DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 1181 of 1502

21

- 180

TRANSMISSION OVERHAUL—32RH

•

REGULATOR VALVE

THROTTLE

PRESSURE

PLUG REGULATOR

VALVE

SPRING

SLEEVE

LINE

PRESSURE

PLUG

REGULATOR VALVE END

PLATE

SHIFT

VALVE END PLATE

2-3 SHIFT

VALVE

AND

SPRING

J912M80

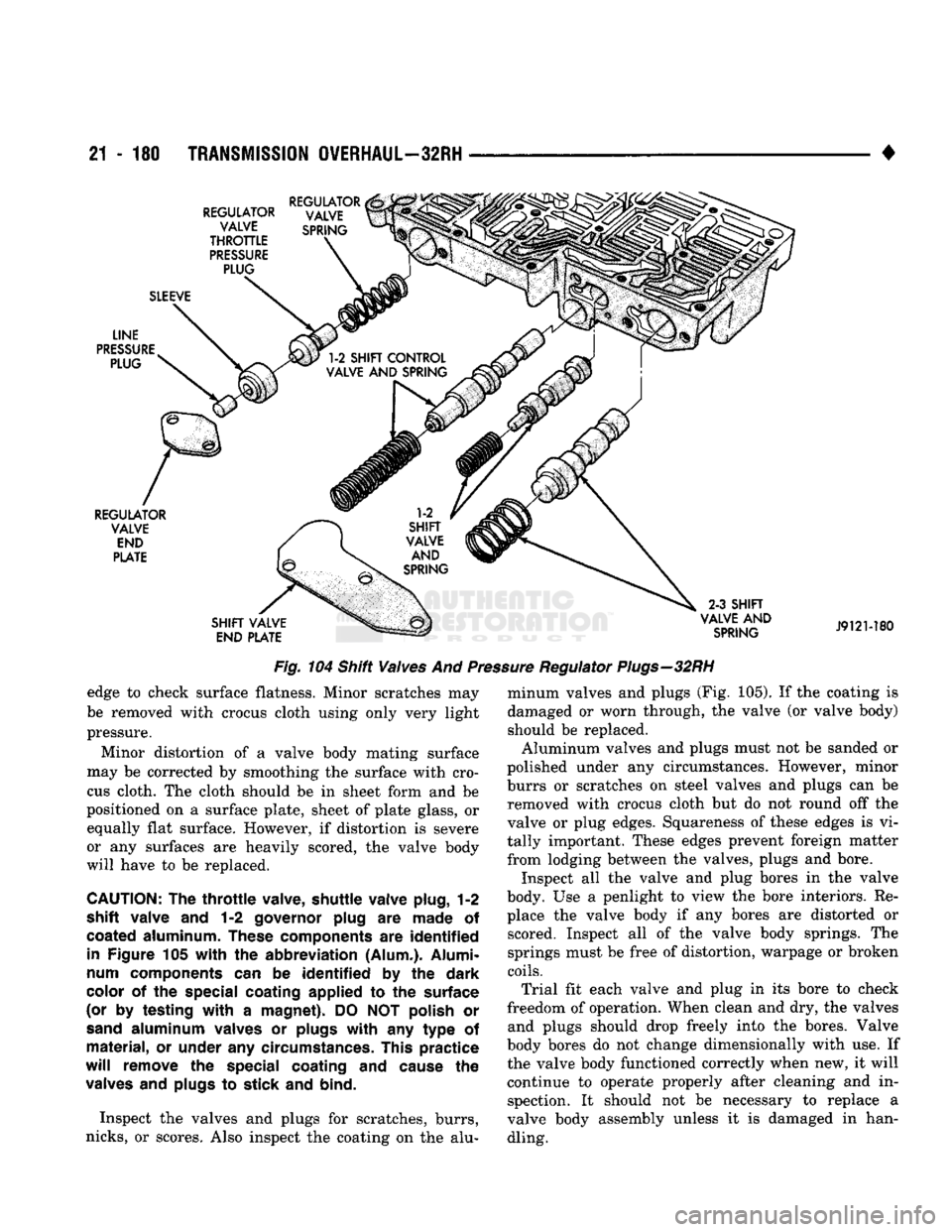

Fig. 104 Shift Valves And Pressure Regulator Plugs—32RH

edge to check surface flatness. Minor scratches may

be removed with crocus cloth using only very light pressure.

Minor distortion of a valve body mating surface

may be corrected by smoothing the surface with cro

cus cloth. The cloth should be in sheet form and be

positioned on a surface plate, sheet of plate glass, or equally flat surface. However, if distortion is severe

or any surfaces are heavily scored, the valve body

will have to be replaced.

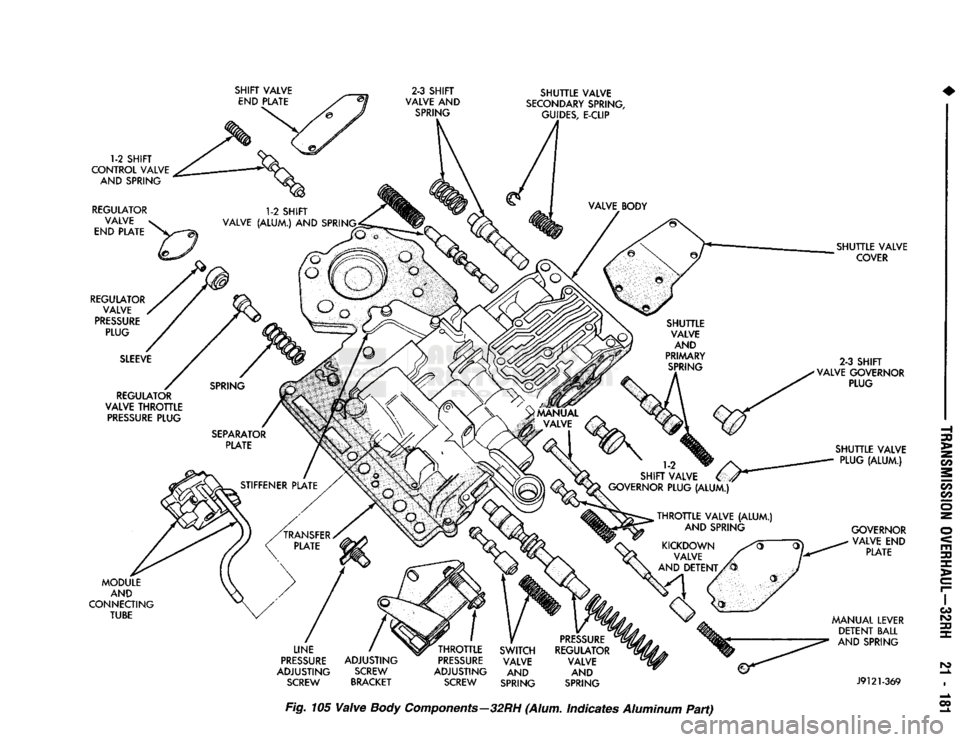

CAUTION:

The

throttle

valve, shuttle valve plug,

1-2

shift valve

and 1-2

governor plug

are

made

of

coated

aluminum.

These

components are

identified

in Figure

105

with

the

abbreviation (Alum.). Alumi

num components

can be

identified

by the

dark

color

of the

special coating applied

to the

surface

(or

by

testing

with

a

magnet).

DO NOT

polish

or

sand

aluminum valves

or

plugs

with

any

type

of

material,

or

under

any

circumstances. This practice

will

remove the special

coating

and

cause

the

valves

and

plugs

to

stick

and

bind.

Inspect the valves and plugs for scratches, burrs,

nicks,

or scores. Also inspect the coating on the alu minum valves and plugs (Fig. 105). If the coating is

damaged or worn through, the valve (or valve body)

should be replaced. Aluminum valves and plugs must not be sanded or

polished under any circumstances. However, minor

burrs or scratches on steel valves and plugs can be removed with crocus cloth but do not round off the

valve or plug edges. Squareness of these edges is vi

tally important. These edges prevent foreign matter from lodging between the valves, plugs and bore.

Inspect all the valve and plug bores in the valve

body. Use a penlight to view the bore interiors. Re place the valve body if any bores are distorted or scored. Inspect all of the valve body springs. The

springs must be free of distortion, warpage or broken

coils.

Trial fit each valve and plug in its bore to check

freedom of operation. When clean and dry, the valves and plugs should drop freely into the bores. Valve

body bores do not change dimensionally with use. If the valve body functioned correctly when new, it will

continue to operate properly after cleaning and inspection. It should not be necessary to replace a

valve body assembly unless it is damaged in handling.

Page 1182 of 1502

SHIFT VALVE

END PLATE 2-3 SHIFT

VALVE

AND

SPRING SHUTTLE VALVE

SECONDARY SPRING, GUIDES,

E-CLIP

1-2 SHIFT

CONTROL VALVE AND SPRING

REGULATOR VALVE

END PLATE

REGULATOR VALVE

PRESSURE PLUG

SLEEVE

MODULE AND

CONNECTING

TUBE SHUTTLE VALVE

COVER

REGULATOR

VALVE THROTTLE PRESSURE PLUG

LINE

PRESSURE

ADJUSTING SCREW ADJUSTING

SCREW

BRACKET THROTTLE

PRESSURE

ADJUSTING SCREW SWITCH

VALVE AND

SPRING PRESSURE

REGULATOR VALVE AND

SPRING

2-3

SHIFT

VALVE GOVERNOR PLUG

SHUTTLE VALVE PLUG (ALUM.)

GOVERNOR VALVE

END

PLATE

MANUAL LEVER DETENT BALL

AND SPRING

J9121-369

Fig. 105

Valve

Body Components—32RH (Alum.

Indicates

Aluminum

Part)

Page 1183 of 1502

21

- 182

TRANSMISSION OVERHAUL—32RH

• VAL VE

BODY

ASSEMBL

Y

CAUTION:

Do not

force

the valves or plugs

into

place

during

reassembly. If the valve body

bores,

valves

and plugs are

free

of

distortion

or burrs, the

valve body components should all slide

into

place

easily. In

addition,

do not

overtighten

the

transfer

plate

and valve body

screws

during

reassembly.

Overtightening

can

distort

the valve body

resulting

in valve sticking,

cross

leakage and

unsatisfactory

operation. Tighten valve body

screws

to recom mended

torque

only.

(1) Lubricate valve body bores, valves and plugs

with transmission fluid.

(2) Insert rear clutch and rear servo check balls in

transfer plate (Fig. 100).

(3) Install filter screen in separator plate (Fig.

100).

(4) Align and install separator plate on transfer

plate. Verify check ball position before installing sep arator plate on transfer plate.

(5) Install new O-ring on converter clutch solenoid

and insert solenoid in separator plate (Fig. 106). Fig. 106

Installing

Converter

Clutch

Solenoid—32RH

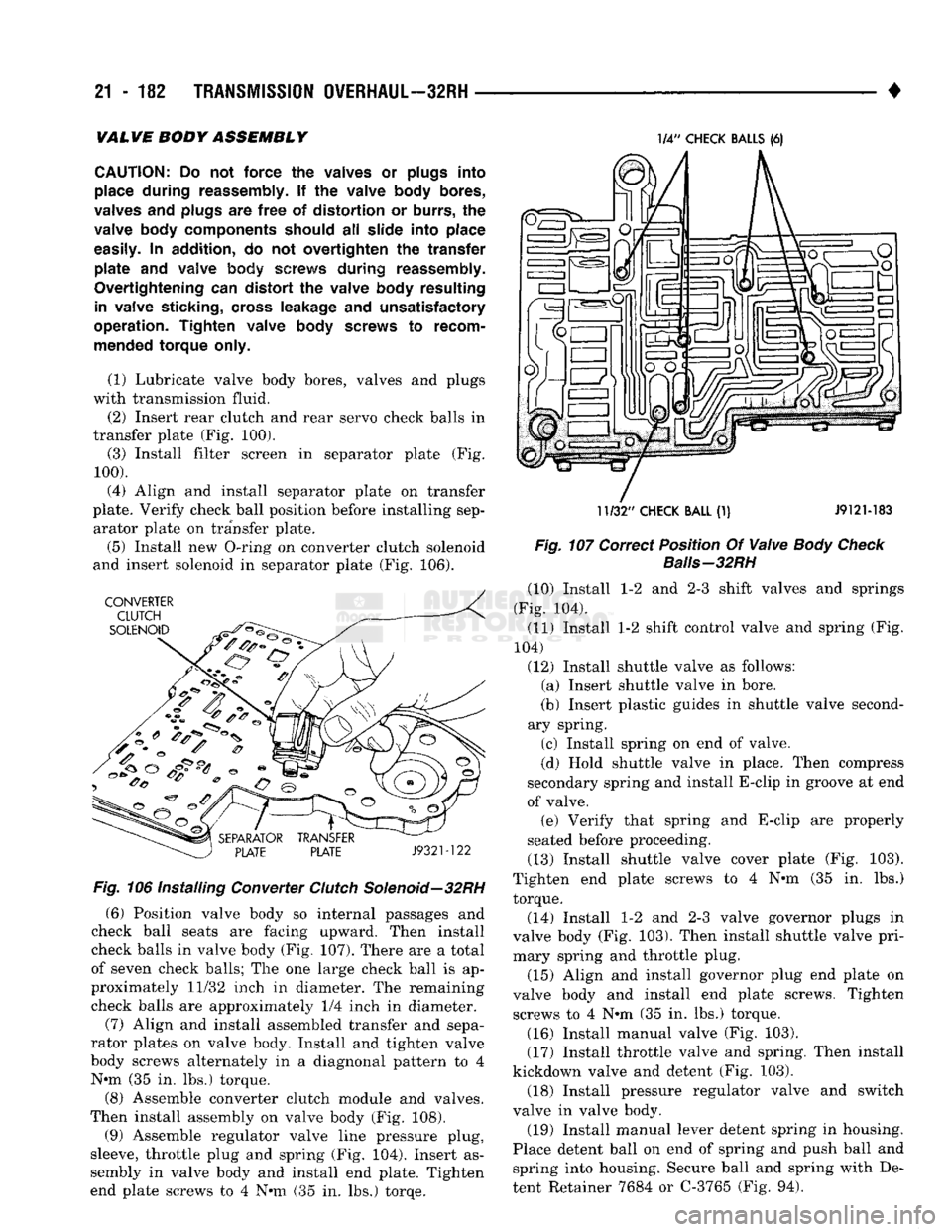

(6) Position valve body so internal passages and

check ball seats are facing upward. Then install

check balls in valve body (Fig. 107). There are a total

of seven check balls; The one large check ball is ap

proximately 11/32 inch in diameter. The remaining

check balls are approximately 1/4 inch in diameter.

(7) Align and install assembled transfer and sepa

rator plates on valve body. Install and tighten valve

body screws alternately in a diagnonal pattern to 4 N»m (35 in. lbs.) torque.

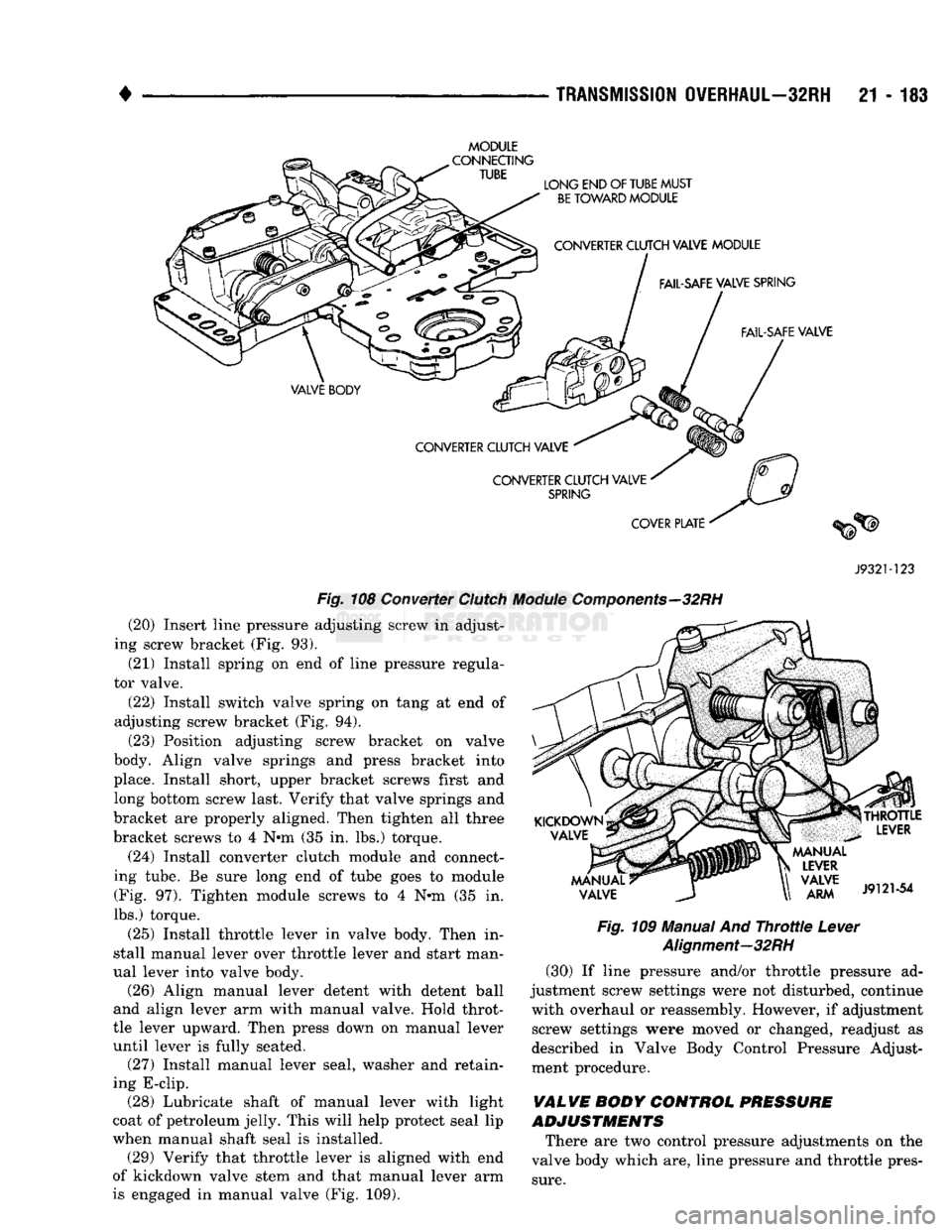

(8) Assemble converter clutch module and valves.

Then install assembly on valve body (Fig. 108).

(9) Assemble regulator valve line pressure plug,

sleeve, throttle plug and spring (Fig. 104). Insert as

sembly in valve body and install end plate. Tighten

end plate screws to 4 N»m (35 in. lbs.) torqe. 1/4"

CHECK

BALLS

(6)

11/32"

CHECK

BALL

(1) J912M83

Fig. 107

Correct

Position

Of

Valve

Body Check

Baiis-32RH

(10) Install 1-2 and 2-3 shift valves and springs

(Fig. 104).

(11) Install 1-2 shift control valve and spring (Fig.

104)

(12) Install shuttle valve as follows: (a) Insert shuttle valve in bore.

(b) Insert plastic guides in shuttle valve second

ary spring.

(c) Install spring on end of valve.

(d) Hold shuttle valve in place. Then compress

secondary spring and install E-clip in groove at end

of valve. (e) Verify that spring and E-clip are properly

seated before proceeding.

(13) Install shuttle valve cover plate (Fig. 103).

Tighten end plate screws to 4 N»m (35 in. lbs.)

torque.

(14) Install 1-2 and 2-3 valve governor plugs in

valve body (Fig. 103). Then install shuttle valve pri

mary spring and throttle plug.

(15) Align and install governor plug end plate on

valve body and install end plate screws. Tighten screws to 4 N*m (35 in. lbs.) torque.

(16) Install manual valve (Fig. 103).

(17) Install throttle valve and spring. Then install

kickdown valve and detent (Fig. 103).

(18) Install pressure regulator valve and switch

valve in valve body.

(19) Install manual lever detent spring in housing.

Place detent ball on end of spring and push ball and spring into housing. Secure ball and spring with De

tent Retainer 7684 or C-3765 (Fig. 94).

Page 1184 of 1502

•

TRANSMISSION

OVERHAUL—32RH

21 - 183

MODULE

J932M23

Fig.

108 Converter

Clutch

Module

Components—32RH

(20) Insert line pressure adjusting screw in adjust

ing screw bracket (Fig. 93).

(21) Install spring on end of line pressure regula

tor valve.

(22) Install switch valve spring on tang at end of

adjusting screw bracket (Fig. 94).

(23) Position adjusting screw bracket on valve

body. Align valve springs and press bracket into

place. Install short, upper bracket screws first and long bottom screw last. Verify that valve springs and

bracket are properly aligned. Then tighten all three

bracket screws to 4 N*m (35 in. lbs.) torque.

(24) Install converter clutch module and connect

ing tube. Be sure long end of tube goes to module (Fig. 97). Tighten module screws to 4 Nrn (35 in.

lbs.) torque.

(25) Install throttle lever in valve body. Then in

stall manual lever over throttle lever and start man

ual lever into valve body. (26) Align manual lever detent with detent ball

and align lever arm with manual valve. Hold throt

tle lever upward. Then press down on manual lever

until lever is fully seated. (27) Install manual lever seal, washer and retain

ing E-clip. (28) Lubricate shaft of manual lever with light

coat of petroleum jelly. This will help protect seal lip

when manual shaft seal is installed. (29) Verify that throttle lever is aligned with end

of kickdown valve stem and that manual lever arm

is engaged in manual valve (Fig. 109).

Fig.

109 Manual And

Throttle

Lever

Alignment—32RH

(30) If line pressure and/or throttle pressure ad

justment screw settings were not disturbed, continue with overhaul or reassembly. However, if adjustment screw settings were moved or changed, readjust as

described in Valve Body Control Pressure Adjust

ment procedure.

VALVE BODY CONTROL PRESSURE

ADJUSTMENTS

There are two control pressure adjustments on the

valve body which are, line pressure and throttle pres

sure.

Page 1185 of 1502

21 - 184

TRANSMISSION

OVERHAUL—32RH

-

Fig. 110 Line Pressure Adjustment—32RH

Throttle

Pressure

Adjustment

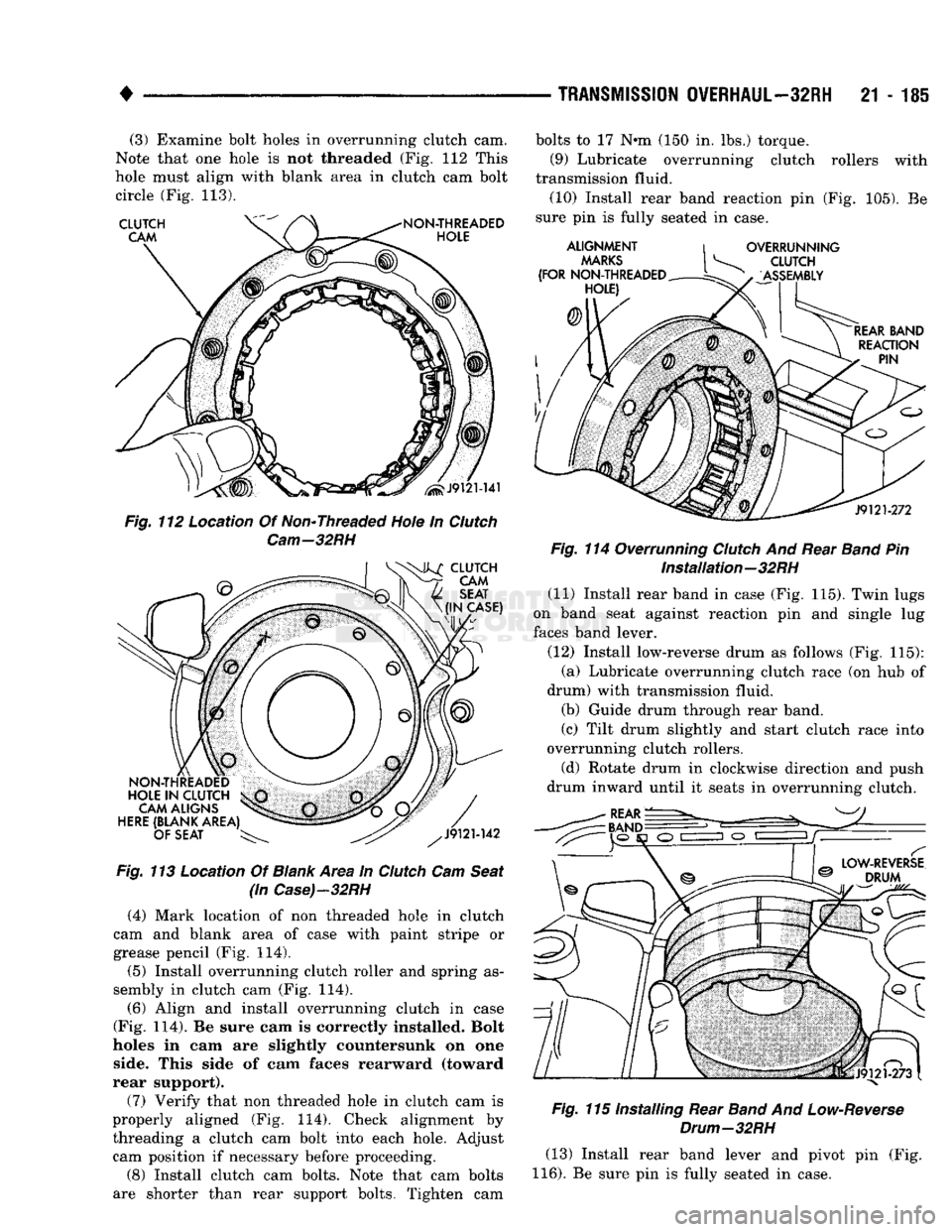

Insert Gauge Tool C-3763 between the throttle le

ver cam and the kickdown valve stem (Fig. 111).

Push the gauge tool inward to compress the kick-

down valve against the spring and bottom the throt

tle valve.

Maintain pressure against kickdown valve spring.

Turn throttle lever stop screw until the screw head

touches throttle lever tang and the throttle lever cam

touches gauge tool.

The kickdown valve spring must be fully com

pressed and the kickdown valve completely bot

tomed to obtain correct adjustment.

•

Fig. 111 Throttle Pressure Adjustment—32RH

TRANSMISSION ASSEMBLY AND ADJUSTMENT

Assembly

Tips

Do not allow dirt, grease, or foreign material to en

ter the case or transmission components during as sembly. Keep the transmission case and components

clean. Also make sure the tools and workbench area

used for assembly are equally clean.

Shop towels used for wiping off your hands and ser

vice tools must be made of lint free materials. Lint

will adhere to tranmission parts and could interfere with valve operation, or even restrict fluid passages.

Lubricate the transmission components with ATF

Plus,

or Dexron II™ during reassembly. Use petro leum jelly, Door Eze, or Ru-Glyde on seals and O-rings to ease installation.

Petroleum jejly can also be used to hold thrust

washers and plates in position during assembly oper ations. However, do not use chassis grease, bearing

grease, white grease, or similar lubricants on any

transmission part. These types of lubricants can eventually block or restrict fluid passages and valve

operation. Use petroleum jelly only.

Do not force parts into place. Most of the transmis

sion components are easily installed by hand when

properly aligned. If a part seems extremely difficult

to install, it is either misaligned or incorrectly as sembled. Also verify that thrust washers, thrust

plates and seal rings are correctly positioned before assembly. These parts can interfere with proper as

sembly if mispositioned or "left out" by accident.

TRANSMISSION

ASSEMBLY PROCEDURE (1) Install rear servo piston, spring and spring re

tainer. Compress rear servo spring and retainer with Compressor Tool C-3422-A or a large C-clamp.

(2) Install front servo piston, spring and rod guide.

Compress front servo rod guide with Valve Spring

Compressor C-3422-B and install servo snap ring.

The two pressures are interdependent because each

affects shift quality and timing. Each pressure ad

justment must be performed properly and in the cor rect sequence. The correct sequence is line pressure adjustment first and throttle pressure adjustment

last.

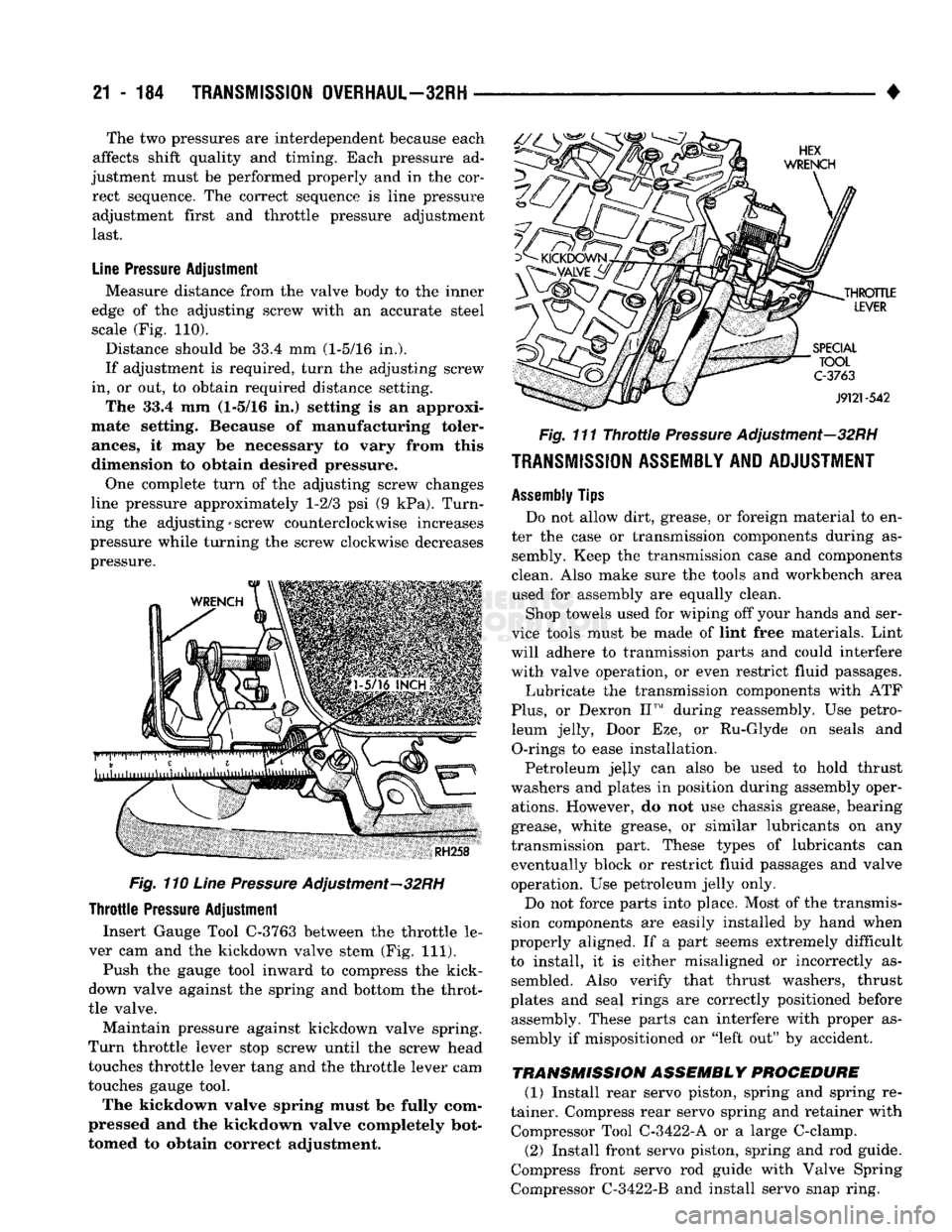

Line

Pressure

Adjustment

Measure distance from the valve body to the inner

edge of the adjusting screw with an accurate steel

scale (Fig. 110).

Distance should be 33.4 mm (1-5/16 in.).

If adjustment is required, turn the adjusting screw

in, or out, to obtain required distance setting.

The 33.4 mm (1-5/16 in,) setting Is an approxi

mate setting. Because of manufacturing toler

ances,

it may be necessary to vary from this

dimension to obtain desired pressure.

One complete turn of the adjusting screw changes

line pressure approximately 1-2/3 psi (9 kPa). Turn

ing the adjusting-screw counterclockwise increases

pressure while turning the screw clockwise decreases

pressure.

Page 1186 of 1502

•

TRANSMISSION

OVERHAUL—32RH

21-185

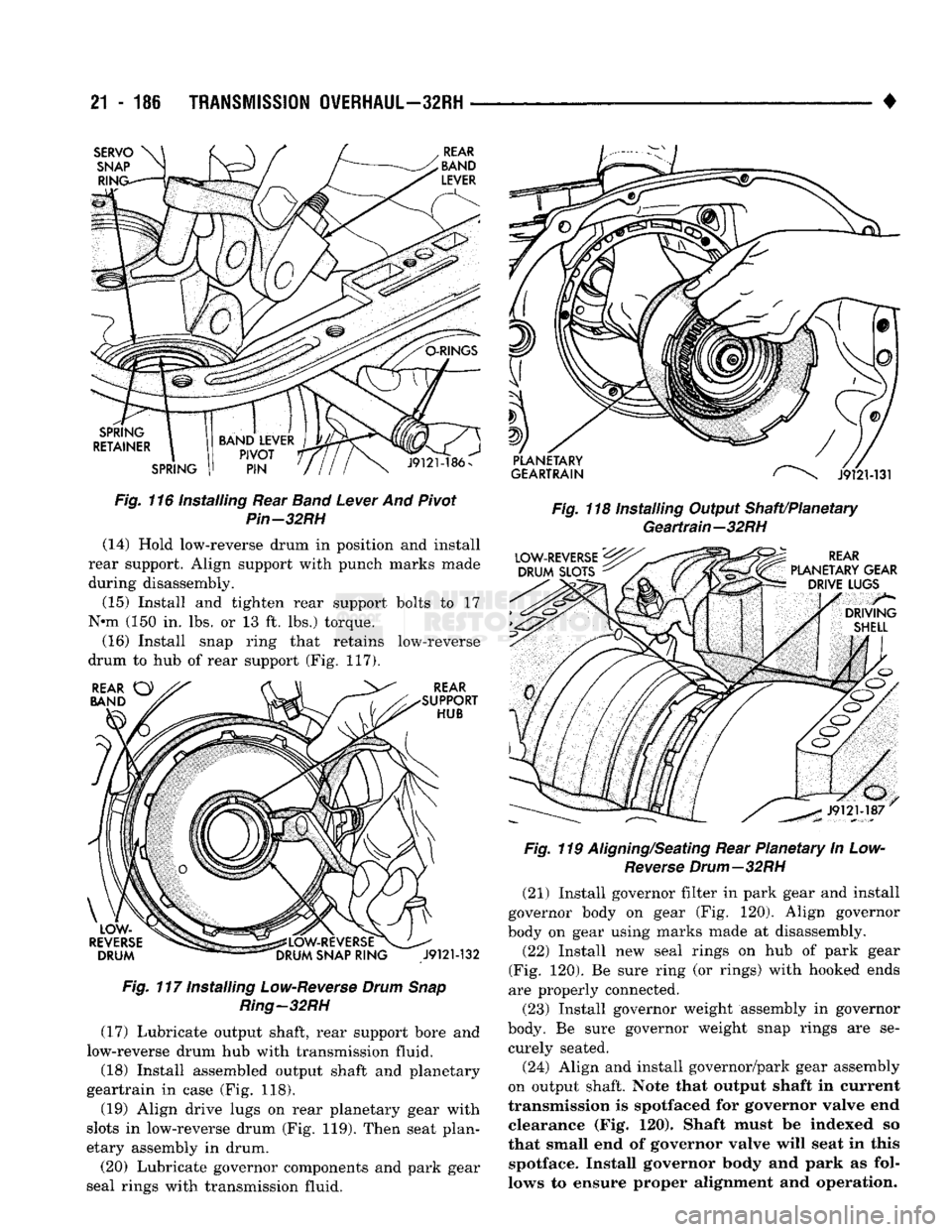

(3) Examine bolt holes in overrunning clutch cam.

Note that one hole is not threaded (Fig. 112 This

hole must align with blank area in clutch cam bolt circle (Fig. 113).

Fig.

113 Location Of

Blank

Area in

Clutch

Cam

Seat

(in

Case)-32RH

(4) Mark location of non threaded hole in clutch

cam and blank area of case with paint stripe or

grease pencil (Fig. 114).

(5) Install overrunning clutch roller and spring as

sembly in clutch cam (Fig. 114).

(6) Align and install overrunning clutch in case

(Fig. 114). Be sure cam is correctly installed. Bolt

holes in cam are slightly countersunk on one side. This side of cam faces rearward (toward

rear support).

(7) Verify that non threaded hole in clutch cam is

properly aligned (Fig. 114). Check alignment by threading a clutch cam bolt into each hole. Adjust cam position if necessary before proceeding.

(8) Install clutch cam bolts. Note that cam bolts

are shorter than rear support bolts. Tighten cam bolts to 17 N»m (150 in. lbs.) torque.

(9) Lubricate overrunning clutch rollers with

transmission fluid. (10) Install rear band reaction pin (Fig. 105). Be

sure pin is fully seated in case.

Fig.

114 Overrunning

Clutch

And Rear

Band

Pin Installation—32RH

(11) Install rear band in case (Fig. 115). Twin lugs

on band seat against reaction pin and single lug

faces band lever.

(12) Install low-reverse drum as follows (Fig. 115): (a) Lubricate overrunning clutch race (on hub of

drum) with transmission fluid. (b) Guide drum through rear band.

(c) Tilt drum slightly and start clutch race into

overrunning clutch rollers.

(d) Rotate drum in clockwise direction and push

drum inward until it seats in overrunning clutch.

Fig.

115 Installing Rear

Band

And

Low-Reverse

Drum—32RH

(13) Install rear band lever and pivot pin (Fig.

116).

Be sure pin is fully seated in case.

Page 1187 of 1502

21

- 186

TRANSMISSION

OVERHAUL—32RH

Fig.

116 Installing Rear

Band

Lever

And Pivot

Pin-32RH

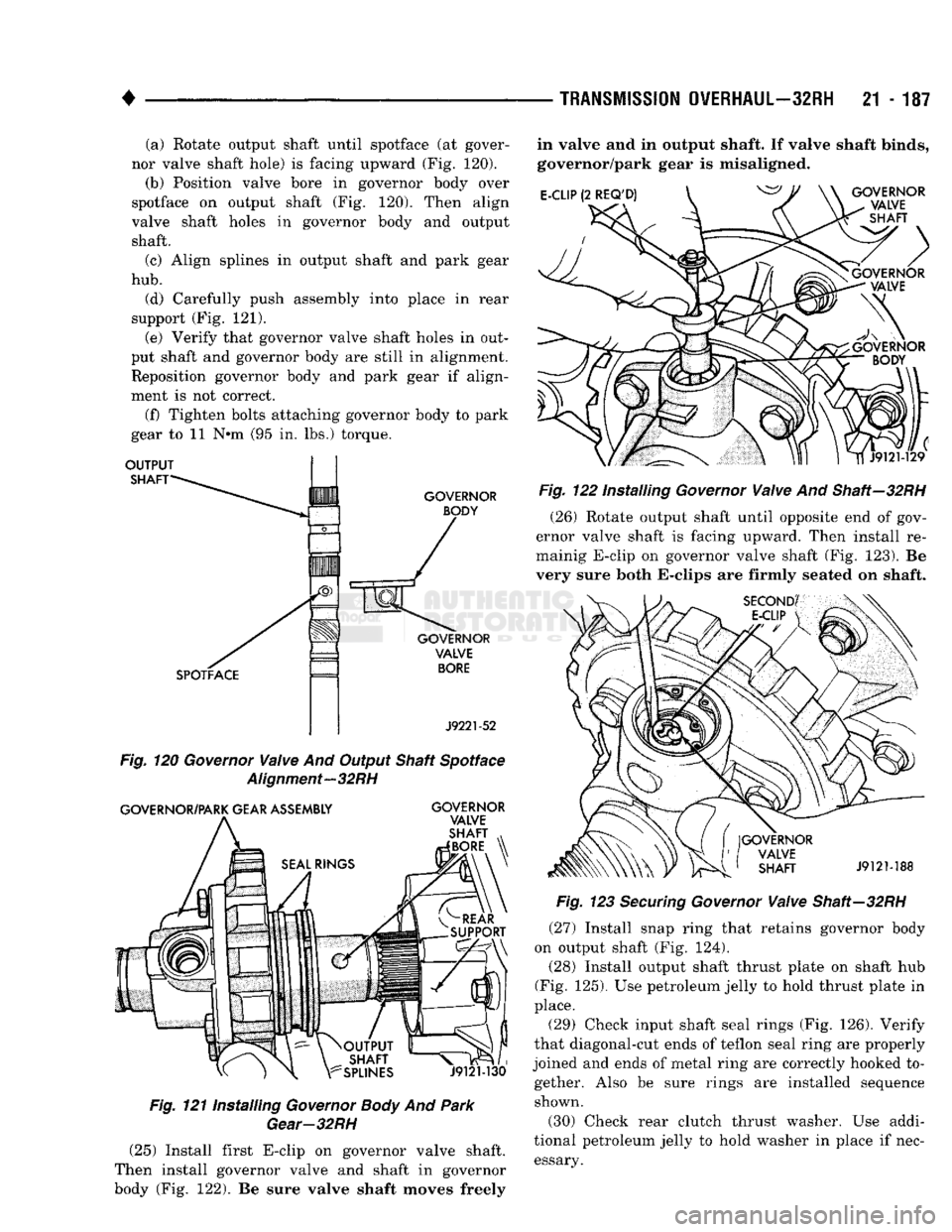

(14) Hold low-reverse drum in position and install

rear support. Align support with punch marks made

during disassembly.

(15) Install and tighten rear support bolts to 17

N*m (150 in. lbs. or 13 ft. lbs.) torque.

(16) Install snap ring that retains low-reverse

drum to hub of rear support (Fig. 117).

Fig.

117 Installing

Low-Reverse

Drum

Snap

Ring—32RH

(17) Lubricate output shaft, rear support bore and

low-reverse drum hub with transmission fluid. (18) Install assembled output shaft and planetary

geartrain in case (Fig. 118).

(19) Align drive lugs on rear planetary gear with

slots in low-reverse drum (Fig. 119). Then seat plan

etary assembly in drum.

(20) Lubricate governor components and park gear

seal rings with transmission fluid. •

Fig.

118 Installing Output Shaft/Planetary Geartrain—32RH

Fig.

119

Aligning/Seating

Rear Planetary In Low-

Reverse

Drum—32RH

(21) Install governor filter in park gear and install

governor body on gear (Fig. 120). Align governor

body on gear using marks made at disassembly.

(22) Install new seal rings on hub of park gear

(Fig. 120). Be sure ring (or rings) with hooked ends

are properly connected.

(23) Install governor weight assembly in governor

body. Be sure governor weight snap rings are se curely seated.

(24) Align and install governor/park gear assembly

on output shaft. Note that output shaft in current

transmission is spotfaced for governor valve end clearance (Fig. 120). Shaft must be indexed so

that small end of governor valve will seat in this spotface. Install governor body and park as fol

lows to ensure proper alignment and operation.

Page 1188 of 1502

•

TRANSMISSION

OVERHAUL—32RH

21 - 187 (a) Rotate output shaft until spotface (at gover

nor valve shaft hole) is facing upward (Fig. 120). (b) Position valve bore in governor body over

spotface on output shaft (Fig. 120). Then align

valve shaft holes in governor body and output shaft.

(c) Align splines in output shaft and park gear

hub.

(d) Carefully push assembly into place in rear

support (Fig. 121). (e) Verify that governor valve shaft holes in out

put shaft and governor body are still in alignment.

Reposition governor body and park gear if align

ment is not correct.

(f) Tighten bolts attaching governor body to park

gear to 11 N*m (95 in. lbs.) torque.

OUTPUT

SHAFT

GOVERNOR BODY

GOVERNOR VALVE

BORE

J9221-52

Fig.

120

Governor

Valve

And Output Shaft Spotface

Alignment—32RH

GOVERNOR/PARK GEAR ASSEMBLY GOVERNOR

VALVE

SHAFT

BORE

J9121-130

Fig.

121 Installing

Governor

Body

And

Park

Gear-32RH

in valve and in output shaft. If valve shaft binds,

governor/park gear is misaligned.

E-CLIP

(2

REQ'D)

GOVERNOR

VALVE

\-

SHAFT

Fig.

122 Installing

Governor

Valve

And Shaft—32RH (26) Rotate output shaft until opposite end of gov

ernor valve shaft is facing upward. Then install re-

mainig E-clip on governor valve shaft (Fig. 123). Be

very sure both E-clips are firmly seated on shaft.

GOVERNOR VALVE SHAFT

J9121-188

Fig.

123

Securing

Governor

Valve

Shaft—32RH

(27) Install snap ring that retains governor body

on output shaft (Fig. 124).

(28) Install output shaft thrust plate on shaft hub

(Fig.

125).

Use petroleum jelly to hold thrust plate in

place.

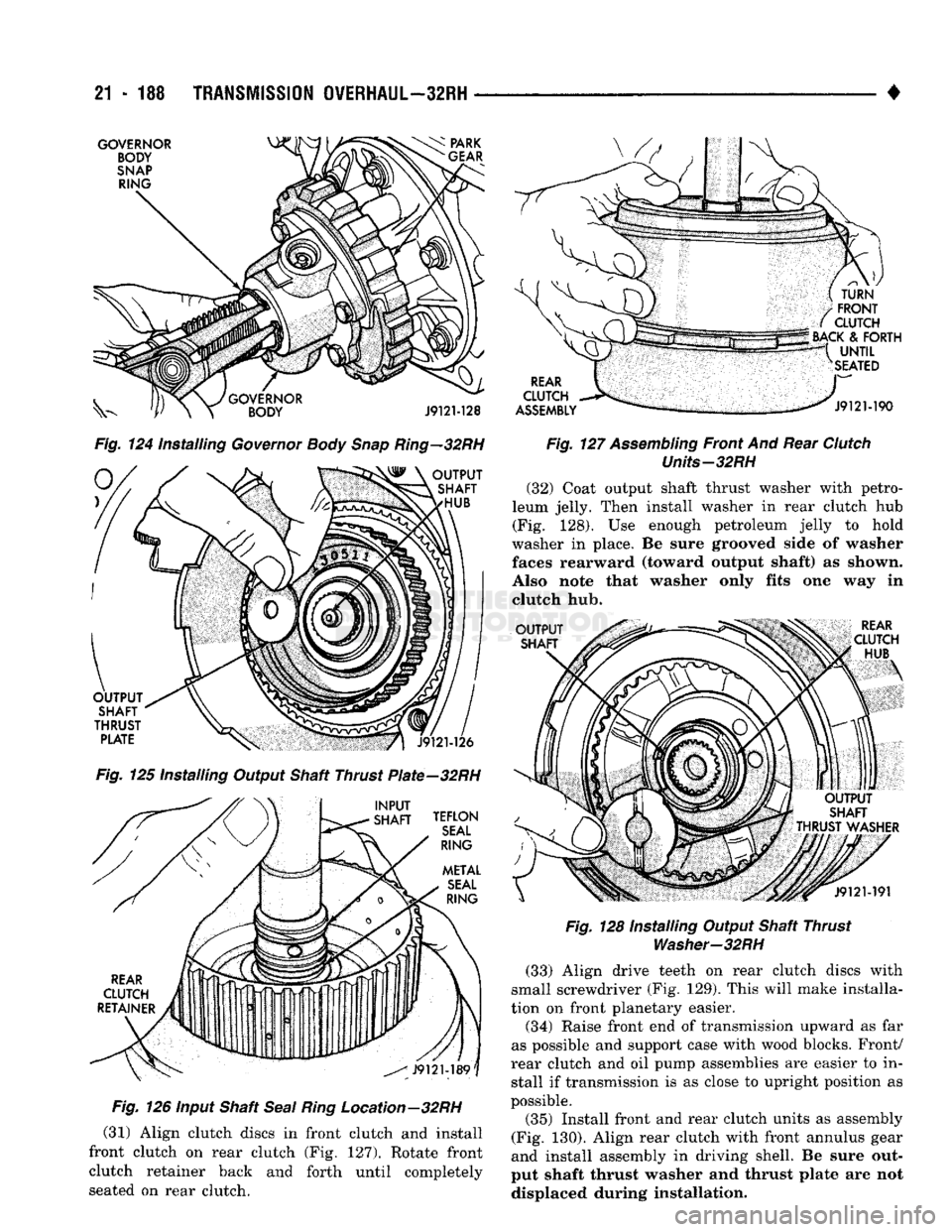

(29) Check input shaft seal rings (Fig. 126). Verify

that diagonal-cut ends of teflon seal ring are properly

joined and ends of metal ring are correctly hooked to gether. Also be sure rings are installed sequence shown.

(30) Check rear clutch thrust washer. Use addi

tional petroleum jelly to hold washer in place if nec essary. (25) Install first E-clip on governor valve shaft.

Then install governor valve and shaft in governor

body (Fig. 122). Be sure valve shaft moves freely

Page 1189 of 1502

21

- 188

TRANSMISSION

OVERHAUL—32RH

•

Fig.

124 Installing

Governor

Body

Snap

Ring—32RH

Fig.

125 Installing Output Shaft Thrust PIate-32RH

Fig.

126 input Shaft

Seal

Ring

Location-32RH

(31) Align clutch discs in front clutch and install

front clutch on rear clutch (Fig. 127). Rotate front

clutch retainer back and forth until completely

seated on rear clutch.

Fig.

127

Assembling

Front And Rear

Clutch

Units-32RH

(32) Coat output shaft thrust washer with petro

leum jelly. Then install washer in rear clutch hub (Fig. 128). Use enough petroleum jelly to hold

washer in place. Be sure grooved side of washer faces rearward (toward output shaft) as shown.

Also note that washer only fits one way in clutch hub.

Fig.

128 Installing Output Shaft Thrust

Washer-32RH

(33) Align drive teeth on rear clutch discs with

small screwdriver (Fig. 129). This will make installa

tion on front planetary easier.

(34) Raise front end of transmission upward as far

as possible and support case with wood blocks. Front/

rear clutch and oil pump assemblies are easier to in stall if transmission is as close to upright position as

possible.

(35) Install front and rear clutch units as assembly

(Fig. 130). Align rear clutch with front annulus gear

and install assembly in driving shell. Be sure out

put shaft thrust washer and thrust plate are not displaced during installation.

Page 1190 of 1502

•

TRANSMISSION

OVERHAUL—32RH

21 - 189

Fig.

129

Aligning

Rear

Clutch

Disc Lugs—32RH

(36) Carefully work assembled clutches back and

forth to engage and seat rear clutch discs on front annulus gear. Verify that front clutch drive lugs are

fully engaged in slots of driving shell after installa

tion.

J9121-124

Fig.

130 Installing Front/Rear

Clutch

Assemblies—32RH

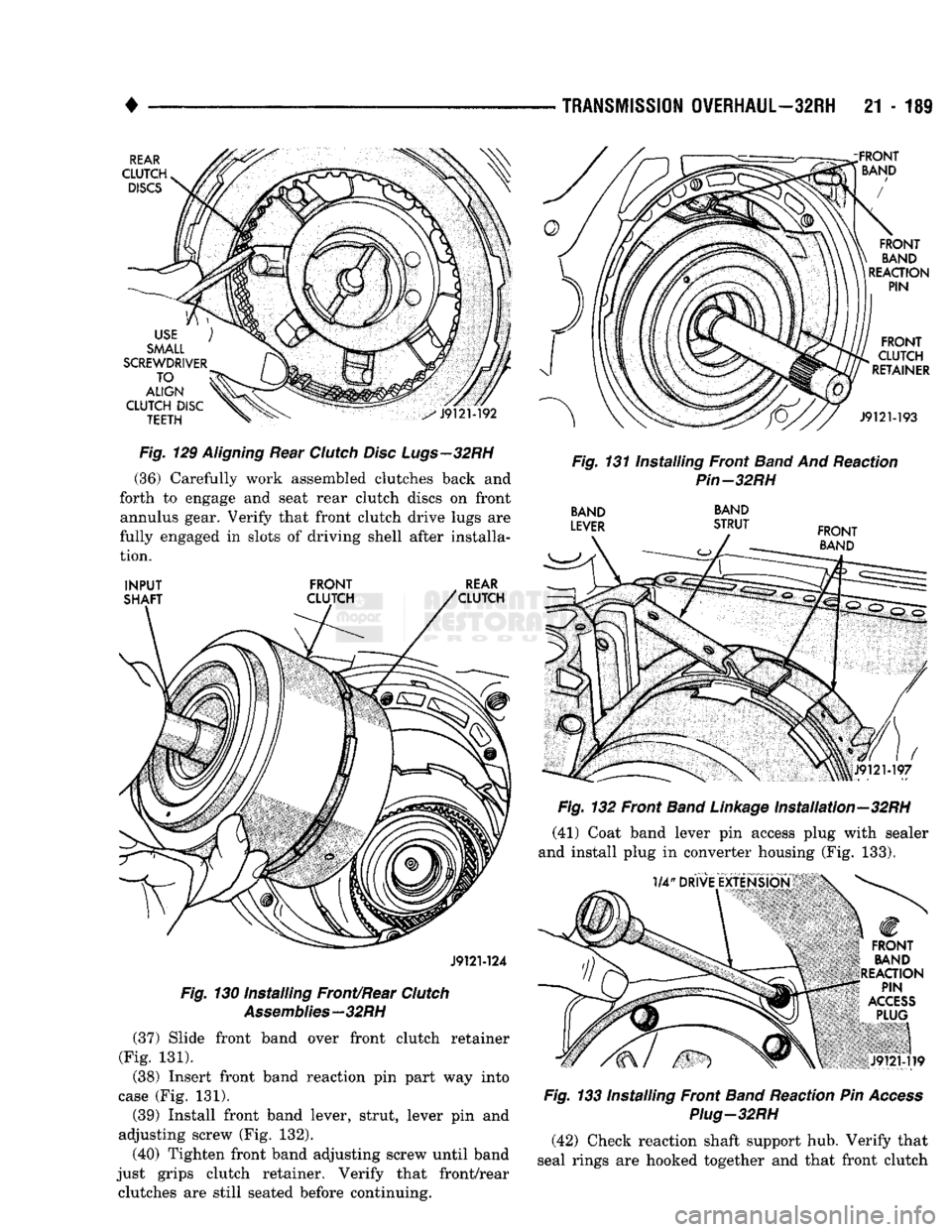

(37) Slide front band over front clutch retainer

(Fig. 131).

(38) Insert front band reaction pin part way into

case (Fig. 131). (39) Install front band lever, strut, lever pin and

adjusting screw (Fig. 132).

(40) Tighten front band adjusting screw until band

just grips clutch retainer. Verify that front/rear clutches are still seated before continuing.

Fig.

131 Installing Front

Band

And Reaction

Pin-32RH

BAND

BAND

Fig.

132 Front

Band

Linkage

Installation—32RH (41) Coat band lever pin access plug with sealer

and install plug in converter housing (Fig. 133).

Fig.

133 Installing Front

Band

Reaction Pin

Access

Plug-32RH

(42) Check reaction shaft support hub. Verify that

seal rings are hooked together and that front clutch