ECU DODGE RAM SRT-10 2006 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2179 of 5267

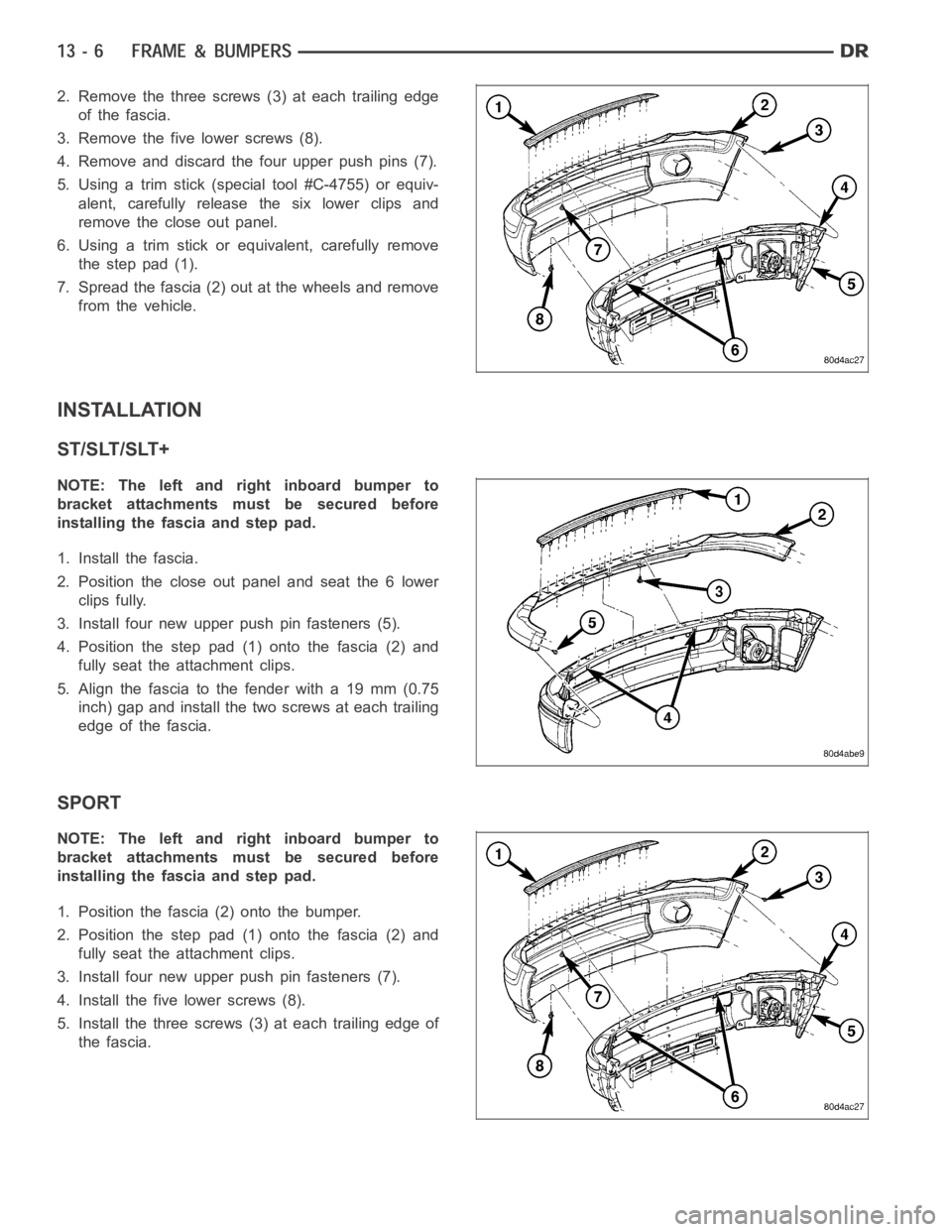

2. Remove the three screws (3) at each trailing edge

of the fascia.

3. Remove the five lower screws (8).

4. Remove and discard the four upper push pins (7).

5. Using a trim stick (special tool #C-4755) or equiv-

alent, carefully release the six lower clips and

remove the close out panel.

6. Using a trim stick or equivalent, carefully remove

the step pad (1).

7. Spread the fascia (2) out at the wheels and remove

from the vehicle.

INSTALLATION

ST/SLT/SLT+

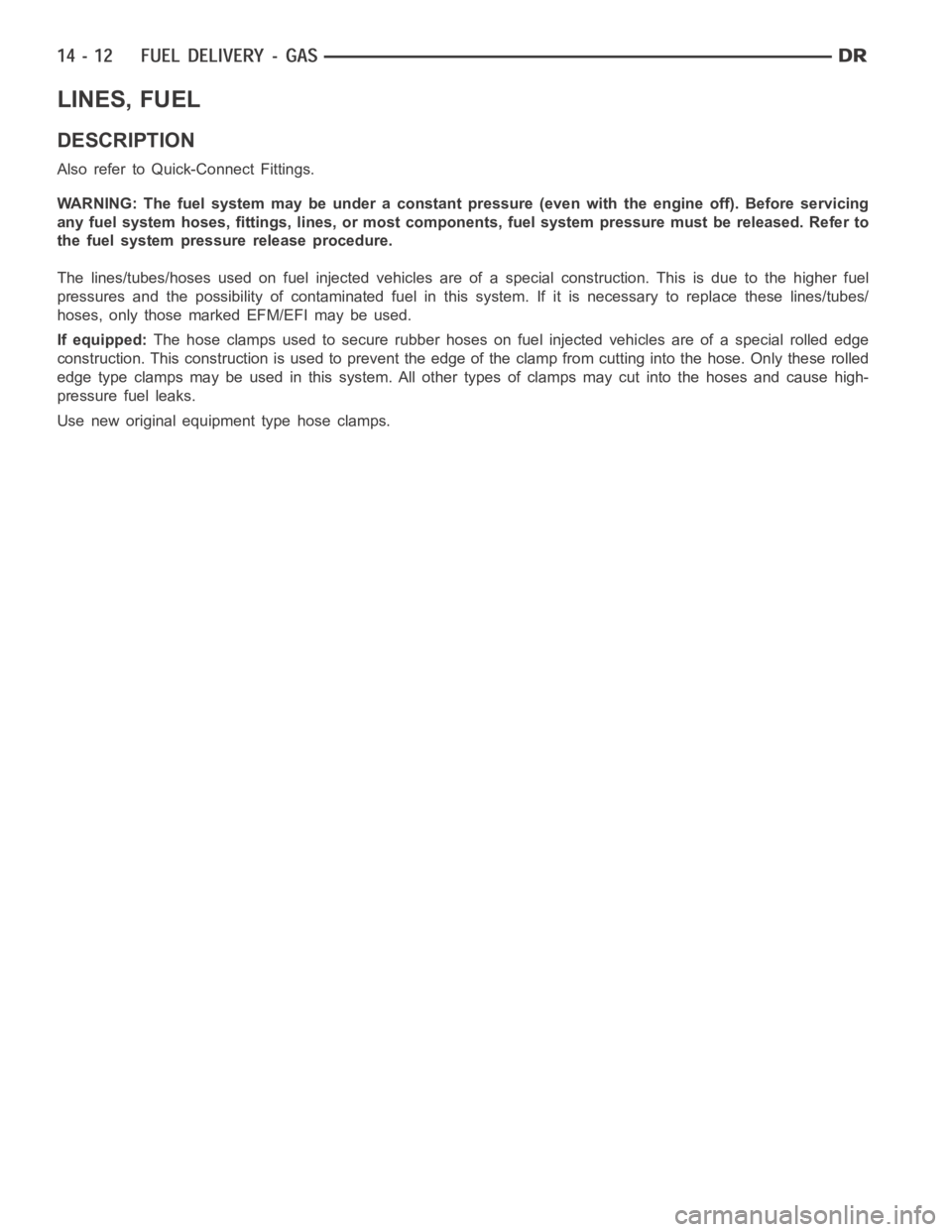

NOTE: The left and right inboard bumper to

bracket attachments must be secured before

installing the fascia and step pad.

1. Install the fascia.

2. Position the close out panel and seat the 6 lower

clips fully.

3. Install four new upper push pin fasteners (5).

4. Position the step pad (1) onto the fascia (2) and

fully seat the attachment clips.

5. Align the fascia to the fender with a 19 mm (0.75

inch) gap and install the two screws at each trailing

edge of the fascia.

SPORT

NOTE: The left and right inboard bumper to

bracket attachments must be secured before

installing the fascia and step pad.

1. Position the fascia (2) onto the bumper.

2. Position the step pad (1) onto the fascia (2) and

fully seat the attachment clips.

3. Install four new upper push pin fasteners (7).

4. Install the five lower screws (8).

5. Install the three screws (3) at each trailing edge of

the fascia.

Page 2249 of 5267

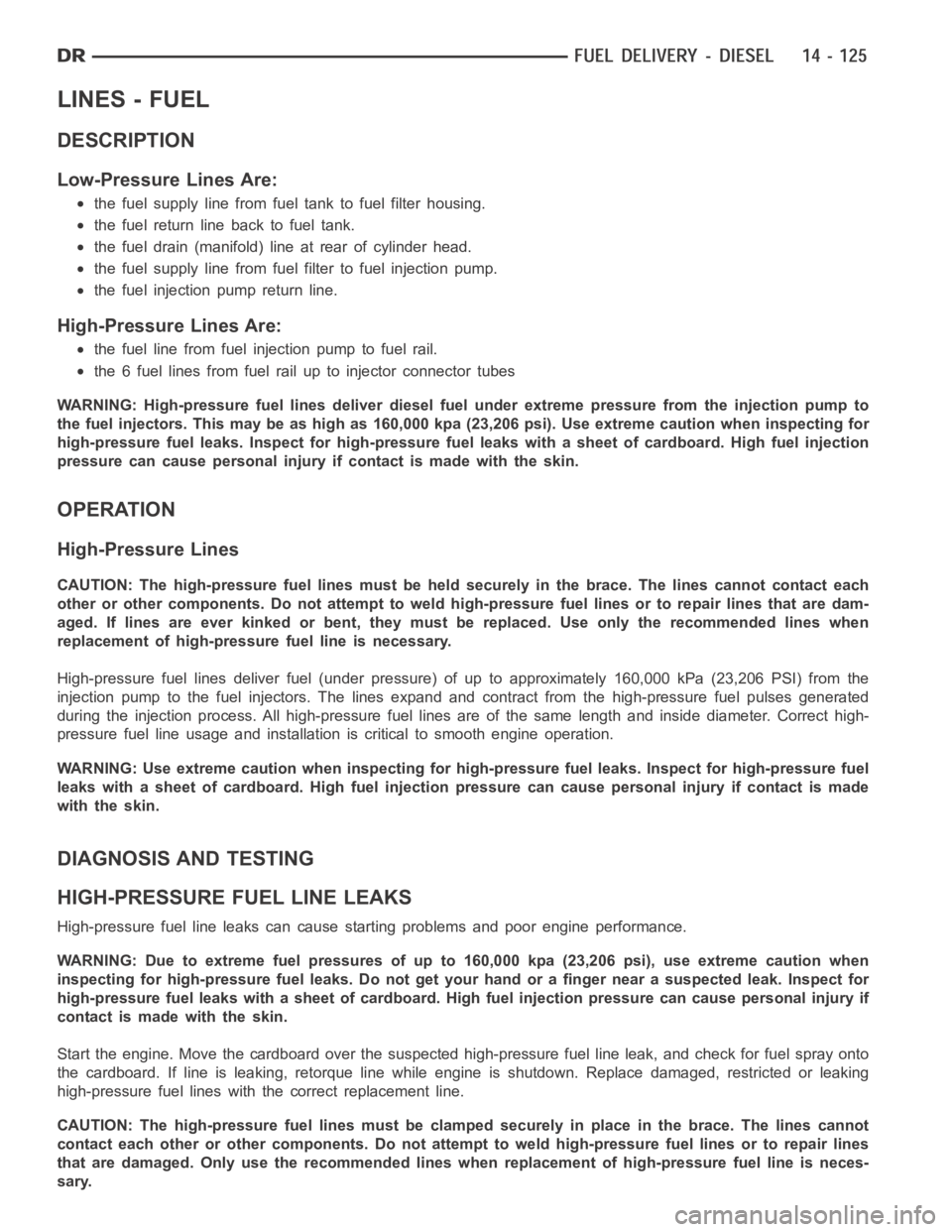

LINES, FUEL

DESCRIPTION

Also refer to Quick-Connect Fittings.

WARNING: The fuel system may be under a constant pressure (even with the engine off). Before servicing

any fuel system hoses, fittings, lines, or most components, fuel system pressure must be released. Refer to

the fuel system pressure release procedure.

The lines/tubes/hoses used on fuel injected vehicles are of a special construction. This is due to the higher fuel

pressures and the possibility of contaminated fuel in this system. If it isnecessary to replace these lines/tubes/

hoses, only those marked EFM/EFI may be used.

If equipped:The hose clamps used to secure rubber hoses on fuel injected vehicles are ofa special rolled edge

construction. This construction is used to prevent the edge of the clamp from cutting into the hose. Only these rolled

edge type clamps may be used in this system. All other types of clamps may cutinto the hoses and cause high-

pressure fuel leaks.

Use new original equipment type hose clamps.

Page 2362 of 5267

LINES - FUEL

DESCRIPTION

Low-Pressure Lines Are:

the fuel supply line from fuel tank to fuel filter housing.

the fuel return line back to fuel tank.

the fuel drain (manifold) line at rear of cylinder head.

the fuel supply line from fuel filter to fuel injection pump.

the fuel injection pump return line.

High-Pressure Lines Are:

the fuel line from fuel injection pump to fuel rail.

the 6 fuel lines from fuel rail up to injector connector tubes

WARNING: High-pressure fuel lines deliver diesel fuel under extreme pressure from the injection pump to

the fuel injectors. This may be as high as 160,000 kpa (23,206 psi). Use extreme caution when inspecting for

high-pressure fuel leaks. Inspect for high-pressure fuel leaks with a sheet of cardboard. High fuel injection

pressure can cause personal injury if contact is made with the skin.

OPERATION

High-Pressure Lines

CAUTION: The high-pressure fuel lines must be held securely in the brace. The lines cannot contact each

other or other components. Do not attempt to weld high-pressure fuel linesor to repair lines that are dam-

aged. If lines are ever kinked or bent, they must be replaced. Use only the recommended lines when

replacement of high-pressure fuel line is necessary.

High-pressure fuel lines deliver fuel (under pressure) of up to approximately 160,000 kPa (23,206 PSI) from the

injection pump to the fuel injectors. The lines expand and contract from the high-pressure fuel pulses generated

during the injection process. All high-pressure fuel lines are of the samelength and inside diameter. Correct high-

pressure fuel line usage and installation is critical to smooth engine operation.

WARNING: Use extreme caution when inspecting for high-pressure fuel leaks. Inspect for high-pressure fuel

leaks with a sheet of cardboard. High fuel injection pressure can cause personal injury if contact is made

with the skin.

DIAGNOSIS AND TESTING

HIGH-PRESSURE FUEL LINE LEAKS

High-pressure fuel line leaks can cause starting problems and poor engineperformance.

WARNING: Due to extreme fuel pressures of up to 160,000 kpa (23,206 psi), use extreme caution when

inspecting for high-pressure fuel leaks. Do not get your hand or a finger near a suspected leak. Inspect for

high-pressure fuel leaks with a sheet of cardboard. High fuel injection pressure can cause personal injury if

contact is made with the skin.

Start the engine. Move the cardboard over the suspected high-pressure fuel line leak, and check for fuel spray onto

the cardboard. If line is leaking, retorque line while engine is shutdown.Replace damaged, restricted or leaking

high-pressure fuel lines with the correct replacement line.

CAUTION: The high-pressure fuel lines must be clamped securely in place inthe brace. The lines cannot

contact each other or other components. Do not attempt to weld high-pressure fuel lines or to repair lines

that are damaged. Only use the recommended lines when replacement of high-pressure fuel line is neces-

sary.

Page 2363 of 5267

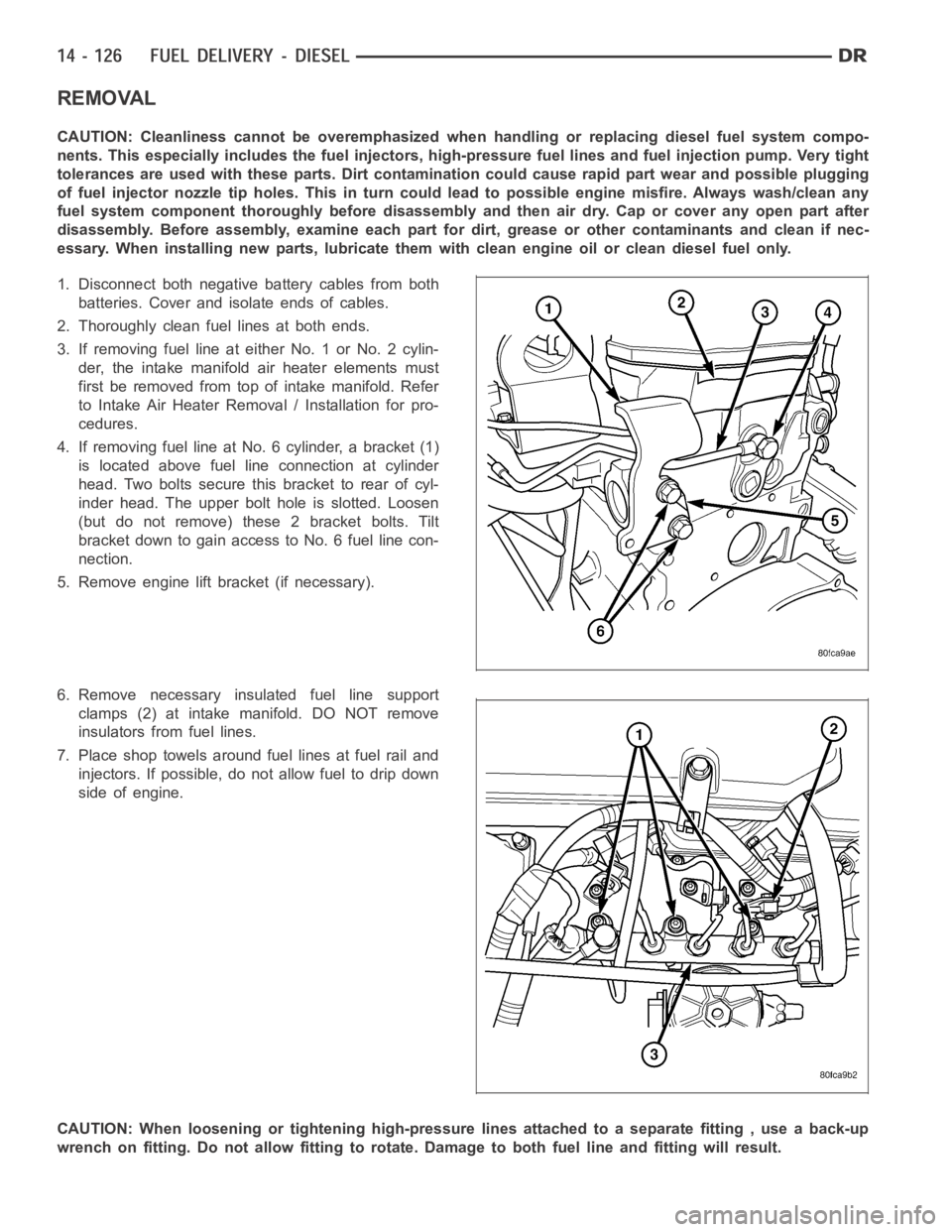

REMOVAL

CAUTION: Cleanliness cannot be overemphasized when handling or replacingdieselfuelsystemcompo-

nents. This especially includes the fuel injectors, high-pressure fuel lines and fuel injection pump. Very tight

tolerances are used with these parts. Dirt contamination could cause rapid part wear and possible plugging

of fuel injector nozzle tip holes. This in turn could lead to possible engine misfire. Always wash/clean any

fuel system component thoroughly before disassembly and then air dry. Capor cover any open part after

disassembly. Before assembly, examine each part for dirt, grease or othercontaminants and clean if nec-

essary. When installing new parts, lubricate them with clean engine oil orclean diesel fuel only.

1. Disconnect both negative battery cables from both

batteries. Cover and isolate ends of cables.

2. Thoroughly clean fuel lines at both ends.

3. If removing fuel line at either No. 1 or No. 2 cylin-

der, the intake manifold air heater elements must

first be removed from top of intake manifold. Refer

to Intake Air Heater Removal / Installation for pro-

cedures.

4. If removing fuel line at No. 6 cylinder, a bracket (1)

is located above fuel line connection at cylinder

head. Two bolts secure this bracket to rear of cyl-

inder head. The upper bolt hole is slotted. Loosen

(but do not remove) these 2 bracket bolts. Tilt

bracket down to gain access to No. 6 fuel line con-

nection.

5. Remove engine lift bracket (if necessary).

6. Remove necessary insulated fuel line support

clamps (2) at intake manifold. DO NOT remove

insulators from fuel lines.

7. Place shop towels around fuel lines at fuel rail and

injectors. If possible, do not allow fuel to drip down

side of engine.

CAUTION: When loosening or tightening high-pressure lines attached to a separate fitting , use a back-up

wrench on fitting. Do not allow fitting to rotate. Damage to both fuel line and fitting will result.

Page 2387 of 5267

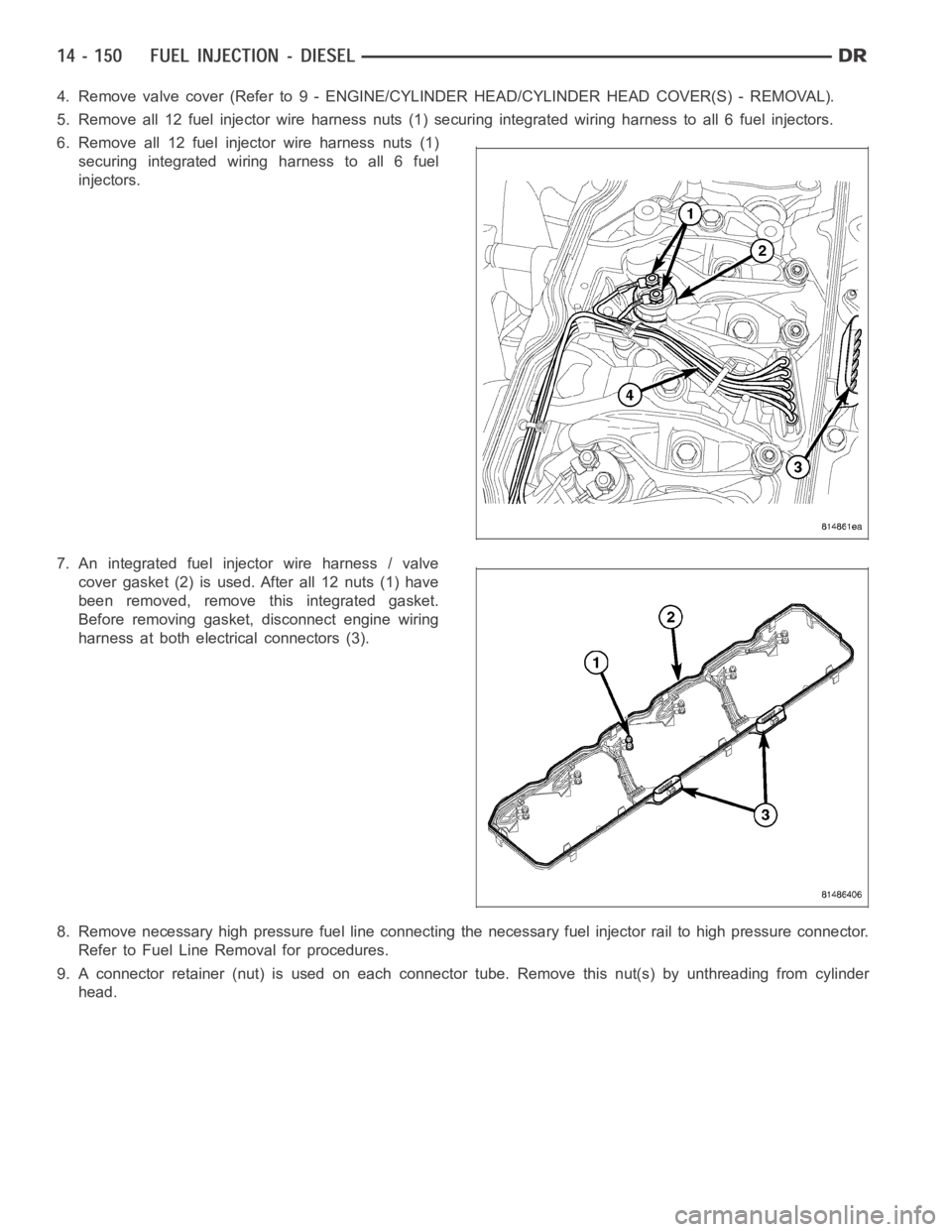

4. Remove valve cover (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) - REMOVAL).

5. Remove all 12 fuel injector wire harness nuts (1) securing integrated wiring harness to all 6 fuel injectors.

6. Remove all 12 fuel injector wire harness nuts (1)

securing integrated wiring harness to all 6 fuel

injectors.

7. An integrated fuel injector wire harness / valve

cover gasket (2) is used. After all 12 nuts (1) have

been removed, remove this integrated gasket.

Before removing gasket, disconnect engine wiring

harness at both electrical connectors (3).

8. Remove necessary high pressure fuel line connecting the necessary fuelinjector rail to high pressure connector.

Refer to Fuel Line Removal for procedures.

9. A connector retainer (nut) is used on each connector tube. Remove this nut(s) by unthreading from cylinder

head.

Page 2415 of 5267

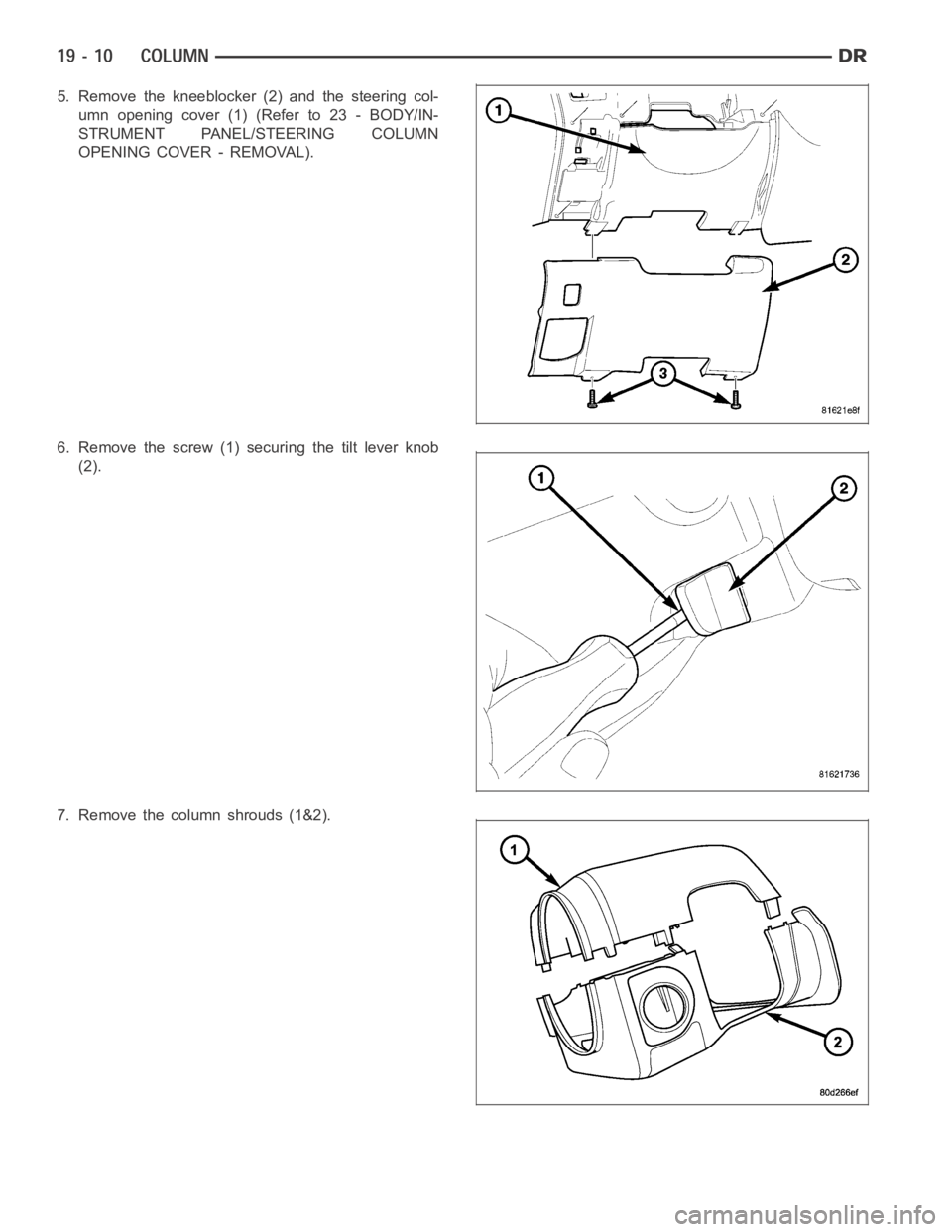

5. Remove the kneeblocker (2) and the steering col-

umn opening cover (1) (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN

OPENING COVER - REMOVAL).

6. Remove the screw (1) securing the tilt lever knob

(2).

7. Remove the column shrouds (1&2).

Page 2430 of 5267

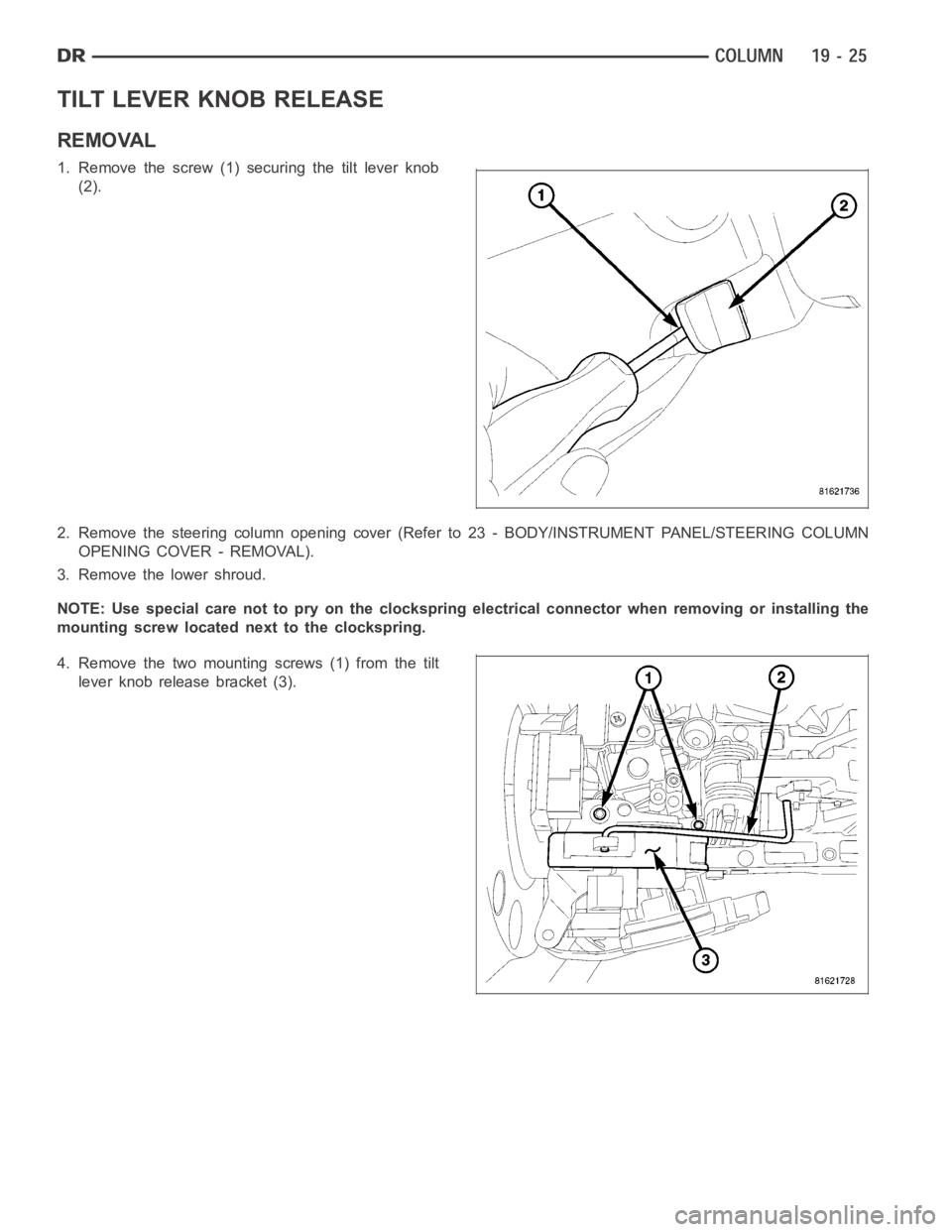

TILT LEVER KNOB RELEASE

REMOVAL

1. Remove the screw (1) securing the tilt lever knob

(2).

2. Remove the steering column opening cover (Refer to 23 - BODY/INSTRUMENTPANEL/STEERING COLUMN

OPENING COVER - REMOVAL).

3. Remove the lower shroud.

NOTE: Use special care not to pry on the clockspring electrical connector whenremovingorinstallingthe

mounting screw located next to the clockspring.

4. Remove the two mounting screws (1) from the tilt

lever knob release bracket (3).

Page 2437 of 5267

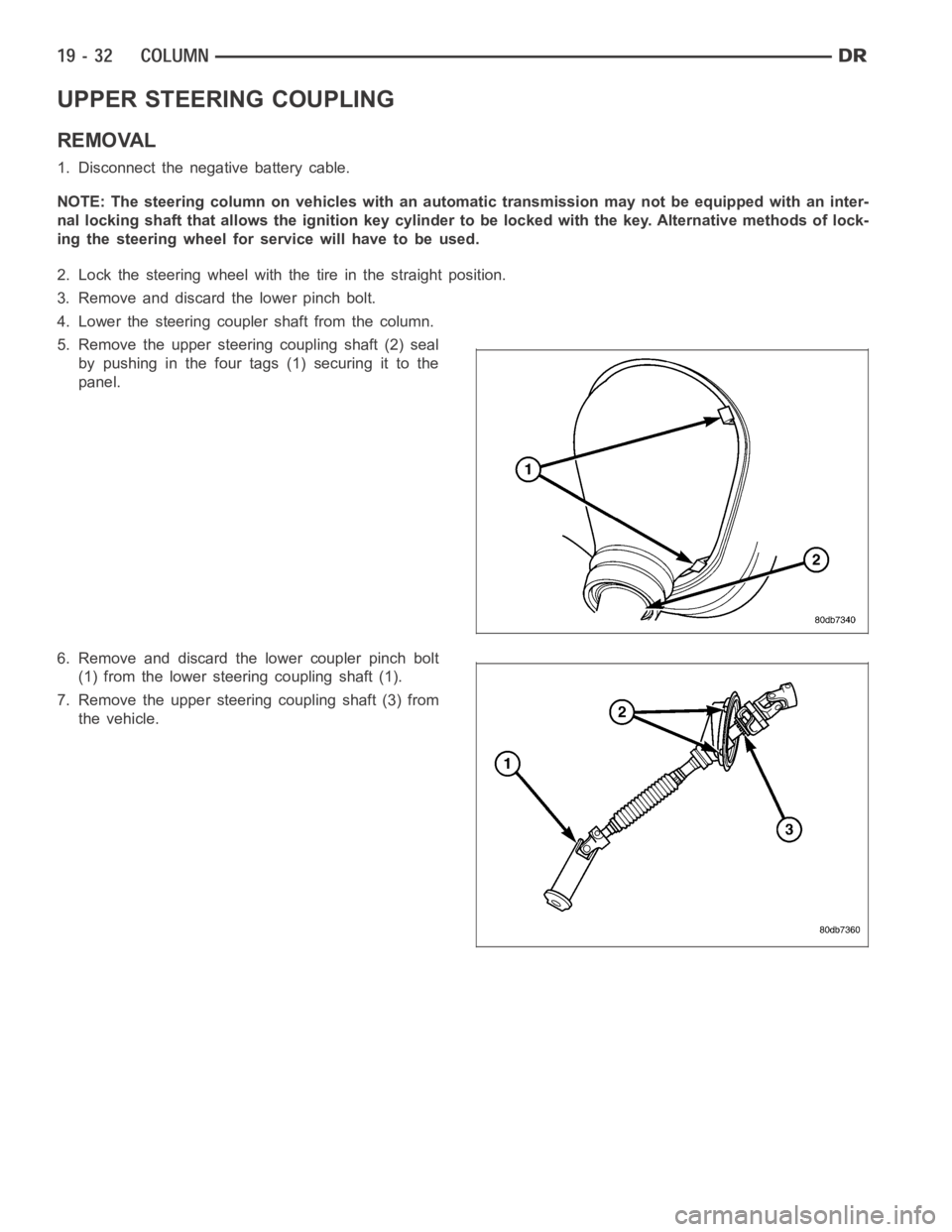

UPPER STEERING COUPLING

REMOVAL

1. Disconnect the negative battery cable.

NOTE: The steering column on vehicles with an automatic transmission may not be equipped with an inter-

nal locking shaft that allows the ignition key cylinder to be locked with the key. Alternative methods of lock-

ing the steering wheel for service will have to be used.

2. Lock the steering wheel with the tire in the straight position.

3. Remove and discard the lower pinch bolt.

4. Lower the steering coupler shaft from the column.

5. Remove the upper steering coupling shaft (2) seal

by pushing in the four tags (1) securing it to the

panel.

6. Remove and discard the lower coupler pinch bolt

(1) from the lower steering coupling shaft (1).

7. Remove the upper steering coupling shaft (3) from

the vehicle.

Page 2438 of 5267

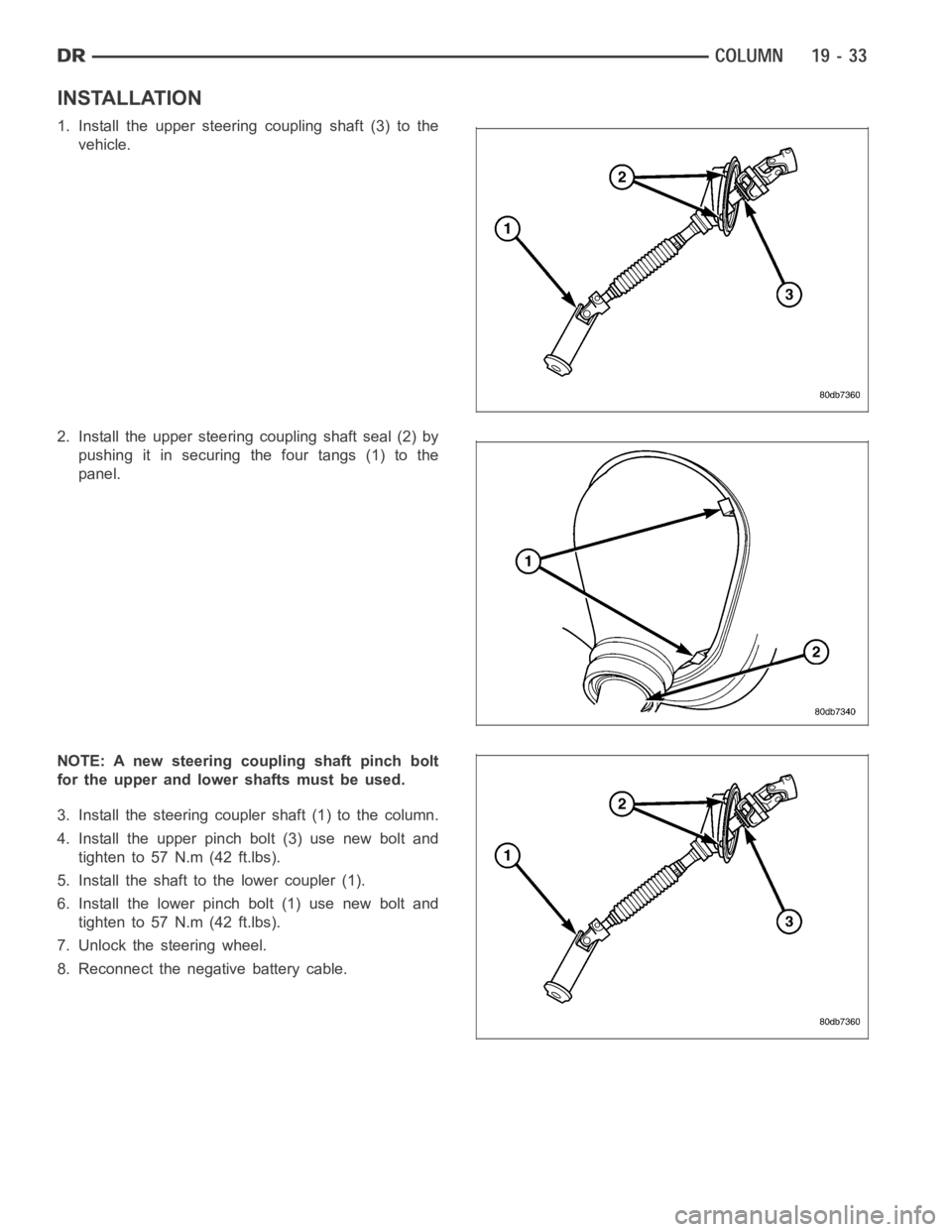

INSTALLATION

1. Install the upper steering coupling shaft (3) to the

vehicle.

2. Install the upper steering coupling shaft seal (2) by

pushing it in securing the four tangs (1) to the

panel.

NOTE: A new steering coupling shaft pinch bolt

for the upper and lower shafts must be used.

3. Install the steering coupler shaft (1) to the column.

4. Install the upper pinch bolt (3) use new bolt and

tighten to 57 N.m (42 ft.lbs).

5. Install the shaft to the lower coupler (1).

6. Install the lower pinch bolt (1) use new bolt and

tighten to 57 N.m (42 ft.lbs).

7. Unlock the steering wheel.

8. Reconnect the negative battery cable.

Page 2459 of 5267

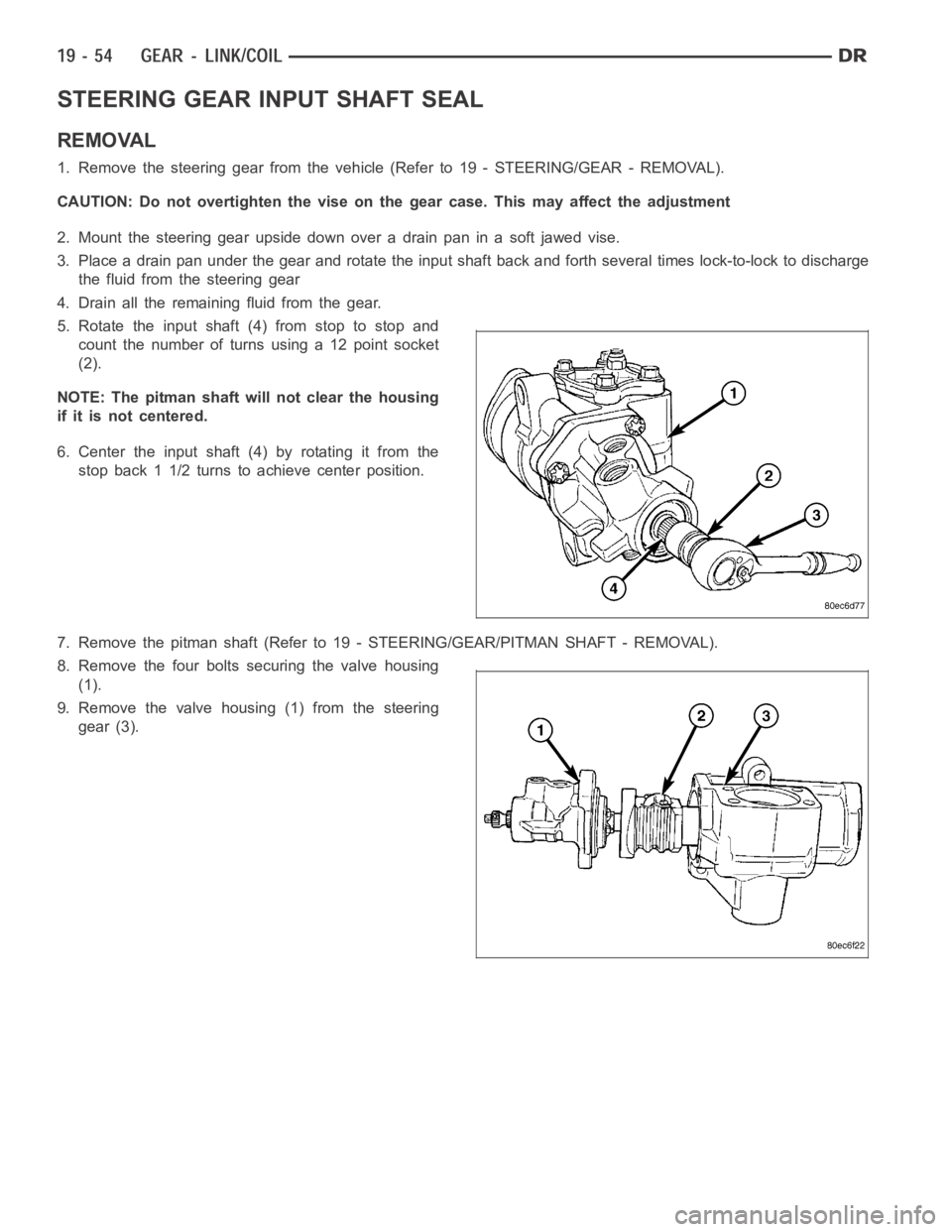

STEERING GEAR INPUT SHAFT SEAL

REMOVAL

1. Remove the steering gear from the vehicle(Referto19-STEERING/GEAR-REMOVAL).

CAUTION: Do not overtighten the vise on the gear case. This may affect the adjustment

2. Mount the steering gear upside down over a drain pan in a soft jawed vise.

3. Place a drain pan under the gear and rotate the input shaft back and forth several times lock-to-lock to discharge

the fluid from the steering gear

4. Drain all the remaining fluid from the gear.

5. Rotate the input shaft (4) from stop to stop and

count the number of turns using a 12 point socket

(2).

NOTE: The pitman shaft will not clear the housing

if it is not centered.

6. Center the input shaft (4) by rotating it from the

stop back 1 1/2 turns to achieve center position.

7. Remove the pitman shaft (Refer to 19 - STEERING/GEAR/PITMAN SHAFT - REMOVA L ) .

8. Remove the four bolts securing the valve housing

(1).

9. Remove the valve housing (1) from the steering

gear (3).