut out old case gasket (1) around piston retainer

with razor knife (2).

4. Use old gasket as template and trim new gasket to

fit.

5. Position new gasket over piston retainer and on

transmission case. Use petroleum jelly to hold gas-

ket in place if necessary. Do not use any type of

sealer to secure gasket. Use petroleum jelly only.

6. Install selective spacer (1) on intermediate shaft

(3), if removed. Spacer goes in groove just rear-

ward of shaft rear splines.

7. Install thrust bearing in overdrive unit sliding hub. Use petroleum jelly to hold bearing in position.

CAUTION: Be sure the shoulder on the inside diameter of the bearing is facingforward.

8. Verify that splines in overdrive planetary gear and overrunning clutchhub are aligned with Alignment Tool 6227-2.

Overdrive unit cannot be installed if splines are not aligned. If splines have rotated out of alignment, unit will

have to be disassembled to realign splines.

9. Carefully slide Alignment Tool 6227-2 out of overdrive planetary gear and overrunning clutch splines.

10. Raise overdrive unit and carefully slide it straight onto intermediate shaft. Insert park rod into park lock reaction

plug at same time. Avoid tilting overdrive during installation as this could cause planetary gear and overrunning

clutch splines to rotate out of alignment. If this occurs, it will be necessary to remove and disassemble overdrive

unit to realign splines.

11. Work overdrive unit forward on intermediate shaft until seated against transmission case.

12. Install bolts attaching overdrive unit to transmission unit. Tightenbolts in diagonal pattern to 34 Nꞏm (25 ft-lbs).

13. Connect the transmission speed sensor and overdrive wiring connectors.

14. Install the transfer case, if equipped. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER CASE - INSTAL-

LATION)

Page 3924 of 5267

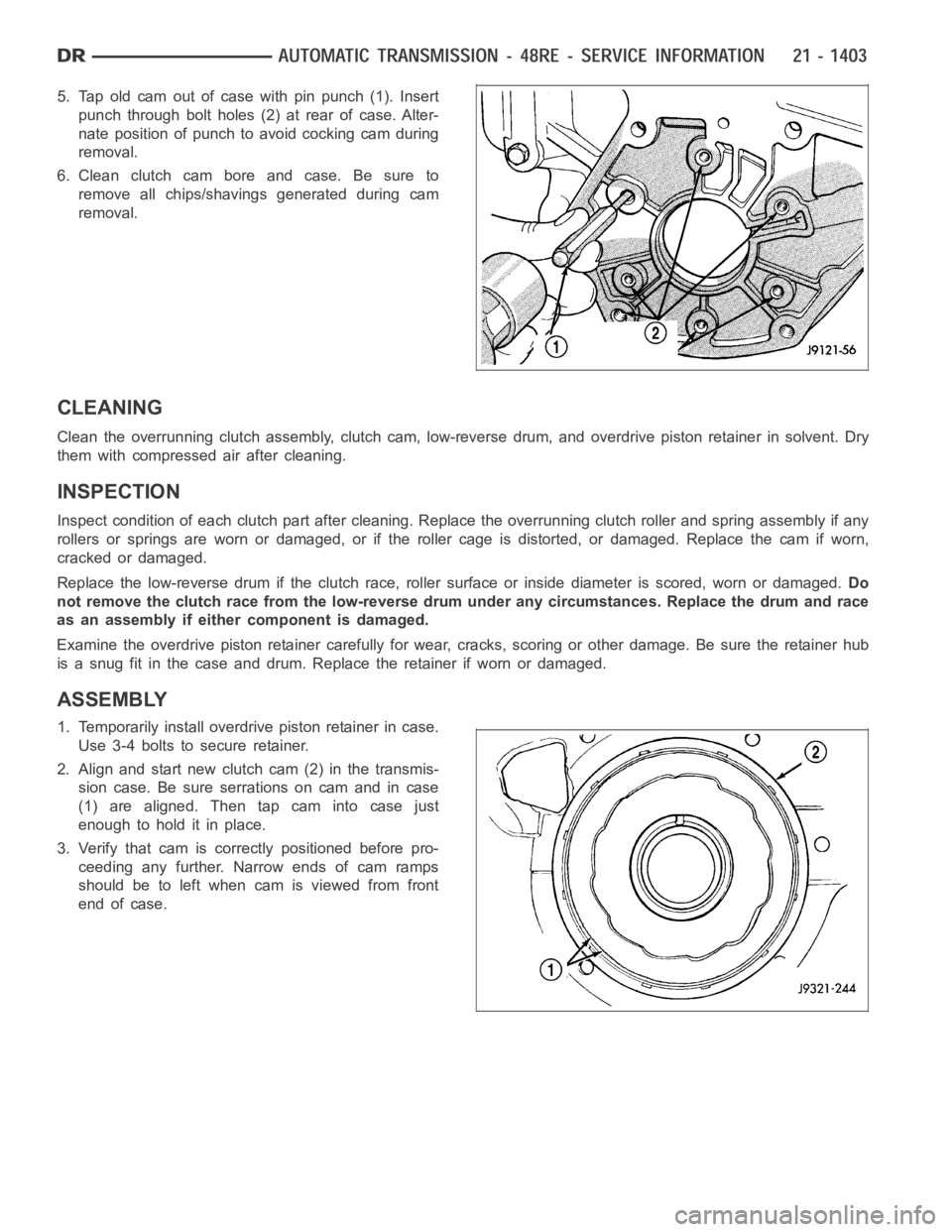

5. Tap old cam out of case with pin punch (1). Insert

punch through bolt holes (2) at rear of case. Alter-

nate position of punch to avoid cocking cam during

removal.

6. Clean clutch cam bore and case. Be sure to

remove all chips/shavings generated during cam

removal.

CLEANING

Clean the overrunning clutch assembly, clutch cam, low-reverse drum, andoverdrive piston retainer in solvent. Dry

them with compressed air after cleaning.

INSPECTION

Inspect condition of each clutch part after cleaning. Replace the overrunning clutch roller and spring assembly if any

rollers or springs are worn or damaged, or if the roller cage is distorted, or damaged. Replace the cam if worn,

cracked or damaged.

Replace the low-reverse drum if the clutch race, roller surface or inside diameter is scored, worn or damaged.Do

not remove the clutch race from the low-reverse drum under any circumstances. Replace the drum and race

as an assembly if either component is damaged.

Examine the overdrive piston retainer carefully for wear, cracks, scoring or other damage. Be sure the retainer hub

is a snug fit in the case and drum. Replace the retainer if worn or damaged.

ASSEMBLY

1. Temporarily install overdrive piston retainer in case.

Use 3-4 bolts to secure retainer.

2. Align and start new clutch cam (2) in the transmis-

sion case. Be sure serrations on cam and in case

(1) are aligned. Then tap cam into case just

enough to hold it in place.

3. Verify that cam is correctly positioned before pro-

ceeding any further. Narrow ends of cam ramps

should be to left when cam is viewed from front

end of case.

Page 3926 of 5267

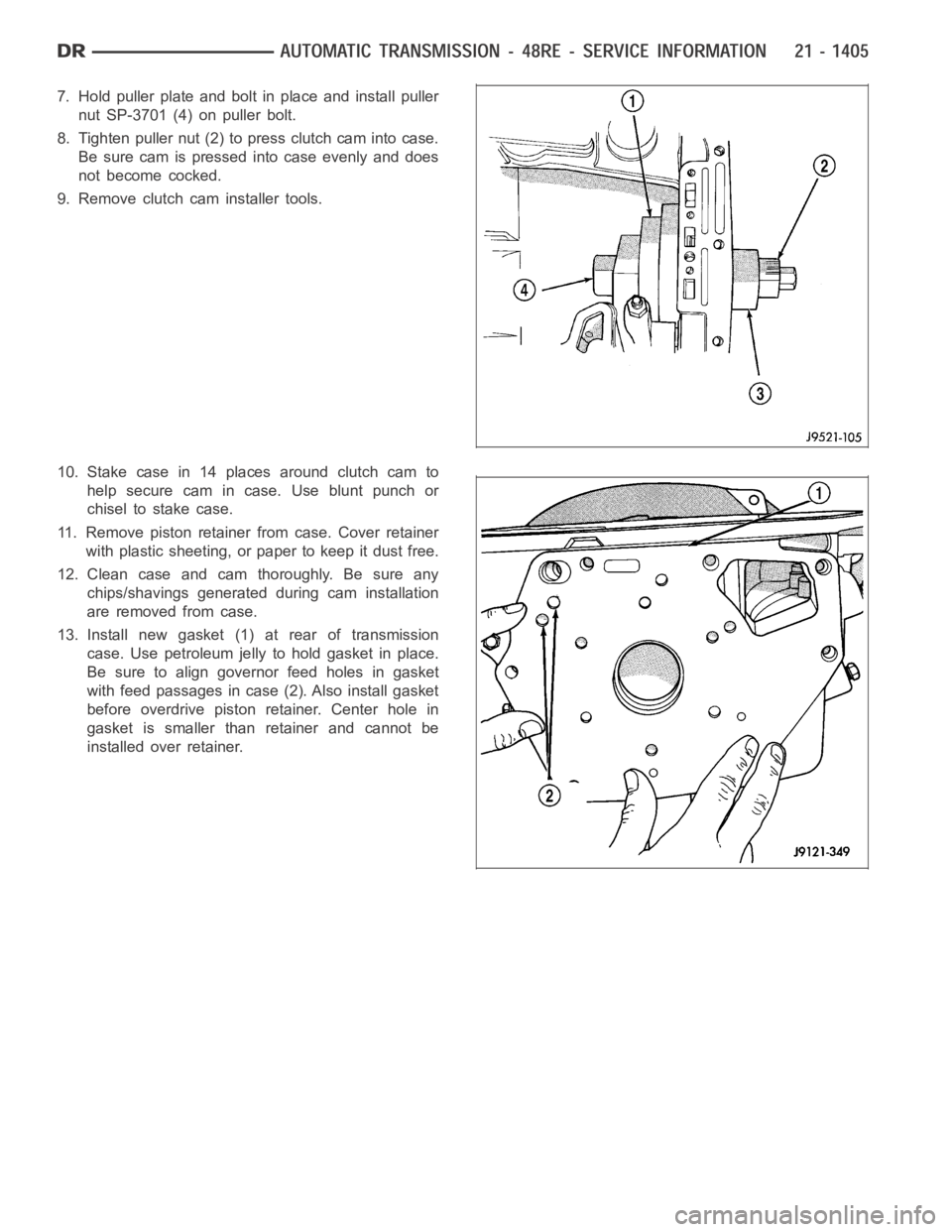

7. Hold puller plate and bolt in place and install puller

nut SP-3701 (4) on puller bolt.

8. Tighten puller nut (2) to press clutch cam into case.

Be sure cam is pressed into case evenly and does

not become cocked.

9. Remove clutch cam installer tools.

10. Stake case in 14 places around clutch cam to

help secure cam in case. Use blunt punch or

chisel to stake case.

11. Remove piston retainer from case. Cover retainer

with plastic sheeting, or paper to keep it dust free.

12. Clean case and cam thoroughly. Be sure any

chips/shavings generated during cam installation

are removed from case.

13. Install new gasket (1) at rear of transmission

case. Use petroleum jelly to hold gasket in place.

Be sure to align governor feed holes in gasket

with feed passages in case (2). Also install gasket

before overdrive piston retainer. Center hole in

gasket is smaller than retainer and cannot be

installed over retainer.

Page 3931 of 5267

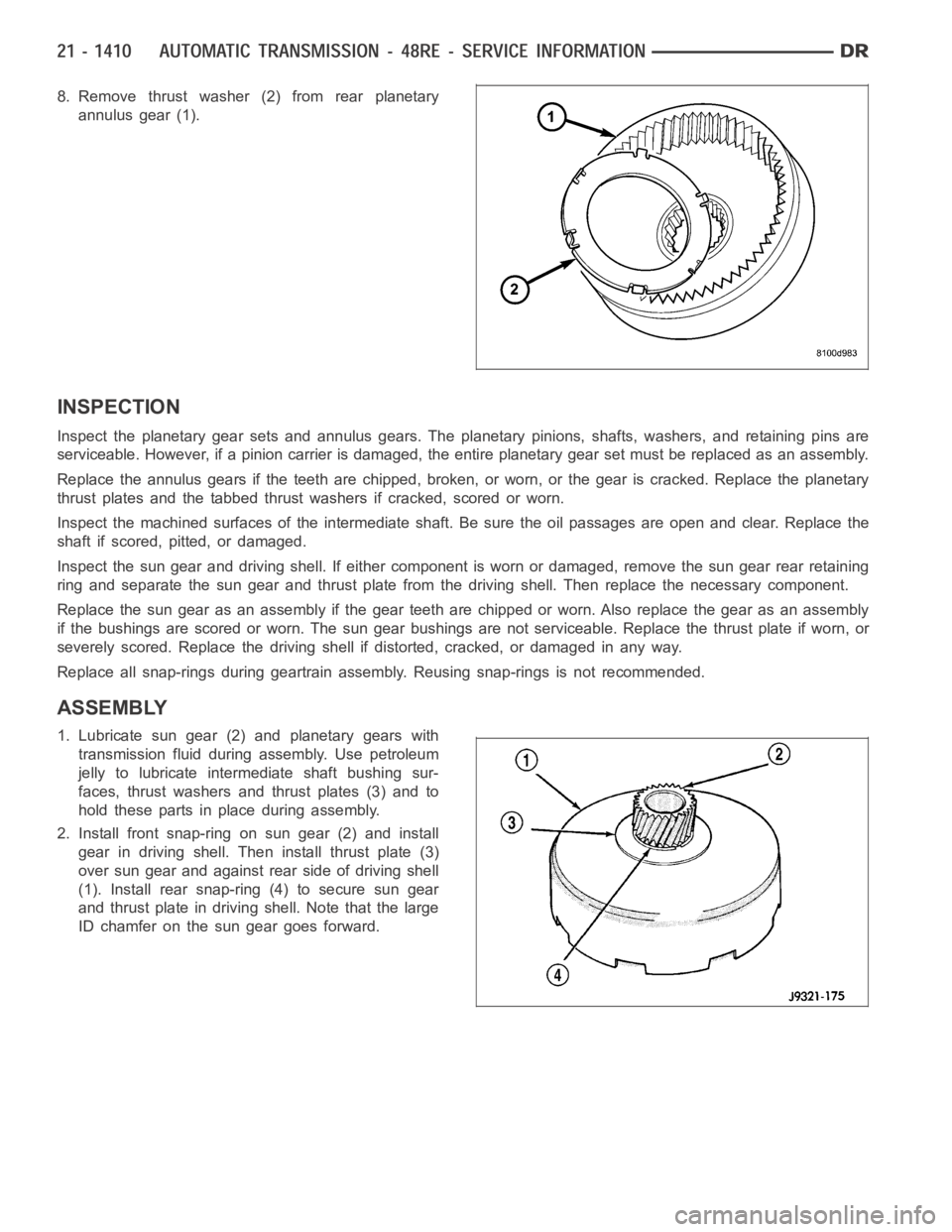

8. Remove thrust washer (2) from rear planetary

annulus gear (1).

INSPECTION

Inspect the planetary gear sets and annulus gears. The planetary pinions,shafts, washers, and retaining pins are

serviceable. However, if a pinion carrier is damaged, the entire planetarygearsetmustbereplacedasanassembly.

Replace the annulus gears if the teeth are chipped, broken, or worn, or the gear is cracked. Replace the planetary

thrust plates and the tabbed thrust washers if cracked, scored or worn.

Inspect the machined surfaces of the intermediate shaft. Be sure the oil passages are open and clear. Replace the

shaft if scored, pitted, or damaged.

Inspect the sun gear and driving shell. If either component is worn or damaged, remove the sun gear rear retaining

ring and separate the sun gear and thrust plate from the driving shell. Thenreplace the necessary component.

Replace the sun gear as an assembly if the gear teeth are chipped or worn. Also replace the gear as an assembly

if the bushings are scored or worn. The sun gear bushings are not serviceable. Replace the thrust plate if worn, or

severely scored. Replace the driving shell if distorted, cracked, or damaged in any way.

Replace all snap-rings during geartrain assembly. Reusing snap-rings isnot recommended.

ASSEMBLY

1. Lubricate sun gear (2) and planetary gears with

transmission fluid during assembly. Use petroleum

jelly to lubricate intermediate shaft bushing sur-

faces, thrust washers and thrust plates (3) and to

hold these parts in place during assembly.

2. Install front snap-ring on sun gear (2) and install

gear in driving shell. Then install thrust plate (3)

over sun gear and against rear side of driving shell

(1). Install rear snap-ring (4) to secure sun gear

and thrust plate in driving shell. Note that the large

ID chamfer on the sun gear goes forward.

Page 3957 of 5267

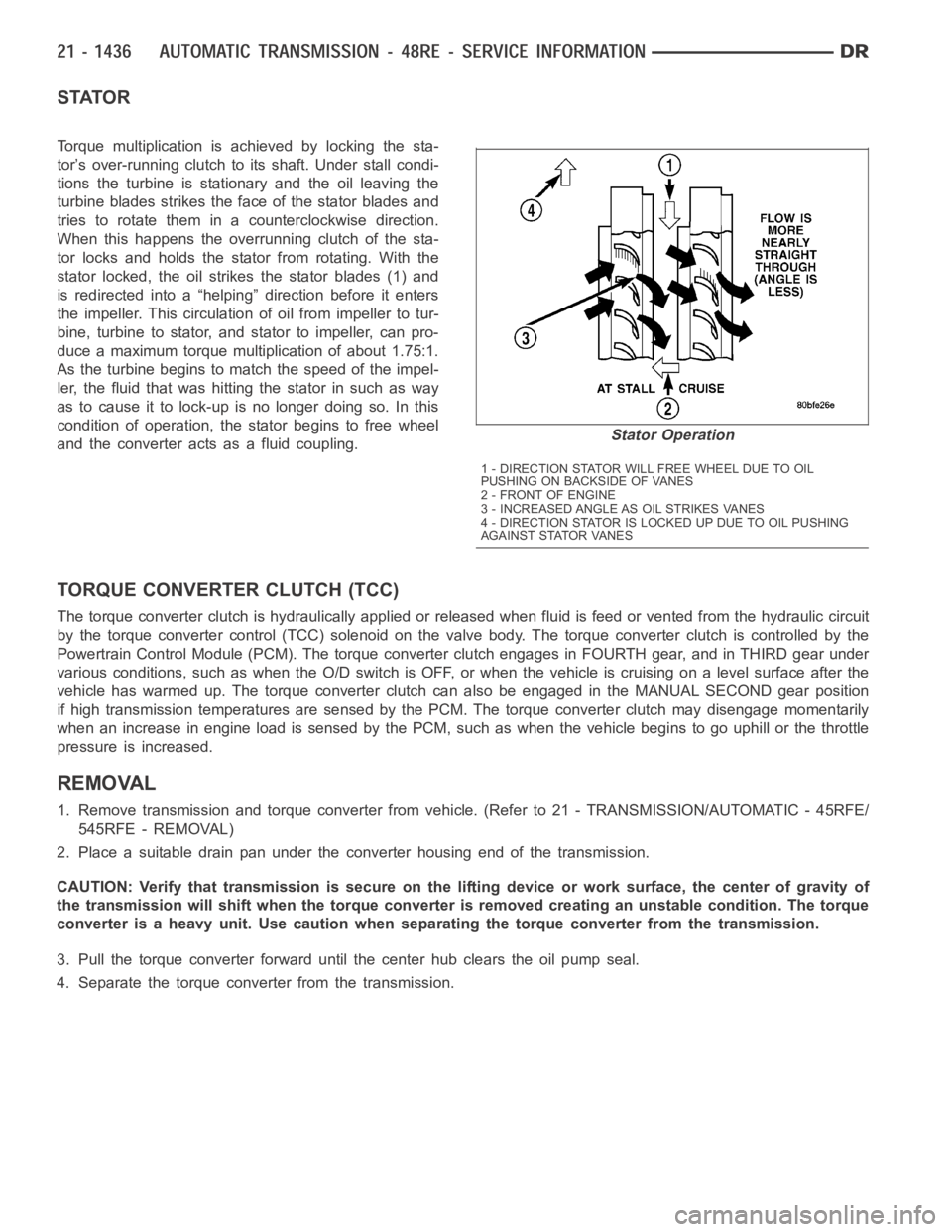

STATOR

Torque multiplication is achieved by locking the sta-

tor’s over-running clutch to its shaft. Under stall condi-

tions the turbine is stationary and the oil leaving the

turbine blades strikes the face of the stator blades and

tries to rotate them in a counterclockwise direction.

When this happens the overrunning clutch of the sta-

tor locks and holds the stator from rotating. With the

stator locked, the oil strikes the stator blades (1) and

is redirected into a “helping” direction before it enters

the impeller. This circulation of oil from impeller to tur-

bine, turbine to stator, and stator to impeller, can pro-

duce a maximum torque multiplication of about 1.75:1.

As the turbine begins to match the speed of the impel-

ler, the fluid that was hitting the stator in such as way

as to cause it to lock-up is no longer doing so. In this

condition of operation, the stator begins to free wheel

and the converter acts as a fluid coupling.

TORQUE CONVERTER CLUTCH (TCC)

The torque converter clutch is hydraulically applied or released when fluid is feed or vented from the hydraulic circuit

by the torque converter control (TCC) solenoid on the valve body. The torque converter clutch is controlled by the

Powertrain Control Module (PCM). The torque converter clutch engages in FOURTH gear, and in THIRD gear under

various conditions, such as when the O/D switch is OFF, or when the vehicle is cruising on a level surface after the

vehicle has warmed up. The torque converter clutch can also be engaged in the MANUAL SECOND gear position

if high transmission temperatures are sensed by the PCM. The torque converter clutch may disengage momentarily

when an increase in engine load is sensed by the PCM, such as when the vehiclebegins to go uphill or the throttle

pressure is increased.

REMOVAL

1. Remove transmission and torque converter from vehicle. (Refer to 21 - TRANSMISSION/AUTOMATIC - 45RFE/

545RFE - REMOVAL)

2. Place a suitable drain pan under the converter housing end of the transmission.

CAUTION: Verify that transmission is secure on the lifting device or work surface, the center of gravity of

the transmission will shift when the torque converter is removed creatingan unstable condition. The torque

converter is a heavy unit. Use caution when separating the torque converter from the transmission.

3. Pull the torque converter forward until the center hub clears the oil pumpseal.

4. Separate the torque converter from the transmission.

Stator Operation

1 - DIRECTION STATOR WILL FREE WHEEL DUE TO OIL

PUSHING ON BACKSIDE OF VANES

2-FRONTOFENGINE

3 - INCREASED ANGLE AS OIL STRIKES VANES

4 - DIRECTION STATOR IS LOCKED UP DUE TO OIL PUSHING

AGAINST STATOR VANES