DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 1171 of 1502

21

- 170

TRANSMISSION OVERHAUL—32RH

•

Fig.

67

Pressing

input Shaft

into

Rear

Clutch

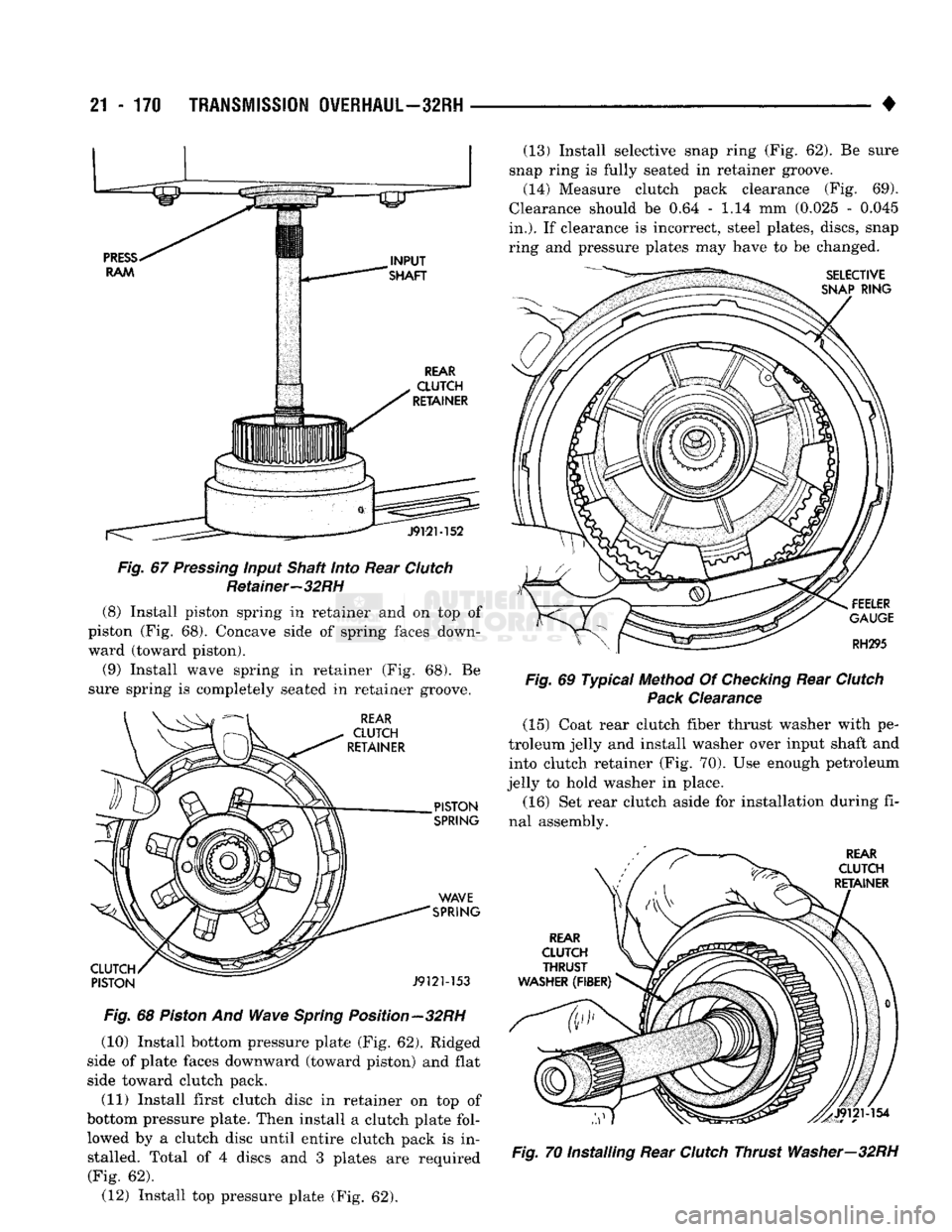

Retainer—32RH (8) Install piston spring in retainer and on top of

piston (Fig. 68). Concave side of spring faces down ward (toward piston).

(9) Install wave spring in retainer (Fig. 68). Be

sure spring is completely seated in retainer groove.

Fig.

68

Piston

And Wave

Spring

Position—32RH

(10) Install bottom pressure plate (Fig. 62). Ridged

side of plate faces downward (toward piston) and flat

side toward clutch pack.

(11) Install first clutch disc in retainer on top of

bottom pressure plate. Then install a clutch plate fol lowed by a clutch disc until entire clutch pack is installed. Total of 4 discs and 3 plates are required (Fig. 62). (12) Install top pressure plate (Fig. 62). (13) Install selective snap ring (Fig. 62). Be sure

snap ring is fully seated in retainer groove. (14) Measure clutch pack clearance (Fig. 69).

Clearance should be 0.64 - 1.14 mm (0.025 - 0.045

in.).

If clearance is incorrect, steel plates, discs, snap

ring and pressure plates may have to be changed.

Fig.

69 Typical Method Of

Checking

Rear

Clutch

Pack

Clearance (15) Coat rear clutch fiber thrust washer with pe

troleum jelly and install washer over input shaft and into clutch retainer (Fig. 70). Use enough petroleum

jelly to hold washer in place.

(16) Set rear clutch aside for installation during fi

nal assembly.

Fig.

70 Installing Rear

Clutch

Thrust Washer—32RH

Page 1172 of 1502

TRANSMISSION

OVERHAUL—32RH

21 - 171

PLANETARY GEAR TRAIN

OVERHAUL

•OUTPUT

SHAFT

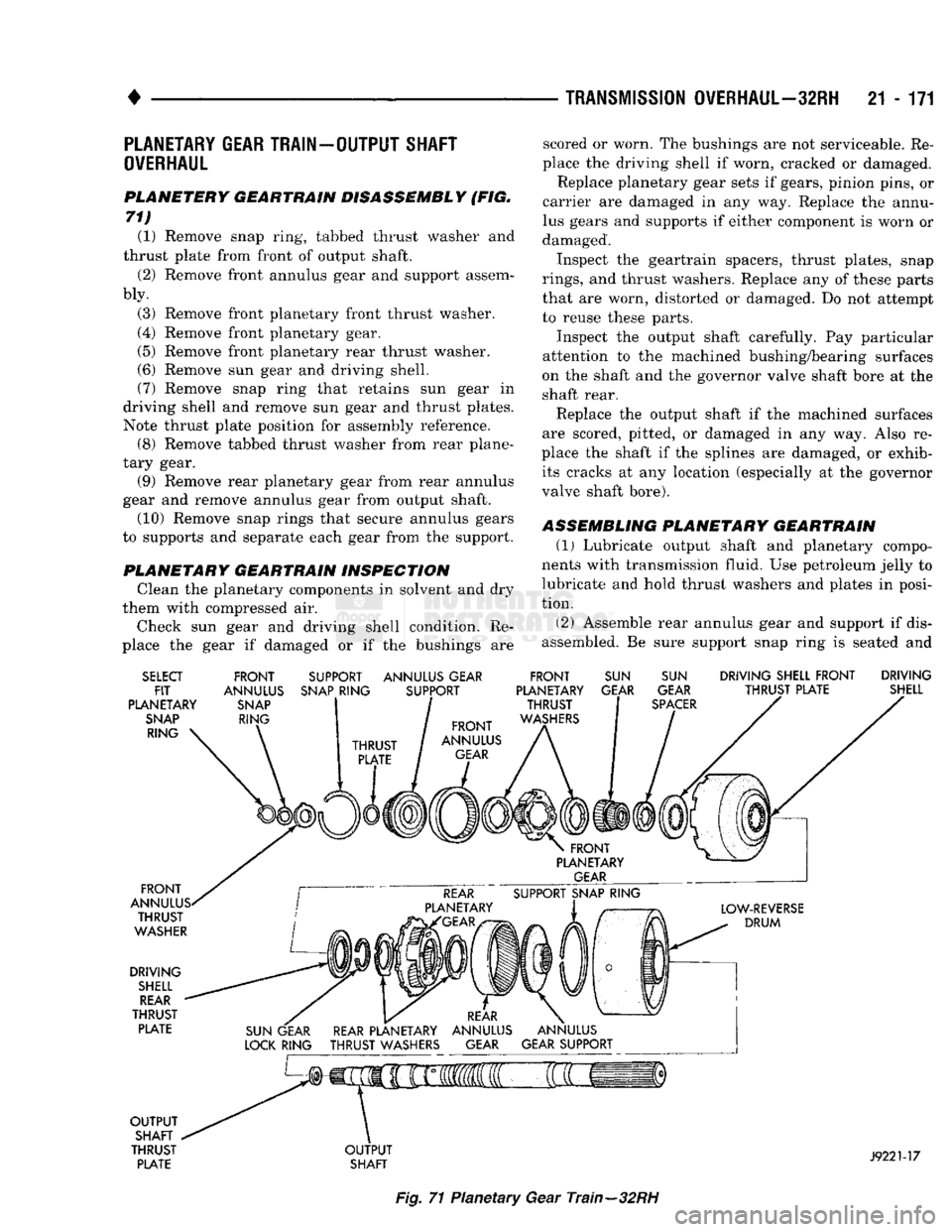

PLANETERY GEARTRAIN DISASSEMBLY (FIG.

71) (1) Remove snap ring, tabbed thrust washer and

thrust plate from front of output shaft.

(2) Remove front annulus gear and support assem

bly.

(3) Remove front planetary front thrust washer.

(4) Remove front planetary gear.

(5) Remove front planetary rear thrust washer.

(6) Remove sun gear and driving shell.

(7) Remove snap ring that retains sun gear in

driving shell and remove sun gear and thrust plates.

Note thrust plate position for assembly reference. (8) Remove tabbed thrust washer from rear plane

tary gear. (9) Remove rear planetary gear from rear annulus

gear and remove annulus gear from output shaft. (10) Remove snap rings that secure annulus gears

to supports and separate each gear from the support.

PLANETARY GEARTRAIN INSPECTION Clean the planetary components in solvent and dry

them with compressed air.

Check sun gear and driving shell condition. Re

place the gear if damaged or if the bushings are scored or worn. The bushings are not serviceable. Re

place the driving shell if worn, cracked or damaged. Replace planetary gear sets if gears, pinion pins, or

carrier are damaged in any way. Replace the annu

lus gears and supports if either component is worn or

damaged.

Inspect the geartrain spacers, thrust plates, snap

rings,

and thrust washers. Replace any of these parts

that are worn, distorted or damaged. Do not attempt

to reuse these parts.

Inspect the output shaft carefully. Pay particular

attention to the machined bushing/bearing surfaces

on the shaft and the governor valve shaft bore at the

shaft rear.

Replace the output shaft if the machined surfaces

are scored, pitted, or damaged in any way. Also re

place the shaft if the splines are damaged, or exhib its cracks at any location (especially at the governor

valve shaft bore).

ASSEMBLING PLANETARY GEARTRAIN

(1)

Lubricate output shaft and planetary compo

nents with transmission fluid. Use petroleum jelly to

lubricate and hold thrust washers and plates in posi

tion.

(2) Assemble rear annulus gear and support if dis

assembled. Be sure support snap ring is seated and

SELECT

FIT

PLANETARY

SNAP

RING FRONT

ANNULUS

SNAP

RING SUPPORT ANNULUS GEAR

SNAP

RING SUPPORT FRONT

PLANETARY THRUST

WASHERS

SUN

GEAR

SUN

GEAR

SPACER

DRIVING SHELL FRONT DRIVING

THRUST PLATE SHELL

FRONT

ANNULUS. THRUST

WASHER

DRIVING

SHELL

REAR

THRUST PLATE

OUTPUT

SHAFT

THRUST PLATE

OUTPUT

SHAFT

J9221-17

Fig.

71 Planetary Gear Train—32RH

Page 1173 of 1502

21

- 172

TRANSMISSION OVERHAUL—32RH

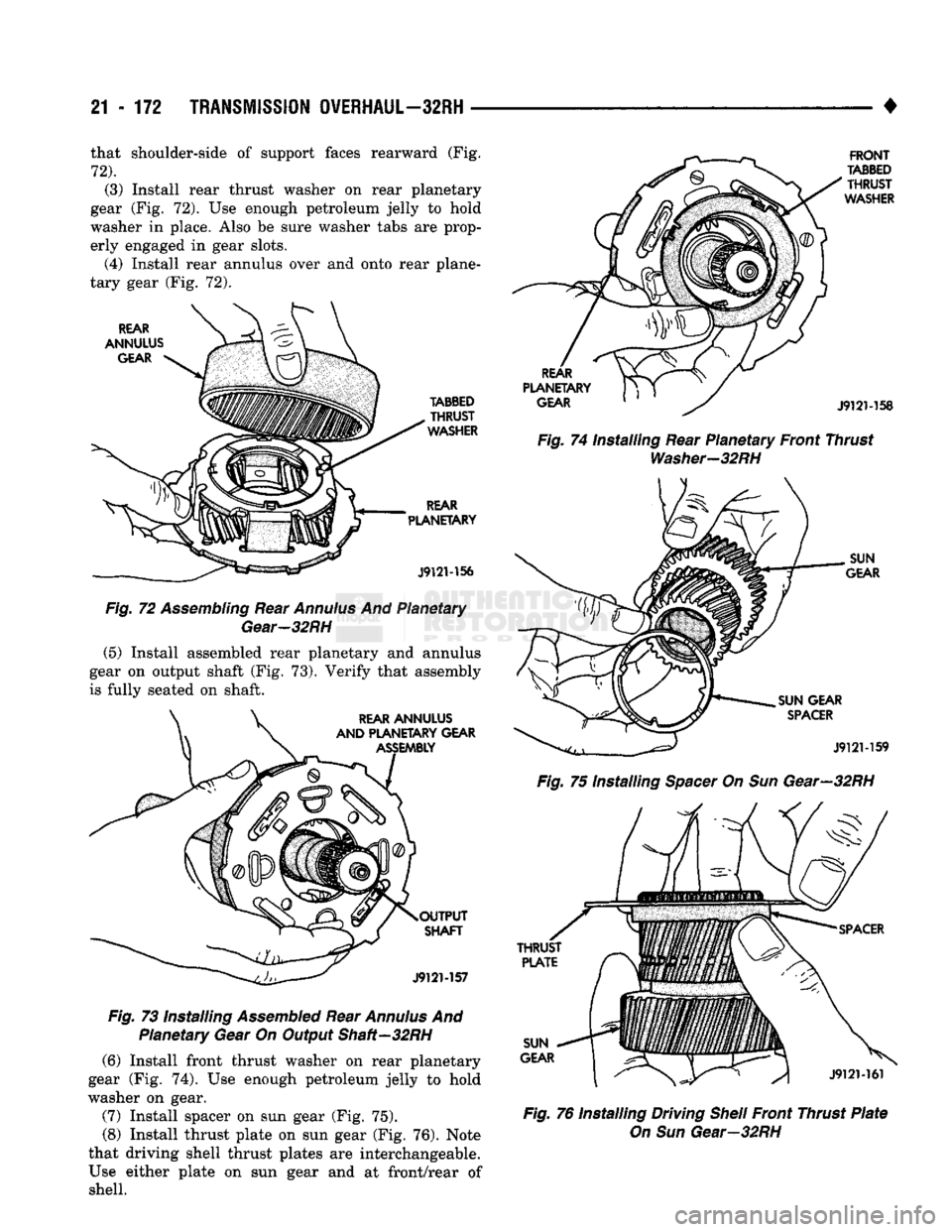

• that shoulder-side of support faces rearward (Fig.

72).

(3) Install rear thrust washer on rear planetary

gear (Fig. 72). Use enough petroleum jelly to hold

washer in place. Also be sure washer tabs are prop

erly engaged in gear slots.

(4) Install rear annulus over and onto rear plane

tary gear (Fig. 72).

Fig. 72

Assembling

Rear

Annulus

And Planetary

Gear-32RH

(5) Install assembled rear planetary and annulus

gear on output shaft (Fig. 73). Verify that assembly

is fully seated on shaft.

Fig.

73 installing Assembled Rear Annulus And Planetary Gear On Output Shaft-32RH

(6) Install front thrust washer on rear planetary

gear (Fig. 74). Use enough petroleum jelly to hold

washer on gear.

(7) Install spacer on sun gear (Fig. 75). (8) Install thrust plate on sun gear (Fig. 76). Note

that driving shell thrust plates are interchangeable. Use either plate on sun gear and at front/rear of shell. Fig. 74 installing Rear Planetary Front Thrust

Washer-32RH

Fig. 75 Installing Spacer On Sun Gear—32RH

Fig. 76 Installing Driving Shell Front Thrust Plate On Sun Gear-32RH

Page 1174 of 1502

•

TRANSMISSION

OVERHAUL—32RH

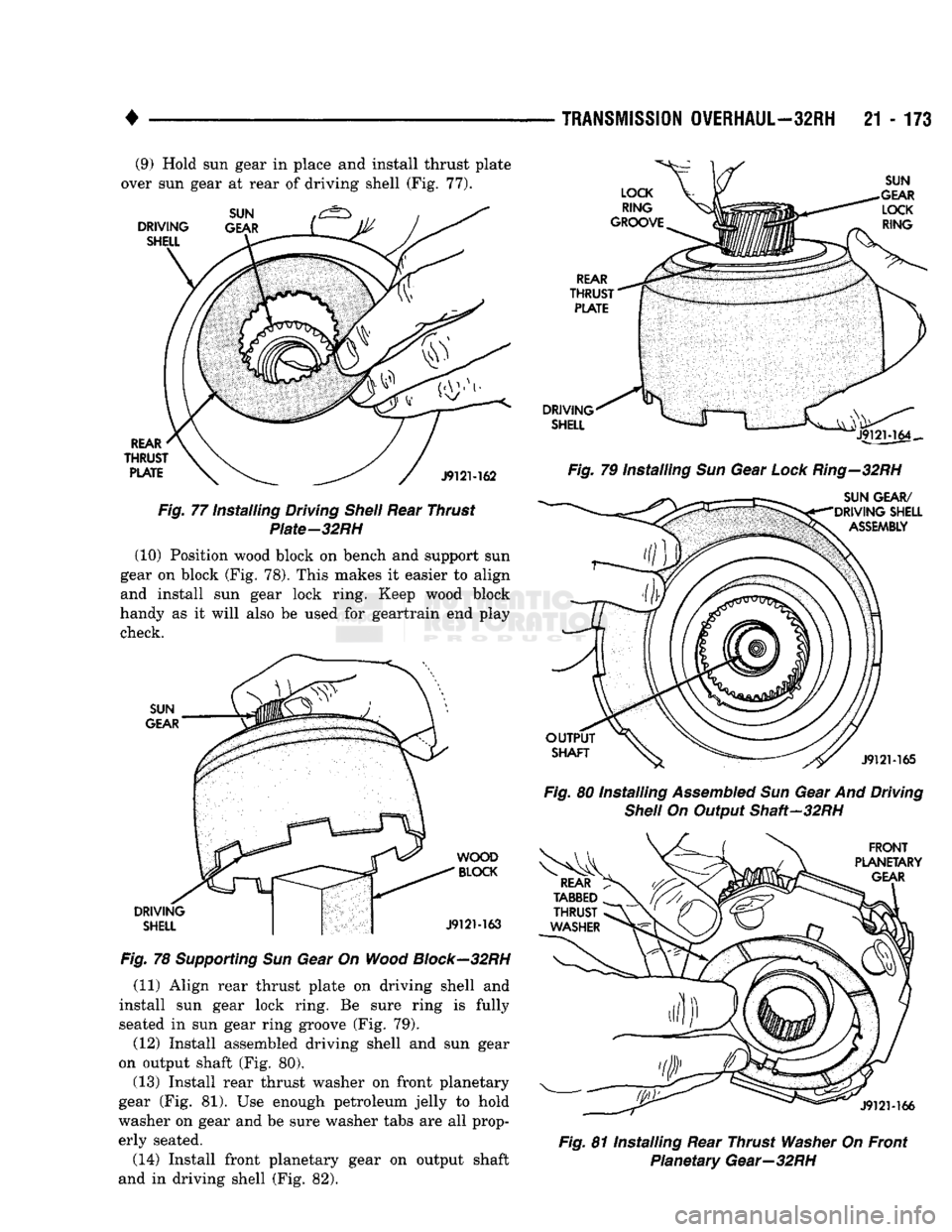

21 - 173 (9) Hold sun gear in place and install thrust plate

over sun gear at rear of driving shell (Fig. 77).

DRIVING

SHELL SUN

GEAR

REAR

THRUST

PLATE

J912M62

Fig.

77 Installing Driving

Shell

Rear Thrust Piate-32RH

(10) Position wood block on bench and support sun

gear on block (Fig. 78). This makes it easier to align

and install sun gear lock ring. Keep wood block

handy as it will also be used for geartrain end play check.

SUN

GEAR

DRIVING SHELL WOOD

BLOCK

J912M63

Fig.

78

Supporting

Sun Gear On

Wood

Block—32RH

(11) Align rear thrust plate on driving shell and

install sun gear lock ring. Be sure ring is fully seated in sun gear ring groove (Fig. 79).

(12) Install assembled driving shell and sun gear

on output shaft (Fig. 80).

(13) Install rear thrust washer on front planetary

gear (Fig. 81). Use enough petroleum jelly to hold

washer on gear and be sure washer tabs are all prop erly seated.

(14) Install front planetary gear on output shaft

and in driving shell (Fig. 82).

LOCK

RING

GROOVE SUN

GEAR LOCK RING

REAR

THRUST

PLATE

DRIVING SHELL

Fig.

79 Installing Sun Gear

Lock

Ring—32RH

SUN GEAR/

DRIVING SHELL

ASSEMBLY

OUTPUT

SHAFT

J912M65

Fig.

80 Installing

Assembled

Sun Gear And Driving

Shell

On Output Shaft-32RH

REAR

TABBED

THRUST

WASHER

FRONT

PLANETARY GEAR

J912M66

Fig.

81 Installing Rear Thrust

Washer

On Front Planetary Gear—32RH

Page 1175 of 1502

21

- 174

TRANSMISSION

OVERHAUL—32RH

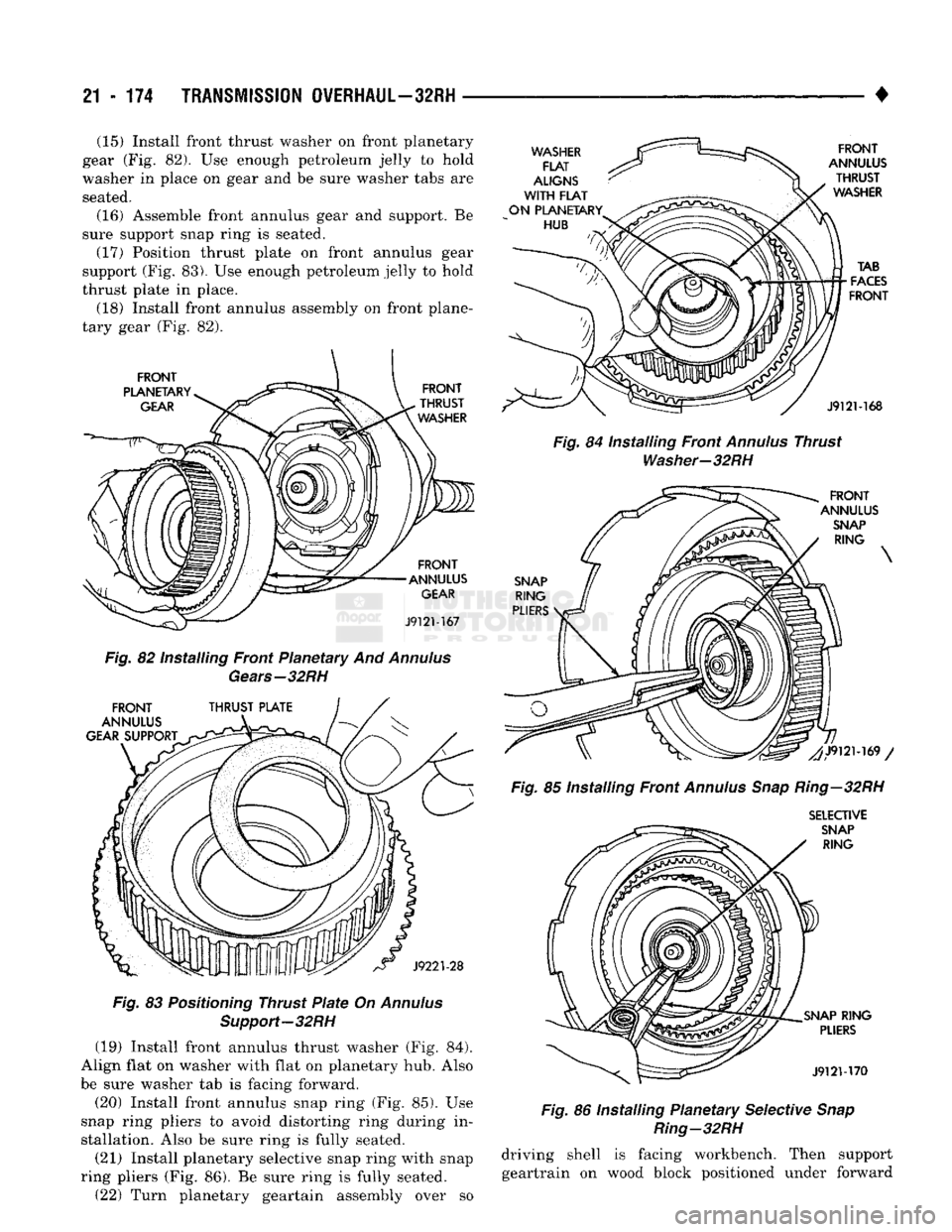

• (15) Install front thrust washer on front planetary

gear (Fig. 82). Use enough petroleum jelly to hold

washer in place on gear and be sure washer tabs are seated.

(16) Assemble front annulus gear and support. Be

sure support snap ring is seated. (17) Position thrust plate on front annulus gear

support (Fig. 83). Use enough petroleum jelly to hold

thrust plate in place. (18) Install front annulus assembly on front plane

tary gear (Fig. 82).

Fig.

82 Installing Front Planetary And

Annulus

Gears—32RH

Fig.

83

Positioning

Thrust

Plate

On

Annulus

Support—32RH

(19) Install front annulus thrust washer (Fig. 84).

Align flat on washer with flat on planetary hub. Also

be sure washer tab is facing forward.

(20) Install front annulus snap ring (Fig. 85). Use

snap ring pliers to avoid distorting ring during in

stallation. Also be sure ring is fully seated. (21) Install planetary selective snap ring with snap

ring pliers (Fig. 86). Be sure ring is fully seated.

(22) Turn planetary geartain assembly over so

Fig.

84 installing Front

Annulus

Thrust

Washer-32RH

Fig.

85 Installing Front

Annulus Snap

Ring—32RH

SELECTIVE

Fig.

86 Installing Planetary Selective

Snap

Ring—32

RH

driving shell is facing workbench. Then support geartrain on wood block positioned under forward

Page 1176 of 1502

•

TRANSMISSION

OVERHAUL—32RH

21 - 175 end of output shaft. This allow geartrain components

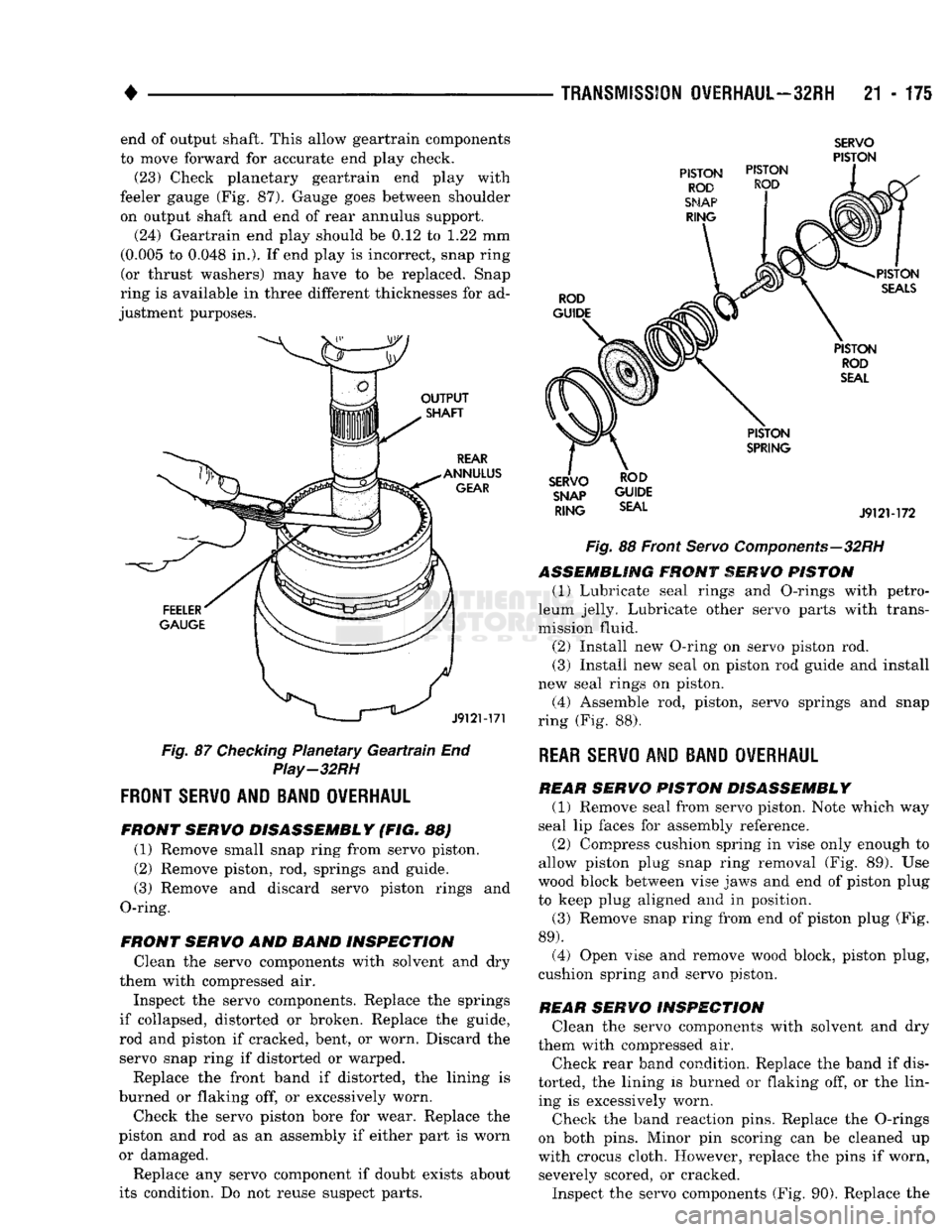

to move forward for accurate end play check. (23) Check planetary geartrain end play with

feeler gauge (Fig. 87). Gauge goes between shoulder on output shaft and end of rear annulus support.

(24) Geartrain end play should be 0.12 to 1.22 mm

(0.005 to 0.048 in.). If end play is incorrect, snap ring (or thrust washers) may have to be replaced. Snap

ring is available in three different thicknesses for ad

justment purposes.

Fig.

87

Checking

Planetary

Geartrain

End

Play-32RH

FRONT

SERVO

AND BAND OVERHAUL

FRONT

SERWO DISASSEMBLY

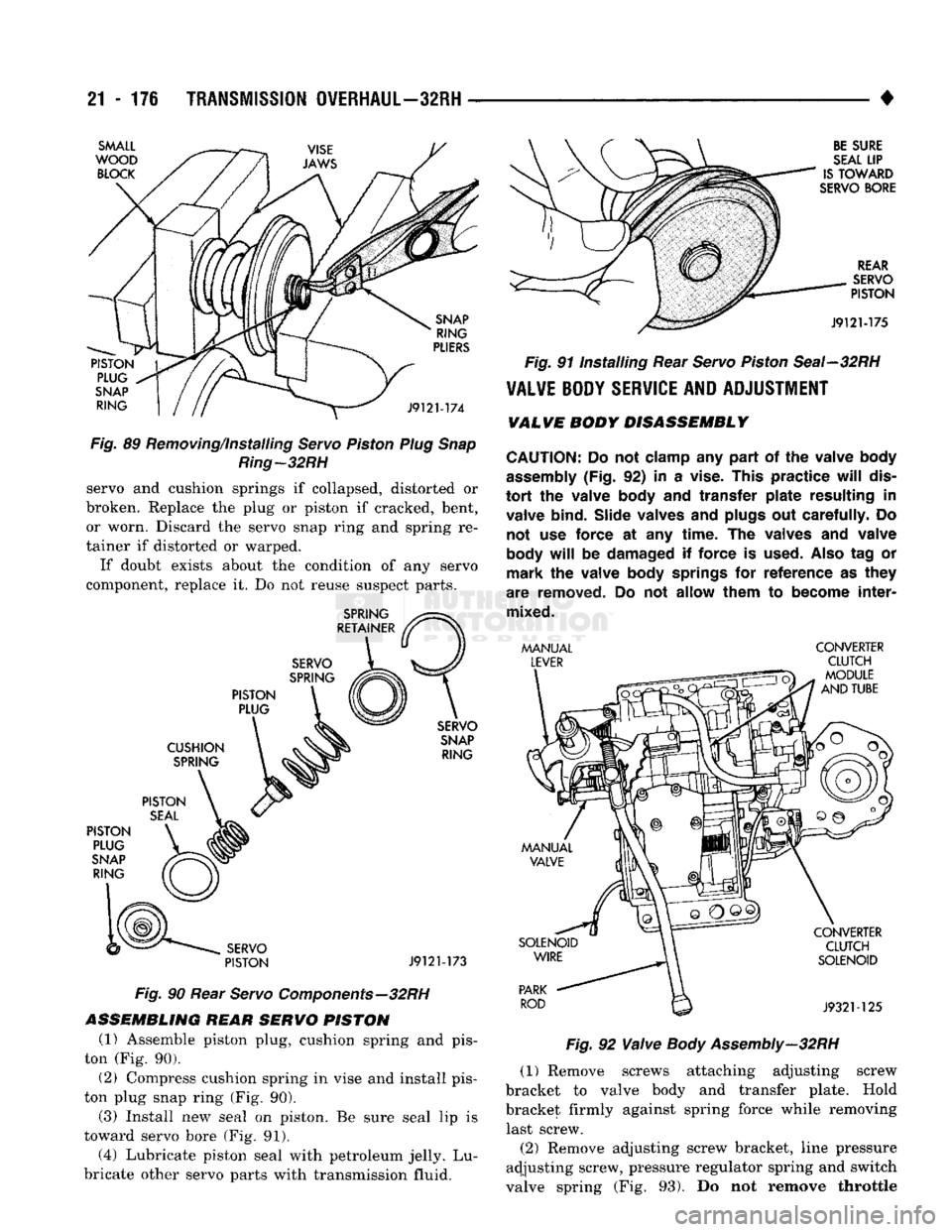

(FIG. 88) (1) Remove small snap ring from servo piston.

(2) Remove piston, rod, springs and guide.

(3) Remove and discard servo piston rings and

O-ring.

FRONT

SERWO

AND

BAND

INSPECTION

Clean the servo components with solvent and dry

them with compressed air.

Inspect the servo components. Replace the springs

if collapsed, distorted or broken. Replace the guide,

rod and piston if cracked, bent, or worn. Discard the servo snap ring if distorted or warped.

Replace the front band if distorted, the lining is

burned or flaking off, or excessively worn.

Check the servo piston bore for wear. Replace the

piston and rod as an assembly if either part is worn

or damaged.

Replace any servo component if doubt exists about

its condition. Do not reuse suspect parts.

SERVO

PISTON

SNAP GUIDE RING

SEAL J912M72

Fig.

88 Front

Servo

Components—32RH

ASSEMBLING

FRONT

SERVO

PISTON

(1) Lubricate seal rings and O-rings with petro

leum jelly. Lubricate other servo parts with trans

mission fluid.

(2) Install new O-ring on servo piston rod.

(3) Install new seal on piston rod guide and install

new seal rings on piston. (4) Assemble rod, piston, servo springs and snap

ring (Fig. 88).

REAR

SERVO

AND BAND OVERHAUL

REAR SERVO

PISTON

DISASSEMBLY

(1) Remove seal from servo piston. Note which way

seal lip faces for assembly reference. (2) Compress cushion spring in vise only enough to

allow piston plug snap ring removal (Fig. 89). Use

wood block between vise jaws and end of piston plug

to keep plug aligned and in position.

(3) Remove snap ring from end of piston plug (Fig.

89).

(4) Open vise and remove wood block, piston plug,

cushion spring and servo piston.

REAR SERVO

INSPECTION

Clean the servo components with solvent and dry

them with compressed air.

Check rear band condition. Replace the band if dis

torted, the lining is burned or flaking off, or the lin ing is excessively worn.

Check the band reaction pins. Replace the O-rings

on both pins. Minor pin scoring can be cleaned up

with crocus cloth. However, replace the pins if worn, severely scored, or cracked.

Inspect the servo components (Fig. 90). Replace the

Page 1177 of 1502

21

- 176

TRANSMISSION

OVERHAUL—32RH

•

SMALL

WOOD

BLOCK

PISTON PLUG

SNAP

RING

SNAP

RING

PLIERS

J912M74

Fig.

89 Removing/installing

Servo

Piston

Plug Snap

Ring-32

RH

servo and cushion springs if collapsed, distorted or

broken. Replace the plug or piston if cracked, bent, or worn. Discard the servo snap ring and spring re

tainer if distorted or warped.

If doubt exists about the condition of any servo

component, replace it. Do not reuse suspect parts.

SPRING

RETAINER

SERVO

SPRING

PISTON PLUG

CUSHION

SPRING

SERVO

SNAP

RING

PISTON

SEAL

PISTON

PLUG

SNAP

RING

SERVO

PISTON

J9121-173

Fig.

90 Rear

Servo

Components—32RH

ASSEMBLING

REAR SERVO PISTON

(1) Assemble piston plug, cushion spring and pis

ton (Fig. 90). (2) Compress cushion spring in vise and install pis

ton plug snap ring (Fig. 90).

(3) Install new seal on piston. Be sure seal lip is

toward servo bore (Fig. 91).

(4) Lubricate piston seal with petroleum jelly. Lu

bricate other servo parts with transmission fluid.

BE

SURE

SEAL

LIP

IS

TOWARD

SERVO

BORE

REAR

SERVO

PISTON

J9121-175

Fig.

91 Installing Rear

Servo

Piston

Seal—32RH

VALVE

BODY

SERVICE

AND ADJUSTMENT

VALVE BODY DISASSEMBLY

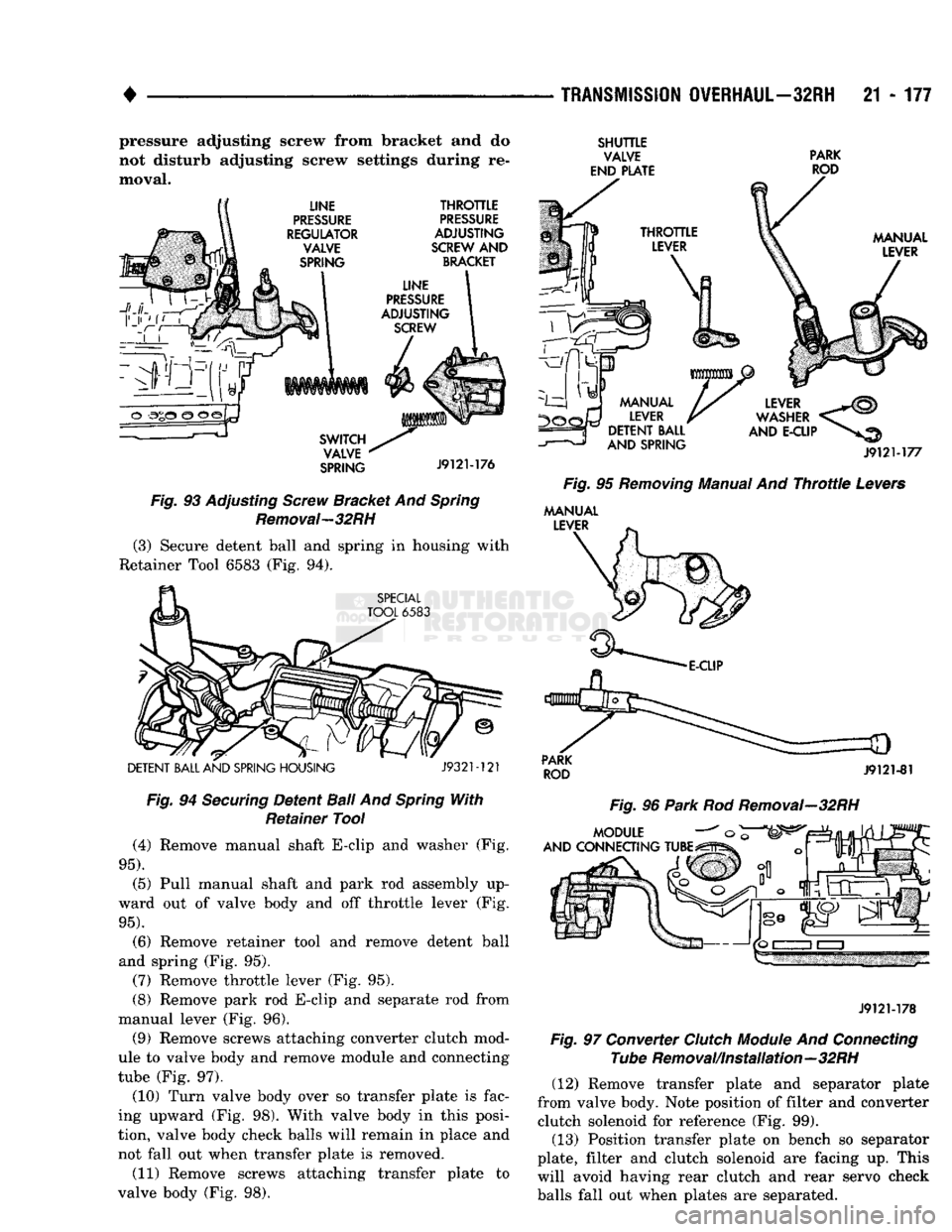

CAUTION:

Do not

clamp

any

part

of the

valve body

assembly

(Fig.

92) in a

vise.

This practice

will

dis

tort

the

valve body

and

transfer plate resulting

in

valve bind. Slide valves

and

plugs

out

carefully.

Do

not

use

force

at any

time.

The

valves

and

valve

body

will

be

damaged

if

force

is

used.

Also

tag or

mark

the

valve body

springs

for

reference

as

they

are removed.

Do not

allow them

to

become

inter

mixed.

MANUAL

LEVER

CONVERTER

CLUTCH

MODULE

AND TUBE MANUAL

VALVE

SOLENOID WIRE

PARK

ROD

CONVERTER

CLUTCH

SOLENOID

J9321-125

Fig.

92 Valve

Body

Assembly—32RH

(1) Remove screws attaching adjusting screw

bracket to valve body and transfer plate. Hold

bracket firmly against spring force while removing last screw.

(2) Remove adjusting screw bracket, line pressure

adjusting screw, pressure regulator spring and switch

valve spring (Fig. 93). Do not remove throttle

Page 1178 of 1502

•

TRANSMISSION

OVERHAUL—32RH

21 - 177 pressure adjusting screw from bracket and do

not disturb adjusting screw settings during re

moval.

SPRING

J912M76

Fig.

93 Adjusting

Screw

Bracket And

Spring

Removal—32RH

(3) Secure detent ball and spring in housing with

Retainer Tool 6583 (Fig. 94).

DETENT BALL

AND

SPRING

HOUSING

J9321-121

Fig.

94

Securing

Detent

Ball

And

Spring

With

Retainer Tool (4) Remove manual shaft E-clip and washer (Fig.

95).

(5) Pull manual shaft and park rod assembly up

ward out of valve body and off throttle lever (Fig.

95).

(6) Remove retainer tool and remove detent ball

and spring (Fig. 95).

(7) Remove throttle lever (Fig. 95).

(8) Remove park rod E-clip and separate rod from

manual lever (Fig. 96). (9) Remove screws attaching converter clutch mod

ule to valve body and remove module and connecting

tube (Fig. 97).

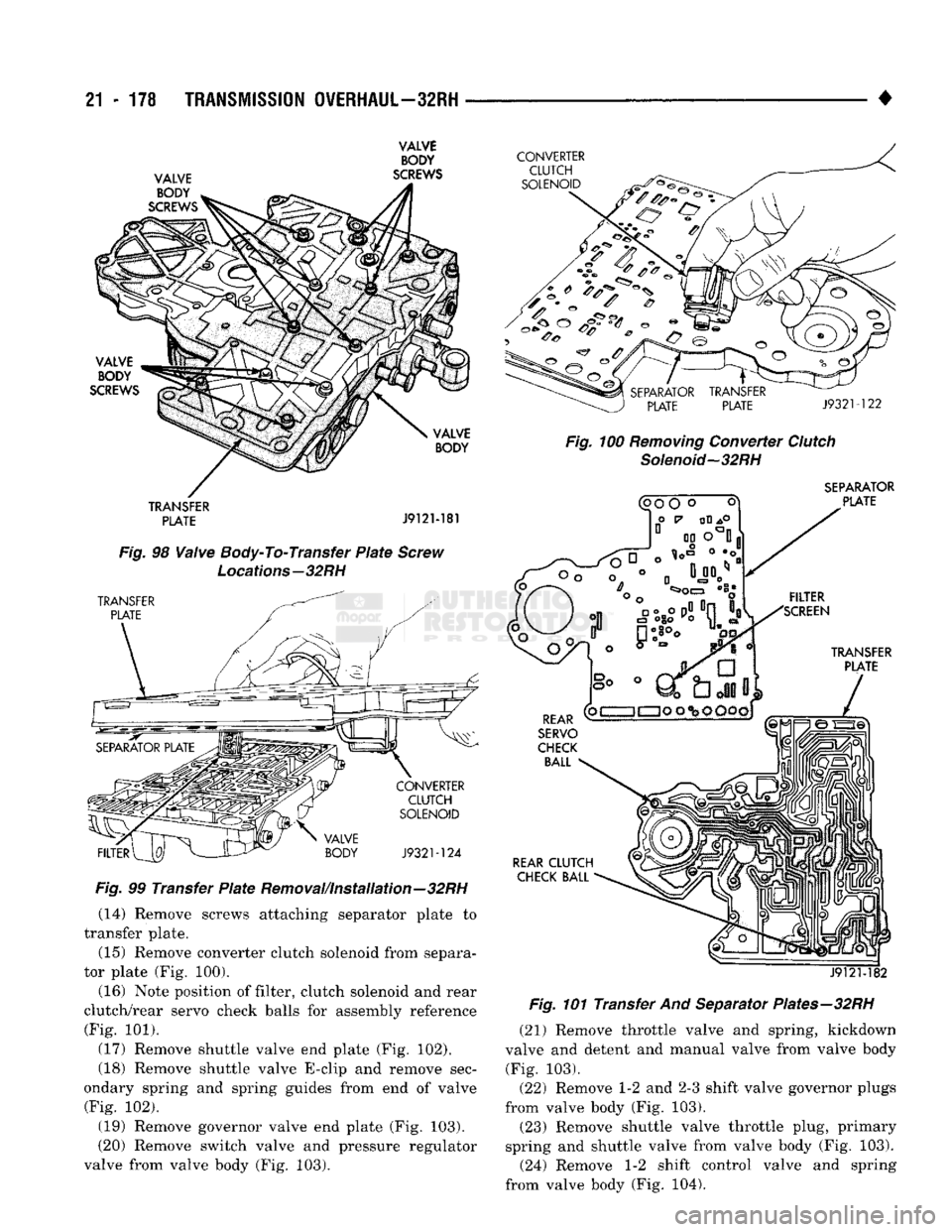

(10) Turn valve body over so transfer plate is fac

ing upward (Fig. 98). With valve body in this posi

tion, valve body check balls will remain in place and

not fall out when transfer plate is removed.

(11) Remove screws attaching transfer plate to

valve body (Fig. 98).

SHUTTLE

VALVE PARK

END PLATE

ROD

Fig.

95

Removing

Manual And

Throttle

Levers

MANUAL

Fig.

96

Park

Rod Removal—32RH J912M78

Fig.

97 Converter

Clutch

Module

And

Connecting

Tube Removal/Installation—32RH (12) Remove transfer plate and separator plate

from valve body. Note position of filter and converter clutch solenoid for reference (Fig. 99).

(13) Position transfer plate on bench so separator

plate, filter and clutch solenoid are facing up. This

will avoid having rear clutch and rear servo check

balls fall out when plates are separated.

Page 1179 of 1502

21

- 178

TRANSMISSION OVERHAUL—32RH

•

VALVE

BODY

TRANSFER

PLATE

J9121-181

Fig.

98

Valve

Body-

To- Transfer

Plate

Screw

Locations—32RH

Fig.

99 Transfer

Plate

Removal/Installation—32RH

(14) Remove screws attaching separator plate to

transfer plate.

(15) Remove converter clutch solenoid from separa

tor plate (Fig. 100).

(16) Note position of filter, clutch solenoid and rear

clutch/rear servo check balls for assembly reference (Fig. 101).

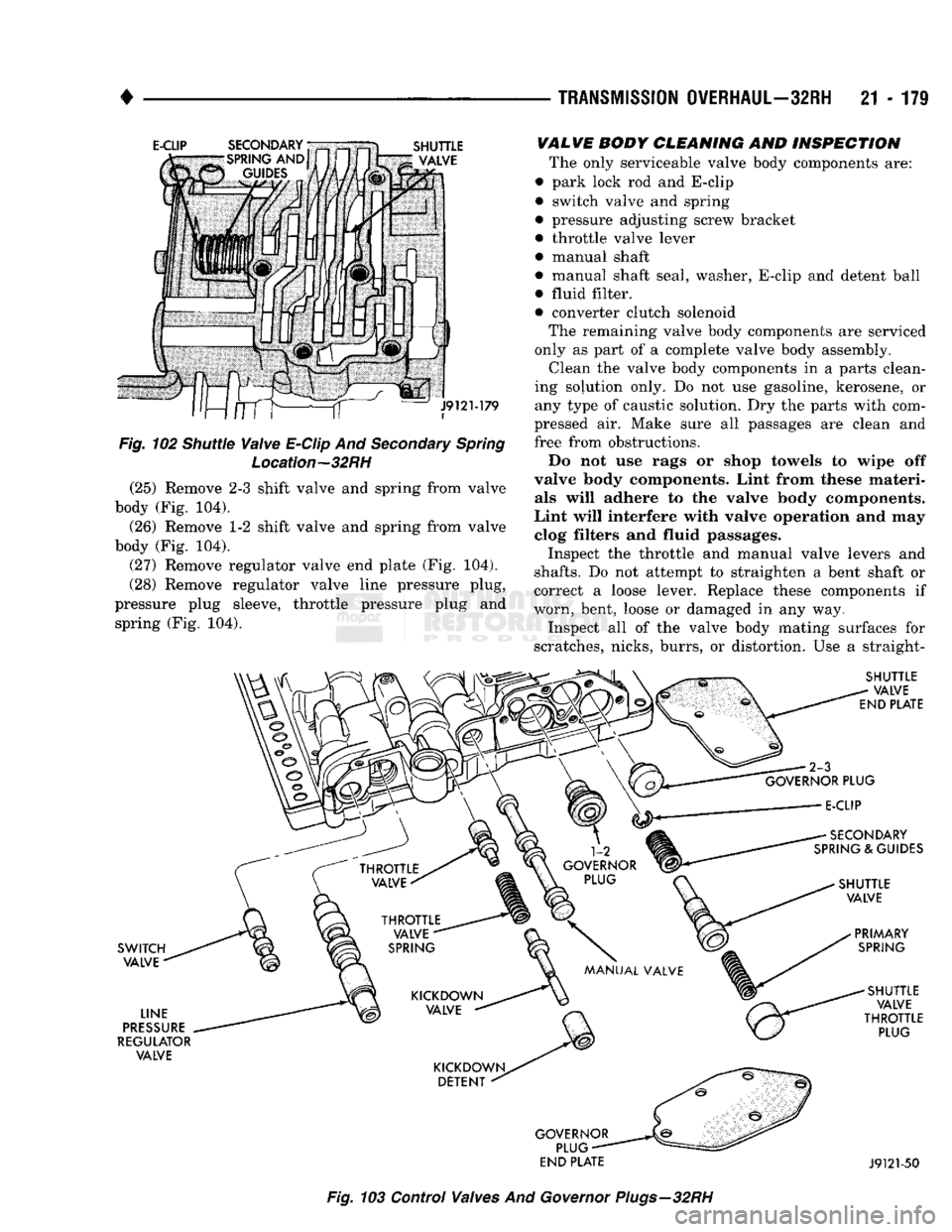

(17) Remove shuttle valve end plate (Fig. 102).

(18) Remove shuttle valve E-clip and remove sec

ondary spring and spring guides from end of valve (Fig. 102).

(19) Remove governor valve end plate (Fig. 103).

(20) Remove switch valve and pressure regulator

valve from valve body (Fig. 103).

Fig.

100

Removing

Converter

Clutch

Solenoid—32RH

SEPARATOR

J9121-

Fig.

101 Transfer And Separator Plates—32RH

(21) Remove throttle valve and spring, kickdown

valve and detent and manual valve from valve body (Fig. 103).

(22) Remove 1-2 and 2-3 shift valve governor plugs

from valve body (Fig. 103).

(23) Remove shuttle valve throttle plug, primary

spring and shuttle valve from valve body (Fig. 103).

(24) Remove 1-2 shift control valve and spring

from valve body (Fig. 104).

Page 1180 of 1502

TRANSMISSION

OVERHAUL—32RH

21 - 171

E-CLIP

SHUTTLE

VALVE

Fig.

102 Shuttle

Valve

E-Clip

And

Secondary

Spring

Location—32RH

(25) Remove

2-3

shift valve

and

spring from valve

body

(Fig. 104).

(26) Remove

1-2

shift valve

and

spring from valve

body

(Fig. 104).

(27) Remove regulator valve

end

plate

(Fig. 104).

(28) Remove regulator valve line pressure plug,

pressure plug sleeve, throttle pressure plug

and

spring

(Fig. 104).

VALVE

BODY

CLEANING

AND

INSPECTION

The only serviceable valve body components

are:

• park lock

rod and

E-clip

• switch valve

and

spring

• pressure adjusting screw bracket • throttle valve lever

• manual shaft

• manual shaft seal, washer, E-clip

and

detent ball • fluid filter.

• converter clutch solenoid

The remaining valve body components

are

serviced

only

as

part

of a

complete valve body assembly.

Clean

the

valve body components

in a

parts clean

ing solution only.

Do not use

gasoline, kerosene,

or

any type

of

caustic solution.

Dry the

parts with com

pressed

air.

Make sure

all

passages

are

clean

and

free from obstructions.

Do

not use

rags

or

shop towels

to

wipe

off

valve body components. Lint from these materi als will adhere

to the

valve body components.

Lint will interfere with valve operation

and may

clog filters

and

fluid passages.

Inspect

the

throttle

and

manual valve levers

and

shafts.

Do not

attempt

to

straighten

a

bent shaft

or

correct

a

loose lever. Replace these components

if

worn, bent, loose

or

damaged

in any way.

Inspect

all of the

valve body mating surfaces

for

scratches, nicks, burrs,

or

distortion.

Use a

straight-

SHUTTLE

VALVE

END

PLATE

SWITCH

VALVE

LINE

PRESSURE

REGULATOR

VALVE

SECONDARY

SPRING

&

GUIDES

SHUTTLE

VALVE

PRIMARY

SPRING

SHUTTLE

VALVE

THROTTLE

PLUG

GOVERNOR

PLUG-

END

PLATE

J9121-50

Fig.

103

Control Valves

And

Governor

Plugs—32RH