ECU DODGE RAM SRT-10 2006 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2656 of 5267

INSTALLATION

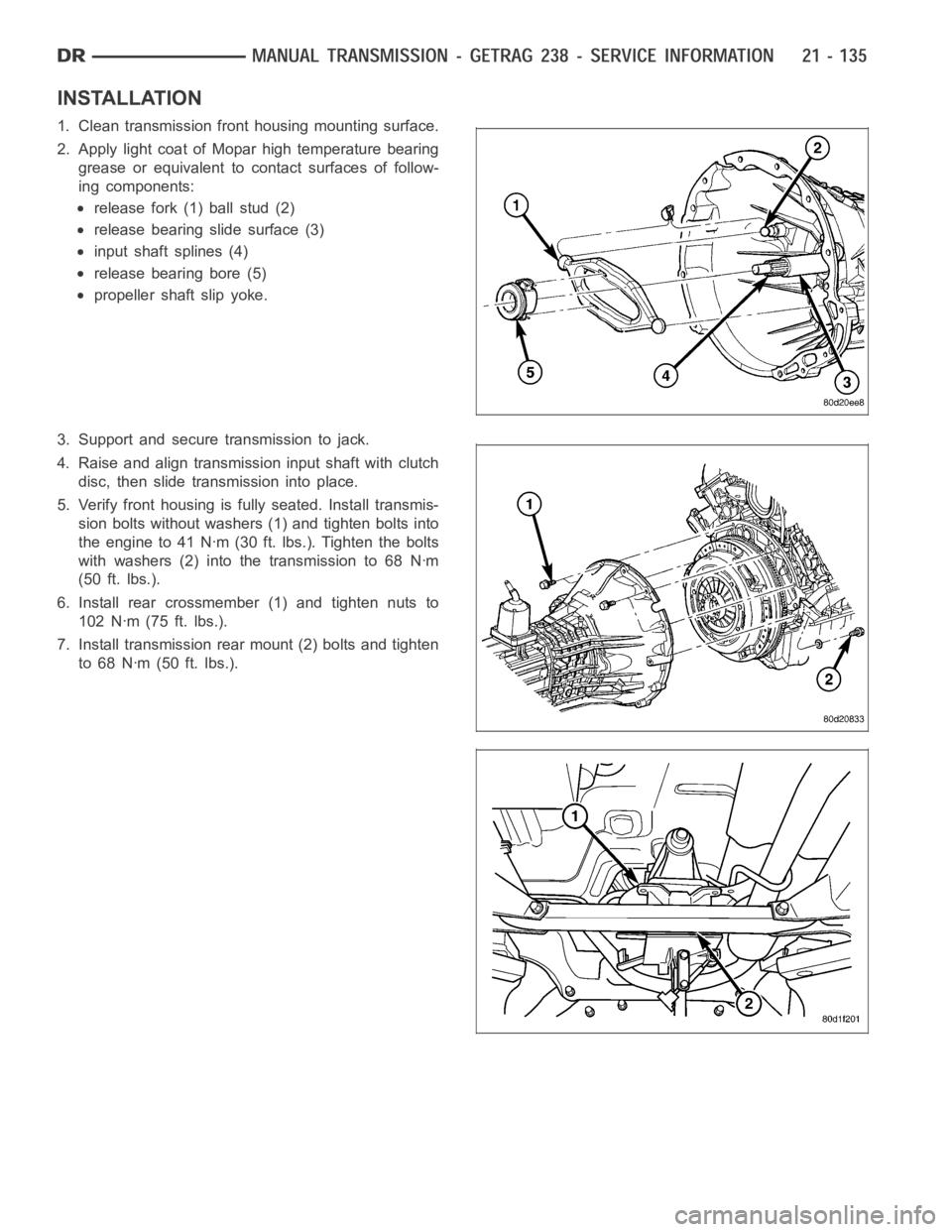

1. Clean transmission front housing mounting surface.

2. Apply light coat of Mopar high temperature bearing

grease or equivalent to contact surfaces of follow-

ing components:

release fork (1) ball stud (2)

release bearing slide surface (3)

input shaft splines (4)

release bearing bore (5)

propeller shaft slip yoke.

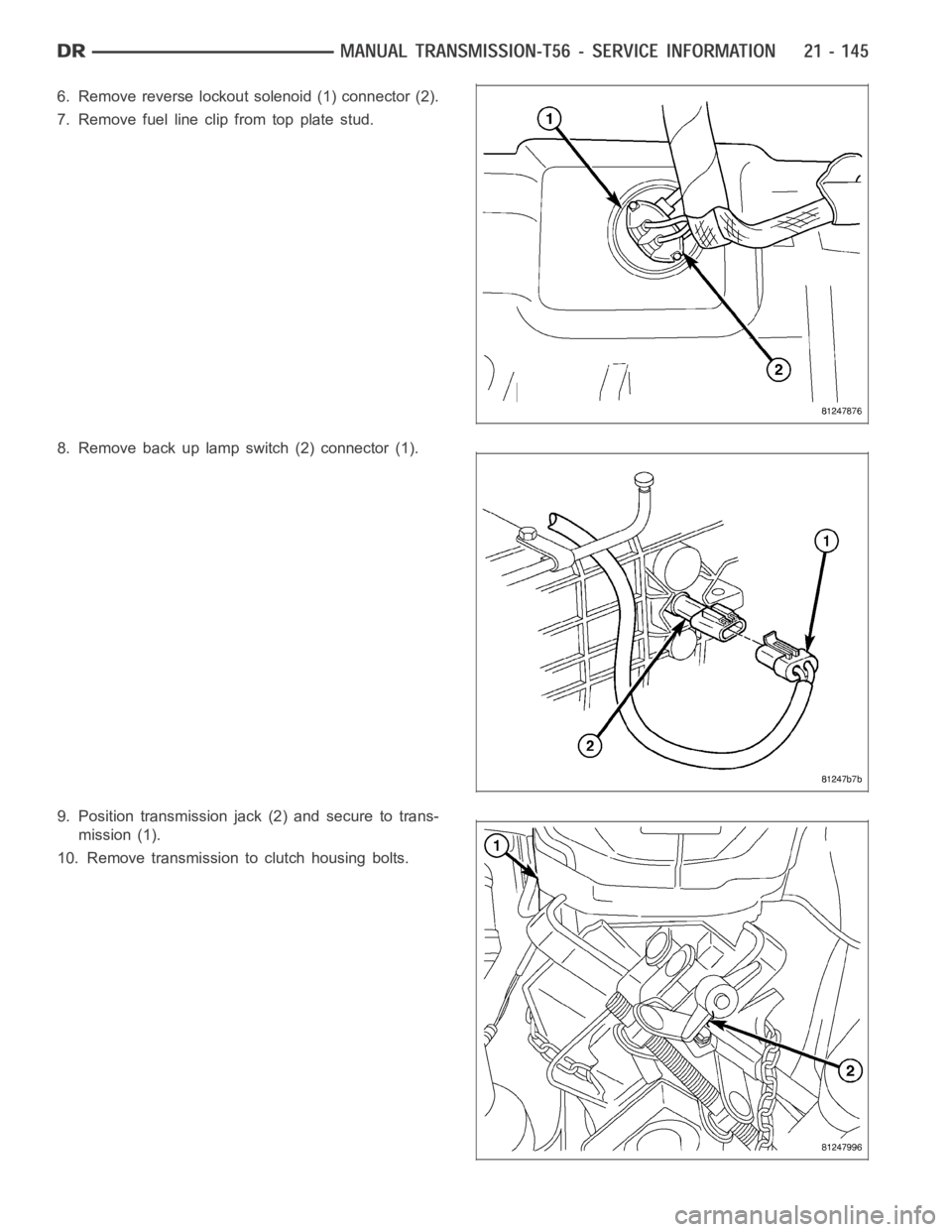

3. Support and secure transmission to jack.

4. Raise and align transmission input shaft with clutch

disc, then slide transmission into place.

5. Verify front housing is fully seated. Install transmis-

sion bolts without washers (1) and tighten bolts into

the engine to 41 Nꞏm (30 ft. lbs.). Tighten the bolts

with washers (2) into the transmission to 68 Nꞏm

(50 ft. lbs.).

6. Install rear crossmember (1) and tighten nuts to

102 Nꞏm (75 ft. lbs.).

7. Install transmission rear mount (2) bolts and tighten

to 68 Nꞏm (50 ft. lbs.).

Page 2666 of 5267

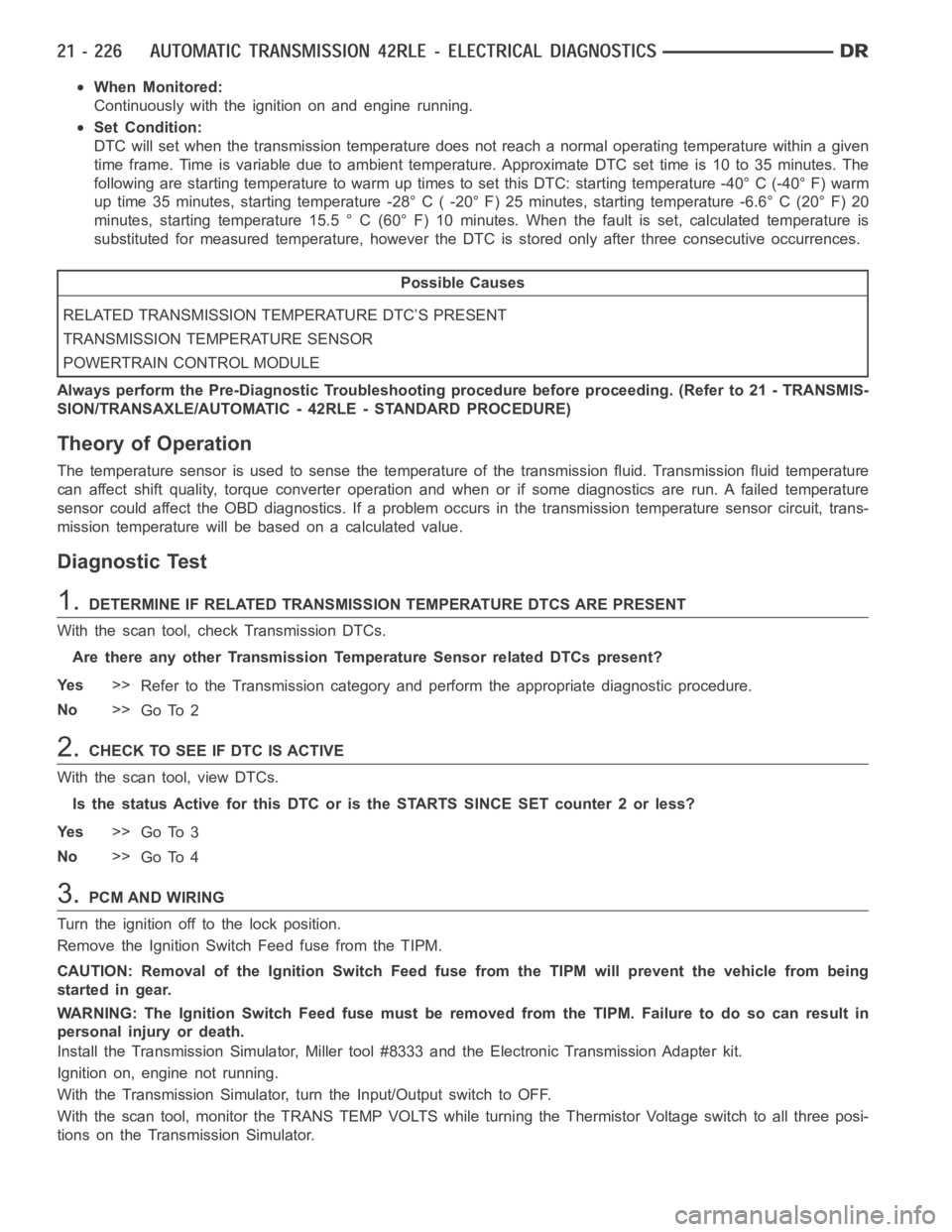

6. Remove reverse lockout solenoid (1) connector (2).

7. Remove fuel line clipfrom top plate stud.

8. Remove back up lamp switch (2) connector (1).

9. Position transmission jack (2) and secure to trans-

mission (1).

10. Remove transmission to clutch housing bolts.

Page 2747 of 5267

When Monitored:

Continuously with the ignition on and engine running.

Set Condition:

DTC will set when the transmission temperature does not reach a normal operating temperature within a given

time frame. Time is variable due to ambient temperature. Approximate DTC set time is 10 to 35 minutes. The

following are starting temperature to warm up times to set this DTC: starting temperature -40° C (-40° F) warm

up time 35 minutes, starting temperature -28° C ( -20° F) 25 minutes, starting temperature -6.6° C (20° F) 20

minutes, starting temperature 15.5 ° C (60° F) 10 minutes. When the fault isset, calculated temperature is

substituted for measured temperature, however the DTC is stored only after three consecutive occurrences.

Possible Causes

RELATED TRANSMISSION TEMPERATURE DTC’S PRESENT

TRANSMISSION TEMPERATURE SENSOR

POWERTRAIN CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

The temperature sensor is used to sense the temperature of the transmission fluid. Transmission fluid temperature

can affect shift quality, torque converter operation and when or if some diagnostics are run. A failed temperature

sensor could affect the OBD diagnostics. If a problem occurs in the transmission temperature sensor circuit, trans-

mission temperature will be based on a calculated value.

Diagnostic Test

1.DETERMINE IF RELATED TRANSMISSION TEMPERATURE DTCS ARE PRESENT

With the scan tool, check Transmission DTCs.

Are there any other Transmission Temperature Sensor related DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate diagnostic procedure.

No>>

Go To 2

2.CHECK TO SEE IF DTC IS ACTIVE

With the scan tool, view DTCs.

Is the status Active for this DTC or is the STARTS SINCE SET counter 2 or less?

Ye s>>

Go To 3

No>>

Go To 4

3.PCM AND WIRING

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator,Miller tool #8333 and the ElectronicTransmission Adapter kit.

Ignition on, engine not running.

With the Transmission Simulator, turn the Input/Output switch to OFF.

With the scan tool, monitor the TRANS TEMP VOLTS while turning the ThermistorVoltageswitchtoallthreeposi-

tions on the Transmission Simulator.

Page 2750 of 5267

When Monitored:

Continuously with the ignition on and engine running.

Set Condition:

The DTC will set when the monitored Temperature Sensor voltage drops below0.078 volts for the period of

1.45 seconds. When the fault is set, calculated temperature is substituted for measured temperature, however

the fault code is stored only after three consecutive occurrences of the fault.

Possible Causes

RELATED DTCS PRESENT

(T54) TRANSMISSION TEMPERATURE SENSOR SIGNAL CIRCUIT SHORT TO GROUND

TRANSMISSION TEMPERATURE SENSOR

POWERTRAIN CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

The temperature sensor is used to sense the temperature of the transmission fluid. Transmission fluid temperature

can affect shift quality, torque converter operation and when or if some diagnostics are run. A failed temperature

sensor could affect the OBD diagnostics. If a problem occurs in the transmission temperature sensor circuit, trans-

mission temperature will be based on a calculated value.

Diagnostic Test

1.DETERMINE IF RELATED DTCS ARE PRESENT

With the scan tool, check Transmission DTCs.

Are there any Speed Sensor DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate diagnostic procedure.

No>>

Go To 2

2.CHECK TO SEE IF DTC IS ACTIVE

With the scan tool, view DTCs.

Is the status Active for this DTC or is the STARTS SINCE SET counter 2 or less?

Ye s>>

Go To 3

No>>

Go To 5

3.CHECK THE PCM AND WIRING WITH THE TRANSMISSION SIMULATOR

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator,Miller tool #8333 and the ElectronicTransmission Adapter kit.

Ignition on, engine not running.

With the Transmission Simulator, turn the Input/Output switch to OFF.

With the scan tool, monitor the TRANS TEMP VOLTS while turning the ThermistorVoltageswitchtoallthreeposi-

tions on the Transmission Simulator.

Page 2753 of 5267

When Monitored:

Continuously with the ignition on and engine running.

Set Condition:

The DTC will set when the monitored Temperature Sensor voltage rises above4.94 volts for the period of 1.45

seconds. When the fault is set, calculated temperature is substituted formeasured temperature, however the

fault code is stored only after three consecutive occurrences of the fault.

Possible Causes

(K900) SENSOR GROUND OPEN

(T54) TRANSMISSION TEMPERATURE SENSOR SIGNAL CIRCUIT OPEN

(T54) TRANSMISSION TEMPERATURE SENSOR SIGNAL CIRCUIT SHORT TO VOLTAGE

TRANSMISSION TEMPERATURE SENSOR

POWERTRAIN CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

The temperature sensor is used to sense the temperature of the transmission fluid. Transmission fluid temperature

can affect shift quality, torque converter operation and when or if some diagnostics are run. A failed temperature

sensor could affect the OBD diagnostics. If a problem occurs in the transmission temperature sensor circuit, trans-

mission temperature will be based on a calculated value.

1.CHECK TO SEE IF DTC IS CURRENT

With the scan tool, view DTCs.

Is the status Active for this DTC or is STARTS SINCE SET counter 2 or less?

Ye s>>

Go To 2

No>>

Go To 6

2.CHECK THE PCM AND WIRING WITH THE TRANSMISSION SIMULATOR

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator,Miller tool #8333 and the ElectronicTransmission Adapter kit 8333-1A.

Ignition on, engine not running.

With the Transmission Simulator, turn the Input/Output switch to OFF.

With the scan tool, monitor the TRANS TEMP VOLTS while turning the ThermistorVoltageswitchtoallthreeposi-

tions on the Transmission Simulator.

Compare the scan tool readings with the numbers listed on the TransmissionSimulator.

Do the readings on the Transmission Simulator match the scan tool readings± 0.2 volts?

Ye s>>

Replace Transmission Solenoid/Pressure Switch Assembly per the ServiceInformation.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Go To 3

Page 2784 of 5267

When Monitored:

Initially at ignition on, then every 10 seconds thereafter. The solenoidswill also be tested immediately after a

gear ratio error or pressure switch error is detected.

Set Condition:

Three consecutive solenoid continuity test failures, or one failure if test is run in response to a gear ratio or

pressure switch error.

Possible Causes

RELATED TIPM TCM POWER CONTROL CIRCUIT DTCS PRESENT

(T20) L/R SOLENOID CONTROL CIRCUIT OPEN

(T20) L/R SOLENOID CONTROL CIRCUIT SHORT TO GROUND

(T20) L/R SOLENOID CONTROL CIRCUIT SHORT TO VOLTAGE

TRANSMISSION SOLENOID/PRESSURE SWITCH ASSEMBLY

POWERTRAIN CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

Four solenoids are used to control the friction elements (clutches). The continuity of the solenoids circuits are peri-

odically tested. Each solenoid is turned on or off depending on its currentstate. An inductive spike should be

detected by the PCM during this test. If no spike is detected, the circuit istested again to verify the failure. In

addition to the periodic testing, the solenoid circuits are tested if a gear ratio or pressure switch error occurs. In this

case, one failure will result in the appropriate DTC being set. The MIL willilluminate and the transmission goes into

neutral, if the DTC is set above 35 Kmh (22 mph), Limp-in mode when vehicle speed is below 35 Kmh (22 mph).

Diagnostic Test

1.DETERMINING IF RELATED TIPM TCM POWER CONTROL CIRCUIT DTCS PRESENT

With the scan tool, read TIPM DTCs.

Are there any TIPM TCM Power Control Circuit DTCs present also?

Ye s>>

Refer to the Transmission category and perform the appropriate diagnostic procedure.

No>>

Go To 2

2.CHECK IF THE DTC IS CURRENT

With the scan tool, view DTCs.

Is the status Active or is STARTS SINCE SET counter set at 0 for this DTC?

Ye s>>

Go To 3

No>>

Go To 7

3.CHECK THE PCM AND WIRING USING THE TRANSMISSION SIMULATOR

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator,Miller tool #8333 and the ElectronicTransmission Adapter kit.

Ignition on, engine not running.

With the scan tool, actuate the L/R Solenoid.

Page 2788 of 5267

When Monitored:

Initially at ignition on, then every 10 seconds thereafter. The solenoidswill also be tested immediately after a

gear ratio error or pressure switch error is detected.

Set Condition:

Three consecutive solenoid continuity test failures, or one failure if test is run in response to a gear ratio or

pressure switch error.

Possible Causes

RELATED TIPM TCM POWER CONTROL CIRCUIT DTCS PRESENT

(T19) 2/4 SOLENOID CONTROL CIRCUIT OPEN

(T19) 2/4 SOLENOID CONTROL CIRCUIT SHORT TO GROUND

(T19) 2/4 SOLENOID CONTROL CIRCUIT SHORT TO VOLTAGE

TRANSMISSION SOLENOID/PRESSURE SWITCH ASSEMBLY

POWERTRAIN CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

Four solenoids are used to control the friction elements (clutches). The continuity of the solenoids circuits are peri-

odically tested. Each solenoid is turned on or off depending on its currentstate. An inductive spike should be

detected by the PCM during this test. If no spike is detected, the circuit istested again to verify the failure. In

addition to the periodic testing, the solenoid circuits are tested if a gear ratio or pressure switch error occurs. In this

case, one failure will result in the appropriate DTC being set. The MIL willilluminate and the transmission goes into

neutral, if the DTC is set above 35 Kmh (22 mph), Limp-in mode when vehicle speed is below 35 Kmh (22 mph).

Diagnostic Test

1.DETERMINING IF RELATED TIPM TCM POWER CONTROL CIRCUIT DTCS PRESENT

With the scan tool, read TIPM DTCs.

Are there any TIPM TCM Power Control Circuit DTCs present also?

Ye s>>

Refer to the Transmission category and perform the appropriate diagnostic procedure.

No>>

Go To 2

2.CHECK TO SEE IF P0755 IS CURRENT

With the scan tool, view DTCs.

Is the status Active or is the STARTS SINCE SET counter set at 0 for this DTC?

Ye s>>

Go To 3

No>>

Go To 7

3.CHECK THE PCM AND WIRING USING THE TRANSMISSION SIMULATOR

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator,Miller tool #8333 and the ElectronicTransmission Adapter kit.

Ignition on, engine not running.

With the scan tool, actuate the 2/4 Solenoid.

Page 2792 of 5267

When Monitored:

Initially at ignition on, then every 10 seconds thereafter. The solenoidswill also be tested immediately after a

gear ratio error or pressure switch error is detected.

Set Condition:

Three consecutive solenoid continuity test failures, or one failure if test is run in response to a gear ratio or

pressure switch error.

Possible Causes

RELATED TIPM TCM POWER CONTROL CIRCUIT DTCS PRESENT

(T60) OD SOLENOID CONTROL CIRCUIT OPEN

(T60) OD SOLENOID CONTROL CIRCUIT SHORT TO GROUND

(T60) OD SOLENOID CONTROL CIRCUIT SHORT TO VOLTAGE

TRANSMISSION SOLENOID/PRESSURE SWITCH ASSEMBLY

POWERTRAIN CONTROL MODULE

Always perform the 42RLE Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

Four solenoids are used to control the friction elements (clutches). The continuity of the solenoid circuits is period-

ically tested. Each solenoid is turned on or off depending on its current state. An inductive spike should be detected

by the PCM during this test. If no spike is detected, the circuit is tested again to verify the failure. In addition to the

periodic testing, the solenoid circuits are tested if a gear ratio or pressure switch error occurs. In this case, one

failure will result in the appropriateDTC being set. The MIL will illuminate and the transmission goes into neutral, if

the DTC is set above 35 Kmh (22 mph), Limp-in mode when vehicle speed is below35 Kmh (22 mph).

Diagnostic Test

1.DETERMINING IF RELATED TIPM TCM POWER CONTROL CIRCUIT DTCS PRESENT

With the scan tool, read TIPM DTCs.

Are there any TIPM TCM Power Control Circuit DTCs present also?

Ye s>>

Refer to the Transmission category and perform the appropriate diagnostic procedure.

No>>

Go To 2

2.CHECK IF DTC IS CURRENT

With the scan tool, view DTCs.

Is the status Active or is the STARTS SINCE SET counter set at 0 for this DTC?

Ye s>>

Go To 3

No>>

Go To 7

3.CHECK THE PCM AND WIRING USING THE TRANSMISSION SIMULATOR

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator,Miller tool #8333 and the ElectronicTransmission Adapter kit.

Ignition on, engine not running.

With the scan tool, actuate the OD Solenoid.

Page 2796 of 5267

When Monitored:

Initially at ignition on, then every 10 seconds thereafter. The solenoidswill also be tested immediately after a

gear ratio error or pressure switch error is detected.

Set Condition:

Three consecutive solenoid continuity test failures, or one failure if test is run in response to a gear ratio or

pressure switch error.

Possible Causes

RELATED TIPM TCM POWER CONTROL CIRCUIT DTCS PRESENT

(T59) UD SOLENOID CONTROL CIRCUIT OPEN

(T59) UD SOLENOID CONTROL CIRCUIT SHORT TO GROUND

(T59) UD SOLENOID CONTROL CIRCUIT SHORT TO VOLTAGE

TRANSMISSION SOLENOID/PRESSURE SWITCH ASSEMBLY

POWERTRAIN CONTROL MODULE

Always perform the 42RLE Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

Four solenoids are used to control the friction elements (clutches). The continuity of the solenoid circuits is period-

ically tested. Each solenoid is turned on or off depending on its current state. An inductive spike should be detected

by the PCM during this test. If no spike is detected, the circuit is tested again to verify the failure. In addition to the

periodic testing, the solenoid circuits are tested if a gear ratio or pressure switch error occurs. In this case, one

failure will result in the appropriateDTC being set. The MIL will illuminate and the transmission goes into neutral, if

the DTC is set above 35 Kmh (22 mph), Limp-in mode when vehicle speed is below35 Kmh (22 mph).

Diagnostic Test

1.DETERMINING IF RELATED TIPM TCM POWER CONTROL CIRCUIT DTCS PRESENT

With the scan tool, read TIPM DTCs.

Are there any TIPM TCM Power Control Circuit DTCs present also?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.CHECK IF THE DTC IS CURRENT

With the scan tool, view DTCs.

Is the status Active or is the STARTS SINCE SET counter set at 0 for this DTC?

Ye s>>

Go To 3

No>>

Go To 7

3.CHECK THE PCM AND WIRING USING THE TRANSMISSION SIMULATOR

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator,Miller tool #8333 and the ElectronicTransmission Adapter kit.

Ignition on, engine not running.

With the scan tool, actuate the UD Solenoid.

Page 2927 of 5267

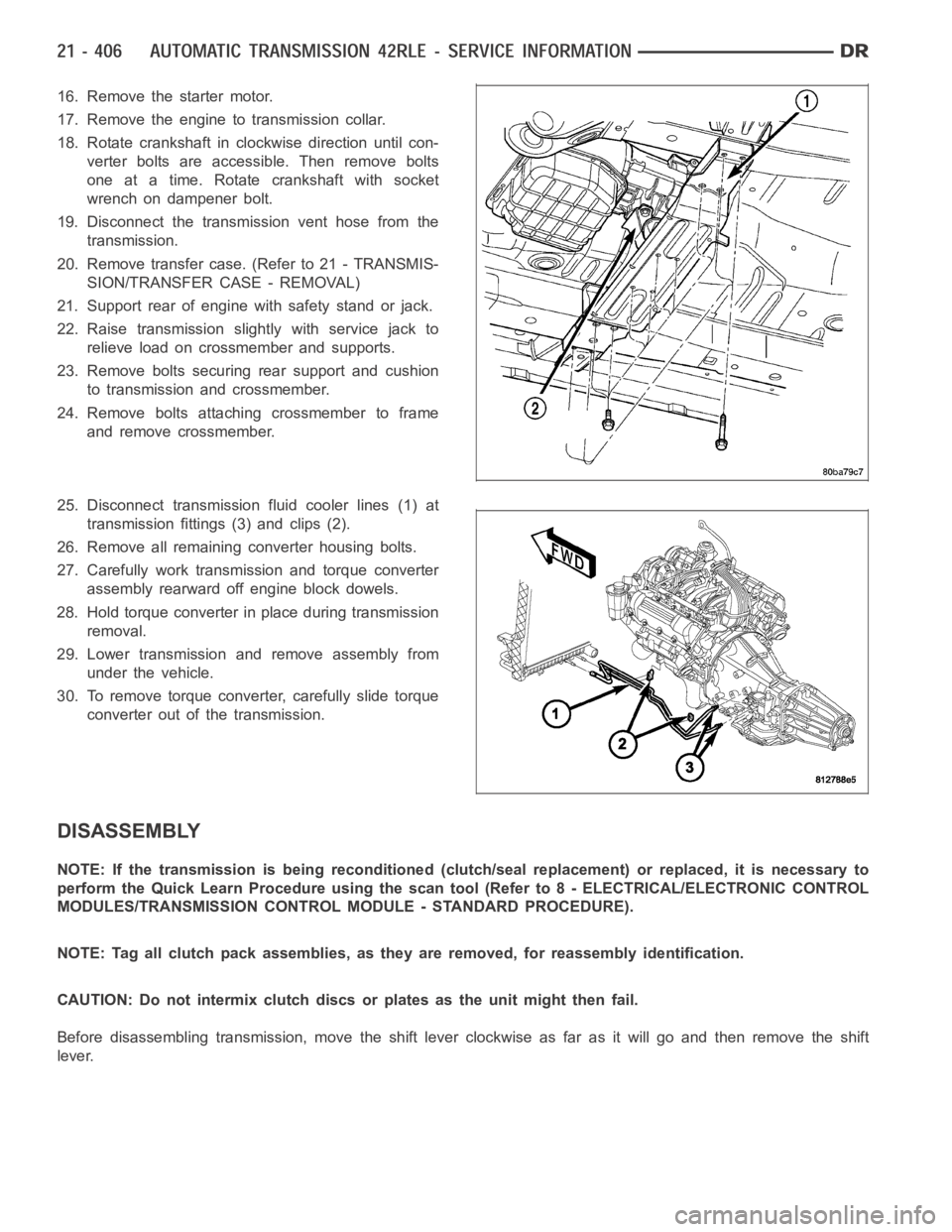

16. Remove the starter motor.

17. Remove the engine to transmission collar.

18. Rotate crankshaft in clockwise direction until con-

verter bolts are accessible. Then remove bolts

one at a time. Rotate crankshaft with socket

wrench on dampener bolt.

19. Disconnect the transmission vent hose from the

transmission.

20. Remove transfer case. (Refer to 21 - TRANSMIS-

SION/TRANSFER CASE - REMOVAL)

21. Support rear of engine with safety stand or jack.

22. Raise transmission slightly with service jack to

relieve load on crossmember and supports.

23. Remove bolts securing rear support and cushion

to transmission and crossmember.

24. Remove bolts attaching crossmember to frame

and remove crossmember.

25. Disconnect transmission fluid cooler lines (1) at

transmission fittings (3) and clips (2).

26. Remove all remaining converter housing bolts.

27. Carefully work transmission and torque converter

assembly rearward off engine block dowels.

28. Hold torque converter in place during transmission

removal.

29. Lower transmission and remove assembly from

under the vehicle.

30. To remove torque converter, carefully slide torque

converter out of the transmission.

DISASSEMBLY

NOTE: If the transmission is being reconditioned (clutch/seal replacement) or replaced, it is necessary to

perform the Quick Learn Procedure using the scan tool (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/TRANSMISSION CONTROL MODULE - STANDARD PROCEDURE).

NOTE: Tag all clutch pack assemblies, as they are removed, for reassembly identification.

CAUTION: Do not intermix clutch discs or plates as the unit might then fail.

Before disassembling transmission, move the shift lever clockwise as faras it will go and then remove the shift

lever.