DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 1411 of 1502

23

- 28

BODY COMPONENTS

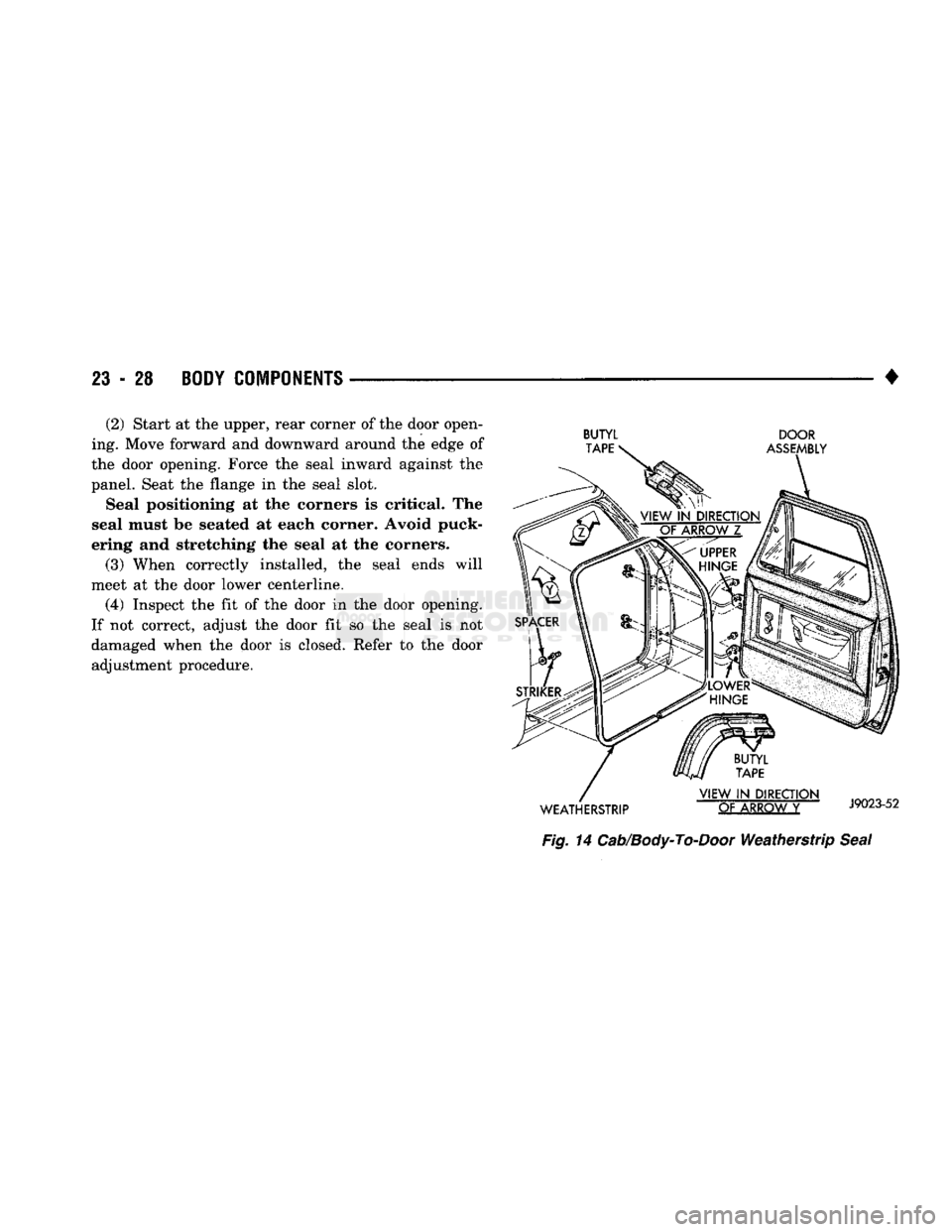

• (2) Start at the upper, rear corner of the door open

ing. Move forward and downward around the edge of

the door opening. Force the seal inward against the

panel. Seat the flange in the seal slot.

Seal positioning at the corners is critical. The

seal must be seated at each corner. Avoid puck

ering and stretching the seal at the corners.

(3) When correctly installed, the seal ends will

meet at the door lower centerline.

(4) Inspect the fit of the door in the door opening.

If not correct, adjust the door fit so the seal is not damaged when the door is closed. Refer to the door adjustment procedure.

BUTYL

DOOR

Fig.

14

Cab/Body-To-Door

Weatherstrip

Seat

Page 1412 of 1502

•

IODY

COMPONENTS 23 - 29

FIXED

GLASS

1NDE1

page

Cab

Rear Window

30

Hatchgate Window Glass—Ramcharger

........ 32

Mirror Support Bracket

29

Quarter Vent Window-Club

Cab 30

page

Quarter Window

Glass

. 32

Rearview

Mirror

.......................... 29

Service

Information

29

Windshield

Glass

29

SERVICE

INFORMATION Do not use a putty knife, a razor blade, or steel

wool to remove foreign material from glass. Glass surfaces are best cleaned with the use of a commer

cial glass cleaner.

REARVIEW

MIRROR

REMOVAL (1) Loosen the mirror base setscrew.

(2)

Slide the mirror base upward and off the sup

port bracket.

INSTALLATION (1) Position the mirror base at the support bracket.

Slide it downward onto the support bracket.

CAUTION:

Do not

over-tighten

the mirror

base

set-

screw.

Windshield

glass

chipping and/or breakage

could

result.

(2)

Tighten the setscrew securely.

MIRROR

SUPPORT BRACKET

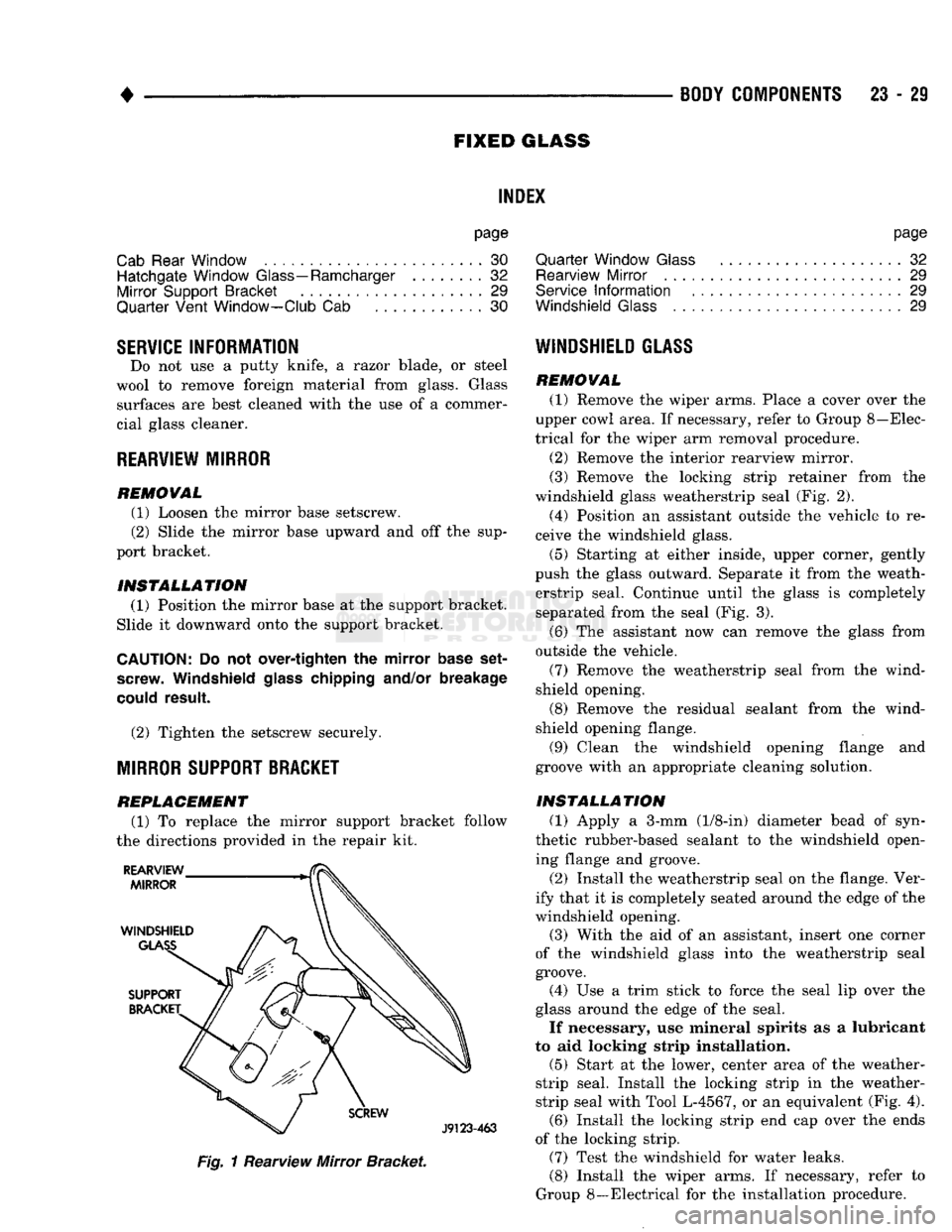

REPLACEMENT (1) To replace the mirror support bracket follow

the directions provided in the repair kit. Fig. 1 Rearview Mirror Bracket.

WINDSHIELD

GLASS

REMOVAL (1) Remove the wiper arms. Place a cover over the

upper cowl area. If necessary, refer to Group 8—Elec

trical for the wiper arm removal procedure.

(2) Remove the interior rearview mirror.

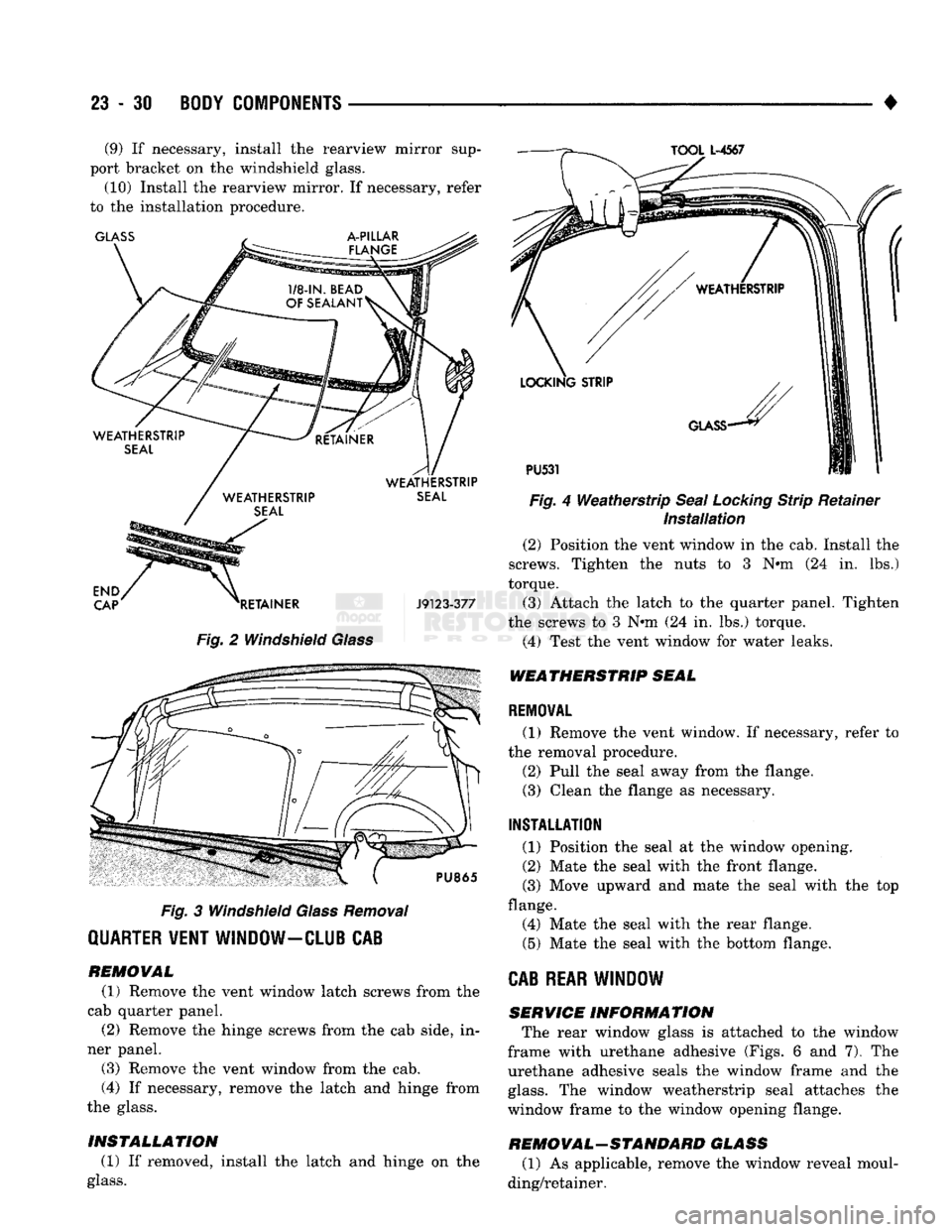

(3) Remove the locking strip retainer from the

windshield glass weatherstrip seal (Fig. 2).

(4) Position an assistant outside the vehicle to re

ceive the windshield glass.

(5)

Starting at either inside, upper corner, gently

push the glass outward. Separate it from the weath erstrip seal. Continue until the glass is completely separated from the seal (Fig. 3).

(6) The assistant now can remove the glass from

outside the vehicle.

(7) Remove the weatherstrip seal from the wind

shield opening. (8) Remove the residual sealant from the wind

shield opening flange.

(9) Clean the windshield opening flange and

groove with an appropriate cleaning solution.

INSTALLATION (1) Apply a 3-mm (1/8-in) diameter bead of syn

thetic rubber-based sealant to the windshield open ing flange and groove.

(2) Install the weatherstrip seal on the flange. Ver

ify that it is completely seated around the edge of the

windshield opening.

(3) With the aid of an assistant, insert one corner

of the windshield glass into the weatherstrip seal groove. (4) Use a trim stick to force the seal lip over the

glass around the edge of the seal. If necessary, use mineral spirits as a lubricant

to aid locking strip installation.

(5)

Start at the lower, center area of the weather

strip seal. Install the locking strip in the weather

strip seal with Tool L-4567, or an equivalent (Fig. 4). (6) Install the locking strip end cap over the ends

of the locking strip. (7) Test the windshield for water leaks. (8) Install the wiper arms. If necessary, refer to

Group 8—Electrical for the installation procedure.

Page 1413 of 1502

23

- 30

BODY COMPONENTS

• (9) If necessary, install the rearview mirror sup

port bracket on the windshield glass. (10) Install the rearview mirror. If necessary, refer

to the installation procedure.

Fig.

2 Windshield

Glass

Fig.

3 Windshield

Glass

Removal

QUARTER WENT WINDOW-CLUB CAB

REMOVAL

(1) Remove the vent window latch screws from the

cab quarter panel.

(2) Remove the hinge screws from the cab side, in

ner panel.

(3) Remove the vent window from the cab.

(4) If necessary, remove the latch and hinge from

the glass.

INSTALLATION

(1) If removed, install the latch and hinge on the

glass.

Fig.

4

Weatherstrip

Seal Locking

Strip Retainer

Installation

(2) Position the vent window in the cab. Install the

screws. Tighten the nuts to 3 N#m (24 in. lbs.)

torque. (3) Attach the latch to the quarter panel. Tighten

the screws to 3 N«m (24 in. lbs.) torque. (4) Test the vent window for water leaks.

WEATHERSTRIP

SEAL

REMOVAL

(1) Remove the vent window. If necessary, refer to

the removal procedure. (2) Pull the seal away from the flange. (3) Clean the flange as necessary.

INSTALLATION

(1) Position the seal at the window opening.

(2) Mate the seal with the front flange.

(3) Move upward and mate the seal with the top

flange. (4) Mate the seal with the rear flange.

(5) Mate the seal with the bottom flange.

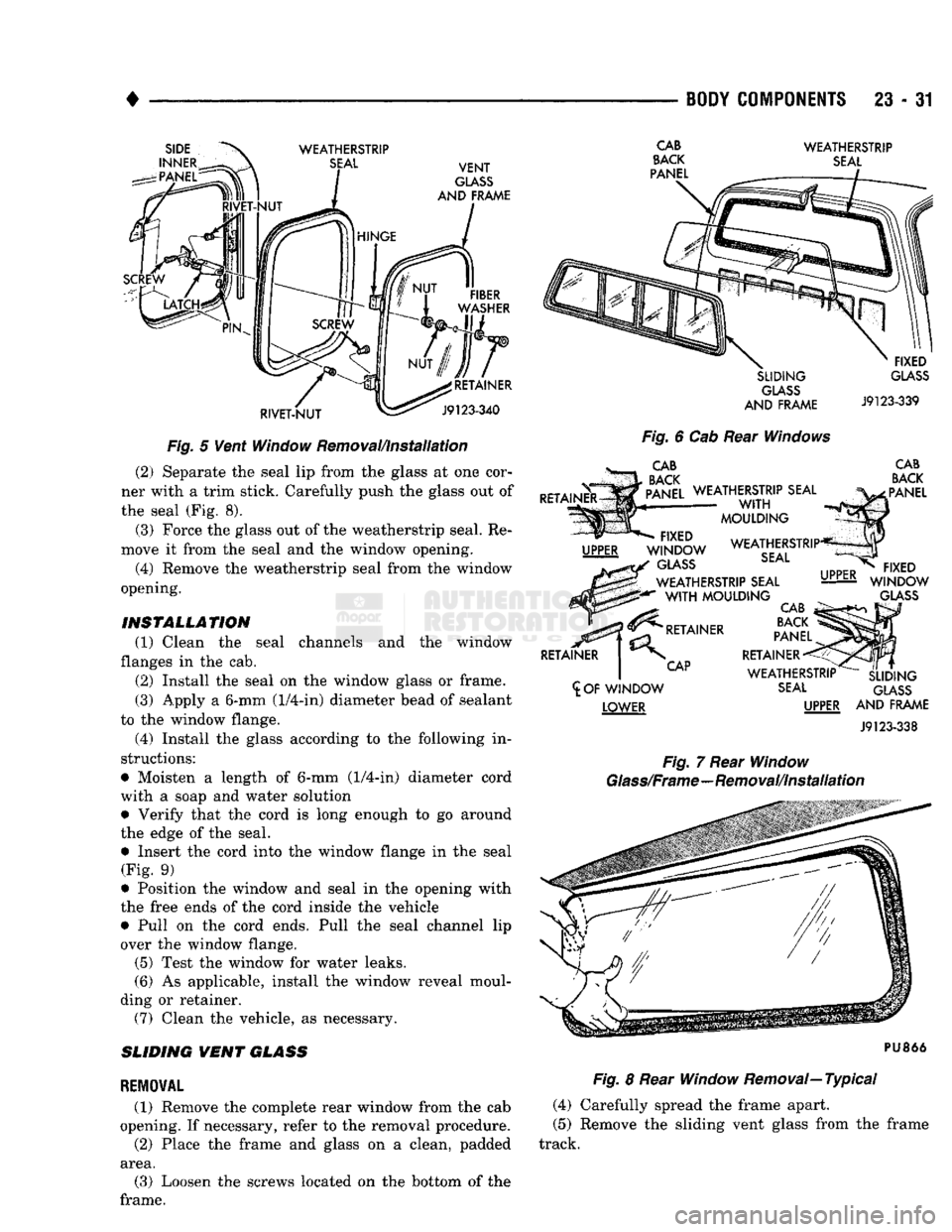

CAB REAR WINDOW

SERVICE

INFORMATION

The rear window glass is attached to the window

frame with urethane adhesive (Figs. 6 and 7). The

urethane adhesive seals the window frame and the

glass.

The window weatherstrip seal attaches the

window frame to the window opening flange.

REMOVAL-STANDARD

GLASS

(1) As applicable, remove the window reveal moul

ding/retainer.

Page 1414 of 1502

•

BODY

COMPONENTS 23 - 31

WEATHERSTRIP

SEAL

VENT

GLASS

AND

FRAME

SCREW

RIVET-NUT

RETAINER

J9123-340

Fig.

5 Vent Window Removal/installation

(2)

Separate the seal lip from the glass at one cor

ner with a trim stick. Carefully push the glass out of

the seal (Fig. 8).

(3) Force the glass out of the weatherstrip seal. Re

move it from the seal and the window opening.

(4) Remove the weatherstrip seal from the window

opening.

INSTALLATION

(1) Clean the seal channels and the window

flanges in the cab.

(2) Install the seal on the window glass or frame.

(3) Apply a 6-mm (1/4-in) diameter bead of sealant

to the window flange.

(4) Install the glass according to the following in

structions:

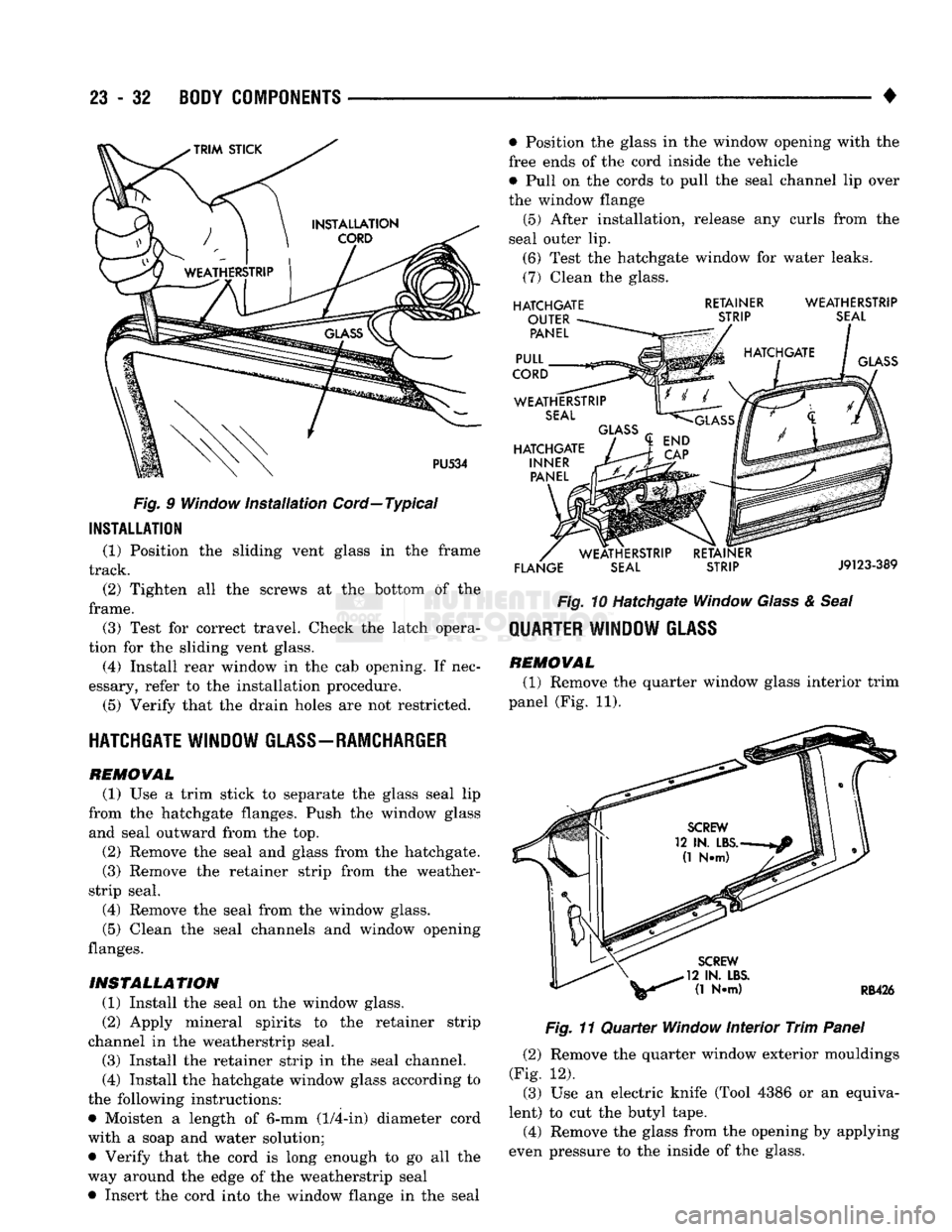

• Moisten a length of 6-mm (1/4-in) diameter cord

with a soap and water solution • Verify that the cord is long enough to go around

the edge of the seal. • Insert the cord into the window flange in the seal (Fig. 9)

• Position the window and seal in the opening with

the free ends of the cord inside the vehicle

• Pull on the cord ends. Pull the seal channel lip over the window flange. (5) Test the window for water leaks.

(6) As applicable, install the window reveal moul

ding or retainer. (7) Clean the vehicle, as necessary.

SLIDING

WENT

GLASS

REMOVAL

(1) Remove the complete rear window from the cab

opening. If necessary, refer to the removal procedure. (2) Place the frame and glass on a clean, padded

area. (3) Loosen the screws located on the bottom of the

frame.

CAB

BACK

PANEL WEATHERSTRIP

SEAL

SLIDING

GLASS

AND FRAME

RETAINER Fig.

6 Cab Rear

Windows

CAB

PANEL WEATHERSTRIP SEAL

WITH

MOULDING

WEATHERSTRIP

SEAL

RETAINER FIXED

WINDOW

GLASS

WEATHERSTRIP SEAL

'

WITH

MOULDING

CAB

BACK

PANEL

RETAINER

CAP

RETAINER

LOWER WEATHERSTRIP

SEAL

UPPER FIXED

GLASS

J9123-339

CAB

BACK

PANEL

FIXED

WINDOW

GLASS

SLIDING

GLASS

AND FRAME

J9123-338

Fig.

7 Rear Window

Glass/Frame—Removal/Installation

PU866

Fig.

8 Rear Window

Removal—

Typical

(4) Carefully spread the frame apart.

(5) Remove the sliding vent glass from the frame

track.

Page 1415 of 1502

23

- 32

BODY COMPONENTS

•

Fig.

9 Window

installation

Cord—Typical

INSTALLATION

(1) Position the sliding vent glass in the frame

track.

(2) Tighten all the screws at the bottom of the

frame, (3) Test for correct travel. Check the latch opera

tion for the sliding vent glass.

(4) Install rear window in the cab opening. If nec

essary, refer to the installation procedure.

(5) Verify that the drain holes are not restricted.

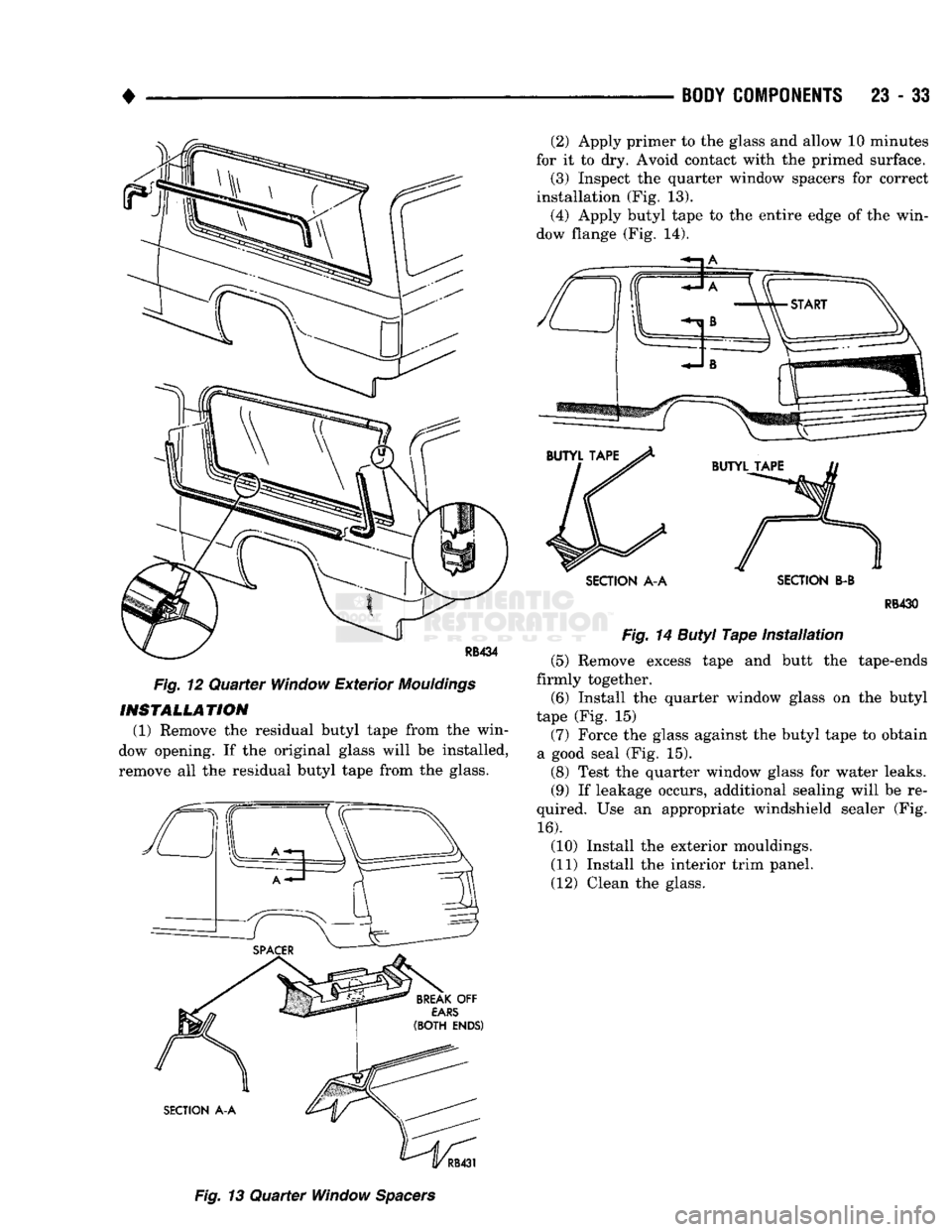

HATCHGATE WINDOW GLASS-RAMCHARGER

REMOVAL (1) Use a trim stick to separate the glass seal lip

from the hatchgate flanges. Push the window glass and seal outward from the top.

(2) Remove the seal and glass from the hatchgate.

(3) Remove the retainer strip from the weather

strip seal.

(4) Remove the seal from the window glass.

(5) Clean the seal channels and window opening

flanges.

INSTALLATION (1) Install the seal on the window glass.

(2) Apply mineral spirits to the retainer strip

channel in the weatherstrip seal. (3) Install the retainer strip in the seal channel.

(4) Install the hatchgate window glass according to

the following instructions: • Moisten a length of 6-mm (1/4-in) diameter cord

with a soap and water solution;

• Verify that the cord is long enough to go all the

way around the edge of the weatherstrip seal

• Insert the cord into the window flange in the seal • Position the glass in the window opening with the

free ends of the cord inside the vehicle • Pull on the cords to pull the seal channel lip over

the window flange

(5) After installation, release any curls from the

seal outer lip.

(6) Test the hatchgate window for water leaks.

(7) Clean the glass.

HATCHGATE RETAINER WEATHERSTRIP

Fig.

10 Hatchgate Window

Glass

&

Seal

QUARTER WINDOW GLASS

REMOVAL (1) Remove the quarter window glass interior trim

panel (Fig. 11).

Fig.

11

Quarter

Window

Interior

Trim

Panel

(2) Remove the quarter window exterior mouldings

(Fig. 12).

(3) Use an electric knife (Tool 4386 or an equiva

lent) to cut the butyl tape.

(4) Remove the glass from the opening by applying

even pressure to the inside of the glass.

Page 1416 of 1502

•

BODY

COMPONENTS

23 - 33

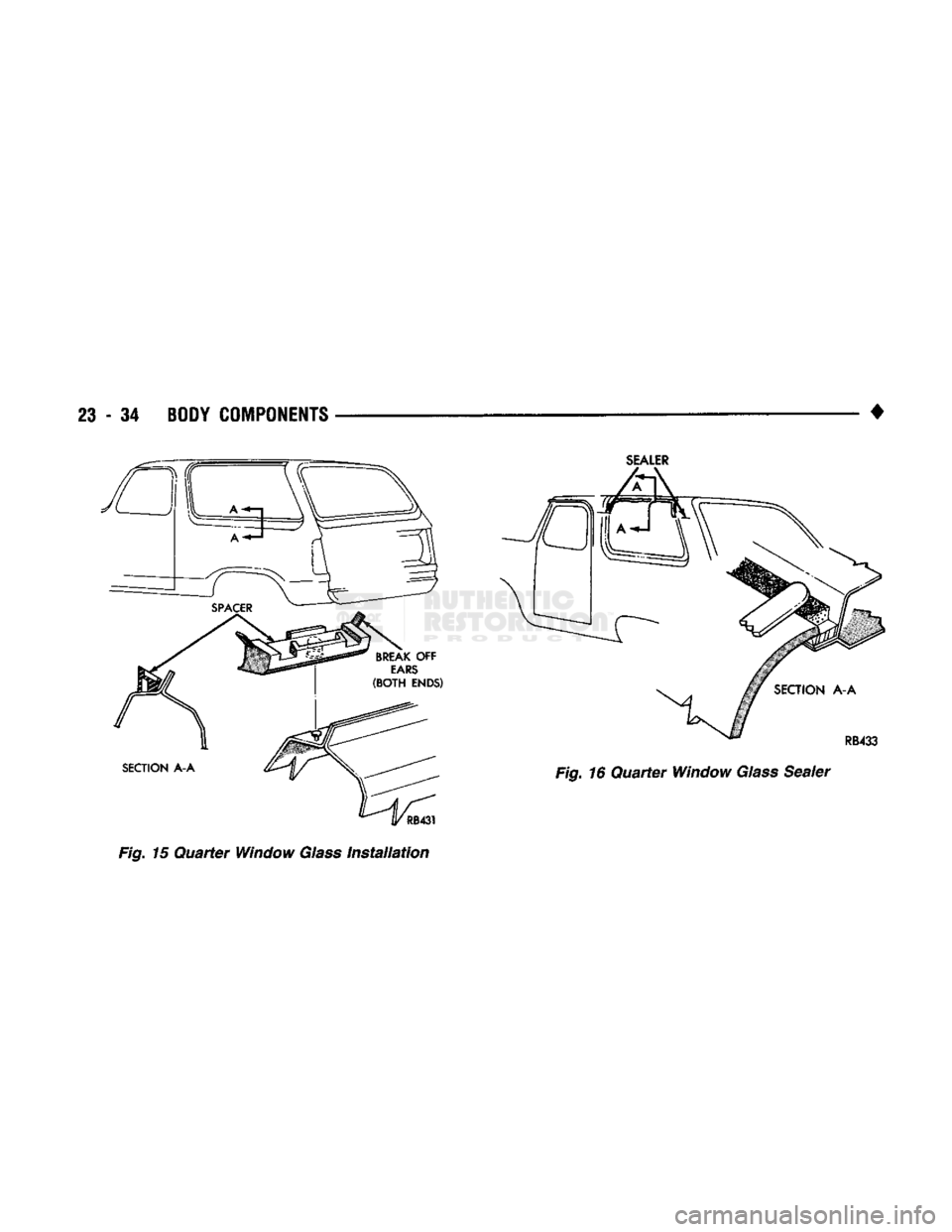

Fig. 12 Quarter Window Exterior

Mouldings

INSTALLATION (1) Remove the residual butyl tape from the win

dow opening. If the original glass will be installed,

remove all the residual butyl tape from the glass. (2) Apply primer to the glass and allow 10 minutes

for it to dry. Avoid contact with the primed surface.

(3) Inspect the quarter window spacers for correct

installation (Fig. 13). (4) Apply butyl tape to the entire edge of the win

dow flange (Fig. 14).

SECTION

A-A

SECTION

B-B

Fig.

14

Butyl

Tape

Installation

(5) Remove excess tape and butt the tape-ends

firmly together. (6) Install the quarter window glass on the butyl

tape (Fig. 15)

(7) Force the glass against the butyl tape to obtain

a good seal (Fig. 15). (8) Test the quarter window glass for water leaks.

(9) If leakage occurs, additional sealing will be re

quired. Use an appropriate windshield sealer (Fig.

16).

(10) Install the exterior mouldings.

(11) Install the interior trim panel.

(12) Clean the glass.

Page 1417 of 1502

Page 1418 of 1502

•

BODY

COMPONENTS

23 - 35

CAB/BODY

INTERIOR COMPONENTS

INDEX

page

Carpets

and

Floor Mats

51

Floor Console

and

Rear Storage Tray

.........

50

Front Seats

38

Headliners

48

Instrument

Panel

35

page

Interior

Trim

Panels

. 42

Rear

Seats

41

Shoulder

Belts/Lap Belt/Buckles

45

Spare

Tire

Carrier

45

INSTRUMENT

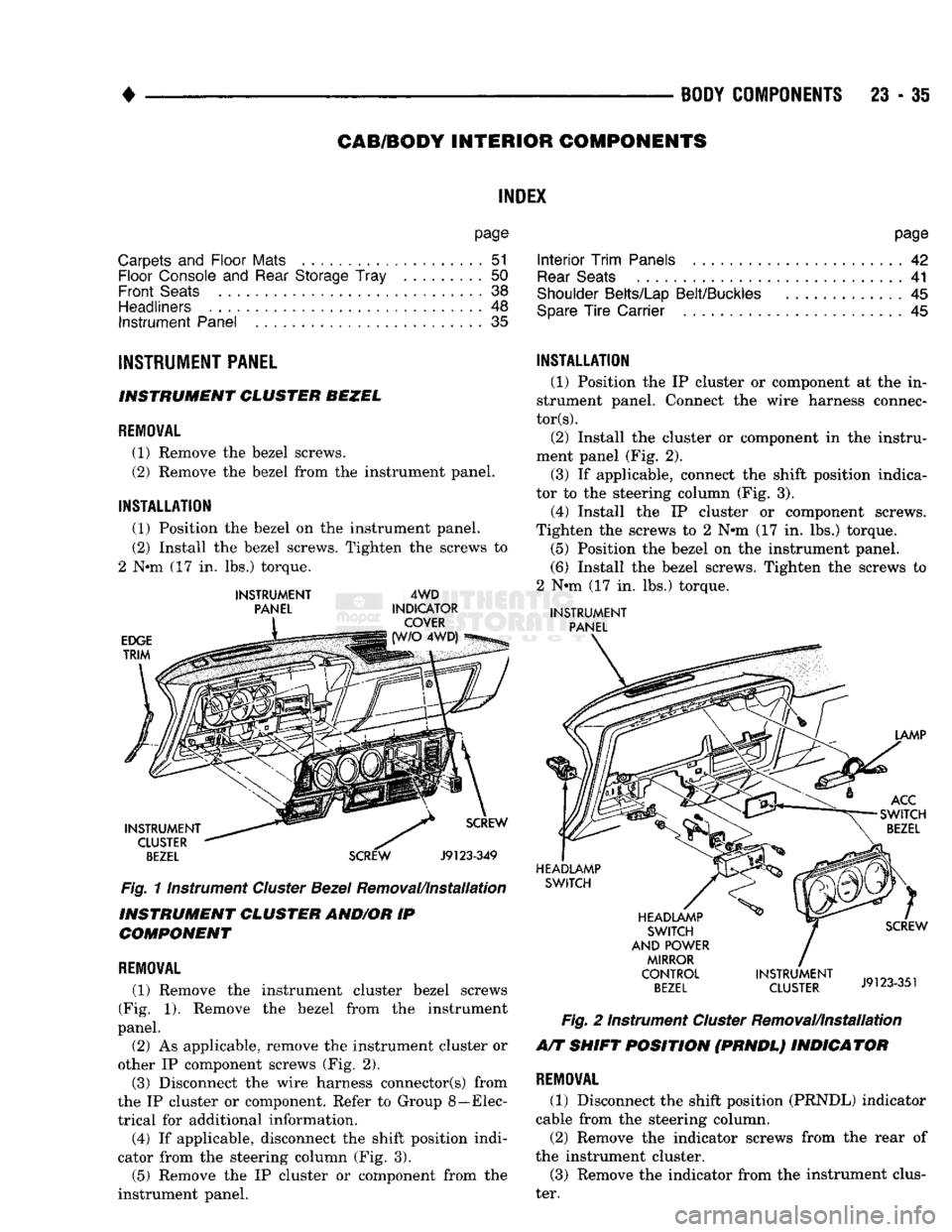

PANEL INSTRUMENT CLUSTER BEZEL

REMOVAL

(1) Remove

the

bezel screws.

(2) Remove

the

bezel from

the

instrument panel.

INSTALLATION

(1) Position

the

bezel

on the

instrument panel.

(2) Install

the

bezel screws. Tighten

the

screws

to

2

Nnn (17 in. lbs.)

torque.

INSTRUMENT

PANEL

EDGE

TRIM

4WD

INDICATOR COVER 4WD)

INSTRUMENT CLUSTER

BEZEL

SCREW

Fig.

11nstrument

Cluster

Bezel

Removal/Installation

INSTRUMENT CLUSTER AND/OR

IP

COMPONENT

REMOVAL

(1) Remove

the

instrument cluster bezel screws

(Fig.

1).

Remove

the

bezel from

the

instrument

panel.

(2)

As

applicable, remove

the

instrument cluster

or

other

IP

component screws

(Fig. 2).

(3) Disconnect

the

wire harness connector(s) from

the

IP

cluster

or

component. Refer

to

Group 8—Elec

trical

for

additional information. (4)

If

applicable, disconnect

the

shift position indi

cator from

the

steering column

(Fig. 3).

(5) Remove

the IP

cluster

or

component from

the

instrument panel.

INSTALLATION

(1) Position

the IP

cluster

or

component

at the in

strument panel. Connect

the

wire harness connec

tors).

(2) Install

the

cluster

or

component

in the

instru

ment panel

(Fig. 2).

(3)

If

applicable, connect

the

shift position indica

tor

to the

steering column

(Fig. 3).

(4) Install

the IP

cluster

or

component screws.

Tighten

the

screws

to 2 N#m (17 in. lbs.)

torque. (5) Position

the

bezel

on the

instrument panel.

(6) Install

the

bezel screws. Tighten

the

screws

to

2

Nnn (17 in. lbs.)

torque.

INSTRUMENT

PANEL

LAMP

ACC

SWITCH

BEZEL

HEADLAMP SWITCH

HEADLAMP SWITCH

AND POWER MIRROR

CONTROL

BEZEL

SCREW

INSTRUMENT

J9123351

CLUSTER

J9123-351

Fig.

2

Instrument

Cluster

Removal/Installation

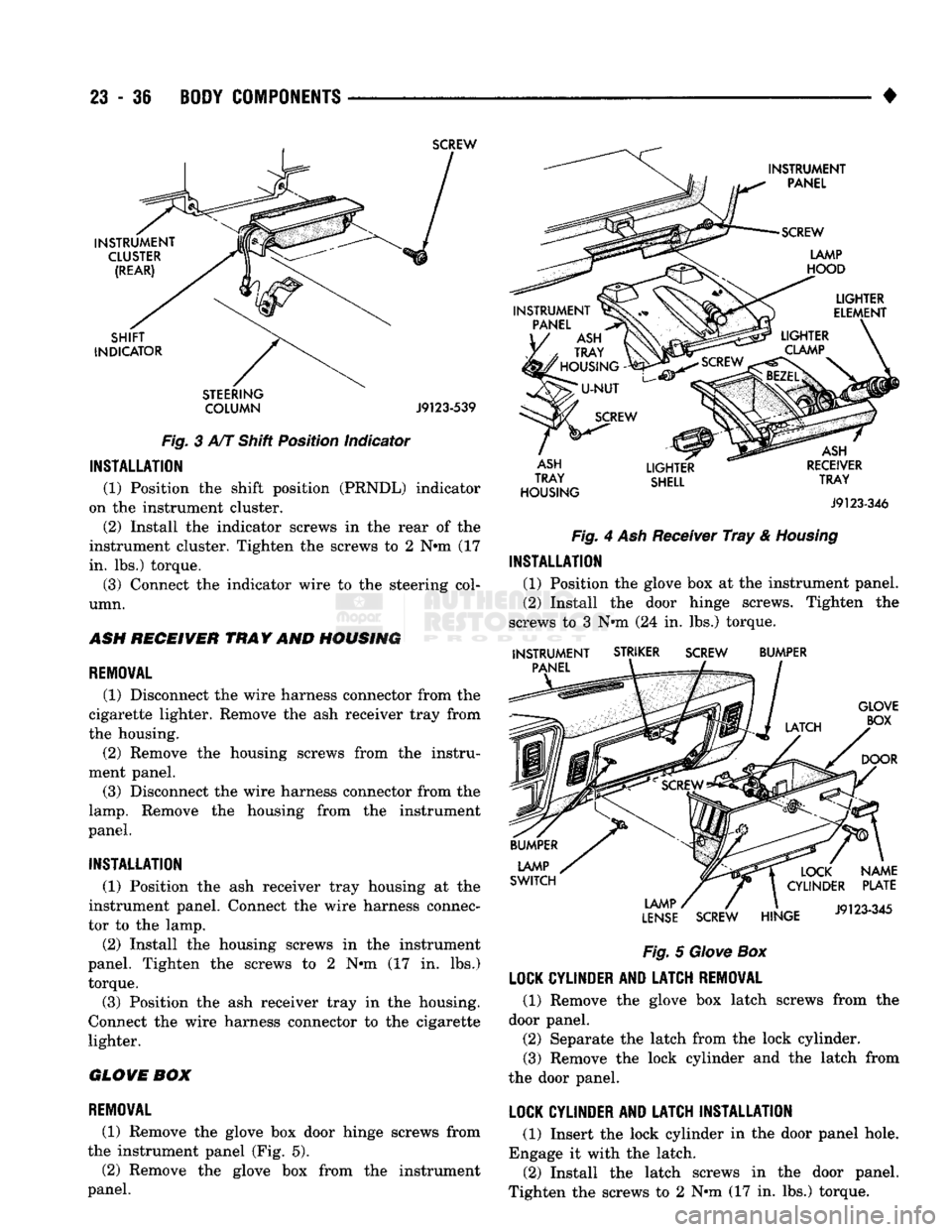

A/T SHIFT POSITION (PRNDL) INDICATOR

REMOVAL

(1) Disconnect

the

shift position (PRNDL) indicator

cable from

the

steering column.

(2) Remove

the

indicator screws from

the

rear

of

the instrument cluster. (3) Remove

the

indicator from

the

instrument clus

ter.

Page 1419 of 1502

23

- 36

BODY COMPONENTS

SCREW

INSTRUMENT

CLUSTER (REAR)

SHIFT

INDICATOR

STEERING COLUMN

J9123-539

Fig.

3 A/T Shift Position Indicator

INSTALLATION

(1) Position the shift position (PRNDL) indicator

on the instrument cluster.

(2) Install the indicator screws in the rear of the

instrument cluster. Tighten the screws to 2 N»m (17

in. lbs.) torque.

(3) Connect the indicator wire to the steering col

umn.

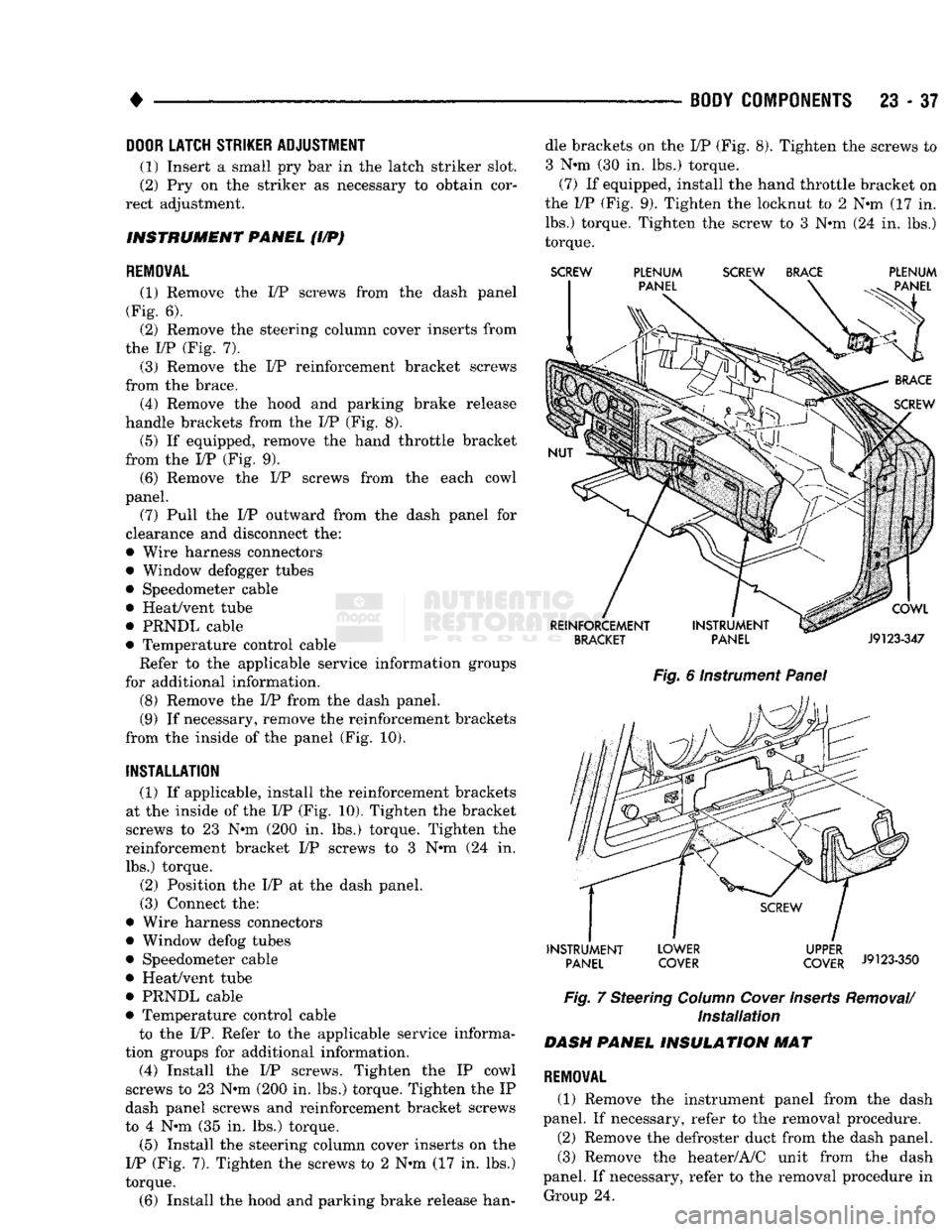

ASH

RECEIVER

TRAY

AND

HOUSING

REMOVAL

(1) Disconnect the wire harness connector from the

cigarette lighter. Remove the ash receiver tray from

the housing. (2) Remove the housing screws from the instru

ment panel. (3) Disconnect the wire harness connector from the

lamp.

Remove the housing from the instrument

panel.

INSTALLATION

(1) Position the ash receiver tray housing at the

instrument panel. Connect the wire harness connec

tor to the lamp.

(2) Install the housing screws in the instrument

panel. Tighten the screws to 2 N«m (17 in. lbs.)

torque. (3) Position the ash receiver tray in the housing.

Connect the wire harness connector to the cigarette

lighter.

GLOVE

BOX

REMOVAL

(1) Remove the glove box door hinge screws from

the instrument panel (Fig. 5).

(2) Remove the glove box from the instrument

panel.

INSTRUMENT

PANEL

SCREW

LAMP

HOOD

PANEL

ASH

TRAY

'

HOUSING

-

LIGHTER

ELEMENT

SCREW

LIGHTER

CLAMP

ASH

TRAY

HOUSING

LIGHTER

SHELL

ASH

RECEIVER

TRAY

J9123-346

Fig.

4 Ash Receiver

Tray

&

Housing

INSTALLATION

(1) Position the glove box at the instrument panel.

(2) Install the door hinge screws. Tighten the

screws to 3 N»m (24 in. lbs.) torque.

INSTRUMENT

PANEL

STRIKER

SCREW

BUMPER

GLOVE BOX

DOOR

LAMP

SWITCH

LAMP

LENSE

SCREW

HINGE

NAME

PLATE

J9123-345

Fig.

5

Glove

Box

LOCK

CYLINDER

AND

LATCH

REMOVAL

(1) Remove the glove box latch screws from the

door panel. (2) Separate the latch from the lock cylinder.

(3) Remove the lock cylinder and the latch from

the door panel.

LOCK

CYLINDER

AND

LATCH

INSTALLATION

(1) Insert the lock cylinder in the door panel hole.

Engage it with the latch. (2) Install the latch screws in the door panel.

Tighten the screws to 2 N»m (17 in. lbs.) torque.

Page 1420 of 1502

BODY

COMPONENTS

23 - 37

DOOR

LATCH STRIKER ADJUSTMENT

(1) Insert a small pry bar in the latch striker slot.

(2) Pry on the striker as necessary to obtain cor

rect adjustment.

INSTRUMENT PANEL

(UP)

REMOVAL

(1) Remove the I/P screws from the dash panel

(Fig. 6). (2) Remove the steering column cover inserts from

the I/P (Fig. 7). (3) Remove the I/P reinforcement bracket screws

from the brace. (4) Remove the hood and parking brake release

handle brackets from the I/P (Fig. 8).

(5) If equipped, remove the hand throttle bracket

from the I/P (Fig. 9).

(6) Remove the I/P screws from the each cowl

panel.

(7) Pull the I/P outward from the dash panel for

clearance and disconnect the:

• Wire harness connectors

• Window defogger tubes

• Speedometer cable

• Heat/vent tube

• PRNDL cable

• Temperature control cable Refer to the applicable service information groups

for additional information.

(8) Remove the I/P from the dash panel.

(9) If necessary, remove the reinforcement brackets

from the inside of the panel (Fig. 10).

INSTALLATION

(1) If applicable, install the reinforcement brackets

at the inside of the I/P (Fig. 10). Tighten the bracket

screws to 23 N#m (200 in. lbs.) torque. Tighten the

reinforcement bracket I/P screws to 3 N*m (24 in. lbs.) torque.

(2) Position the I/P at the dash panel. (3) Connect the:

• Wire harness connectors

• Window defog tubes

• Speedometer cable

• Heat/vent tube

• PRNDL cable

• Temperature control cable

to the I/P. Refer to the applicable service informa

tion groups for additional information. (4) Install the I/P screws. Tighten the IP cowl

screws to 23 N-m (200 in. lbs.) torque. Tighten the IP

dash panel screws and reinforcement bracket screws

to 4 N»m (35 in. lbs.) torque.

(5) Install the steering column cover inserts on the

17P (Fig. 7). Tighten the screws to 2 N*m (17 in. lbs.)

torque.

(6) Install the hood and parking brake release han dle brackets on the I/P (Fig. 8). Tighten the screws to

3 N*m (30 in. lbs.) torque. (7) If equipped, install the hand throttle bracket on

the I/P (Fig. 9). Tighten the locknut to 2 N*m (17 in. lbs.) torque. Tighten the screw to 3 N*m (24 in. lbs.)

torque.

SCREW

PLENUM SCREW BRACE PLENUM

Fig.

6 Instrument

Panel

INSTRUMENT LOWER UPPER

irt

PANEL COVER COVER

J9123-350

Fig.

7 Steering

Column

Cover

Inserts

Removal/

Installation

DASH

PANEL INSULATION

MAT

REMOVAL

(1) Remove the instrument panel from the dash

panel. If necessary, refer to the removal procedure. (2) Remove the defroster duct from the dash panel. (3) Remove the heater/A/C unit from the dash

panel. If necessary, refer to the removal procedure in Group 24.