torque DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2446 of 5267

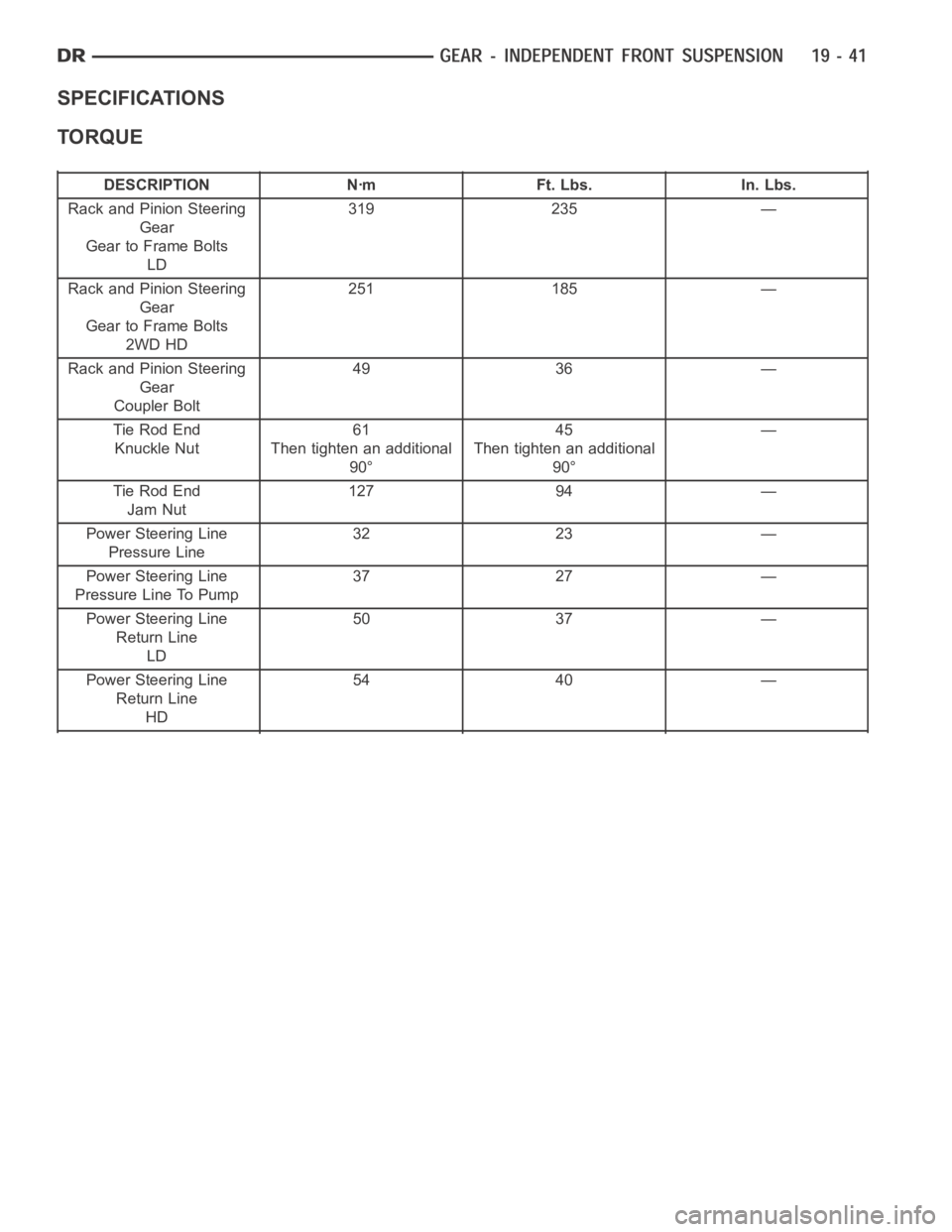

SPECIFICATIONS

TORQUE

DESCRIPTION Nꞏm Ft. Lbs. In. Lbs.

Rack and Pinion Steering

Gear

Gear to Frame Bolts

LD319 235 —

Rack and Pinion Steering

Gear

Gear to Frame Bolts

2WD HD251 185 —

Rack and Pinion Steering

Gear

Coupler Bolt49 36 —

Tie Rod End

Knuckle Nut61

Then tighten an additional

90°45

Then tighten an additional

90°—

Tie Rod End

Jam Nut127 94 —

Power Steering Line

Pressure Line32 23 —

Power Steering Line

Pressure Line To Pump37 27 —

Power Steering Line

Return Line

LD50 37 —

Power Steering Line

Return Line

HD54 40 —

Page 2448 of 5267

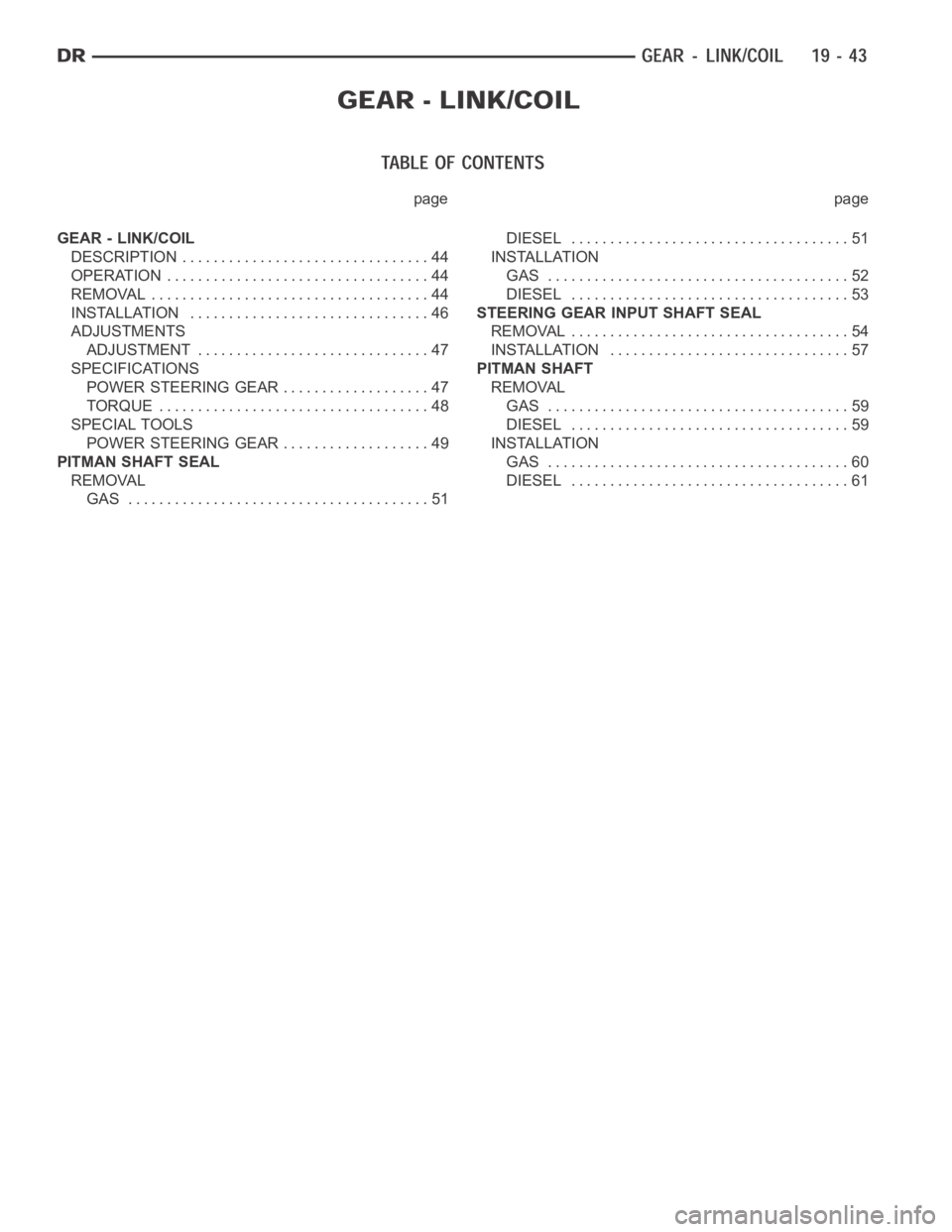

page page

GEAR - LINK/COIL

DESCRIPTION ................................ 44

OPERATION .................................. 44

REMOVAL .................................... 44

INSTALLATION ............................... 46

ADJUSTMENTS

ADJUSTMENT .............................. 47

SPECIFICATIONS

POWER STEERING GEAR ................... 47

TORQUE ................................... 48

SPECIAL TOOLS

POWER STEERING GEAR ................... 49

PITMAN SHAFT SEAL

REMOVAL

GAS ....................................... 51DIESEL .................................... 51

INSTALLATION

GAS ....................................... 52

DIESEL .................................... 53

STEERING GEAR INPUT SHAFT SEAL

REMOVAL .................................... 54

INSTALLATION ............................... 57

PITMAN SHAFT

REMOVAL

GAS ....................................... 59

DIESEL .................................... 59

INSTALLATION

GAS ....................................... 60

DIESEL .................................... 61

Page 2451 of 5267

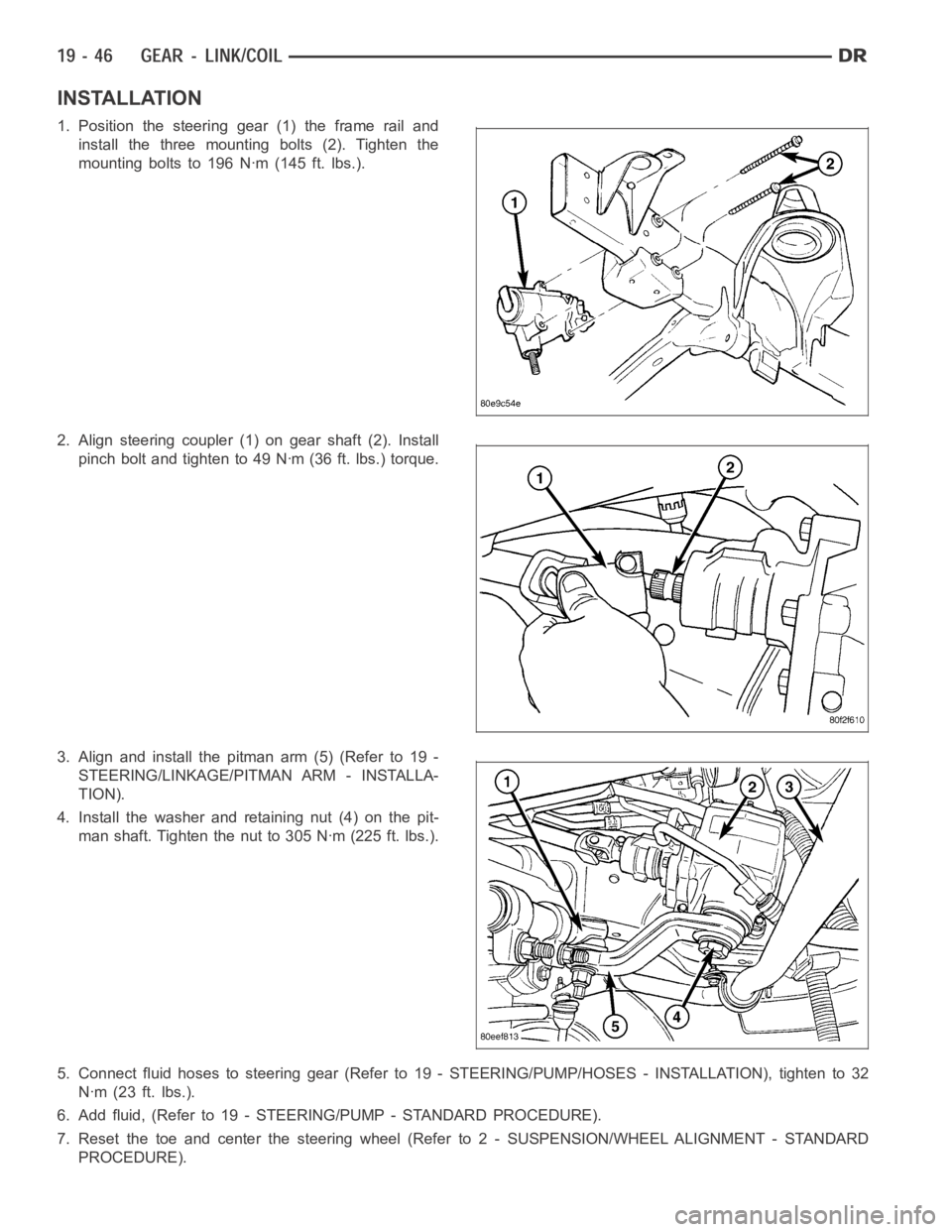

INSTALLATION

1. Position the steering gear (1) the frame rail and

install the three mounting bolts (2). Tighten the

mounting bolts to 196 Nꞏm (145 ft. lbs.).

2. Align steering coupler (1) on gear shaft (2). Install

pinch bolt and tighten to 49 Nꞏm (36 ft. lbs.) torque.

3. Align and install the pitman arm (5) (Refer to 19 -

STEERING/LINKAGE/PITMAN ARM - INSTALLA-

TION).

4. Install the washer and retaining nut (4) on the pit-

man shaft. Tighten the nut to 305 Nꞏm (225 ft. lbs.).

5. Connect fluid hoses to steering gear (Refer to 19 - STEERING/PUMP/HOSES- INSTALLATION), tighten to 32

Nꞏm (23 ft. lbs.).

6. Add fluid, (Refer to 19 - STEERING/PUMP - STANDARD PROCEDURE).

7. Reset the toe and center the steering wheel (Refer to 2 - SUSPENSION/WHEELALIGNMENT - STANDARD

PROCEDURE).

Page 2452 of 5267

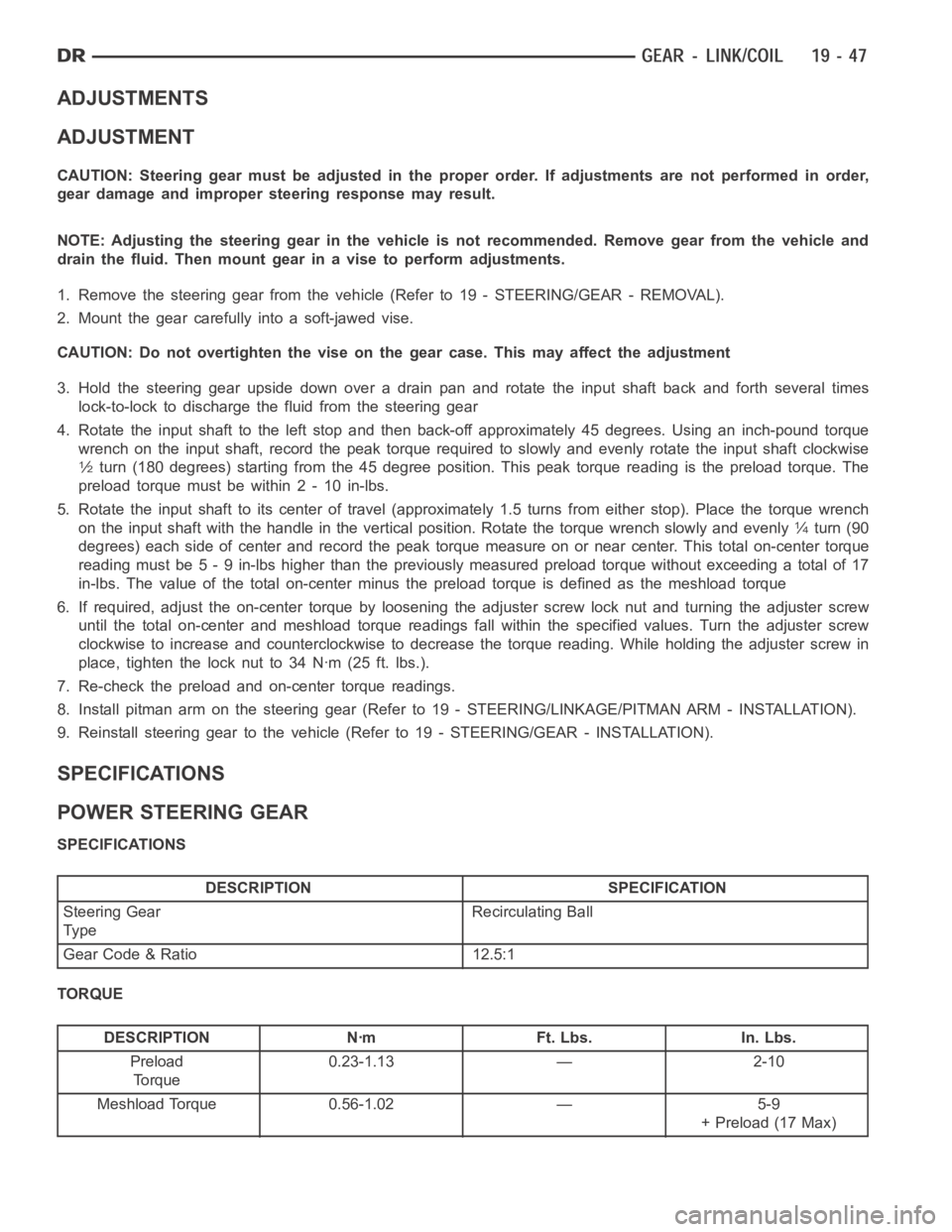

ADJUSTMENTS

ADJUSTMENT

CAUTION: Steering gear must be adjusted in the proper order. If adjustments are not performed in order,

gear damage and improper steering response may result.

NOTE: Adjusting the steering gear in the vehicle is not recommended. Remove gear from the vehicle and

drain the fluid. Then mount gear in a vise to perform adjustments.

1. Remove the steering gear from the vehicle(Referto19-STEERING/GEAR-REMOVAL).

2. Mount the gear carefully into a soft-jawed vise.

CAUTION: Do not overtighten the vise on the gear case. This may affect the adjustment

3. Hold the steering gear upside down over a drain pan and rotate the input shaft back and forth several times

lock-to-lock to discharge the fluid from the steering gear

4. Rotate the input shaft to the left stop and then back-off approximately 45 degrees. Using an inch-pound torque

wrench on the input shaft, record the peak torque required to slowly and evenly rotate the input shaft clockwise

1⁄2turn (180 degrees) starting from the 45 degree position. This peak torque reading is the preload torque. The

preload torque must be within 2 - 10 in-lbs.

5. Rotate the input shaft to its center of travel (approximately 1.5 turns from either stop). Place the torque wrench

on the input shaft with the handle in the vertical position. Rotate the torque wrench slowly and evenly

1⁄4turn (90

degrees) each side of center and record the peak torque measure on or near center. This total on-center torque

reading must be 5 - 9 in-lbs higher than the previously measured preload torque without exceeding a total of 17

in-lbs. The value of the total on-center minus the preload torque is defined as the meshload torque

6. If required, adjust the on-center torque by loosening the adjuster screw lock nut and turning the adjuster screw

until the total on-center and meshload torque readings fall within the specified values. Turn the adjuster screw

clockwise to increase and counterclockwise to decrease the torque reading. While holding the adjuster screw in

place, tighten the lock nut to 34 Nꞏm (25 ft. lbs.).

7. Re-check the preload and on-center torque readings.

8. Install pitman arm on the steering gear (Refer to 19 - STEERING/LINKAGE/PITMAN ARM - INSTALLATION).

9. Reinstall steering gear to the vehicle (Refer to 19 - STEERING/GEAR - INSTALLATION).

SPECIFICATIONS

POWER STEERING GEAR

SPECIFICATIONS

DESCRIPTION SPECIFICATION

Steering Gear

Ty peRecirculating Ball

Gear Code & Ratio 12.5:1

TORQUE

DESCRIPTION Nꞏm Ft. Lbs. In. Lbs.

Preload

To r q u e0.23-1.13 — 2-10

Meshload Torque 0.56-1.02 — 5-9

+ Preload (17 Max)

Page 2453 of 5267

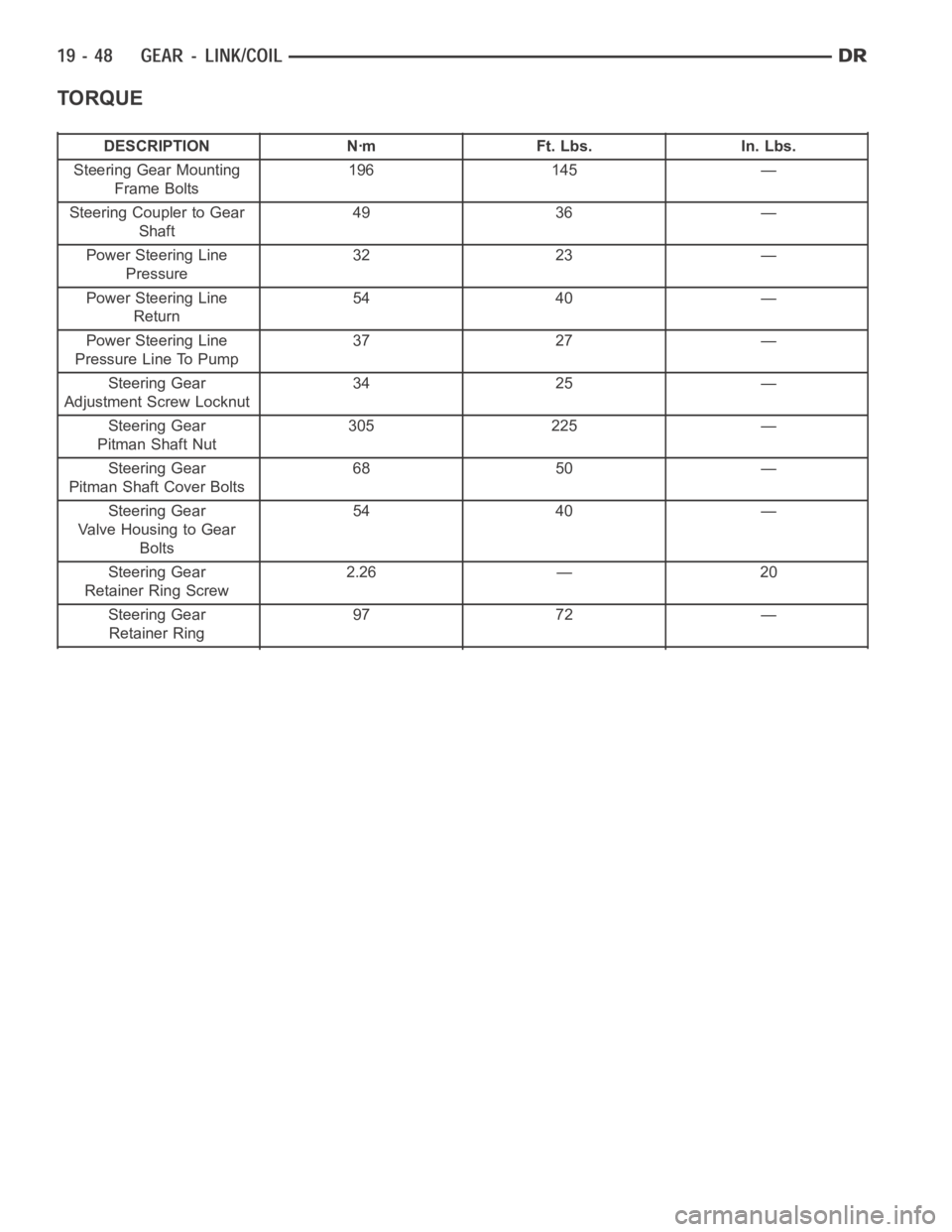

TORQUE

DESCRIPTION Nꞏm Ft. Lbs. In. Lbs.

Steering Gear Mounting

Frame Bolts196 145 —

Steering Coupler to Gear

Shaft49 36 —

Power Steering Line

Pressure32 23 —

Power Steering Line

Return54 40 —

Power Steering Line

Pressure Line To Pump37 27 —

Steering Gear

Adjustment Screw Locknut34 25 —

Steering Gear

Pitman Shaft Nut305 225 —

Steering Gear

Pitman Shaft Cover Bolts68 50 —

Steering Gear

Valve Housing to Gear

Bolts54 40 —

Steering Gear

Retainer Ring Screw2.26 — 20

Steering Gear

Retainer Ring97 72 —

Page 2462 of 5267

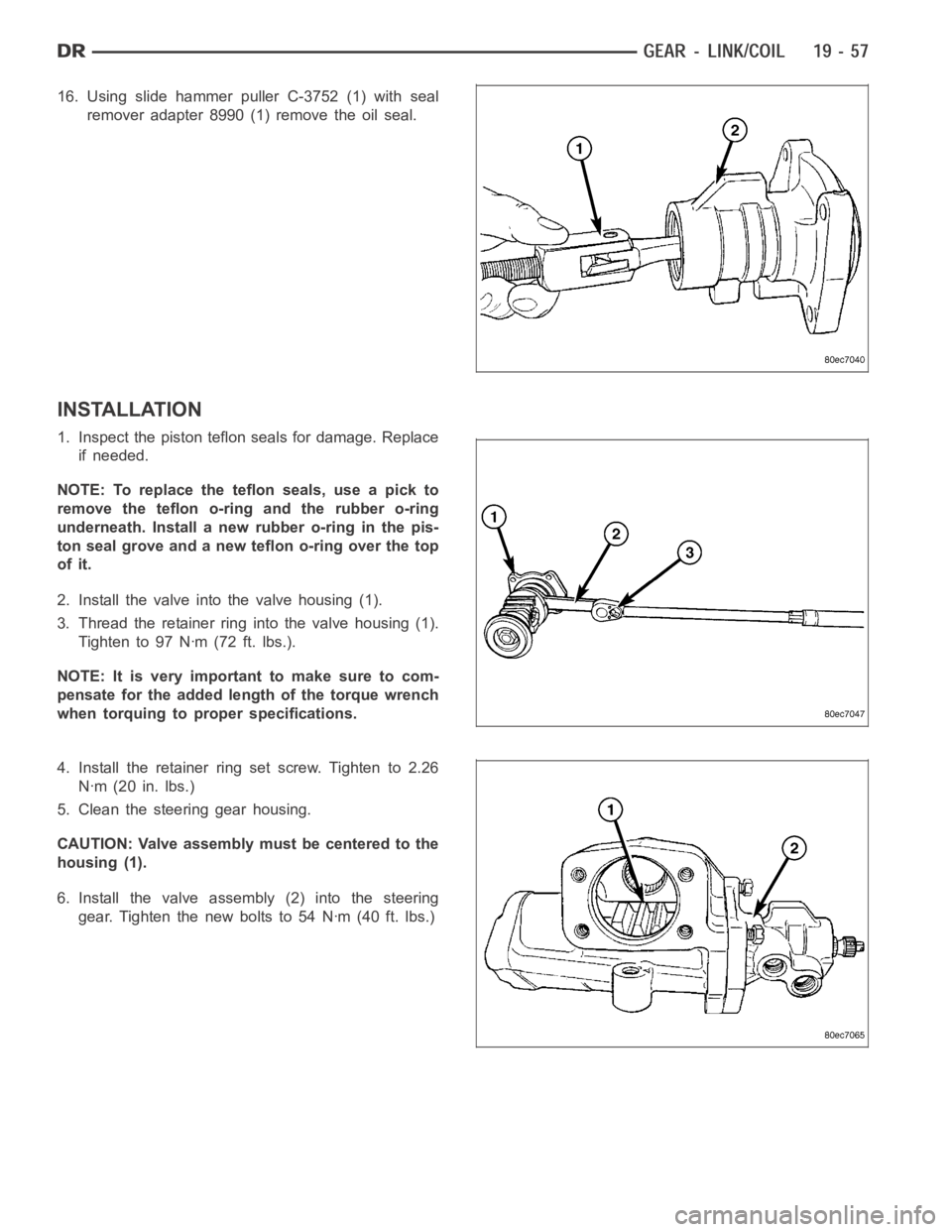

16. Using slide hammer puller C-3752 (1) with seal

remover adapter 8990 (1) remove the oil seal.

INSTALLATION

1. Inspect the piston teflon seals for damage. Replace

if needed.

NOTE: To replace the teflon seals, use a pick to

remove the teflon o-ring and the rubber o-ring

underneath. Install a new rubber o-ring in the pis-

ton seal grove and a new teflon o-ring over the top

of it.

2. Install the valve into the valve housing (1).

3. Threadtheretainerringintothevalvehousing(1).

Tightento97Nꞏm(72ft.lbs.).

NOTE: It is very important to make sure to com-

pensate for the added length of the torque wrench

when torquing to proper specifications.

4. Install the retainer ring set screw. Tighten to 2.26

Nꞏm (20 in. lbs.)

5. Clean the steering gear housing.

CAUTION: Valve assembly must be centered to the

housing (1).

6. Install the valve assembly (2) into the steering

gear. Tighten the new bolts to 54 Nꞏm (40 ft. lbs.)

Page 2471 of 5267

page page

LINKAGE - LINK/COIL

DESCRIPTION ................................ 67

STANDARD PROCEDURE

LUBRICATION .............................. 67

SPECIFICATIONS

TORQUE ................................... 68

SPECIAL TOOLS

STEERING LINKAGE ........................ 69

DAMPER

REMOVAL .................................... 70

INSTALLATION ............................... 70

DRAG LINK

REMOVAL .................................... 71INSTALLATION ............................... 71

PITMAN ARM

REMOVAL .................................... 72

INSTALLATION ............................... 73

TIE ROD END

REMOVAL .................................... 74

INSTALLATION ............................... 74

TRACK BAR

REMOVAL .................................... 75

INSTALLATION ............................... 75

Page 2473 of 5267

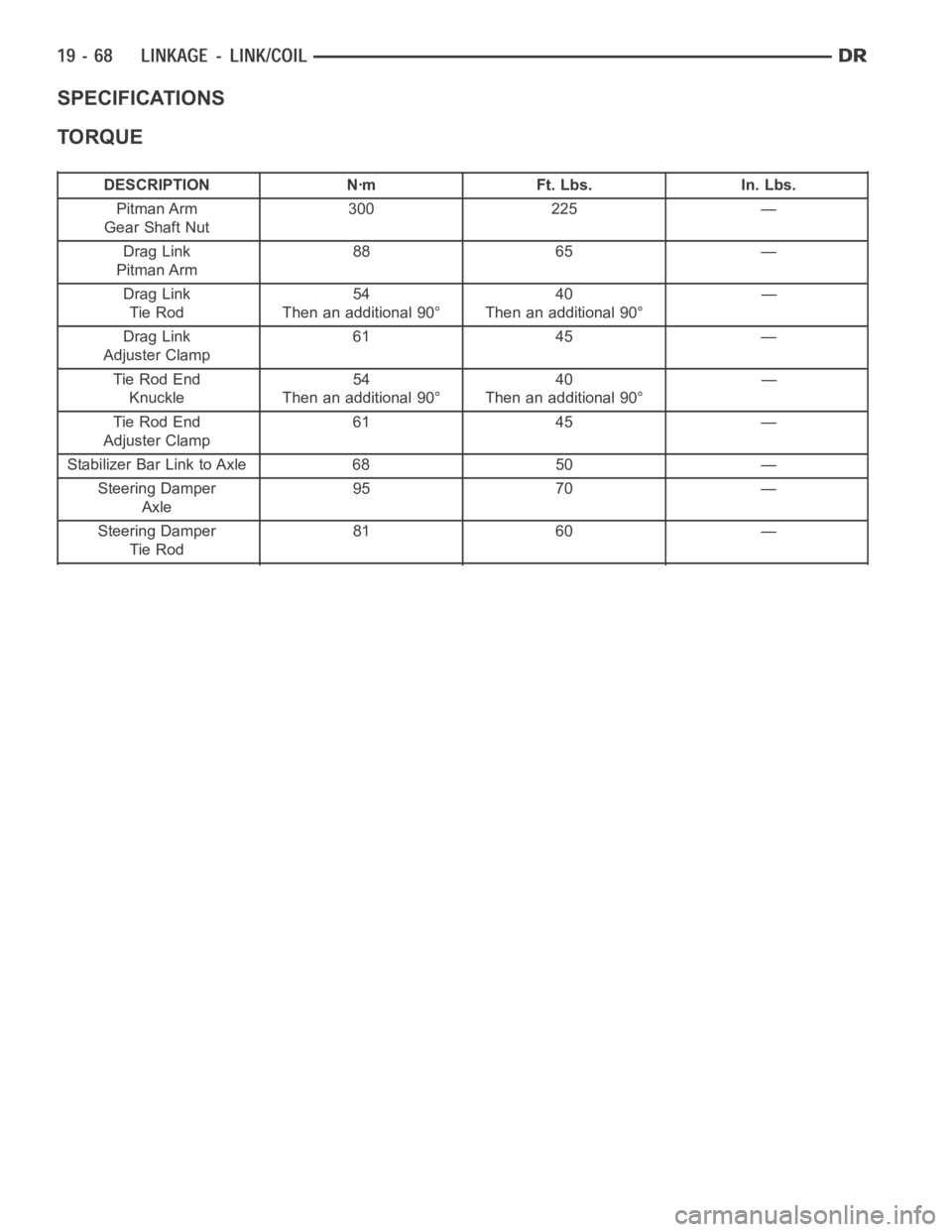

SPECIFICATIONS

TORQUE

DESCRIPTION Nꞏm Ft. Lbs. In. Lbs.

Pitman Arm

Gear Shaft Nut300 225 —

Drag Link

Pitman Arm88 65 —

Drag Link

Tie Rod54

Then an additional 90°40

Then an additional 90°—

Drag Link

Adjuster Clamp61 45 —

Tie Rod End

Knuckle54

Then an additional 90°40

Then an additional 90°—

Tie Rod End

Adjuster Clamp61 45 —

Stabilizer Bar Link to Axle 68 50 —

Steering Damper

Axle95 70 —

Steering Damper

Tie Rod81 60 —

Page 2481 of 5267

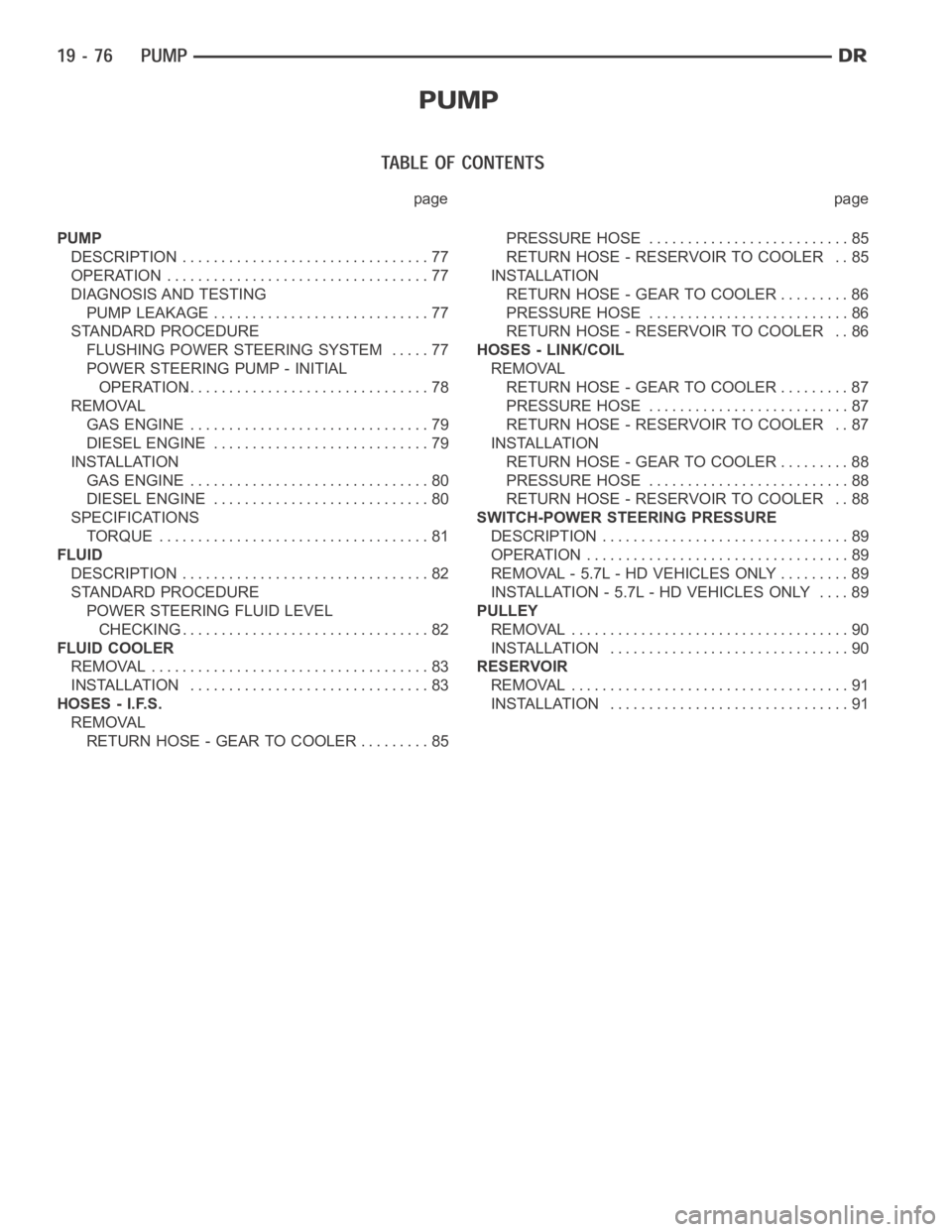

page page

PUMP

DESCRIPTION ................................ 77

OPERATION .................................. 77

DIAGNOSIS AND TESTING

PUMP LEAKAGE ............................ 77

STANDARD PROCEDURE

FLUSHING POWER STEERING SYSTEM . . . . . 77

POWER STEERING PUMP - INITIAL

OPERATION................................ 78

REMOVAL

GAS ENGINE ............................... 79

DIESEL ENGINE............................ 79

INSTALLATION

GAS ENGINE ............................... 80

DIESEL ENGINE............................ 80

SPECIFICATIONS

TORQUE ................................... 81

FLUID

DESCRIPTION ................................ 82

STANDARD PROCEDURE

POWER STEERING FLUID LEVEL

CHECKING................................. 82

FLUID COOLER

REMOVAL .................................... 83

INSTALLATION ............................... 83

HOSES - I.F.S.

REMOVAL

RETURN HOSE - GEAR TO COOLER ......... 85PRESSURE HOSE .......................... 85

RETURN HOSE - RESERVOIR TO COOLER . . 85

INSTALLATION

RETURN HOSE - GEAR TO COOLER ......... 86

PRESSURE HOSE .......................... 86

RETURN HOSE - RESERVOIR TO COOLER . . 86

HOSES - LINK/COIL

REMOVAL

RETURN HOSE - GEAR TO COOLER ......... 87

PRESSURE HOSE .......................... 87

RETURN HOSE - RESERVOIR TO COOLER . . 87

INSTALLATION

RETURN HOSE - GEAR TO COOLER ......... 88

PRESSURE HOSE .......................... 88

RETURN HOSE - RESERVOIR TO COOLER . . 88

SWITCH-POWER STEERING PRESSURE

DESCRIPTION ................................ 89

OPERATION .................................. 89

REMOVAL - 5.7L - HD VEHICLES ONLY ......... 89

INSTALLATION - 5.7L - HD VEHICLES ONLY .... 89

PULLEY

REMOVAL .................................... 90

INSTALLATION ............................... 90

RESERVOIR

REMOVAL .................................... 91

INSTALLATION ............................... 91

Page 2486 of 5267

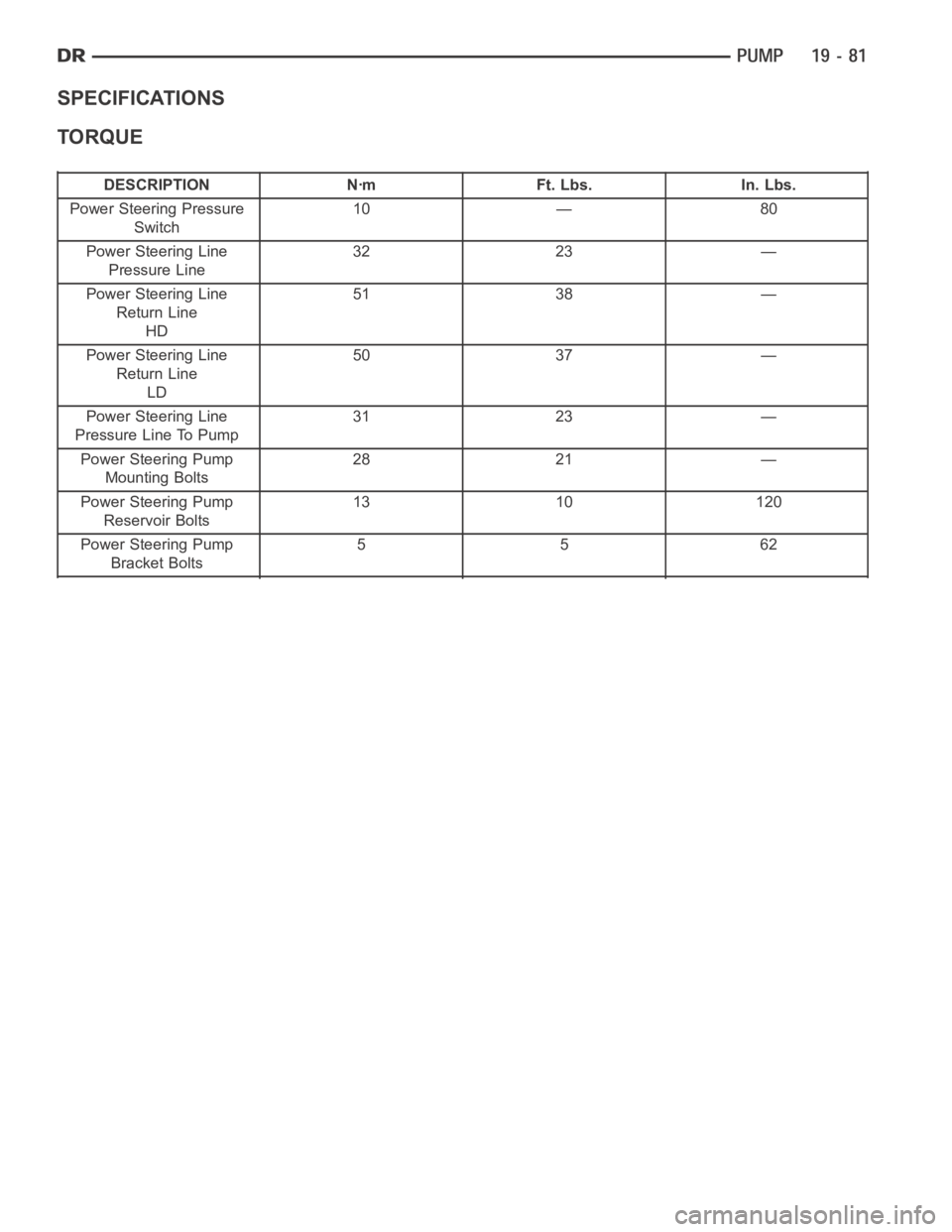

SPECIFICATIONS

TORQUE

DESCRIPTION Nꞏm Ft. Lbs. In. Lbs.

Power Steering Pressure

Switch10 — 80

Power Steering Line

Pressure Line32 23 —

Power Steering Line

Return Line

HD51 38 —

Power Steering Line

Return Line

LD50 37 —

Power Steering Line

Pressure Line To Pump31 23 —

Power Steering Pump

Mounting Bolts28 21 —

Power Steering Pump

Reservoir Bolts13 10 120

Power Steering Pump

Bracket Bolts5562