DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 351 of 1502

Page 352 of 1502

•

IGNITION

SYSTEMS

8D

- 1

CONTENTS

page page

COMPONENT IDENTIFICATION/SYSTEM DIAGNOSTICS/SERVICE PROCEDURES

7

OPERATION

1

IGNITION SWITCH

25

COMPONENT REMOVAL/INSTALLATION

..... 18

SPECIFICATIONS

28

COMPONENT

IDENTIFICATION/SYSTEM OPERATION

INDEX

page

Automatic

Shut Down (ASD) Relay

1

Camshaft Position Sensor

2

Crankshaft Position Sensor

2

Distributors

3

Engine Coolant

Temperature

Sensor

...........

4

General

Information

1

page

Ignition

Coil

3

Intake

Manifold Charge

Air

Temperature

Sensor

. . 4

Manifold Absolute Pressure (MAP) Sensor

4

Powertrain

Control

Module (PCM)

. 5

Throttle

Position Sensor

5

GENERAL

INFORMATION

Throughout this group, references

are

made

to

par

ticular vehicle models

by

alphabetical designation

or

by

the

particular vehicle nameplate.

A

chart showing a breakdown

of

alphabetical designations

is

included

in

the

Introduction group

at the

beginning

of

this

manual. 5.9L

gas

powered engines will

be

referred

to as ei

ther: LDC (Light Duty Cycle),

or

HDC (Heavy Duty Cycle). This section

of the

group, Component Identifica

tion/System Operation, will discuss ignition system operation

and

will identify ignition system compo

nents.

For diagnostic procedures

and

adjustments, refer

to

the Diagnostics/Service Procedures section

of

this

group.

For removal

and

installation

of

ignition system

components, refer

to the

Component Removal/Instal

lation section

of

this group. For other useful information, refer

to

On-Board

Di

agnostics

in the

General Diagnosis sections

of

Group

14,

Fuel System

in

this manual. For operation

of the DRB II

Diagnostic Scan Tool,

refer

to the

appropriate Powertrain Diagnostic Proce

dures service manual.

An Ignition specifications section

is

included

at the

end

of

this group.

A

general Maintenance Schedule (mileage intervals)

for

ignition related items

can be

found

in

Group

0,

Lubrication and Maintenance. This

schedule

can

also

be

found

in the

Owners Manual.

IGNITION

SYSTEMS

The ignition systems used

on all

engines

are

basi

cally identical. Similarities

and

differences between

the systems will

be

discussed.

A sequential multi-port fuel injection system

is

used

on all gas

powered engines.

The ignition system

is

controlled

by the

powertrain

control module (PCM)

on all

engines.

The

PCM

was

formerly referred

to as the

SBEC

or

engine control ler.

The ignition system consists

of:

• Spark Plugs

• Ignition Coil

• Secondary Ignition Cables

• Ignition distributor. Contains rotor

and

camshaft

position sensor • Powertrain Control Module (PCM)

• Crankshaft Position Sensor

AUTOMATIC SHUT DOWN (ASD) RELAY

The automatic shut down (ASD) relay

is

located

in

the engine compartment (Fig.

1). As one of its

func

tions,

the ASD

relay will supply battery voltage

to

the ignition coil.

The

ground circuit

for the

ASD

re

lay

is

controlled

by the

powertrain control module (PCM).

The PCM

regulates

ASD

relay operation

by

switching

the

ground circuit on-and-off.

IGNITION

SYSTEMS

Page 353 of 1502

8D

- 2

IGNITION

SYSTEMS

•

A/C

CLUTCH RELAY STARTER RELAY

DATA LINK CONTROL

CONNECTOR

MODULE J9314-164

Fig.

1

Auto

Shut Down

Relay

CAMSHAFT POSITION SENSOR

The camshaft position sensor is located in the igni

tion distributor (Fig. 2) on all engines.

Fig.

2 Camshaft Position

Sensor—

Typical

The camshaft position sensor contains a hall effect

device called a sync signal generator to generate a

fuel sync signal. This sync signal generator detects a

rotating pulse ring (shutter) on the distributor shaft.

The pulse ring rotates 180 degrees through the sync signal generator. Its signal is used in conjunction

with the crankshaft position sensor to differentiate

between fuel injection and spark events. It is also

used to synchronize the fuel injectors with their re spective cylinders.

When the leading edge of the pulse ring (shutter)

enters the sync signal generator, the following oc

curs:

The interruption of magnetic field causes the

voltage to switch high resulting in a sync signal of approximately 5 volts.

When the trailing edge of the pulse ring (shutter)

leaves the sync signal generator, the following oc

curs:

The change of the magnetic field causes the sync signal voltage to switch low to 0 volts. For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group. For removal and installation of this component, re

fer to the Component Removal/Installation section of this group.

CRANKSHAFT

POSITION

SENSOR

The sensor is bolted to the top of cylinder block

near the rear of the right cylinder head (Fig. 3).

Fig.

3 Crankshaft Position Sensor—Typical

*

Engine speed and crankshaft position are provided

through the crankshaft position sensor. The sensor generates pulses that are the input sent to the pow

ertrain control module (PCM). The PCM interprets

the sensor input to determine the crankshaft posi

tion. The PCM then uses this position, along with other inputs, to determine injector sequence and ig

nition timing.

The sensor is a hall effect device combined with an

internal magnet. It is also sensitive to steel within a

certain distance from it.

SENSOR

OPERATION-3.9L

ENGINE

The flywheel/drive plate has groups of notches at

its outer edge. On 3.9L V-6 engines, there are three sets of double notches and three sets of single

notches (Fig.

4).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input to the PCM.

The engine will not operate if the PCM does not re

ceive a crankshaft position sensor input.

For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group.

Page 354 of 1502

•

IGNITION

SYSTEMS

8D - 3 For removal and installation of this sensor, refer to

the Component Removal/Installation section of this

group.

CRANKSHAFT

POSITION

SENSOR

NOTCHES- FLYWHEEL CRANKSHAFT

POSITION-

SENSOR

NOTCHES* .FLYWHEEL

J9314-88

—^^j^jV^

J9314-89

Fig.

4

Sensor

Operation—3.9L

Engine

SENSOR

OPERATION'-5.2U5.9L

ENGINES On 5.2L and 5.9L engines, the flywheel/drive plate

has 8 single notches, spaced every 45 degrees, at its outer edge (Fig. 5).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input to the PCM. For each engine revolution, there are 8

pulses generated on V-8 engines.

The engine will not operate if the PCM does not re

ceive a crankshaft position sensor input. For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group.

For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

DISTRIBUTORS

For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group.

ALL

ENGINES All engines are equipped with a camshaft driven

mechanical distributor, containing a shaft driven dis

tributor rotor. They are equipped with an internal camshaft position (fuel sync) sensor. This sensor pro

vides fuel injection synchronization and cylinder identification.

Distributors do not have built in centrifugal or vac

uum assisted advance. Base ignition timing and all

timing advance is controlled by the powertrain con

trol module (PCM). Because ignition timing is con-

Fig.

5

Sensor

Opera tion—5.2L/5.9L

Engine

trolled by the PCM, base ignition timing is not adjustable on any of these engines.

The distributor is held to the engine in the conven

tional method using a holddown clamp and bolt. Al

though the distributor can be rotated, it will

have no effect on ignition timing.

All distributors contain an internal oil seal that

prevents oil from entering the distributor housing.

The seal is not serviceable.

For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

IGNITION

COIL

Battery voltage is supplied to the ignition coil pos

itive terminal from the ASD relay. The powertrain control module (PCM) opens and

closes the ignition coil ground circuit for ignition coil operation. Base ignition timing is not adjustable on any

engine. By controlling the coil ground circuit, the

PCM is able to set the base timing and adjust the ig nition timing advance. This is done to meet changing engine operating conditions. The ignition coil is not oil filled. The windings are

embedded in an epoxy compound. This provides heat and vibration resistance that allows the ignition coil

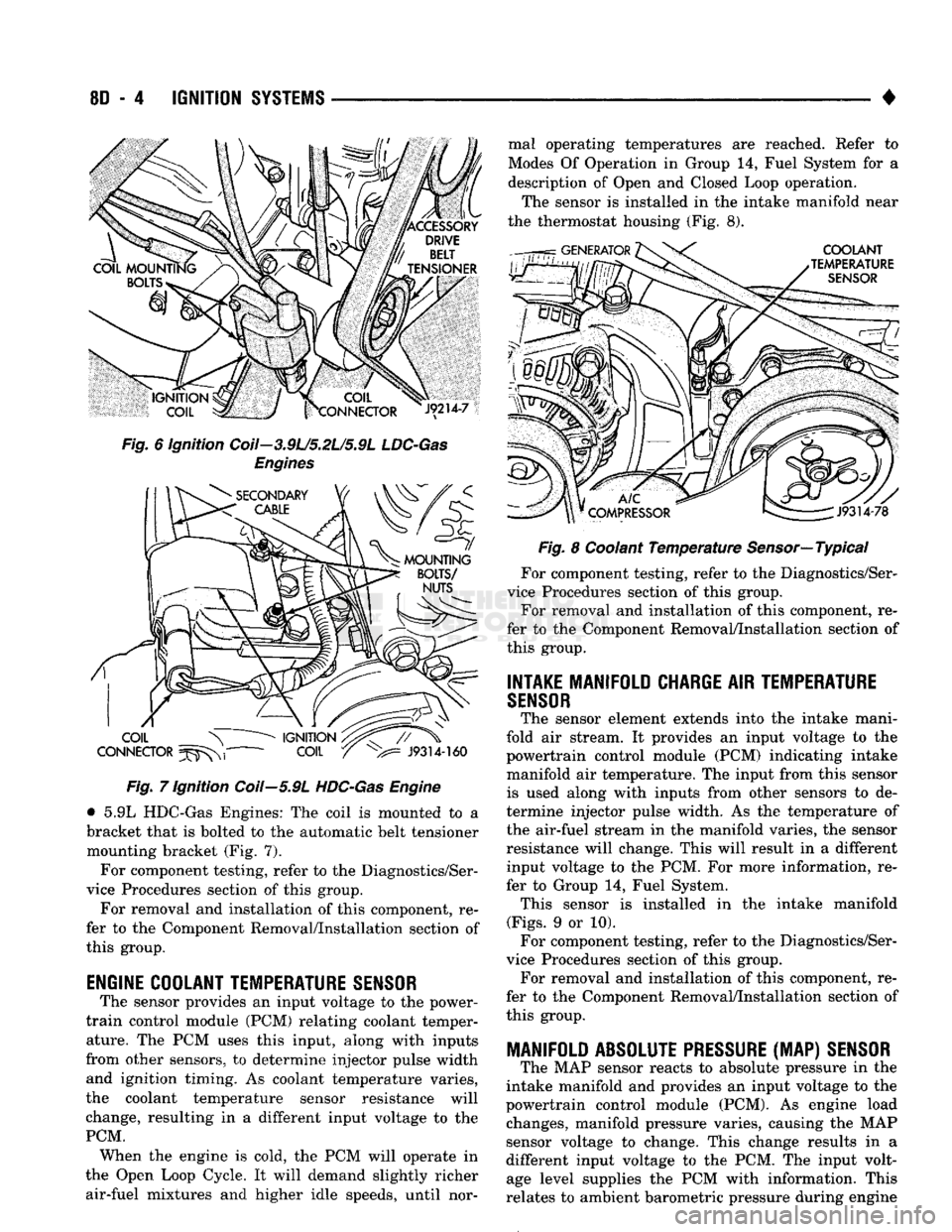

to be mounted on the engine. • 3.9L/5.2L/5.9L LDC-Gas Engines: The coil is

mounted to a bracket that is bolted to the front of the right engine cylinder head (Fig. 6). This bracket is also used to mount the automatic belt tensioner.

Page 355 of 1502

8D

- 4

IGNITION

SYSTEMS

•

Fig. 6 ignition Coil—3.9L/5.2L/5.9L

LDC-Gas

Engines Fig. 7 Ignition Coil—5.9L

HDC-Gas

Engine

• 5.9L HDC-Gas Engines: The coil is mounted to a

bracket that is bolted to the automatic belt tensioner mounting bracket (Fig. 7).

For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group.

For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

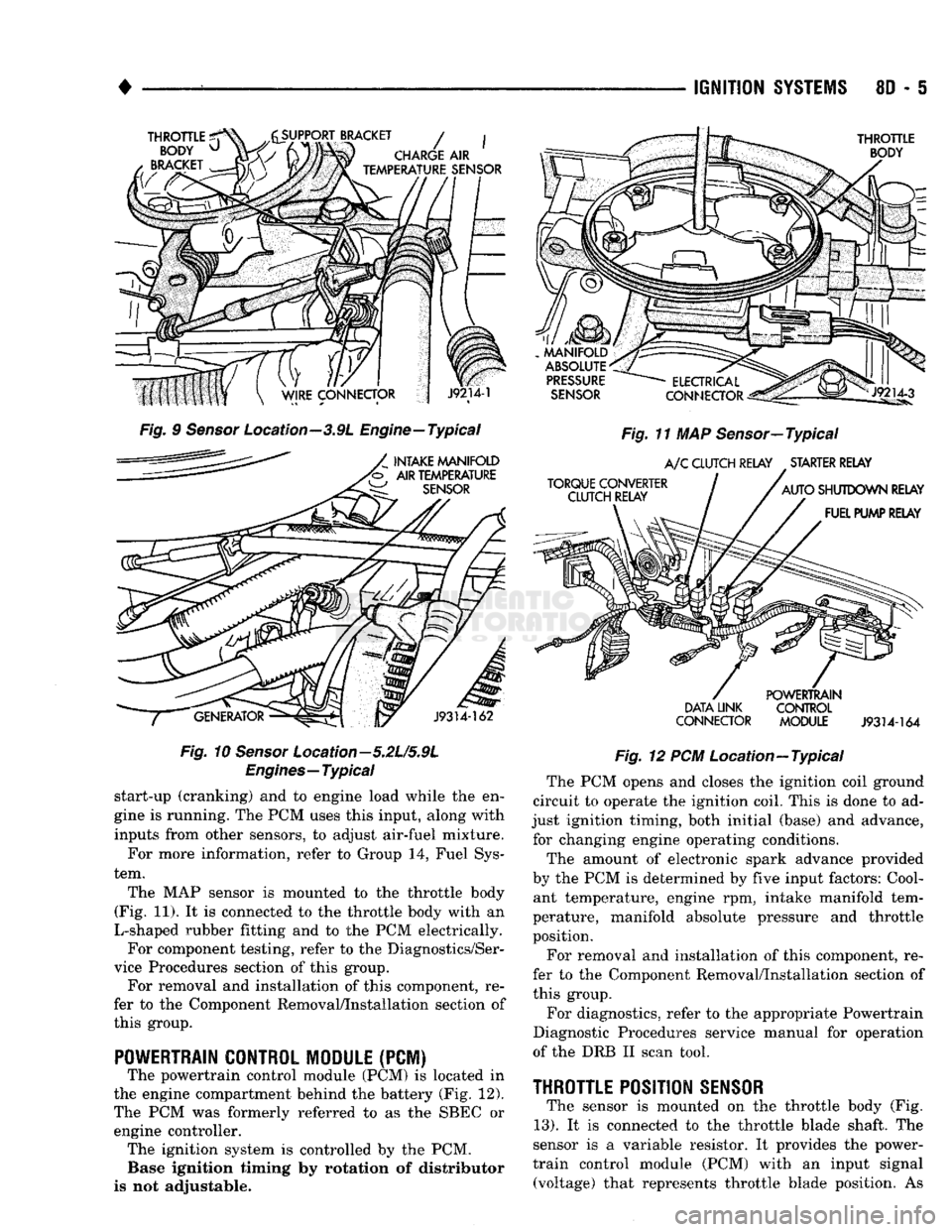

ENGINE COOLANT TEMPERATURE

SENSOR

The sensor provides an input voltage to the power-

train control module (PCM) relating coolant temper ature. The PCM uses this input, along with inputs

from other sensors, to determine injector pulse width and ignition timing. As coolant temperature varies,

the coolant temperature sensor resistance will

change, resulting in a different input voltage to the

PCM. When the engine is cold, the PCM will operate in

the Open Loop Cycle. It will demand slightly richer air-fuel mixtures and higher idle speeds, until nor mal operating temperatures are reached. Refer to

Modes Of Operation in Group 14, Fuel System for a

description of Open and Closed Loop operation.

The sensor is installed in the intake manifold near

the thermostat housing (Fig. 8).

Fig. 8 Coolant Temperature Sensor—Typical

For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group. For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

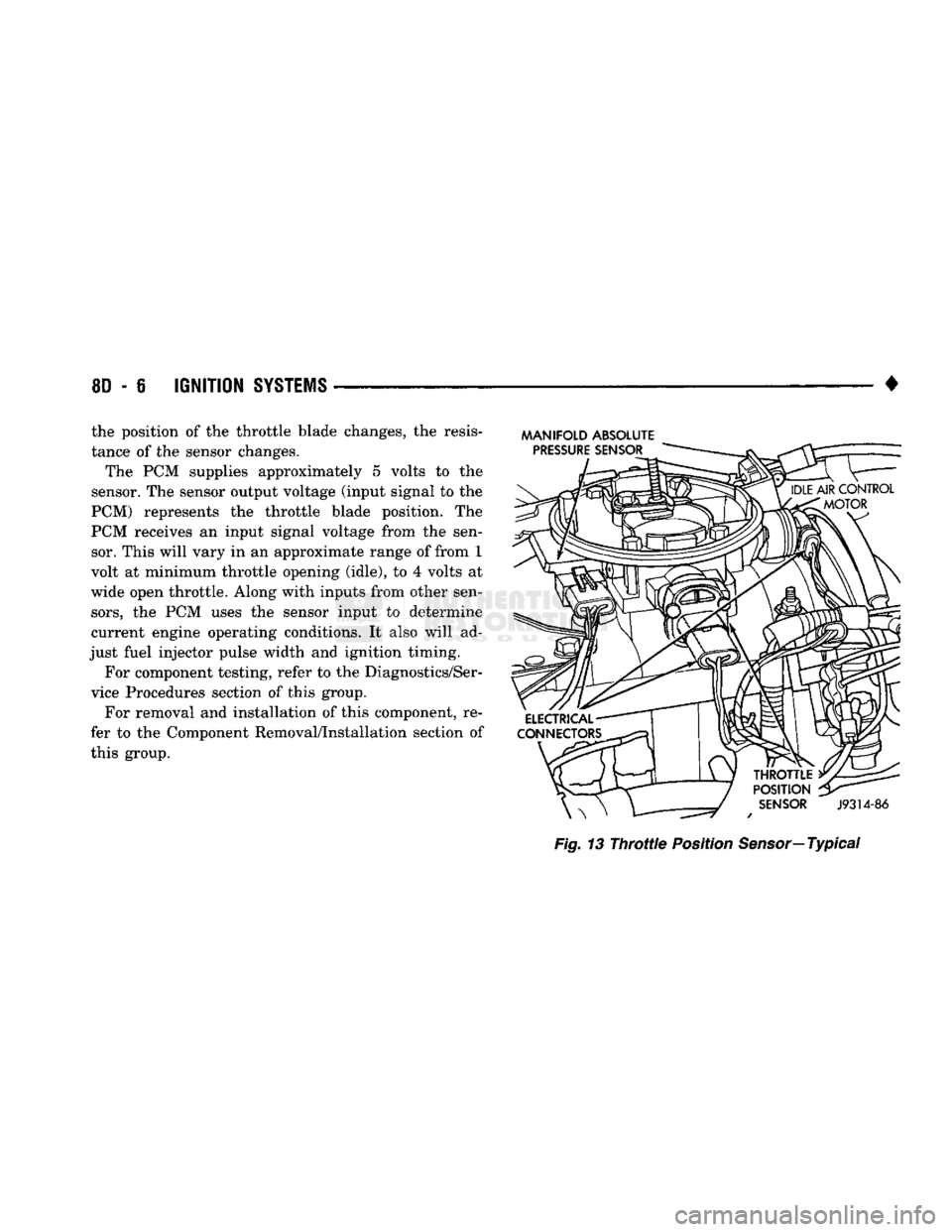

INTAKE MANIFOLD CHARGE

AIR

TEMPERATURE

SENSOR

The sensor element extends into the intake mani

fold air stream. It provides an input voltage to the

powertrain control module (PCM) indicating intake

manifold air temperature. The input from this sensor is used along with inputs from other sensors to de

termine injector pulse width. As the temperature of

the air-fuel stream in the manifold varies, the sensor

resistance will change. This will result in a different input voltage to the PCM. For more information, re

fer to Group 14, Fuel System. This sensor is installed in the intake manifold

(Figs.

9 or 10). For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group. For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

MANIFOLD ABSOLUTE

PRESSURE

(MAP)

SENSOR

The MAP sensor reacts to absolute pressure in the

intake manifold and provides an input voltage to the

powertrain control module (PCM). As engine load changes, manifold pressure varies, causing the MAP

sensor voltage to change. This change results in a

different input voltage to the PCM. The input volt age level supplies the PCM with information. This

relates to ambient barometric pressure during engine

Page 356 of 1502

•

IGNITION

SYSTEMS

8D - 5

THROTTLE

^

BODY

u

BRACKET

y^SUPPORT

BRACKET

/ |

CHARGE

AIR

ijmmmmk

TEMPERATURE

SENSOR

THROTTLE

BODY

Fig.

9

Sensor

Location—3.9L Engine—Typical

INTAKE MANIFOLD

'b AIR TEMPERATURE

SENSOR

J9314-162

Fig.

10

Sensor

Location—5.2L/5.9L

Engines—Typical

start-up (cranking) and to engine load while the en

gine is running. The PCM uses this input, along with

inputs from other sensors, to adjust air-fuel mixture.

For more information, refer to Group 14, Fuel Sys

tem.

The MAP sensor is mounted to the throttle body

(Fig. 11). It is connected to the throttle body with an

L-shaped rubber fitting and to the PCM electrically. For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group. For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

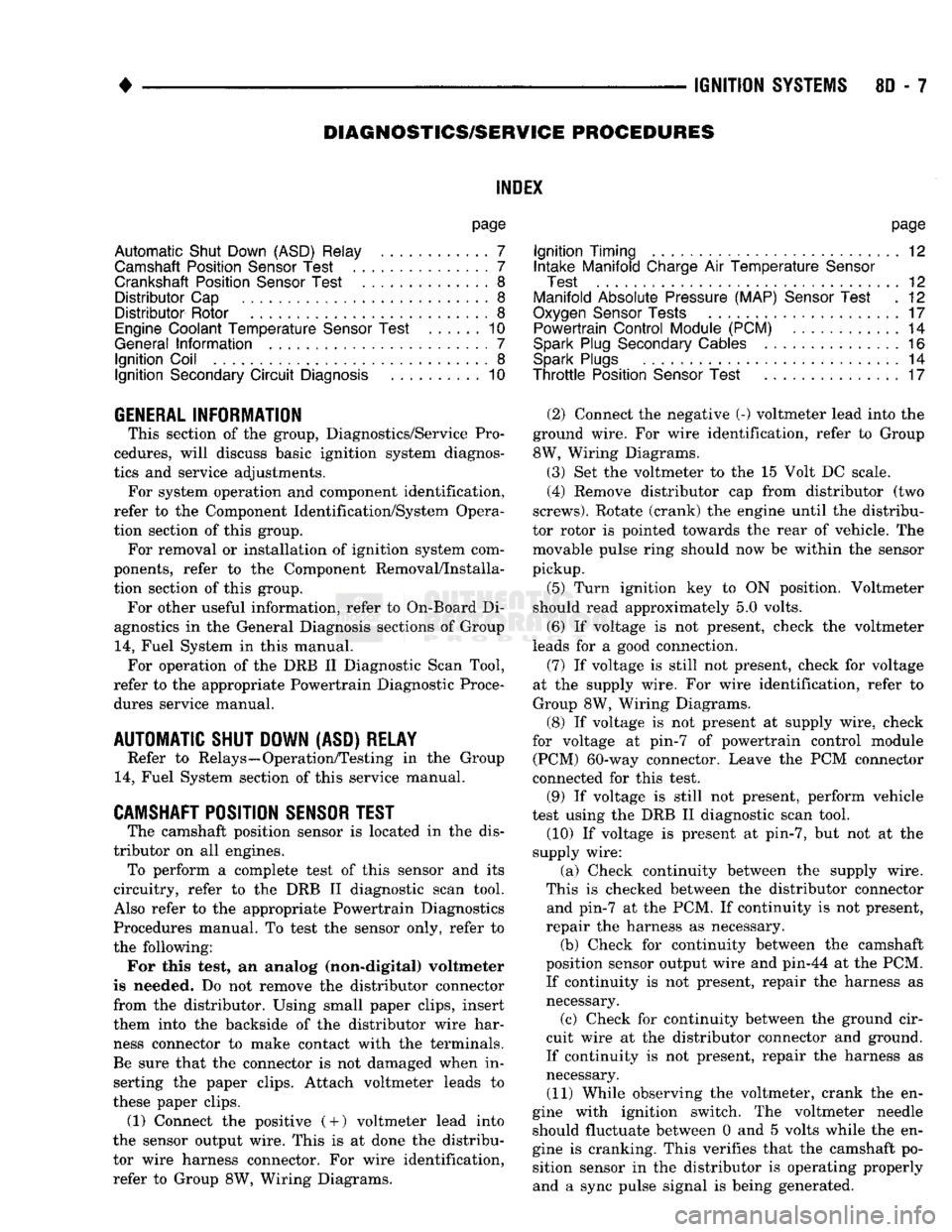

POWERTRAIN CONTROL MODULE

(PCM) The powertrain control module (PCM) is located in

the engine compartment behind the battery (Fig. 12).

The PCM was formerly referred to as the SBEC or engine controller. The ignition system is controlled by the PCM. Base ignition timing by rotation of distributor

is not adjustable.

MANIFOLD

ABSOLUTE

PRESSURE

SENSOR

TORQUE CONVERTER CLUTCH RELAY

ELECTRICAL

Jlp^

CONNECTOR

^gis!—

Fig.

11 MAP Sensor—Typical

A/C

CLUTCH RELAY STARTER RELAY

AUTO

SHUTDOWN RELAY FUEL PUMP RELAY

DATA LINK

CONNECTOR POWERTRAIN

CONTROL

MODULE

J9314-164

Fig.

12 PCM Location—Typical The PCM opens and closes the ignition coil ground

circuit to operate the ignition coil. This is done to ad

just ignition timing, both initial (base) and advance, for changing engine operating conditions.

The amount of electronic spark advance provided

by the PCM is determined by five input factors: Cool ant temperature, engine rpm, intake manifold tem

perature, manifold absolute pressure and throttle

position.

For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

For diagnostics, refer to the appropriate Powertrain

Diagnostic Procedures service manual for operation

of the DRB II scan tool.

THROTTLE

POSITION

SENSOR

The sensor is mounted on the throttle body (Fig.

13).

It is connected to the throttle blade shaft. The

sensor is a variable resistor. It provides the power-

train control module (PCM) with an input signal (voltage) that represents throttle blade position. As

Page 357 of 1502

8D

- 6

IGNITION

SYSTEMS

• the position of the throttle blade changes, the resis

tance of the sensor changes.

The PCM supplies approximately 5 volts to the

sensor. The sensor output voltage (input signal to the

PCM) represents the throttle blade position. The

PCM receives an input signal voltage from the sen sor. This will vary in an approximate range of from 1

volt at minimum throttle opening (idle), to 4 volts at

wide open throttle. Along with inputs from other sen

sors,

the PCM uses the sensor input to determine

current engine operating conditions. It also will ad

just fuel injector pulse width and ignition timing.

For component testing, refer to the Diagnostics/Ser

vice Procedures section of this group.

For removal and installation of this component, re

fer to the Component Removal/Installation section of

this group.

MANIFOLD ABSOLUTE

Fig.

13

Throttle

Position

Sensor—

Typical

Page 358 of 1502

•

IGNITION

SYSTEMS

80 - 7

DIAGNOSTICS/SERW1CE

PROCEDURES

INDEX

page

Automatic Shut Down (ASD) Relay

7

Camshaft Position

Sensor

Test

...............

7

Crankshaft Position

Sensor

Test

8

Distributor

Cap

8

Distributor

Rotor

8

Engine

Coolant Temperature

Sensor

Test

10

General

Information

7

Ignition

Coil

8

Ignition

Secondary

Circuit

Diagnosis

10

GENERAL

INFORMATION

This section

of the

group, Diagnostics/Service Pro

cedures, will discuss basic ignition system diagnos

tics

and

service adjustments. For system operation

and

component identification,

refer

to the

Component Identification/System Opera

tion section

of

this group. For removal

or

installation

of

ignition system com

ponents, refer

to the

Component Removal/Installa

tion section

of

this group. For other useful information, refer

to

On-Board

Di

agnostics

in the

General Diagnosis sections

of

Group

14,

Fuel System

in

this manual. For operation

of the DRB II

Diagnostic Scan Tool,

refer

to the

appropriate Powertrain Diagnostic Proce

dures service manual.

AUTOMATIC SHUT DOWN

(ASD)

RELAY

Refer

to

Relays—Operation/Testing

in the

Group

14,

Fuel System section

of

this service manual.

CAMSHAFT POSITION SENSOR TEST

The camshaft position sensor

is

located

in the

dis

tributor

on all

engines. To perform

a

complete test

of

this sensor

and its

circuitry, refer

to the DRB II

diagnostic scan tool.

Also refer

to the

appropriate Powertrain Diagnostics

Procedures manual.

To

test

the

sensor only, refer

to

the following: For this test,

an

analog (non-digital) voltmeter

is needed.

Do not

remove

the

distributor connector from

the

distributor. Using small paper clips, insert

them into

the

backside

of the

distributor wire har ness connector

to

make contact with

the

terminals.

Be sure that

the

connector

is not

damaged when

in

serting

the

paper clips. Attach voltmeter leads

to

these paper clips. (1) Connect

the

positive (

+

)

voltmeter lead into

the sensor output wire. This

is at

done

the

distribu tor wire harness connector.

For

wire identification,

refer

to

Group

8W,

Wiring Diagrams.

page

Ignition

Timing

12

Intake Manifold Charge

Air

Temperature

Sensor

Test

12

Manifold Absolute Pressure (MAP)

Sensor

Test

. 12

Oxygen

Sensor

Tests

17

Powertrain Control Module (PCM)

............

14

Spark

Plug Secondary Cables

16

Spark

Plugs

............................

14

Throttle

Position

Sensor

Test

17

(2) Connect

the

negative

(-)

voltmeter lead into

the

ground wire.

For

wire identification, refer

to

Group

8W, Wiring Diagrams.

(3)

Set the

voltmeter

to the 15

Volt

DC

scale. (4) Remove distributor

cap

from distributor

(two

screws). Rotate (crank)

the

engine until

the

distribu

tor rotor

is

pointed towards

the

rear

of

vehicle.

The

movable pulse ring should

now be

within

the

sensor

pickup.

(5) Turn ignition

key to ON

position. Voltmeter

should read approximately

5.0

volts.

(6)

If

voltage

is not

present, check

the

voltmeter

leads

for a

good connection.

(7)

If

voltage

is

still

not

present, check

for

voltage

at

the

supply wire.

For

wire identification, refer

to

Group

8W,

Wiring Diagrams.

(8)

If

voltage

is not

present

at

supply wire, check

for voltage

at

pin-7

of

powertrain control module (PCM) 60-way connector. Leave

the PCM

connector

connected

for

this test. (9)

If

voltage

is

still

not

present, perform vehicle

test using

the DRB II

diagnostic scan tool. (10)

If

voltage

is

present

at

pin-7,

but not at the

supply wire: (a) Check continuity between

the

supply wire.

This

is

checked between

the

distributor connector and pin-7

at the PCM. If

continuity

is not

present,

repair

the

harness

as

necessary. (b) Check

for

continuity between

the

camshaft

position sensor output wire

and

pin-44

at the PCM.

If continuity

is not

present, repair

the

harness

as

necessary. (c) Check

for

continuity between

the

ground cir

cuit wire

at the

distributor connector

and

ground.

If continuity

is not

present, repair

the

harness

as

necessary. (11) While observing

the

voltmeter, crank

the en

gine with ignition switch.

The

voltmeter needle should fluctuate between

0 and 5

volts while

the en

gine

is

cranking. This verifies that

the

camshaft

po

sition sensor

in the

distributor

is

operating properly

and

a

sync pulse signal

is

being generated.

Page 359 of 1502

8D

- 8

IGNITION

SYSTEMS

• If sync pulse signal is not present, replacement of

the camshaft position sensor is necessary. For removal or installation of ignition system com

ponents, refer to the Component Removal/Installa

tion section of this group.

For system operation and component identification,

refer to the Component Identification/System Opera

tion section of this group.

CRANKSHAFT POSITION

SENSOR

TEST

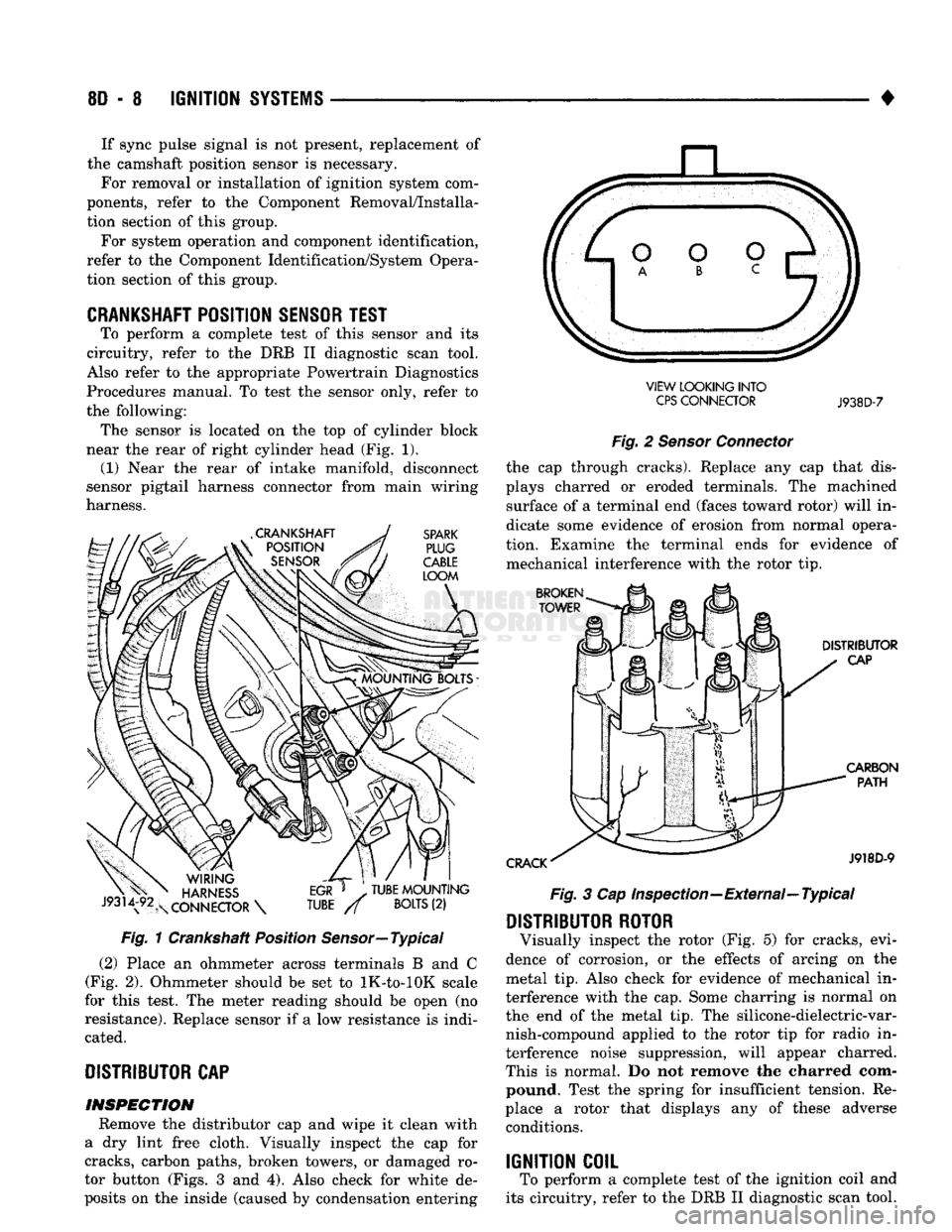

To perform a complete test of this sensor and its

circuitry, refer to the DRB II diagnostic scan tool.

Also refer to the appropriate Powertrain Diagnostics

Procedures manual. To test the sensor only, refer to

the following: The sensor is located on the top of cylinder block

near the rear of right cylinder head (Fig. 1). (1) Near the rear of intake manifold, disconnect

sensor pigtail harness connector from main wiring

harness. Fig. 1 Crankshaft Position Sensor—Typical

(2) Place an ohmmeter across terminals B and C

(Fig. 2). Ohmmeter should be set to lK-to-lOK scale

for this test. The meter reading should be open (no

resistance). Replace sensor if a low resistance is indi cated.

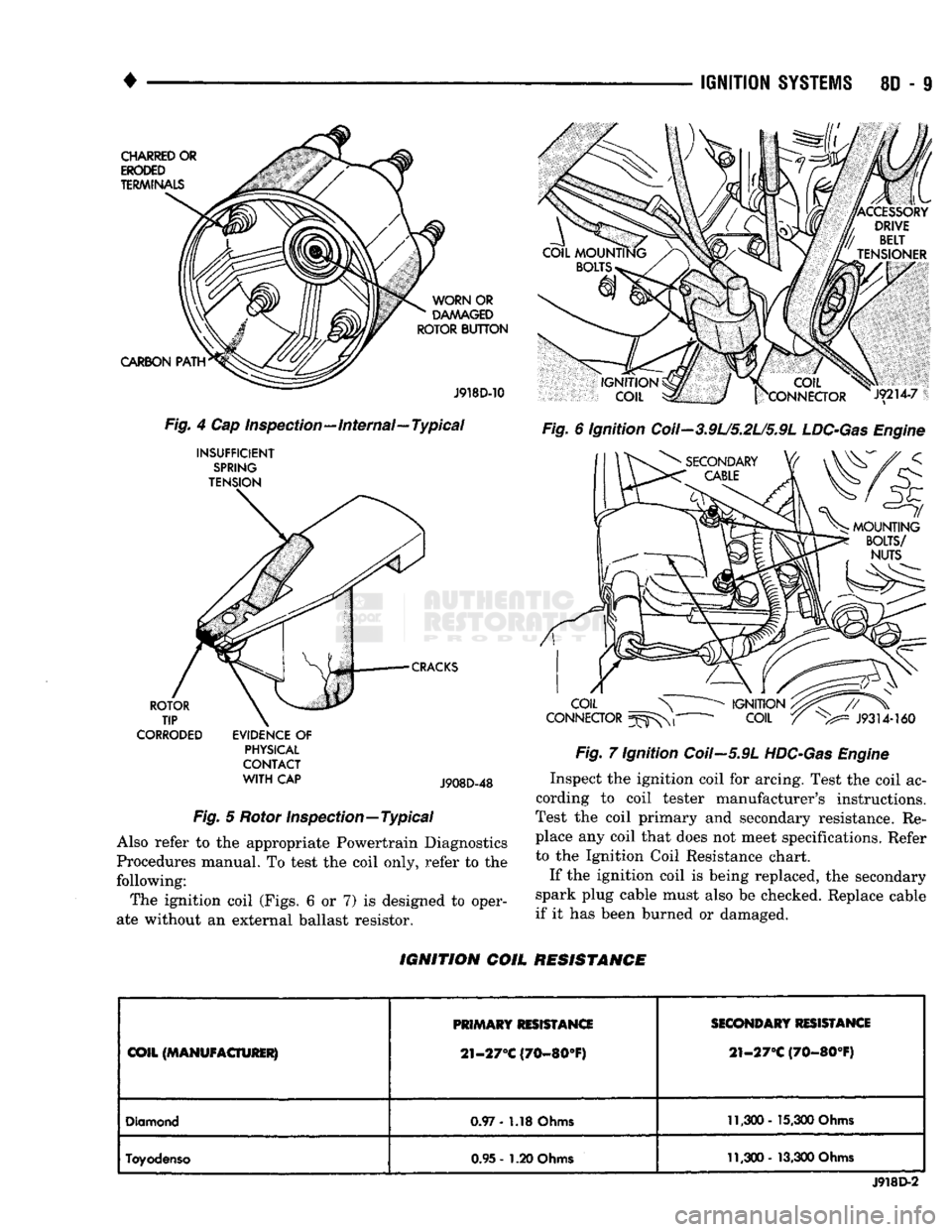

DISTRIBUTOR

CAP INSPECTION Remove the distributor cap and wipe it clean with

a dry lint free cloth. Visually inspect the cap for

cracks, carbon paths, broken towers, or damaged ro

tor button (Figs. 3 and 4). Also check for white de

posits on the inside (caused by condensation entering VIEW LOOKING INTO

CPS

CONNECTOR

J938D-7

Fig. 2 Sensor Connector the cap through cracks). Replace any cap that dis

plays charred or eroded terminals. The machined surface of a terminal end (faces toward rotor) will in

dicate some evidence of erosion from normal opera

tion. Examine the terminal ends for evidence of mechanical interference with the rotor tip. Fig. 3 Cap Inspection—External—Typical

DISTRIBUTOR ROTOR

Visually inspect the rotor (Fig. 5) for cracks, evi

dence of corrosion, or the effects of arcing on the

metal tip. Also check for evidence of mechanical in

terference with the cap. Some charring is normal on

the end of the metal tip. The silicone-dielectric-var nish-compound applied to the rotor tip for radio in

terference noise suppression, will appear charred.

This is normal. Do not remove the charred com pound. Test the spring for insufficient tension. Re

place a rotor that displays any of these adverse conditions.

IGNITION COIL

To perform a complete test of the ignition coil and

its circuitry, refer to the DRB II diagnostic scan tool.

Page 360 of 1502

•

IGNITION

SYSTEMS

80 - 9

Fig.

4 Cap Inspection—internal—Typical

INSUFFICIENT

SPRING

TENSION

CORRODED

EVIDENCE

OF

PHYSICAL

CONTACT

WITH

CAP

J908D-48

Fig.

5 Rotor Inspection—Typical

Also refer to the appropriate Powertrain Diagnostics

Procedures manual. To test the coil only, refer to the

following:

The ignition coil (Figs. 6 or 7) is designed to oper

ate without an external ballast resistor.

Fig.

6 Ignition Coil-3.9U5.2U5.9L

LDC-Gas

Engine

Fig.

7 Ignition Coil—5.9L

HDC-Gas

Engine

Inspect the ignition coil for arcing. Test the coil ac

cording to coil tester manufacturer's instructions.

Test the coil primary and secondary resistance. Re

place any coil that does not meet specifications. Refer

to the Ignition Coil Resistance chart.

If the ignition coil is being replaced, the secondary

spark plug cable must also be checked. Replace cable

if it has been burned or damaged.

IGNITION

COIL RESISTANCE

PRIMARY RESISTANCE SECONDARY RESISTANCE

COIL

(MANUFACTURER)

2!-27°C (70-80°F)

21-27°C

(70-80°F)

Diamond

0.97 - 1.18

Ohms

11,300-

15,300

Ohms

Toyodenso

0.95- 1.20

Ohms

11,300-

13,300

Ohms

J918D-2