torque DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2359 of 5267

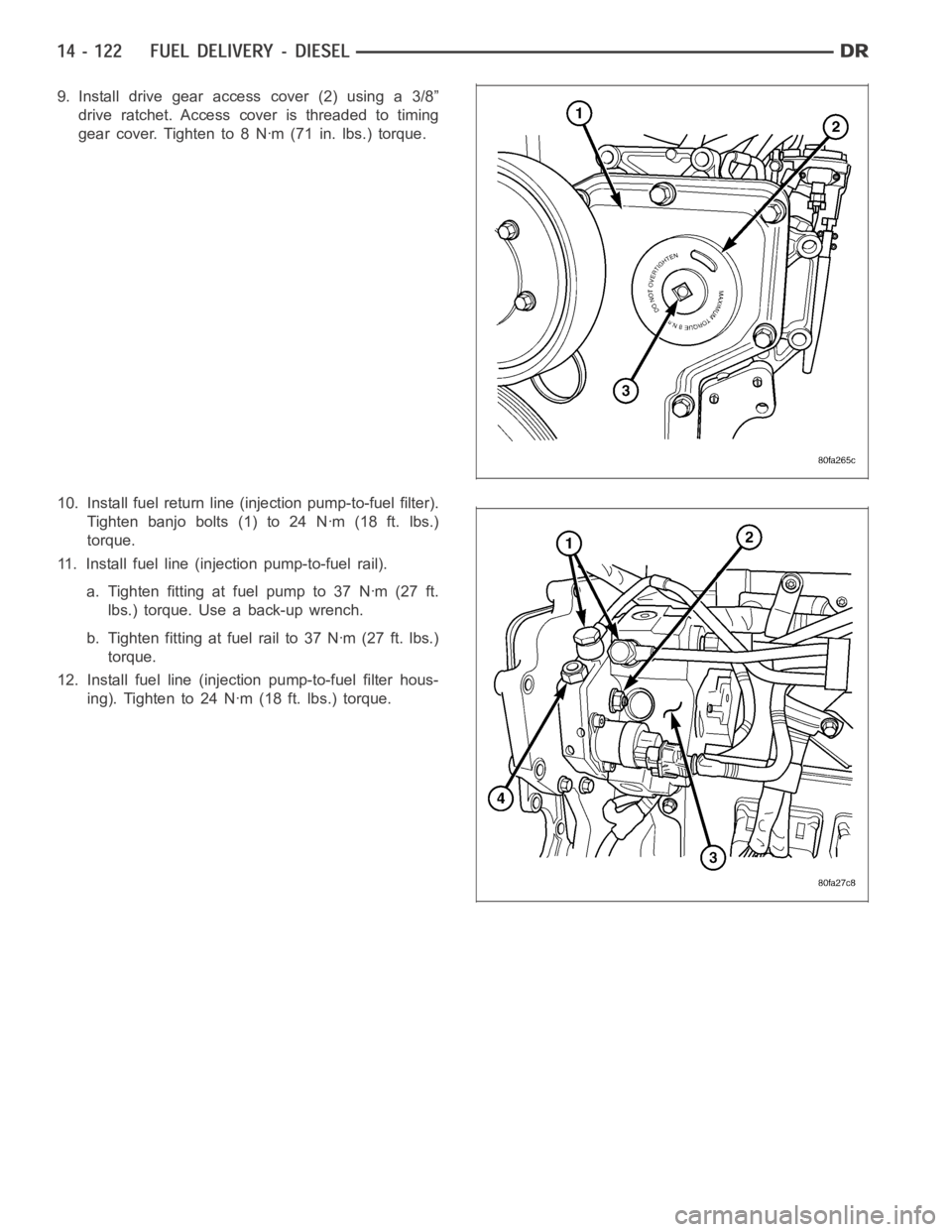

9. Install drive gear access cover (2) using a 3/8”

drive ratchet. Access cover is threaded to timing

gear cover. Tighten to 8 Nꞏm (71 in. lbs.) torque.

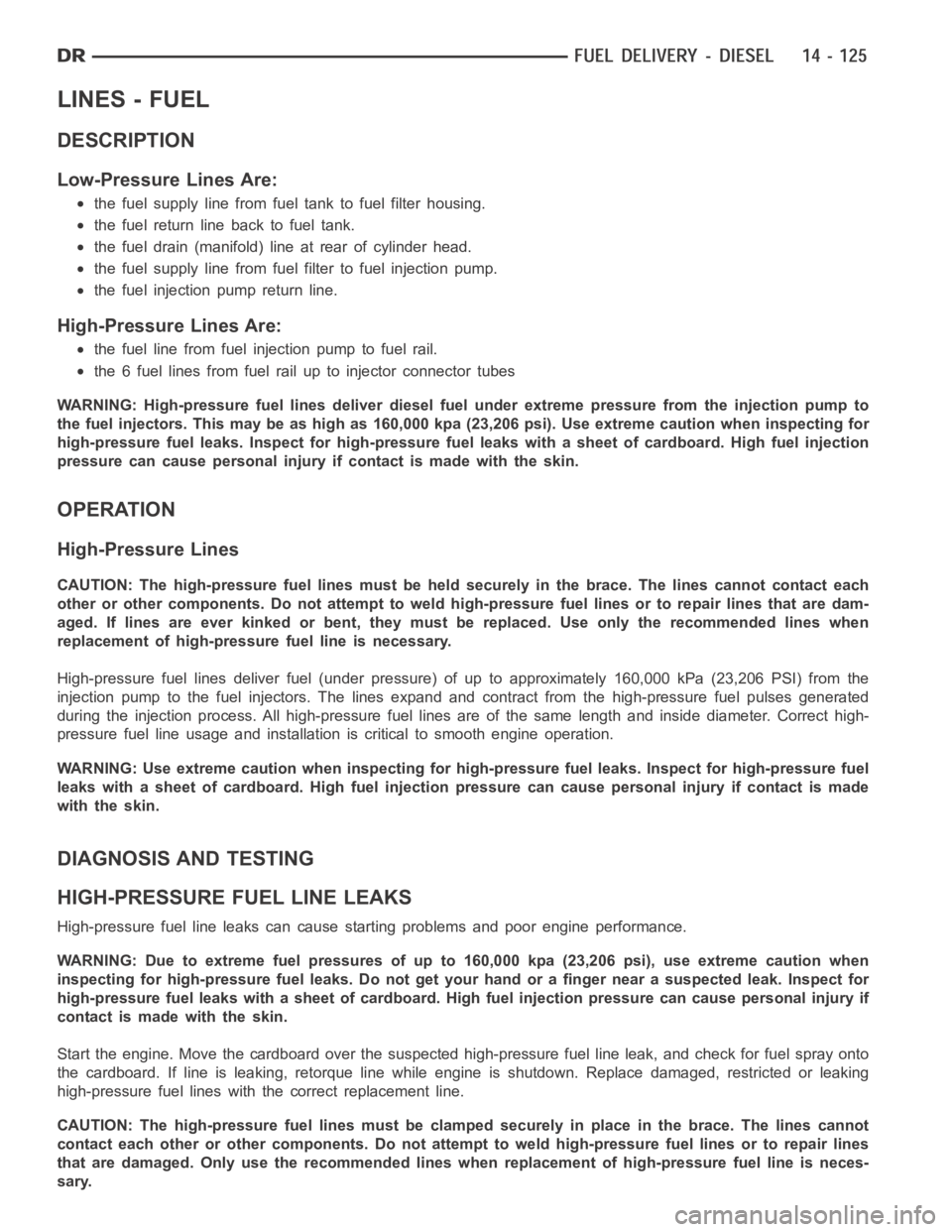

10. Install fuel return line (injection pump-to-fuel filter).

Tighten banjo bolts (1) to 24 Nꞏm (18 ft. lbs.)

torque.

11. Install fuel line (injection pump-to-fuel rail).

a. Tighten fitting at fuel pump to 37 Nꞏm (27 ft.

lbs.) torque. Use a back-up wrench.

b. Tighten fitting at fuel rail to 37 Nꞏm (27 ft. lbs.)

torque.

12. Install fuel line (injection pump-to-fuel filter hous-

ing). Tighten to 24 Nꞏm (18 ft. lbs.) torque.

Page 2362 of 5267

LINES - FUEL

DESCRIPTION

Low-Pressure Lines Are:

the fuel supply line from fuel tank to fuel filter housing.

the fuel return line back to fuel tank.

the fuel drain (manifold) line at rear of cylinder head.

the fuel supply line from fuel filter to fuel injection pump.

the fuel injection pump return line.

High-Pressure Lines Are:

the fuel line from fuel injection pump to fuel rail.

the 6 fuel lines from fuel rail up to injector connector tubes

WARNING: High-pressure fuel lines deliver diesel fuel under extreme pressure from the injection pump to

the fuel injectors. This may be as high as 160,000 kpa (23,206 psi). Use extreme caution when inspecting for

high-pressure fuel leaks. Inspect for high-pressure fuel leaks with a sheet of cardboard. High fuel injection

pressure can cause personal injury if contact is made with the skin.

OPERATION

High-Pressure Lines

CAUTION: The high-pressure fuel lines must be held securely in the brace. The lines cannot contact each

other or other components. Do not attempt to weld high-pressure fuel linesor to repair lines that are dam-

aged. If lines are ever kinked or bent, they must be replaced. Use only the recommended lines when

replacement of high-pressure fuel line is necessary.

High-pressure fuel lines deliver fuel (under pressure) of up to approximately 160,000 kPa (23,206 PSI) from the

injection pump to the fuel injectors. The lines expand and contract from the high-pressure fuel pulses generated

during the injection process. All high-pressure fuel lines are of the samelength and inside diameter. Correct high-

pressure fuel line usage and installation is critical to smooth engine operation.

WARNING: Use extreme caution when inspecting for high-pressure fuel leaks. Inspect for high-pressure fuel

leaks with a sheet of cardboard. High fuel injection pressure can cause personal injury if contact is made

with the skin.

DIAGNOSIS AND TESTING

HIGH-PRESSURE FUEL LINE LEAKS

High-pressure fuel line leaks can cause starting problems and poor engineperformance.

WARNING: Due to extreme fuel pressures of up to 160,000 kpa (23,206 psi), use extreme caution when

inspecting for high-pressure fuel leaks. Do not get your hand or a finger near a suspected leak. Inspect for

high-pressure fuel leaks with a sheet of cardboard. High fuel injection pressure can cause personal injury if

contact is made with the skin.

Start the engine. Move the cardboard over the suspected high-pressure fuel line leak, and check for fuel spray onto

the cardboard. If line is leaking, retorque line while engine is shutdown.Replace damaged, restricted or leaking

high-pressure fuel lines with the correct replacement line.

CAUTION: The high-pressure fuel lines must be clamped securely in place inthe brace. The lines cannot

contact each other or other components. Do not attempt to weld high-pressure fuel lines or to repair lines

that are damaged. Only use the recommended lines when replacement of high-pressure fuel line is neces-

sary.

Page 2364 of 5267

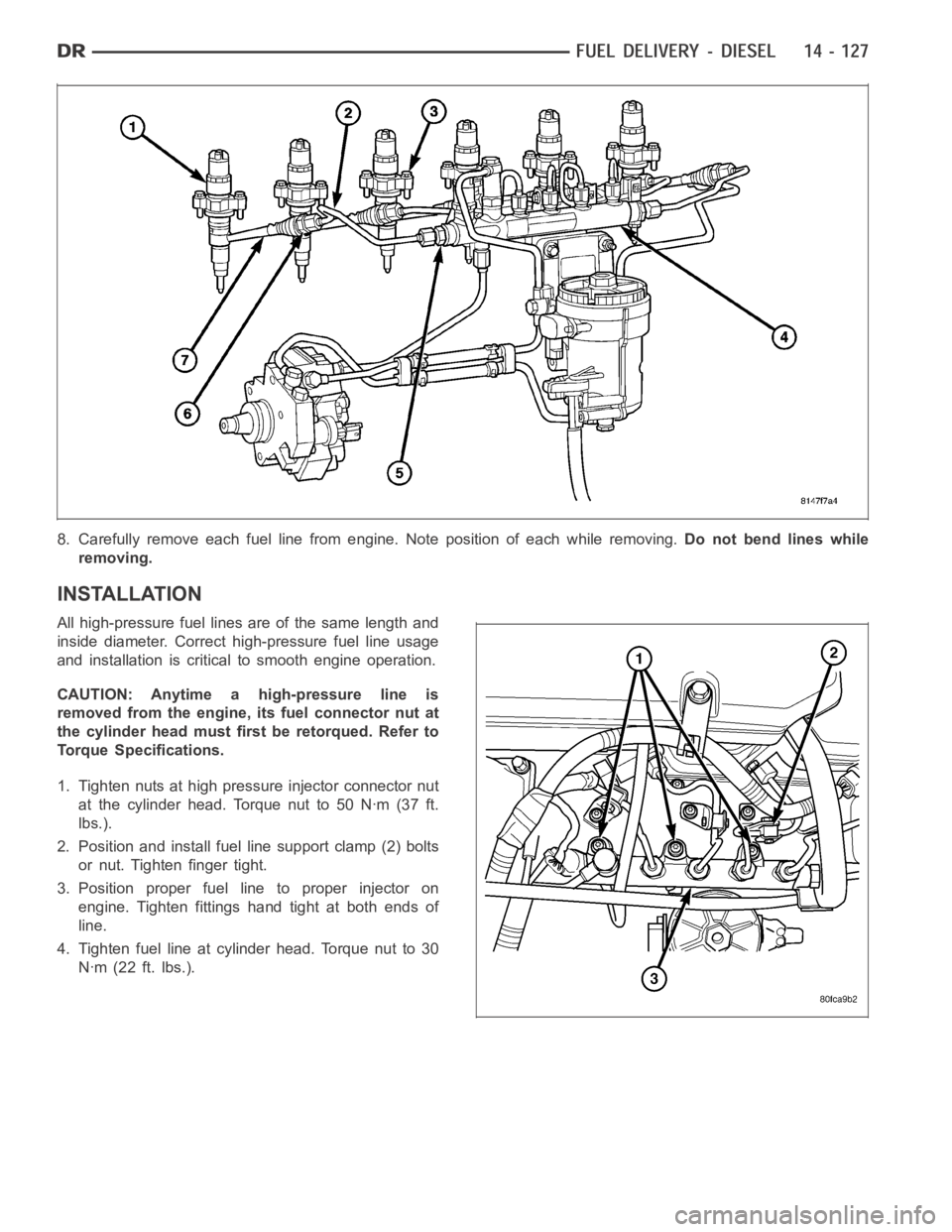

8. Carefully remove each fuel line from engine. Note position of each whileremoving.Do not bend lines while

removing.

INSTALLATION

All high-pressure fuel lines are of the same length and

inside diameter. Correct high-pressure fuel line usage

and installation is critical to smooth engine operation.

CAUTION: Anytime a high-pressure line is

removed from the engine, its fuel connector nut at

the cylinder head must first be retorqued. Refer to

Torque Specifications.

1. Tighten nuts at high pressure injector connector nut

at the cylinder head. Torque nut to 50 Nꞏm (37 ft.

lbs.).

2. Position and install fuel line support clamp (2) bolts

or nut. Tighten finger tight.

3. Position proper fuel line to proper injector on

engine. Tighten fittings hand tight at both ends of

line.

4. Tighten fuel line at cylinder head. Torque nut to 30

Nꞏm (22 ft. lbs.).

Page 2365 of 5267

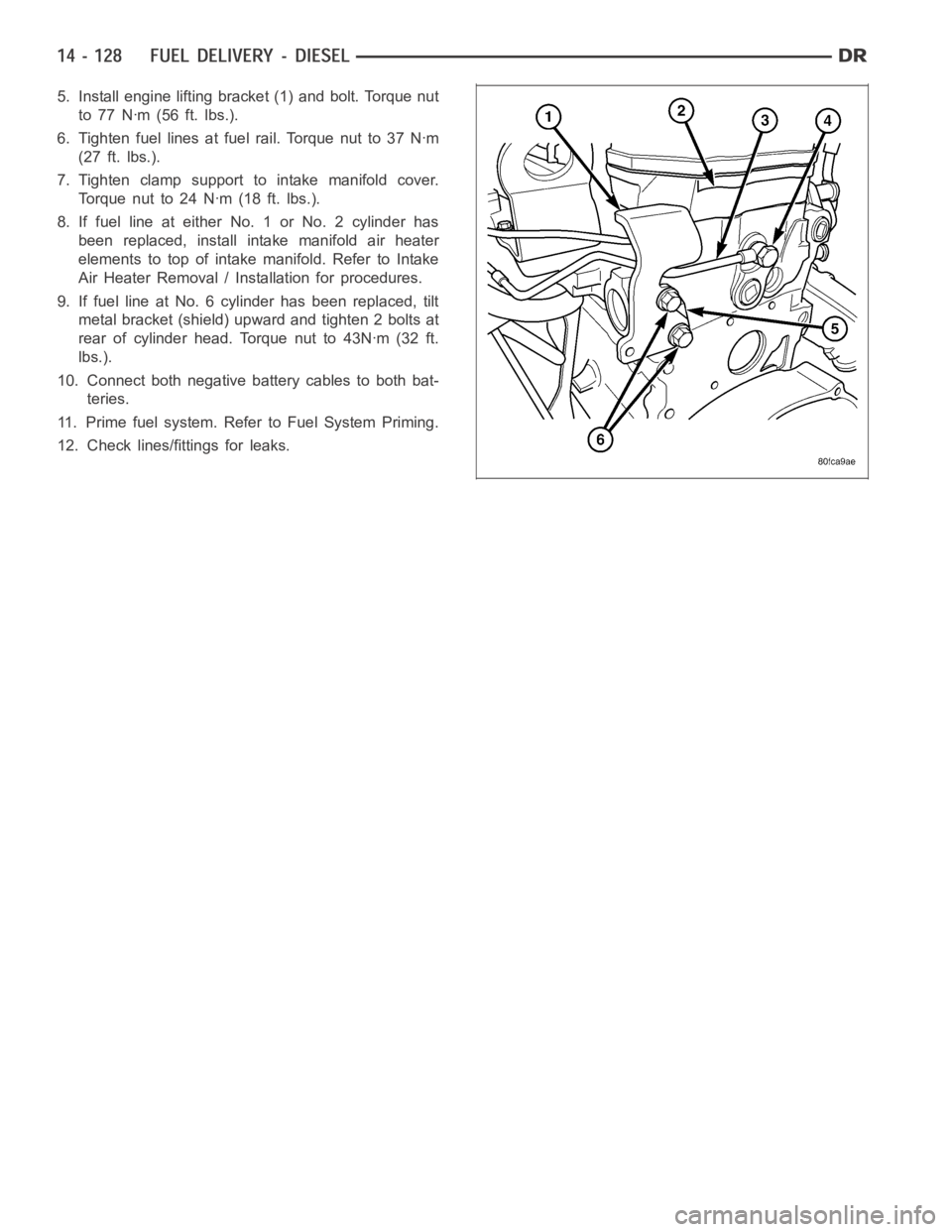

5. Install engine lifting bracket (1) and bolt. Torque nut

to 77 Nꞏm (56 ft. lbs.).

6. Tighten fuel lines at fuel rail. Torque nut to 37 Nꞏm

(27 ft. lbs.).

7. Tighten clamp support to intake manifold cover.

Torque nut to 24 Nꞏm (18 ft. lbs.).

8. If fuel line at either No. 1 or No. 2 cylinder has

been replaced, install intake manifold air heater

elements to top of intake manifold. Refer to Intake

Air Heater Removal / Installation for procedures.

9. If fuel line at No. 6 cylinder has been replaced, tilt

metal bracket (shield) upward and tighten 2 bolts at

rear of cylinder head. Torque nut to 43Nꞏm (32 ft.

lbs.).

10. Connect both negative battery cables to both bat-

teries.

11. Prime fuel system. Refer to Fuel System Priming.

12. Check lines/fittings for leaks.

Page 2368 of 5267

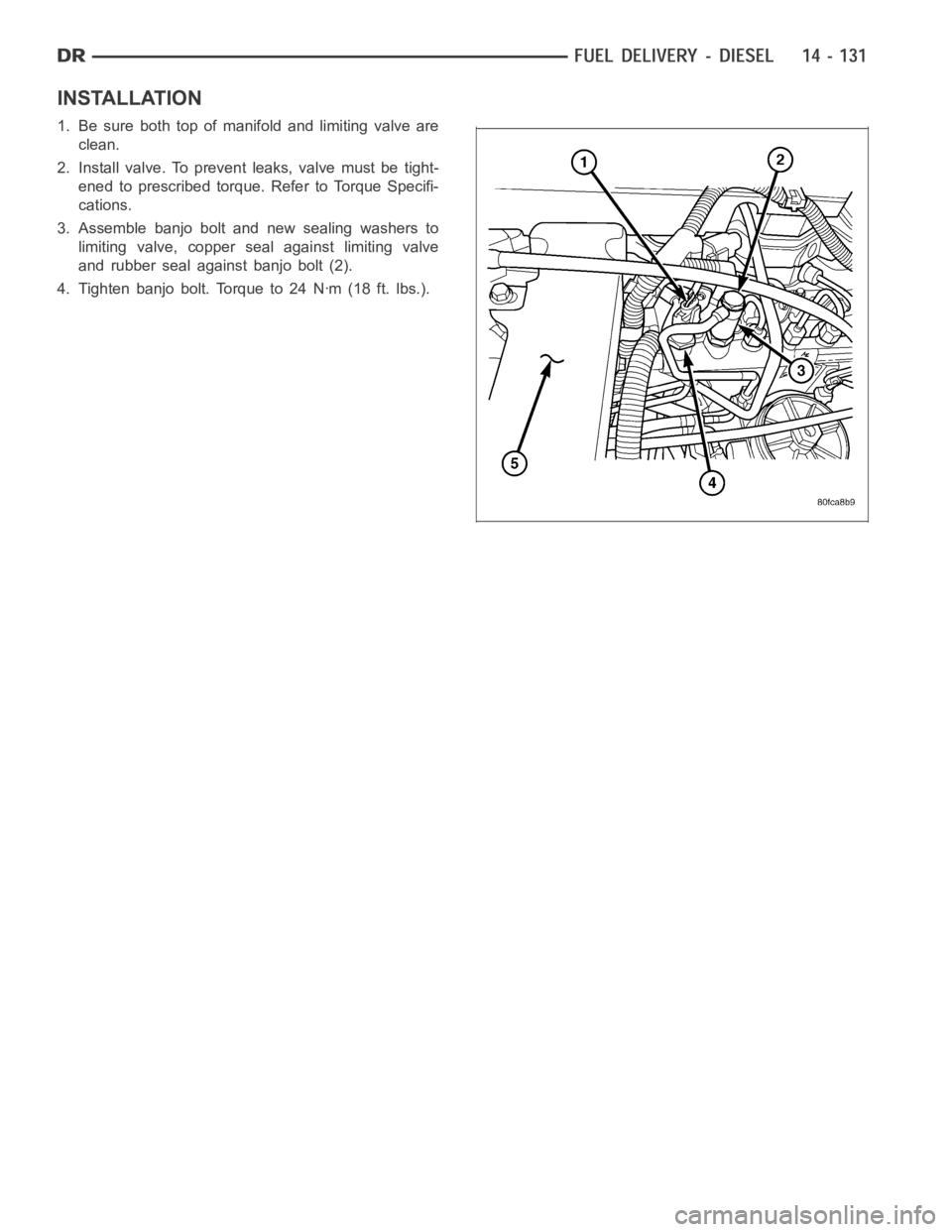

INSTALLATION

1. Be sure both top of manifold and limiting valve are

clean.

2. Install valve. To prevent leaks, valve must be tight-

ened to prescribed torque. Refer to Torque Specifi-

cations.

3. Assemble banjo bolt and new sealing washers to

limiting valve, copper seal against limiting valve

and rubber seal against banjo bolt (2).

4. Tighten banjo bolt. Torque to 24 Nꞏm (18 ft. lbs.).

Page 2381 of 5267

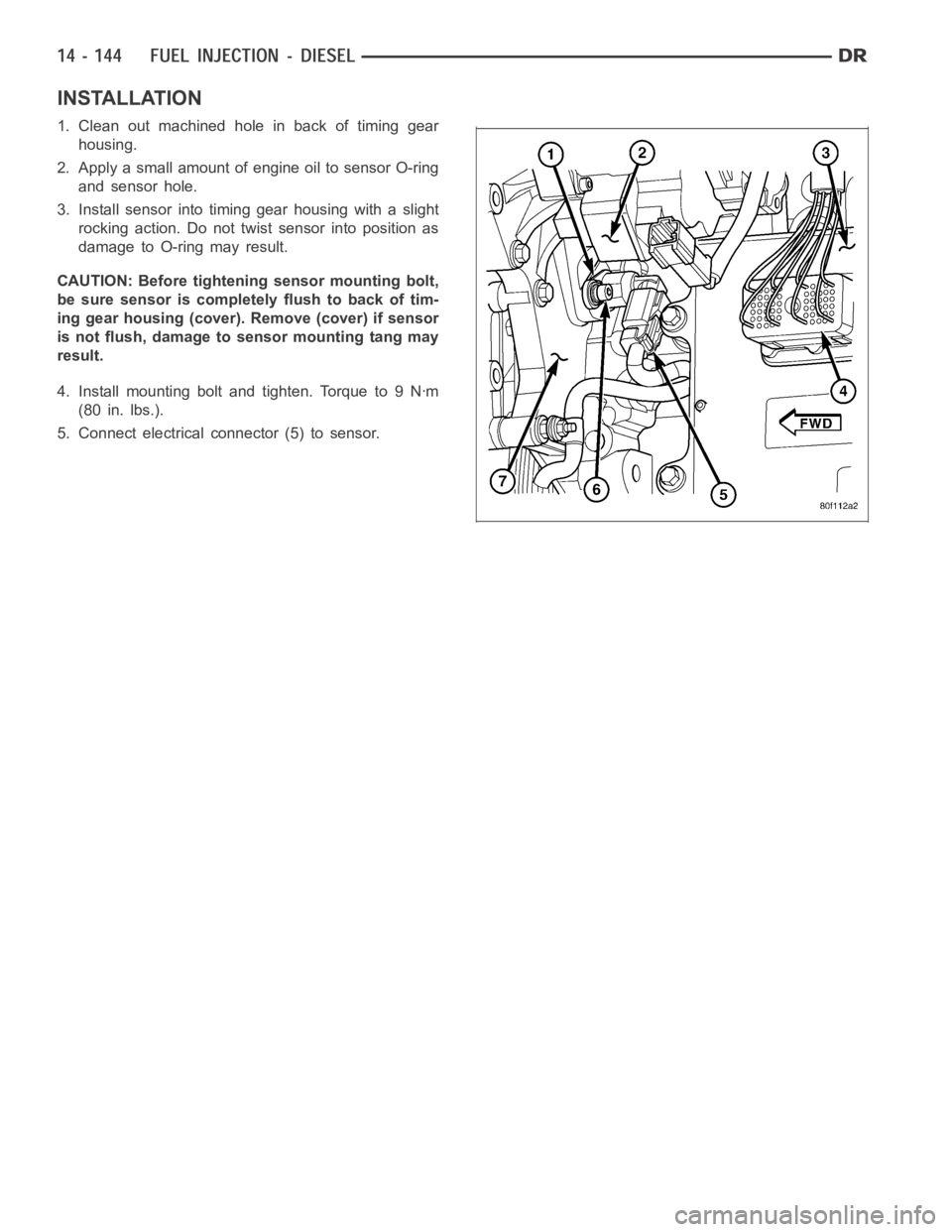

INSTALLATION

1. Clean out machined hole in back of timing gear

housing.

2. Apply a small amount of engine oil to sensor O-ring

and sensor hole.

3. Install sensor into timing gear housing with a slight

rocking action. Do not twist sensor into position as

damagetoO-ringmayresult.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to back of tim-

ing gear housing (cover). Remove (cover) if sensor

is not flush, damage to sensor mounting tang may

result.

4. Install mounting bolt and tighten. Torque to 9 Nꞏm

(80 in. lbs.).

5. Connect electrical connector (5) to sensor.

Page 2383 of 5267

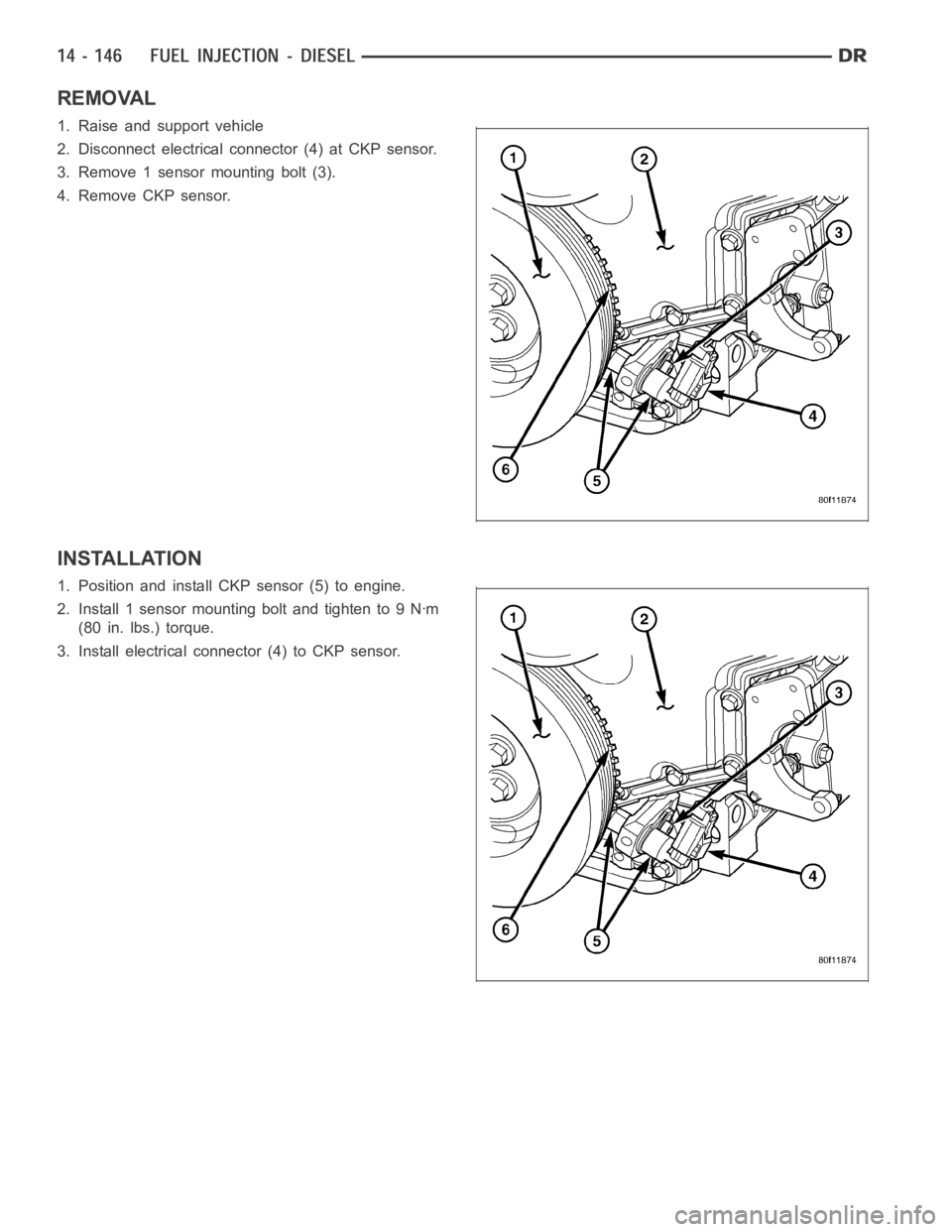

REMOVAL

1. Raise and support vehicle

2. Disconnect electrical connector (4) at CKP sensor.

3. Remove 1 sensor mounting bolt (3).

4. Remove CKP sensor.

INSTALLATION

1. Position and install CKP sensor (5) to engine.

2. Install 1 sensor mounting bolt and tighten to 9 Nꞏm

(80 in. lbs.) torque.

3. Install electrical connector (4) to CKP sensor.

Page 2386 of 5267

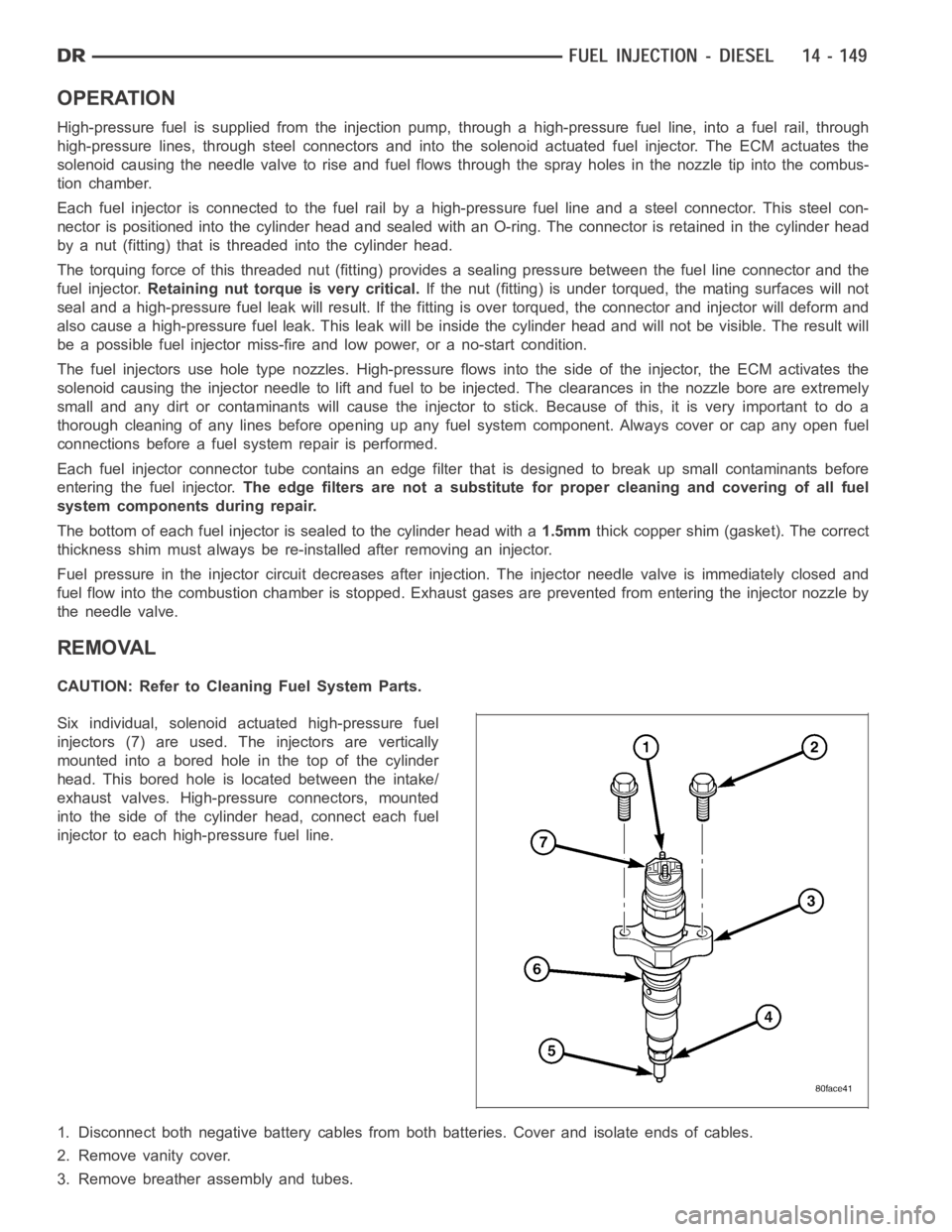

OPERATION

High-pressure fuel is supplied from the injection pump, through a high-pressure fuel line, into a fuel rail, through

high-pressure lines, through steel connectors and into the solenoid actuated fuel injector. The ECM actuates the

solenoid causing the needle valve to rise and fuel flows through the spray holes in the nozzle tip into the combus-

tion chamber.

Each fuel injector is connected to the fuel rail by a high-pressure fuel line and a steel connector. This steel con-

nector is positioned into the cylinder head and sealed with an O-ring. The connector is retained in the cylinder head

by a nut (fitting) that is threaded into the cylinder head.

The torquing force of this threaded nut (fitting) provides a sealing pressure between the fuel line connector and the

fuel injector.Retaining nut torque is very critical.If the nut (fitting) is under torqued, the mating surfaces will not

seal and a high-pressure fuel leak will result. If the fitting is over torqued, the connector and injector will deform and

also cause a high-pressure fuel leak. This leak will be inside the cylinderhead and will not be visible. The result will

be a possible fuel injector miss-fire and low power, or a no-start condition.

The fuel injectors use hole type nozzles. High-pressure flows into the side of the injector, the ECM activates the

solenoid causing the injector needle to lift and fuel to be injected. The clearances in the nozzle bore are extremely

small and any dirt or contaminants will cause the injector to stick. Because of this, it is very important to do a

thorough cleaning of any lines before opening up any fuel system component. Always cover or cap any open fuel

connections before a fuel system repair is performed.

Each fuel injector connector tube contains an edge filter that is designedto break up small contaminants before

entering the fuel injector.The edge filters are not a substitute for proper cleaning and covering of allfuel

system components during repair.

The bottom of each fuel injector is sealed to the cylinder head with a1.5mmthick copper shim (gasket). The correct

thickness shim must always be re-installed after removing an injector.

Fuel pressure in the injector circuit decreases after injection. The injector needle valve is immediately closed and

fuel flow into the combustion chamber is stopped. Exhaust gases are prevented from entering the injector nozzle by

the needle valve.

REMOVAL

CAUTION: Refer to Cleaning Fuel System Parts.

Six individual, solenoid actuated high-pressure fuel

injectors (7) are used. The injectors are vertically

mounted into a bored hole in the top of the cylinder

head. This bored hole is located between the intake/

exhaust valves. High-pressure connectors, mounted

into the side of the cylinder head, connect each fuel

injector to each high-pressure fuel line.

1. Disconnect both negative battery cables from both batteries. Cover andisolate ends of cables.

2. Remove vanity cover.

3. Remove breather assembly and tubes.

Page 2391 of 5267

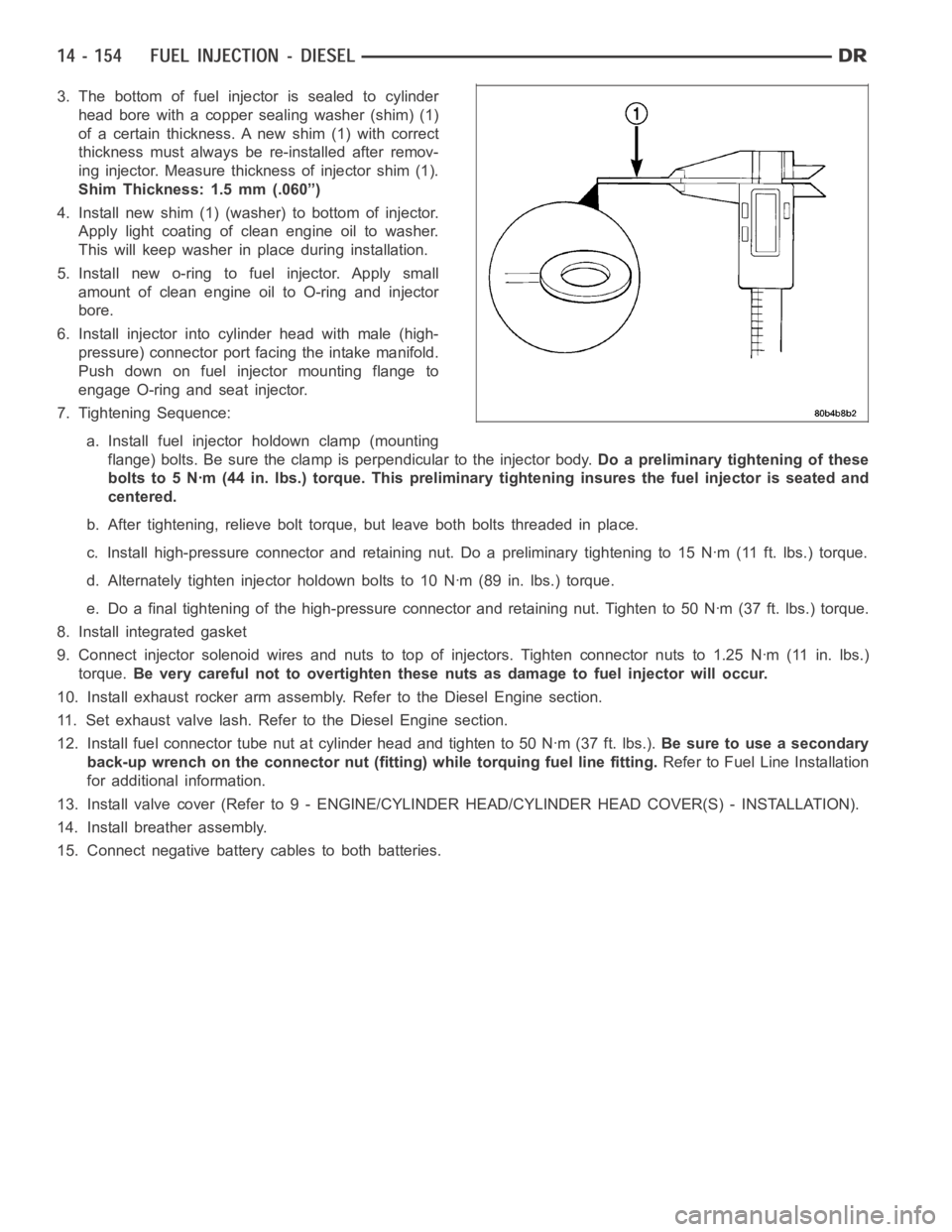

3. The bottom of fuel injector is sealed to cylinder

head bore with a copper sealing washer (shim) (1)

of a certain thickness. A new shim (1) with correct

thickness must always be re-installed after remov-

ing injector. Measure thickness of injector shim (1).

Shim Thickness: 1.5 mm (.060”)

4. Install new shim (1) (washer) to bottom of injector.

Apply light coating of clean engine oil to washer.

This will keep washer in place during installation.

5. Install new o-ring to fuel injector. Apply small

amount of clean engine oil to O-ring and injector

bore.

6. Install injector into cylinder head with male (high-

pressure) connector port facing the intake manifold.

Push down on fuel injector mounting flange to

engage O-ring and seat injector.

7. Tightening Sequence:

a. Install fuel injector holdown clamp (mounting

flange) bolts. Be sure the clamp is perpendicular to the injector body.Do a preliminary tightening of these

bolts to 5 Nꞏm (44 in. lbs.) torque. This preliminary tightening insures the fuel injector is seated and

centered.

b. After tightening, relieve bolt torque, but leave both bolts threaded inplace.

c. Install high-pressure connector and retaining nut. Do a preliminary tightening to 15 Nꞏm (11 ft. lbs.) torque.

d. Alternately tighten injector holdown bolts to 10 Nꞏm (89 in. lbs.) torque.

e. Do a final tightening of the high-pressure connector and retaining nut.Tighten to 50 Nꞏm (37 ft. lbs.) torque.

8. Install integrated gasket

9. Connect injector solenoid wires and nuts to top of injectors. Tighten connector nuts to 1.25 Nꞏm (11 in. lbs.)

torque.Be very careful not to overtighten these nuts as damage to fuel injector willoccur.

10. Install exhaust rocker arm assembly. Refer to the Diesel Engine section.

11. Set exhaust valve lash. Refer to the Diesel Engine section.

12. Install fuel connector tube nut at cylinder head and tighten to 50 Nꞏm (37ft.lbs.).Be sure to use a secondary

back-up wrench on the connector nut (fitting) while torquing fuel line fitting.Refer to Fuel Line Installation

for additional information.

13. Install valve cover (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) - INSTALLATION).

14. Install breather assembly.

15. Connect negative battery cables to both batteries.

Page 2393 of 5267

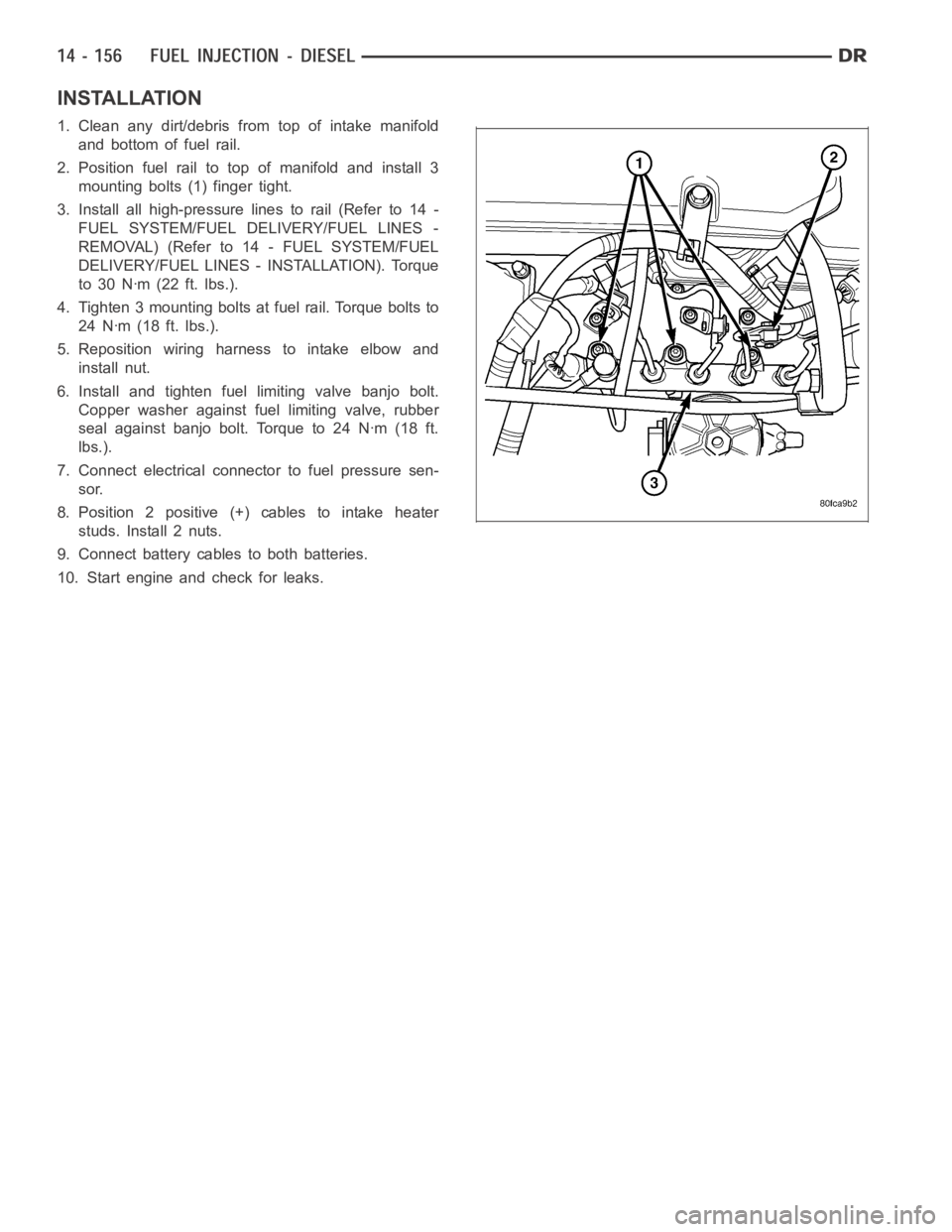

INSTALLATION

1. Clean any dirt/debris from top of intake manifold

and bottom of fuel rail.

2. Position fuel rail to top of manifold and install 3

mounting bolts (1) finger tight.

3. Install all high-pressure lines to rail (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/FUEL LINES -

REMOVAL) (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/FUEL LINES - INSTALLATION). Torque

to 30 Nꞏm (22 ft. lbs.).

4. Tighten 3 mounting bolts at fuel rail. Torque bolts to

24 Nꞏm (18 ft. lbs.).

5. Reposition wiring harness to intake elbow and

install nut.

6. Install and tighten fuel limiting valve banjo bolt.

Copper washer against fuel limiting valve, rubber

seal against banjo bolt. Torque to 24 Nꞏm (18 ft.

lbs.).

7. Connect electrical connector to fuel pressure sen-

sor.

8. Position 2 positive (+) cables to intake heater

studs. Install 2 nuts.

9. Connect battery cables to both batteries.

10. Start engine and check for leaks.