ECU DODGE RAM SRT-10 2006 Service Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3189 of 5267

When Monitored:

Initially at power-up, then every 10 seconds thereafter. The solenoid circuits will also be tested immediately

after a gear ratio or pressure switch error is detected.

Set Condition:

After three consecutive solenoid continuity test failures, or one failure if test is run in response to a gear ratio

or pressure switch error.Note: This DTC is strictly an electrical fault and does not apply to any internal

transmission failures.

Possible Causes

RELATED TIPM TCM DTCS PRESENT

(T59) UD SOLENOID CONTROL CIRCUIT SHORT TO OTHER CIRCUITS

(T59) UD SOLENOID CONTROL CIRCUIT OPEN

(T59) UD SOLENOID CONTROL CIRCUIT SHORT TO GROUND

TRANSMISSION SOLENOID/TRS ASSEMBLY

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The Transmission Control System uses six electronically controlled solenoids that allow hydraulic fluid to be applied

to various friction elements (clutches), which enables the gear requested. The continuity of each solenoid circuit is

periodically tested. Each inactive solenoid is turned on for a few milliseconds, then off. Each active solenoid is

turned off for a few milliseconds, then on. This pulsing of voltage to the solenoid causes an inductive spike which

can be sensed by the Transmission Control System. If an inductive spike is not sensed by the Transmission Control

System during the continuity check, it is tested again. If the test fails three consecutive times, the appropriate Diag-

nostic Trouble Code (DTC) is set. If the solenoid test is run in response to agear ratio or pressure switch error, one

failure will result in setting the appropriate DTC.Note: This DTC is strictly an electrical fault and does not apply

to any internal transmission failures.

Diagnostic Test

1.CHECK FOR TCM TIPM DTCS

With the scan tool under TIPM, check for TCM Power Input DTCs.

Are there any TIPM TCM Power Input DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.CHECK IF P0765 IS PRESENT

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the scan tool, actuate the UD Solenoid.

Page 3193 of 5267

When Monitored:

Initially at power-up, then every 10 seconds thereafter. The solenoid circuits will also be tested immediately

after a gear ratio or pressure switch error is detected.

Set Condition:

After three consecutive solenoid continuity test failures, or one failure if test is run in response to a gear ratio

or pressure switch error.Note: This DTC is strictly an electrical fault and does not apply to any internal

transmission failures.

Possible Causes

RELATED TIPM TCM DTCS PRESENT

(T259) 4C SOLENOID CONTROL CIRCUIT SHORT TO OTHER CIRCUITS

(T259) 4C SOLENOID CONTROL CIRCUIT OPEN

(T259) 4C SOLENOID CONTROL CIRCUIT SHORT TO GROUND

TRANSMISSION SOLENOID/TRS ASSEMBLY

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The Transmission Control System uses six electronically controlled solenoids that allow hydraulic fluid to be applied

to various friction elements (clutches), which enables the gear requested. The continuity of each solenoid circuit is

periodically tested. Each inactive solenoid is turned on for a few milliseconds, then off. Each active solenoid is

turned off for a few milliseconds, then on. This pulsing of voltage to the solenoid causes an inductive spike which

can be sensed by the Transmission Control System. If an inductive spike is not sensed by the Transmission Control

System during the continuity check, it is tested again. If the test fails three consecutive times, the appropriate Diag-

nostic Trouble Code (DTC) is set. If the solenoid test is run in response to agear ratio or pressure switch error, one

failure will result in setting the appropriate DTC.Note: This DTC is strictly an electrical fault and does not apply

to any internal transmission failures.

Diagnostic Test

1.CHECK FOR TCM TIPM DTCS

With the scan tool under TIPM, check for TCM Power Input DTCs.

Are there any TIPM TCM Power Input DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.CHECK TO SEE IF P0770 IS PRESENT

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the scan tool, actuate the 4C Solenoid.

Page 3350 of 5267

When Monitored:

Initially at power-up, then every 10 seconds thereafter. The solenoid circuits will also be tested immediately

after a gear ratio or pressure switch error is detected.

Set Condition:

After three consecutive solenoid continuity test failures, or one failure if test is run in response to a gear ratio

or pressure switch error.Note: This DTC is strictly an electrical fault and does not apply to any internal

transmission failures.

Possible Causes

RELATED TCM POWER INPUT DTCS PRESENT

(T118) MS SOLENOID CONTROL CIRCUIT SHORT TO OTHER CIRCUITS

(T118) MS SOLENOID CONTROL CIRCUIT OPEN

(T118) MS SOLENOID CONTROL CIRCUIT SHORT TO GROUND

TRANSMISSION SOLENOID/TRS ASSEMBLY

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The Transmission Control System uses six electronically controlled solenoids that allow hydraulic fluid to be applied

to various friction elements (clutches), which enables the gear requested. The continuity of each solenoid circuit is

periodically tested. Each inactive solenoid is turned on for a few milliseconds, then off. Each active solenoid is

turned off for a few milliseconds, then on. This pulsing of voltage to the solenoid causes an inductive spike which

can be sensed by the Transmission Control System. If an inductive spike is not sensed by the Transmission Control

System during the continuity check, it is tested again. If the test fails three consecutive times, the appropriate Diag-

nostic Trouble Code (DTC) is set. If the solenoid test is run in response to agear ratio or pressure switch error, one

failure will result in setting the appropriate DTC.Note: This DTC is strictly an electrical fault and does not apply

to any internal transmission failures.

Diagnostic Test

1.RELATED TCM POWER INPUT DTCS PRESENT

With the scan tool, check for other transmission DTCs.

Are there any TCM Power Input DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.TRANSMISSION SOLENOID/TRS ASSEMBLY

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the scan tool, actuate the MS Solenoid.

Page 3374 of 5267

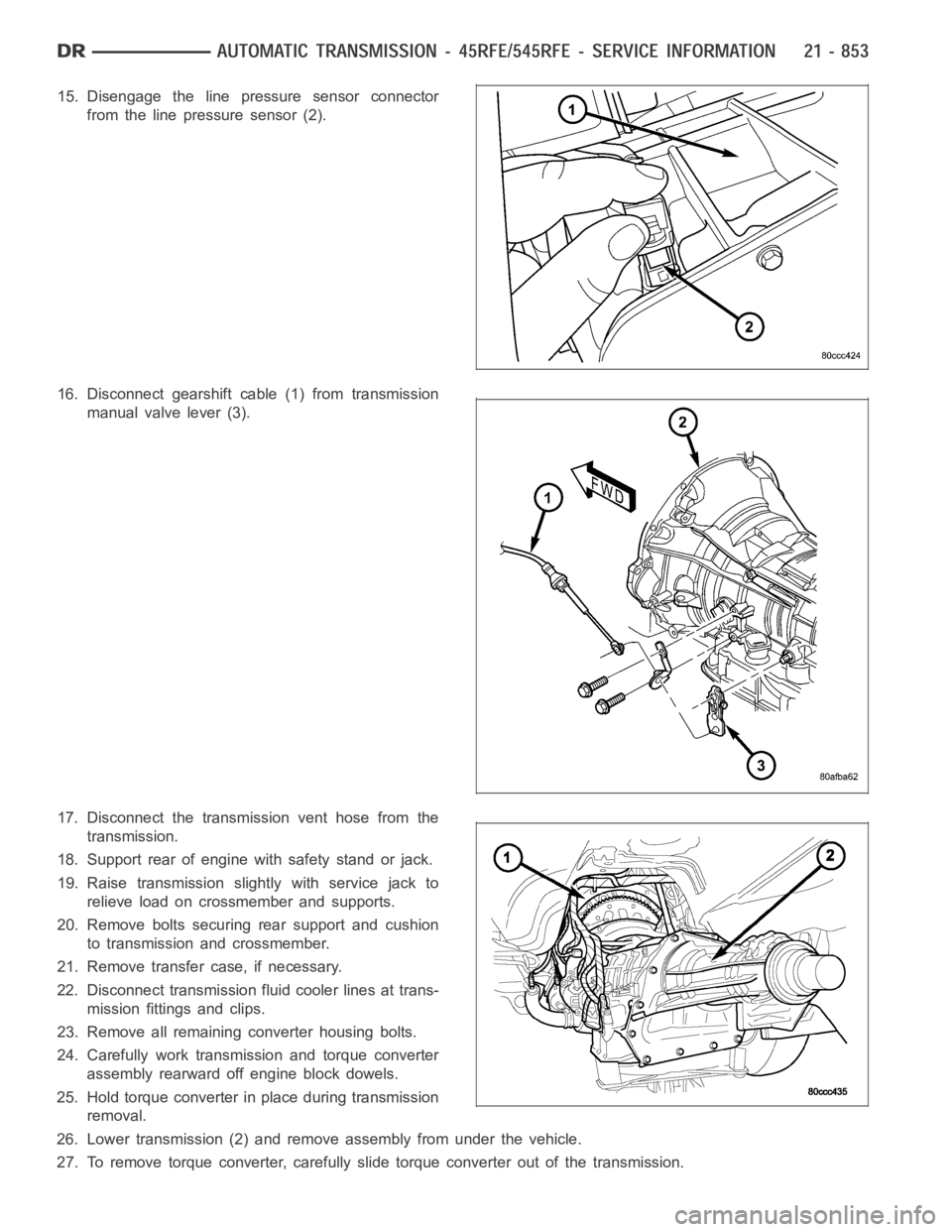

15. Disengage the line pressure sensor connector

from the line pressure sensor (2).

16. Disconnect gearshift cable (1) from transmission

manual valve lever (3).

17. Disconnect the transmission vent hose from the

transmission.

18. Support rear of engine with safety stand or jack.

19. Raise transmission slightly with service jack to

relieve load on crossmember and supports.

20. Remove bolts securing rear support and cushion

to transmission and crossmember.

21. Remove transfer case, if necessary.

22. Disconnect transmission fluid cooler lines at trans-

mission fittings and clips.

23. Remove all remaining converter housing bolts.

24. Carefully work transmission and torque converter

assembly rearward off engine block dowels.

25. Hold torque converter in place during transmission

removal.

26. Lower transmission (2) and remove assembly from under the vehicle.

27. To remove torque converter, carefully slide torque converter out of the transmission.

Page 3377 of 5267

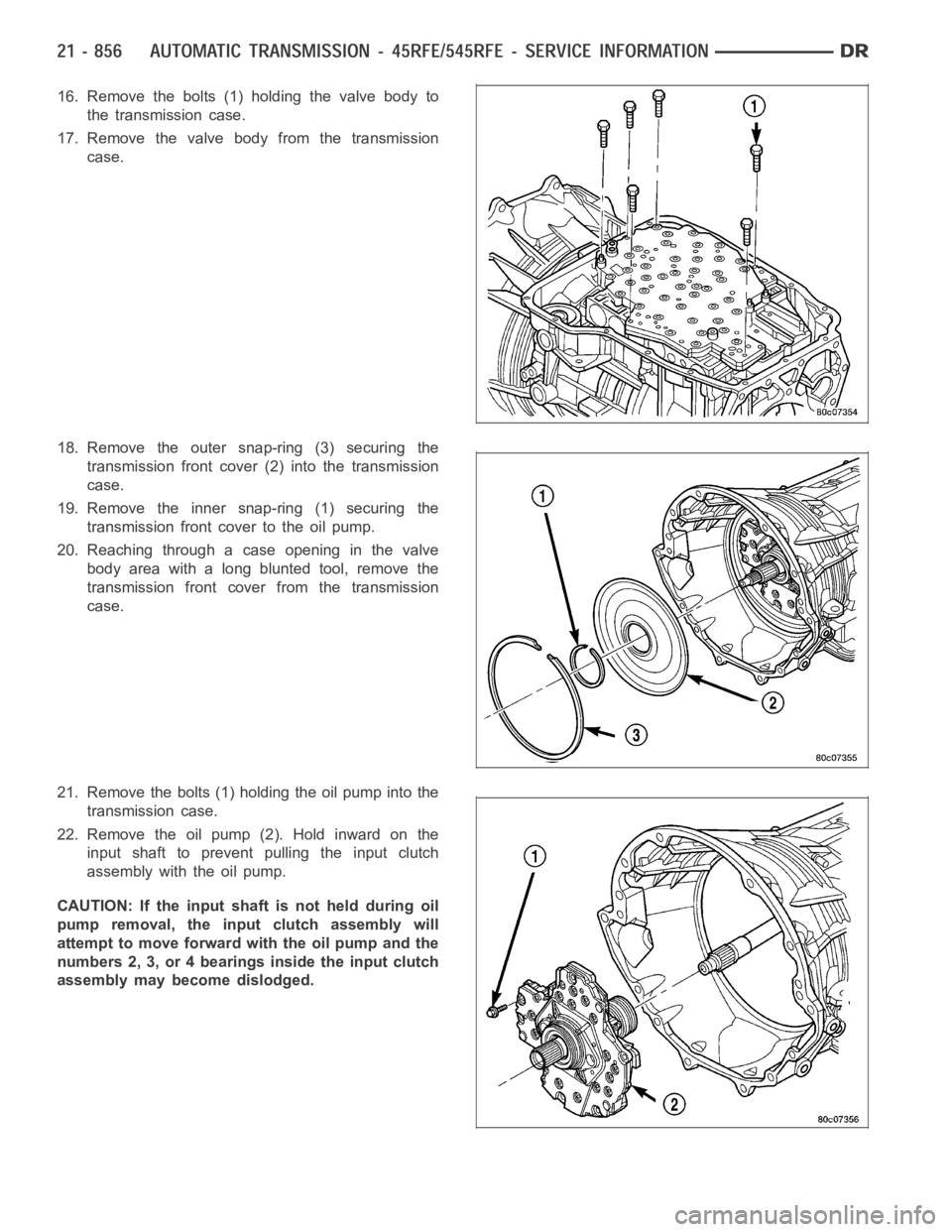

16. Remove the bolts (1) holding the valve body to

the transmission case.

17. Remove the valve body from the transmission

case.

18. Remove the outer snap-ring (3) securing the

transmission front cover (2) into the transmission

case.

19. Remove the inner snap-ring (1) securing the

transmission front cover to the oil pump.

20. Reaching through a case opening in the valve

body area with a long blunted tool, remove the

transmission front cover from the transmission

case.

21. Remove the bolts (1) holding the oil pump into the

transmission case.

22. Remove the oil pump (2). Hold inward on the

input shaft to prevent pulling the input clutch

assembly with the oil pump.

CAUTION: If the input shaft is not held during oil

pump removal, the input clutch assembly will

attempt to move forward with the oil pump and the

numbers 2, 3, or 4 bearings inside the input clutch

assembly may become dislodged.

Page 3392 of 5267

INSTALLATION

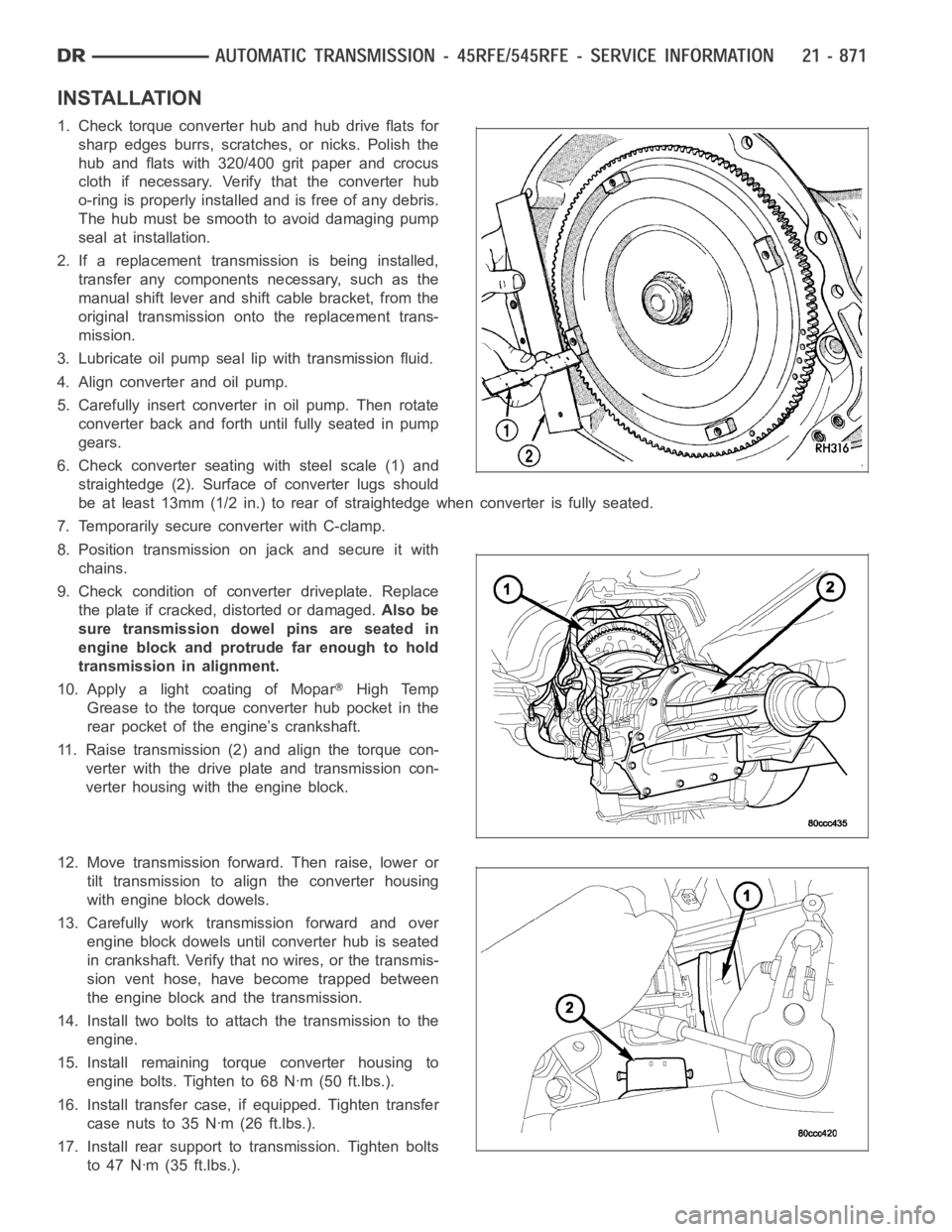

1. Check torque converter hub and hub drive flats for

sharp edges burrs, scratches, or nicks. Polish the

hub and flats with 320/400 grit paper and crocus

cloth if necessary. Verify that the converter hub

o-ring is properly installed and is free of any debris.

The hub must be smooth to avoid damaging pump

seal at installation.

2. If a replacement transmission is being installed,

transfer any components necessary, such as the

manual shift lever and shift cable bracket, from the

original transmission onto the replacement trans-

mission.

3. Lubricate oil pump seal lip with transmission fluid.

4. Align converter and oil pump.

5. Carefully insert converter in oil pump. Then rotate

converter back and forth until fully seated in pump

gears.

6. Check converter seating with steel scale (1) and

straightedge (2). Surface of converter lugs should

be at least 13mm (1/2 in.) to rear of straightedge when converter is fully seated.

7. Temporarily secure converter with C-clamp.

8. Position transmission on jack and secure it with

chains.

9. Check condition of converter driveplate. Replace

the plate if cracked, distorted or damaged.Also be

sure transmission dowel pins are seated in

engine block and protrude far enough to hold

transmission in alignment.

10. Apply a light coating of Mopar

High Temp

Grease to the torque converter hub pocket in the

rear pocket of the engine’s crankshaft.

11. Raise transmission (2) and align the torque con-

verter with the drive plate and transmission con-

verter housing with the engine block.

12. Move transmission forward. Then raise, lower or

tilt transmission to align the converter housing

with engine block dowels.

13. Carefully work transmission forward and over

engine block dowels until converter hub is seated

in crankshaft. Verify that no wires, or the transmis-

sion vent hose, have become trapped between

theengineblockandthetransmission.

14. Install two bolts to attach the transmission to the

engine.

15. Install remaining torque converter housing to

engine bolts. Tighten to 68 Nꞏm (50 ft.lbs.).

16. Install transfer case, if equipped. Tighten transfer

case nuts to 35 Nꞏm (26 ft.lbs.).

17. Install rear support to transmission. Tighten bolts

to 47 Nꞏm (35 ft.lbs.).

Page 3435 of 5267

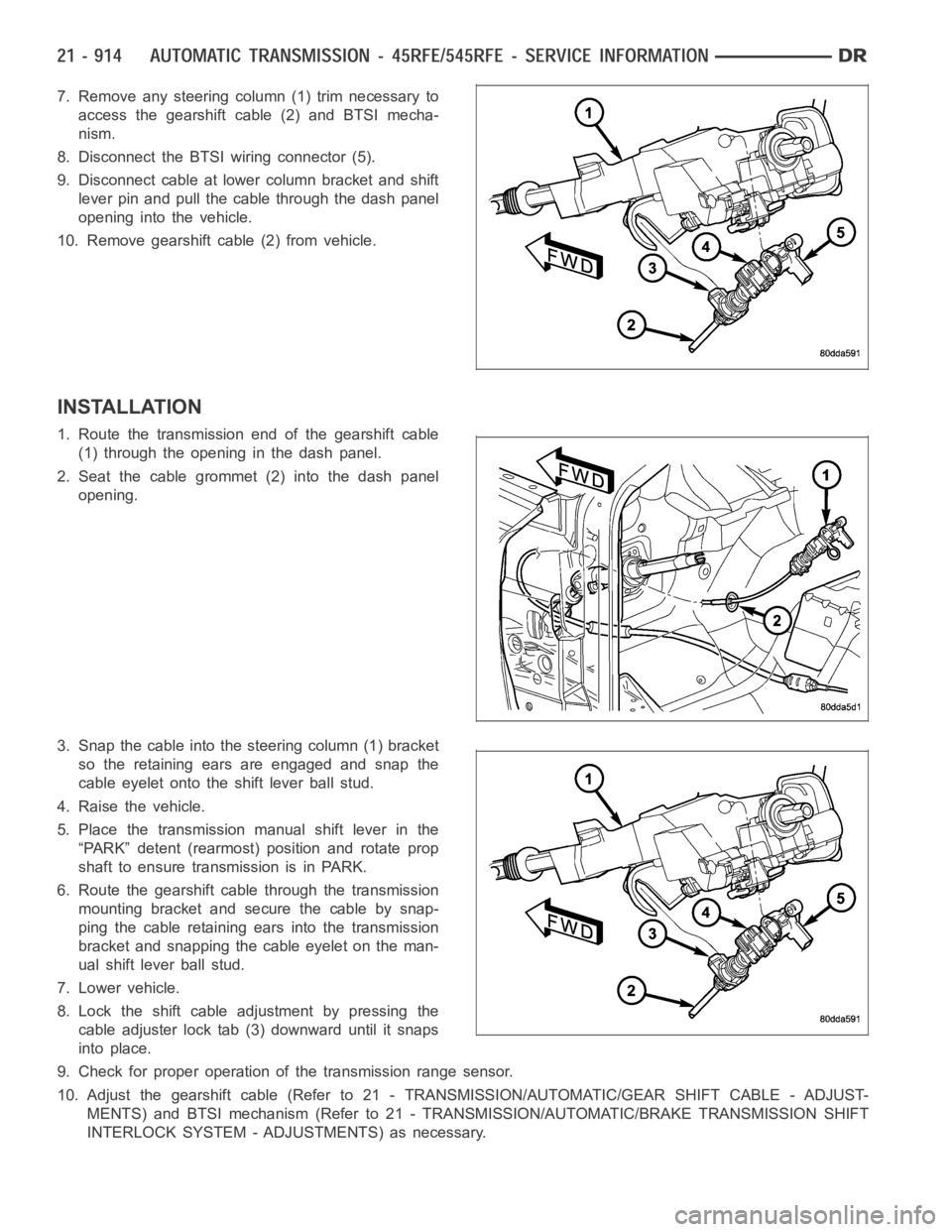

7. Remove any steering column (1) trim necessary to

access the gearshift cable (2) and BTSI mecha-

nism.

8. Disconnect the BTSI wiring connector (5).

9. Disconnect cable at lower column bracket and shift

lever pin and pull the cable through the dash panel

opening into the vehicle.

10. Remove gearshift cable (2) from vehicle.

INSTALLATION

1. Route the transmission end of the gearshift cable

(1) through the opening in the dash panel.

2. Seat the cable grommet (2) into the dash panel

opening.

3. Snap the cable into the steering column (1) bracket

so the retaining ears are engaged and snap the

cable eyelet onto the shift lever ball stud.

4. Raise the vehicle.

5. Place the transmission manual shift lever in the

“PARK” detent (rearmost) position and rotate prop

shaft to ensure transmission is in PARK.

6. Route the gearshift cable through the transmission

mounting bracket and secure the cable by snap-

ping the cable retaining ears into the transmission

bracket and snapping the cable eyelet on the man-

ual shift lever ball stud.

7. Lower vehicle.

8. Lock the shift cable adjustment by pressing the

cable adjuster lock tab (3) downward until it snaps

into place.

9. Check for proper operation of the transmission range sensor.

10. Adjust the gearshift cable (Refer to 21 - TRANSMISSION/AUTOMATIC/GEAR SHIFT CABLE - ADJUST-

MENTS) and BTSI mechanism (Refer to 21 - TRANSMISSION/AUTOMATIC/BRAKE TRANSMISSION SHIFT

INTERLOCK SYSTEM - ADJUSTMENTS) as necessary.

Page 3447 of 5267

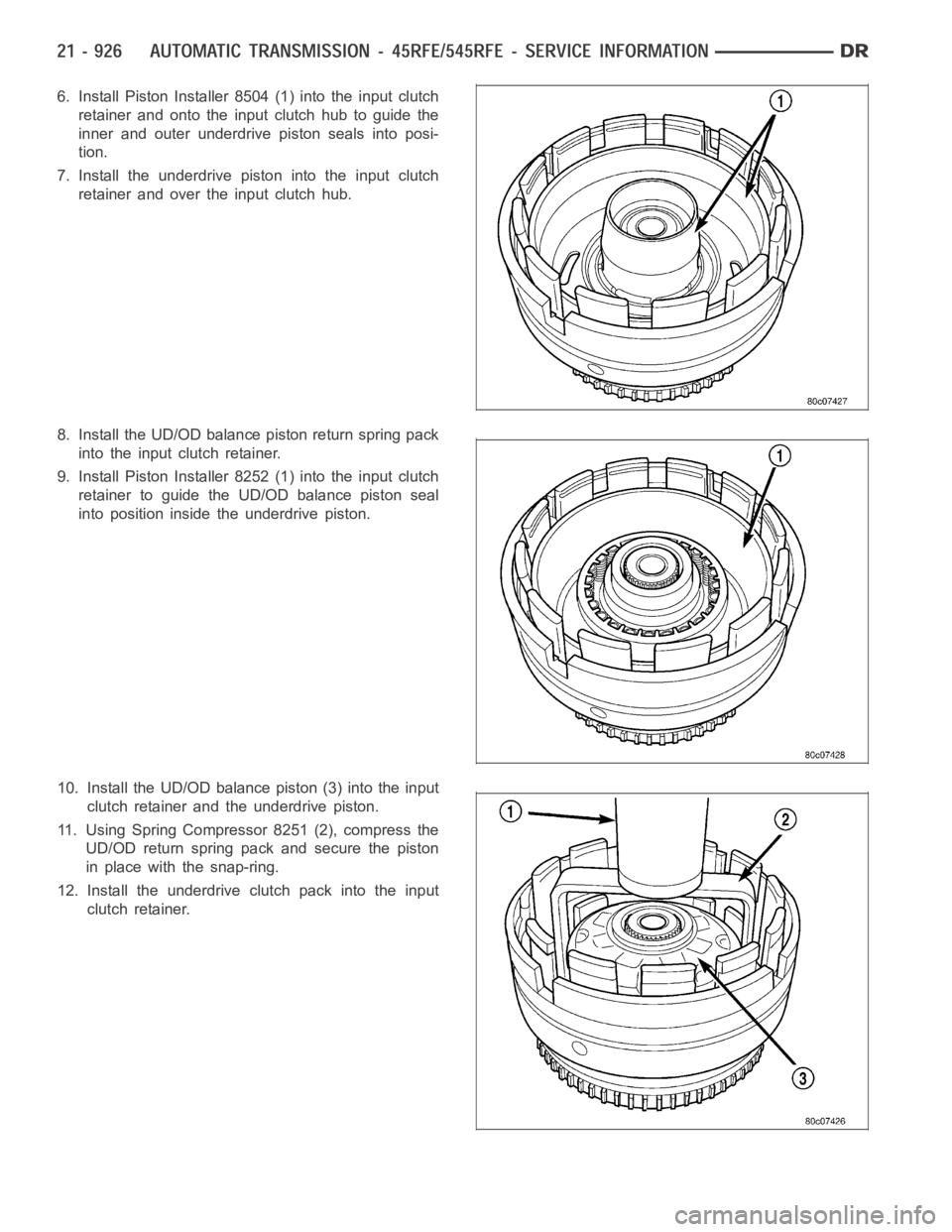

6. Install Piston Installer 8504 (1) into the input clutch

retainer and onto the input clutch hub to guide the

inner and outer underdrive piston seals into posi-

tion.

7. Install the underdrive piston into the input clutch

retainer and over the input clutch hub.

8. Install the UD/OD balance piston return spring pack

into the input clutch retainer.

9. Install Piston Installer 8252 (1) into the input clutch

retainer to guide the UD/OD balance piston seal

into position inside the underdrive piston.

10. Install the UD/OD balance piston (3) into the input

clutch retainer and the underdrive piston.

11. Using Spring Compressor 8251 (2), compress the

UD/OD return spring pack and secure the piston

in place with the snap-ring.

12. Install the underdrive clutch pack into the input

clutch retainer.

Page 3487 of 5267

TORQUE CONVERTER CLUTCH (TCC)

In a standard torque converter, the impeller and tur-

bine are rotating at about the same speed and the

stator is freewheeling, providing no torque multiplica-

tion. By applying the turbine’s piston and friction mate-

rial to the front cover, a total converter engagement

can be obtained. The result of this engagement is a

direct 1:1 mechanical link between the engine and the

transmission.

The clutch can be engaged in second, third, fourth,

and fifth (if appicable) gear ranges depending on over-

drive control switch position. If the overdrive control

switch is in the normal ON position, the clutch will

engage after the shift to fourth gear. If the control

switch is in the OFF position, the clutch will engage

after the shift to third gear.

The TCM controls the torque converter by way of

internal logic software. The programming of the soft-

ware provides the TCM with control over the L/R-CC

Solenoid. There are four output logic states that can

be applied as follows:

No EMCC

Partial EMCC

Full EMCC

Gradual-to-no EMCC

NO EMCC

Under No EMCC conditions, the L/R Solenoid is OFF. There are several conditions that can result in NO EMCC

operations. No EMCC can be initiated due to a fault in the transmission or because the TCM does not see the need

for EMCC under current driving conditions.

PARTIAL EMCC

Partial EMCC operation modulates the L/R Solenoid (duty cycle) to obtain partial torque converter clutch application.

Partial EMCC operation is maintaineduntil Full EMCC is called for and actuated. During Partial EMCC some slip

does occur. Partial EMCC will usually occur at low speeds, low load and light throttle situations.

FULL EMCC

During Full EMCC operation, the TCM increases the L/R Solenoid duty cycle to full ON after Partial EMCC control

brings the engine speed within the desired slip range of transmission input speed relative to engine rpm.

GRADUAL-TO-NO EMCC

This operation is to soften the change from Full or Partial EMCC to No EMCC. This is done at mid-throttle by

decreasing the L/R Solenoid duty cycle.

REMOVAL

1. Remove transmission and torque converter from vehicle. (Refer to 21 - TRANSMISSION/AUTOMATIC - 45RFE/

545RFE - REMOVAL)

2. Place a suitable drain pan under the converter housing end of the transmission.

CAUTION: Verify that transmission is secure on the lifting device or work surface, the center of gravity of

the transmission will shift when the torque converter is removed creatingan unstable condition. The torque

converter is a heavy unit. Use caution when separating the torque converter from the transmission.

3. Pull the torque converter forward until the center hub clears the oil pumpseal.

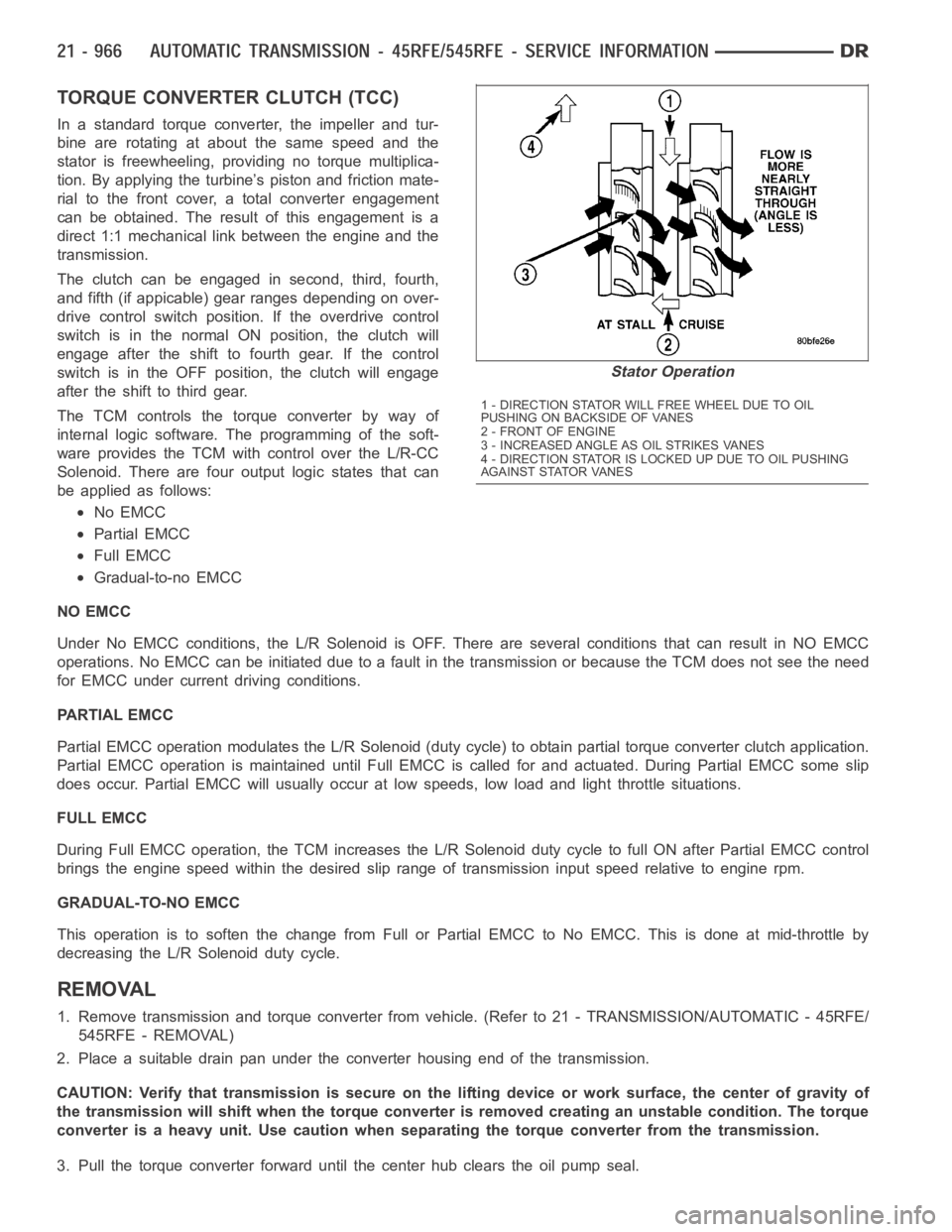

Stator Operation

1 - DIRECTION STATOR WILL FREE WHEEL DUE TO OIL

PUSHING ON BACKSIDE OF VANES

2-FRONTOFENGINE

3 - INCREASED ANGLE AS OIL STRIKES VANES

4 - DIRECTION STATOR IS LOCKED UP DUE TO OIL PUSHING

AGAINST STATOR VANES

Page 3488 of 5267

4. Separate the torque converter from the transmission.

INSTALLATION

NOTE: Check converter hub and drive flats for sharp edges, burrs, scratches, or nicks. Polish the hub and

flats with 320/400 grit paper or crocus cloth if necessary. Verify that theconverter hub o-ring is properly

installed and is free from debris. The hub must be smooth to avoid damaging the pump seal at installation.

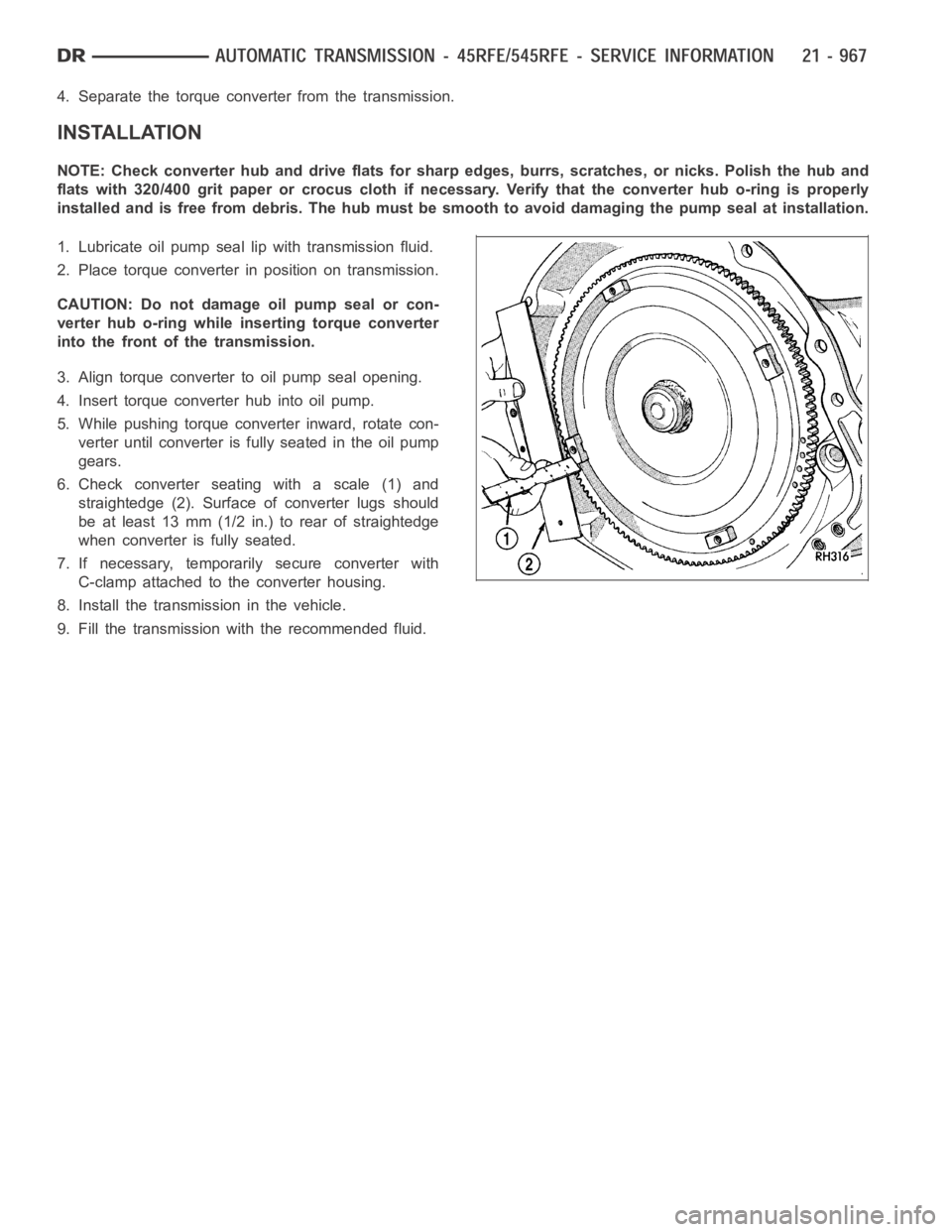

1. Lubricate oil pump seal lip with transmission fluid.

2. Place torque converter in position on transmission.

CAUTION: Do not damage oil pump seal or con-

verter hub o-ring while inserting torque converter

into the front of the transmission.

3. Align torque converter to oil pump seal opening.

4. Insert torque converter hub into oil pump.

5. While pushing torque converter inward, rotate con-

verter until converter is fully seated in the oil pump

gears.

6. Check converter seating with a scale (1) and

straightedge (2). Surface of converter lugs should

be at least 13 mm (1/2 in.) to rear of straightedge

when converter is fully seated.

7. If necessary, temporarily secure converter with

C-clamp attached to the converter housing.

8. Install the transmission in the vehicle.

9. Fill the transmission with the recommended fluid.