ECU DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3817 of 5267

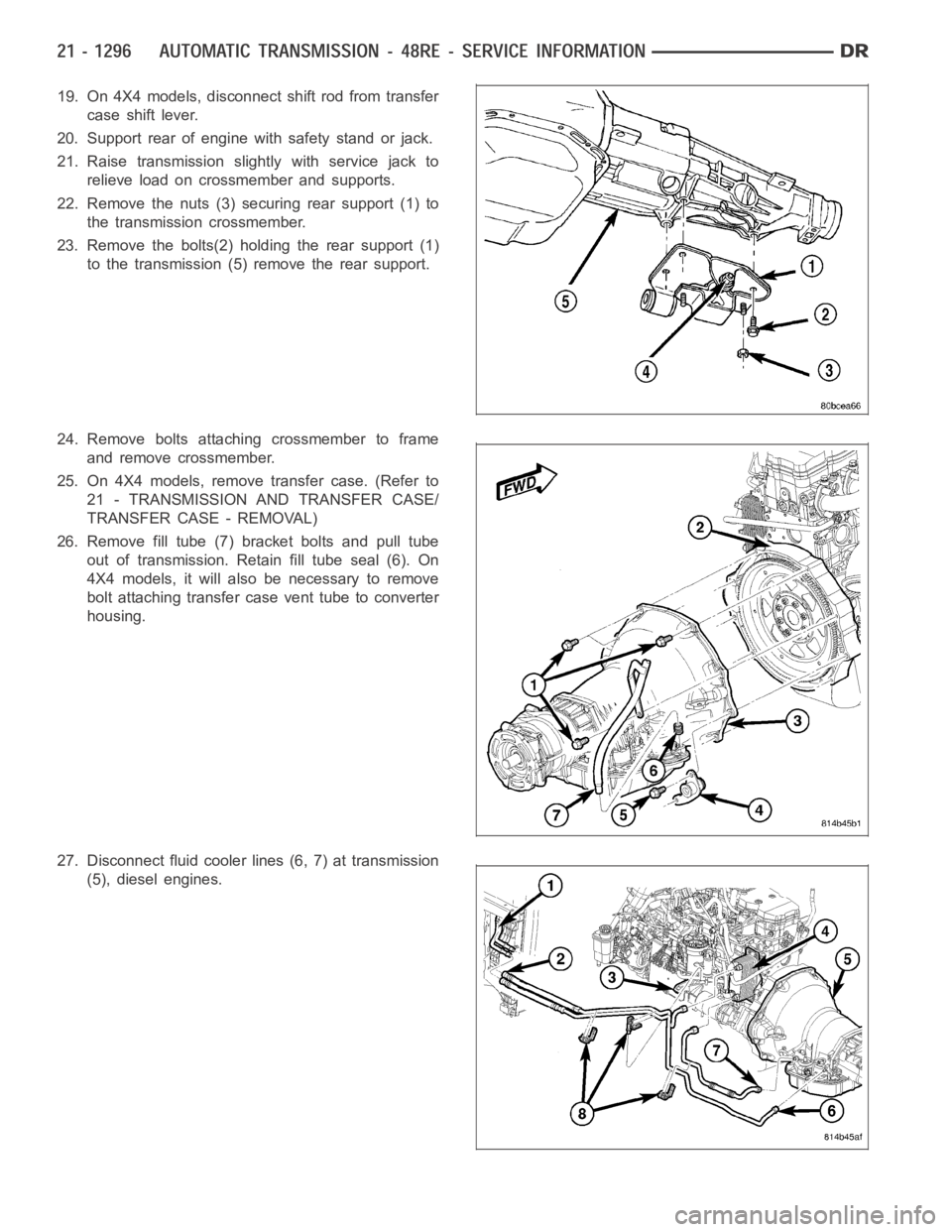

19. On 4X4 models, disconnect shift rod from transfer

case shift lever.

20. Support rear of engine with safety stand or jack.

21. Raise transmission slightly with service jack to

relieve load on crossmember and supports.

22. Remove the nuts (3) securing rear support (1) to

the transmission crossmember.

23. Remove the bolts(2) holding the rear support (1)

to the transmission (5) remove the rear support.

24. Remove bolts attaching crossmember to frame

and remove crossmember.

25. On 4X4 models, remove transfer case. (Refer to

21 - TRANSMISSION AND TRANSFER CASE/

TRANSFER CASE - REMOVAL)

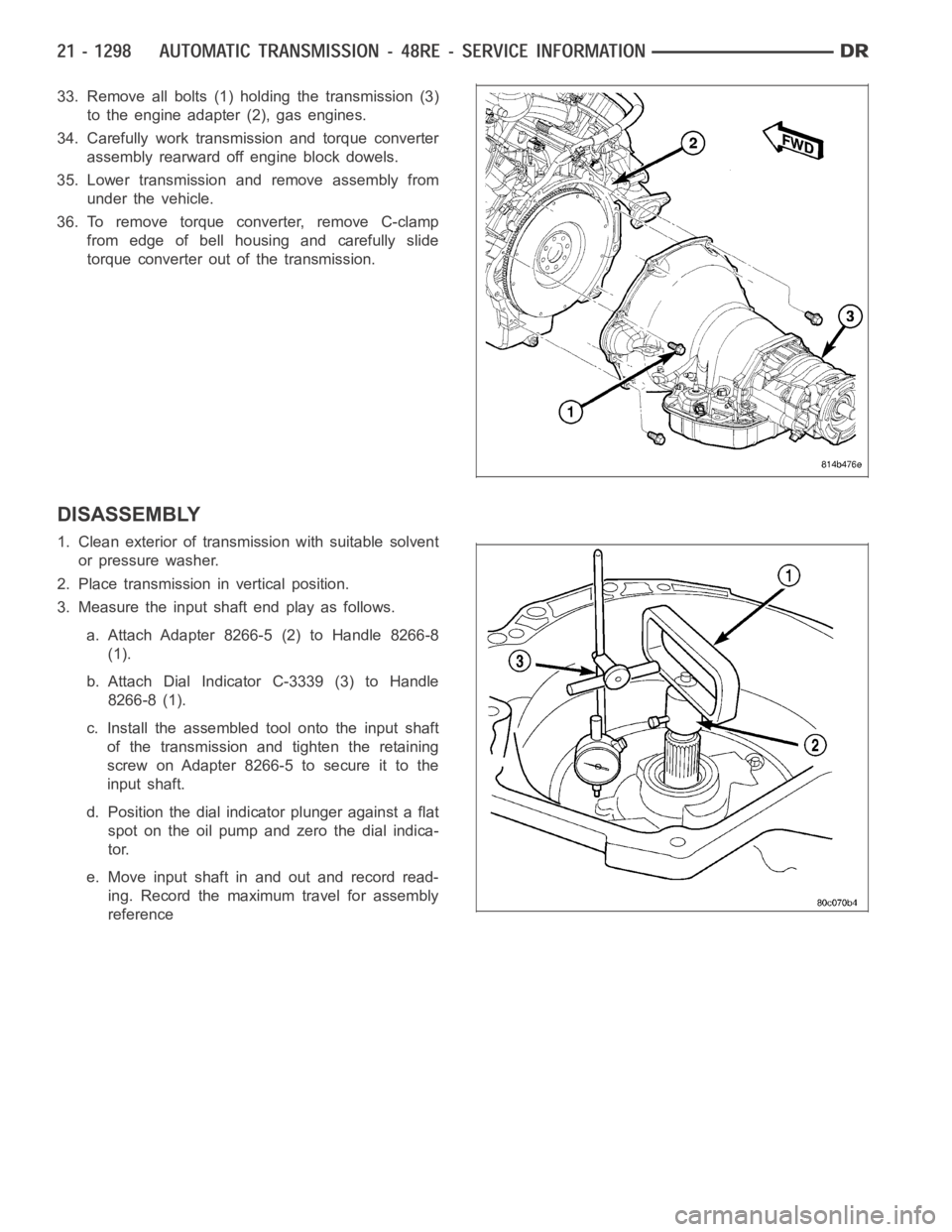

26. Remove fill tube (7) bracket bolts and pull tube

out of transmission. Retain fill tube seal (6). On

4X4 models, it will also be necessary to remove

bolt attaching transfer case vent tube to converter

housing.

27. Disconnect fluid cooler lines (6, 7) at transmission

(5), diesel engines.

Page 3819 of 5267

33. Remove all bolts (1) holding the transmission (3)

to the engine adapter (2), gas engines.

34. Carefully work transmission and torque converter

assembly rearward off engine block dowels.

35. Lower transmission and remove assembly from

under the vehicle.

36. To remove torque converter, remove C-clamp

from edge of bell housing and carefully slide

torque converter out of the transmission.

DISASSEMBLY

1. Clean exterior of transmission with suitable solvent

or pressure washer.

2. Place transmission in vertical position.

3. Measure the input shaft end play as follows.

a. Attach Adapter 8266-5 (2) to Handle 8266-8

(1).

b. Attach Dial Indicator C-3339 (3) to Handle

8266-8 (1).

c. Install the assembled tool onto the input shaft

of the transmission and tighten the retaining

screw on Adapter 8266-5 to secure it to the

input shaft.

d. Position the dial indicator plunger against a flat

spot on the oil pump and zero the dial indica-

tor.

e. Move input shaft in and out and record read-

ing. Record the maximum travel for assembly

reference

Page 3830 of 5267

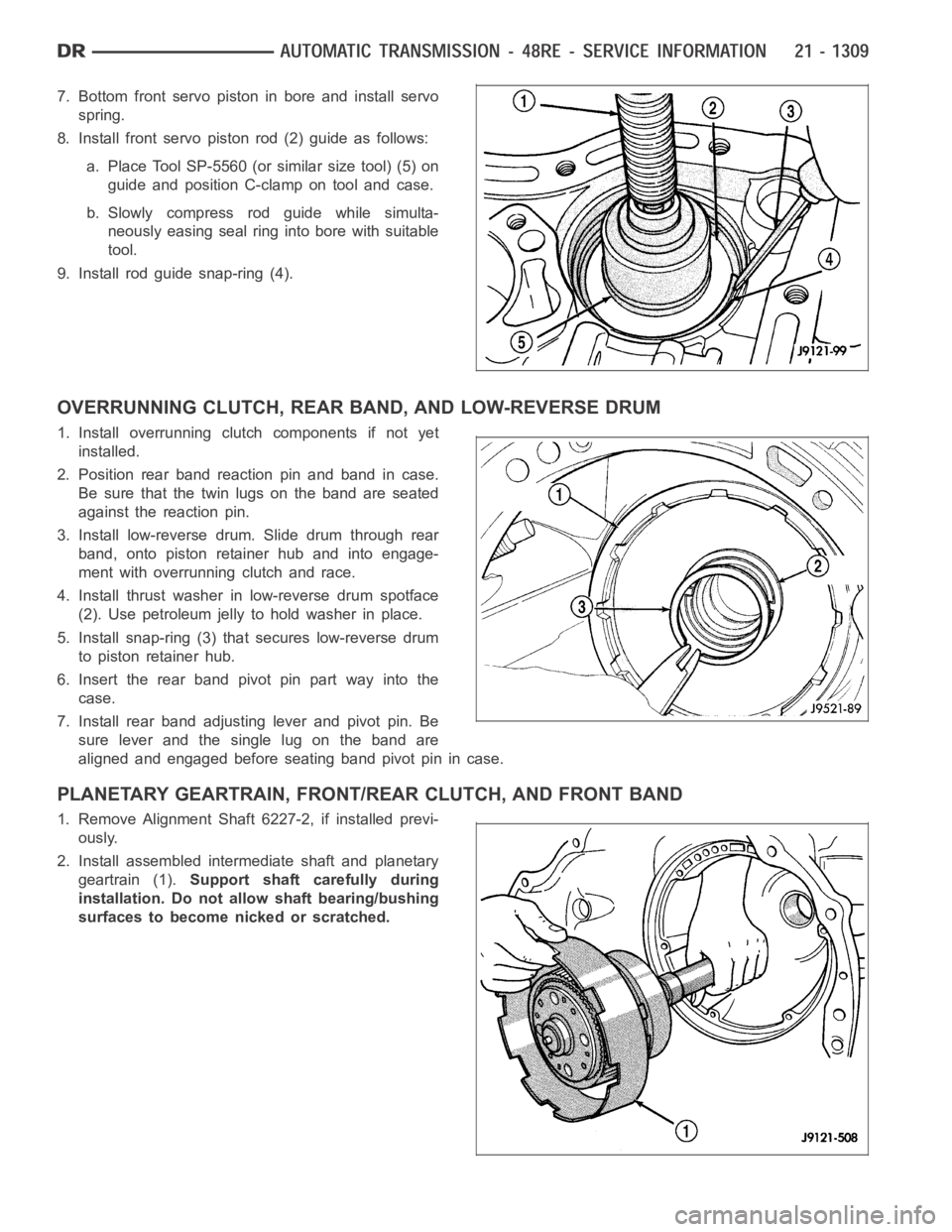

7. Bottom front servo piston in bore and install servo

spring.

8. Install front servo piston rod (2) guide as follows:

a. Place Tool SP-5560 (or similar size tool) (5) on

guide and position C-clamp on tool and case.

b. Slowly compress rod guide while simulta-

neously easing seal ring into bore with suitable

tool.

9. Install rod guide snap-ring (4).

OVERRUNNING CLUTCH, REAR BAND, AND LOW-REVERSE DRUM

1. Install overrunning clutch components if not yet

installed.

2. Position rear band reaction pin and band in case.

Be sure that the twin lugs on the band are seated

against the reaction pin.

3. Install low-reverse drum. Slide drum through rear

band, onto piston retainer hub and into engage-

ment with overrunning clutch and race.

4. Install thrust washer in low-reverse drum spotface

(2). Use petroleum jelly to hold washer in place.

5. Install snap-ring (3) that secures low-reverse drum

to piston retainer hub.

6. Insert the rear band pivot pin part way into the

case.

7. Install rear band adjusting lever and pivot pin. Be

sure lever and the single lug on the band are

aligned and engaged before seating band pivot pin in case.

PLANETARY GEARTRAIN, FRONT/REAR CLUTCH, AND FRONT BAND

1. Remove Alignment Shaft 6227-2, if installed previ-

ously.

2. Install assembled intermediate shaft and planetary

geartrain (1).Support shaft carefully during

installation. Do not allow shaft bearing/bushing

surfaces to become nicked or scratched.

Page 3835 of 5267

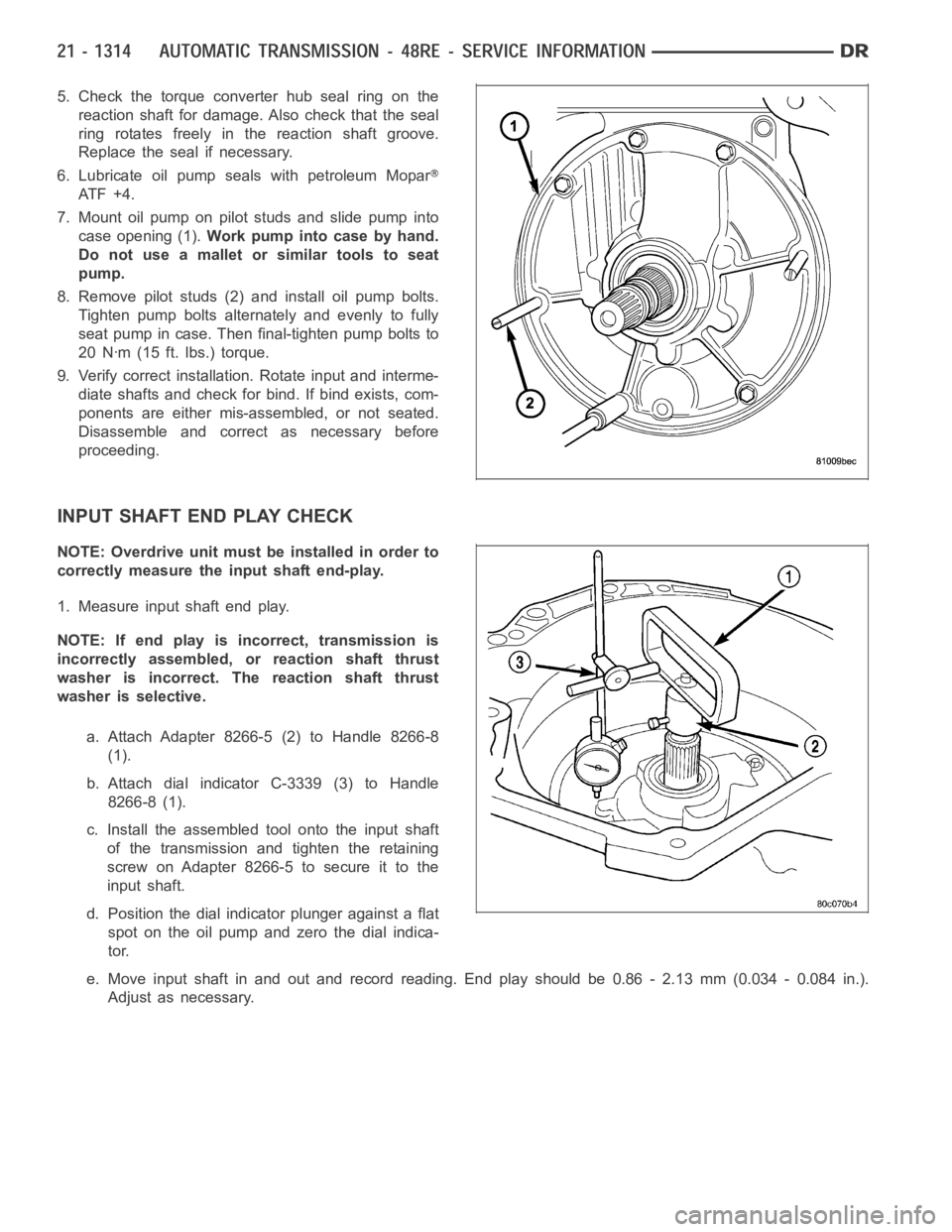

5. Check the torque converter hub seal ring on the

reaction shaft for damage. Also check that the seal

ring rotates freely in the reaction shaft groove.

Replace the seal if necessary.

6. Lubricate oil pump seals with petroleum Mopar

AT F + 4 .

7. Mount oil pump on pilot studs and slide pump into

case opening (1).Work pump into case by hand.

Do not use a mallet or similar tools to seat

pump.

8. Remove pilot studs (2) and install oil pump bolts.

Tighten pump bolts alternately and evenly to fully

seat pump in case. Then final-tighten pump bolts to

20 Nꞏm (15 ft. lbs.) torque.

9. Verify correct installation. Rotate input and interme-

diate shafts and check for bind. If bind exists, com-

ponents are either mis-assembled, or not seated.

Disassemble and correct as necessary before

proceeding.

INPUT SHAFT END PLAY CHECK

NOTE: Overdrive unit must be installed in order to

correctly measure the input shaft end-play.

1. Measure input shaft end play.

NOTE: If end play is incorrect, transmission is

incorrectly assembled, or reaction shaft thrust

washer is incorrect. The reaction shaft thrust

washer is selective.

a. Attach Adapter 8266-5 (2) to Handle 8266-8

(1).

b. Attach dial indicator C-3339 (3) to Handle

8266-8 (1).

c. Install the assembled tool onto the input shaft

of the transmission and tighten the retaining

screw on Adapter 8266-5 to secure it to the

input shaft.

d. Position the dial indicator plunger against a flat

spot on the oil pump and zero the dial indica-

tor.

e. Move input shaft in and out and record reading. End play should be 0.86 - 2.13 mm (0.034 - 0.084 in.).

Adjust as necessary.

Page 3838 of 5267

INSTALLATION

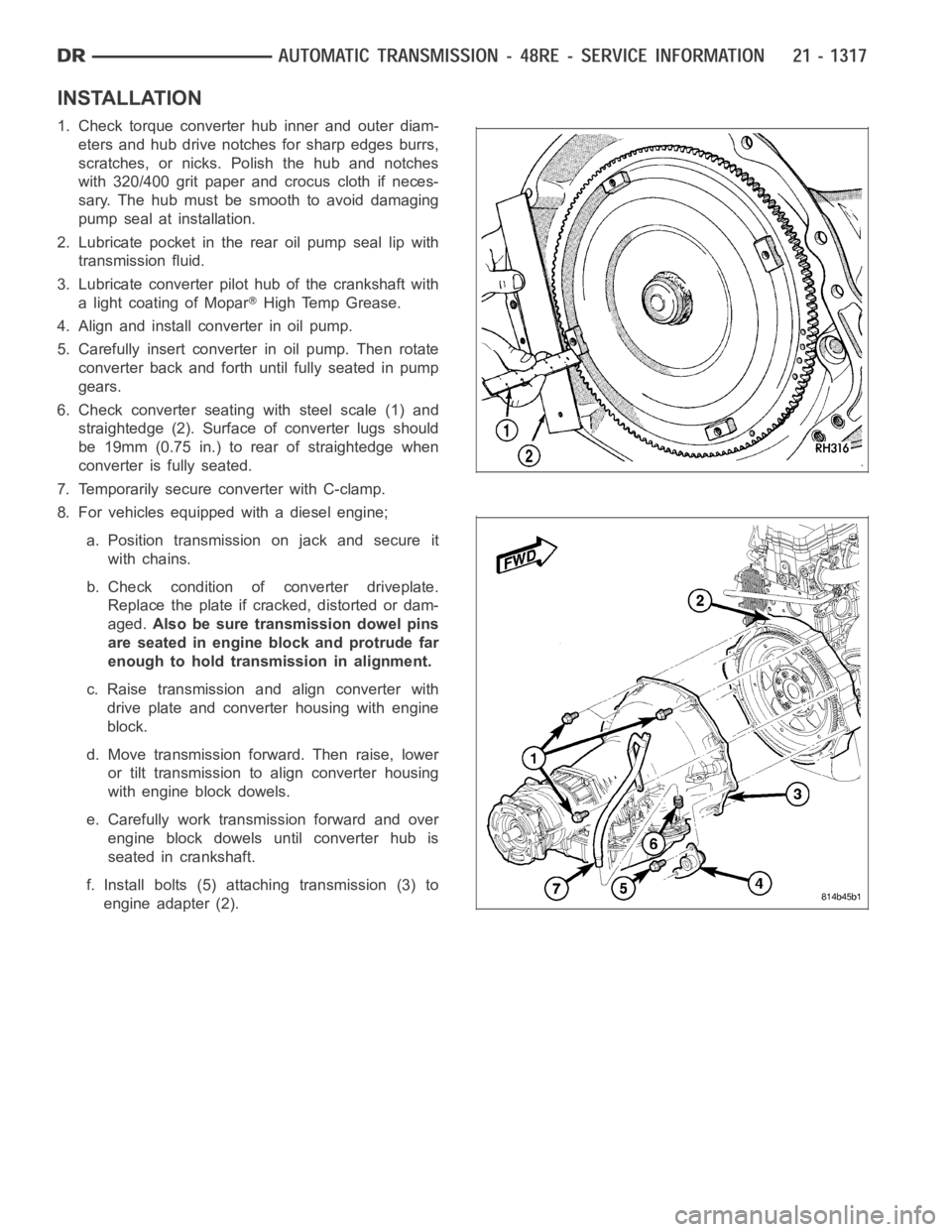

1. Check torque converter hub inner and outer diam-

eters and hub drive notches for sharp edges burrs,

scratches, or nicks. Polish the hub and notches

with 320/400 grit paper and crocus cloth if neces-

sary. The hub must be smooth to avoid damaging

pump seal at installation.

2. Lubricate pocket in the rear oil pump seal lip with

transmission fluid.

3. Lubricate converter pilot hub of the crankshaft with

a light coating of Mopar

High Temp Grease.

4. Align and install converter in oil pump.

5. Carefully insert converter in oil pump. Then rotate

converter back and forth until fully seated in pump

gears.

6. Check converter seating with steel scale (1) and

straightedge (2). Surface of converter lugs should

be 19mm (0.75 in.) to rear of straightedge when

converter is fully seated.

7. Temporarily secure converter with C-clamp.

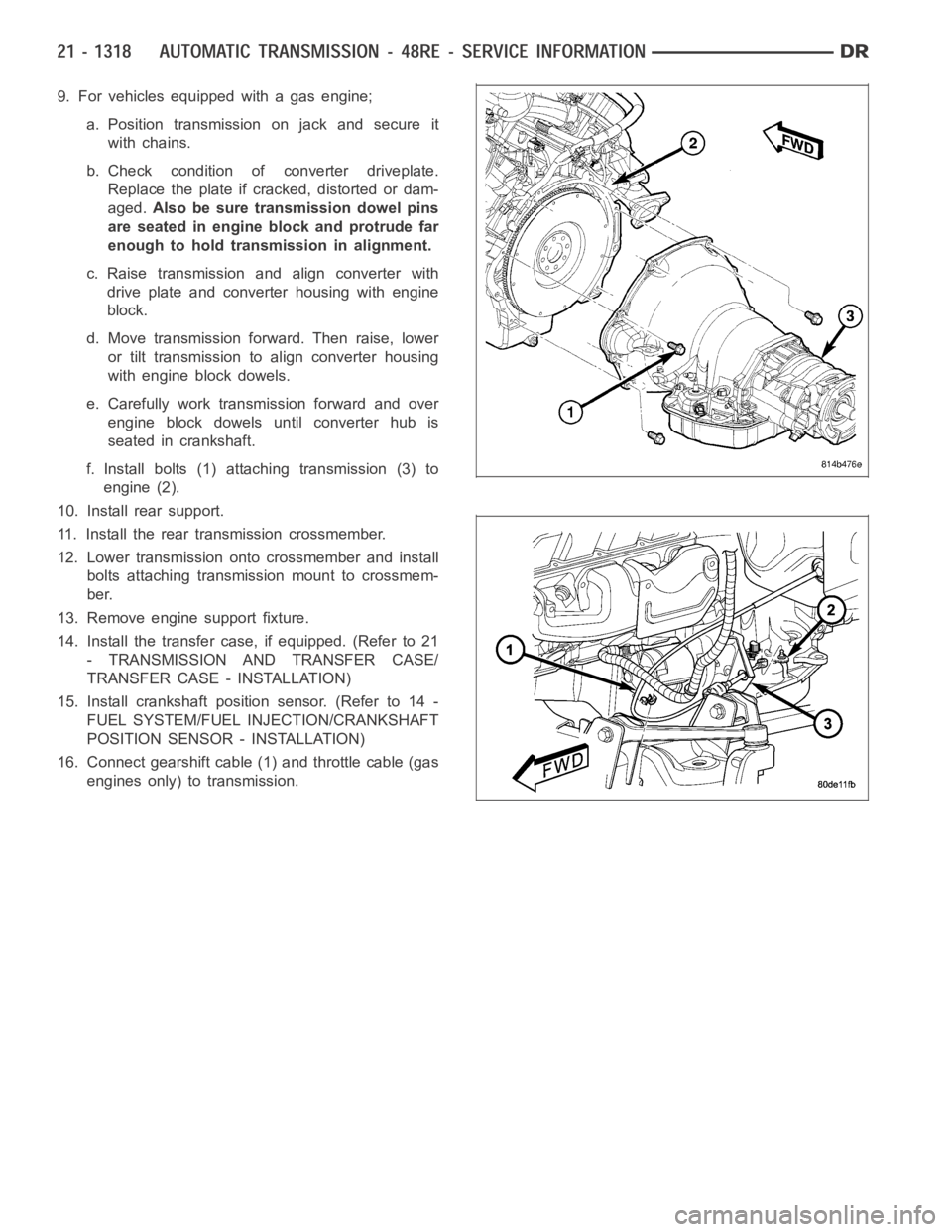

8. For vehicles equipped with a diesel engine;

a. Position transmission on jack and secure it

with chains.

b. Check condition of converter driveplate.

Replace the plate if cracked, distorted or dam-

aged.Also be sure transmission dowel pins

are seated in engine block and protrude far

enough to hold transmission in alignment.

c. Raise transmission and align converter with

drive plate and converter housing with engine

block.

d. Move transmission forward. Then raise, lower

or tilt transmission to align converter housing

with engine block dowels.

e. Carefully work transmission forward and over

engine block dowels until converter hub is

seated in crankshaft.

f. Install bolts (5) attaching transmission (3) to

engine adapter (2).

Page 3839 of 5267

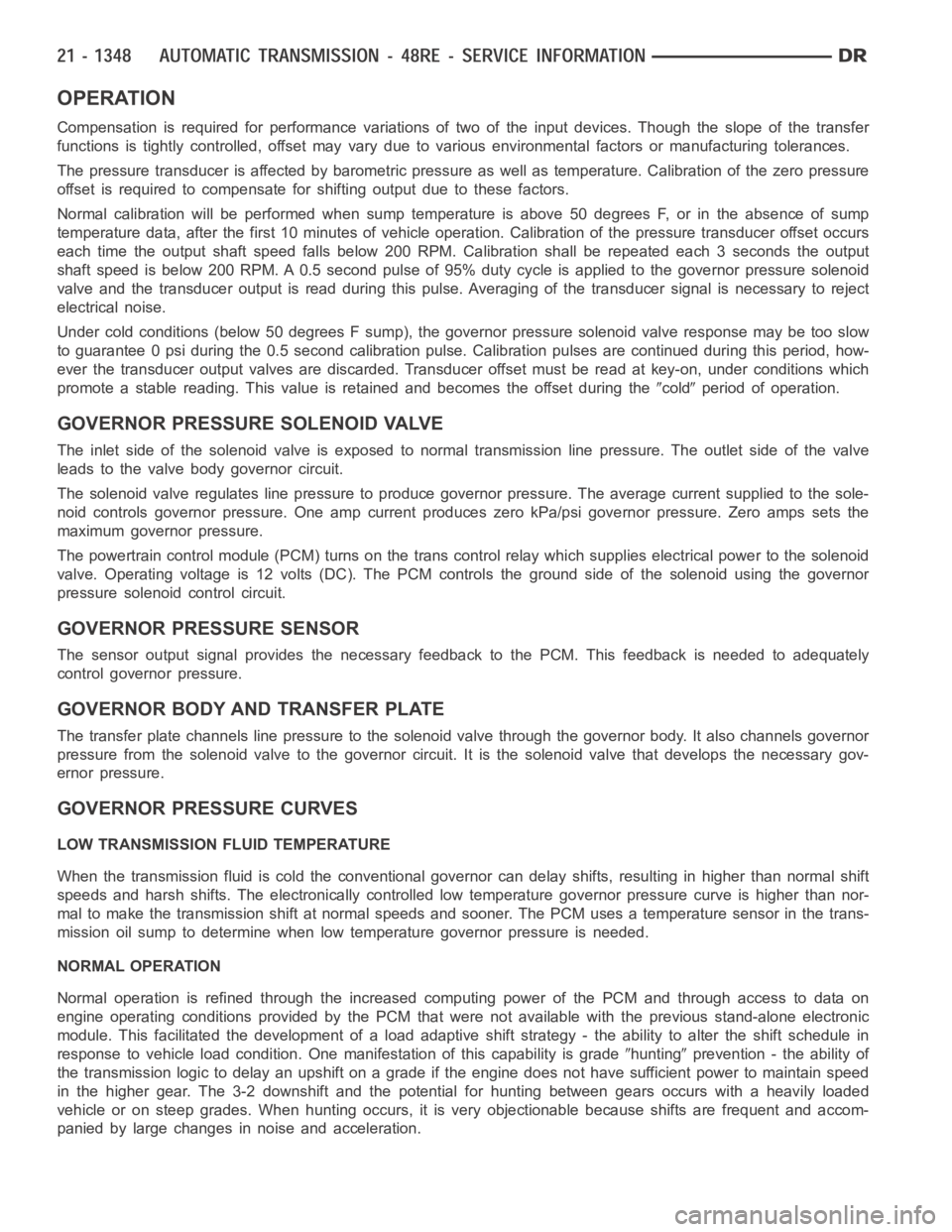

9. For vehicles equipped with a gas engine;

a. Position transmission on jack and secure it

with chains.

b. Check condition of converter driveplate.

Replace the plate if cracked, distorted or dam-

aged.Also be sure transmission dowel pins

are seated in engine block and protrude far

enough to hold transmission in alignment.

c. Raise transmission and align converter with

drive plate and converter housing with engine

block.

d. Move transmission forward. Then raise, lower

or tilt transmission to align converter housing

with engine block dowels.

e. Carefully work transmission forward and over

engine block dowels until converter hub is

seated in crankshaft.

f. Install bolts (1) attaching transmission (3) to

engine (2).

10. Install rear support.

11. Install the rear transmission crossmember.

12. Lower transmission onto crossmember and install

bolts attaching transmission mount to crossmem-

ber.

13. Remove engine support fixture.

14. Install the transfer case, if equipped. (Refer to 21

- TRANSMISSION AND TRANSFER CASE/

TRANSFER CASE - INSTALLATION)

15. Install crankshaft position sensor. (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/CRANKSHAFT

POSITION SENSOR - INSTALLATION)

16. Connect gearshift cable (1) and throttle cable (gas

engines only) to transmission.

Page 3869 of 5267

OPERATION

Compensation is required for performance variations of two of the input devices. Though the slope of the transfer

functions is tightly controlled, offset may vary due to various environmental factors or manufacturing tolerances.

The pressure transducer is affected by barometric pressure as well as temperature. Calibration of the zero pressure

offset is required to compensate for shifting output due to these factors.

Normal calibration will be performed when sump temperature is above 50 degrees F, or in the absence of sump

temperature data, after the first 10 minutes of vehicle operation. Calibration of the pressure transducer offset occurs

each time the output shaft speed falls below 200 RPM. Calibration shall be repeated each 3 seconds the output

shaft speed is below 200 RPM. A 0.5 second pulse of 95% duty cycle is applied to the governor pressure solenoid

valve and the transducer output is read during this pulse. Averaging of thetransducer signal isnecessary to reject

electrical noise.

Under cold conditions (below 50 degrees F sump), the governor pressure solenoid valve response may be too slow

to guarantee 0 psi during the 0.5 second calibration pulse. Calibration pulses are continued during this period, how-

ever the transducer output valves are discarded. Transducer offset must be read at key-on, under conditions which

promote a stable reading. This value is retained and becomes the offset during the

coldperiod of operation.

GOVERNOR PRESSURE SOLENOID VALVE

The inlet side of the solenoid valve is exposed to normal transmission linepressure. The outlet side of the valve

leads to the valve body governor circuit.

The solenoid valve regulates line pressure to produce governor pressure.Theaveragecurrentsuppliedtothesole-

noid controls governor pressure. One amp current produces zero kPa/psi governor pressure. Zero amps sets the

maximum governor pressure.

The powertrain control module (PCM) turns on the trans control relay whichsupplies electrical power to the solenoid

valve. Operating voltage is 12 volts (DC). The PCM controls the ground sideof the solenoid using the governor

pressure solenoidcontrol circuit.

GOVERNOR PRESSURE SENSOR

The sensor output signal provides the necessary feedback to the PCM. This feedback is needed to adequately

control governor pressure.

GOVERNOR BODY AND TRANSFER PLATE

The transfer plate channels line pressure to the solenoid valve through the governor body. It also channels governor

pressure from the solenoid valve to the governor circuit. It is the solenoid valve that develops the necessary gov-

ernor pressure.

GOVERNOR PRESSURE CURVES

LOW TRANSMISSION FLUID TEMPERATURE

When the transmission fluid is cold the conventional governor can delay shifts, resulting in higher than normal shift

speeds and harsh shifts. The electronically controlled low temperature governor pressure curve is higher than nor-

mal to make the transmission shift at normal speeds and sooner. The PCM usesa temperature sensor in the trans-

mission oil sump to determine when low temperature governor pressure is needed.

NORMAL OPERATION

Normal operation is refined through the increased computing power of the PCM and through access to data on

engine operating conditions provided by the PCM that were not available with the previous stand-alone electronic

module. This facilitated the development of a load adaptive shift strategy - the ability to alter the shift schedule in

response to vehicle load condition. One manifestation of this capabilityis grade

huntingprevention - the ability of

the transmission logic to delay an upshift on a grade if the engine does not have sufficient power to maintain speed

in the higher gear. The 3-2 downshift and the potential for hunting betweengears occurs with a heavily loaded

vehicle or on steep grades. When hunting occurs, it is very objectionable because shifts are frequent and accom-

panied by large changes in noise and acceleration.

Page 3881 of 5267

INSPECTION

Inspect the front clutch components. Replace the clutch discs if warped, worn, scored, burned or charred, the lugs

are damaged, or if the facing is flaking off. Replace the steel plates and reaction plate if heavily scored, warped, or

broken. Be sure the driving lugs on the discs and plate are also in good condition. The lugs must not be bent,

cracked or damaged in any way.

Replace the piston springs and spring retainer if either are distorted, warped or broken.

Check the lug grooves in the clutch piston retainer. The steel plates should slide freely in the slots. Replace the

piston retainer if the grooves are worn or damaged. Also check action of thecheck ball in the piston retainer. The

ball must move freely and not stick.

Replace the retainer bushing if worn, scored, or there is any doubt about bushing condition.

Inspect the piston and retainer seal surfaces for nicks or scratches. Minor scratches can be removed with crocus

cloth. However, replace the piston and/or retainer if the seal surfaces are seriously scored.

Check the clutch piston check ball. The ball should be securely in place. Replace the piston if the ball is missing,

or seized in place.

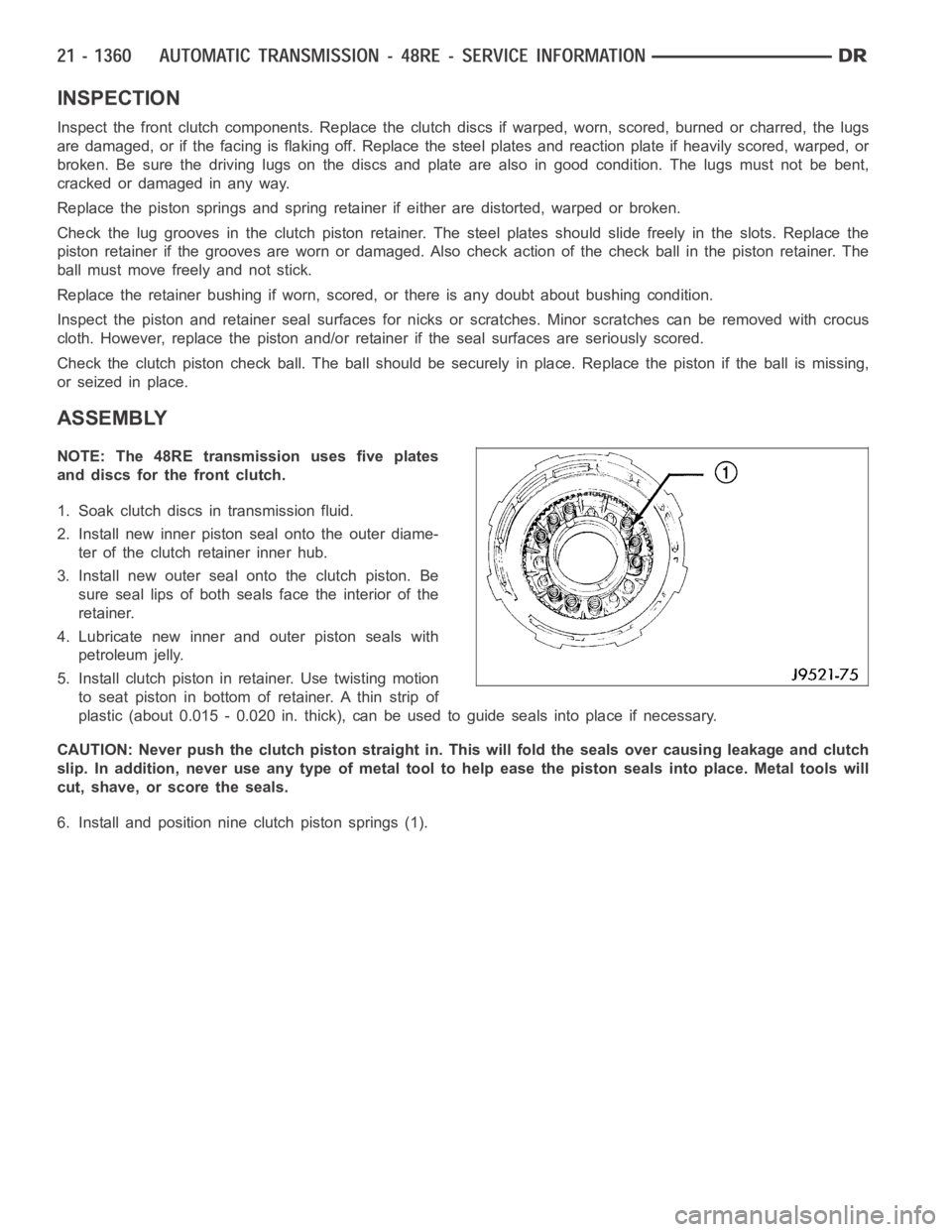

ASSEMBLY

NOTE: The 48RE transmission uses five plates

and discs for the front clutch.

1. Soak clutch discs in transmission fluid.

2. Install new inner piston seal onto the outer diame-

ter of the clutch retainer inner hub.

3. Install new outer seal onto the clutch piston. Be

sure seal lips of both seals face the interior of the

retainer.

4. Lubricate new inner and outer piston seals with

petroleum jelly.

5. Install clutch piston in retainer. Use twisting motion

to seat piston in bottom of retainer. A thin strip of

plastic (about 0.015 - 0.020 in. thick), can be used to guide seals into placeifnecessary.

CAUTION: Never push the clutch piston straight in. This will fold the sealsover causing leakage and clutch

slip. In addition, never use any type of metal tool to help ease the piston seals into place. Metal tools will

cut, shave, or score the seals.

6. Install and position nine clutch piston springs (1).

Page 3888 of 5267

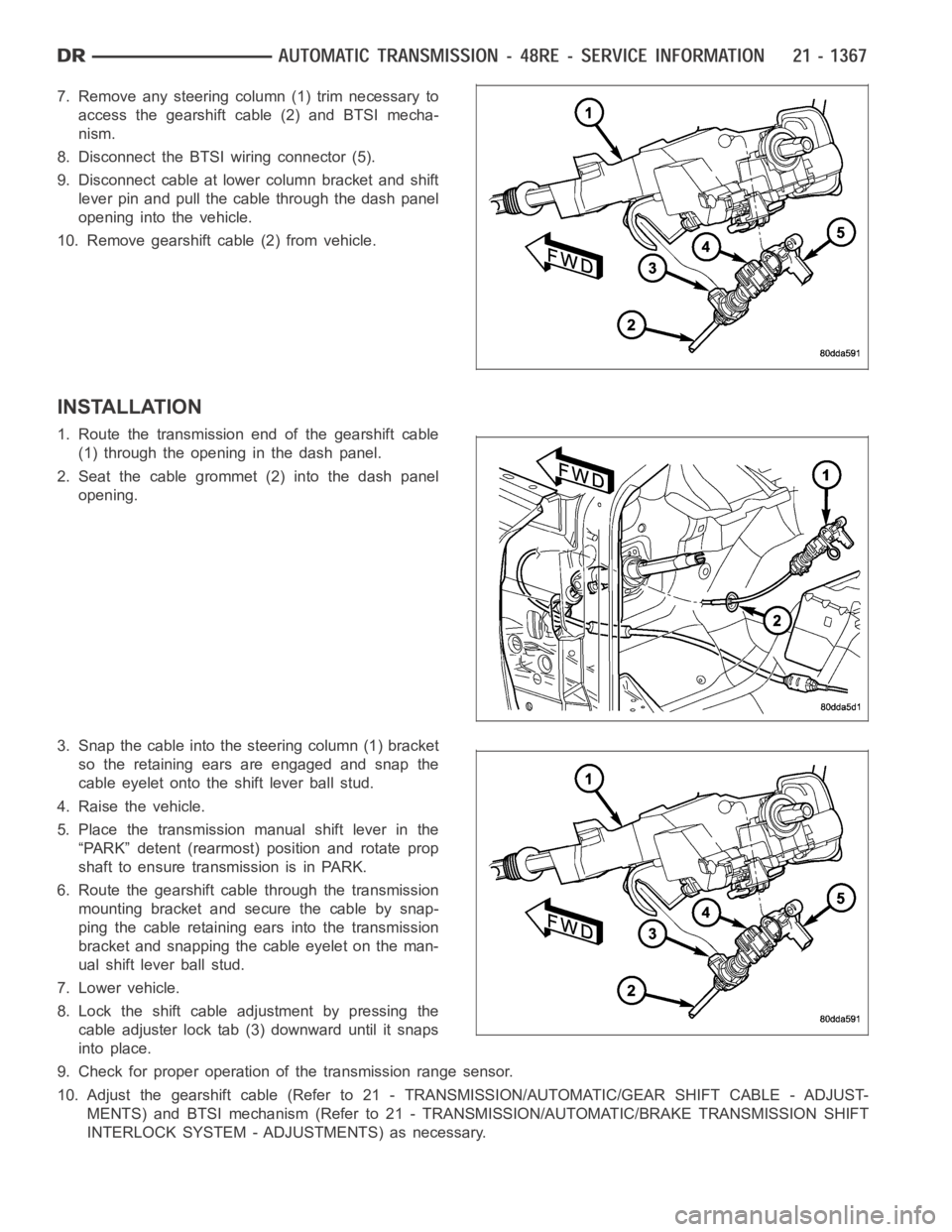

7. Remove any steering column (1) trim necessary to

access the gearshift cable (2) and BTSI mecha-

nism.

8. Disconnect the BTSI wiring connector (5).

9. Disconnect cable at lower column bracket and shift

lever pin and pull the cable through the dash panel

opening into the vehicle.

10. Remove gearshift cable (2) from vehicle.

INSTALLATION

1. Route the transmission end of the gearshift cable

(1) through the opening in the dash panel.

2. Seat the cable grommet (2) into the dash panel

opening.

3. Snap the cable into the steering column (1) bracket

so the retaining ears are engaged and snap the

cable eyelet onto the shift lever ball stud.

4. Raise the vehicle.

5. Place the transmission manual shift lever in the

“PARK” detent (rearmost) position and rotate prop

shaft to ensure transmission is in PARK.

6. Route the gearshift cable through the transmission

mounting bracket and secure the cable by snap-

ping the cable retaining ears into the transmission

bracket and snapping the cable eyelet on the man-

ual shift lever ball stud.

7. Lower vehicle.

8. Lock the shift cable adjustment by pressing the

cable adjuster lock tab (3) downward until it snaps

into place.

9. Check for proper operation of the transmission range sensor.

10. Adjust the gearshift cable (Refer to 21 - TRANSMISSION/AUTOMATIC/GEAR SHIFT CABLE - ADJUST-

MENTS) and BTSI mechanism (Refer to 21 - TRANSMISSION/AUTOMATIC/BRAKE TRANSMISSION SHIFT

INTERLOCK SYSTEM - ADJUSTMENTS) as necessary.

Page 3894 of 5267

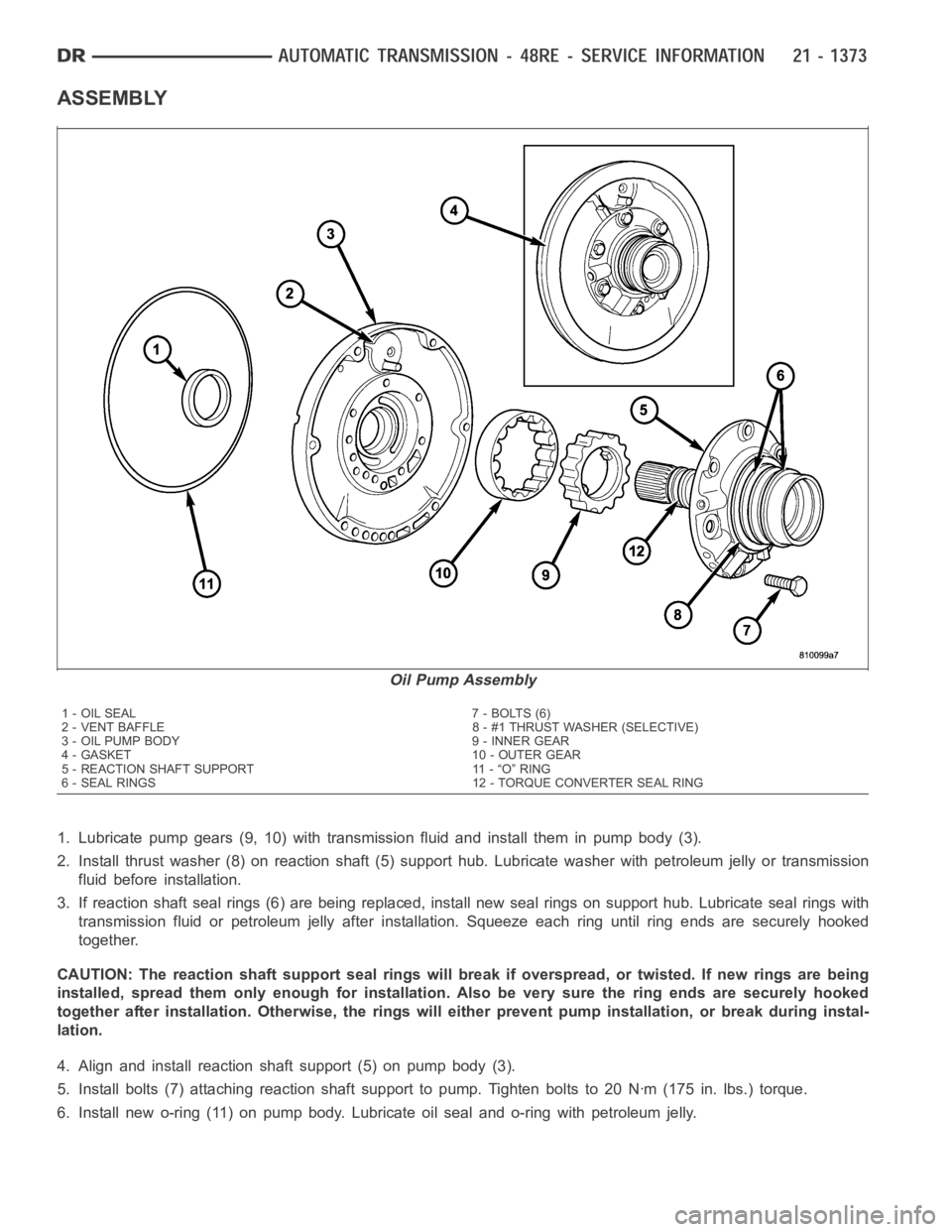

ASSEMBLY

1. Lubricate pump gears (9, 10) with transmission fluid and install them inpump body (3).

2. Install thrust washer (8) on reaction shaft (5) support hub. Lubricate washer with petroleum jelly or transmission

fluid before installation.

3. If reaction shaft seal rings (6) are being replaced, install new seal rings on support hub. Lubricate seal rings with

transmission fluid or petroleum jelly after installation. Squeeze each ring until ring ends are securely hooked

together.

CAUTION: The reaction shaft support seal rings will break if overspread, or twisted. If new rings are being

installed, spread them only enough forinstallation. Also be very sure thering ends are securely hooked

together after installation. Otherwise, the rings will either prevent pump installation, or break during instal-

lation.

4. Align and install reaction shaft support (5) on pump body (3).

5. Install bolts (7) attaching reaction shaft support to pump. Tighten bolts to 20 Nꞏm (175 in. lbs.) torque.

6. Install new o-ring (11) on pump body. Lubricate oil seal and o-ring with petroleum jelly.

Oil Pump Assembly

1 - OIL SEAL 7 - BOLTS (6)

2 - VENT BAFFLE 8 - #1 THRUST WASHER (SELECTIVE)

3 - OIL PUMP BODY 9 - INNER GEAR

4 - GASKET 10 - OUTER GEAR

5 - REACTION SHAFT SUPPORT 11 - “O” RING

6 - SEAL RINGS 12 - TORQUE CONVERTER SEAL RING