DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 1161 of 1502

21-160

TRANSMISSION OVERHAUL—32RH

• before final assembly, install cam only as de

scribed in Transmission Assembly And Adjust

ment section. Clutch cam must be properly

indexed in case to fit and operate properly.

EXTENSION

HOUSING AND PARK LOCK

COMPONENT OVERHAUL

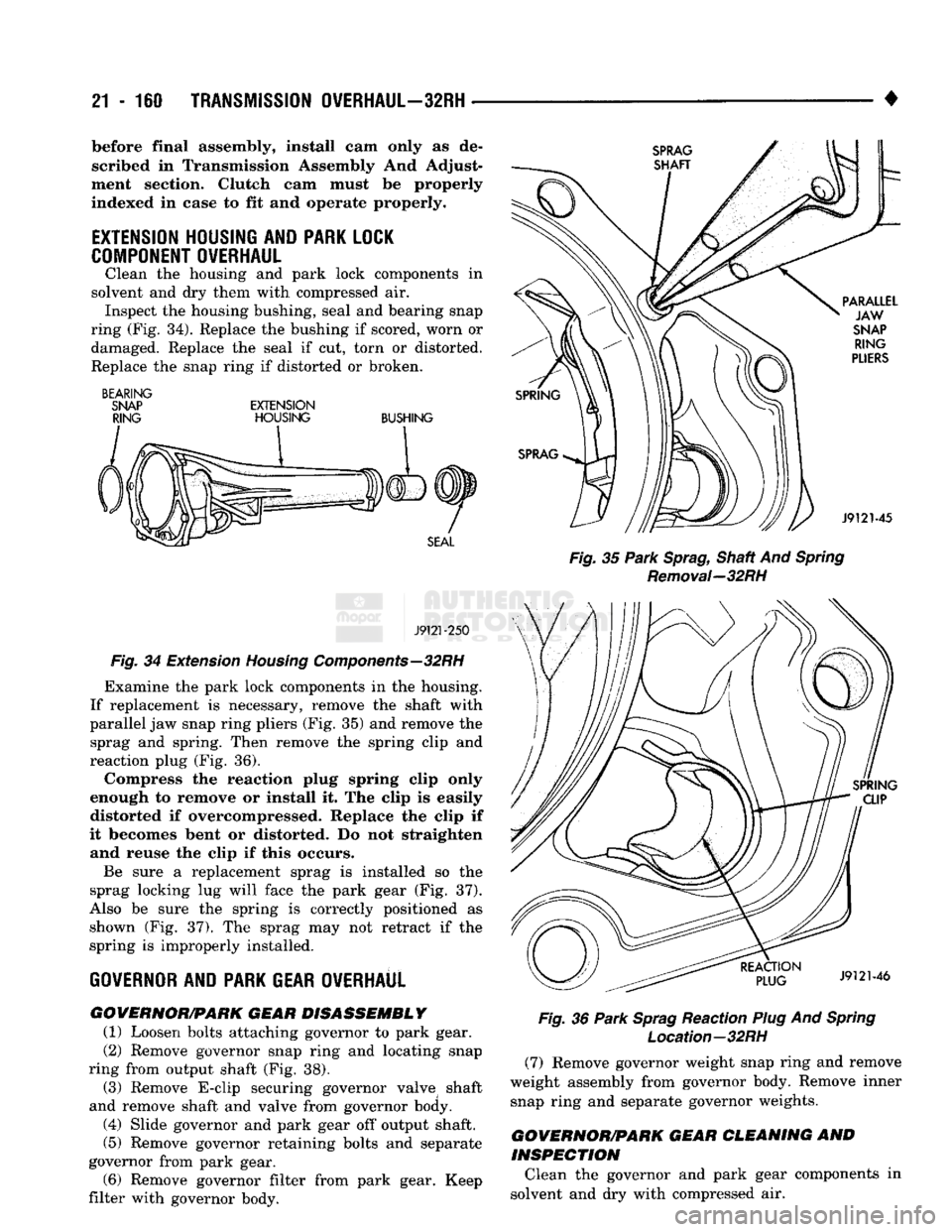

Clean the housing and park lock components in

solvent and dry them with compressed air. Inspect the housing bushing, seal and bearing snap

ring (Fig. 34). Replace the bushing if scored, worn or damaged. Replace the seal if cut, torn or distorted.

Replace the snap ring if distorted or broken.

BEARING

SNAP EXTENSION RING HOUSING BUSHING

J9121-250

Fig.

34 Extension

Housing

Components—32RH

Examine the park lock components in the housing.

If replacement is necessary, remove the shaft with

parallel jaw snap ring pliers (Fig. 35) and remove the sprag and spring. Then remove the spring clip and

reaction plug (Fig. 36). Compress the reaction plug spring clip only

enough to remove or install it. The clip is easily

distorted if overcompressed. Replace the clip if

it becomes bent or distorted. Do not straighten and reuse the clip if this occurs.

Be sure a replacement sprag is installed so the

sprag locking lug will face the park gear (Fig. 37).

Also be sure the spring is correctly positioned as shown (Fig. 37). The sprag may not retract if the

spring is improperly installed.

GOVERNOR

AND PARK GEAR OVERHAUL GOVERNOR/PARK GEAR DISASSEMBLY

(1) Loosen bolts attaching governor to park gear.

(2)

Remove governor snap ring and locating snap

ring from output shaft (Fig. 38). (3) Remove E-clip securing governor valve shaft

and remove shaft and valve from governor body.

(4) Slide governor and park gear off output shaft.

(5) Remove governor retaining bolts and separate

governor from park gear. (6) Remove governor filter from park gear. Keep

filter with governor body.

Fig.

35

Park

Sprag,

Shaft And

Spring

Removal—32RH

Fig.

36

Park

Sprag

Reaction

Plug

And

Spring

Location—32RH

(7) Remove governor weight snap ring and remove

weight assembly from governor body. Remove inner snap ring and separate governor weights.

GOVERNOR/PARK GEAR CLEANING

AND

INSPECTION

Clean the governor and park gear components in

solvent and dry with compressed air.

Page 1162 of 1502

•

J9121-47

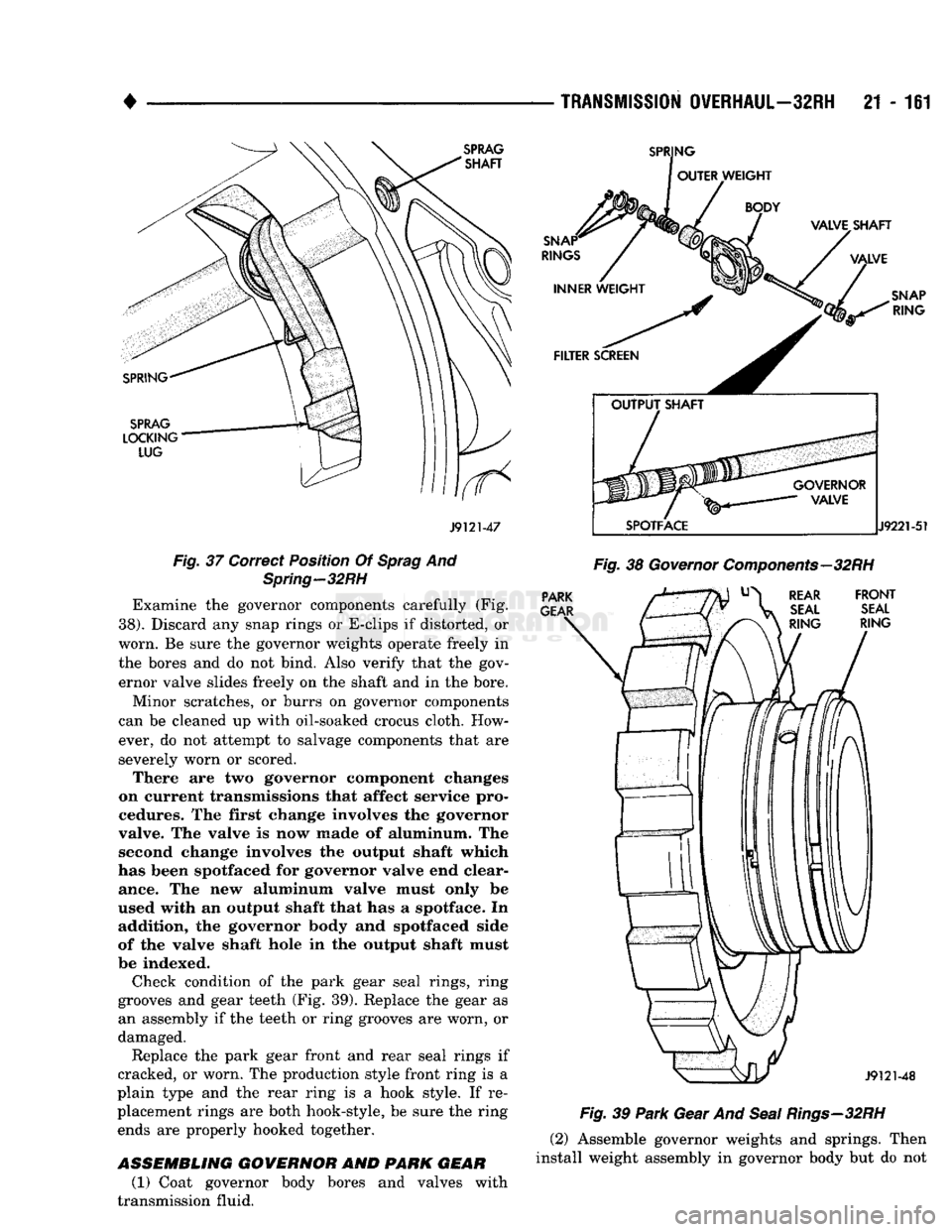

Fig.

37 Correct Position Of

Sprag

And

Spring—32RH

Examine the governor components carefully (Fig.

38). Discard any snap rings or E-clips if distorted, or

worn. Be sure the governor weights operate freely in the bores and do not bind. Also verify that the gov

ernor valve slides freely on the shaft and in the bore.

Minor scratches, or burrs on governor components

can be cleaned up with oil-soaked crocus cloth. How ever, do not attempt to salvage components that are

severely worn or scored. There are two governor component changes

on current transmissions that affect service pro

cedures. The first change involves the governor

valve. The valve is now made of aluminum. The second change involves the output shaft which

has been spotfaced for governor valve end clear ance. The new aluminum valve must only be

used with an output shaft that has a spotface. In addition, the governor body and spotfaced side

of the valve shaft hole in the output shaft must

be indexed.

Check condition of the park gear seal rings, ring

grooves and gear teeth (Fig. 39). Replace the gear as an assembly if the teeth or ring grooves are worn, or

damaged.

Replace the park gear front and rear seal rings if

cracked, or worn. The production style front ring is a

plain type and the rear ring is a hook style. If re

placement rings are both hook-style, be sure the ring ends are properly hooked together.

ASSEMBLING

GOVERNOR

AND

PARK GEAR

(1) Coat governor body bores and valves with

transmission fluid.

TRANSMISSION

OVERHAUL—32RH

21 - 161

Fig.

39

Park

Gear And

Seal

Rings—32RH

(2) Assemble governor weights and springs. Then

install weight assembly in governor body but do not

Page 1163 of 1502

21

- 162

TRANSMISSION

OVERHAUL—32RH

• install valve and shaft at this time. These parts are

not installed until after governor and park gear are

in place on output shaft.

(3) Install new seal rings on park gear if neces

sary.

(4) Insert filter screen in park gear and install

governor body on park gear. Tighten attaching bolts

finger tight only. Bolts will not be final tightened

until after governor and park gear are mounted on

output shaft.

OIL

PUMP

AND

REACTION

SHAFT

SUPPORT

OVERHAUL

PUMP

AND

SUPPORT

DISASSEMBLY

(1) Remove seal from around pump housing (Fig.

40).

Fig.

40

Removing

Pump

Housing

Seal—32RH

(2) Mark pump housing and support assembly for

alignment reference.

(3) Loosen bolts that attach pump body to support

(Fig. 41).

Fig.

41

Loosening

Pump

Support

Bolts

(4) Remove pump-to-support bolts and separate

support from pump housing (Fig. 42).

(5) Remove inner and outer gears from reaction

shaft support (Fig. 43).

(6) If pump seal was not removed during transmis

sion disassembly, remove seal with punch and ham

mer.

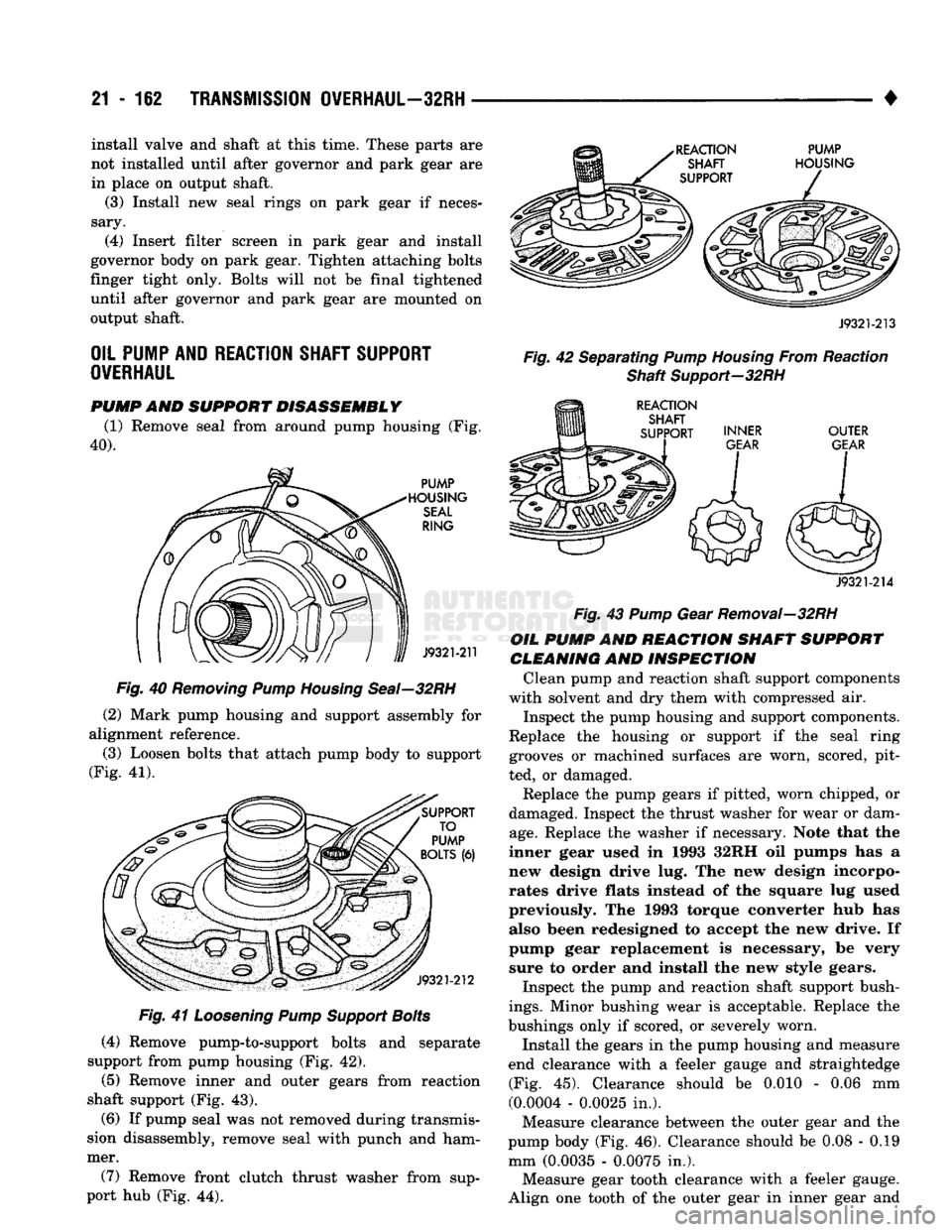

(7) Remove front clutch thrust washer from sup

port hub (Fig. 44).

J9321-213

Fig.

42 Separating

Pump

Housing

From Reaction

Shaft

Support-32RH

J9321-214

Fig.

43

Pump

Gear Removal—32RH

OIL

PUMP

AND

REACTION

SHAFT

SUPPORT

CLEANING

AND

INSPECTION

Clean pump and reaction shaft support components

with solvent and dry them with compressed air.

Inspect the pump housing and support components.

Replace the housing or support if the seal ring grooves or machined surfaces are worn, scored, pit

ted, or damaged.

Replace the pump gears if pitted, worn chipped, or

damaged. Inspect the thrust washer for wear or dam

age.

Replace the washer if necessary. Note that the

inner gear used in 1993 32RH oil pumps has a

new design drive lug. The new design incorpo

rates drive flats instead of the square lug used previously. The 1993 torque converter hub has also been redesigned to accept the new drive. If

pump gear replacement is necessary, be very sure to order and install the new style gears.

Inspect the pump and reaction shaft support bush

ings.

Minor bushing wear is acceptable. Replace the

bushings only if scored, or severely worn.

Install the gears in the pump housing and measure

end clearance with a feeler gauge and straightedge (Fig. 45). Clearance should be 0.010 - 0.06 mm

(0.0004 - 0.0025 in.).

Measure clearance between the outer gear and the

pump body (Fig. 46). Clearance should be 0.08 - 0.19

mm (0.0035 - 0.0075 in.). Measure gear tooth clearance with a feeler gauge.

Align one tooth of the outer gear in inner gear and

Page 1164 of 1502

TRANSMISSION

OVERHAUL—32RH

21 • 163

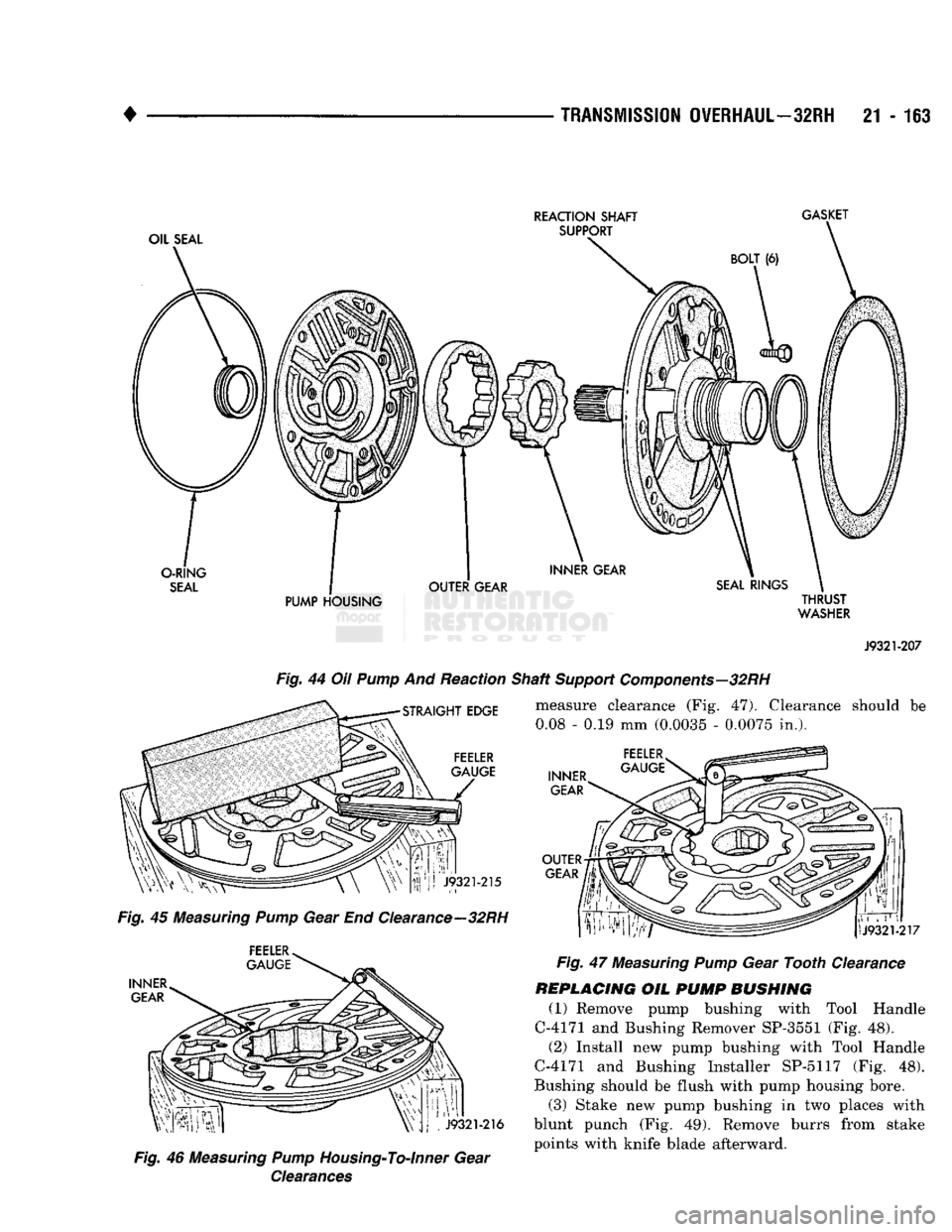

OIL SEAL REACTION SHAFT

SUPPORT GASKET

BOLT (6)

O-RING

SEAL

PUMP HOUSING THRUST

WASHER

J9321-207

Fig.

44 Oil

Pump

And Reaction Shaft

Support

Components—32RH

measure clearance (Fig. 47). Clearance should be

STRAIGHT

EDGE

FEELER

GAUGE

0.08

- 0.19 mm

(0.0035

- 0.0075 in.),

INNER

GEAR

J9321-215

Fig.

45 Measuring

Pump

Gear End Clearance—32RH FEELER

GAUGE

INNER GEAR

J9321-216

Fig.

46 Measuring

Pump

Housing-To-Inner

Gear

Clearances

OUTER

GEAR

If!

Fig.

47 Measuring

Pump

Gear Tooth Clearance

REPLACING

OIL

PUMP

BUSHING

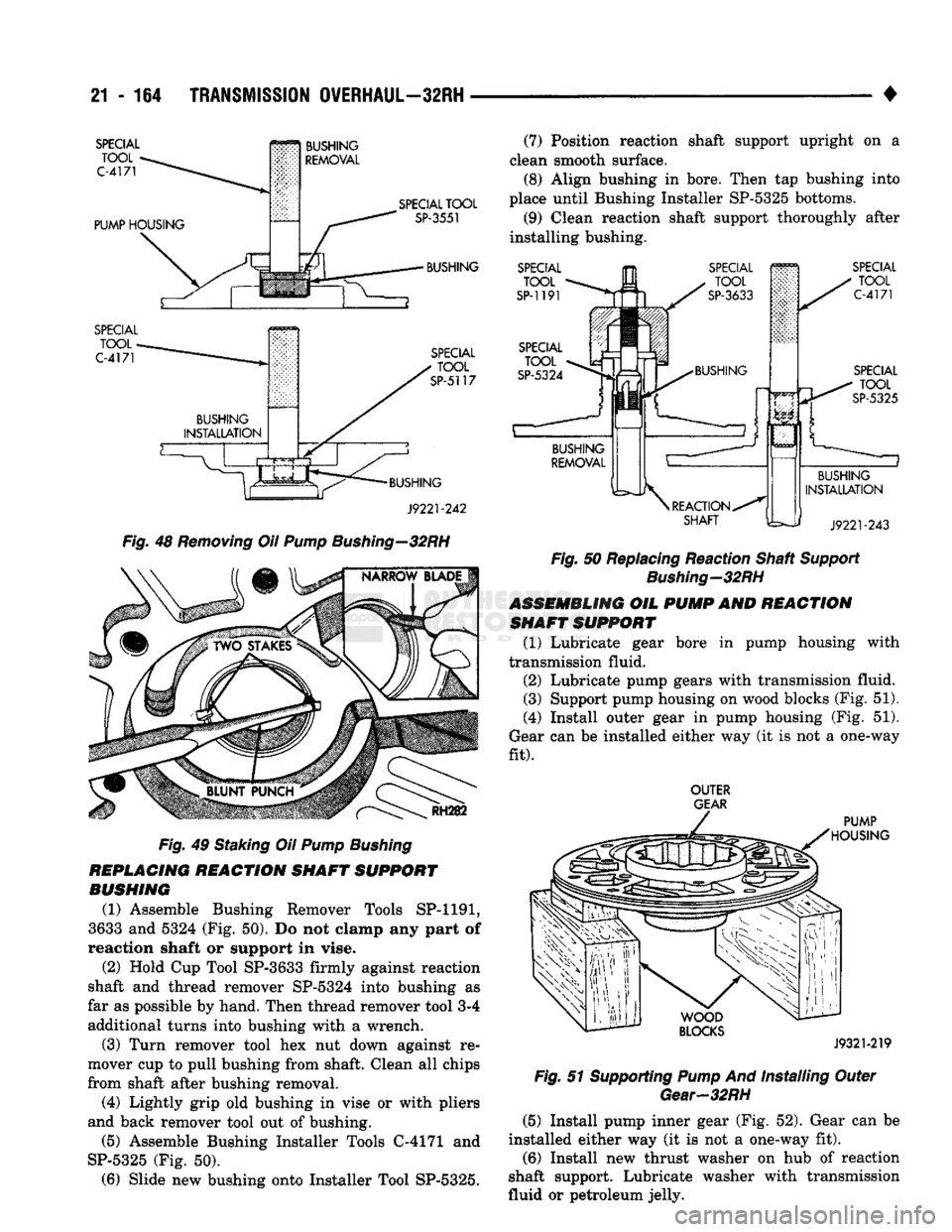

(1) Remove pump bushing with Tool Handle

C-4171 and Bushing Remover SP-3551 (Fig. 48). (2) Install new pump bushing with Tool Handle

C-4171 and Bushing Installer SP-5117 (Fig. 48).

Bushing should be flush with pump housing bore.

(3) Stake new pump bushing in two places with

blunt punch (Fig. 49). Remove burrs from stake points with knife blade afterward.

Page 1165 of 1502

21

- 164

TRANSMISSION

OVERHAUL—32RH

•

SPECIAL TOOL

C-4171

PUMP

HOUSING

BUSHING

REMOVAL

SPECIAL TOOL

C-4171

SPECIAL

TOOL

SP-3551

BUSHING

SPECIAL TOOL

SP-5117

BUSHING

J9221-242

Fig.

48

Removing

OH

Pump

Bushing—32RH

RH282

Fig.

49 Staking Oil

Pump

Bushing

REPLACING

REACTION

SHAFT

SUPPORT

BUSHING

(1) Assemble Bushing Remover Tools SP-1191,

3633 and 5324 (Fig. 50). Do not clamp any part of

reaction shaft or support in vise.

(2) Hold Cup Tool SP-3633 firmly against reaction

shaft and thread remover SP-5324 into bushing as

far as possible by hand. Then thread remover tool 3-4 additional turns into bushing with a wrench.

(3) Turn remover tool hex nut down against re

mover cup to pull bushing from shaft. Clean all chips

from shaft after bushing removal.

(4) Lightly grip old bushing in vise or with pliers

and back remover tool out of bushing.

(5) Assemble Bushing Installer Tools C-4171 and

SP-5325 (Fig. 50). (6) Slide new bushing onto Installer Tool SP-5325. (7) Position reaction shaft support upright on a

clean smooth surface. (8) Align bushing in bore. Then tap bushing into

place until Bushing Installer SP-5325 bottoms.

(9) Clean reaction shaft support thoroughly after

installing bushing.

SPECIAL

TOOL

SP-1191 SPECIAL

TOOL

C-4171

SPECIAL

_ U TQQL

SP-5325

BUSHING

INSTALLATION

J9221-243

Fig.

50 Replacing Reaction Shaft

Support

Bushing—32RH

ASSEMBLING

OIL

PUMP

AND

REACTION

SHAFT

SUPPORT

(1) Lubricate gear bore in pump housing with

transmission fluid.

(2) Lubricate pump gears with transmission fluid.

(3) Support pump housing on wood blocks (Fig. 51).

(4) Install outer gear in pump housing (Fig. 51).

Gear can be installed either way (it is not a one-way

fit).

OUTER

GEAR

PUMP

HOUSING

WOOD

BLOCKS

J9321-219

Fig.

51 Supporting

Pump

And Installing Outer

Gear-32RH

(5) Install pump inner gear (Fig. 52). Gear can be

installed either way (it is not a one-way fit). (6) Install new thrust washer on hub of reaction

shaft support. Lubricate washer with transmission

fluid or petroleum jelly.

Page 1166 of 1502

TRANSMISSION

OVERHAUL—32RH

21 - 165

OUTER

GEAR

INNER

GEAR

PUMP

HOUSING'

REACTION

SHAFT

SUPPORT

J9321-220

Fig.

52

Pump

Inner

Gear Installation—32RH

(7) If reaction shaft seal rings are being replaced,

install new seal rings on support hub (Fig. 53). Lu

bricate seal rings with transmission fluid or petro leum jelly after installation. Squeeze each ring until

ring ends are securely hooked together.

CAUTION:

The

reaction shaft support seal

rings

will

break

if

overspread,

or

twisted.

If new

rings

are be

ing installed, spread them only enough

for

installa

tion.

Also

be

very sure

the

ring ends

are

securely hooked together

after

installation. Otherwise,

the

rings

will

either

prevent pump installation,

or

break

during installation.

SEAL

RINGS SUPPORT

S*^

HUB

J9321-218

Fig.

53 Hub

Seal

Ring

Position—32RH

(8) Install reaction shaft support on pump housing

(Fig. 54).

(9) Align reaction support on pump housing. Use

alignment marks made at disassembly. Or, rotate

support until bolt holes in support and pump housing

are all aligned (holes are offset for one-way fit).

(10) Install all bolts that attach support to pump

housing. Then tighten bolts finger tight.

(11) Tighten support-to-pump bolts to required

torque as follows:

(a) Reverse pump assembly and install it in

transmission case. Position pump so bolts are fac ing out and are accessible.

|lrJ9321-221

Fig.

54

Assembling

Reaction Shaft

Support

And

Pump

Housing—32RH

(b) Secure pump assembly in case with 2 or 3

bolts,

or with pilot studs. (c) Tighten support-to-pump bolts to 20 N»m (15

ft. lbs.).

(d) Remove pump assembly from transmission

case.

(12) Install new oil seal in pump with Special Tool

C-4193 and Tool Handle C-4171 (Fig. 55). Be sure

seal lip faces inward.

(13) Install new seal ring around pump housing.

Be sure seal is properly seated in groove.

(14) Lubricate lip of pump oil seal with petroleum

jelly. Lubricate pump seal with Ru-Glyde or petro leum jelly.

SPECIAL

TOOL

C-4193

PUMP

BODY

PUMP

SEAL

LCC.

,^77/OS

J9321-183

Fig.

55

Pump

Oil

Seal

Installation-32RH

FRONT CLUTCH OVERHAUL

FRONT

CLUTCH

DISASSEMBLY

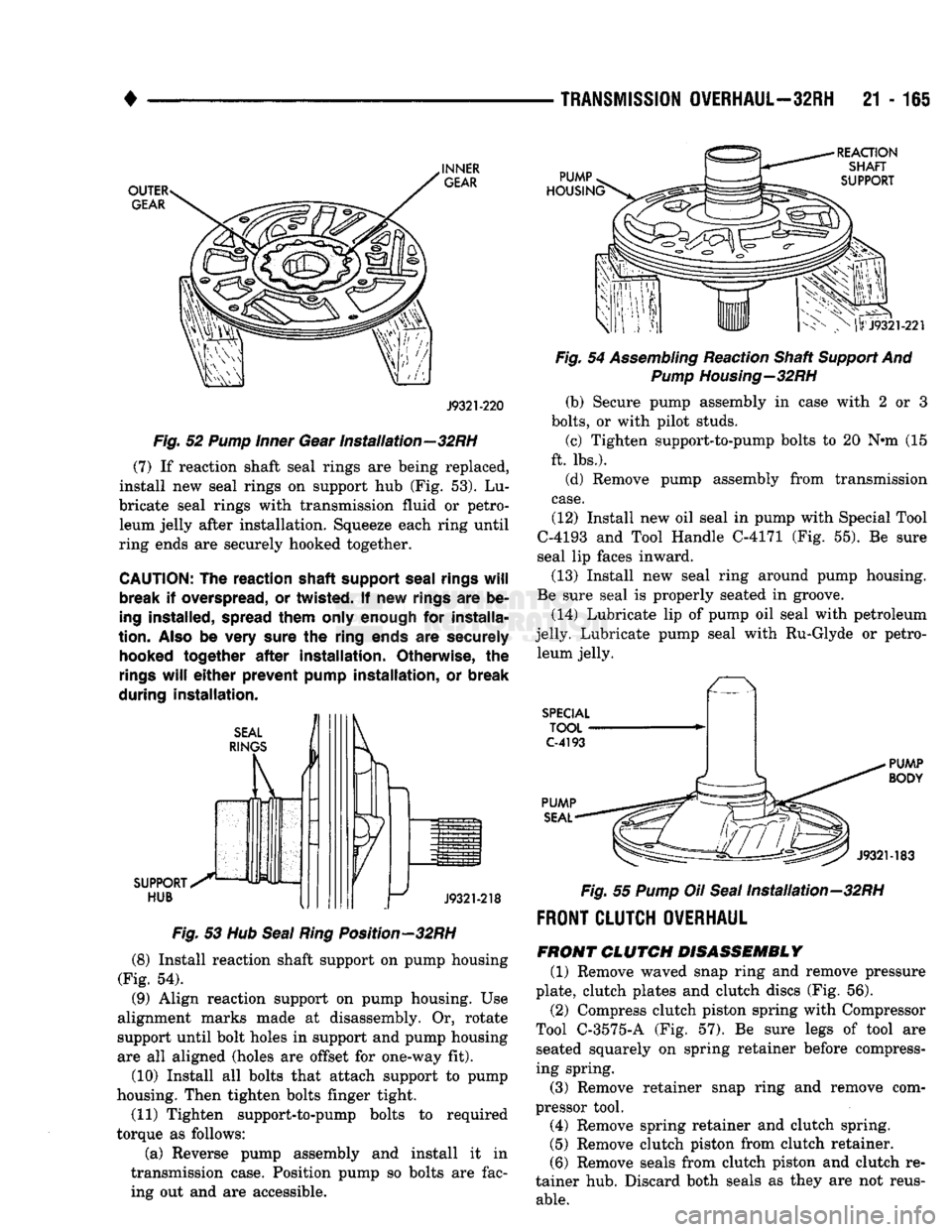

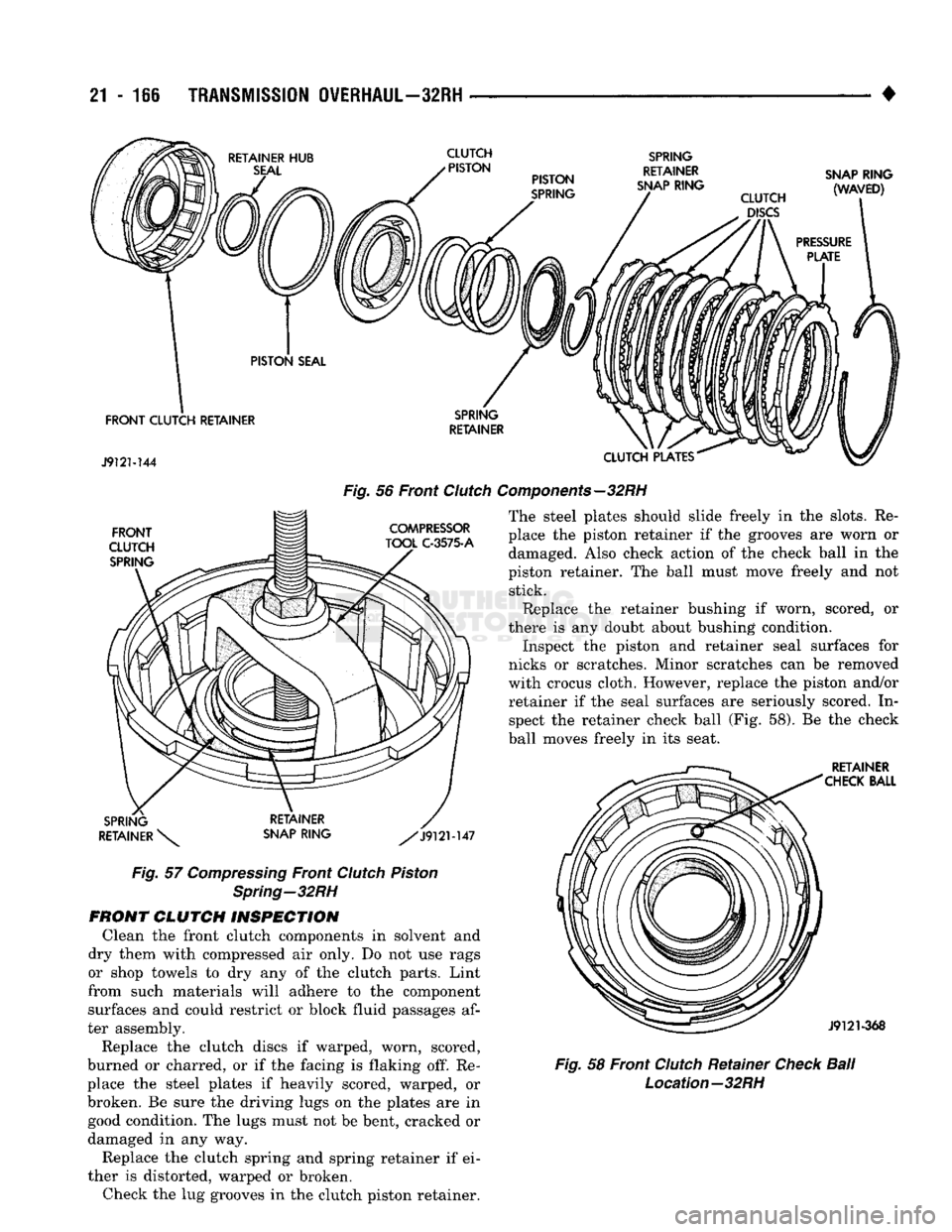

(1) Remove waved snap ring and remove pressure

plate, clutch plates and clutch discs (Fig. 56).

(2) Compress clutch piston spring with Compressor

Tool C-3575-A (Fig. 57). Be sure legs of tool are seated squarely on spring retainer before compress

ing spring.

(3) Remove retainer snap ring and remove com

pressor tool. (4) Remove spring retainer and clutch spring.

(5) Remove clutch piston from clutch retainer.

(6) Remove seals from clutch piston and clutch re

tainer hub. Discard both seals as they are not reus

able.

Page 1167 of 1502

21

- 116

TRANSMISSION

OVERHAUL—32RH

CLUTCH

>

PISTON SPRING

RETAINER

SNAP RING SNAP RING

(WAVED)

FRONT CLUTCH RETAINER

J9121-144

CLUTCH PLATES

Fig.

56 Front

Clutch

Components—32RH

FRONT

CLUTCH SPRING COMPRESSOR

TOOL C-3575-A The steel plates should slide freely in the slots. Re

place the piston retainer if the grooves are worn or damaged. Also check action of the check ball in the

piston retainer. The ball must move freely and not stick.

Replace the retainer bushing if worn, scored, or

there is any doubt about bushing condition. Inspect the piston and retainer seal surfaces for

nicks or scratches. Minor scratches can be removed

with crocus cloth. However, replace the piston and/or retainer if the seal surfaces are seriously scored. Inspect the retainer check ball (Fig. 58). Be the check

ball moves freely in its seat. RETAINER

CHECK BALL

SPRING

RETAINER \^ RETAINER

SNAP RING ^/J912M47

Fig.

57

Compressing

Front

Clutch

Piston

Spring—32RH

FRONT CLUTCH INSPECTION

Clean the front clutch components in solvent and

dry them with compressed air only. Do not use rags

or shop towels to dry any of the clutch parts. Lint

from such materials will adhere to the component surfaces and could restrict or block fluid passages af

ter assembly.

Replace the clutch discs if warped, worn, scored,

burned or charred, or if the facing is flaking off. Re

place the steel plates if heavily scored, warped, or

broken. Be sure the driving lugs on the plates are in good condition. The lugs must not be bent, cracked or

damaged in any way.

Replace the clutch spring and spring retainer if ei

ther is distorted, warped or broken. Check the lug grooves in the clutch piston retainer.

J9121-368

Fig.

58 Front

Clutch

Retainer

Check

Ball

Location—32RH

Page 1168 of 1502

TRANSMISSION

OVERHAUL—32RH

21 - 167

REPLACING

FRONT

CLUTCH RETAINER

BUSHING

(1) Assemble Tool Handle C-4171 and Bushing Re

mover SP-3627 (Fig. 59).

(2) Insert remover tool in bushing and drive old

bushing out of retainer (Fig. 59). (3) Mount Bushing Installer SP-3626 on Tool Han

dle C-4171. Then slide new bushing onto installer

tool. (4) Align and install new bushing. Tap bushing

into retainer until installer tool bottoms against re

tainer (Fig. 59). (5) Remove bushing replacement tools and clean

retainer thoroughly.

SPECIAL

TOOL

C-4171

FRONT

CLUTCH

RETAINER

SPECIAL

TOOL

SP-3627 SPECIAL

TOOL

C-4171

SPECIAL

TOOL

SP-3626

BUSHING

BUSHING

REMOVAL

BUSHING

INSTALLATION

J9221-246

Fig.

59

Replacing

Front

Clutch

Retainer

Bushing—32RH

ASSEMBLING

FRONT CLUTCH

(1) Lubricate clutch plates and soak clutch discs in

transmission fluid. (2) Install new seals on piston and in hub of re

tainer. Be sure lip of each seal faces interior of clutch retainer.

(3) Lubricate lip of piston and retainer seals with

liberal quantity of Door Eze, or petroleum jelly. Then

lubricate retainer hub, bore and piston with trans

mission fluid.

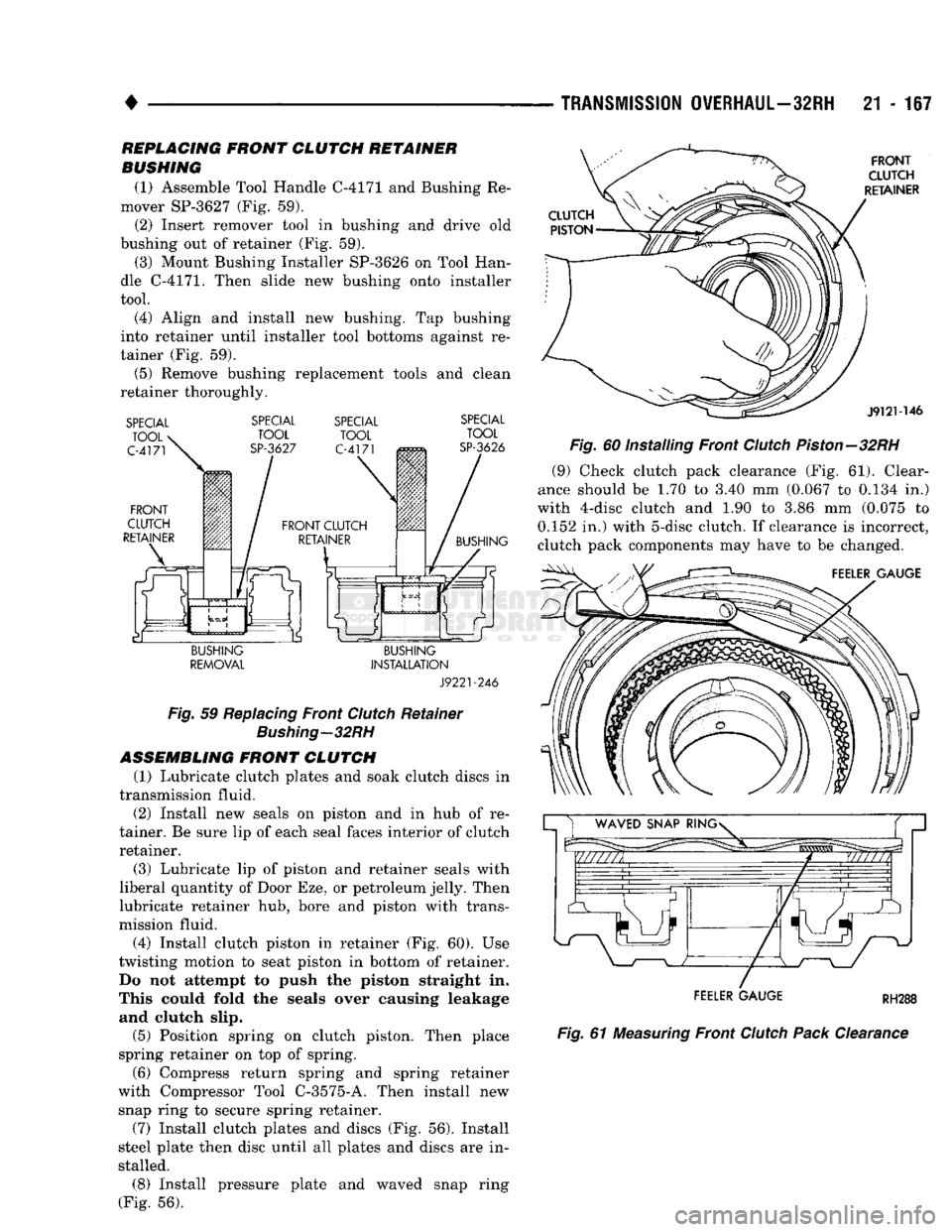

(4) Install clutch piston in retainer (Fig. 60). Use

twisting motion to seat piston in bottom of retainer. Do not attempt to push the piston straight in.

This could fold the seals over causing leakage and clutch slip.

(5) Position spring on clutch piston. Then place

spring retainer on top of spring.

(6) Compress return spring and spring retainer

with Compressor Tool C-3575-A. Then install new snap ring to secure spring retainer.

(7) Install clutch plates and discs (Fig. 56). Install

steel plate then disc until all plates and discs are in

stalled.

(8) Install pressure plate and waved snap ring

(Fig. 56).

FRONT

CLUTCH

RETAINER

J9121-146

Fig.

60 Installing Front

Clutch

Piston—32RH

(9) Check clutch pack clearance (Fig. 61). Clear

ance should be 1.70 to 3.40 mm (0.067 to 0.134 in.)

with 4-disc clutch and 1.90 to 3.86 mm (0.075 to 0.152 in.) with 5-disc clutch. If clearance is incorrect,

clutch pack components may have to be changed.

FEELER GAUGE

FEELER GAUGE

RH288

Fig.

61

Measuring

Front

Clutch

Pack

Clearance

Page 1169 of 1502

21-168

TRANSMISSION

OVERHAUL—32RH

REAR

CLUTCH PISTON CLUTCH

PISTON

SEALS

OUTPUT

SHAFT

THRUST

WASHER

(METAL) INPUT

SHAFT

SNAP

RING

REAR

CLUTCH

RETAINER INPUT

SHAFT

-REAR

CLUTCH

.

THRUST

" /

SHAFT WASHER

/

FRONT

('I"")

SHAFT SEAL

REAR

RING

rniTru

SEAL

(TEFLON)

C^TCH

RING PACK

SNAP

RING

(SELECTIVE)

PISTON

SPRING

BOTTOM

PRESSURE

PLATE CLUTCH

DISCS

(4)

TOP

PRESSURE

PLATE

J9121-539

Fig.

62 Rear

Clutcl

REAR

CLUTCH OVERHAUL

REAR

CLUTCH DISASSEMBLY

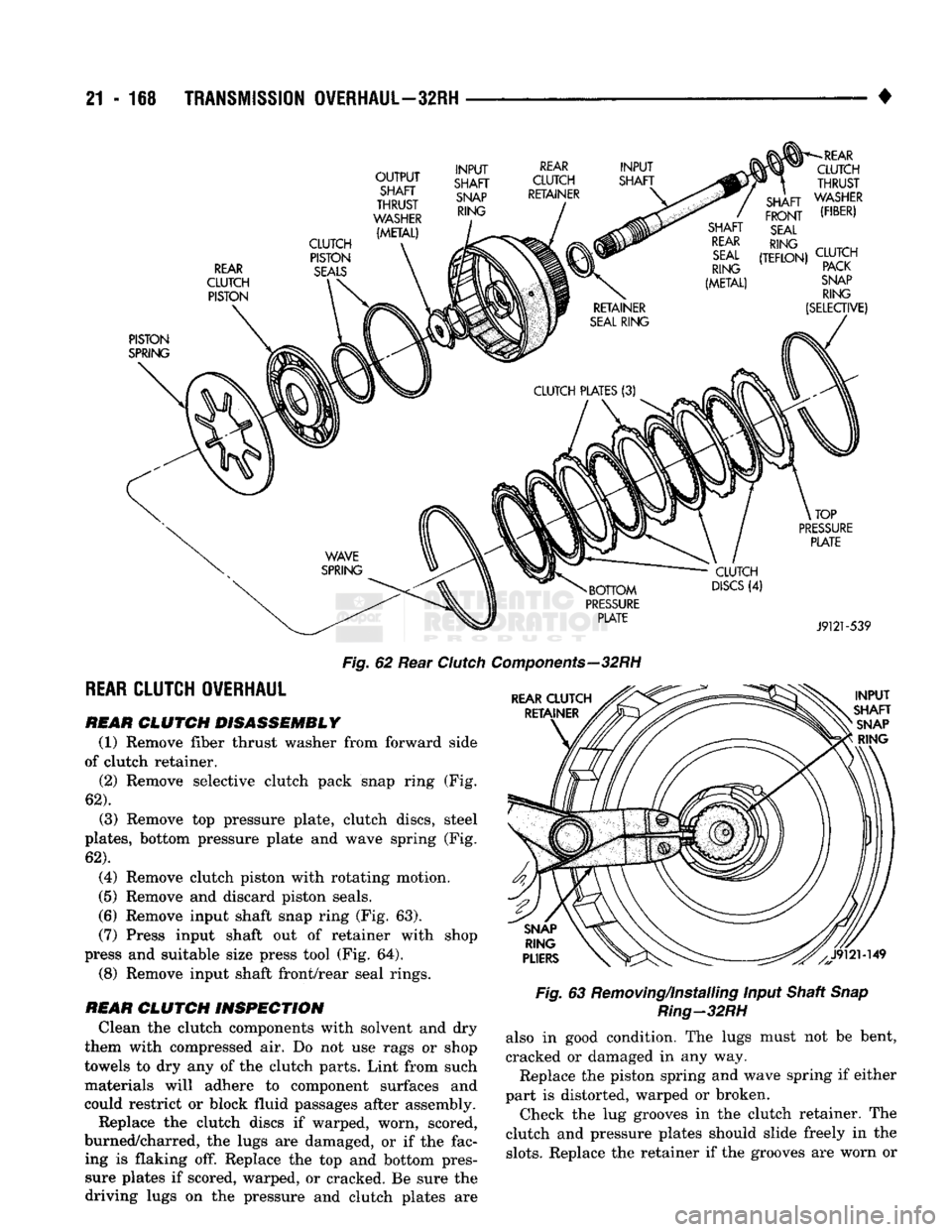

(1) Remove fiber thrust washer from forward side

of clutch retainer. (2) Remove selective clutch pack snap ring (Fig.

62).

(3) Remove top pressure plate, clutch discs, steel

plates,

bottom pressure plate and wave spring (Fig.

62).

(4) Remove clutch piston with rotating motion.

(5) Remove and discard piston seals.

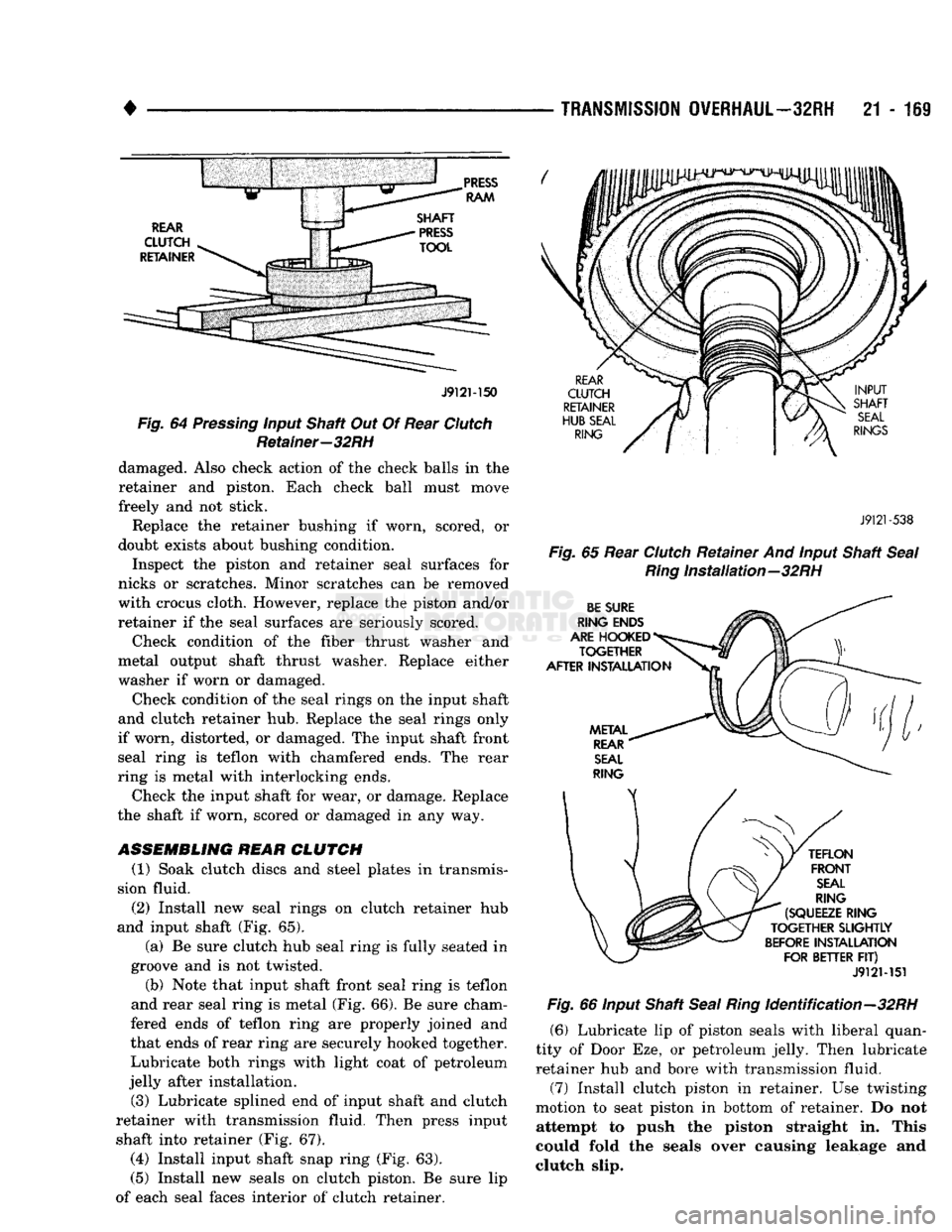

(6) Remove input shaft snap ring (Fig. 63). (7) Press input shaft out of retainer with shop

press and suitable size press tool (Fig. 64).

(8) Remove input shaft front/rear seal rings.

REAR

CLUTCH INSPECTION

Clean the clutch components with solvent and dry

them with compressed air. Do not use rags or shop

towels to dry any of the clutch parts. Lint from such materials will adhere to component surfaces and

could restrict or block fluid passages after assembly.

Replace the clutch discs if warped, worn, scored,

burned/charred, the lugs are damaged, or if the fac ing is flaking off. Replace the top and bottom pressure plates if scored, warped, or cracked. Be sure the

driving lugs on the pressure and clutch plates are

Components—32

RH

Fig.

63 Removing/Installing Input Shaft

Snap

Ring-32RH

also in good condition. The lugs must not be bent,

cracked or damaged in any way. Replace the piston spring and wave spring if either

part is distorted, warped or broken. Check the lug grooves in the clutch retainer. The

clutch and pressure plates should slide freely in the

slots.

Replace the retainer if the grooves are worn or

Page 1170 of 1502

•

TRANSMISSION

OVERHAUL—32RH

21 - 111

J9121-150

Fig. 64 Pressing input Shaft Out Of Rear Clutch Retainer—32RH damaged. Also check action of the check balls in the

retainer and piston. Each check ball must move

freely and not stick.

Replace the retainer bushing if worn, scored, or

doubt exists about bushing condition.

Inspect the piston and retainer seal surfaces for

nicks or scratches. Minor scratches can be removed

with crocus cloth. However, replace the piston and/or

retainer if the seal surfaces are seriously scored.

Check condition of the fiber thrust washer and

metal output shaft thrust washer. Replace either

washer if worn or damaged.

Check condition of the seal rings on the input shaft

and clutch retainer hub. Replace the seal rings only

if worn, distorted, or damaged. The input shaft front seal ring is teflon with chamfered ends. The rear

ring is metal with interlocking ends.

Check the input shaft for wear, or damage. Replace

the shaft if worn, scored or damaged in any way.

ASSEMBLING REAR

CLUTCH

(1) Soak clutch discs and steel plates in transmis

sion fluid.

(2)

Install new seal rings on clutch retainer hub

and input shaft (Fig. 65).

(a) Be sure clutch hub seal ring is fully seated in

groove and is not twisted.

(b) Note that input shaft front seal ring is teflon

and rear seal ring is metal (Fig. 66). Be sure cham

fered ends of teflon ring are properly joined and

that ends of rear ring are securely hooked together. Lubricate both rings with light coat of petroleum

jelly after installation.

(3) Lubricate splined end of input shaft and clutch

retainer with transmission fluid. Then press input shaft into retainer (Fig. 67).

(4)

Install input shaft snap ring (Fig. 63).

(5) Install new seals on clutch piston. Be sure lip

of each seal faces interior of clutch retainer.

J9121

-538

Fig.

65 Rear Clutch Retainer And input Shaft

Seal Ring

Installation—32RH

J912M51 Fig. 66 input Shaft Seal

Ring

Identification—32RH

(6) Lubricate lip of piston seals with liberal quan

tity of Door Eze, or petroleum jelly. Then lubricate

retainer hub and bore with transmission fluid. (7) Install clutch piston in retainer. Use twisting

motion to seat piston in bottom of retainer. Do not attempt to push the piston straight in. This

could fold the seals over causing leakage and

clutch slip.