ECU DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 4284 of 5267

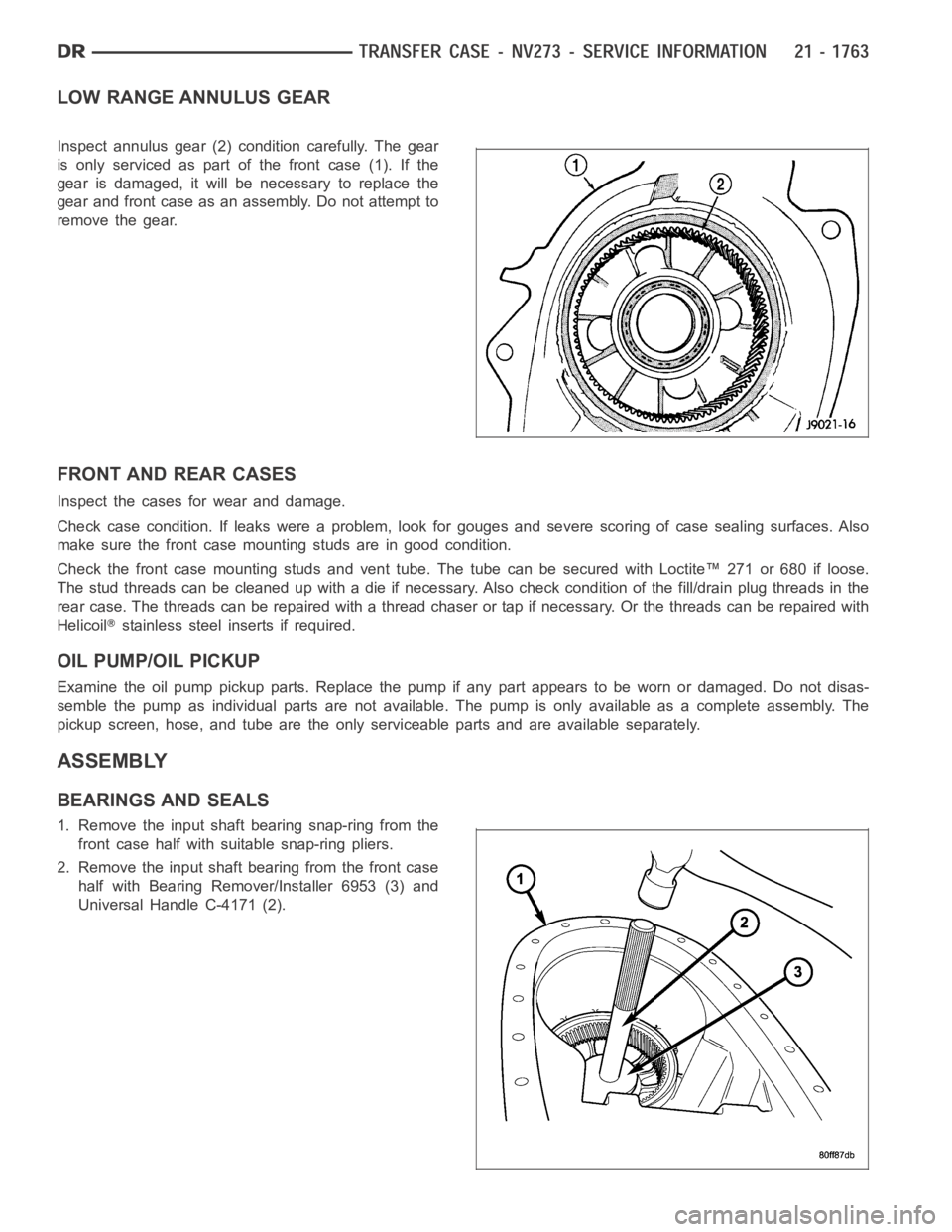

LOW RANGE ANNULUS GEAR

Inspect annulus gear (2) condition carefully. The gear

is only serviced as part of the front case (1). If the

gear is damaged, it will be necessary to replace the

gear and front case as an assembly. Do not attempt to

remove the gear.

FRONT AND REAR CASES

Inspect the cases for wear and damage.

Check case condition. If leaks were a problem, look for gouges and severe scoring of case sealing surfaces. Also

make sure the front case mounting studs are in good condition.

Check the front case mounting studs and vent tube. The tube can be secured with Loctite™ 271 or 680 if loose.

Thestudthreadscanbecleanedupwithadieifnecessary.Alsocheckcondition of the fill/drain plug threads in the

rear case. The threads can be repaired with a thread chaser or tap if necessary. Or the threads can be repaired with

Helicoil

stainless steel inserts if required.

OIL PUMP/OIL PICKUP

Examine the oil pump pickup parts. Replace the pump if any part appears to beworn or damaged. Do not disas-

semble the pump as individual parts are not available. The pump is only available as a complete assembly. The

pickup screen, hose, and tube are the only serviceable parts and are available separately.

ASSEMBLY

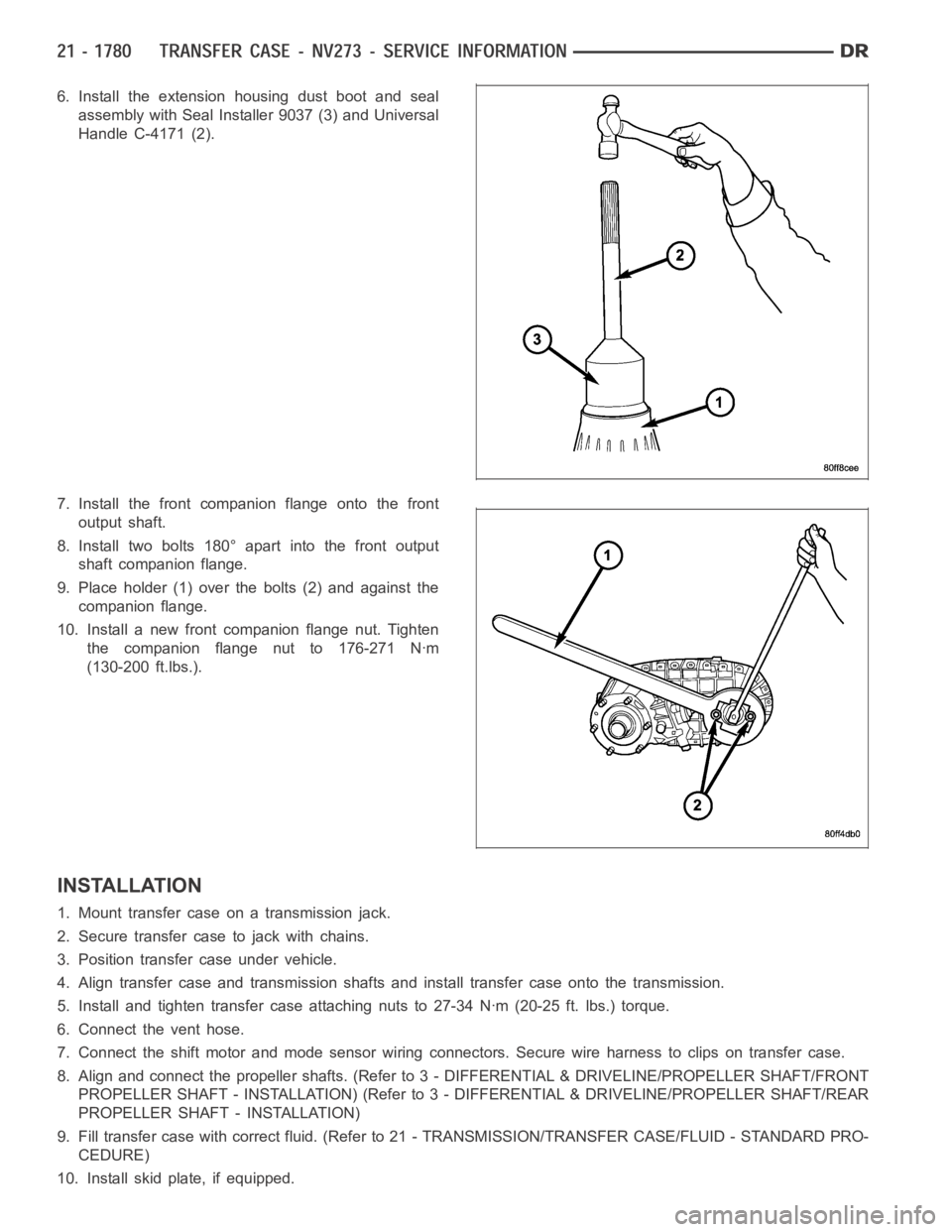

BEARINGS AND SEALS

1. Remove the input shaft bearing snap-ring from the

front case half with suitable snap-ring pliers.

2. Remove the input shaft bearing from the front case

half with Bearing Remover/Installer 6953 (3) and

Universal Handle C-4171 (2).

Page 4301 of 5267

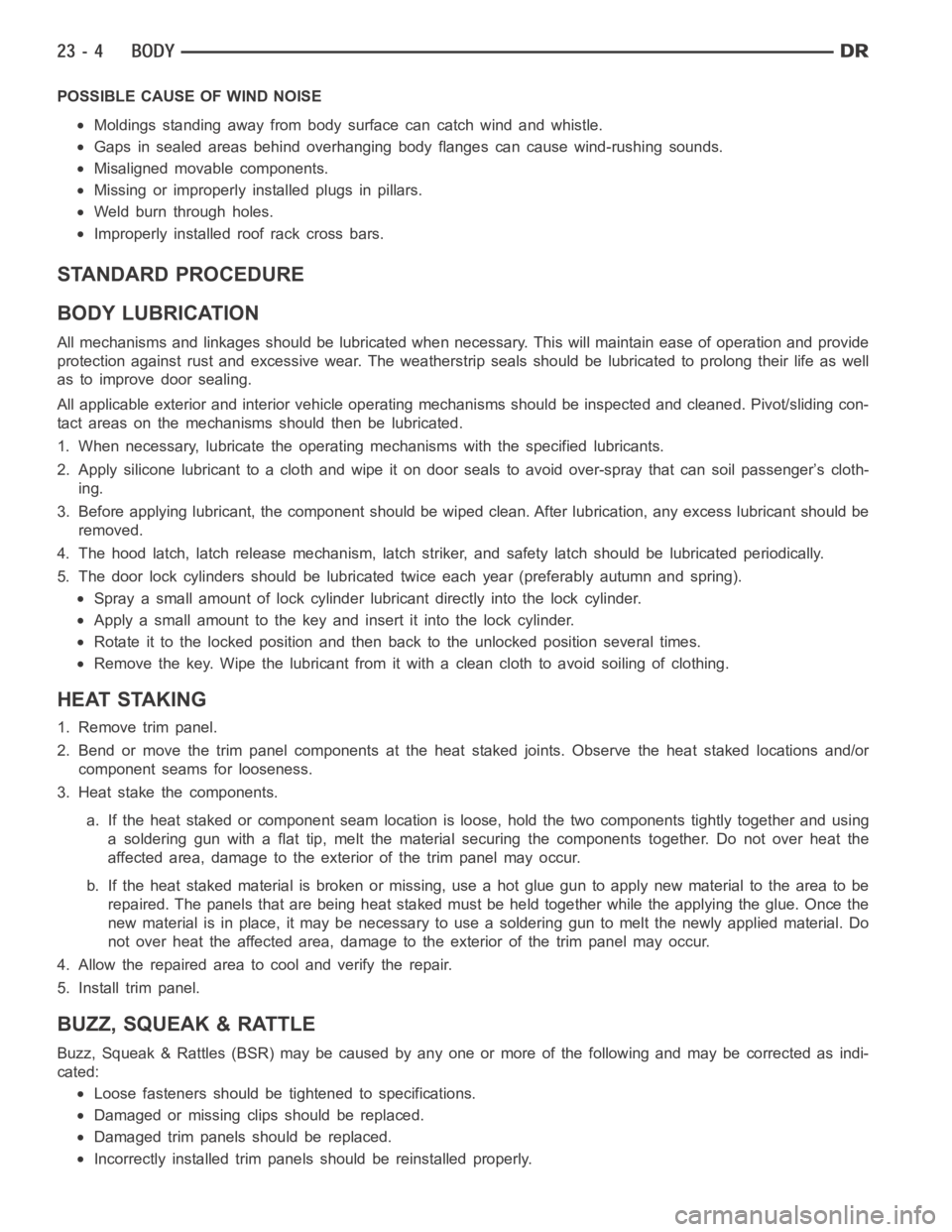

6. Install the extension housing dust boot and seal

assembly with Seal Installer 9037 (3) and Universal

Handle C-4171 (2).

7. Install the front companion flange onto the front

output shaft.

8. Install two bolts 180° apart into the front output

shaft companion flange.

9. Place holder (1) over the bolts (2) and against the

companion flange.

10. Install a new front companion flange nut. Tighten

the companion flange nut to 176-271 Nꞏm

(130-200 ft.lbs.).

INSTALLATION

1. Mount transfer case on a transmission jack.

2. Secure transfer case to jack with chains.

3. Position transfer case under vehicle.

4. Align transfer case and transmission shafts and install transfer case onto the transmission.

5. Install and tighten transfer case attaching nuts to 27-34 Nꞏm (20-25 ft.lbs.) torque.

6. Connect the vent hose.

7. Connect the shift motor and mode sensor wiring connectors. Secure wire harness to clips on transfer case.

8. Align and connect the propeller shafts. (Refer to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER SHAFT/FRONT

PROPELLER SHAFT - INSTALLATION) (Refer to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER SHAFT/REAR

PROPELLER SHAFT - INSTALLATION)

9. Fill transfer case with correct fluid. (Refer to 21 - TRANSMISSION/TRANSFER CASE/FLUID - STANDARD PRO-

CEDURE)

10. Install skid plate, if equipped.

Page 4341 of 5267

POSSIBLE CAUSE OF WIND NOISE

Moldings standing away from body surface can catch wind and whistle.

Gaps in sealed areas behind overhanging body flanges can cause wind-rushing sounds.

Misaligned movable components.

Missing or improperly installed plugs in pillars.

Weld burn through holes.

Improperly installed roof rack cross bars.

STANDARD PROCEDURE

BODY LUBRICATION

All mechanisms and linkages should be lubricated when necessary. This will maintain ease of operation and provide

protection against rust and excessive wear. The weatherstrip seals should be lubricated to prolong their life as well

as to improve door sealing.

All applicable exterior and interior vehicle operating mechanisms should be inspected and cleaned. Pivot/sliding con-

tact areas on the mechanisms should then be lubricated.

1. When necessary, lubricate the operating mechanisms with the specifiedlubricants.

2. Apply silicone lubricant to a clothand wipe it on door seals to avoid over-spray that can soil passenger’s cloth-

ing.

3. Before applying lubricant, the component should be wiped clean. After lubrication, any excess lubricant should be

removed.

4. The hood latch, latch release mechanism, latch striker, and safety latch should be lubricated periodically.

5. The door lock cylinders should be lubricated twice each year (preferably autumn and spring).

Spray a small amount of lock cylinder lubricant directly into the lock cylinder.

Apply a small amount to the key and insert it into the lock cylinder.

Rotate it to the locked position and then back to the unlocked position several times.

Remove the key. Wipe the lubricant from it with a clean cloth to avoid soiling of clothing.

HEAT STAKING

1. Remove trim panel.

2. Bend or move the trim panel components at the heat staked joints. Observethe heat staked locations and/or

component seams for looseness.

3. Heat stake the components.

a. If the heat staked or component seam location is loose, hold the two components tightly together and using

a soldering gun with a flat tip, melt the material securing the components together. Do not over heat the

affected area, damage to the exterior of the trim panel may occur.

b. Iftheheatstakedmaterialisbrokenormissing,useahotglueguntoapplynewmaterialtotheareatobe

repaired. The panels that are being heat staked must be held together whiletheapplyingtheglue.Oncethe

new material is in place, it may be necessary to use a soldering gun to melt the newly applied material. Do

not over heat the affected area, damage to the exterior of the trim panel mayoccur.

4. Allow the repaired area to cool and verify the repair.

5. Install trim panel.

BUZZ, SQUEAK & RATTLE

Buzz, Squeak & Rattles (BSR) may be caused by any one or more of the followingand may be corrected as indi-

cated:

Loose fasteners should be tightened to specifications.

Damaged or missing clips should be replaced.

Damaged trim panels should be replaced.

Incorrectly installed trim panels should be reinstalled properly.

Page 4348 of 5267

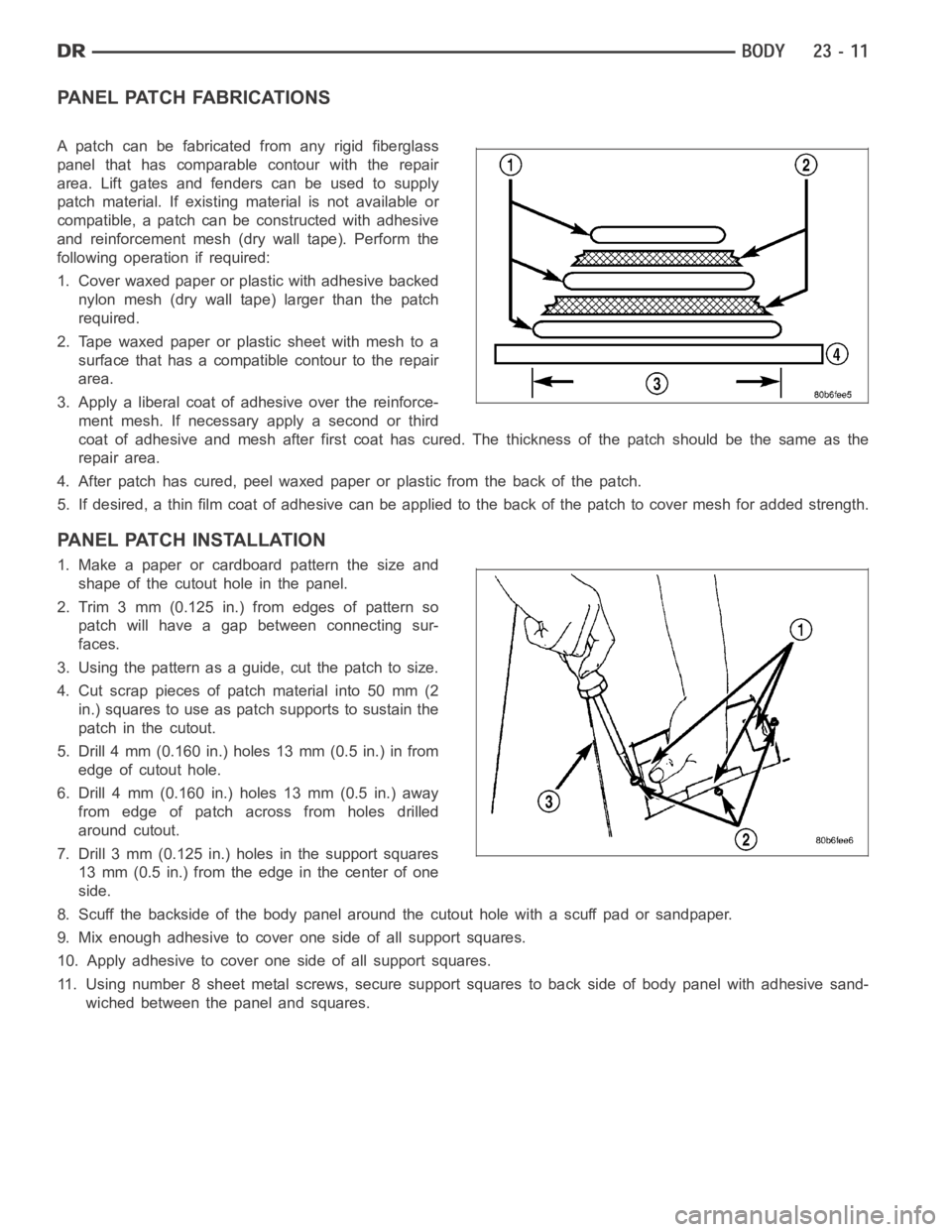

PANEL PATCH FABRICATIONS

A patch can be fabricated from any rigid fiberglass

panel that has comparable contour with the repair

area. Lift gates and fenders can be used to supply

patch material. If existing material is not available or

compatible, a patch can be constructed with adhesive

and reinforcement mesh (dry wall tape). Perform the

following operation if required:

1. Cover waxed paper or plastic with adhesive backed

nylon mesh (dry wall tape) larger than the patch

required.

2. Tape waxed paper or plastic sheet with mesh to a

surface that has a compatible contour to the repair

area.

3. Apply a liberal coat of adhesive over the reinforce-

ment mesh. If necessary apply a second or third

coat of adhesive and mesh after first coat has cured. The thickness of the patch should be the same as the

repair area.

4. After patch has cured, peel waxed paper or plastic from the back of the patch.

5. If desired, a thin film coat of adhesive can be applied to the back of the patch to cover mesh for added strength.

PANEL PATCH INSTALLATION

1. Make a paper or cardboard pattern the size and

shape of the cutout hole in the panel.

2. Trim 3 mm (0.125 in.) from edges of pattern so

patch will have a gap between connecting sur-

faces.

3. Using the pattern as a guide, cut the patch to size.

4. Cut scrap pieces of patch material into 50 mm (2

in.) squares to use as patch supports to sustain the

patch in the cutout.

5. Drill 4 mm (0.160 in.) holes 13 mm (0.5 in.) in from

edge of cutout hole.

6. Drill 4 mm (0.160 in.) holes 13 mm (0.5 in.) away

from edge of patch across from holes drilled

around cutout.

7. Drill 3 mm (0.125 in.) holes in the support squares

13 mm (0.5 in.) from the edge in the center of one

side.

8. Scuff the backside of the body panel around the cutout hole with a scuff pad or sandpaper.

9. Mix enough adhesive to cover one side of all support squares.

10. Apply adhesive to cover one side of all support squares.

11. Using number 8 sheet metal screws,secure support squares to back side of body panel with adhesive sand-

wiched between the panel and squares.

Page 4355 of 5267

CABLE-CHECK

REMOVAL

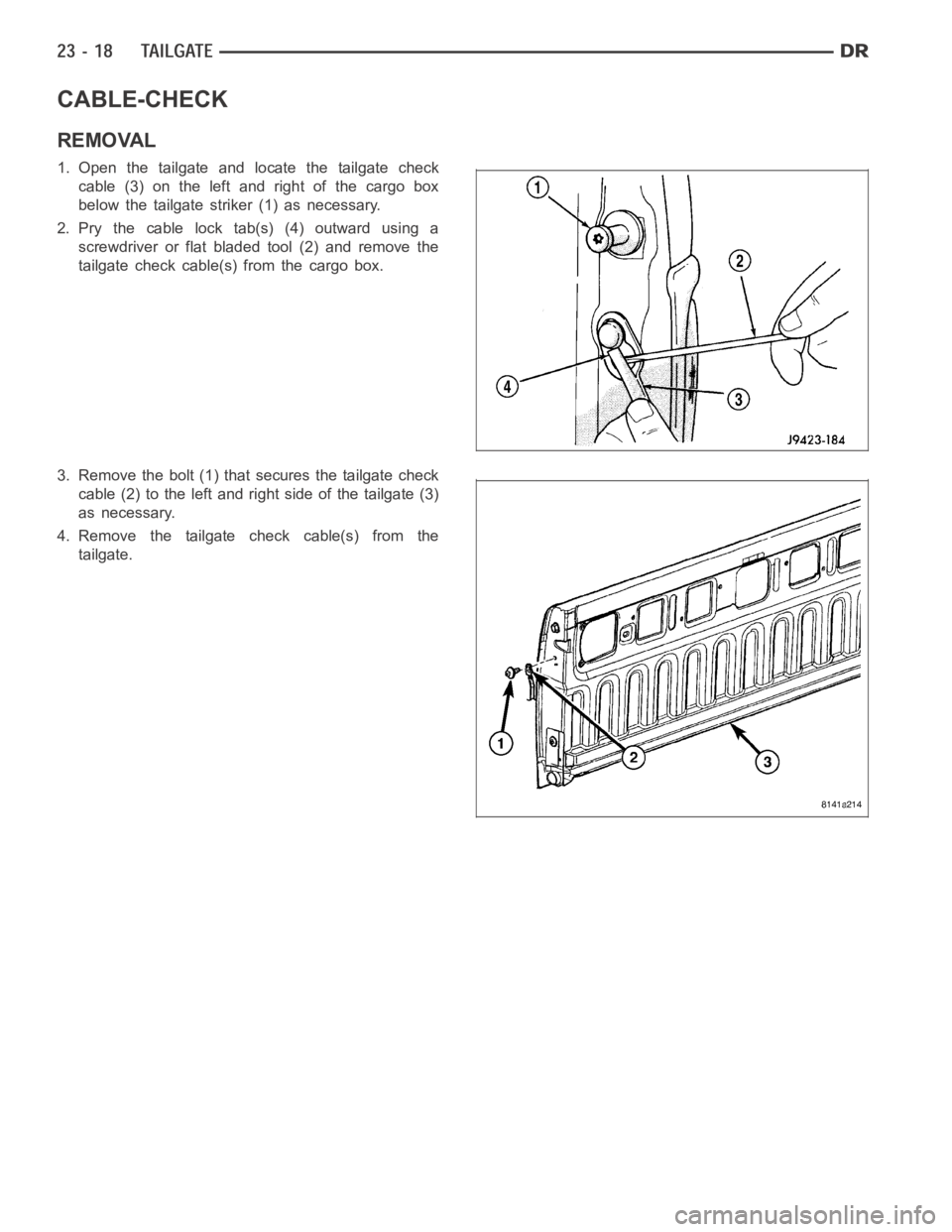

1. Open the tailgate and locate the tailgate check

cable (3) on the left and right of the cargo box

below the tailgate striker (1) as necessary.

2. Pry the cable lock tab(s) (4) outward using a

screwdriver or flat bladed tool (2) and remove the

tailgate check cable(s) from the cargo box.

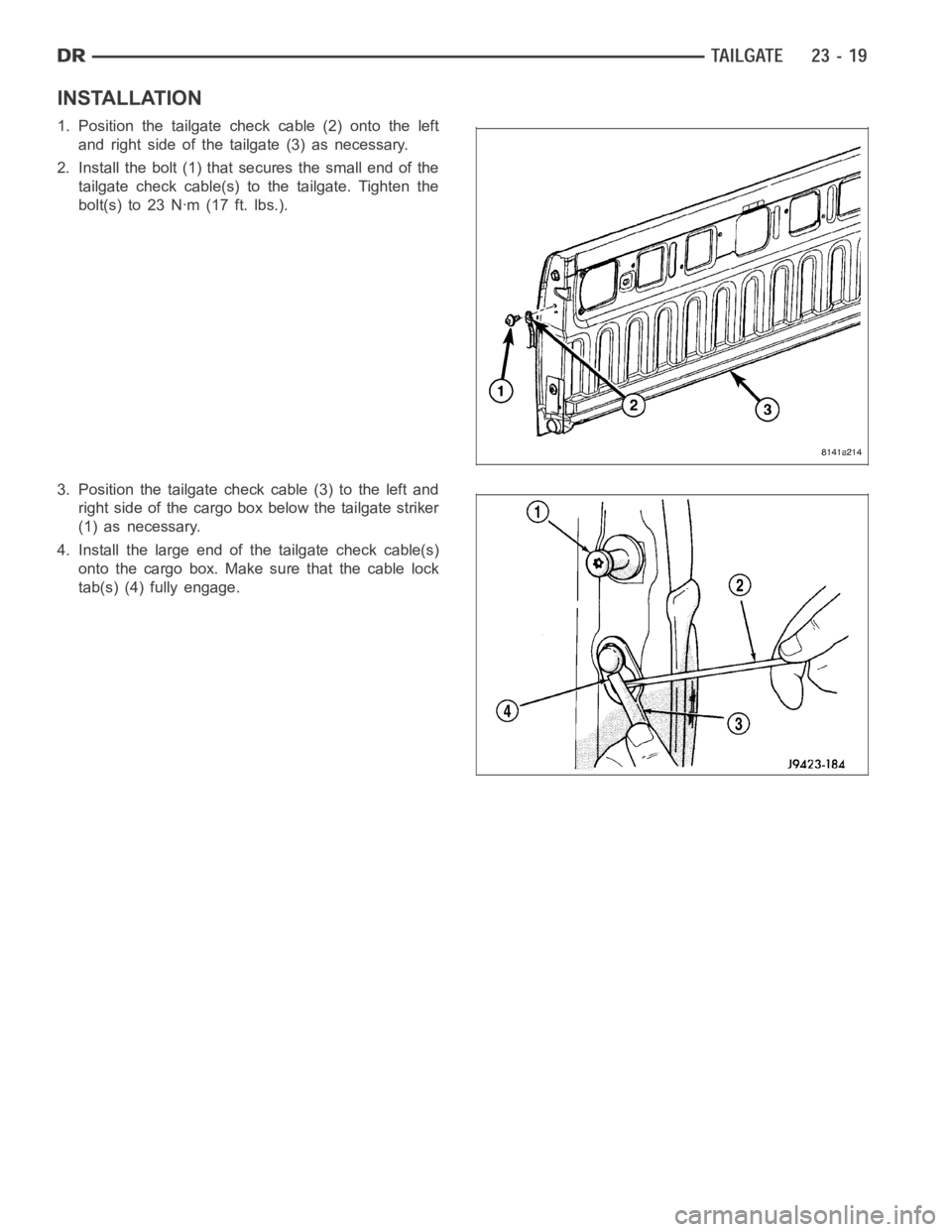

3. Remove the bolt (1) that secures the tailgate check

cable (2) to the left and right side of the tailgate (3)

as necessary.

4. Remove the tailgate check cable(s) from the

tailgate.

Page 4356 of 5267

INSTALLATION

1. Position the tailgate check cable (2) onto the left

and right side of the tailgate (3) as necessary.

2. Install the bolt (1) that secures the small end of the

tailgate check cable(s) to the tailgate. Tighten the

bolt(s) to 23 Nꞏm (17 ft. lbs.).

3. Position the tailgate check cable (3) to the left and

right side of the cargo box below the tailgate striker

(1) as necessary.

4. Install the large end of the tailgate check cable(s)

onto the cargo box. Make sure that the cable lock

tab(s) (4) fully engage.

Page 4357 of 5267

COVER

REMOVAL

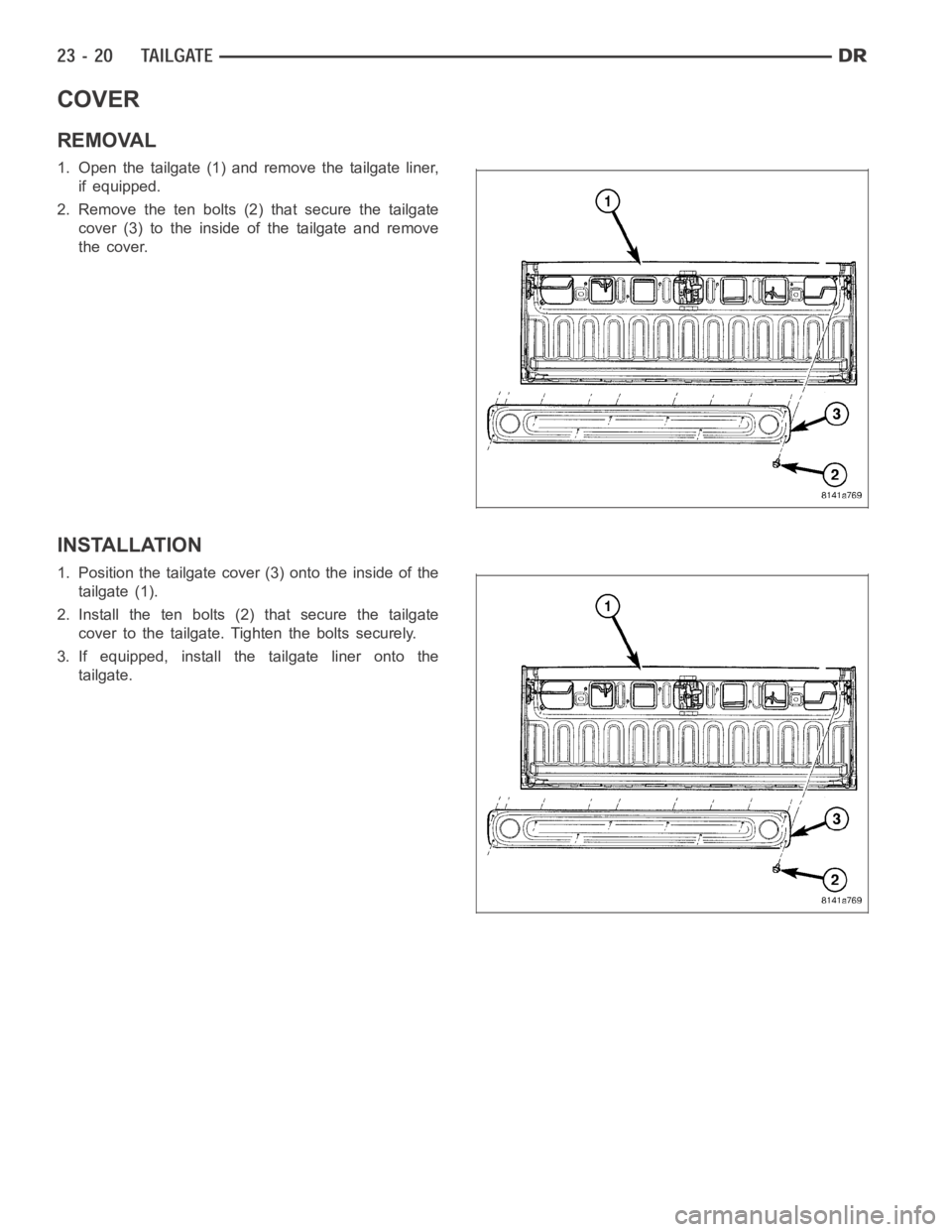

1. Open the tailgate (1) and remove the tailgate liner,

if equipped.

2. Remove the ten bolts (2) that secure the tailgate

cover (3) to the inside of the tailgate and remove

the cover.

INSTALLATION

1. Position the tailgate cover (3) onto the inside of the

tailgate (1).

2. Install the ten bolts (2) that secure the tailgate

cover to the tailgate. Tighten the bolts securely.

3. If equipped, install the tailgate liner onto the

tailgate.

Page 4358 of 5267

HINGE

REMOVAL

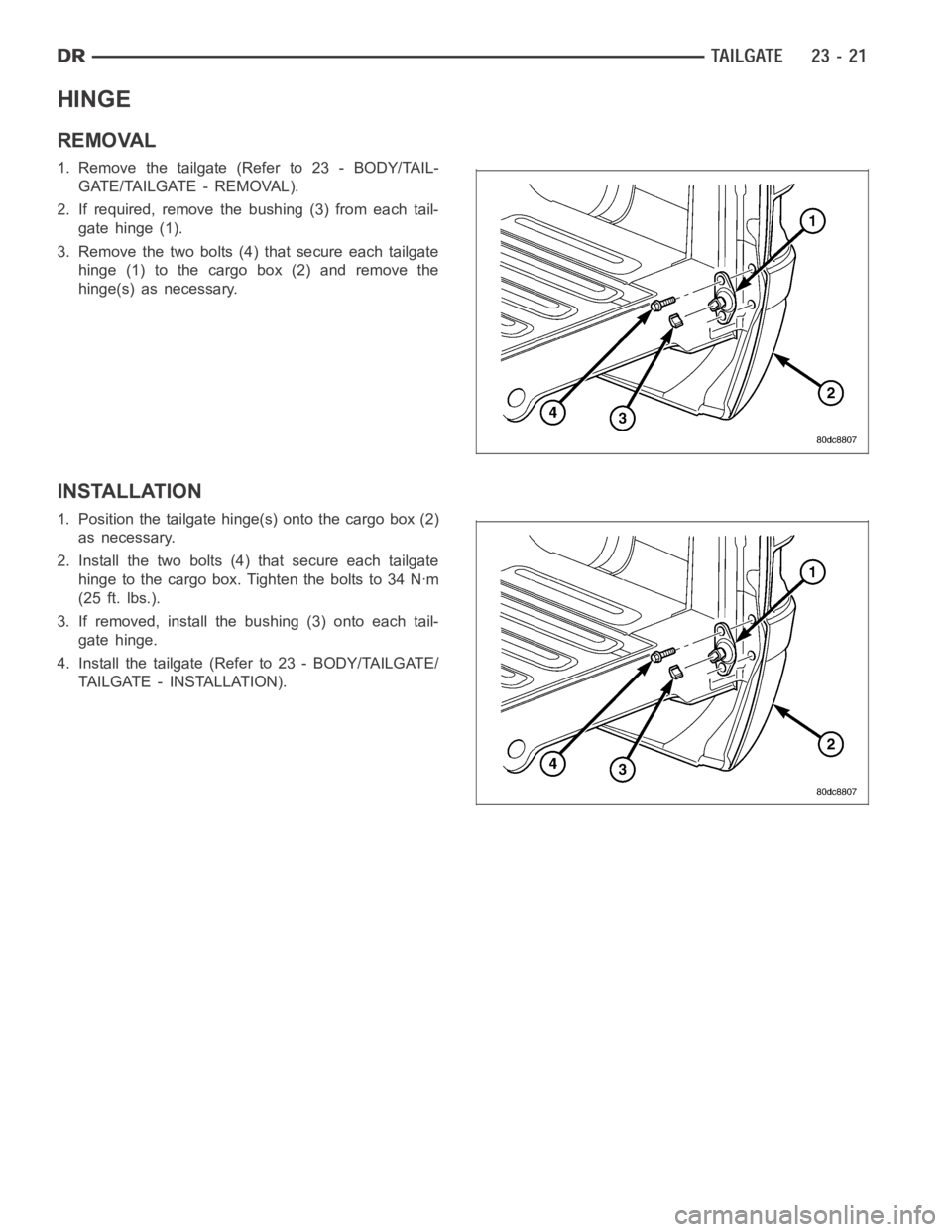

1. Remove the tailgate (Refer to 23 - BODY/TAIL-

GATE/TAILGATE - REMOVAL).

2. If required, remove the bushing (3) from each tail-

gate hinge (1).

3. Remove the two bolts (4)that secure each tailgate

hinge (1) to the cargo box (2) and remove the

hinge(s) as necessary.

INSTALLATION

1. Position the tailgate hinge(s) onto the cargo box (2)

as necessary.

2. Install the two bolts (4) that secure each tailgate

hinge to the cargo box. Tighten the bolts to 34 Nꞏm

(25 ft. lbs.).

3. If removed, install the bushing (3) onto each tail-

gate hinge.

4. Install the tailgate (Refer to 23 - BODY/TAILGATE/

TA I L G AT E - I N S TA L L AT I O N ) .

Page 4359 of 5267

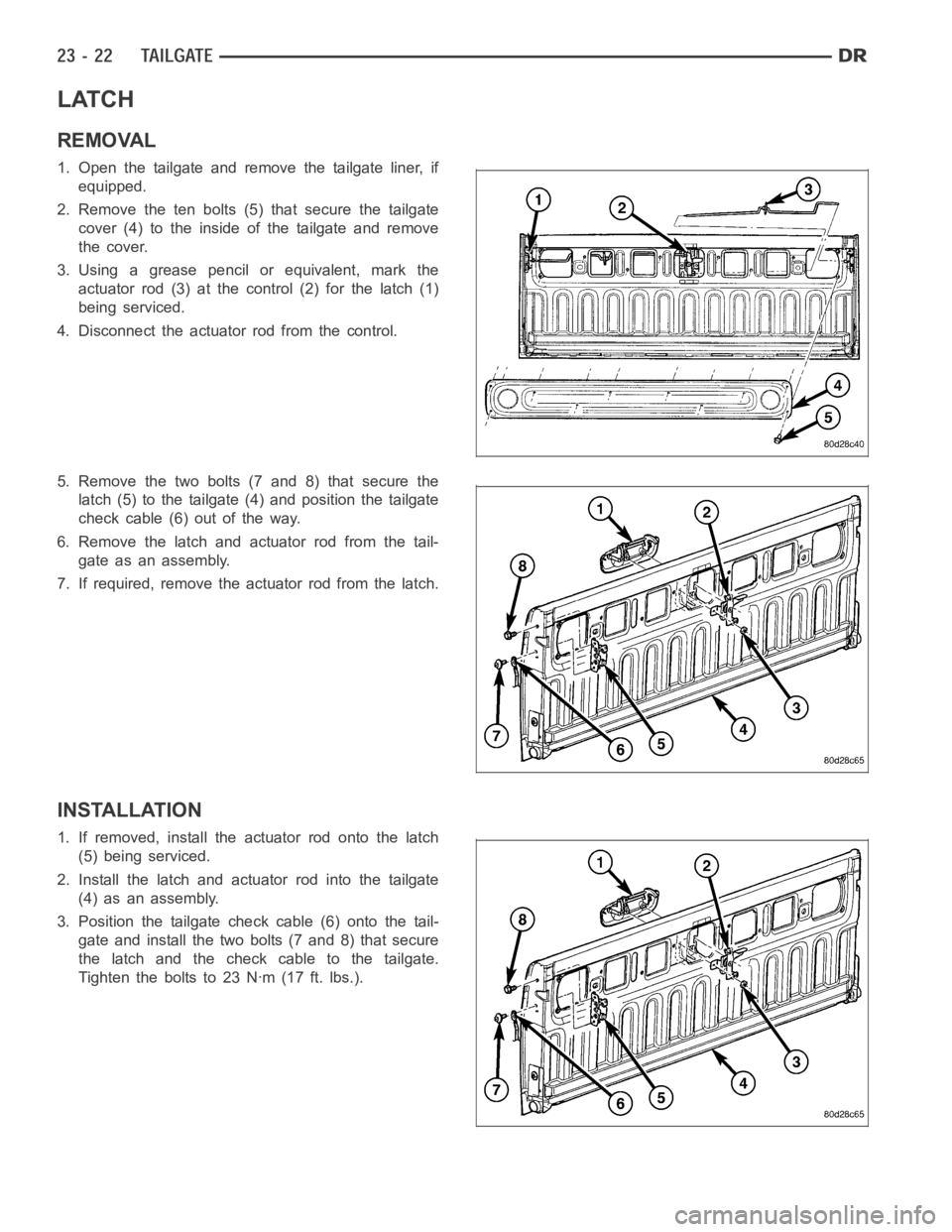

LATCH

REMOVAL

1. Open the tailgate and remove the tailgate liner, if

equipped.

2. Remove the ten bolts (5) that secure the tailgate

cover (4) to the inside of the tailgate and remove

the cover.

3. Using a grease pencil or equivalent, mark the

actuator rod (3) at the control (2) for the latch (1)

being serviced.

4. Disconnect the actuator rod from the control.

5. Remove the two bolts (7 and 8) that secure the

latch (5) to the tailgate (4) and position the tailgate

check cable (6) out of the way.

6. Remove the latch and actuator rod from the tail-

gate as an assembly.

7. If required, remove the actuator rod from the latch.

INSTALLATION

1. If removed, install the actuator rod onto the latch

(5) being serviced.

2. Install the latch and actuator rod into the tailgate

(4) as an assembly.

3. Position the tailgate check cable (6) onto the tail-

gate and install the two bolts (7 and 8) that secure

the latch and the check cable to the tailgate.

Tighten the bolts to 23 Nꞏm (17 ft. lbs.).

Page 4360 of 5267

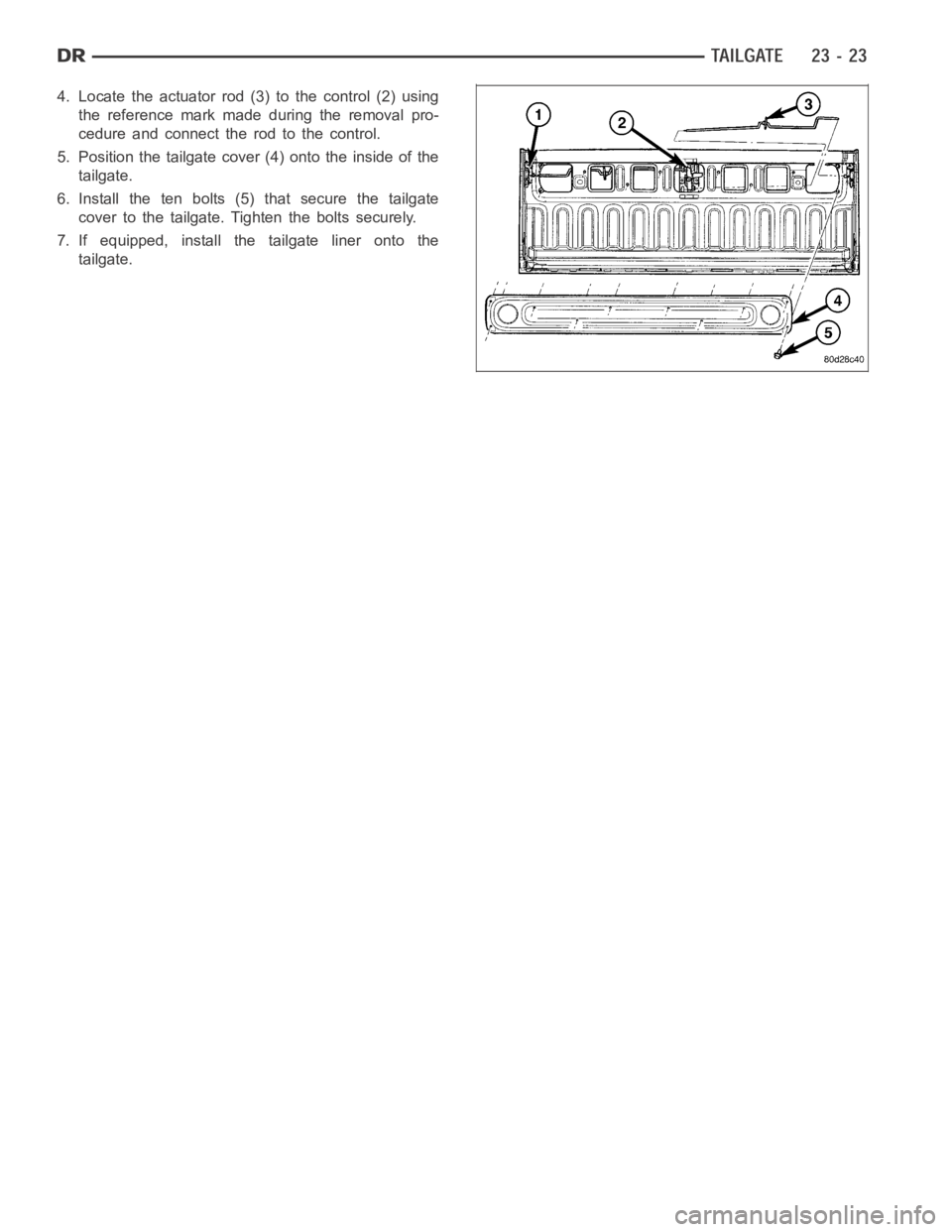

4. Locate the actuator rod (3) to the control (2) using

the reference mark made during the removal pro-

cedure and connect the rod to the control.

5. Position the tailgate cover (4) onto the inside of the

tailgate.

6. Install the ten bolts (5) that secure the tailgate

cover to the tailgate. Tighten the bolts securely.

7. If equipped, install the tailgate liner onto the

tailgate.