ECU DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3958 of 5267

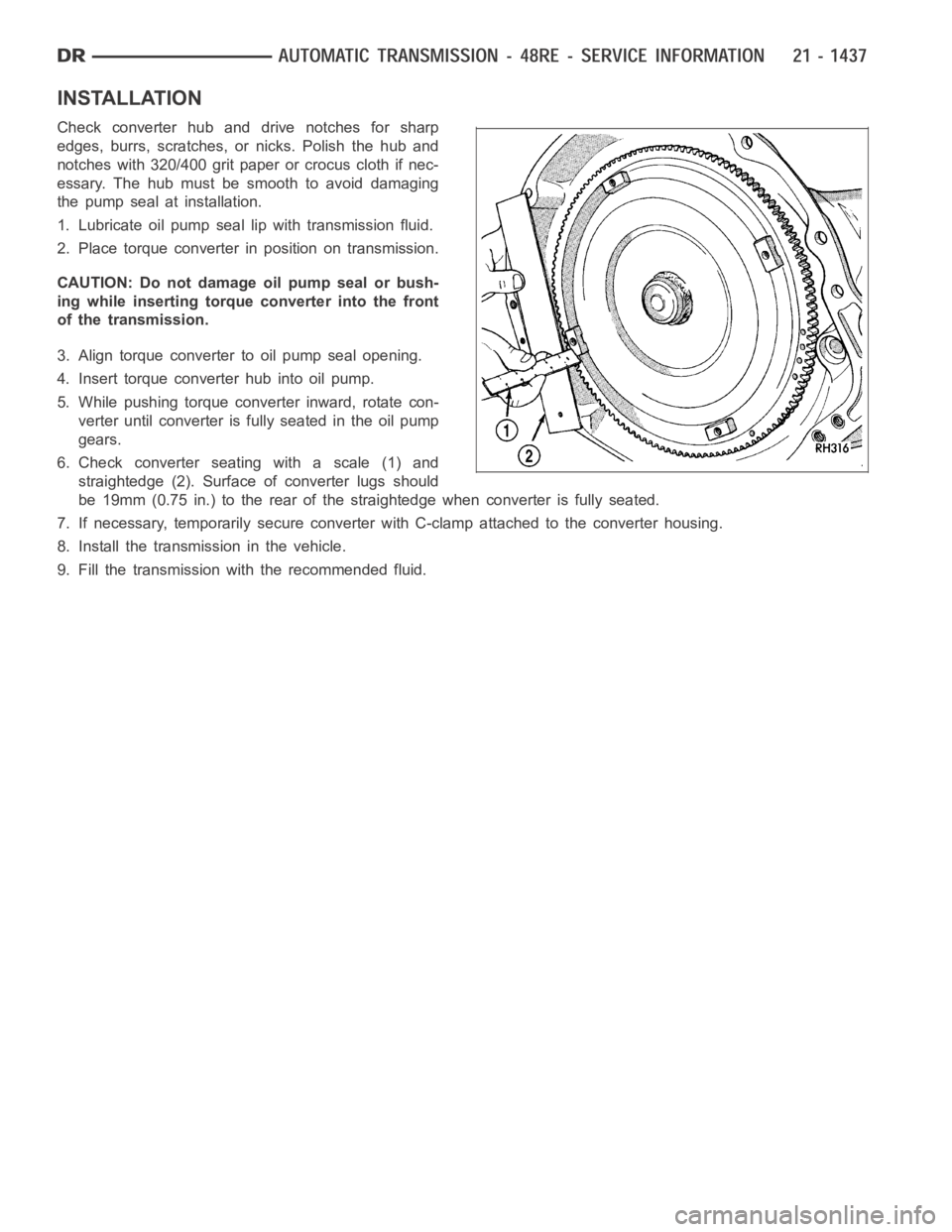

INSTALLATION

Check converter hub and drive notches for sharp

edges, burrs, scratches, or nicks. Polish the hub and

notches with 320/400 grit paper or crocus cloth if nec-

essary. The hub must be smooth to avoid damaging

the pump seal at installation.

1. Lubricate oil pump seal lip with transmission fluid.

2. Place torque converter in position on transmission.

CAUTION: Do not damage oil pump seal or bush-

ing while inserting torqueconverterintothefront

of the transmission.

3. Align torque converter to oil pump seal opening.

4. Insert torque converter hub into oil pump.

5. While pushing torque converter inward, rotate con-

verter until converter is fully seated in the oil pump

gears.

6. Check converter seating with a scale (1) and

straightedge (2). Surface of converter lugs should

be 19mm (0.75 in.) to the rear of the straightedge when converter is fully seated.

7. If necessary, temporarily secure converter with C-clamp attached to the converter housing.

8. Install the transmission in the vehicle.

9. Fill the transmission with the recommended fluid.

Page 3994 of 5267

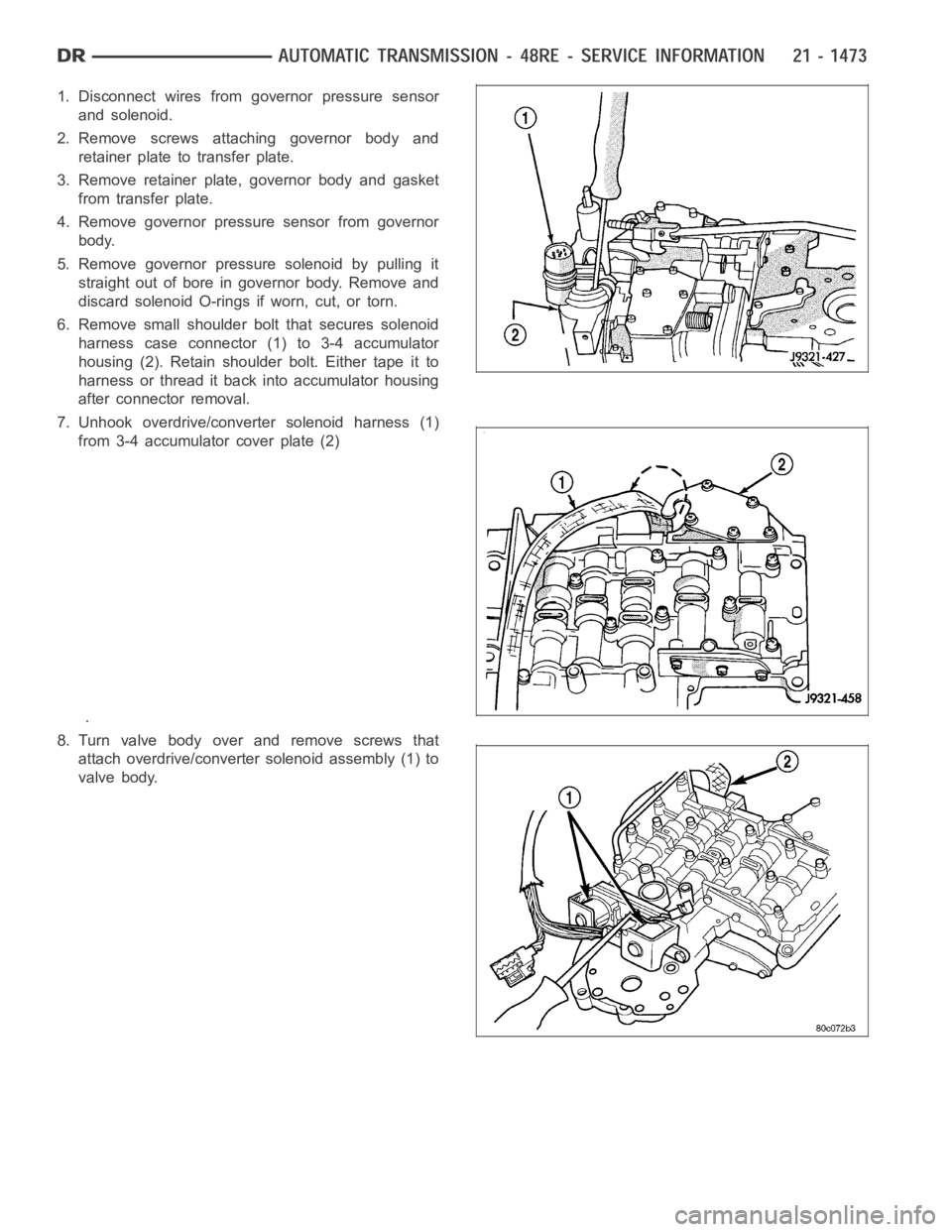

1. Disconnect wires from governor pressure sensor

and solenoid.

2. Remove screws attaching governor body and

retainer plate to transfer plate.

3. Remove retainer plate, governor body and gasket

from transfer plate.

4. Remove governor pressure sensor from governor

body.

5. Remove governor pressure solenoid by pulling it

straight out of bore in governor body. Remove and

discard solenoid O-rings if worn, cut, or torn.

6. Remove small shoulder bolt that secures solenoid

harness case connector (1) to 3-4 accumulator

housing (2). Retain shoulder bolt. Either tape it to

harness or thread it back into accumulator housing

after connector removal.

7. Unhook overdrive/converter solenoid harness (1)

from 3-4 accumulator cover plate (2)

.

8. Turn valve body over and remove screws that

attach overdrive/converter solenoid assembly (1) to

valve body.

Page 3996 of 5267

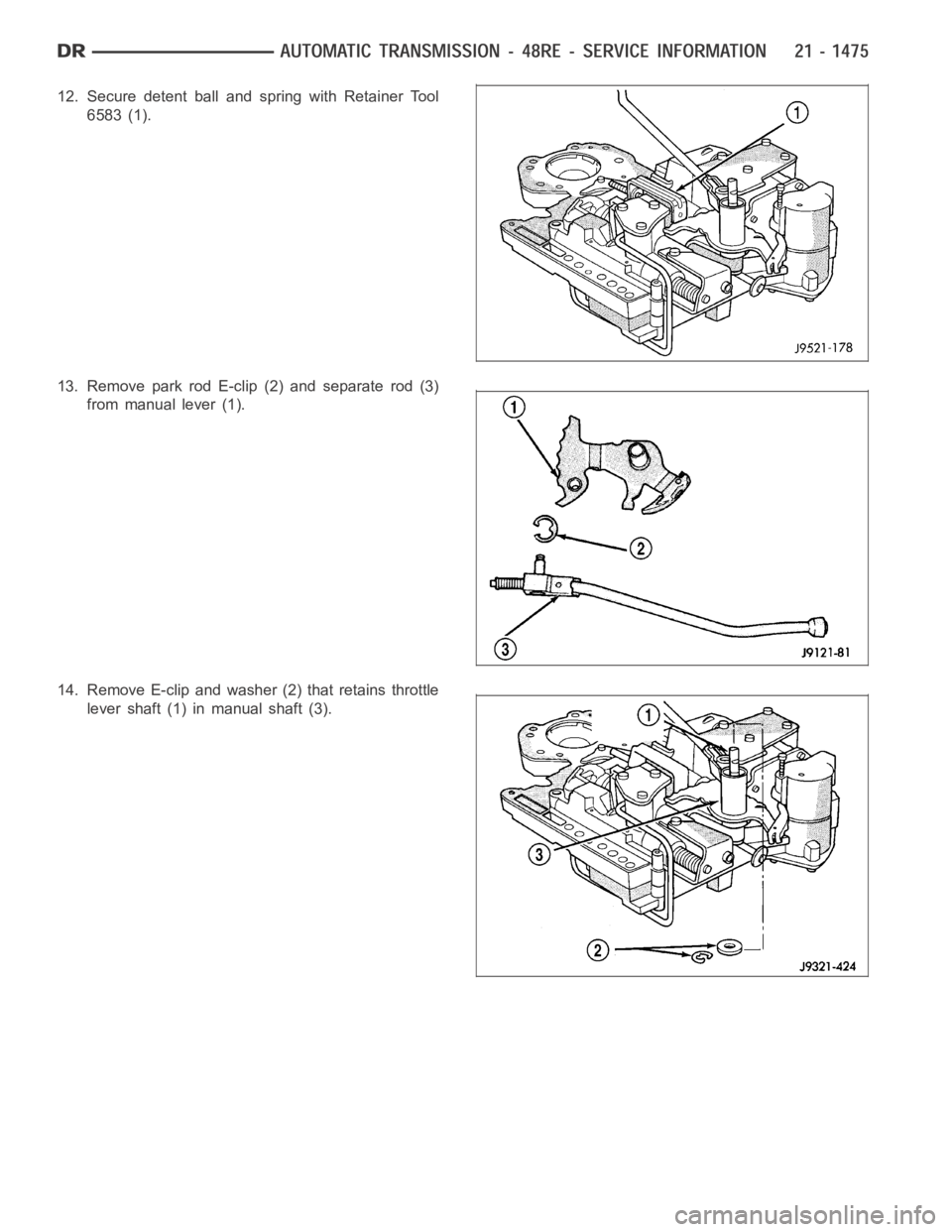

12. Secure detent ball and spring with Retainer Tool

6583 (1).

13. Remove park rod E-clip (2) and separate rod (3)

from manual lever (1).

14. Remove E-clip and washer (2) that retains throttle

lever shaft (1) in manual shaft (3).

Page 4002 of 5267

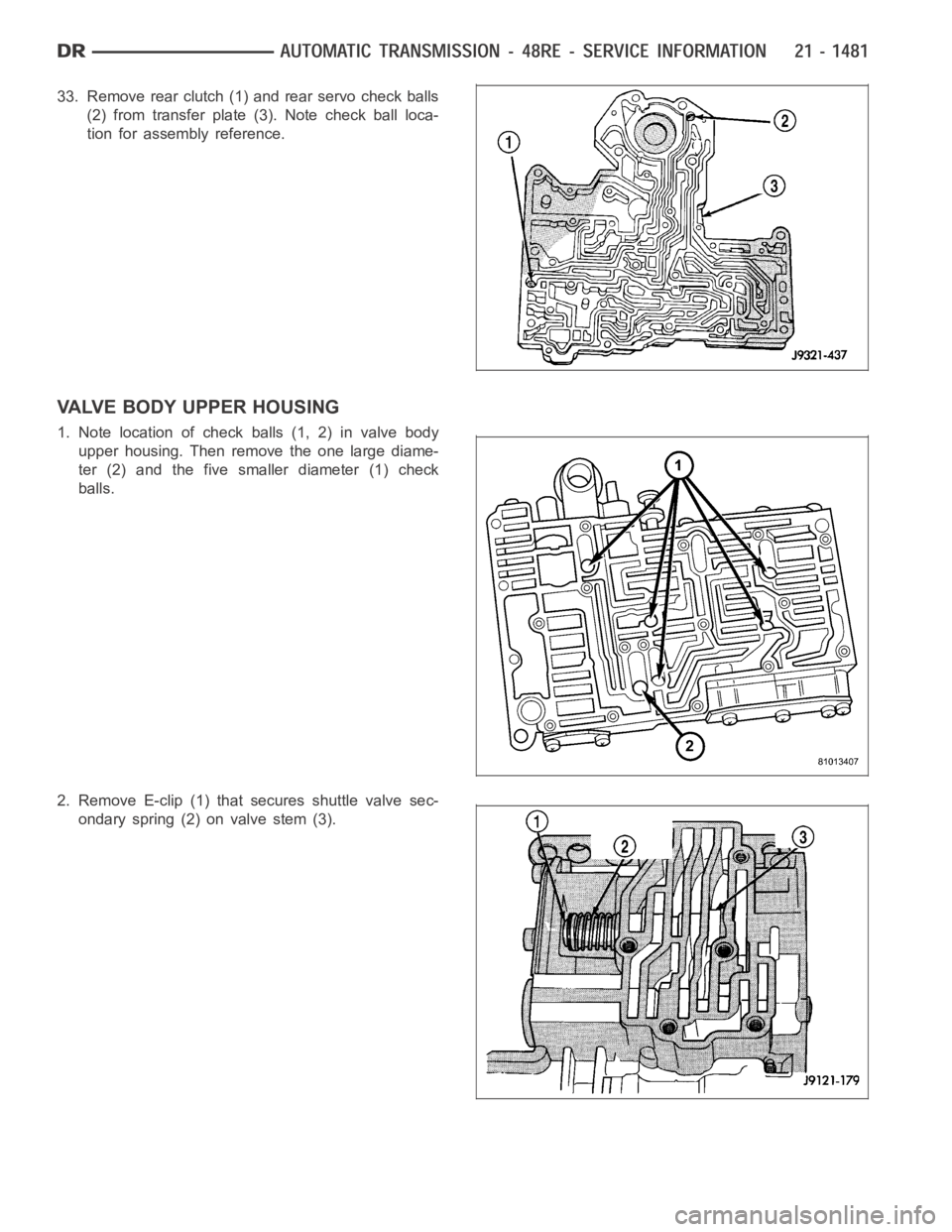

33. Remove rear clutch (1) and rear servo check balls

(2) from transfer plate (3). Note check ball loca-

tion for assembly reference.

VALVE BODY UPPER HOUSING

1. Note location of check balls (1, 2) in valve body

upper housing. Then remove the one large diame-

ter (2) and the five smaller diameter (1) check

balls.

2. Remove E-clip (1) that secures shuttle valve sec-

ondary spring (2) on valve stem (3).

Page 4015 of 5267

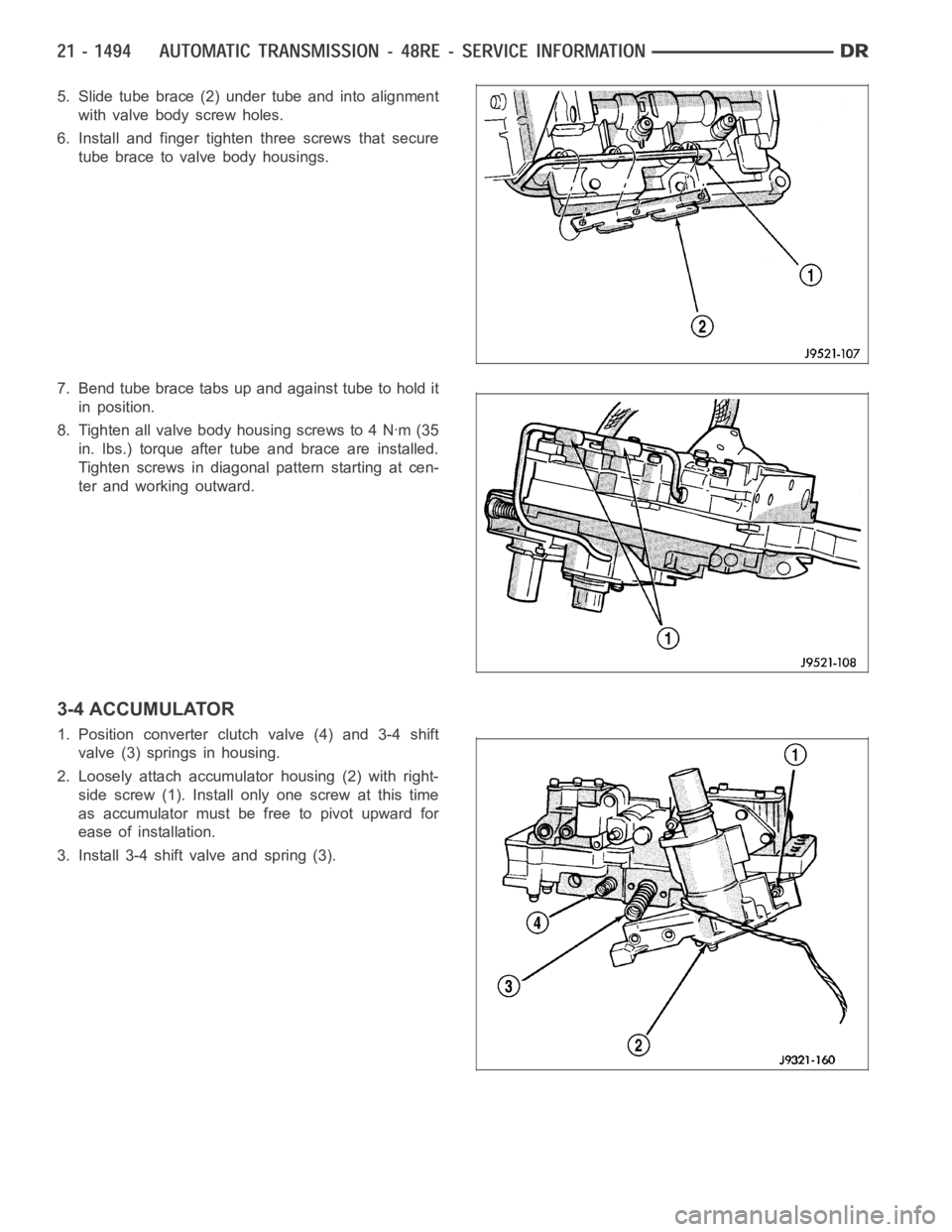

5. Slide tube brace (2) under tube and into alignment

with valve body screw holes.

6. Install and finger tighten three screws that secure

tube brace to valve body housings.

7. Bend tube brace tabs up and against tube to hold it

in position.

8. Tighten all valve body housing screws to 4 Nꞏm (35

in. lbs.) torque after tube and brace are installed.

Tighten screws in diagonal pattern starting at cen-

ter and working outward.

3-4 ACCUMULATOR

1. Position converter clutch valve (4) and 3-4 shift

valve (3) springs in housing.

2. Loosely attach accumulator housing (2) with right-

side screw (1). Install only one screw at this time

as accumulator must be free to pivot upward for

ease of installation.

3. Install 3-4 shift valve and spring (3).

Page 4087 of 5267

Condition Possible Cause Correction

Lubricant leaking from output shaft

seal or vent.1) Transfer case overfilled. 1) Drain lubricant to the correct

level.

2) Vent closed or restricted. 2) Clear or replace vent as

necessary.

3) Output shaft seals damaged or

installed incorrectly.3) Replace seal as necessary.

Check to ensure that another

component, the propeller shaft slip

yoke for example, is not causing

damage to seal.

Abnormal tire wear. 1) Extended operation on hard, dry

surfaces in the 4H position.1) Operate vehicle in the 2H

position on hard, dry surfaces.

REMOVAL

1. Raise and support vehicle.

2. Remove skid plate, if equipped. (Refer to 13 - FRAMES & BUMPERS/FRAME/TRANSFER CASE SKID PLATE

- REMOVAL)

3. Position drain oil container under transfer case.

4. Remove transfer case drain plug and drain lubricant into container.

5. Disconnect vent hose and transfer case position sensor connector.

6. Disconnect shift rod from grommet in transfer case shift lever, or from floor shift arm whichever provides easy

access. Use channel lock style pliers to press rod out of lever grommet.

7. Support transmission with jack stand.

8. Mark front and rear propeller shafts for assembly reference.

9. Remove front and rear propeller shafts. (Refer to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER SHAFT/PRO-

PELLER SHAFT - REMOVAL)

10. Support transfer case with suitable jack. Secure transfer case to jackwith safety chains.

11. Remove nuts attaching transfer case to transmission.

12. Move transfer case assembly rearward until free of transmission outputshaft.

13. Lower jack and move transfer case from under vehicle.

DISASSEMBLY

Position transfer case in a shallow drain pan. Remove drain plug and drain any remaining lubricant remaining in

case.

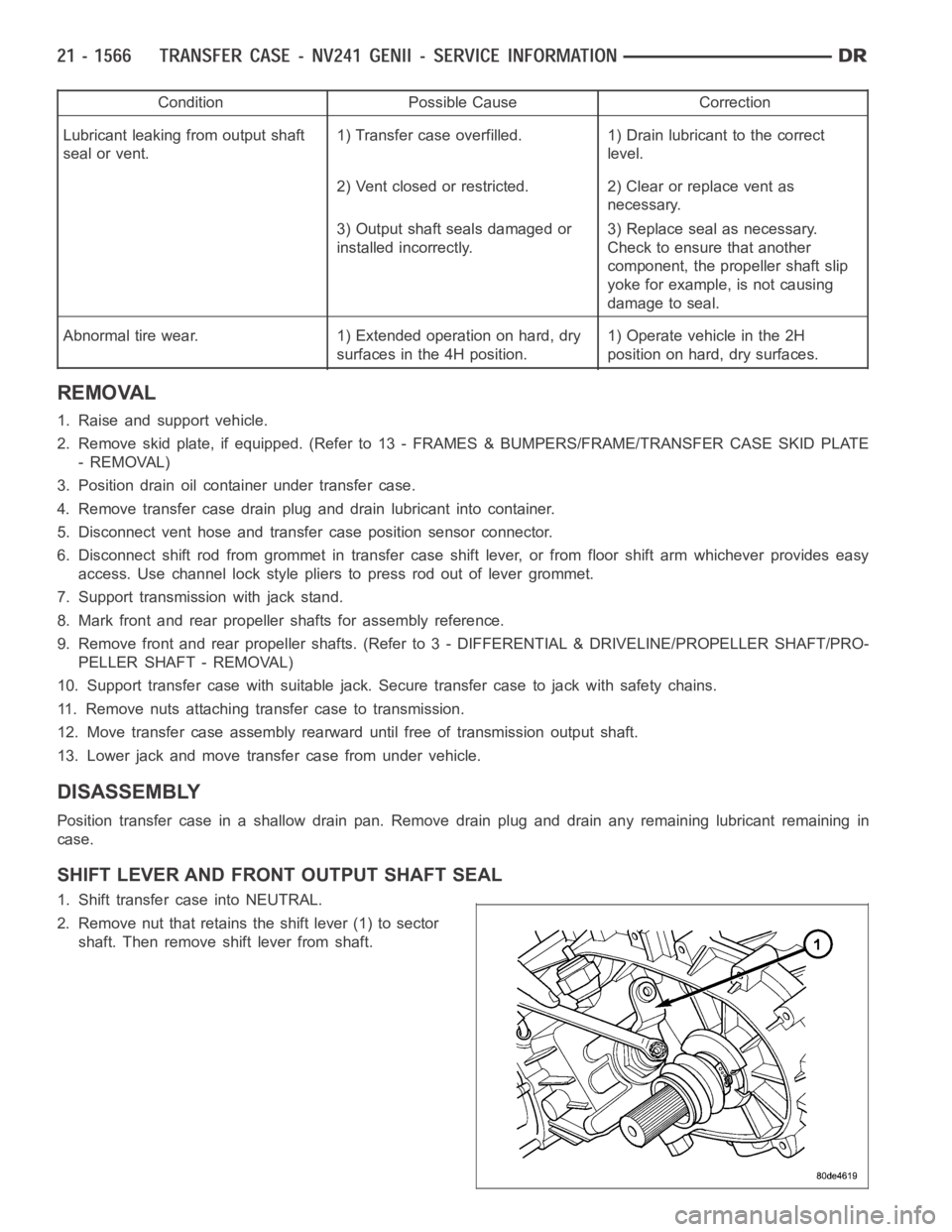

SHIFT LEVER AND FRONT OUTPUT SHAFT SEAL

1. Shift transfer case into NEUTRAL.

2. Remove nut that retains the shift lever (1) to sector

shaft. Then remove shift lever from shaft.

Page 4102 of 5267

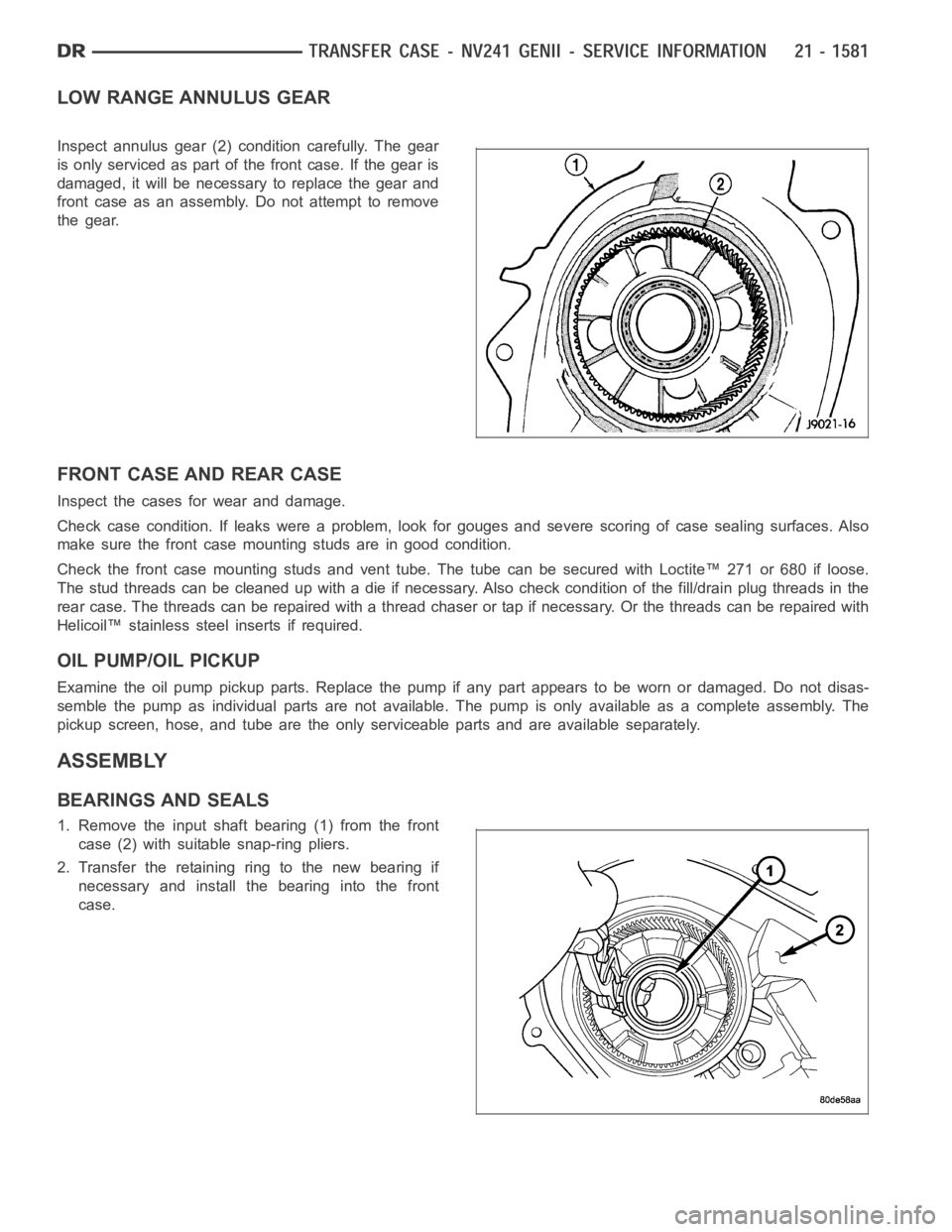

LOW RANGE ANNULUS GEAR

Inspect annulus gear (2) condition carefully. The gear

is only serviced as part of the front case. If the gear is

damaged, it will be necessary to replace the gear and

front case as an assembly. Do not attempt to remove

the gear.

FRONT CASE AND REAR CASE

Inspect the cases for wear and damage.

Check case condition. If leaks were a problem, look for gouges and severe scoring of case sealing surfaces. Also

make sure the front case mounting studs are in good condition.

Check the front case mounting studs and vent tube. The tube can be secured with Loctite™ 271 or 680 if loose.

Thestudthreadscanbecleanedupwithadieifnecessary.Alsocheckcondition of the fill/drain plug threads in the

rear case. The threads can be repaired with a thread chaser or tap if necessary. Or the threads can be repaired with

Helicoil™ stainless steel inserts if required.

OIL PUMP/OIL PICKUP

Examine the oil pump pickup parts. Replace the pump if any part appears to beworn or damaged. Do not disas-

semble the pump as individual parts are not available. The pump is only available as a complete assembly. The

pickup screen, hose, and tube are the only serviceable parts and are available separately.

ASSEMBLY

BEARINGS AND SEALS

1. Remove the input shaft bearing (1) from the front

case (2) with suitable snap-ring pliers.

2. Transfer the retaining ring to the new bearing if

necessary and install the bearing into the front

case.

Page 4111 of 5267

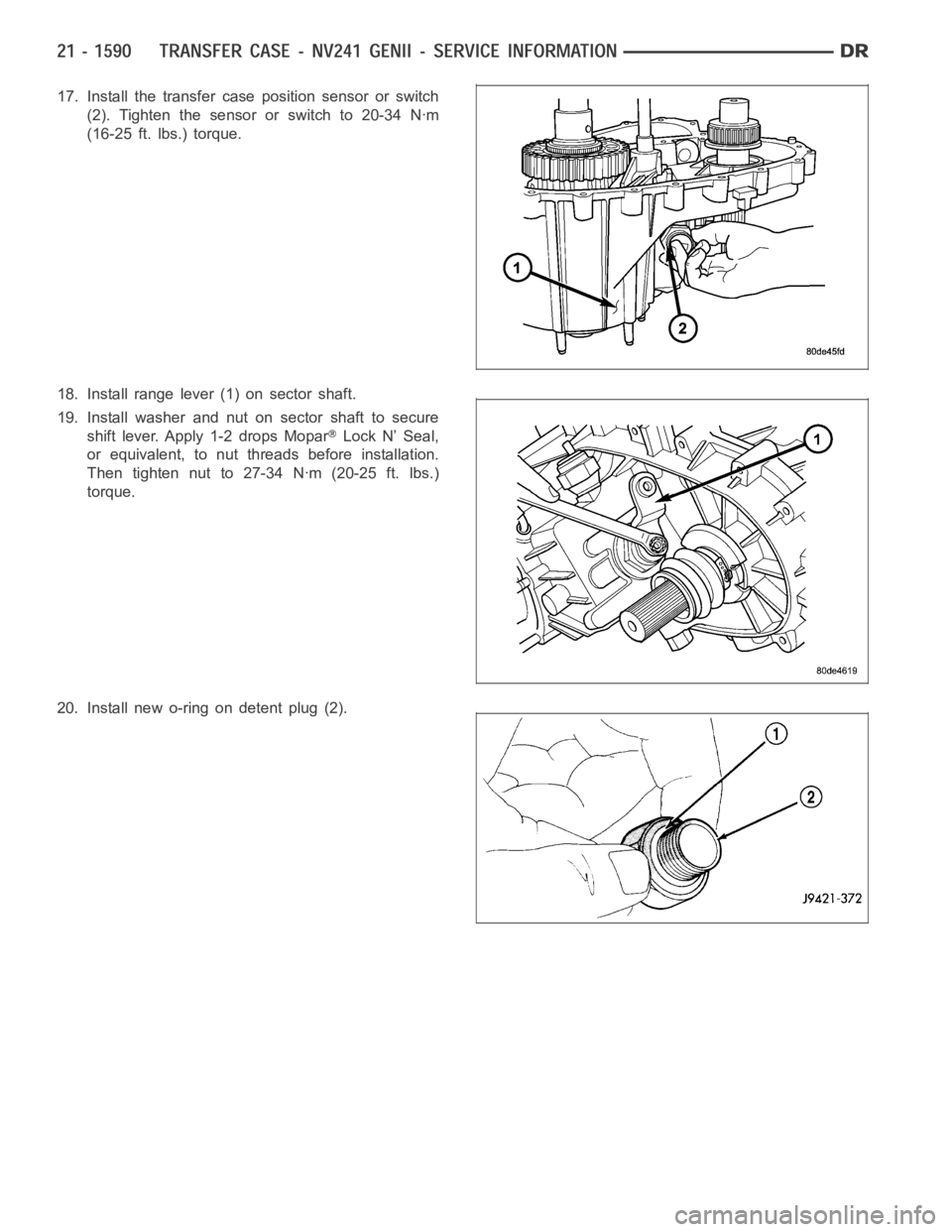

17. Install the transfer case position sensor or switch

(2). Tighten the sensor or switch to 20-34 Nꞏm

(16-25 ft. lbs.) torque.

18. Install range lever (1) on sector shaft.

19. Install washer and nut on sector shaft to secure

shift lever. Apply 1-2 drops Mopar

Lock N’ Seal,

or equivalent, to nut threads before installation.

Then tighten nut to 27-34 Nꞏm (20-25 ft. lbs.)

torque.

20. Install new o-ring on detent plug (2).

Page 4123 of 5267

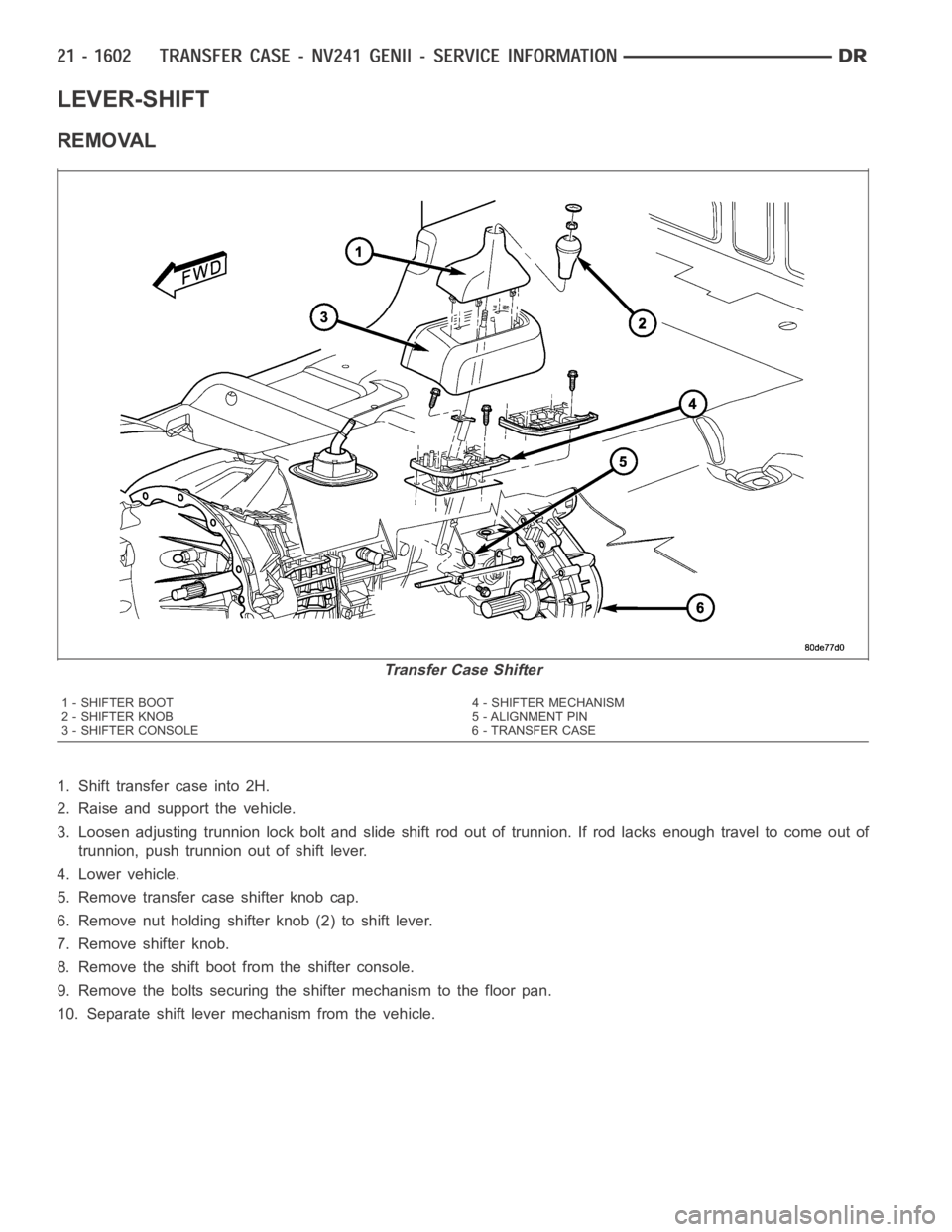

LEVER-SHIFT

REMOVAL

1. Shift transfer case into 2H.

2. Raise and support the vehicle.

3. Loosen adjusting trunnion lock bolt and slide shift rod out of trunnion.If rod lacks enough travel to come out of

trunnion, push trunnion out of shift lever.

4. Lower vehicle.

5. Remove transfer case shifter knob cap.

6. Remove nut holding shifter knob (2) to shift lever.

7. Remove shifter knob.

8. Remove the shift boot from the shifter console.

9. Remove the bolts securing the shifter mechanism to the floor pan.

10. Separate shift lever mechanism from the vehicle.

Transfer Case Shifter

1 - SHIFTER BOOT 4 - SHIFTER MECHANISM

2-SHIFTERKNOB 5-ALIGNMENTPIN

3 - SHIFTER CONSOLE 6 - TRANSFER CASE

Page 4129 of 5267

Condition Possible Cause Correction

Lubricant leaking from output shaft

seal or vent.1) Transfer case overfilled. 1) Drain lubricant to the correct

level.

2) Vent closed or restricted. 2) Clear or replace vent as

necessary.

3) Output shaft seals damaged or

installed incorrectly.3) Replace seal as necessary.

Check to ensure that another

component, the propeller shaft slip

yoke for example, is not causing

damage to seal.

Abnormal tire wear. 1) Extended operation on hard, dry

surfaces in the 4H position.1) Operate vehicle in the 2H

position on hard, dry surfaces.

REMOVAL

1. Raise and support vehicle.

2. Remove skid plate, if equipped. (Refer to 13 - FRAMES & BUMPERS/FRAME/TRANSFER CASE SKID PLATE

- REMOVAL)

3. Position drain oil container under transfer case.

4. Remove transfer case drain plug and drain lubricant into container.

5. Disconnect vent hose and transfer case position sensor connector.

6. Disconnect shift rod from grommet in transfer case shift lever, or from floor shift arm whichever provides easy

access. Use channel lock style pliers to press rod out of lever grommet.

7. Support transmission with jack stand.

8. Mark front and rear propeller shafts for assembly reference.

9. Remove front and rear propeller shafts. (Refer to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER SHAFT/PRO-

PELLER SHAFT - REMOVAL)

10. Support transfer case with suitable jack. Secure transfer case to jackwith safety chains.

11. Remove nuts attaching transfer case to transmission.

12. Move transfer case assembly rearward until free of transmission outputshaft.

13. Lower jack and move transfer case from under vehicle.

DISASSEMBLY

Position transfer case in a shallow drain pan. Remove drain plug and drain any remaining lubricant remaining in

case.