ECU DODGE RAM SRT-10 2006 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1304 of 5267

4.GATEWAY MODULE

Turn the ignition off.

Replace and program the Gateway Module in accordance with Service Information.

Ignition on, engine not running.

With the scan tool, erase all SKREEM and PCM DTCs.

Attempt to start and idle the engine.

With the scan tool, read the Gateway Module DTCs.

Does the scan tool display this code?

Ye s>>

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or termi-

nal push out. Repair as necessary. Replace and program the Powertrain Control Module per Service

Information.

Perform SKREEM VERIFICATION. (Refer to 8 - ELECTRICAL/VEHICLE THEFT SECURITY - STAN-

DARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 1410 of 5267

When Monitored:

Engine running or cranking.

Set Condition:

When the failure counter reaches 20 for 2 consecutive trips.

Possible Causes

GOOD TRIP EQUAL TO ZERO

CMP WIRE HARNESS INSPECTION

TONE WHEEL/PULSE RING INSPECTION

CKP WIRE HARNESS INSPECTION

TONE WHEEL/PULSE RING INSPECTION

CHECKING INTERMITTENT CKP SIGNAL WITH LAB SCOPE

CAMSHAFT POSITION SENSOR

CRANKSHAFT POSITION SENSOR

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

1.GOOD TRIP EQUAL TO ZERO

Ignition on, engine not running.

WARNING: When the engine is operating, do not stand in a direct line with thefan. Do not put your hand

near the pulleys, belts, or fan. Do not wear loose clothing.

With the scan tool, read DTCs and record the related Freeze Frame data.

Start the engine and run until operating temp is reached. (Closed Loop)

If the DTC does not return right away it may be necessary to test drive the vehicle to duplicate the DTC.

Does the P1391 return?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITIONSymptom (Diagnostic Procedure).

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.INTERMITTENT CAM POSITION SENSOR SIGNAL

Turn the ignition off.

With the scan tool as a Dual Channel Lab Scope and Miller special tool #6801,backprobe the (K44) CMP Signal

circuit in the CMP harness connector and PCM harness connector.

WARNING: When the engine is operating, do not stand in a direct line with thefan. Do not put your hand

near the pulleys, belts, or fan. Do not wear loose clothing.

Start the engine.

Observe the lab scope screen.

Are there any irregular or missing signals?

Ye s>>

Go To 3

No>>

Go To 6

Page 1482 of 5267

When Monitored:

With the ignition on.

Set Condition:

If the Gateway Module looses communication with the Anti-Lock Brake Module.

Refer to U0121-LOST COMMUNICATION WITH ANTI-LOCK BRAKE MODULE(in 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES - DIAGNOSIS AND TESTING)for the diagnostic test procedure.

U0155–LOST COMMUNICATION WITH CLUSTER/CCN (GATEWAY)

For a complete wiring diagramRefer to Section 8W.

When Monitored:

With the ignition on.

Set Condition:

If the Gateway Module looses communication with the Cluster (CCN).

Refer to U0155-LOST COMMUNICATION WITH CLUSTER/CCN(in 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - DIAGNOSIS AND TESTING)for the diagnostic test procedure.

U0168–LOST COMMUNICATION WITHVEHICLE SECURITY CONTROL MODULE -

SKREEM/WCM (GATEWAY)

For a complete wiring diagramRefer to Section 8W.

When Monitored:

With the ignition on.

Set Condition:

If the Gateway Module looses communication with the Vehicle Security Control Module (SKREEM/WCM).

Refer to U0168-LOST COMMUNICATION WITH VEHICLE SECURITY CONTROL MODULE (SKREEM/WCM)(in 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES - DIAGNOSIS AND TESTING)for the diagnostic test proce-

dure.

STANDARD PROCEDURE

Page 1496 of 5267

MoparGasket Maker is an anaerobic type gasket material. The material cures in the absence of air when

squeezed between two metallic surfaces. It will not cure if left in the uncovered tube. The anaerobic material is for

use between two machined surfaces. Do not use on flexible metal flanges.

MOPAR

GASKET SEALANT

Mopar

Gasket Sealant is a slow drying, permanently soft sealer. This material isrecommended for sealing

threaded fittings and gaskets against leakage of oil and coolant. Can be used on threaded and machined parts

under all temperatures. This material is used on engines with multi-layersteel (MLS) cylinder head gaskets. This

material also will prevent corrosion. Mopar

Gasket Sealant is available in a 13 oz. aerosol can or 4oz./16 oz. can

w/applicator.

FORM-IN-PLACE GASKET AND SEALER APPLICATION

Assembling parts using a form-in-place gasket requires care but it’s easier than using precut gaskets.

Mopar

Gasket Maker material should be applied sparingly 1 mm (0.040 in.) diameter or less of sealant to one

gasket surface. Be certain the material surrounds each mounting hole. Excess material can easily be wiped off.

Components should be torqued in place within 15 minutes. The use of a locating dowel is recommended during

assembly to prevent smearing material off the location.

Mopar

Engine RTV GEN II or ATF RTV gasket material should be applied in a continuous bead approximately 3

mm (0.120 in.) in diameter. All mounting holes must be circled. For corner sealing, a 3.17 or 6.35 mm (1/8 or 1/4 in.)

drop is placed in the center of the gasket contact area. Uncured sealant maybe removed with a shop towel. Com-

ponents should be torqued in place while the sealant is still wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to prevent smearing material off the location.

Mopar

Gasket Sealant in an aerosol can should be applied using a thin, even coat sprayed completely over both

surfaces to be joined, and both sides of a gasket. Then proceed with assembly. Material in a can w/applicator can

be brushed on evenly over the sealing surfaces. Material in an aerosol can shouldbeusedonengineswithmulti-

layer steel gaskets.

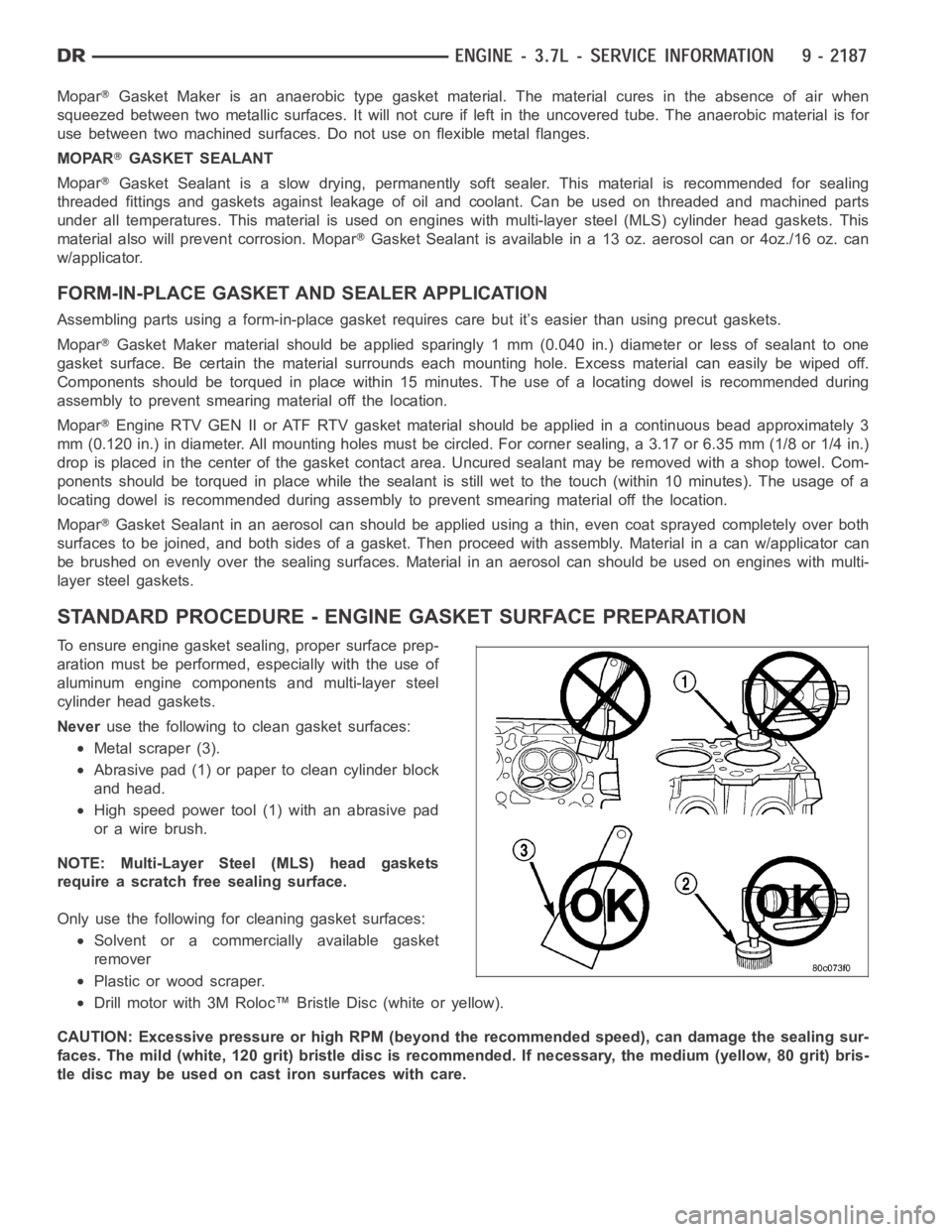

STANDARD PROCEDURE - ENGINE GASKET SURFACE PREPARATION

To ensure engine gasket sealing, proper surface prep-

aration must be performed, especially with the use of

aluminum engine components and multi-layer steel

cylinder head gaskets.

Neveruse the following to clean gasket surfaces:

Metal scraper (3).

Abrasive pad (1) or paper to clean cylinder block

and head.

High speed power tool (1) with an abrasive pad

orawirebrush.

NOTE: Multi-Layer Steel (MLS) head gaskets

require a scratch free sealing surface.

Only use the following for cleaning gasket surfaces:

Solvent or a commercially available gasket

remover

Plastic or wood scraper.

Drill motor with 3M Roloc™ Bristle Disc (white or yellow).

CAUTION: Excessive pressure or high RPM (beyond the recommended speed), can damage the sealing sur-

faces. The mild (white, 120 grit) bristle disc is recommended. If necessary, the medium (yellow, 80 grit) bris-

tle disc may be used on cast iron surfaces with care.

Page 1497 of 5267

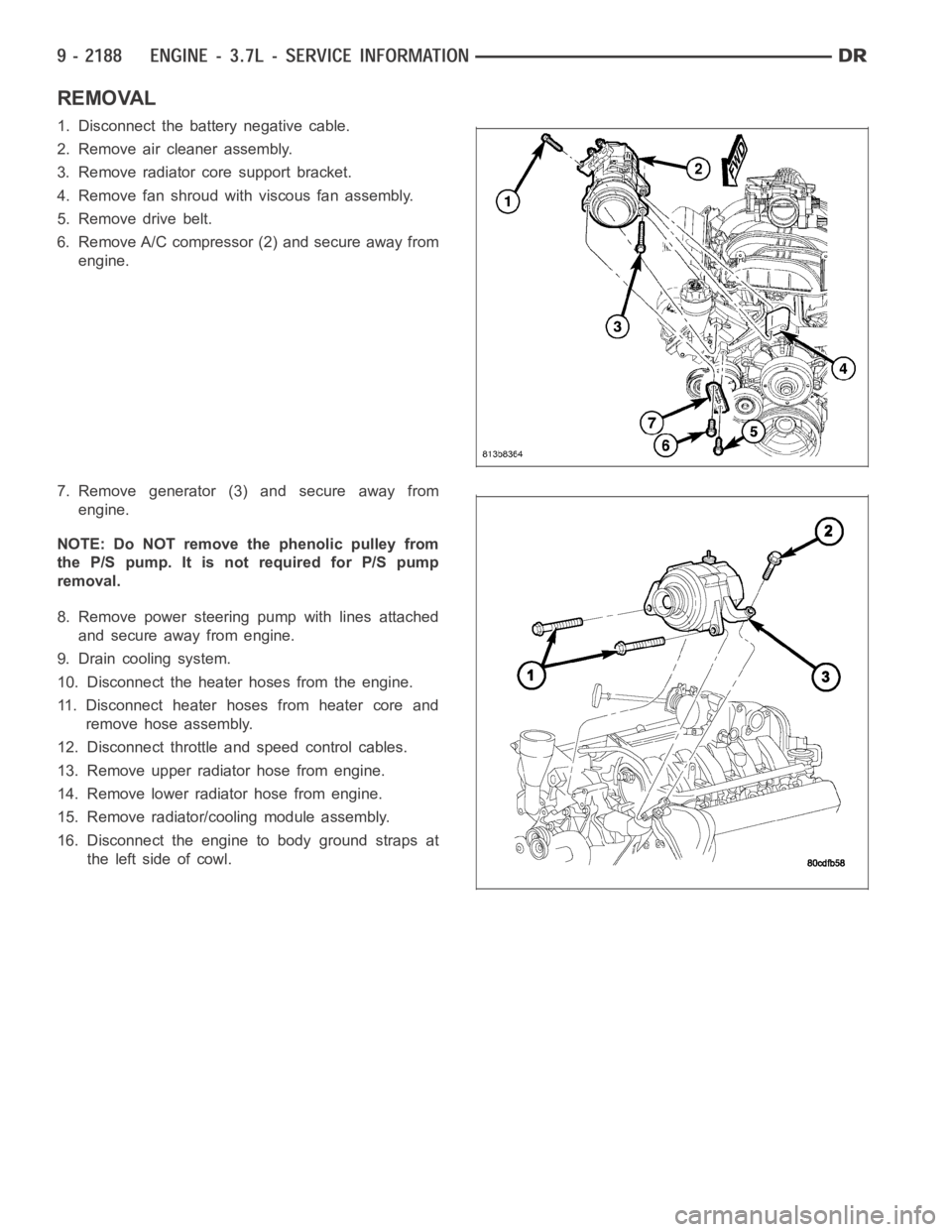

REMOVAL

1. Disconnect the battery negative cable.

2. Remove air cleaner assembly.

3. Remove radiator core support bracket.

4. Remove fan shroud with viscous fan assembly.

5. Remove drive belt.

6. Remove A/C compressor (2) and secure away from

engine.

7. Remove generator (3) and secure away from

engine.

NOTE: Do NOT remove the phenolic pulley from

the P/S pump. It is not required for P/S pump

removal.

8. Remove power steering pump with lines attached

and secure away from engine.

9. Drain cooling system.

10. Disconnect the heater hoses from the engine.

11. Disconnect heater hoses from heater core and

remove hose assembly.

12. Disconnect throttle and speed control cables.

13. Remove upper radiator hose from engine.

14. Remove lower radiator hose from engine.

15. Remove radiator/cooling module assembly.

16. Disconnect the engine to body ground straps at

theleftsideofcowl.

Page 1498 of 5267

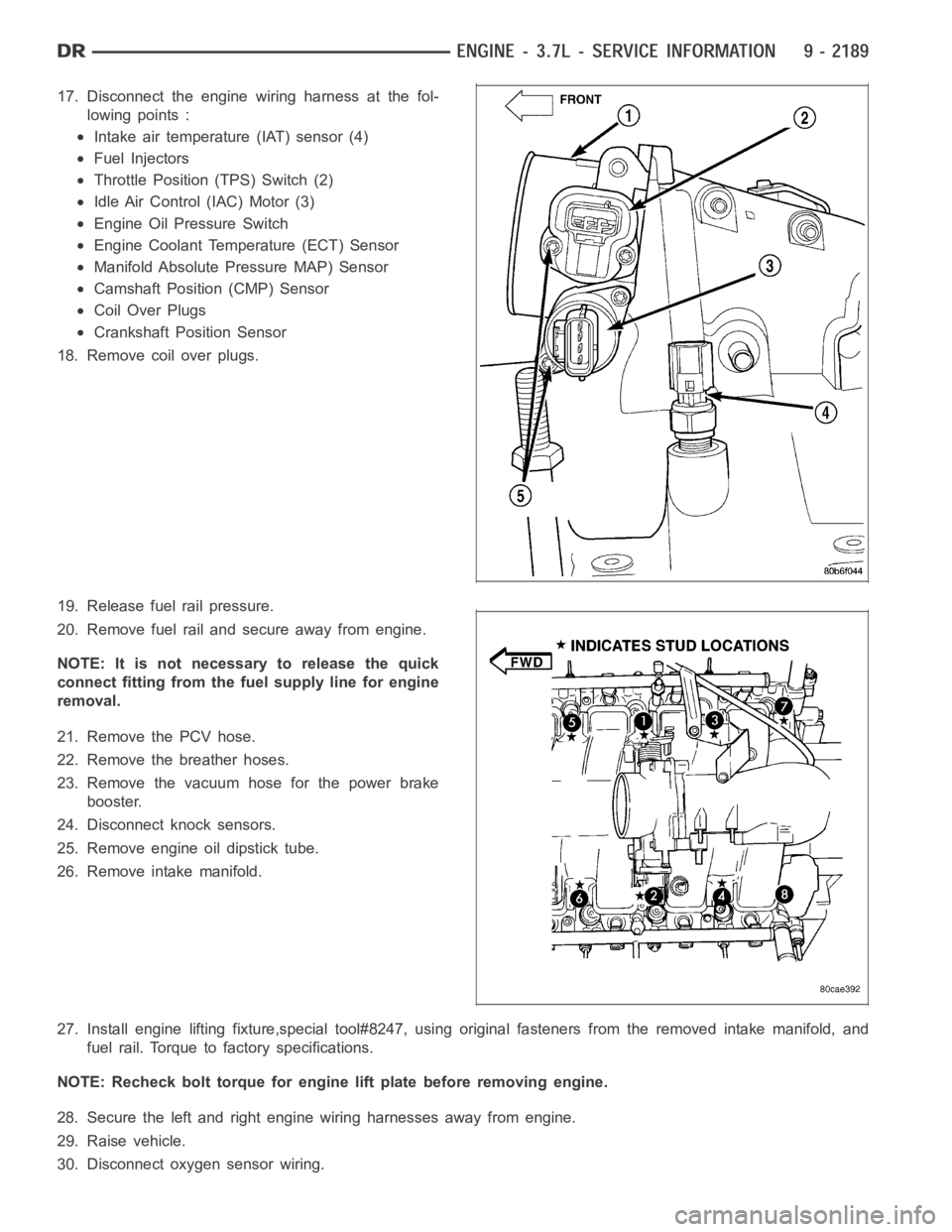

17. Disconnect the engine wiring harness at the fol-

lowing points :

Intake air temperature (IAT) sensor (4)

Fuel Injectors

Throttle Position (TPS) Switch (2)

Idle Air Control (IAC) Motor (3)

Engine Oil Pressure Switch

Engine Coolant Temperature (ECT) Sensor

Manifold Absolute Pressure MAP) Sensor

Camshaft Position (CMP) Sensor

Coil Over Plugs

Crankshaft Position Sensor

18. Remove coil over plugs.

19. Release fuel rail pressure.

20. Remove fuel rail and secure away from engine.

NOTE: It is not necessary to release the quick

connect fitting from the fuel supply line for engine

removal.

21. Remove the PCV hose.

22. Remove the breather hoses.

23. Remove the vacuum hose for the power brake

booster.

24. Disconnect knock sensors.

25. Remove engine oil dipstick tube.

26. Remove intake manifold.

27. Install engine lifting fixture,special tool#8247, using original fasteners from the removed intake manifold, and

fuel rail. Torque to factory specifications.

NOTE: Recheck bolt torque for engine lift plate before removing engine.

28. Secure the left and right engine wiring harnesses away from engine.

29. Raise vehicle.

30. Disconnect oxygen sensor wiring.

Page 1499 of 5267

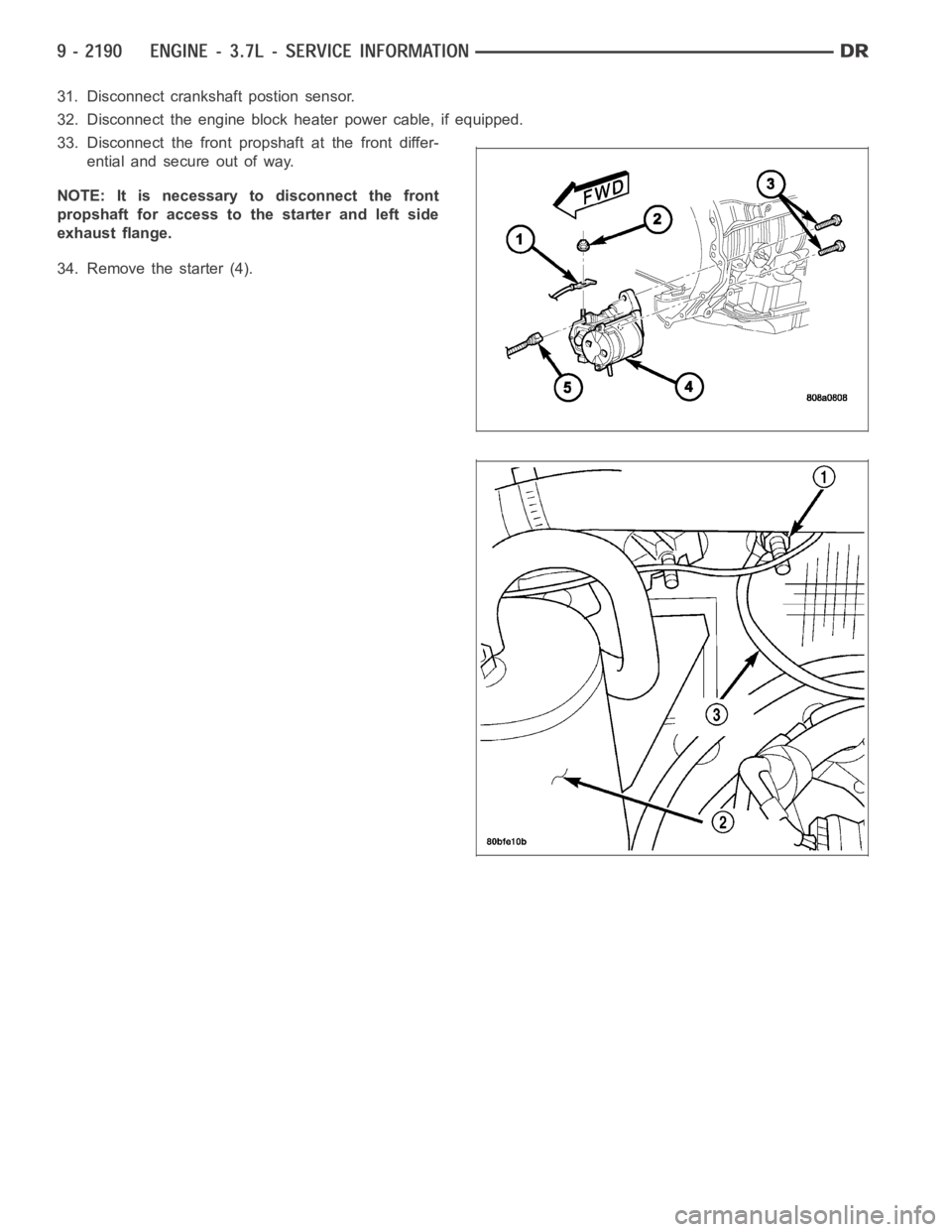

31. Disconnect crankshaft postion sensor.

32. Disconnect the engine block heater power cable, if equipped.

33. Disconnect the front propshaft at the front differ-

ential and secure out of way.

NOTE: It is necessary to disconnect the front

propshaft for access to the starter and left side

exhaust flange.

34. Remove the starter (4).

Page 1523 of 5267

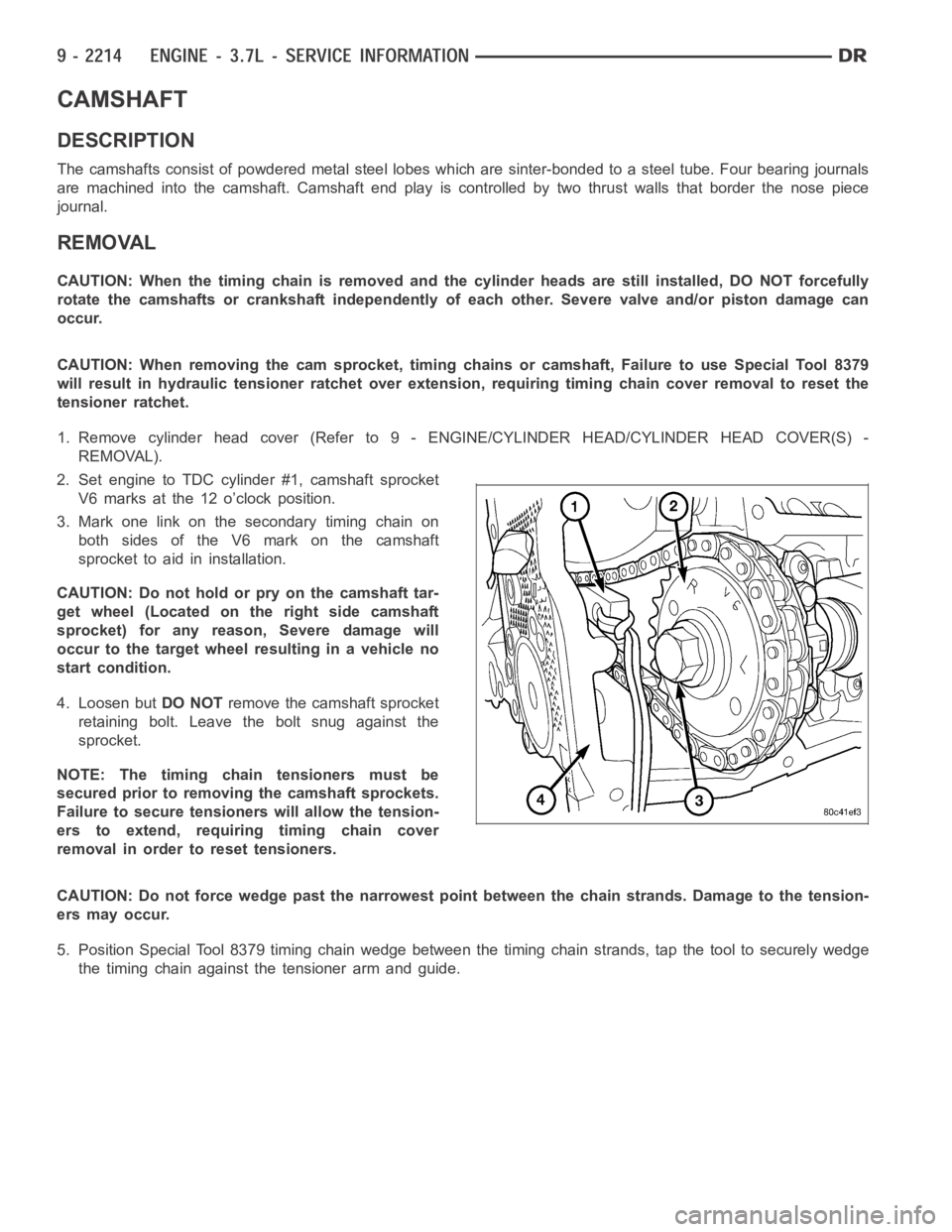

CAMSHAFT

DESCRIPTION

The camshafts consist of powdered metal steel lobes which are sinter-bonded to a steel tube. Four bearing journals

are machined into the camshaft. Camshaft end play is controlled by two thrust walls that border the nose piece

journal.

REMOVAL

CAUTION: When the timing chain is removed and the cylinder heads are still installed, DO NOT forcefully

rotate the camshafts or crankshaft independently of each other. Severe valve and/or piston damage can

occur.

CAUTION: When removing the cam sprocket, timing chains or camshaft, Failure to use Special Tool 8379

will result in hydraulic tensioner ratchet over extension, requiring timing chain cover removal to reset the

tensioner ratchet.

1. Remove cylinder head cover (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDERHEAD COVER(S) -

REMOVAL).

2. Set engine to TDC cylinder #1, camshaft sprocket

V6 marks at the 12 o’clock position.

3. Mark one link on the secondary timing chain on

both sides of the V6 mark on the camshaft

sprocket to aid in installation.

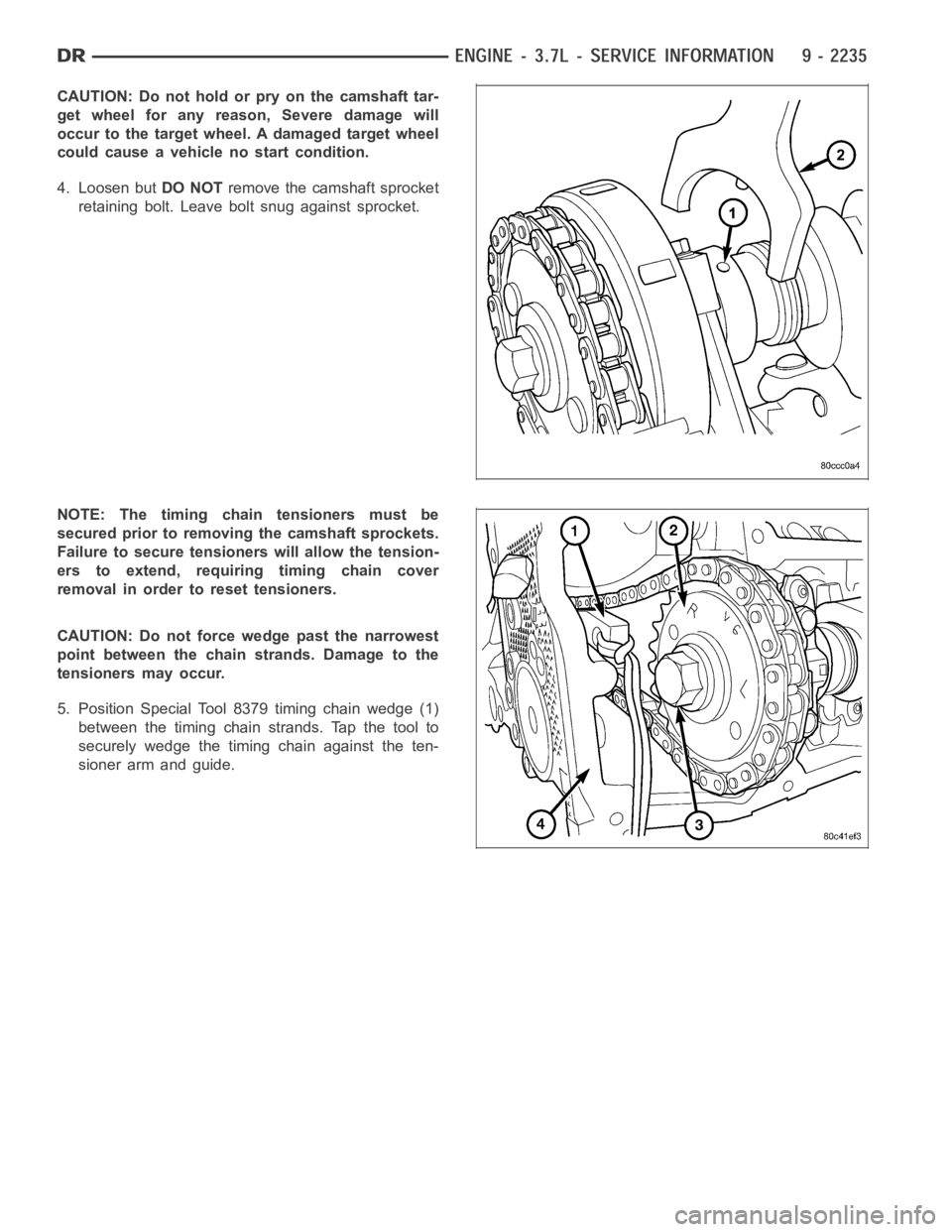

CAUTION: Do not hold or pry on the camshaft tar-

get wheel (Located on the right side camshaft

sprocket) for any reason, Severe damage will

occur to the target wheel resulting in a vehicle no

start condition.

4. Loosen butDO NOTremove the camshaft sprocket

retaining bolt. Leave the bolt snug against the

sprocket.

NOTE: The timing chain tensioners must be

secured prior to removing the camshaft sprockets.

Failure to secure tensioners will allow the tension-

erstoextend,requiringtimingchaincover

removal in order to reset tensioners.

CAUTION: Do not force wedge past the narrowest point between the chain strands. Damage to the tension-

ers may occur.

5. Position Special Tool 8379 timing chain wedge between the timing chain strands, tap the tool to securely wedge

the timing chain against the tensioner arm and guide.

Page 1544 of 5267

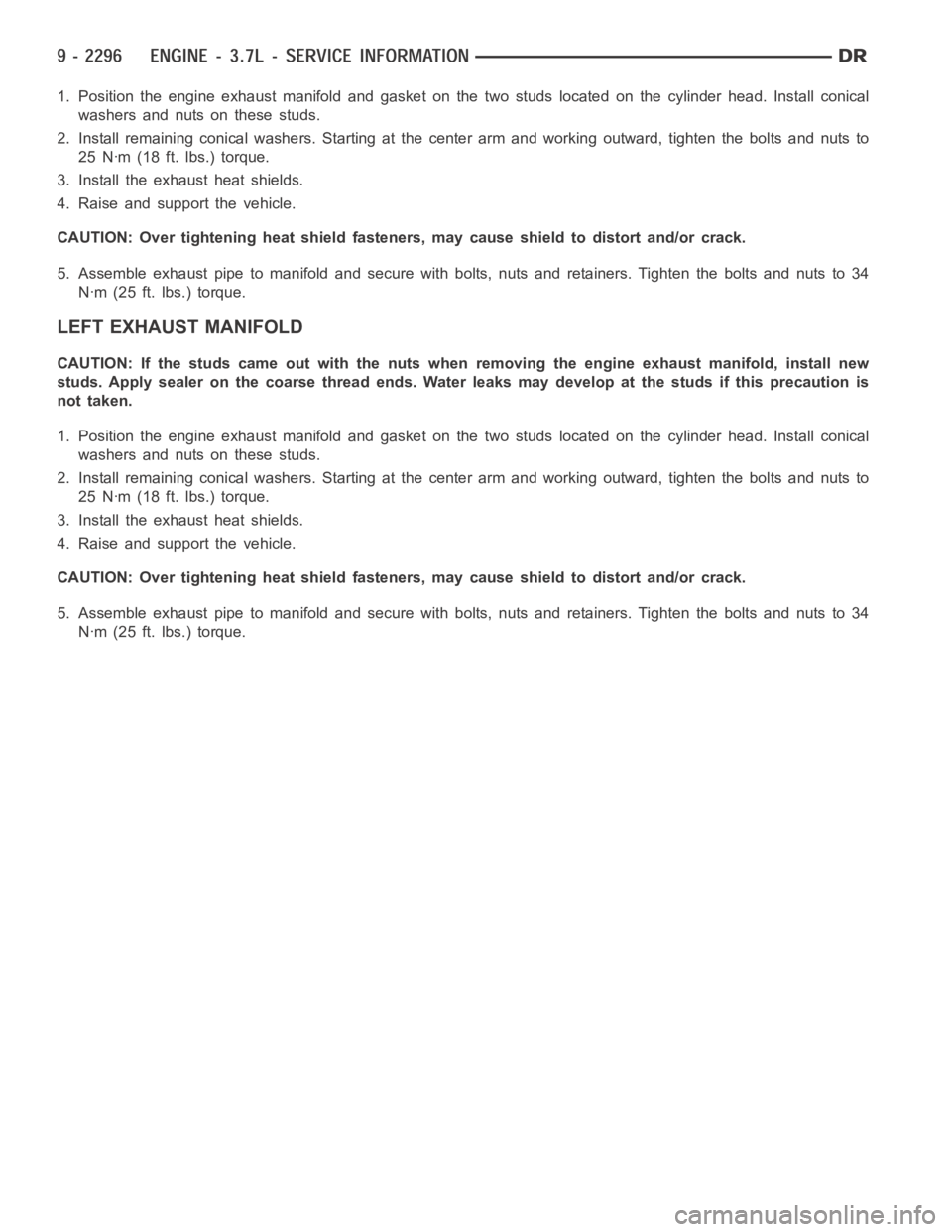

CAUTION: Do not hold or pry on the camshaft tar-

get wheel for any reason, Severe damage will

occur to the target wheel. A damaged target wheel

could cause a vehicle no start condition.

4. Loosen butDO NOTremove the camshaft sprocket

retaining bolt. Leave bolt snug against sprocket.

NOTE: The timing chain tensioners must be

secured prior to removing the camshaft sprockets.

Failure to secure tensioners will allow the tension-

erstoextend,requiringtimingchaincover

removal in order to reset tensioners.

CAUTION: Do not force wedge past the narrowest

point between the chain strands. Damage to the

tensioners may occur.

5. Position Special Tool 8379 timing chain wedge (1)

between the timing chain strands. Tap the tool to

securely wedge the timing chain against the ten-

sioner arm and guide.

Page 1605 of 5267

1. Position the engine exhaust manifold and gasket on the two studs locatedon the cylinder head. Install conical

washers and nuts on these studs.

2. Install remaining conical washers. Starting at the center arm and working outward, tighten the bolts and nuts to

25 Nꞏm (18 ft. lbs.) torque.

3. Install the exhaust heat shields.

4. Raise and support the vehicle.

CAUTION: Over tightening heat shield fasteners, may cause shield to distort and/or crack.

5. Assemble exhaust pipe to manifold and secure with bolts, nuts and retainers. Tighten the bolts and nuts to 34

Nꞏm (25 ft. lbs.) torque.

LEFT EXHAUST MANIFOLD

CAUTION: If the studs came out with the nuts when removing the engine exhaust manifold, install new

studs. Apply sealer on the coarse thread ends. Water leaks may develop at the studs if this precaution is

not taken.

1. Position the engine exhaust manifold and gasket on the two studs locatedon the cylinder head. Install conical

washers and nuts on these studs.

2. Install remaining conical washers. Starting at the center arm and working outward, tighten the bolts and nuts to

25 Nꞏm (18 ft. lbs.) torque.

3. Install the exhaust heat shields.

4. Raise and support the vehicle.

CAUTION: Over tightening heat shield fasteners, may cause shield to distort and/or crack.

5. Assemble exhaust pipe to manifold and secure with bolts, nuts and retainers. Tighten the bolts and nuts to 34

Nꞏm (25 ft. lbs.) torque.