torque DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2399 of 5267

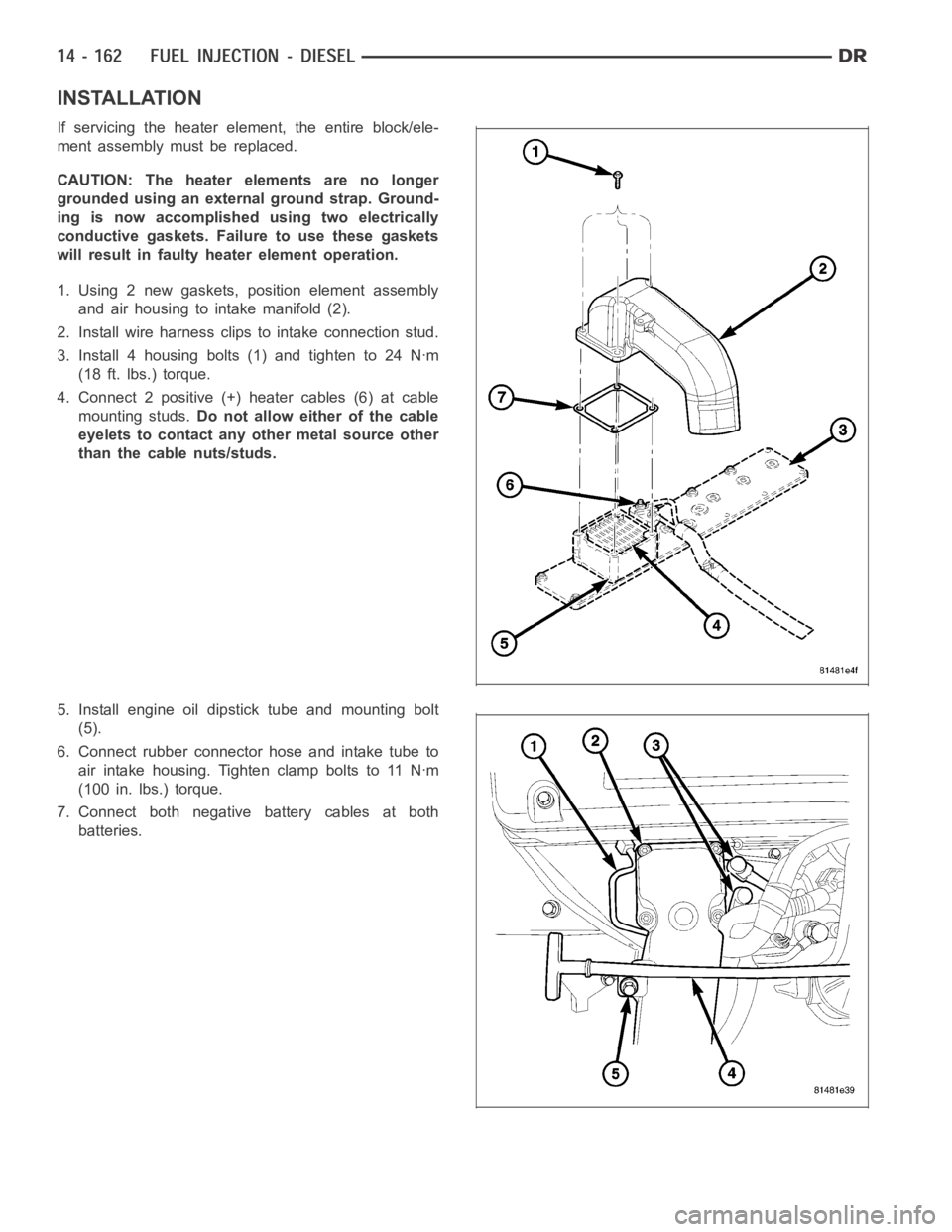

INSTALLATION

If servicing the heater element, the entire block/ele-

ment assembly must be replaced.

CAUTION: The heater elements are no longer

grounded using an external ground strap. Ground-

ing is now accomplished using two electrically

conductive gaskets. Failure to use these gaskets

will result in faulty heater element operation.

1. Using 2 new gaskets, position element assembly

and air housing to intake manifold (2).

2. Install wire harness clips to intake connection stud.

3. Install 4 housing bolts (1) and tighten to 24 Nꞏm

(18 ft. lbs.) torque.

4. Connect 2 positive (+) heater cables (6) at cable

mounting studs.Do not allow either of the cable

eyelets to contact any other metal source other

than the cable nuts/studs.

5. Install engine oil dipstick tube and mounting bolt

(5).

6. Connect rubber connector hose and intake tube to

air intake housing. Tighten clamp bolts to 11 Nꞏm

(100 in. lbs.) torque.

7. Connect both negative battery cables at both

batteries.

Page 2401 of 5267

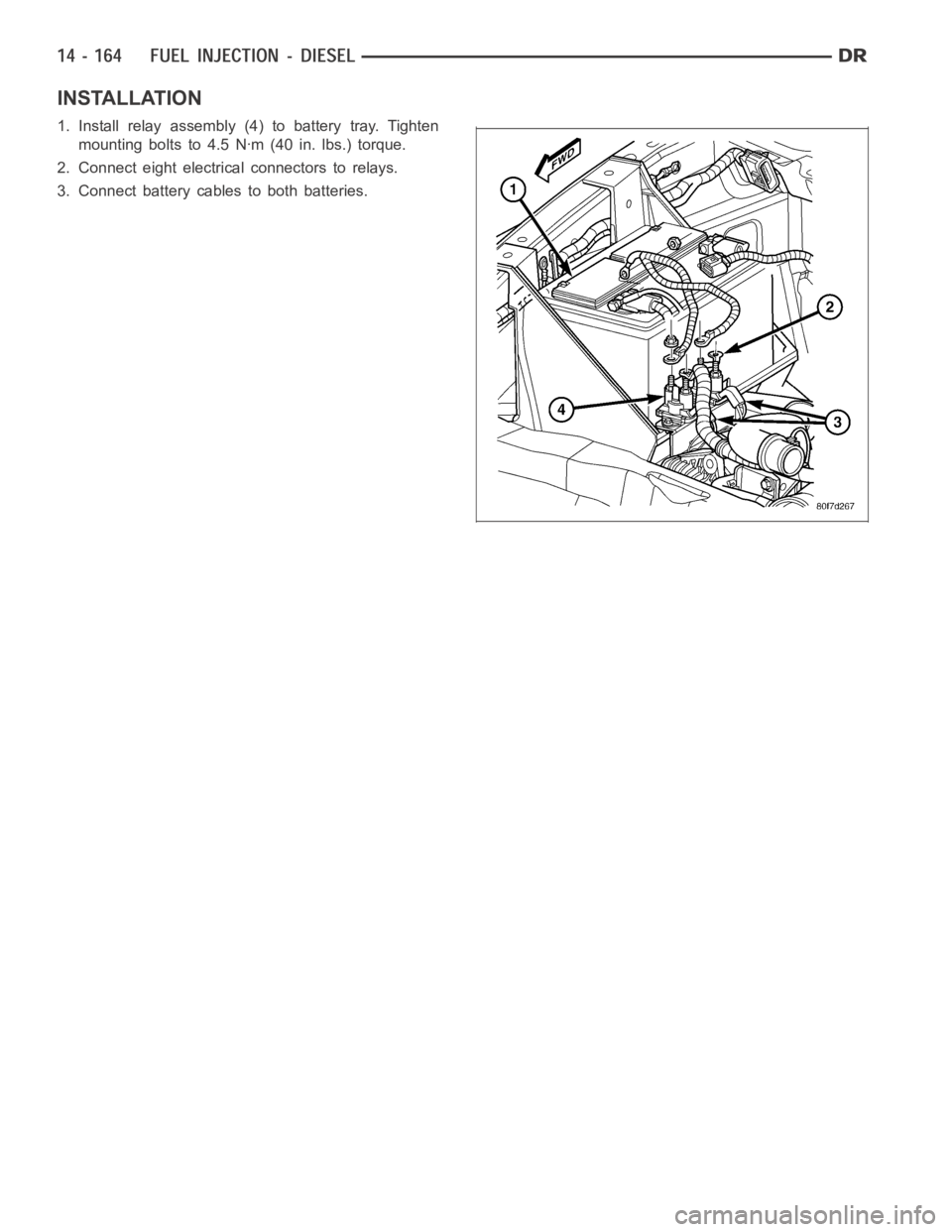

INSTALLATION

1. Install relay assembly (4) to battery tray. Tighten

mounting bolts to 4.5 Nꞏm (40 in. lbs.) torque.

2. Connect eight electrical connectors to relays.

3. Connect battery cables to both batteries.

Page 2403 of 5267

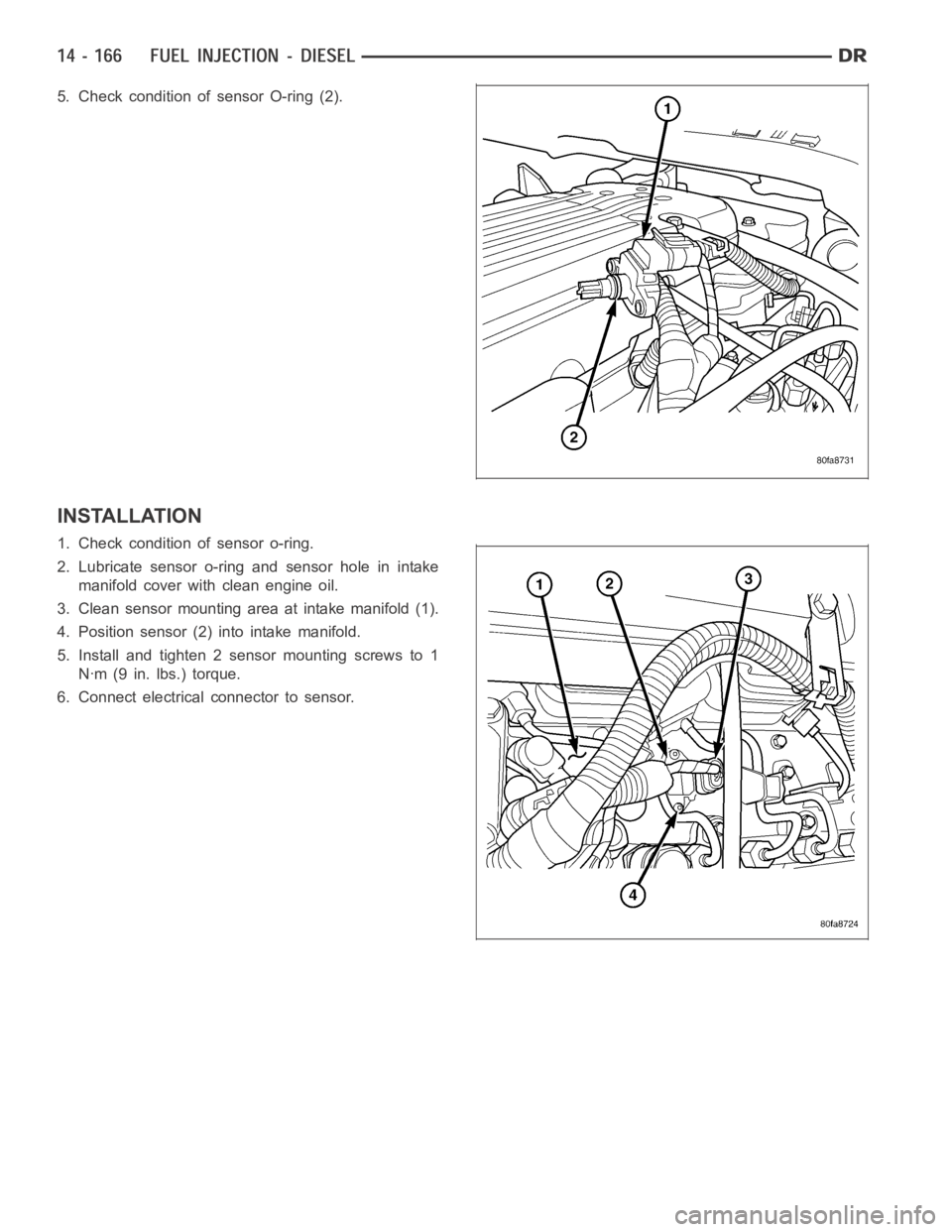

5. Check condition of sensor O-ring (2).

INSTALLATION

1. Check condition of sensor o-ring.

2. Lubricate sensor o-ring and sensor hole in intake

manifold cover with clean engine oil.

3. Clean sensor mounting area at intake manifold (1).

4. Position sensor (2) into intake manifold.

5. Install and tighten 2 sensor mounting screws to 1

Nꞏm (9 in. lbs.) torque.

6. Connect electrical connector to sensor.

Page 2412 of 5267

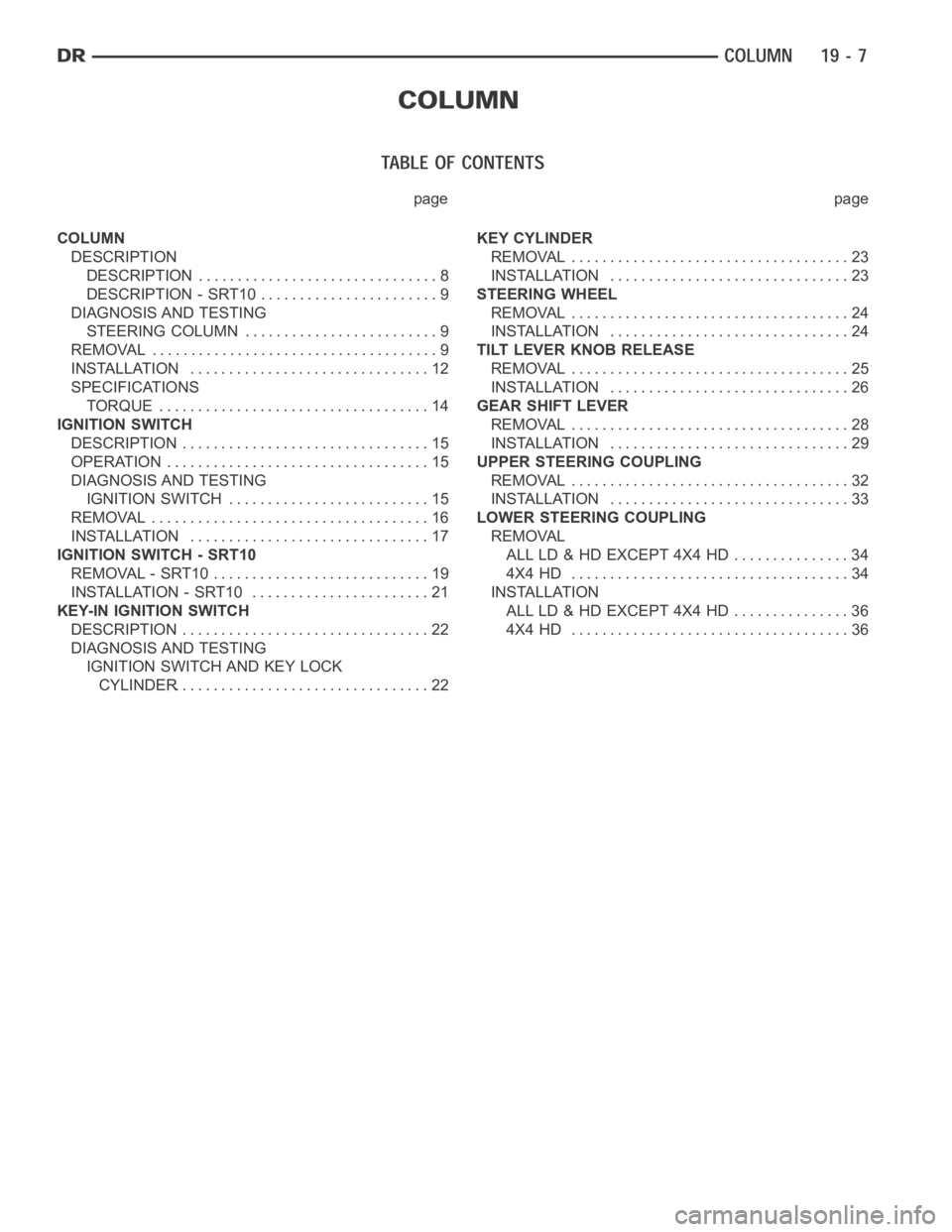

page page

COLUMN

DESCRIPTION

DESCRIPTION ............................... 8

DESCRIPTION - SRT10 ....................... 9

DIAGNOSIS AND TESTING

STEERING COLUMN ......................... 9

REMOVAL ..................................... 9

INSTALLATION ............................... 12

SPECIFICATIONS

TORQUE ................................... 14

IGNITION SWITCH

DESCRIPTION ................................ 15

OPERATION .................................. 15

DIAGNOSIS AND TESTING

IGNITION SWITCH .......................... 15

REMOVAL .................................... 16

INSTALLATION ............................... 17

IGNITION SWITCH - SRT10

REMOVAL - SRT10 ............................ 19

INSTALLATION - SRT10 ....................... 21

KEY-IN IGNITION SWITCH

DESCRIPTION ................................ 22

DIAGNOSIS AND TESTING

IGNITION SWITCH AND KEY LOCK

CYLINDER................................. 22KEY CYLINDER

REMOVAL .................................... 23

INSTALLATION ............................... 23

STEERING WHEEL

REMOVAL .................................... 24

INSTALLATION ............................... 24

TILT LEVER KNOB RELEASE

REMOVAL .................................... 25

INSTALLATION ............................... 26

GEAR SHIFT LEVER

REMOVAL .................................... 28

INSTALLATION ............................... 29

UPPER STEERING COUPLING

REMOVAL .................................... 32

INSTALLATION ............................... 33

LOWER STEERING COUPLING

REMOVAL

ALL LD & HD EXCEPT 4X4 HD ............... 34

4X4 HD .................................... 34

INSTALLATION

ALL LD & HD EXCEPT 4X4 HD ............... 36

4X4 HD .................................... 36

Page 2414 of 5267

DESCRIPTION - SRT10

The SRT-10 column has noSTARTposition on the key cylinder. The push starter button switch is mounted on the

Instrument panel center stack. All SRT-10 columns are Tilt columns, Standard cab trucks come with manual trans-

missions, Quad cab trucks come equipped with automatic transmissions.

DIAGNOSIS AND TESTING

STEERING COLUMN

If the vehicle is involved in a front end collision/the air bag has deployedthe column must be inspected. This

inspection will determine if the Column has collapsed. Inspect the columnmounting capsules visually and manually

push and pull them to check for separation or fractures. If capsules are fractured or have moved the column MUST

be replaced.

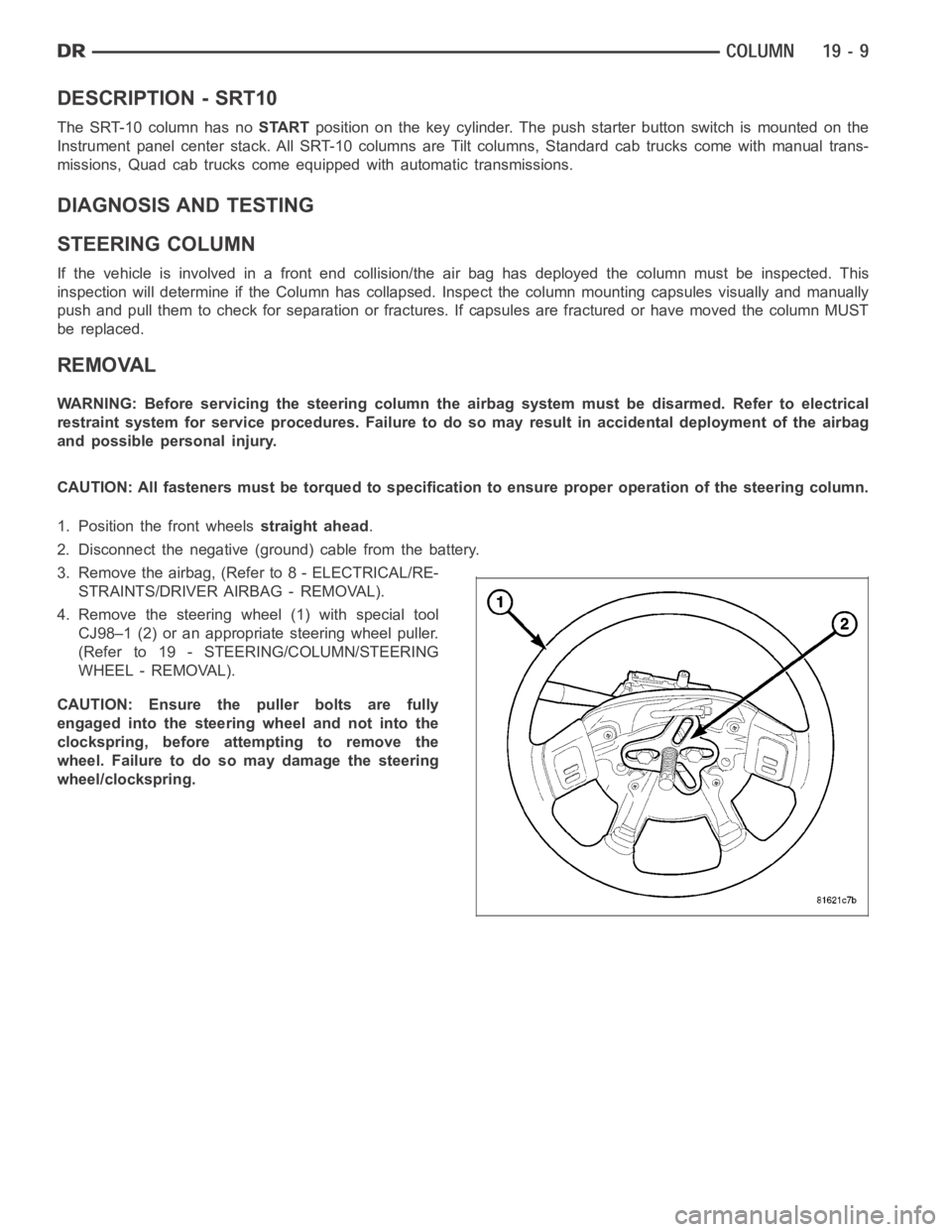

REMOVAL

WARNING: Before servicing the steering column the airbag system must be disarmed. Refer to electrical

restraint system for service procedures. Failure to do so may result in accidental deployment of the airbag

and possible personal injury.

CAUTION: All fasteners must be torqued to specification to ensure proper operation of the steering column.

1. Position the front wheelsstraight ahead.

2. Disconnect the negative (ground) cable from the battery.

3. Remove the airbag, (Refer to 8 - ELECTRICAL/RE-

STRAINTS/DRIVER AIRBAG - REMOVAL).

4. Remove the steering wheel (1) with special tool

CJ98–1 (2) or an appropriate steering wheel puller.

(Refer to 19 - STEERING/COLUMN/STEERING

WHEEL - REMOVAL).

CAUTION: Ensure the puller bolts are fully

engaged into the steering wheel and not into the

clockspring, before attempting to remove the

wheel. Failure to do so may damage the steering

wheel/clockspring.

Page 2417 of 5267

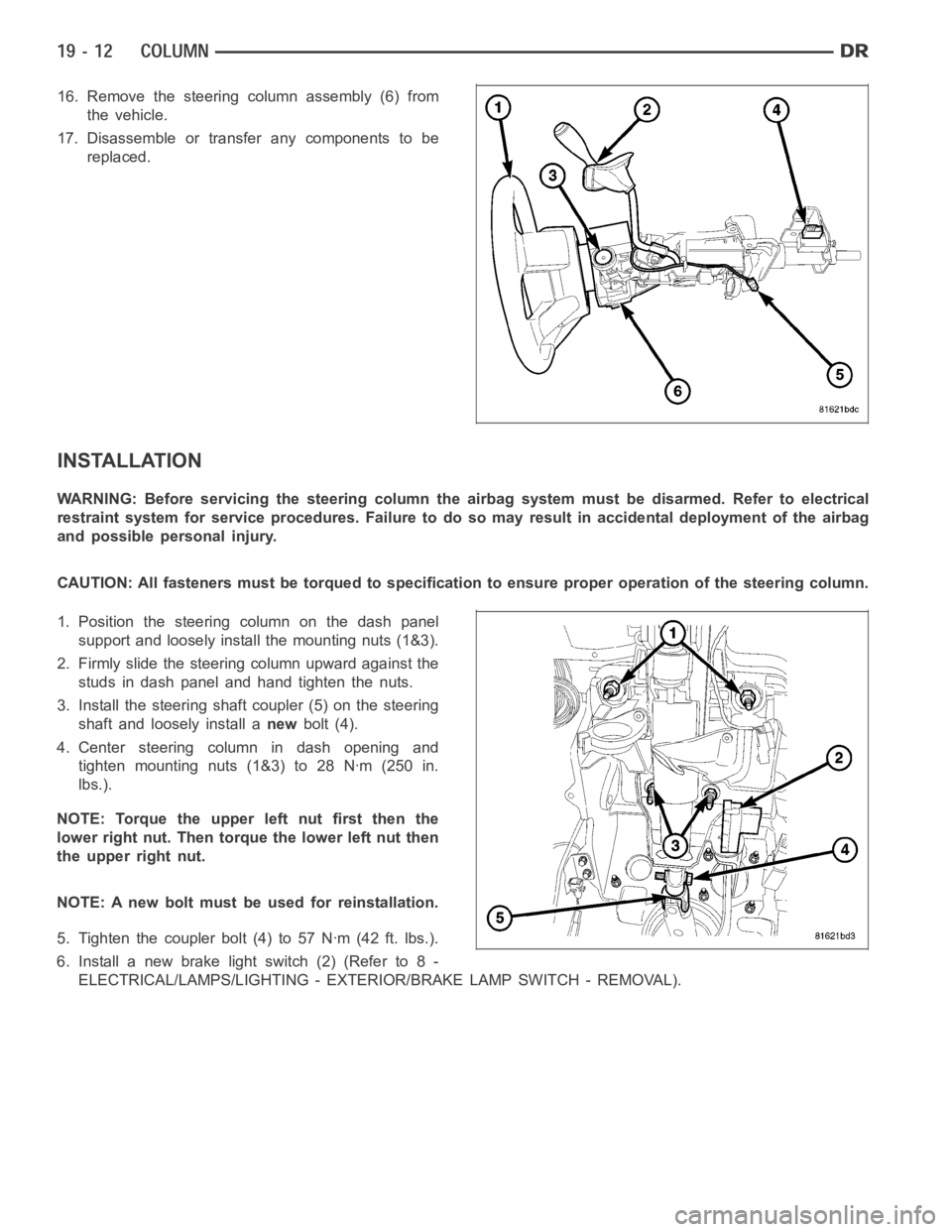

16. Remove the steering column assembly (6) from

the vehicle.

17. Disassemble or transfer any components to be

replaced.

INSTALLATION

WARNING: Before servicing the steering column the airbag system must be disarmed. Refer to electrical

restraint system for service procedures. Failure to do so may result in accidental deployment of the airbag

and possible personal injury.

CAUTION: All fasteners must be torqued to specification to ensure proper operation of the steering column.

1. Position the steering column on the dash panel

support and loosely install the mounting nuts (1&3).

2. Firmly slide the steering column upward against the

studs in dash panel and hand tighten the nuts.

3. Install the steering shaft coupler (5) on the steering

shaft and loosely install anewbolt (4).

4. Center steering column in dash opening and

tighten mounting nuts (1&3) to 28 Nꞏm (250 in.

lbs.).

NOTE: Torque the upper left nut first then the

lower right nut. Then torque the lower left nut then

the upper right nut.

NOTE: A new bolt must be used for reinstallation.

5. Tighten the coupler bolt (4) to 57 Nꞏm (42 ft. lbs.).

6. Install a new brake light switch (2) (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP SWITCH - REMOVAL).

Page 2419 of 5267

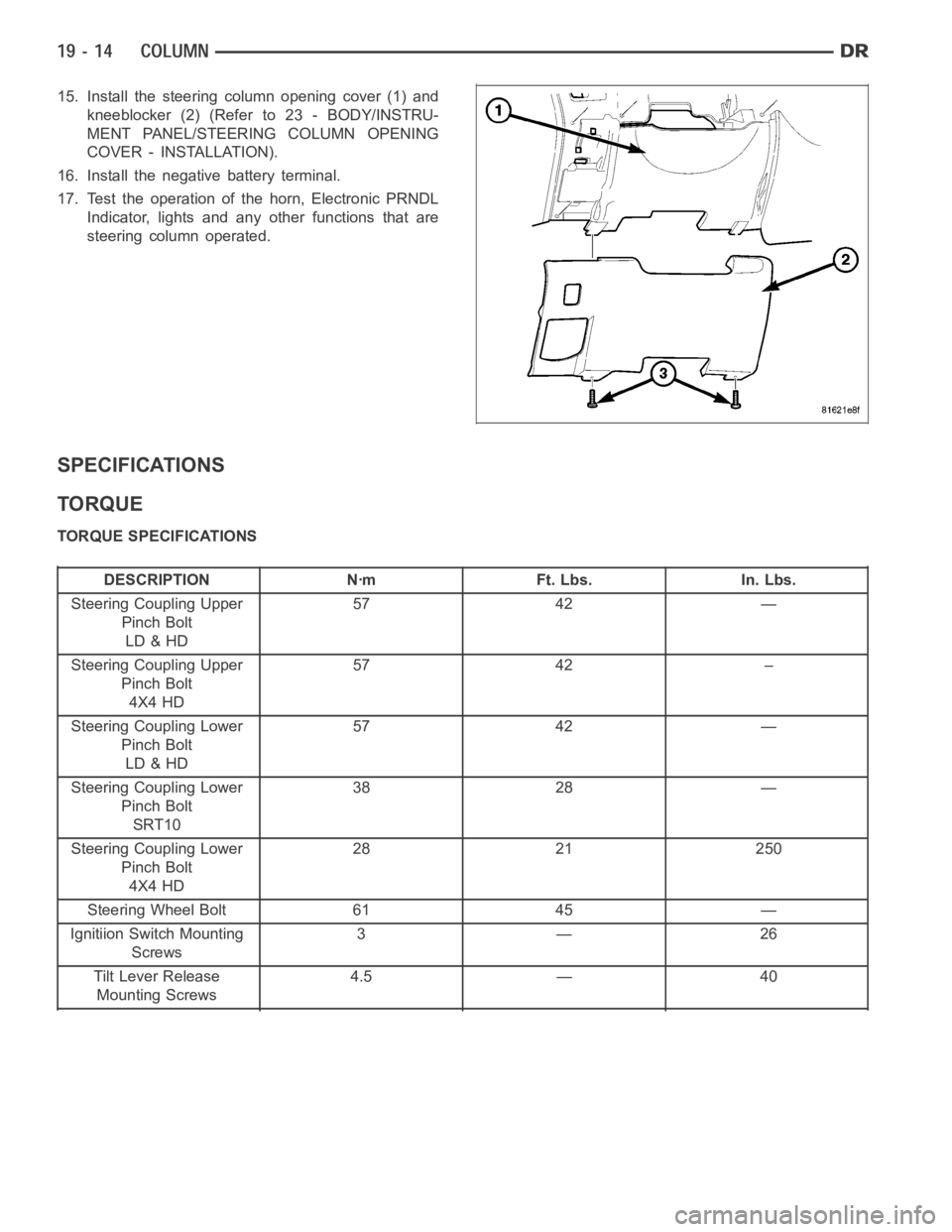

15. Install the steering column opening cover (1) and

kneeblocker (2) (Refer to 23 - BODY/INSTRU-

MENT PANEL/STEERING COLUMN OPENING

COVER - INSTALLATION).

16. Install the negative battery terminal.

17. Test the operation of the horn, Electronic PRNDL

Indicator, lights and any other functions that are

steering column operated.

SPECIFICATIONS

TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION Nꞏm Ft. Lbs. In. Lbs.

Steering Coupling Upper

Pinch Bolt

LD & HD57 42 —

Steering Coupling Upper

Pinch Bolt

4X4 HD57 42 –

Steering Coupling Lower

Pinch Bolt

LD & HD57 42 —

Steering Coupling Lower

Pinch Bolt

SRT1038 28 —

Steering Coupling Lower

Pinch Bolt

4X4 HD28 21 250

Steering Wheel Bolt 61 45 —

Ignitiion Switch Mounting

Screws3—26

Tilt Lever Release

Mounting Screws4.5 — 40

Page 2429 of 5267

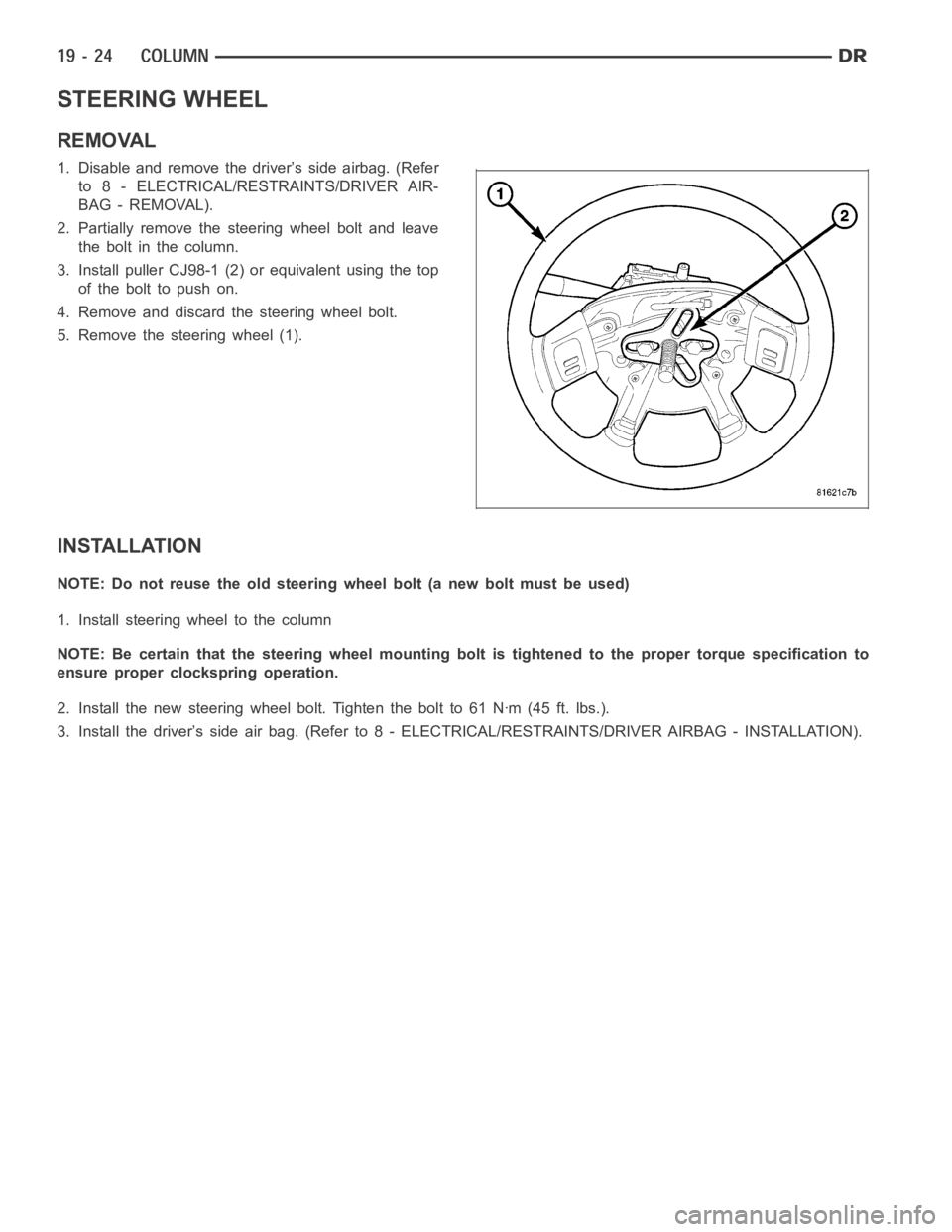

STEERING WHEEL

REMOVAL

1. Disable and remove the driver’s side airbag. (Refer

to 8 - ELECTRICAL/RESTRAINTS/DRIVER AIR-

BAG - REMOVAL).

2. Partially remove the steering wheel bolt and leave

theboltinthecolumn.

3. Install puller CJ98-1 (2) or equivalent using the top

ofthebolttopushon.

4. Remove and discard the steering wheel bolt.

5. Remove the steering wheel (1).

INSTALLATION

NOTE: Do not reuse the old steering wheel bolt (a new bolt must be used)

1. Install steering wheel to the column

NOTE: Be certain that the steering wheel mounting bolt is tightened to the proper torque specification to

ensure proper clockspring operation.

2. Install the new steering wheel bolt. Tighten the bolt to 61 Nꞏm (45 ft. lbs.).

3. Install the driver’s side air bag. (Refer to 8 - ELECTRICAL/RESTRAINTS/DRIVER AIRBAG - INSTALLATION).

Page 2443 of 5267

page page

GEAR - INDEPENDENT FRONT SUSPENSION

DESCRIPTION ................................ 39

REMOVAL .................................... 39

INSTALLATION ............................... 40

SPECIFICATIONS

TORQUE ................................... 41BUSHING

REMOVAL .................................... 42

INSTALLATION ............................... 42

Page 2445 of 5267

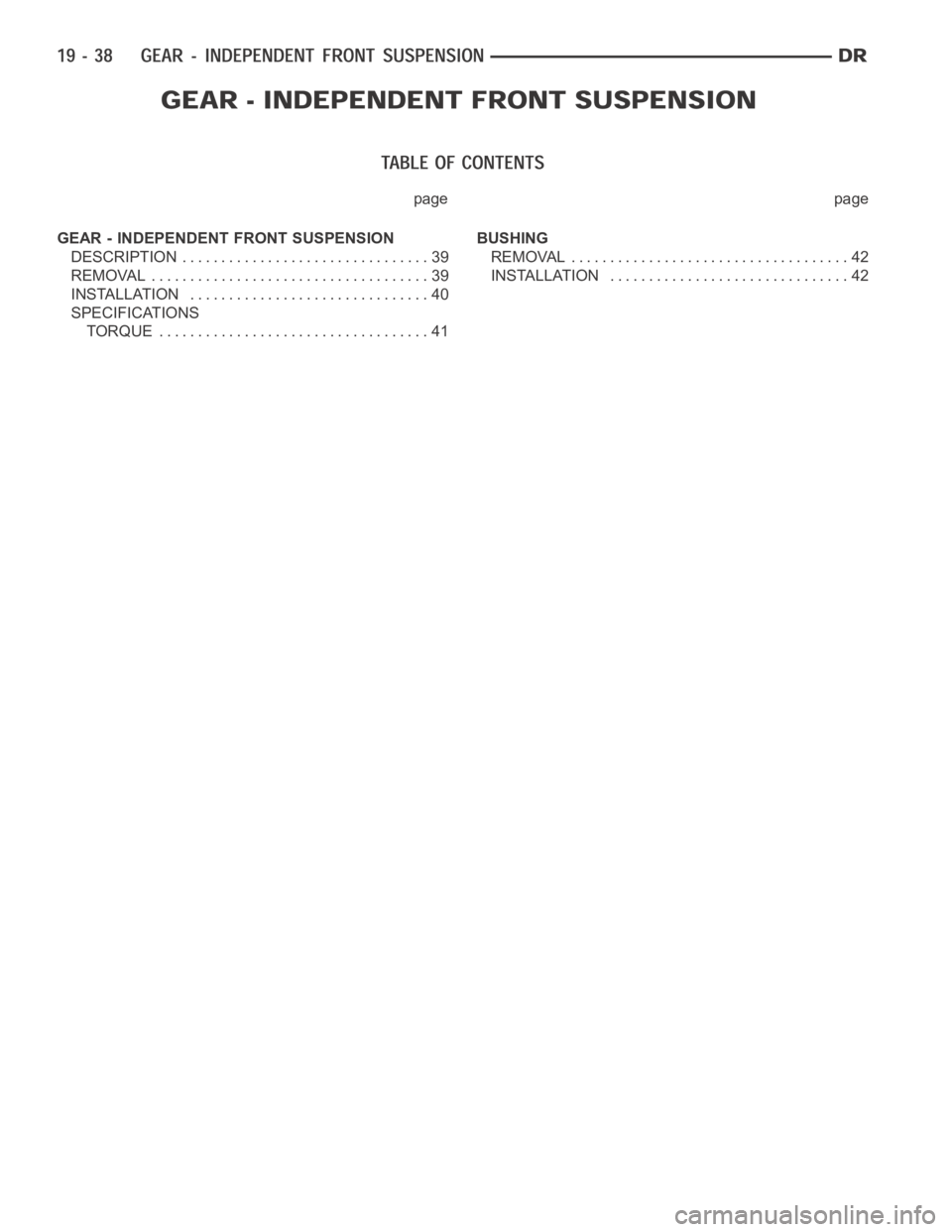

10. Remove the rack & pinion (2) from the vehicle.

INSTALLATION

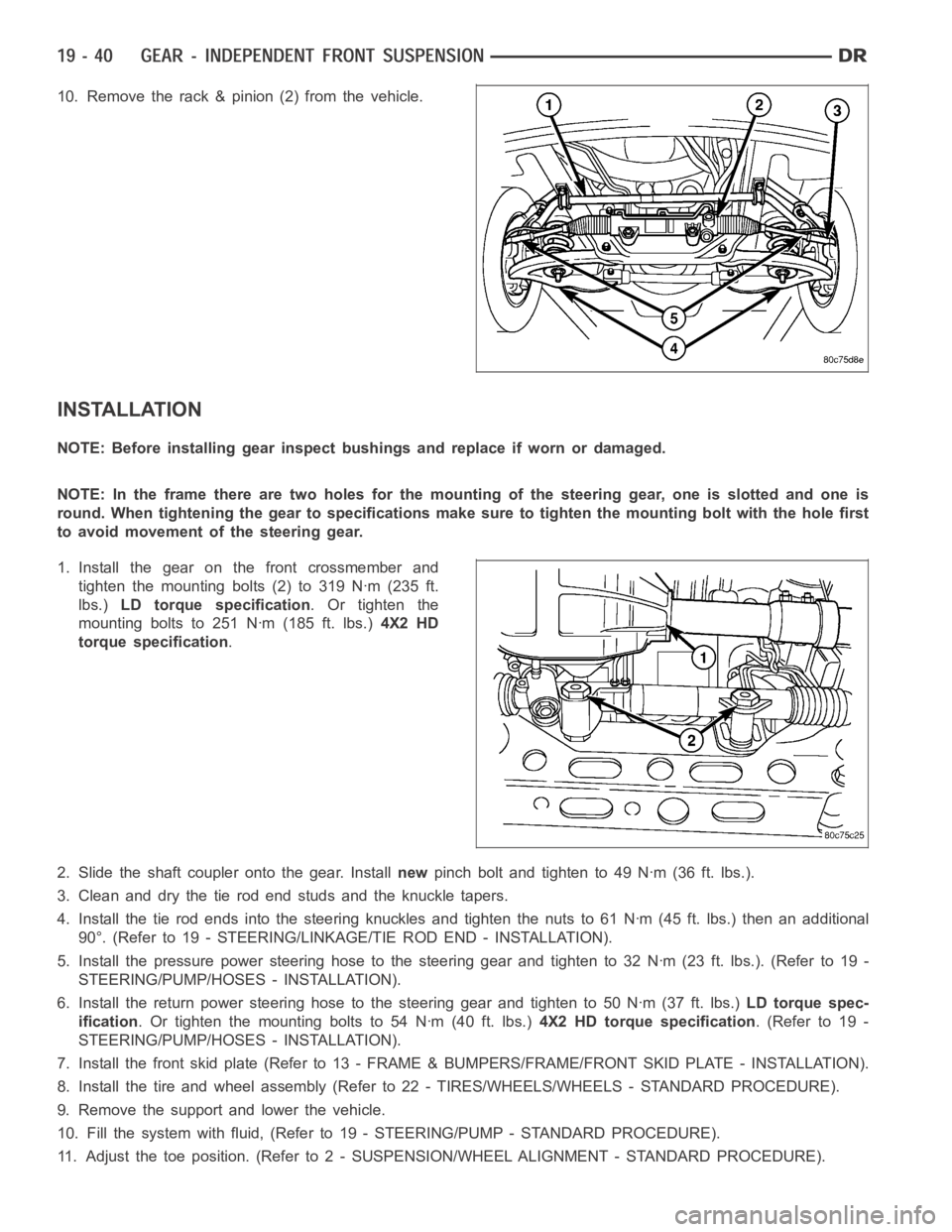

NOTE: Before installing gear inspect bushings and replace if worn or damaged.

NOTE: In the frame there are two holes for the mounting of the steering gear,oneisslottedandoneis

round. When tightening the gear to specificationsmakesuretotightenthemounting bolt with the hole first

to avoid movement of the steering gear.

1. Install the gear on the front crossmember and

tighten the mounting bolts (2) to 319 Nꞏm (235 ft.

lbs.)LD torque specification.Ortightenthe

mounting bolts to 251 Nꞏm (185 ft. lbs.)4X2 HD

torque specification.

2. Slide the shaft coupler onto the gear. Installnewpinch bolt and tighten to 49 Nꞏm (36 ft. lbs.).

3. Clean and dry the tie rod end studs and the knuckle tapers.

4. Install the tie rod ends into the steering knuckles and tighten the nuts to61Nꞏm(45ft.lbs.)thenanadditional

90°. (Refer to 19 - STEERING/LINKAGE/TIE ROD END - INSTALLATION).

5. Install the pressure power steering hose to the steering gear and tightento32Nꞏm(23ft.lbs.).(Referto19-

STEERING/PUMP/HOSES - INSTALLATION).

6. Install the return power steering hose to the steering gear and tighten to50Nꞏm(37ft.lbs.)LD torque spec-

ification. Or tighten the mounting bolts to 54 Nꞏm (40 ft. lbs.)4X2 HD torque specification.(Referto19-

STEERING/PUMP/HOSES - INSTALLATION).

7. Install the front skid plate (Refer to 13 - FRAME & BUMPERS/FRAME/FRONT SKID PLATE - INSTALLATION).

8. Install the tire and wheel assembly (Refer to 22 - TIRES/WHEELS/WHEELS -STANDARD PROCEDURE).

9. Remove the support and lower the vehicle.

10. Fill the system with fluid, (Refer to 19 - STEERING/PUMP - STANDARD PROCEDURE).

11. Adjust the toe position. (Refer to 2 - SUSPENSION/WHEEL ALIGNMENT - STANDARD PROCEDURE).