DODGE RAM SRT-10 2006 Service Manual PDF

RAM SRT-10 2006

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56917/w960_56917-0.png

DODGE RAM SRT-10 2006 Service Manual PDF

Page 2484 of 5267

CAUTION: Do not run a vehicle with foamy fluid for an extended period. This may cause pump damage.

REMOVAL

GAS ENGINE

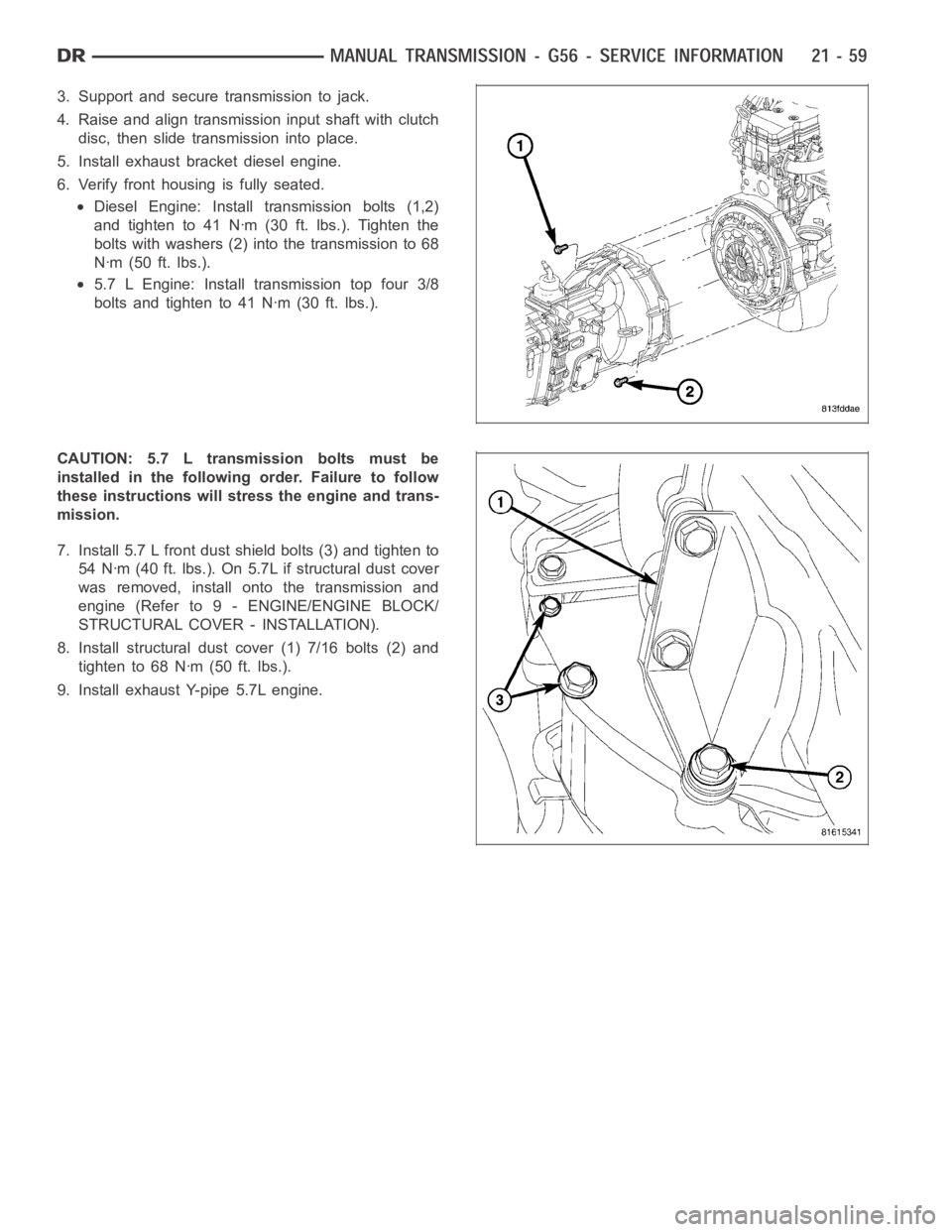

1. Drain and siphon the power steering fluid from the

reservoir.

2. Remove the serpentine belt.

CAUTION: Do not remove the fitting on the pump

that the high pressure hose screws into. The fit-

ting may come loose unless it is backed up using

another wrench. If the fitting does come loose, it

must be retightened before continuing. (57 - 67

Nm, 40 - 50 lb.ft.). If this fitting comes out of the

pump body, the internal spring and valve parts will

fall out of the pump and they cannot be reinstalled

properly. If this occurs the pump needs to be

replaced with a new pump.

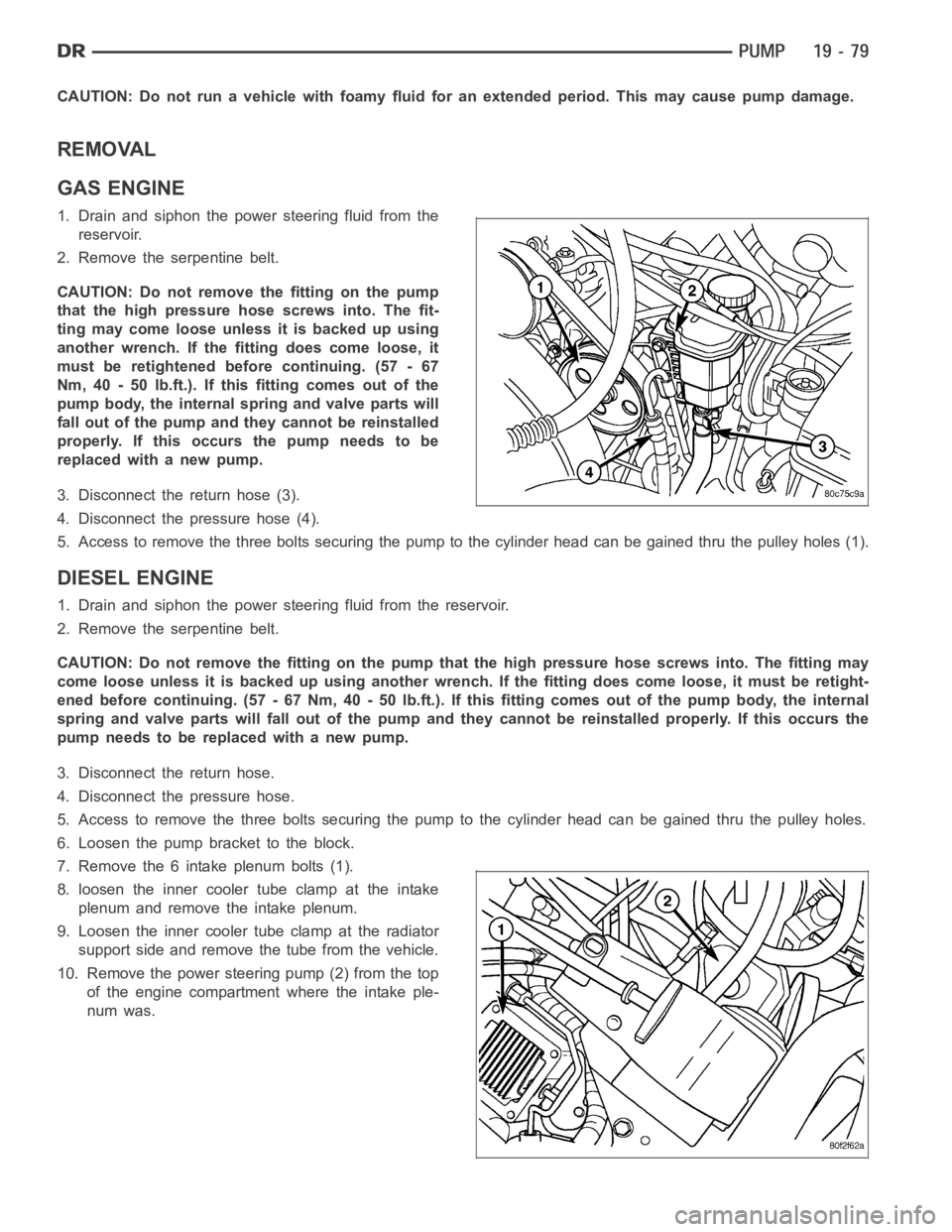

3. Disconnect the return hose (3).

4. Disconnect the pressure hose (4).

5. Access to remove the three bolts securing the pump to the cylinder head can be gained thru the pulley holes (1).

DIESEL ENGINE

1. Drain and siphon the power steering fluid from the reservoir.

2. Remove the serpentine belt.

CAUTION: Do not remove the fitting on the pump that the high pressure hose screws into. The fitting may

come loose unless it is backed up using another wrench. If the fitting does come loose, it must be retight-

ened before continuing. (57 - 67 Nm, 40 - 50 lb.ft.). If this fitting comes out of the pump body, the internal

spring and valve parts will fall out of the pump and they cannot be reinstalled properly. If this occurs the

pump needs to be replaced with a new pump.

3. Disconnect the return hose.

4. Disconnect the pressure hose.

5. Access to remove the three bolts securing the pump to the cylinder head can be gained thru the pulley holes.

6. Loosen the pump bracket to the block.

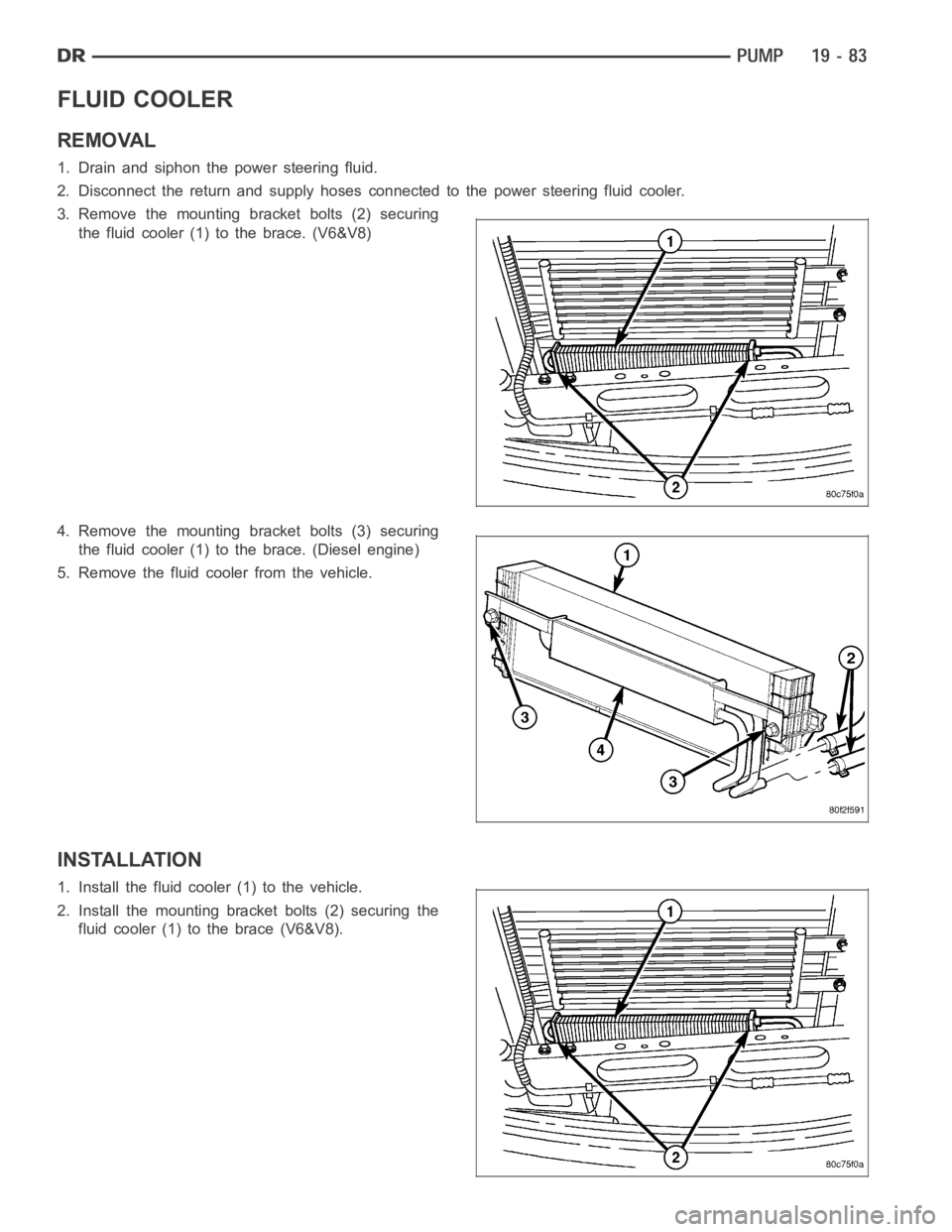

7. Remove the 6 intake plenum bolts (1).

8. loosen the inner cooler tube clamp at the intake

plenum and remove the intake plenum.

9. Loosen the inner cooler tube clamp at the radiator

support side and remove the tube from the vehicle.

10. Remove the power steering pump (2) from the top

of the engine compartment where the intake ple-

num was.

Page 2488 of 5267

FLUID COOLER

REMOVAL

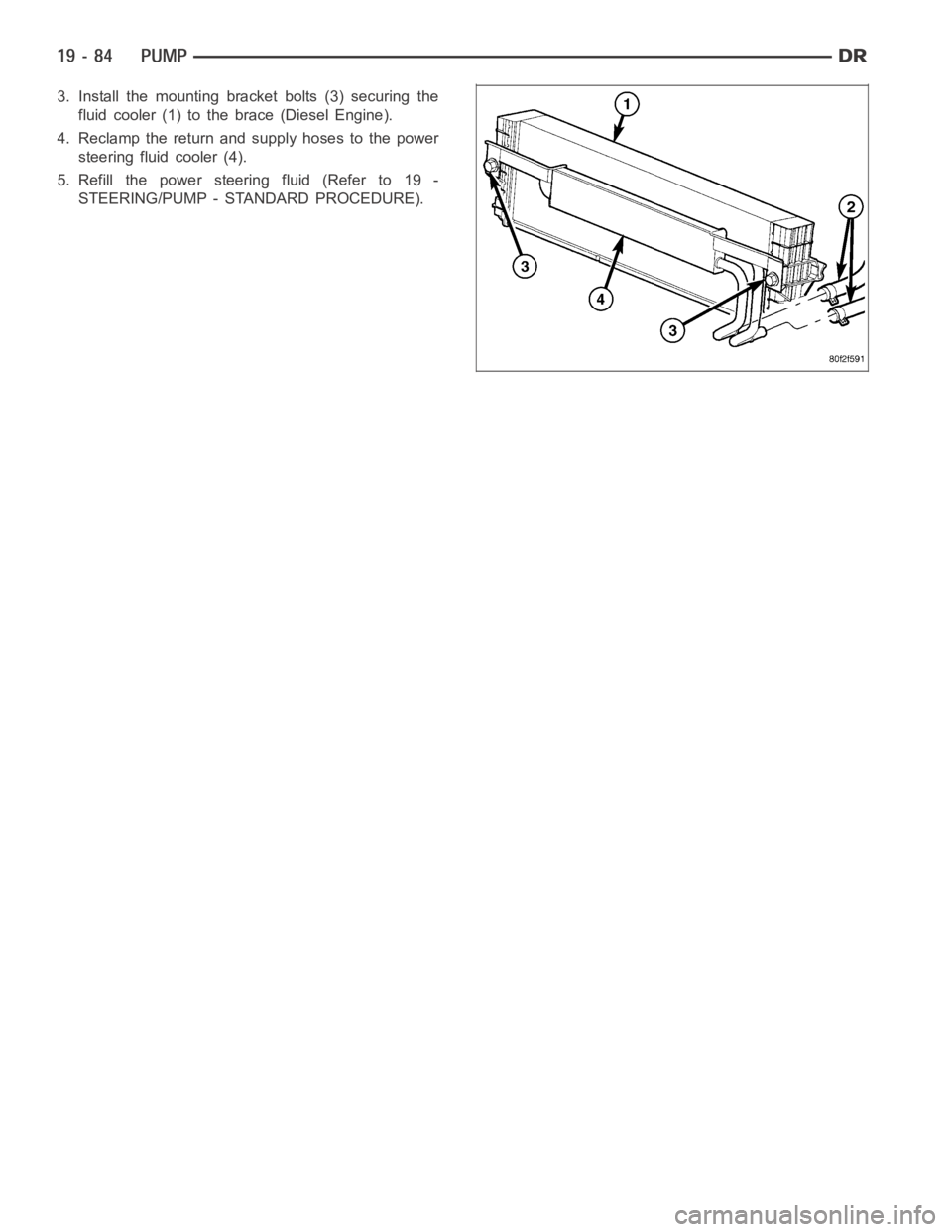

1. Drain and siphon the power steering fluid.

2. Disconnect the return and supply hoses connected to the power steering fluid cooler.

3. Remove the mounting bracket bolts (2) securing

the fluid cooler (1) to the brace. (V6&V8)

4. Remove the mounting bracket bolts (3) securing

the fluid cooler (1) to the brace. (Diesel engine)

5. Remove the fluid cooler from the vehicle.

INSTALLATION

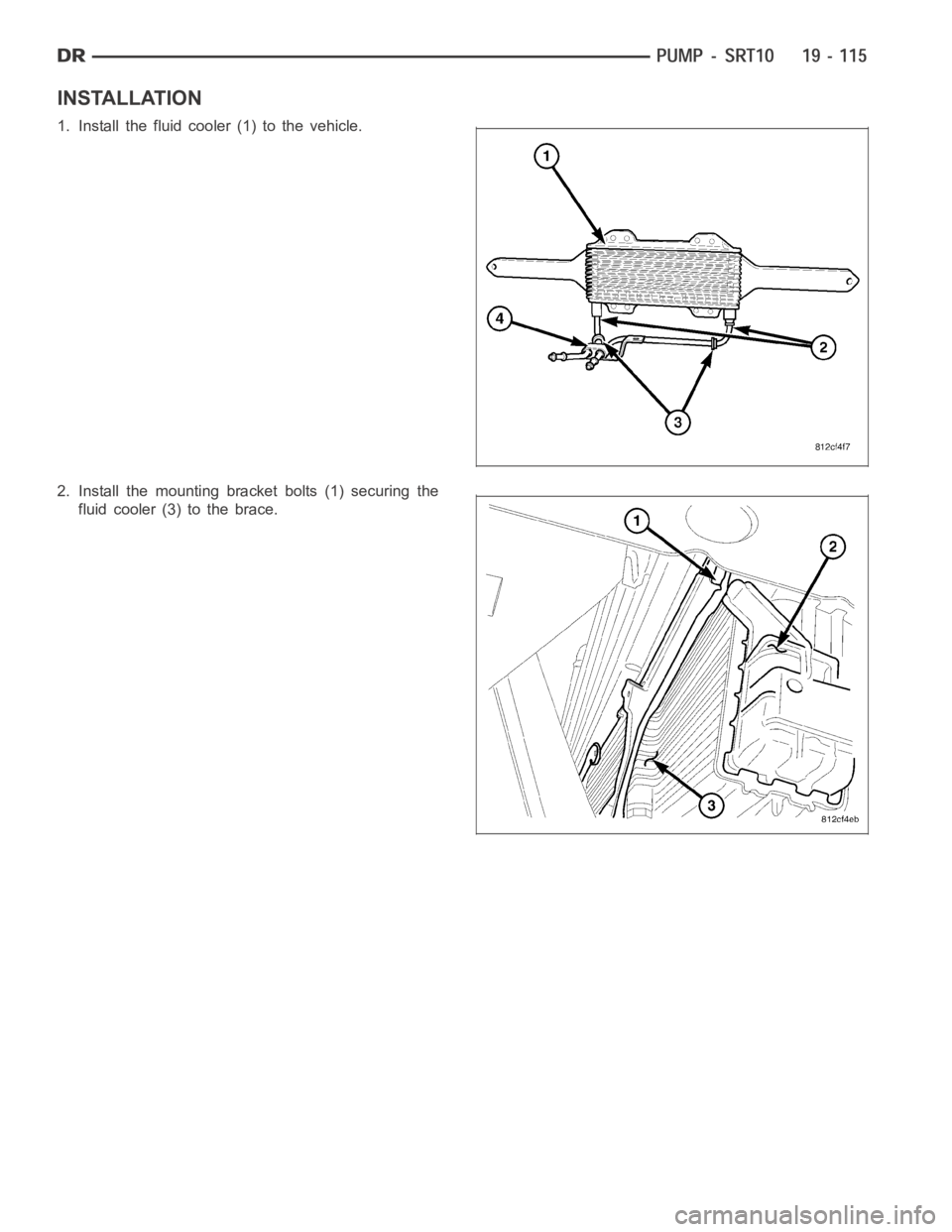

1. Install the fluid cooler (1) to the vehicle.

2. Install the mounting bracket bolts (2) securing the

fluid cooler (1) to the brace (V6&V8).

Page 2489 of 5267

3. Install the mounting bracket bolts (3) securing the

fluid cooler (1) to the brace (Diesel Engine).

4. Reclamp the return and supply hoses to the power

steering fluid cooler (4).

5. Refill the power steering fluid (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

Page 2519 of 5267

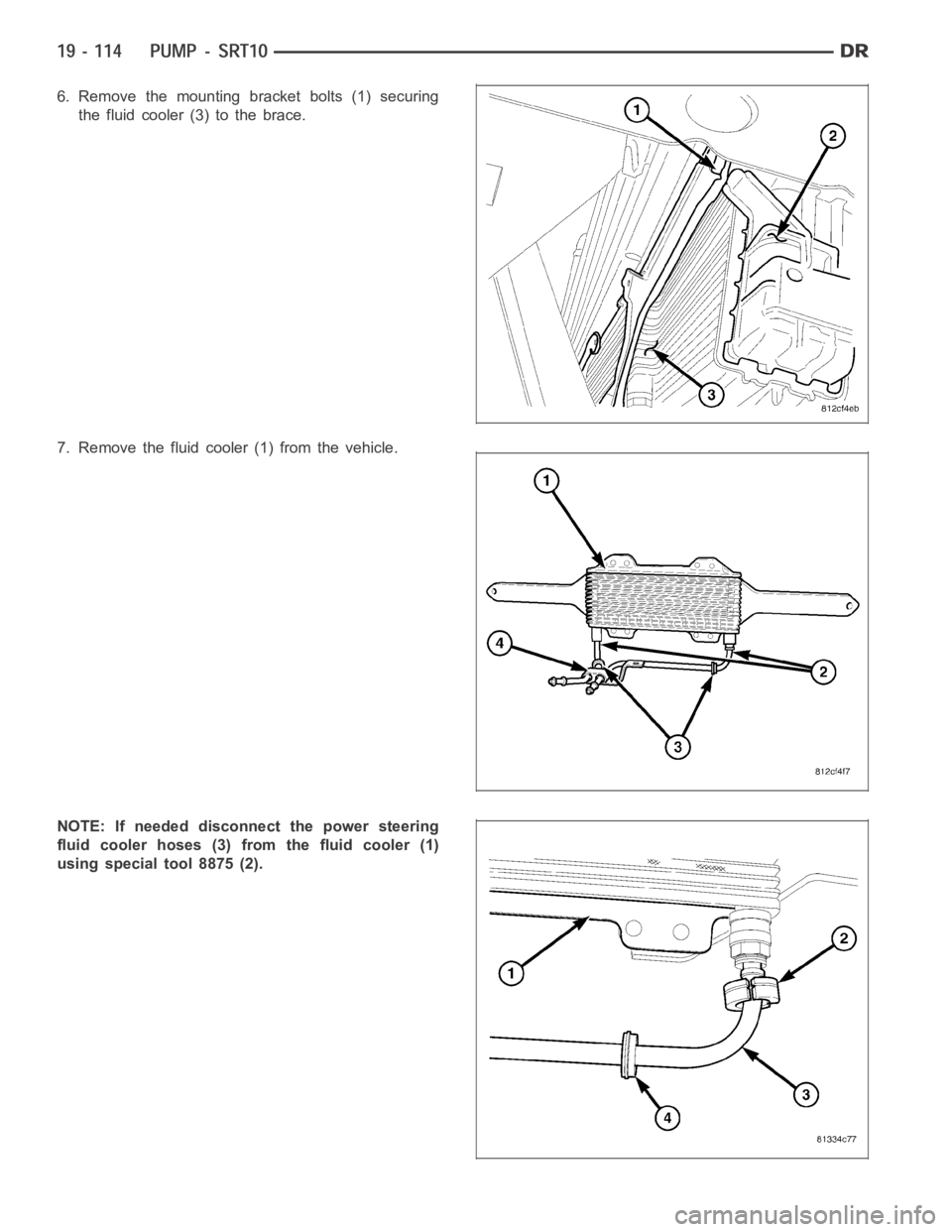

6. Remove the mounting bracket bolts (1) securing

the fluid cooler (3) to the brace.

7. Remove the fluid cooler (1) from the vehicle.

NOTE: If needed disconnect the power steering

fluid cooler hoses (3) from the fluid cooler (1)

using special tool 8875 (2).

Page 2520 of 5267

INSTALLATION

1. Install the fluid cooler (1) to the vehicle.

2. Install the mounting bracket bolts (1) securing the

fluid cooler (3) to the brace.

Page 2528 of 5267

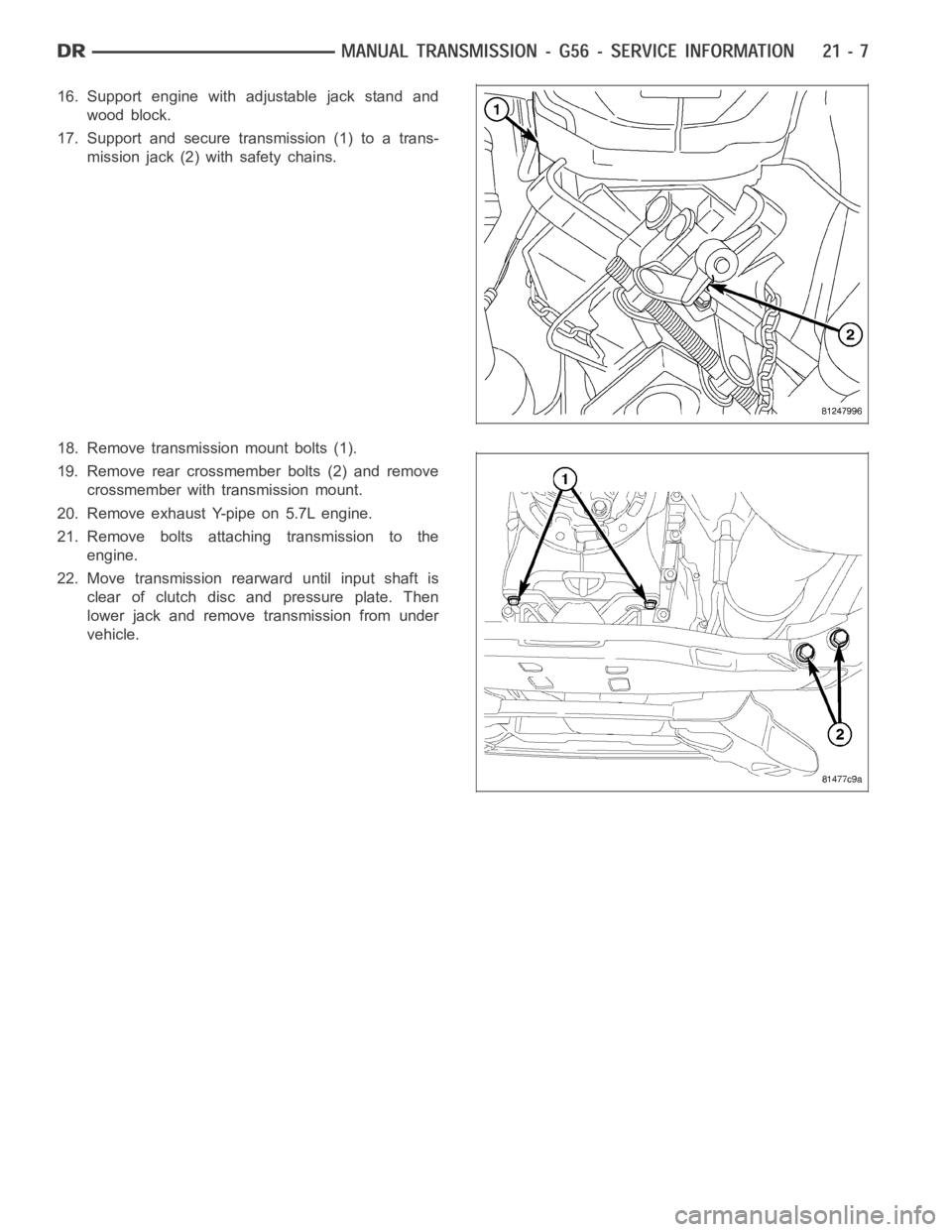

16. Support engine with adjustable jack stand and

wood block.

17. Support and secure transmission (1) to a trans-

mission jack (2) with safety chains.

18. Remove transmission mount bolts (1).

19. Remove rear crossmember bolts (2) and remove

crossmember with transmission mount.

20. Remove exhaust Y-pipe on 5.7L engine.

21. Remove bolts attaching transmission to the

engine.

22. Move transmission rearward until input shaft is

clear of clutch disc and pressure plate. Then

lower jack and remove transmission from under

vehicle.

Page 2539 of 5267

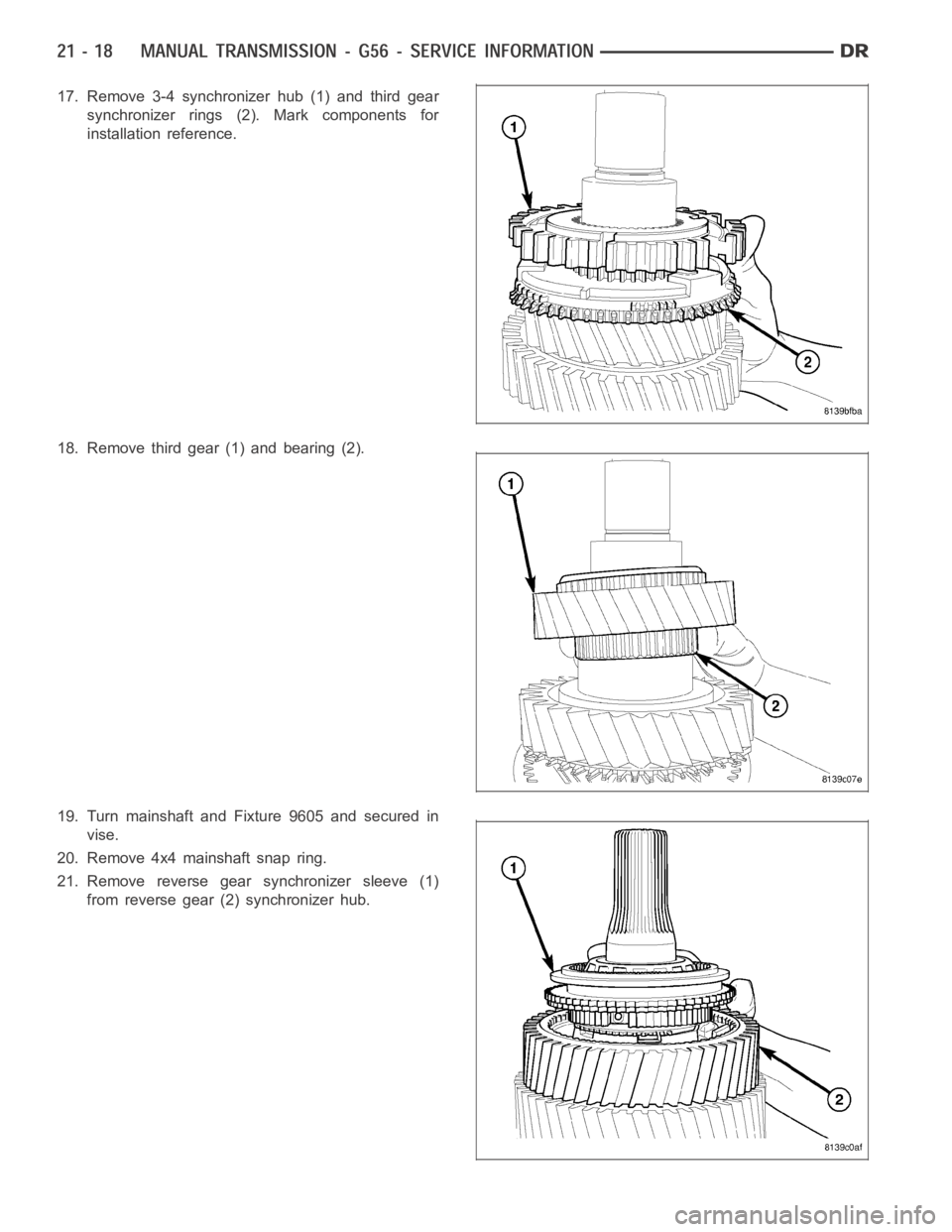

17. Remove 3-4 synchronizer hub (1) and third gear

synchronizer rings (2). Mark components for

installation reference.

18. Remove third gear (1) and bearing (2).

19. Turn mainshaft and Fixture 9605 and secured in

vise.

20. Remove 4x4 mainshaft snap ring.

21. Remove reverse gear synchronizer sleeve (1)

from reverse gear (2) synchronizer hub.

Page 2562 of 5267

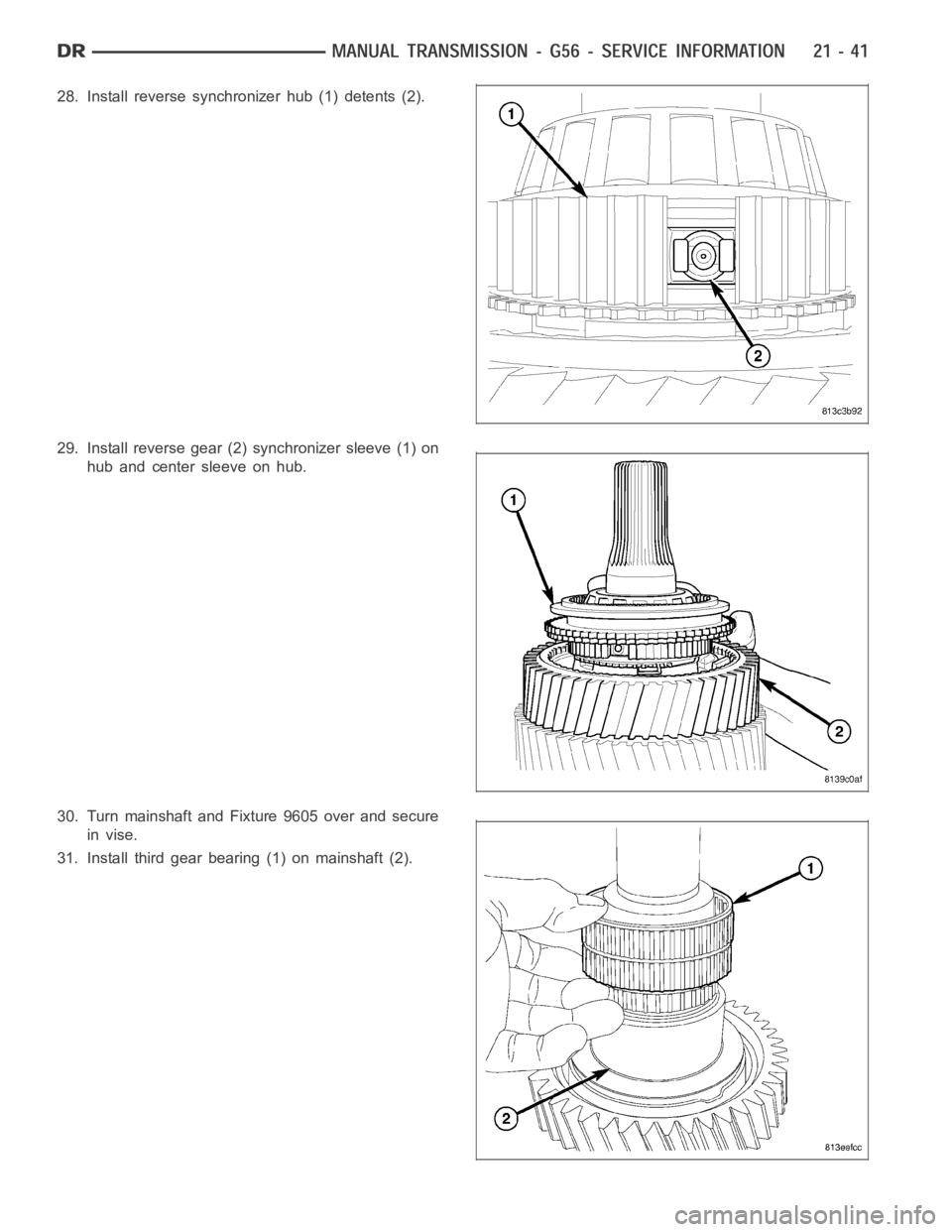

28. Install reverse synchronizer hub (1) detents (2).

29. Install reverse gear (2) synchronizer sleeve (1) on

hub and center sleeve on hub.

30. Turn mainshaft and Fixture 9605 over and secure

in vise.

31. Install third gear bearing (1) on mainshaft (2).

Page 2580 of 5267

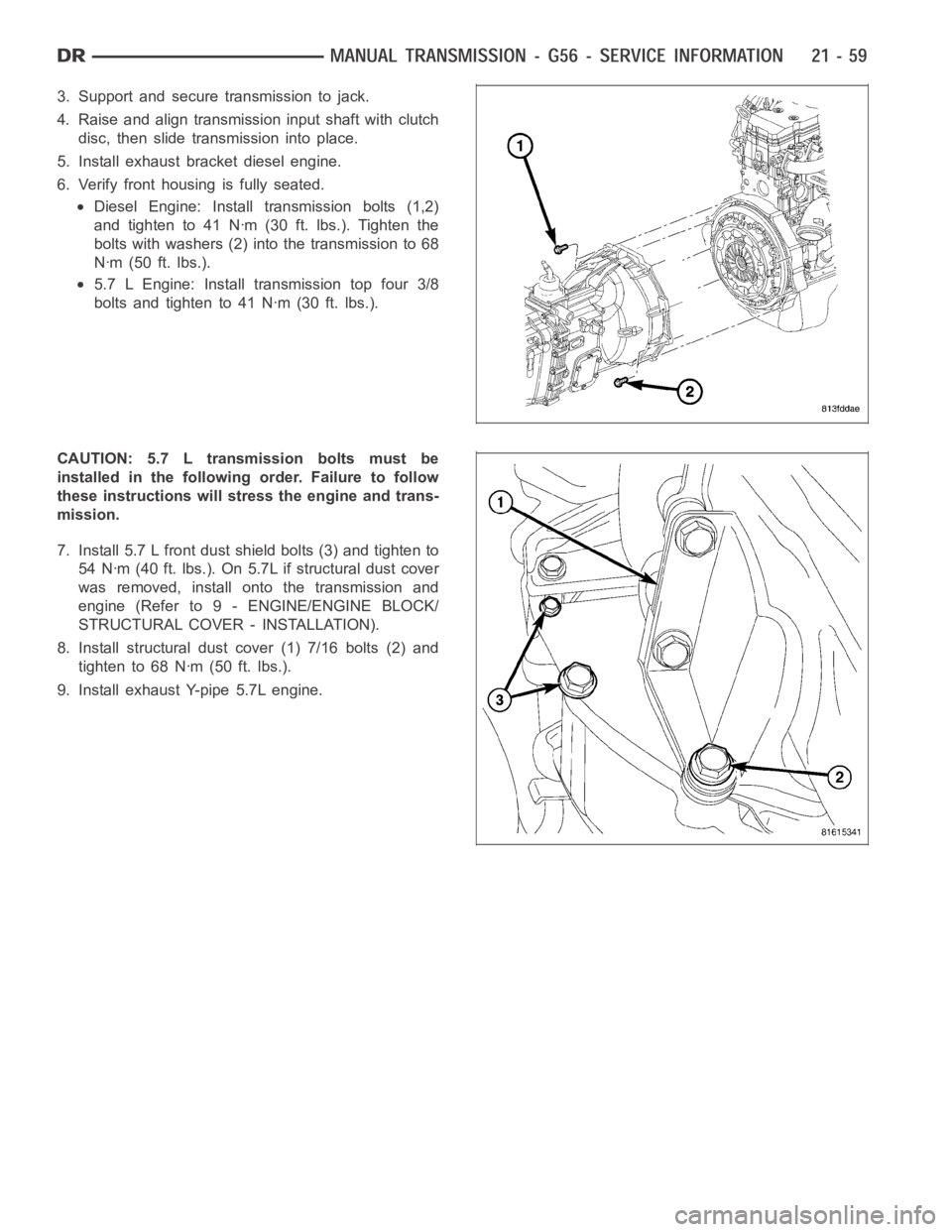

3. Support and secure transmission to jack.

4. Raise and align transmission input shaft with clutch

disc, then slide transmission into place.

5. Install exhaust bracket diesel engine.

6. Verify front housing is fully seated.

Diesel Engine: Install transmission bolts (1,2)

and tighten to 41 Nꞏm (30 ft. lbs.). Tighten the

bolts with washers (2) into the transmission to 68

Nꞏm (50 ft. lbs.).

5.7 L Engine: Install transmission top four 3/8

bolts and tighten to 41 Nꞏm (30 ft. lbs.).

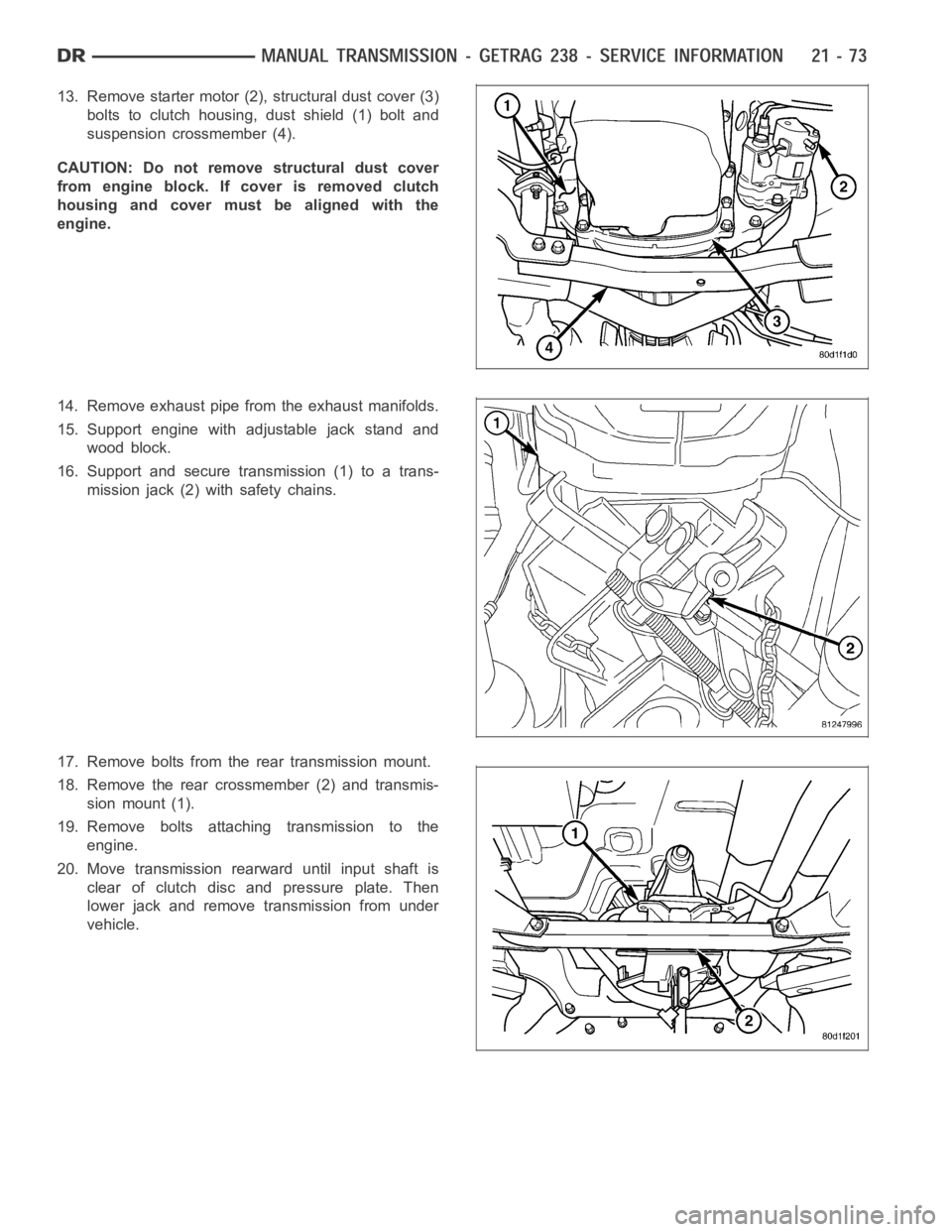

CAUTION: 5.7 L transmission bolts must be

installed in the followingorder. Failure to follow

these instructions will stress the engine and trans-

mission.

7. Install 5.7 L front dust shield bolts (3) and tighten to

54 Nꞏm (40 ft. lbs.). On 5.7L if structural dust cover

was removed, install onto the transmission and

engine (Refer to 9 - ENGINE/ENGINE BLOCK/

STRUCTURAL COVER - INSTALLATION).

8. Install structural dust cover (1) 7/16 bolts (2) and

tighten to 68 Nꞏm (50 ft. lbs.).

9. Install exhaust Y-pipe 5.7L engine.

Page 2594 of 5267

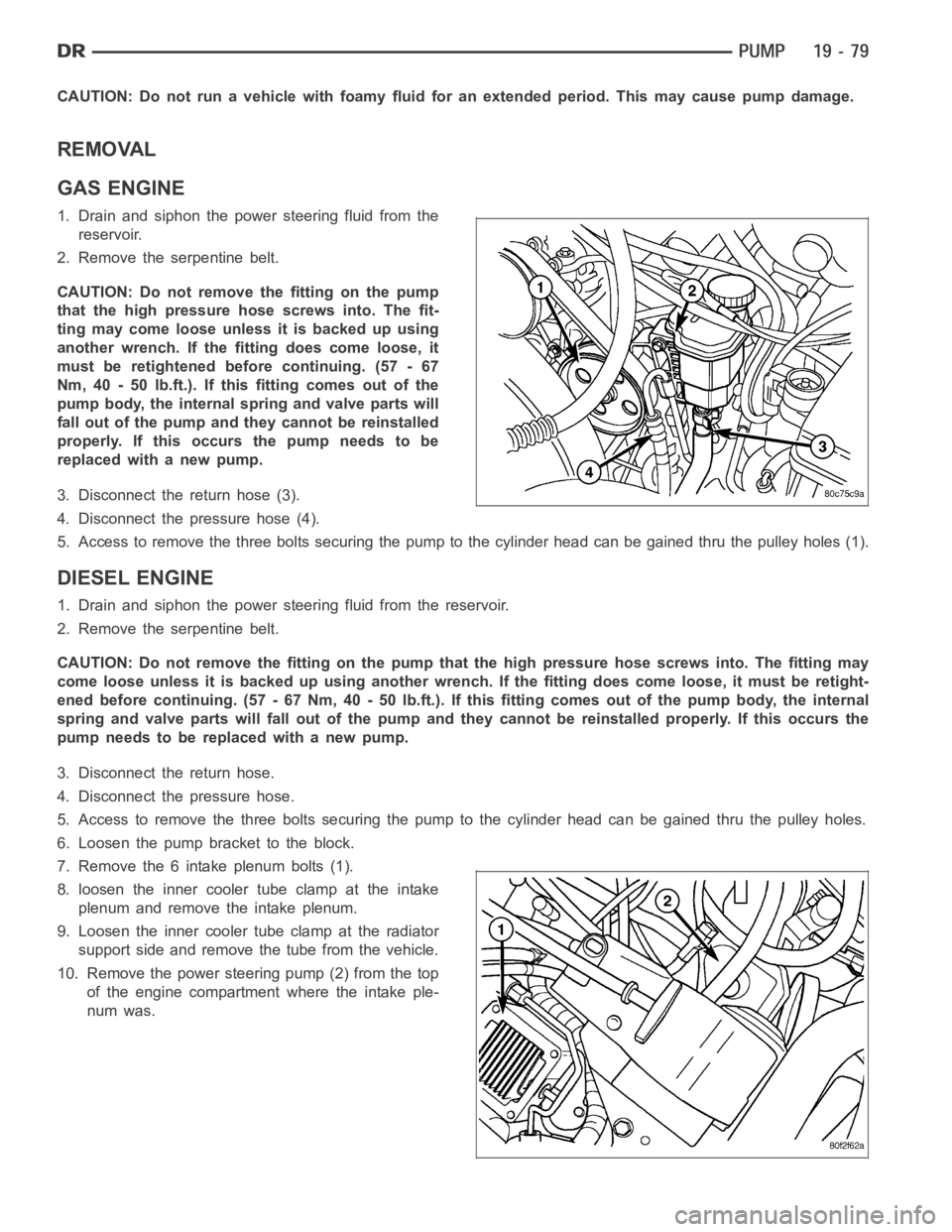

13. Remove starter motor (2), structural dust cover (3)

bolts to clutch housing, dust shield (1) bolt and

suspension crossmember (4).

CAUTION: Do not remove structural dust cover

from engine block. If cover is removed clutch

housing and cover must be aligned with the

engine.

14. Remove exhaust pipe from the exhaust manifolds.

15. Support engine with adjustable jack stand and

wood block.

16. Support and secure transmission (1) to a trans-

mission jack (2) with safety chains.

17. Remove bolts from the rear transmission mount.

18. Remove the rear crossmember (2) and transmis-

sion mount (1).

19. Remove bolts attaching transmission to the

engine.

20. Move transmission rearward until input shaft is

clear of clutch disc and pressure plate. Then

lower jack and remove transmission from under

vehicle.