DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 1371 of 1502

22 - 2

WHEELS

AND

TIRES

•

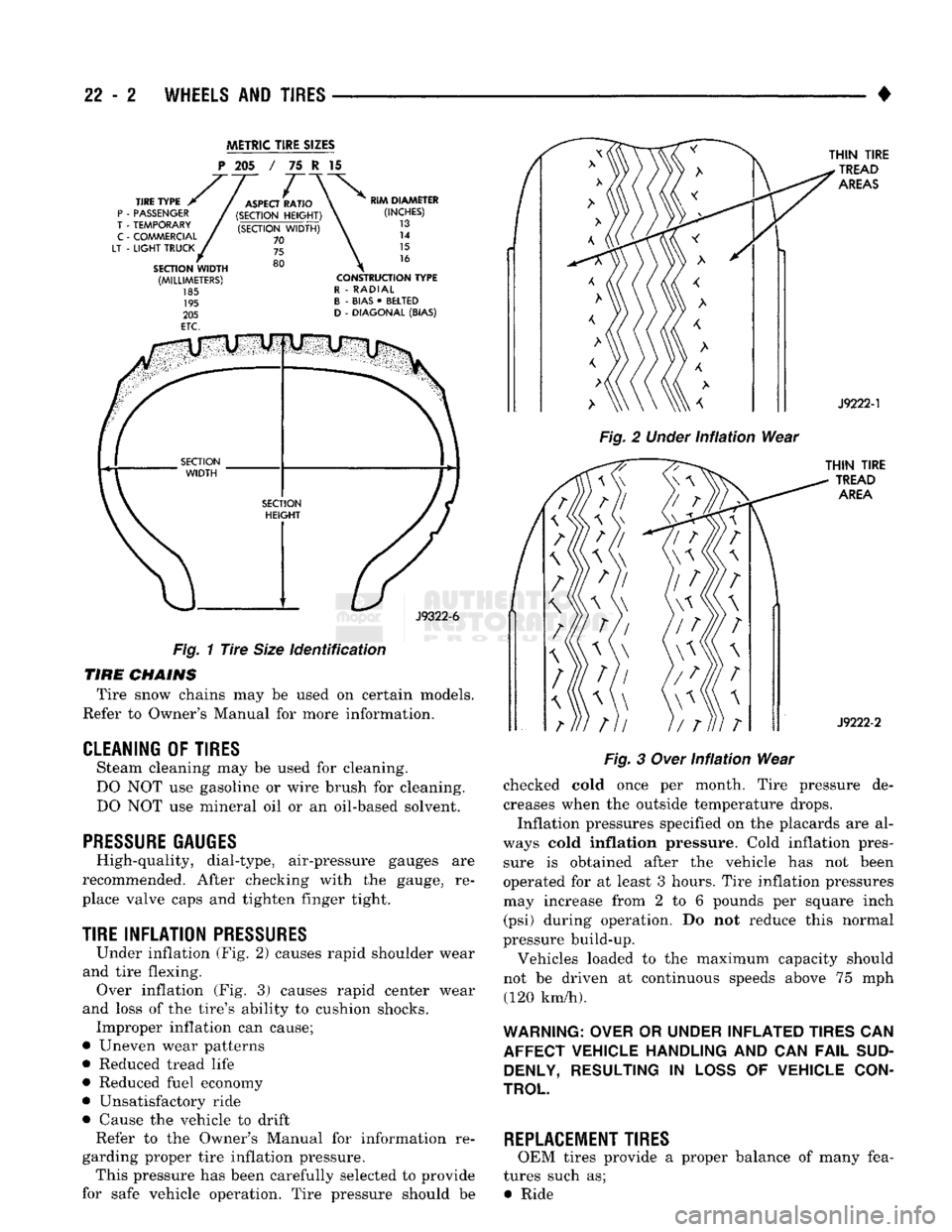

METRIC

TIRE

SIZES

P

205 / 75 I 15

J9322-6

Fig.

1

Tire

Size

identification

TIRE

CHAINS

Tire snow chains may be used on certain models.

Refer to Owner's Manual for more information.

CLEANING

OF

TIRES

Steam cleaning may be used for cleaning.

DO NOT use gasoline or wire brush for cleaning.

DO NOT use mineral oil or an oil-based solvent.

PRESSURE GAUGES

High-quality, dial-type, air-pressure gauges are

recommended. After checking with the gauge, re

place valve caps and tighten finger tight.

TIRE

INFLATION

PRESSURES

Under inflation (Fig. 2) causes rapid shoulder wear

and tire flexing. Over inflation (Fig. 3) causes rapid center wear

and loss of the tire's ability to cushion shocks. Improper inflation can cause;

• Uneven wear patterns

• Reduced tread life

• Reduced fuel economy

• Unsatisfactory ride

• Cause the vehicle to drift Refer to the Owner's Manual for information re

garding proper tire inflation pressure. This pressure has been carefully selected to provide

for safe vehicle operation. Tire pressure should be

Fig.

2

Under

infiation

Wear

Fig.

3

Over

Infiation

Wear

checked cold once per month. Tire pressure de creases when the outside temperature drops.

Inflation pressures specified on the placards are al

ways cold

inflation

pressure. Cold inflation pres sure is obtained after the vehicle has not been

operated for at least 3 hours. Tire inflation pressures may increase from 2 to 6 pounds per square inch (psi) during operation. Do not reduce this normal

pressure build-up.

Vehicles loaded to the maximum capacity should

not be driven at continuous speeds above 75 mph (120 km/h).

WARNING: OVER

OR

UNDER INFLATED TIRES

CAN

AFFECT VEHICLE HANDLING

AND CAN

FAIL

SUD DENLY, RESULTING

IN

LOSS

OF

VEHICLE CON

TROL

REPLACEMENT TIRES

OEM tires provide a proper balance of many fea

tures such as; • Ride

Page 1372 of 1502

•

WHEELS

AND

TIRES

22 - 3 • Noise

• Handling

• Durability

• Tread life

• Traction

• Rolling resistance

• Speed capability

We recommend that tires equivalent to the original

equipment tires be used when replacement is needed. Refer to the placard on the vehicle or the

Owner's Manual for the correct replacement

tire.

Failure to use original equipment replacement

tires may adversely affect the handling of the vehi

cle.

The use of oversize tires is not

recommended.

They may cause interference with vehicle suspension and steering travel. This can cause tire damage or

failure.

WARNING: FAILURE

TO

EQUIP

THE

VEHICLE

WITH

TIRES

HAVING ADEQUATE LOAD CAPABILITY

CAN

RESULT

IN

SUDDEN TIRE FAILURE.

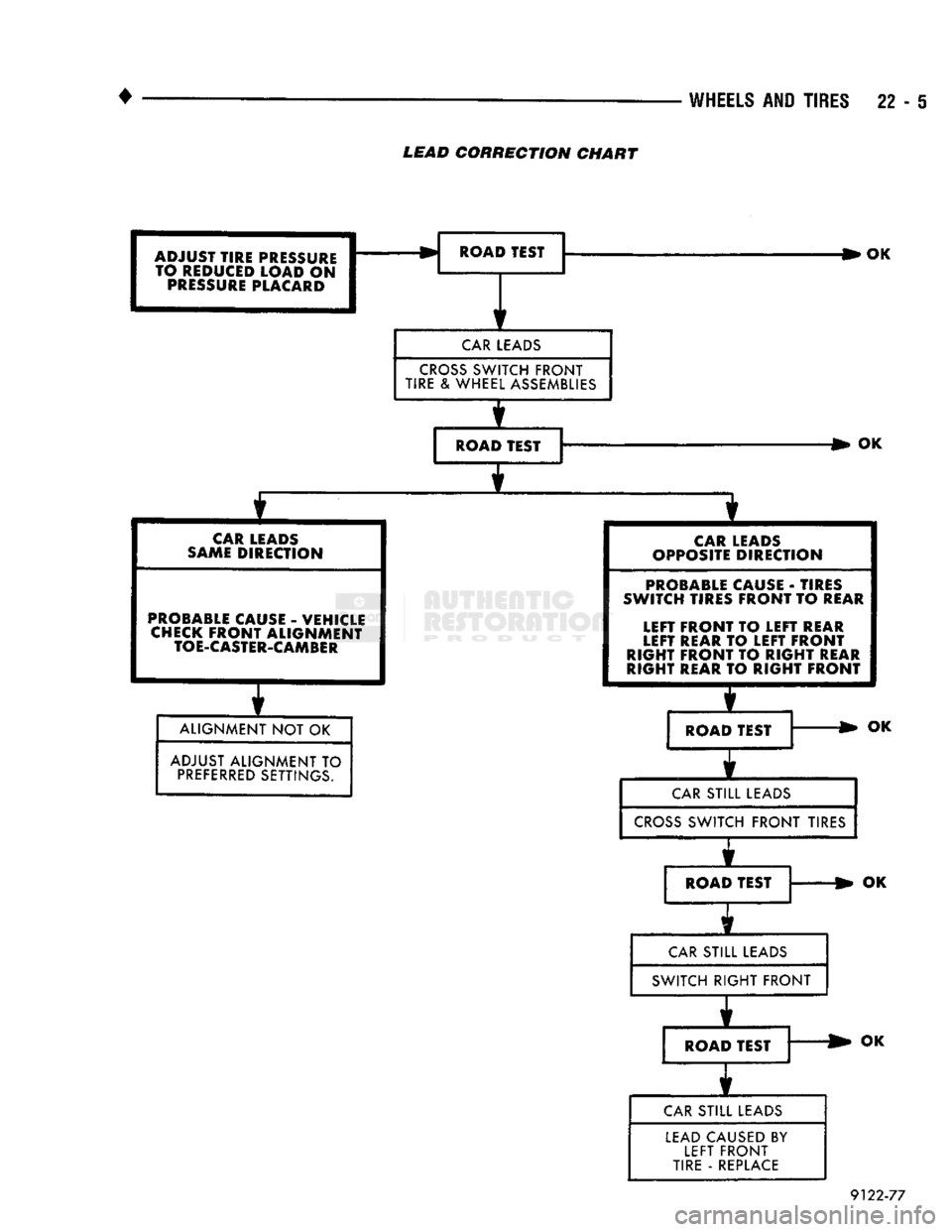

ROTATION

Tires on the front and rear axles operate at differ

ent loads and perform different steering, driving, and

braking functions. For these reasons; • They wear at unequal rates

• Tend to develop irregular wear patterns These effects can be reduced by timely rotation of

tires.

The benefits of rotation are especially worth

while. Rotation will: • Increase tread life

• Help to maintain mud, snow, and wet traction levels

• Contribute to a smooth, quiet ride The suggested method of tire rotation is the

same

side front

to

rear

pattern (Fig. 4). Other rotation

methods can be used, but they will not provide all

the tire longevity benefits. Dual wheel vehicles require a different tire rota

tion than that of the conventional four wheel type.

Refer to Figure 5 for the proper tire rotation with

dual wheels.

FRONT m kz

—~i

J9222-8 LEFT

'I

RIGHT

FRONT

II

FRONT

LEFT

II

RIGHT

REAR

p

REAR

1

|| | L HN838

Fig.

5

Dual

Wheel

Tire

Rotation

Pattern

TREAD

WEAR INDICATORS Tread

wear indicators are molded into the bottom

of the tread grooves. When

tread

is 1.6 mm (1/16 in.),

the tread wear indicators will appear as a 13 mm (1/2 in.) band. Tire replacement is necessary when indicators ap

pear in two or more grooves, or if localized balding occurs (Fig. 6).

TREAD

ACCEPTABLE TREAD

UNACCEPTABLE

WEAR

INDICATOR

v

J8922-5

Fig.

4

Tire

Rotation

Pattern

Fig.

6

Tread

Wear Indicators

REPAIRING

LEAKS

For proper repairing, a radial tire must be removed

from the wheel. Repairs should only be made if the

Page 1373 of 1502

22 - 4

WHEELS

AND

TIRES

• puncture is in the tread area (Fig. 7). If outside the

tread area the tire should be replaced.

J8922-6

Fig.

7

Tire

Repair Area

Deflate tire completely before dismounting tire

from the wheel. Use lubrication such as a mild soap solution when dismounting or mounting tire. Use

tools free of burrs or sharp edges.

Before mounting tire on wheel, make sure all rust

scale is removed from the rim. Repaint or seal if nec

essary.

TIRE NOISE

OR

VIBRATION

The radial-ply tire on your vehicle is more sensi

tive to improper mounting, or imbalance. To determine if tires are the cause of vibration,

drive the vehicle over a smooth road at different speeds. Note the effect of acceleration and decelera

tion on noise level. Differential and exhaust noise

will change in intensity as speed varies. Tire noise

will usually remain constant.

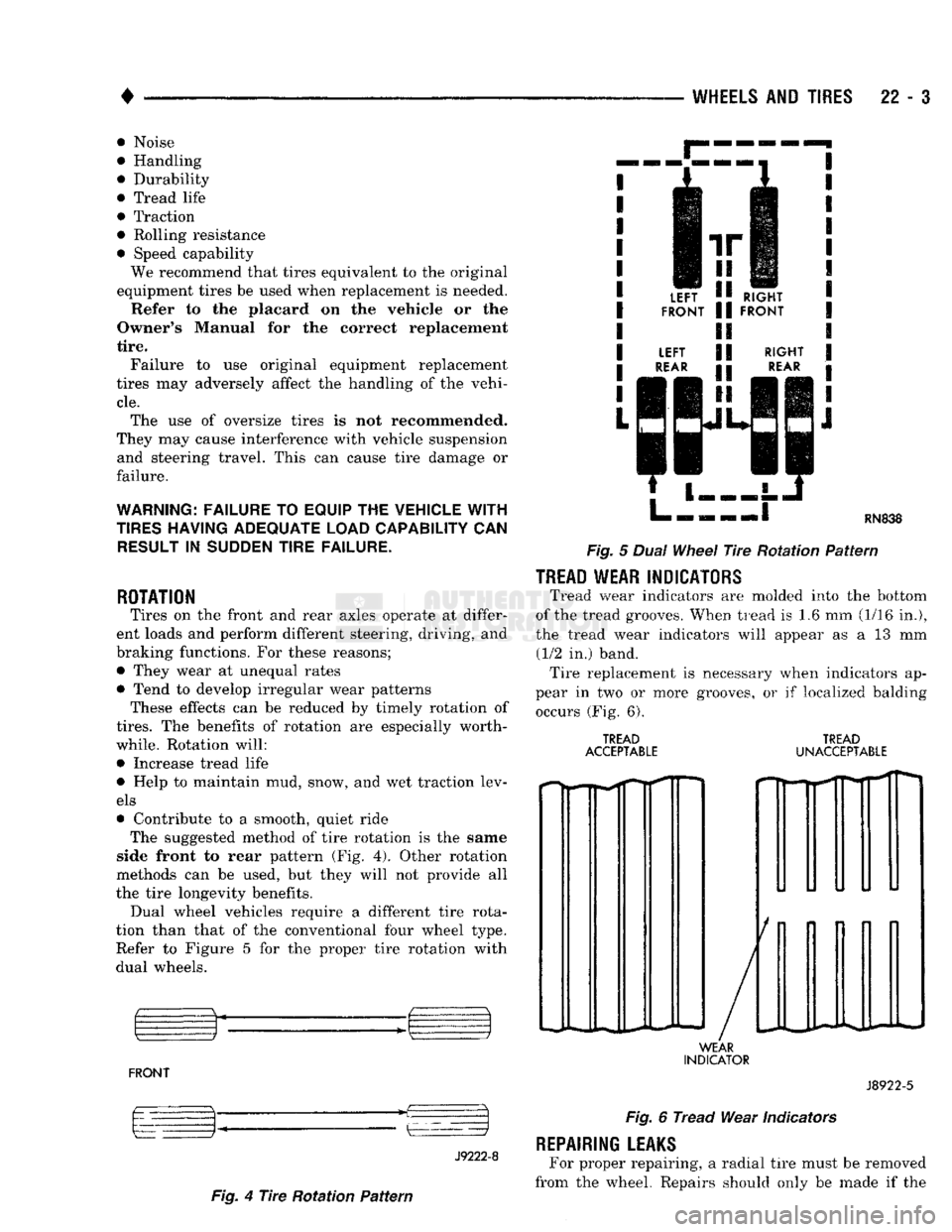

TIRE WEAR PATTERNS

Under inflation results in faster wear on shoulders

of tire. Over inflation causes faster wear at center of

tread. Excessive camber causes the tire to run at an angle

to the road. One side of tread is worn more than the other. Excessive toe-in or toe-out causes wear on the

tread edges of the tire, from dragging of tire. There is a feathered effect across the tread (Fig. 8).

CRACKED

TREADS

WEAR

ON

ONE SIDE FEATHERED EDGE

BALD

SPOTS

IP

fa

SCALLOPED

WEAR

EXCESSIVE

CAMBER INCORRECT

TOE

EXCESSIVE

SPEED*

UNBALANCED

WHEEL LACK

OF

ROTATION

OF TIRES

OR

WORN

OR OUT-

OF-ALIGNMENT

SUSPENSION.

OR

TIRE

DEFECT* ADJUST

PRESSURE

TO

SPECIFICATIONS

WHEN

TIRES ARE COOL

ROTATE

TIRES ADJUST CAMBER

TO

SPECIFICATIONS ADJUST

TOE-IN

TO

SPECIFICATIONS DYNAMIC

OR

STATIC

BALANCE

WHEELS

ROTATE

TIRES

AND

INSPECT SUSPENSION

SEE

GROUP

2

•HAVE

TIRE

INSPECTED

FOR

FURTHER

USE.

RN797

Fig.

8 Abnormal Tire Tread Wear Patterns

Page 1374 of 1502

WHEELS

AND

TIRES

22 - 5

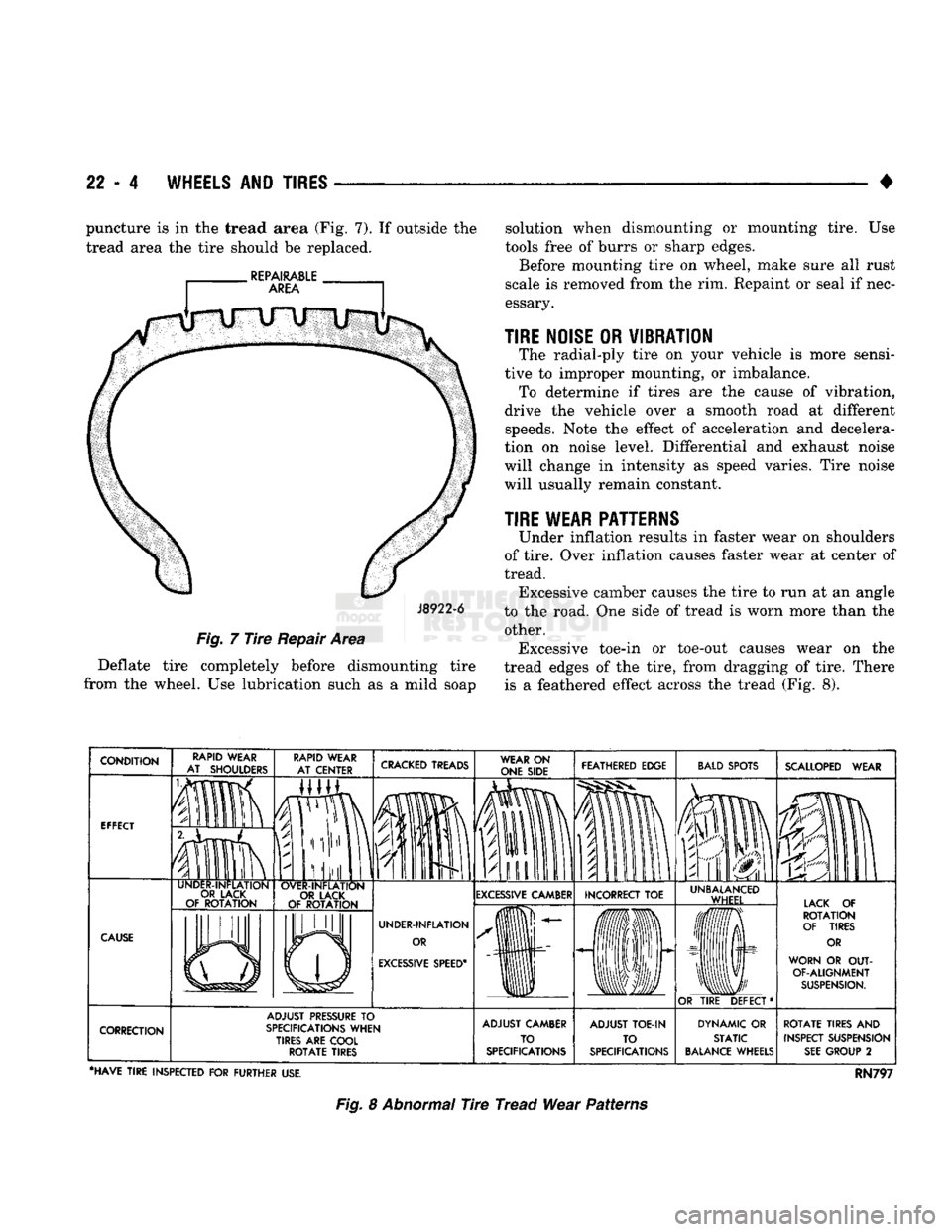

LEAD

CORRECTION CHART

ADJUST TIRE PRESSURE TO REDUCED LOAD

ON

PRESSURE

PLACARD ROAD TEST

OK

I

CAR LEADS

SAME

DIRECTION

CAR LEADS

CROSS SWITCH FRONT

TIRE & WHEEL ASSEMBLIES

I

ROAD TEST

I

PROBABLE CAUSE

-

VEHICLE CHECK

FRONT

ALIGNMENT TOE-CASTER-CAMBER

I

ALIGNMENT NOT OK

ADJUST ALIGNMENT TO PREFERRED SETTINGS.

OK

1

CAR LEADS

OPPOSITE DIRECTION

PROBABLE CAUSE

-

TIRES

SWITCH TIRES

FRONT

TO

REAR

LEFT

FRONT

TO

LEFT

REAR

LEFT

REAR

TO

LEFT

FRONT

RIGHT

FRONT

TO

RIGHT

REAR

RIGHT

REAR

TO

RIGHT

FRONT

ROAD TEST £ OK

CAR STILL LEADS

CROSS SWITCH FRONT TIRES

ROAD TEST A

CAR STILL LEADS

SWITCH RIGHT FRONT

1

ROAD TEST

CAR

STILL

LEADS LEAD CAUSED BY

LEFT FRONT

TIRE

-

REPLACE OK

9122-77

Page 1375 of 1502

22 - e

WHEELS

AND

TIRES

• WHEELS

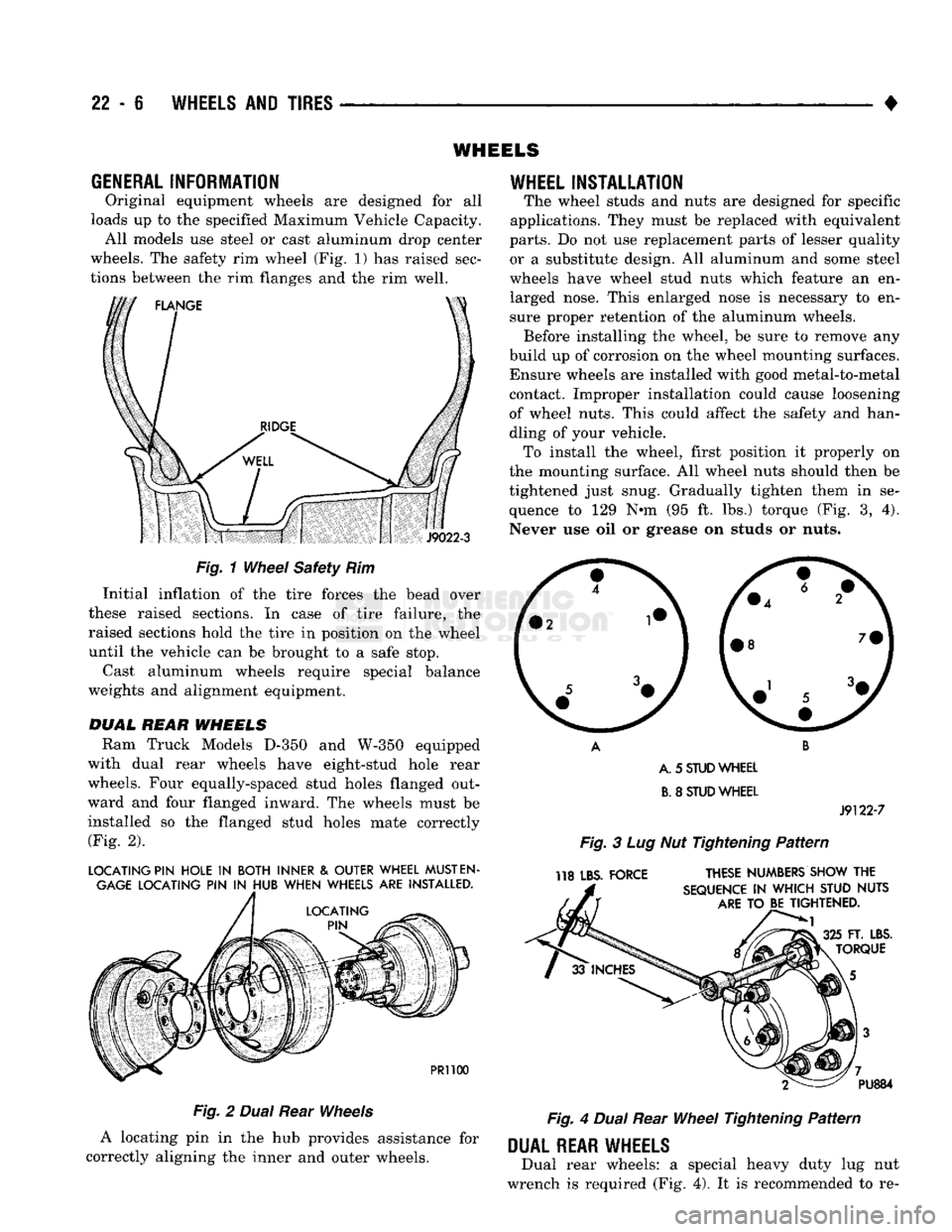

GENERAL

INFORMATION

Original equipment wheels are designed for all

loads up to the specified Maximum Vehicle Capacity. All models use steel or cast aluminum drop center

wheels. The safety rim wheel (Fig. 1) has raised sec

tions between the rim flanges and the rim well.

S

J9022-3

Fig.

1

Wheel

Safety Rim Initial inflation of the tire forces the bead over

these raised sections. In case of tire failure, the

raised sections hold the tire in position on the wheel

until the vehicle can be brought to a safe stop.

Cast aluminum wheels require special balance

weights and alignment equipment.

DUAL

REAR

WHEELS

Ram Truck Models

D-350

and

W-350

equipped

with dual rear wheels have eight-stud hole rear

wheels. Four equally-spaced stud holes flanged out

ward and four flanged inward. The wheels must be

installed so the flanged stud holes mate correctly (Fig. 2).

LOCATING PIN HOLE

IN

BOTH INNER

&

OUTER WHEEL

MUST

EN

GAGE

LOCATING PIN

IN

HUB WHEN WHEELS ARE INSTALLED.

PR1100

Fig.

2

Dual

Rear

Wheels

A locating pin in the hub provides assistance for

correctly aligning the inner and outer wheels.

WHEEL

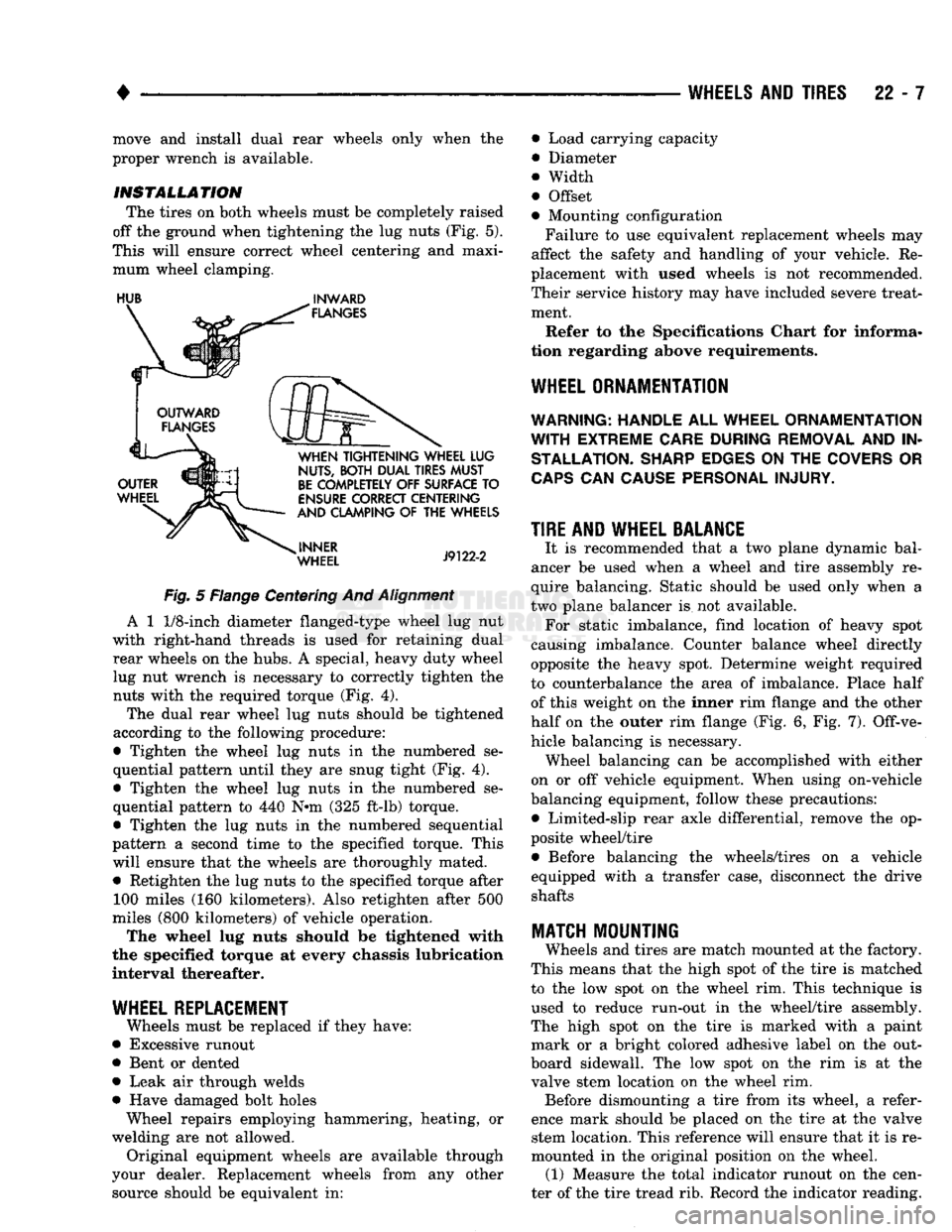

INSTALLATION

The wheel studs and nuts are designed for specific

applications. They must be replaced with equivalent

parts.

Do not use replacement parts of lesser quality or a substitute design. All aluminum and some steel

wheels have wheel stud nuts which feature an en larged nose. This enlarged nose is necessary to en

sure proper retention of the aluminum wheels. Before installing the wheel, be sure to remove any

build up of corrosion on the wheel mounting surfaces. Ensure wheels are installed with good metal-to-metal contact. Improper installation could cause loosening

of wheel nuts. This could affect the safety and han

dling of your vehicle. To install the wheel, first position it properly on

the mounting surface. All wheel nuts should then be

tightened just snug. Gradually tighten them in se

quence to 129 N-m (95 ft. lbs.) torque (Fig. 3, 4).

Never use oil or grease on studs or nuts.

A. 5

STUD

WHEEL

B.

8

STUD

WHEEL

J9122-7

Fig.

3 Lug Nut Tightening

Pattern

118 LBS. FORCE THESE NUMBERS SHOW THE

SEQUENCE

IN

WHICH STUD NUTS

ARE

TO BE TIGHTENED.

FT. LBS.

TORQUE PU884

Fig.

4

Dual

Rear

Wheel

Tightening

Pattern

DUAL

REAR WHEELS

Dual rear wheels: a special heavy duty lug nut

wrench is required (Fig. 4). It is recommended to re-

Page 1376 of 1502

•

WHEELS

AND

TIRES

22 - 7 move and install dual rear wheels only when the

proper wrench is available.

INSTALLATION

The tires on both wheels must be completely raised

off the ground when tightening the lug nuts (Fig. 5).

This will ensure correct wheel centering and maxi mum wheel clamping.

HUB

^

INWARD

Fig.

5 Flange Centering And

Alignment

A 1

1/8-inch

diameter flanged-type wheel lug nut

with right-hand threads is used for retaining dual rear wheels on the hubs. A special, heavy duty wheel lug nut wrench is necessary to correctly tighten the nuts with the required torque (Fig. 4).

The dual rear wheel lug nuts should be tightened

according to the following procedure:

• Tighten the wheel lug nuts in the numbered se

quential pattern until they are snug tight (Fig. 4).

• Tighten the wheel lug nuts in the numbered se

quential pattern to 440 N#m (325 ft-lb) torque.

• Tighten the lug nuts in the numbered sequential

pattern a second time to the specified torque. This will ensure that the wheels are thoroughly mated. • Retighten the lug nuts to the specified torque after 100 miles (160 kilometers). Also retighten after 500

miles (800 kilometers) of vehicle operation.

The wheel lug nuts should be tightened with

the specified torque at every chassis lubrication

interval thereafter.

WHEEL REPLACEMENT

Wheels must be replaced if they have:

• Excessive runout

• Bent or dented

• Leak air through welds

• Have damaged bolt holes Wheel repairs employing hammering, heating, or

welding are not allowed. Original equipment wheels are available through

your dealer. Replacement wheels from any other source should be equivalent in: • Load carrying capacity

• Diameter

® Width

• Offset

• Mounting configuration

Failure to use equivalent replacement wheels may

affect the safety and handling of your vehicle. Re

placement with used wheels is not recommended.

Their service history may have included severe treat ment.

Refer to the Specifications Chart for informa

tion regarding above requirements.

WHEEL ORNAMENTATION

WARNING; HANDLE

ALL

WHEEL ORNAMENTATION

WITH

EXTREME CARE DURING REMOVAL

AND IN

STALLATION. SHARP EDGES

ON THE

COVERS

OR

CAPS

CAN

CAUSE PERSONAL INJURY.

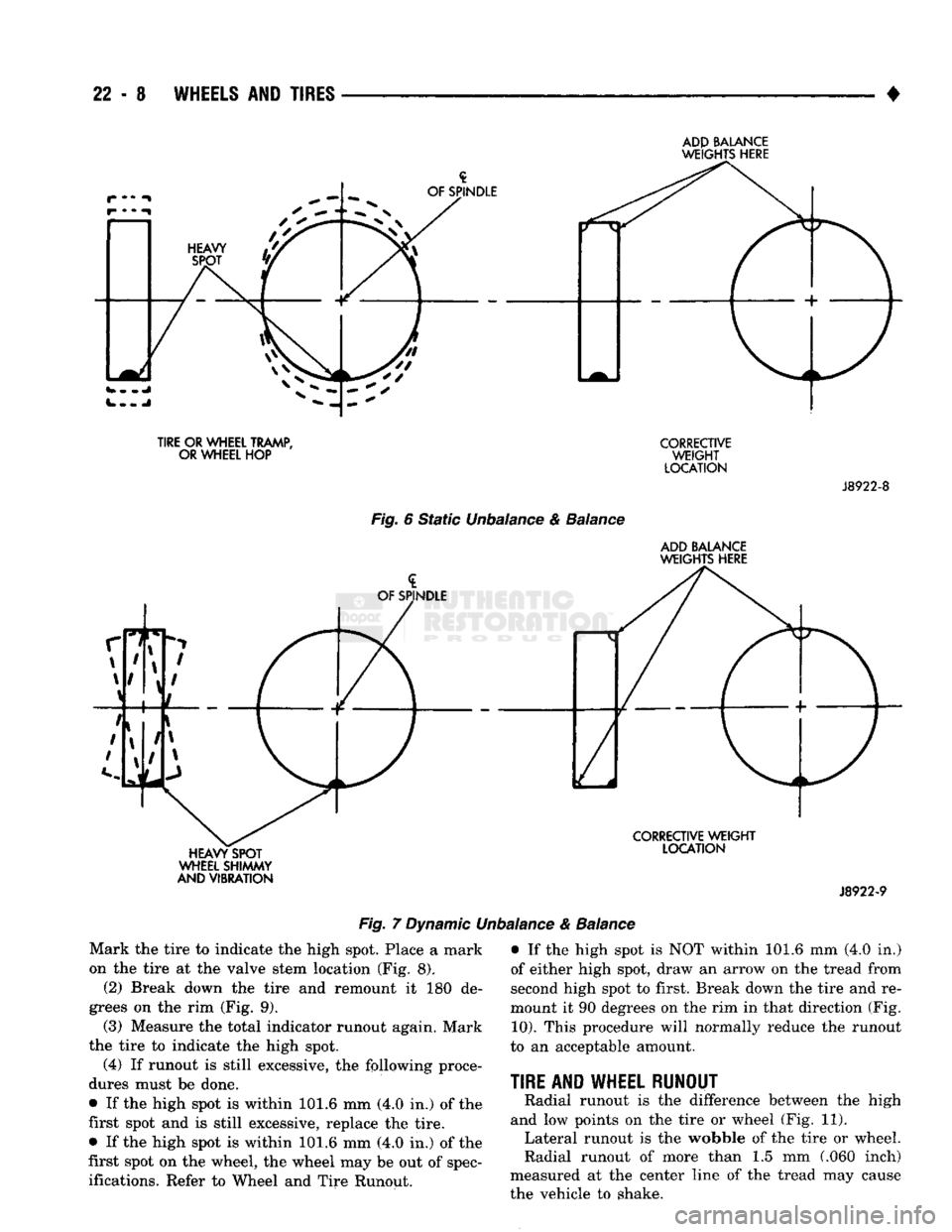

TIRE AND WHEEL BALANCE

It is recommended that a two plane dynamic bal

ancer be used when a wheel and tire assembly re

quire balancing. Static should be used only when a

two plane balancer is not available. For static imbalance, find location of heavy spot

causing imbalance. Counter balance wheel directly

opposite the heavy spot. Determine weight required

to counterbalance the area of imbalance. Place half of this weight on the inner rim flange and the other

half on the outer rim flange (Fig. 6, Fig. 7). Off-ve

hicle balancing is necessary. Wheel balancing can be accomplished with either

on or off vehicle equipment. When using on-vehicle

balancing equipment, follow these precautions: • Limited-slip rear axle differential, remove the op

posite wheel/tire • Before balancing the wheels/tires on a vehicle

equipped with a transfer case, disconnect the drive shafts

MATCH

MOUNTING

Wheels and tires are match mounted at the factory.

This means that the high spot of the tire is matched

to the low spot on the wheel rim. This technique is used to reduce run-out in the wheel/tire assembly.

The high spot on the tire is marked with a paint mark or a bright colored adhesive label on the out

board sidewall. The low spot on the rim is at the

valve stem location on the wheel rim. Before dismounting a tire from its wheel, a refer

ence mark should be placed on the tire at the valve stem location. This reference will ensure that it is re

mounted in the original position on the wheel. (1) Measure the total indicator runout on the cen

ter of the tire tread rib. Record the indicator reading.

Page 1377 of 1502

22 - 8

WHEELS

AND

TIRES

•

ADP

BALANCE

WEIGHTS

HERE

TIRE

OR

WHEEL TRAMP,

OR WHEEL

HOP Fig. 6 Static Unbalance & Balance

CORRECTIVE

WEIGHT

LOCATION ADD BALANCE

WEIGHTS HERE

J8922-8

HEAVY SPOT

WHEEL SHIMMY

AND VIBRATION

CORRECTIVE

WEIGHT

LOCATION

J8922-9

Fig. 7 Dynamic Unbalance & Balance

Mark the tire to indicate the high spot. Place a mark

on the tire at the valve stem location (Fig. 8). (2) Break down the tire and remount it 180 de

grees on the rim (Fig. 9).

(3)

Measure the total indicator runout again. Mark

the tire to indicate the high spot. (4) If runout is still excessive, the following proce

dures must be done.

• If the high spot is within 101.6 mm (4.0 in.) of the

first spot and is still excessive, replace the tire.

• If the high spot is within 101.6 mm (4.0 in.) of the

first spot on the wheel, the wheel may be out of spec

ifications. Refer to Wheel and Tire Runout. • If the high spot is NOT within 101.6 mm (4.0 in.)

of either high spot, draw an arrow on the tread from

second high spot to first. Break down the tire and re

mount it 90 degrees on the rim in that direction (Fig.

10).

This procedure will normally reduce the runout

to an acceptable amount.

TIRE

AND WHEEL RUNOUT

Radial runout is the difference between the high

and low points on the tire or wheel (Fig. 11). Lateral runout is the wobble of the tire or wheel.

Radial runout of more than 1.5 mm (.060 inch)

measured at the center line of the tread may cause

the vehicle to shake.

Page 1378 of 1502

•

WHEELS

AND

TIRES

22 - 9

Fig.

8 First Measurement On

Tire

VALVE STEM

REFERENCE

AAARK J9322-4

Fig.

9

Remount

Tire

180

Degrees

Lateral runout of more than 2.0 mm (.080 inch)

measured near the shoulder of the tire may cause the

vehicle to shake.

Sometimes radial runout can be reduced. Relocate

the wheel and tire assembly on the mounting studs (See Method 1). If this does not reduce runout to an

acceptable level, the tire can be rotated on the wheel. (See Method 2). 2ND HIGH SPOT

ON TIRE

SPOT ON TIRE J9322-5

Fig.

10

Remount

Tire

90

Degrees

In Direction of

Arrow

J9022-4

Fig.

11

Checking

Tire

Runout

METHOD

1

(RELOCATE WHEEL

ON HUB) Check accuracy of the wheel mounting surface; ad

just wheel bearings.

Drive vehicle a short distance to eliminate tire flat

spotting from a parked position. Make sure all wheel nuts are properly torqued.

Relocate wheel on the mounting, two studs over

from the original position.

Re-tighten wheel nuts until all are properly

torqued, to eliminate brake distortion.

Check radial runout. If still excessive, mark tire

sidewall, wheel, and stud at point of maximum

runout and proceed to Method 2.

Page 1379 of 1502

22

- 10

WHEELS

AND

TIRES

•

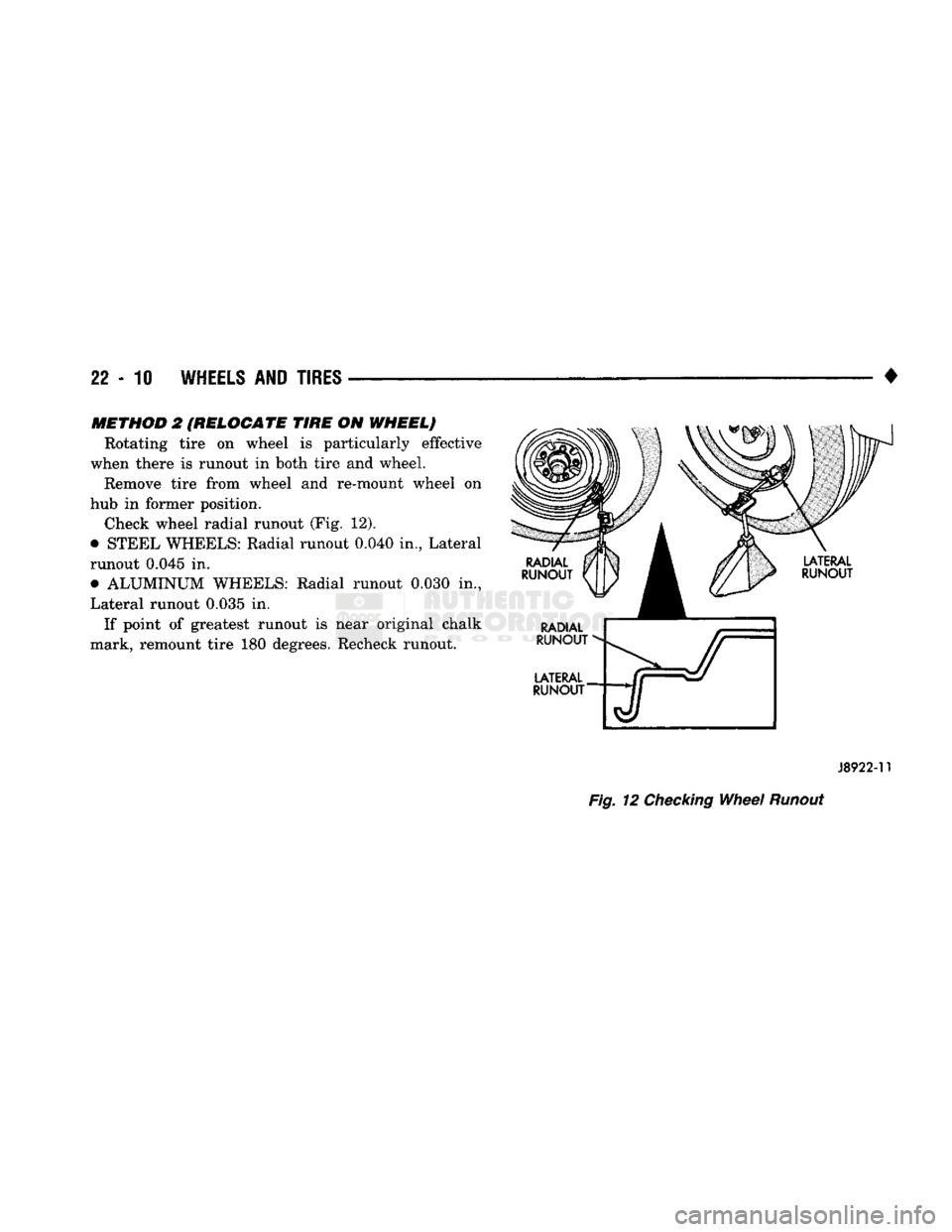

J8922-11

Fig.

12

Checking

Wheel

Runout

METHOD

2

(RELOCATE

TIRE

ON

WHEEL)

Rotating tire on wheel is particularly effective

when there is runout in both tire and wheel. Remove tire from wheel and re-mount wheel on

hub in former position. Check wheel radial runout (Fig. 12).

• STEEL WHEELS: Radial runout 0.040 in., Lateral

runout 0.045 in. • ALUMINUM WHEELS: Radial runout 0.030 in.,

Lateral runout 0.035 in.

If point of greatest runout is near original chalk

mark, remount tire 180 degrees. Recheck runout.

Page 1380 of 1502

•

WHEELS

AND

TIRES

22-11 VEHICLE VIBRATION

Vehicle vibration can

be

caused by:

• Tire/wheel unbalance

or

excessive runout

• Defective tires with extreme tread wear

• Nylon overlay flat spots (performance tires only)

• Incorrect wheel bearing adjustment

(if

applicable)

• Loose

or

worn suspension/steering components

• Certain tire tread patterns

• Incorrect drive shaft angles

or

excessive drive

shaft/yoke runout

• Defective

or

worn U-joints

• Excessive brake rotor

or

drum runout

• Loose engine

or

transmission supports/mounts

• And

by

engine operated accessories Refer

to the

appropriate Groups

in

this man

ual for additional information.

VIBRATION

TYPES

There are two types

of

vehicle vibration:

• Mechanical

• Audible. Mechanical vehicle vibration

can be

felt through

the seats, floor pan and/or steering wheel. Audible vehicle vibration

is

heard above normal

background noise.

The

sound

can be a

droning

or

drumming noise. Vibrations

are

sensitive

to

change

in

engine

torque, vehicle speed

or

engine speed.

ENGINE TORQUE SENSITIVE VIBRATION

This vibration can

be

increased

or

decreased by:

• Accelerating

• Decelerating

• Coasting

• Maintaining

a

constant vehicle speed

VEHICLE SPEED SENSITIVE VIBRATION

This vibration condition always occurs

at

the same

vehicle speed regardless

of

the engine torque

or en

gine speed.

ENGINE SPEED

{RPM}

SENSITIVE VIBRATION

This vibration occurs

at

varying engine speeds.

It

can

be

isolated

by

increasing

or

decreasing

the en

gine speed with the transmission

in

NEUTRAL posi

tion.

VIBRATION

DIAGNOSIS

A vibration diagnosis should always begin with

a

10 mile (16 km) trip (to warm the vehicle and tires).

Then

a

road test

to

identify the vibration. Corrective action should

not be

attempted until

the

vibration

type has been identified

via a

road test. During the road test, drive the vehicle

on a

smooth

surface.

If

vibration exists, note

and

record

the

fol

lowing information: • Identify

the

vehicle speed range when

the

vibra

tion occurs

• Identify the type

of

vibration

• Identify the vibration sensitivity

• Determine

if

the vibration

is

affected

by

changes

in vehicle speed, engine speed and engine torque. When the vibration has been identified, refer to the

Vibration Diagnosis chart

for

causes. Consider cor

recting only those causes coded

in

the chart that

are

related

to

the vibration condition.

Refer

to

the following cause codes and descriptions

for explanations when referring

to

the chart.

TRR—Tire

and

Wheel Radial Runout: Vehicle

speed sensitive, mechanical vibration.

The

runout

will not cause vibration below

20

mph (32 km/h).

WH—Wheel Hop: Vehicle speed sensitive,

me

chanical vibration.

The

wheel

hop

generates rapid

up-down movement

in

the steering wheel. The vibra

tion

is

most noticeable

in the 20 - 40

mph

(32 - 64

km/h) range. The wheel hop will not cause vibration

below

20

mph (32 km/h). Wheel hop

is

caused

by a

tire/wheel that

has a

radial runout

of

more than 0.045 of-an-inch (1.14 mm).

If

wheel runout

is

accept

able

and

combined runout cannot

be

reduced

by re

positioning the tire

on

wheel, replace tire.

TB—Tire/Wheel Balance: Vehicle speed sensitive,

mechanical vibration. Static tire/wheel unbalance

will not cause vibration below 30 mph (46 km/h). Dy

namic tire/wheel unbalance will

not

cause vibration

below

40

mph (64 km/h). TLR—Tire/Wheel Lateral runout: Vehicle speed

sensitive, mechanical vibration. The runout will

not

cause vibration below

50 - 55 mph (80 - 88

km/h).

Excessive lateral runout will also cause front-end shimmy. TW—Tire Wear: Vehicle speed sensitive, audible

vibration. Abnormal tire wear causes small vibration in

the 30 - 55

mph

(88

km/h) range. This will pro

duce

a

whine noise

at

high speed.

The

whine will

change

to a

growl noise when the speed

is

reduced. W—Tire Waddle: Vehicle speed sensitive, mechan

ical vibration. Irregular tire uniformity

can

cause

side-to-side motion during speeds

up to 15

mph

(24

km/h).

If

the motion

is

excessive, identify

the

defec

tive tire and replace

it.

U A J—Universal Joint (Drive Shaft) Angles:

Torque/vehicle speed sensitive, mechanical/audible

vibration. Incorrect drive shaft angles cause mechan ical vibration below

20

mph (32 km/h) and

in

the

70

mph (112 km/h) range. The incorrect angles can also

produce

an

audible vibration

in

the 20

-

50 mph (32

-

80 km/h) range. Caster adjustment could

be

required

to correct the angles. UJ—Universal Joints: Engine torque/vehicle

speed sensitive, mechanical/audible vibration.

If

the