DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 341 of 1502

Page 342 of 1502

• BATTERY/STARTER/GENERATOR

SERVICE

8B - 1

CONTENTS

page page

BATTERY

SERVICE

PROCEDURES

1 SPECIFICATIONS 9

GENERATOR

SERVICE

6 STARTER

SERVICE

PROCEDURES

4

BATTERY SERVICE PROCEDURES

GENERAL

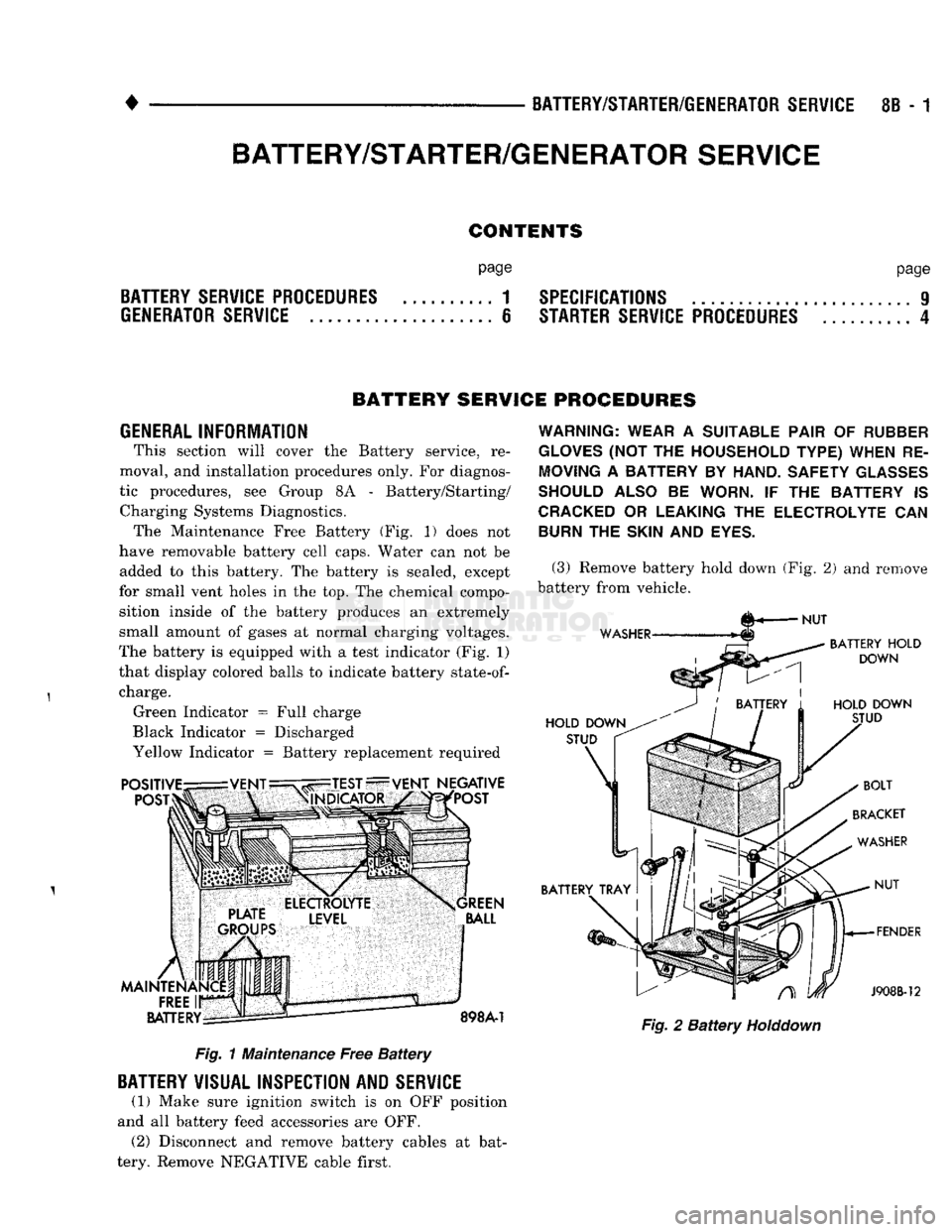

INFORMATION This section will cover the Battery service, re

moval, and installation procedures only. For diagnos

tic procedures, see Group 8A - Battery/Starting/ Charging Systems Diagnostics. The Maintenance Free Battery (Fig. 1) does not

have removable battery cell caps. Water can not be added to this battery. The battery is sealed, except

for small vent holes in the top. The chemical compo sition inside of the battery produces an extremely

small amount of gases at normal charging voltages.

The battery is equipped with a test indicator (Fig. 1)

that display colored balls to indicate battery

state-of-

charge. Green Indicator = Full charge

Black Indicator = Discharged

Yellow Indicator = Battery replacement required Fig. 1 Maintenance Free Battery

BATTERY

VISUAL INSPECTION AND

SERVICE

(1) Make sure ignition switch is on OFF position

and all battery feed accessories are OFF. (2) Disconnect and remove battery cables at bat

tery. Remove NEGATIVE cable first.

WARNING: WEAR

A

SUITABLE PAIR

OF

RUBBER

GLOVES

(NOT THE

HOUSEHOLD TYPE) WHEN

RE

MOVING

A

BATTERY

BY

HAND. SAFETY

GLASSES

SHOULD ALSO

BE

WORN.

IF THE

BATTERY

IS

CRACKED

OR

LEAKING

THE

ELECTROLYTE

CAN

BURN

THE

SKIN

AND

EYES.

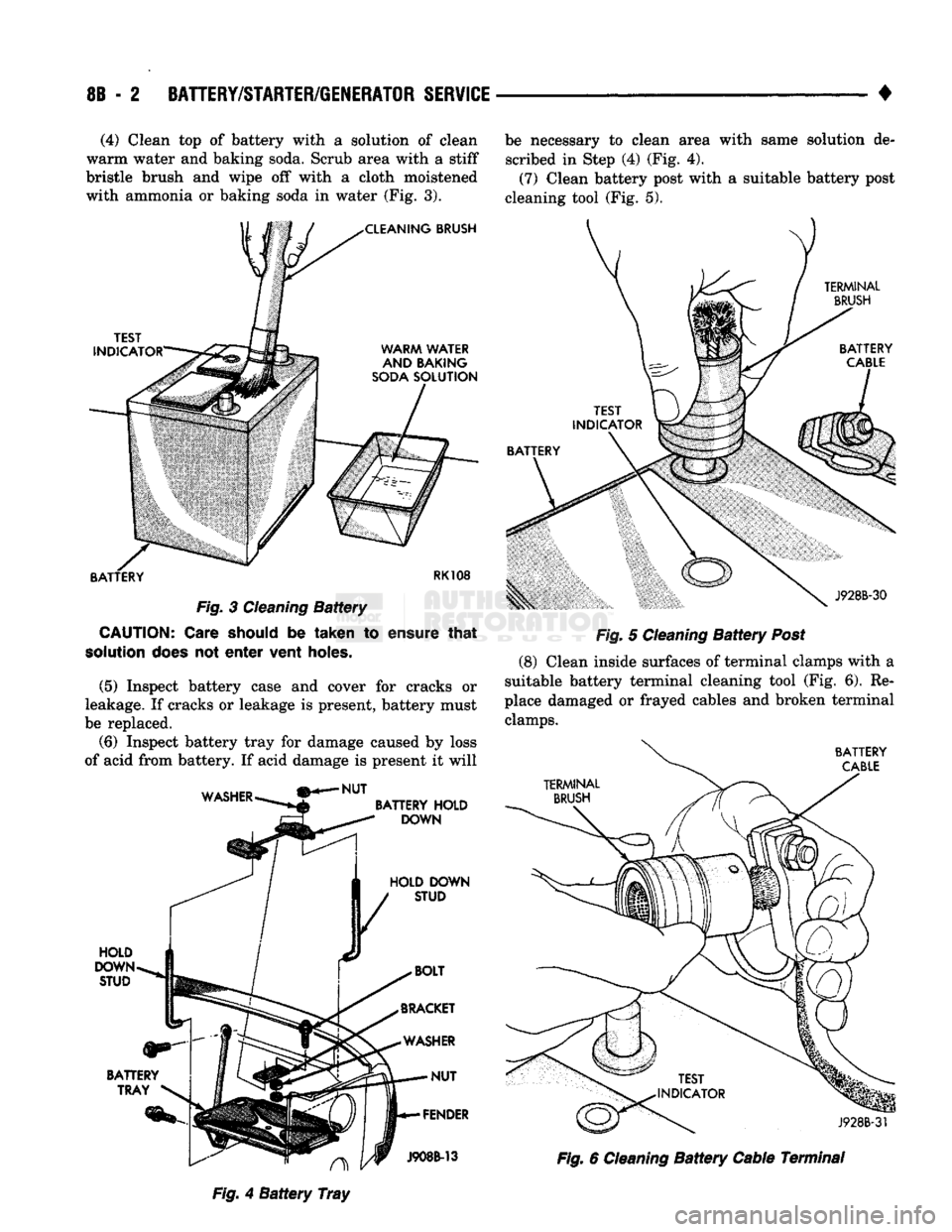

(3) Remove battery hold down (Fig. 2) and remove

battery from vehicle. Fig. 2 Battery

Holddown

BATTERY/STARTER/GENERATOR

SERVICE

Page 343 of 1502

8B

- 2

BATTERY/STARTER/GENERATOR SERVICE

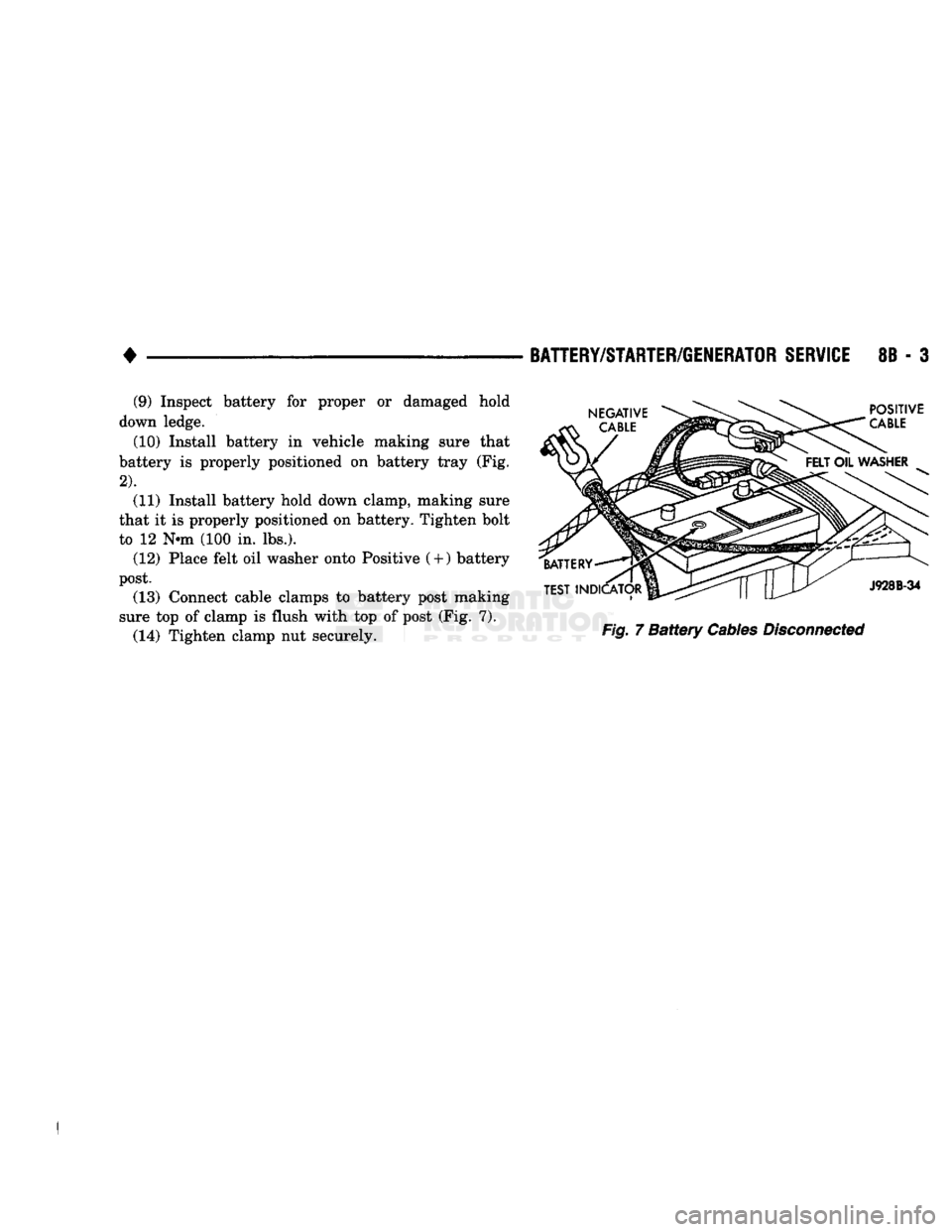

• (4) Clean top of battery with a solution of clean

warm water and baking soda. Scrub area with a stiff

bristle brush and wipe off with a cloth moistened

with ammonia or baking soda in water (Fig. 3). be necessary to clean area with same solution de

scribed in Step (4) (Fig. 4).

(7) Clean battery post with a suitable battery post

cleaning tool (Fig. 5).

TERMINAL

BRUSH

TEST

INDICATOR

BATTERY Fig.

3

Cleaning

Battery

CAUTION:

Care should

be

taken

to

ensure

that

solution

does

not

enter

vent holes.

(5) Inspect battery case and cover for cracks or

leakage. If cracks or leakage is present, battery must

be replaced.

(6) Inspect battery tray for damage caused by loss

of acid from battery. If acid damage is present it will J928B-30

Fig.

5

Cleaning

Battery

Post

(8)

Clean inside surfaces of terminal clamps with a

suitable battery terminal cleaning tool (Fig. 6). Re

place damaged or frayed cables and broken terminal clamps.

BATTERY

CABLE

WASHER

NUT

BATTERY

HOLD

DOWN

HOLD DOWN STUD HOLD

DOWN

STUD

BATTERY TRAY

J928B-3f A

Fig.

4

Battery

Tray

J908B-13

Fig.

6

Cleaning

Battery

Cable Terminal

Page 344 of 1502

•

BATTERY/STARTER/GENERATOR

SERVICE

8B - 3

Fig.

7

Battery

Cables

Disconnected

(9) Inspect battery for proper or damaged hold

down ledge.

(10) Install battery in vehicle making sure that

battery is properly positioned on battery tray (Fig.

2).

(11) Install battery hold down clamp, making sure

that it is properly positioned on battery. Tighten bolt

to 12 N-m (100 in. lbs.). (12) Place felt oil washer onto Positive

(

+

)

battery

post. (13) Connect cable clamps to battery post making

sure top of clamp is flush with top of post (Fig. 7). (14) Tighten clamp nut securely.

Page 345 of 1502

8B

- 4

BATTERY/STARTER/GENERATOR SERVICE

•

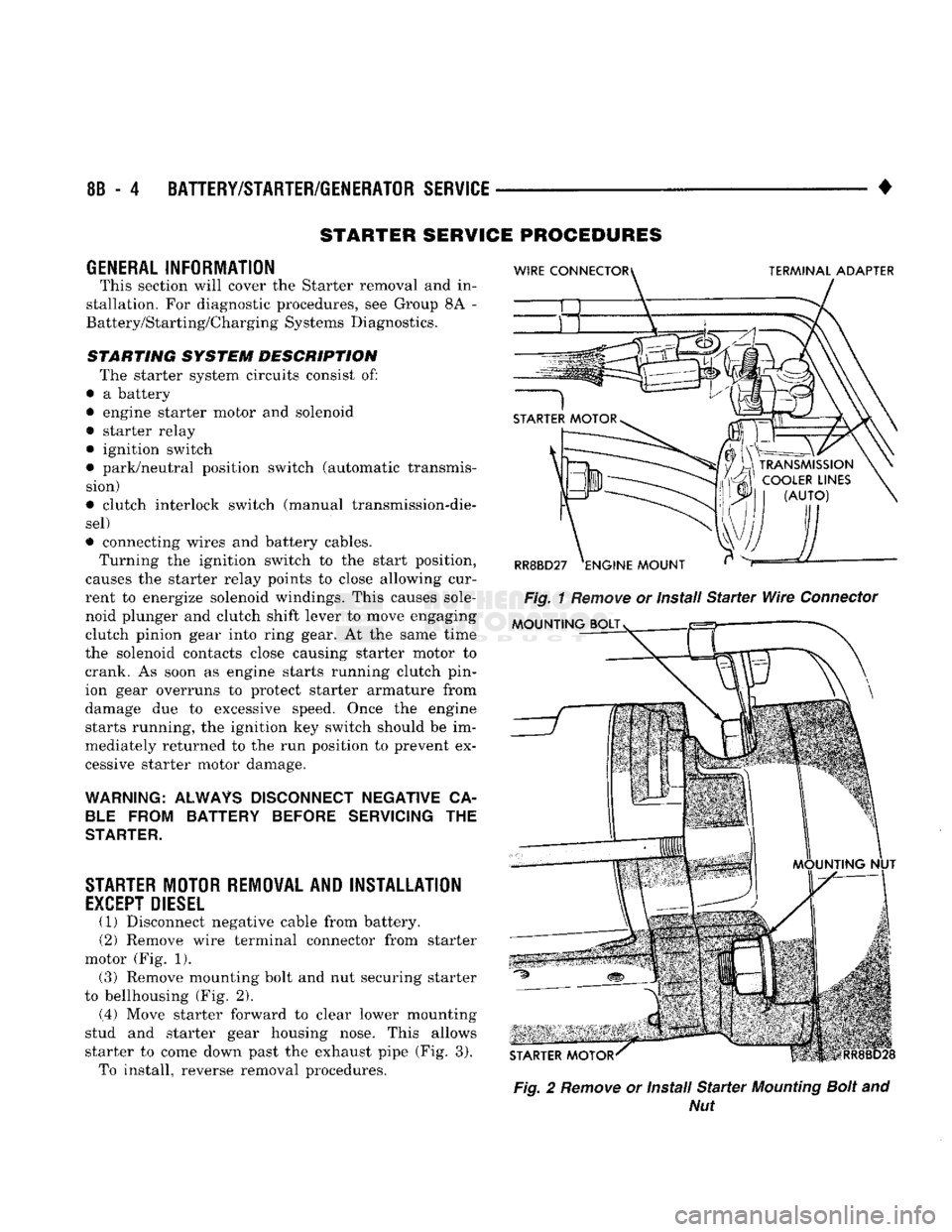

STARTER SERVICE PROCEDURES

GENERAL INFORMATION

This section will cover the Starter removal and in

stallation. For diagnostic procedures, see Group 8A -

Battery/Starting/Charging Systems Diagnostics.

STARTING

SYSTEM DESCRIPTION

The starter system circuits consist of:

• a battery

• engine starter motor and solenoid

• starter relay

• ignition switch

© park/neutral position switch (automatic transmis sion)

• clutch interlock switch (manual transmission-die-

sel)

• connecting wires and battery cables. Turning the ignition switch to the start position,

causes the starter relay points to close allowing cur

rent to energize solenoid windings. This causes sole

noid plunger and clutch shift lever to move engaging

clutch pinion gear into ring gear. At the same time

the solenoid contacts close causing starter motor to

crank. As soon as engine starts running clutch pin ion gear overruns to protect starter armature from

damage due to excessive speed. Once the engine starts running, the ignition key switch should be im

mediately returned to the run position to prevent ex

cessive starter motor damage.

WARNING:

ALWAYS DISCONNECT NEGATIVE

CA

BLE FROM

BATTERY

BEFORE SERVICING

THE

STARTER.

STARTER

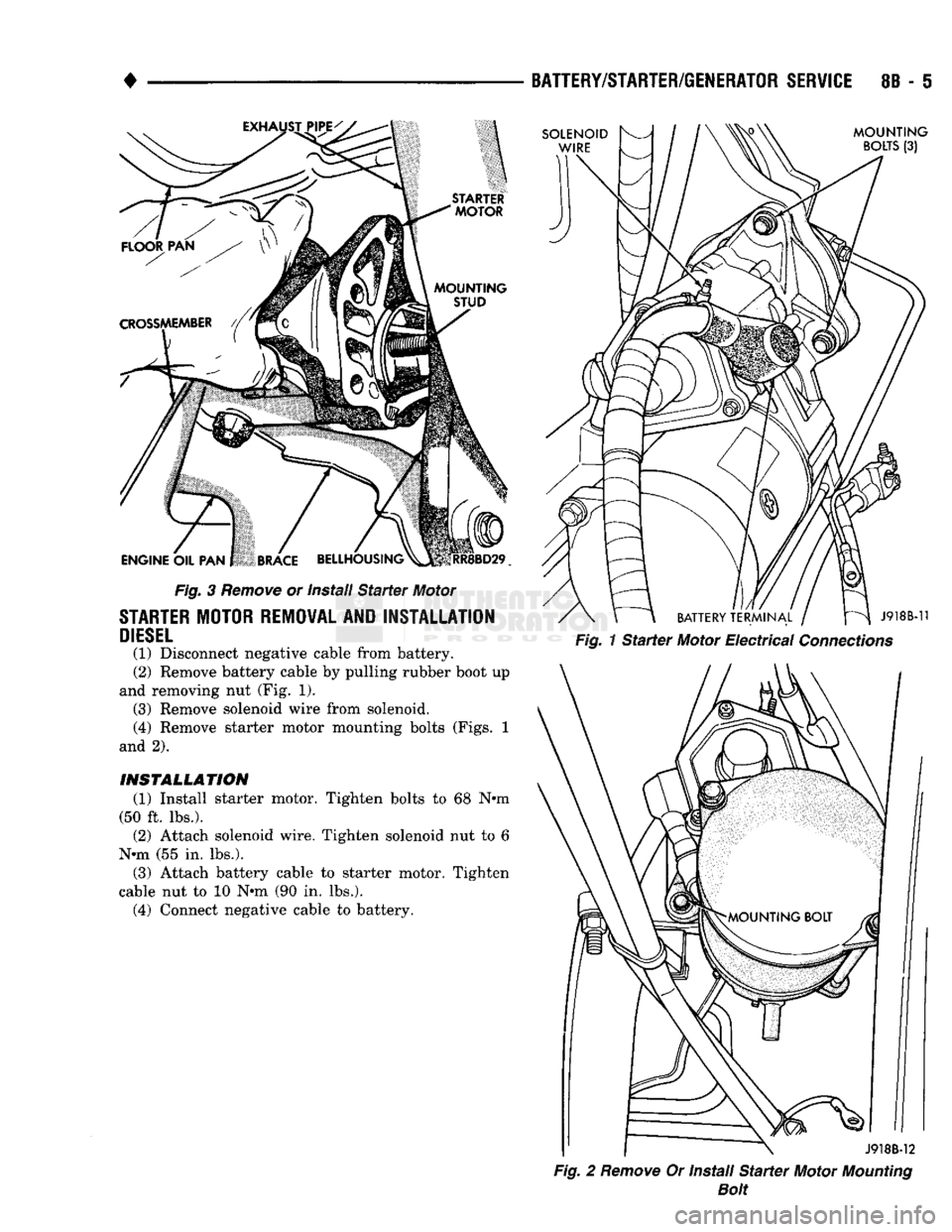

MOTOR REMOVAL AND INSTALLATION EXCEPT DIESEL

(1) Disconnect negative cable from battery.

(2) Remove wire terminal connector from starter

motor (Fig. 1). (3) Remove mounting bolt and nut securing starter

to bellhousing (Fig. 2).

(.4) Move starter forward to clear lower mounting

stud and starter gear housing nose. This allows

starter to come down past the exhaust pipe (Fig. 3). To install, reverse removal procedures.

Fig.

2

Remove

or Install

Starter

Mounting

Bolt

and

Nut

Page 346 of 1502

•

Fig.

3

Remove

or Install

Starter

Motor

STARTER

MOTOR REMOVAL AND INSTALLATION

DIESEL

(1) Disconnect negative cable from battery.

(2) Remove battery cable by pulling rubber boot up

and removing nut (Fig. 1). (3) Remove solenoid wire from solenoid.

(4) Remove starter motor mounting bolts (Figs. 1

and 2).

INSTALLATION

(1) Install starter motor. Tighten bolts to 68 N»m

(50 ft. lbs.). (2) Attach solenoid wire. Tighten solenoid nut to 6

N»m (55 in. lbs.). (3) Attach battery cable to starter motor. Tighten

cable nut to 10 N*m (90 in. lbs.). (4) Connect negative cable to battery.

BATTERY/STARTER/GENERATOR SERVICE

8B - 5

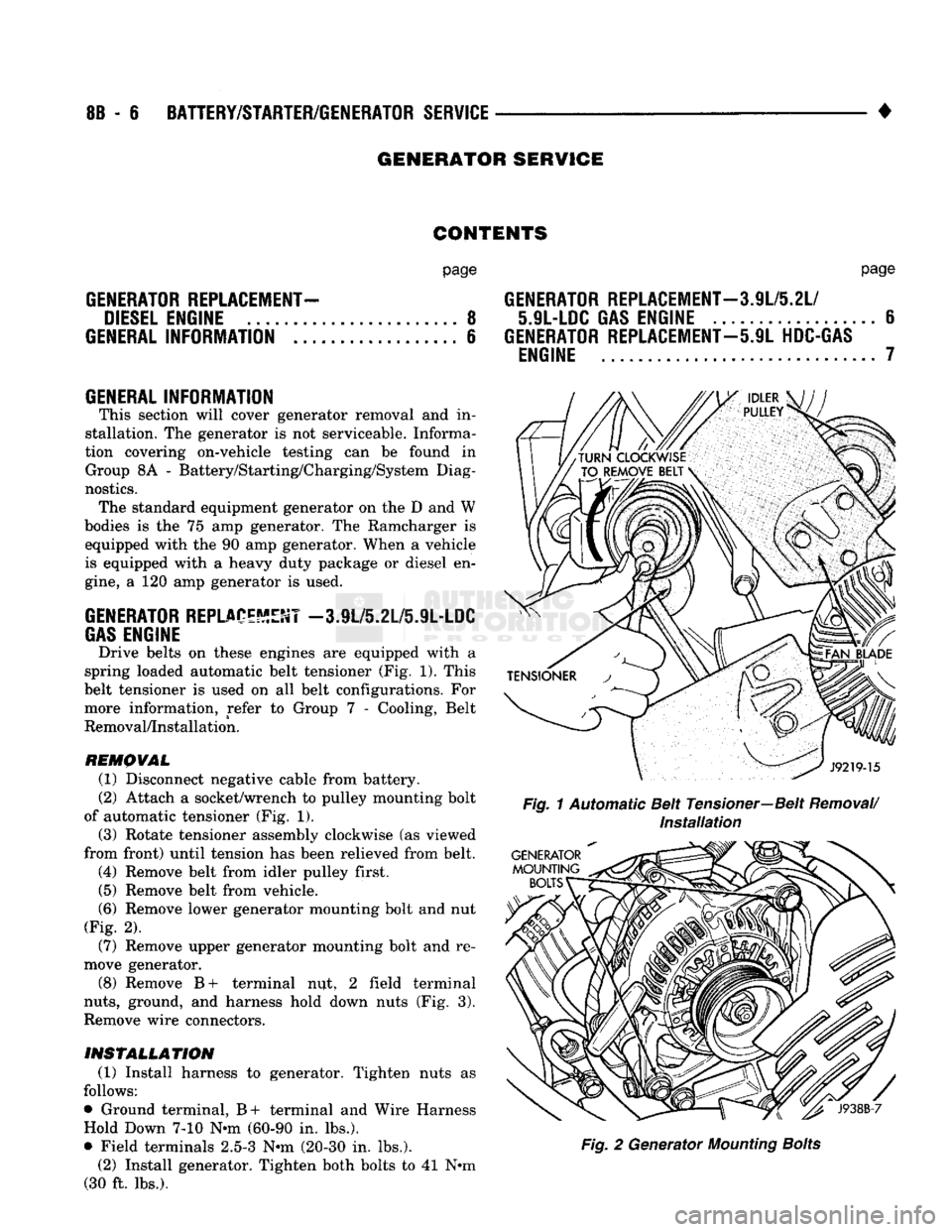

Fig.

2

Remove

Or Install

Starter

Motor

Mounting

Bolt

Page 347 of 1502

8B

- 6

BATTERY/STARTER/GENERATOR

SERVICE

•

GENERATOR SERVICE

CONTENTS

page

GENERATOR

REPLACEMENT-

DIESEL

ENGINE

8

GENERAL

INFORMATION

6

GENERAL

INFORMATION This section will cover generator removal

and in

stallation.

The

generator

is not

serviceable. Informa

tion covering on-vehicle testing

can be

found

in

Group

8A -

Battery/Starting/Charging/System Diag

nostics. The standard equipment generator

on the D and W

bodies

is the 75 amp

generator.

The

Ramcharger

is

equipped with

the 90 amp

generator. When

a

vehicle

is equipped with

a

heavy duty package

or

diesel

en

gine,

a 120 amp

generator

is

used.

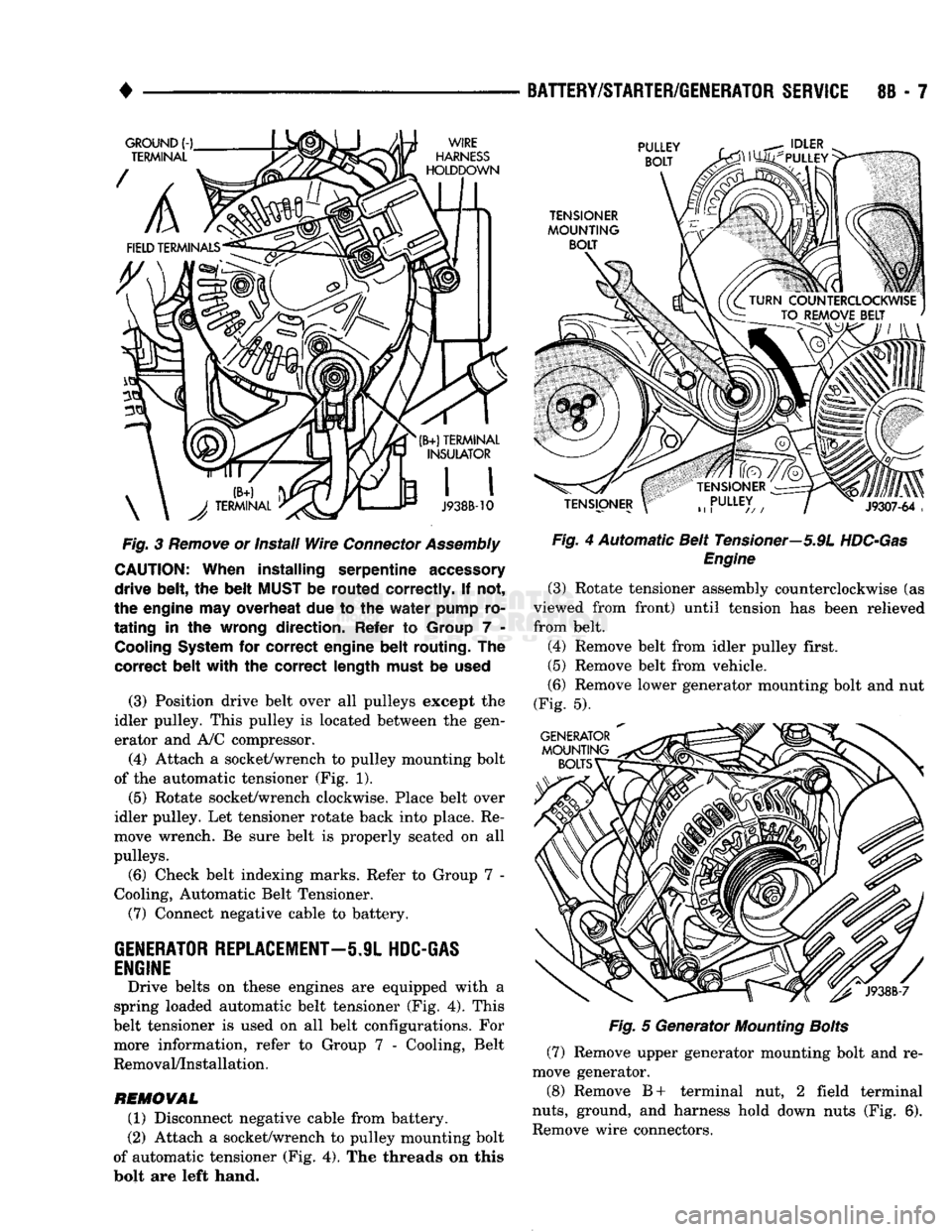

GENERATOR

REPLACEMENT

-3.9L/5.2L/5.9L-LDC

GAS

ENGINE

Drive belts

on

these engines

are

equipped with

a

spring loaded automatic belt tensioner

(Fig. 1).

This

belt tensioner

is

used

on all

belt configurations.

For

more information, refer

to

Group

7 -

Cooling, Belt

Removal/Installation.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Attach

a

socket/wrench

to

pulley mounting bolt

of automatic tensioner

(Fig. 1).

(3) Rotate tensioner assembly clockwise

(as

viewed

from front) until tension

has

been relieved from belt. (4) Remove belt from idler pulley first.

(5) Remove belt from vehicle.

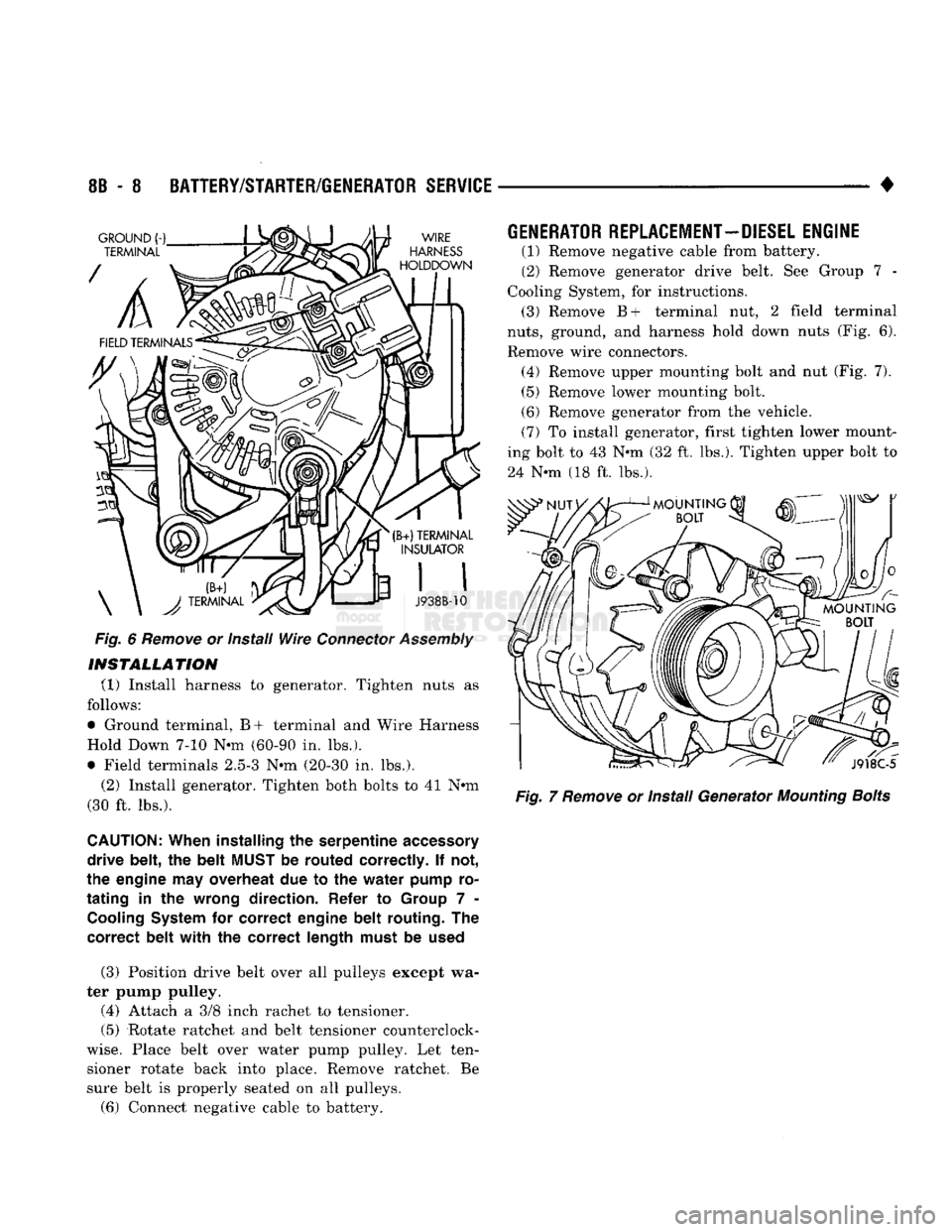

(6)

Remove lower generator mounting bolt

and nut

(Fig.

2).

(7) Remove upper generator mounting bolt

and re

move generator.

(8) Remove

B+

terminal

nut, 2

field terminal

nuts,

ground,

and

harness hold down nuts

(Fig. 3).

Remove wire connectors.

INSTALLATION

(1) Install harness

to

generator. Tighten nuts

as

follows:

• Ground terminal,

B+

terminal

and

Wire Harness Hold Down

7-10 N*m

(60-90

in.

lbs.).

• Field terminals

2.5-3 N-m

(20-30

in.

lbs.). (2) Install generator. Tighten both bolts

to 41 N»m

(30

ft.

lbs.).

page

GENERATOR

REPLACEMENT—3.9L/5.2L/

5.9L-LDC

GAS

ENGINE

6

GENERATOR

REPLACEMENT—5.9L

HDC-GAS

ENGINE

7

Fig.

1 Automatic Belt Tensioner—Belt

Removal/

Installation

Fig.

2

Generator

Mounting

Bolts

Page 348 of 1502

•

Fig.

3

Remove

or install

Wire

Connector

Assembly

CAUTION:

When

installing

serpentine

accessory

drive

belt,

the

belt

MUST

be

routed

correctly.

If not,

the engine may overheat due to the

water

pump ro

tating

in the wrong

direction.

Refer to Group 7 -

Cooling

System

for

correct

engine

belt

routing.

The

correct

belt

with

the

correct

length

must be

used

(3) Position drive belt over all pulleys except the

idler pulley. This pulley is located between the gen

erator and A/C compressor.

(4) Attach a socket/wrench to pulley mounting bolt

of the automatic tensioner (Fig. 1).

(5)

Rotate socket/wrench clockwise. Place belt over

idler pulley. Let tensioner rotate back into place. Re

move wrench. Be sure belt is properly seated on all

pulleys.

(6) Check belt indexing marks. Refer to Group 7 -

Cooling, Automatic Belt Tensioner.

(7) Connect negative cable to battery.

GENERATOR

REPLACEMENT—5.9L

HDC-GAS

ENGINE

Drive belts on these engines are equipped with a

spring loaded automatic belt tensioner (Fig. 4). This

belt tensioner is used on all belt configurations. For more information, refer to Group 7 - Cooling, Belt

Removal/Installation.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Attach a socket/wrench to pulley mounting bolt

of automatic tensioner (Fig. 4). The threads on this

bolt are left hand.

BATTERY/STARTER/GENERATOR

SERVICE

8B - 7

Fig.

4 Automatic Belt Tensioner—5.9L

HDC-Gas

Engine

(3) Rotate tensioner assembly counterclockwise (as

viewed from front) until tension has been relieved

from belt.

(4) Remove belt from idler pulley first.

(5) Remove belt from vehicle.

(6) Remove lower generator mounting bolt and nut

(Fig. 5).

Fig.

5 Generator

Mounting

Bolts

(7) Remove upper generator mounting bolt and re

move generator.

(8) Remove B+ terminal nut, 2 field terminal

nuts,

ground, and harness hold down nuts (Fig. 6).

Remove wire connectors.

Page 349 of 1502

8B

- 8

BATTERY/STARTER/GENERATOR

SERVICE

•

Fig.

6

Remove

or Install

Wire

Connector

Assembly

INSTALLATION

(1) Install harness to generator. Tighten nuts as

follows:

• Ground terminal, B+ terminal and Wire Harness

Hold Down 7-10 Nun (60-90 in. lbs.).

• Field terminals 2.5-3 Nun (20-30 in. lbs.).

(2) Install generator. Tighten both bolts to 41 Nun

(30 ft. lbs.).

CAUTION:

When

installing

the

serpentine

accessory

drive

belt,

the

belt

MUST

be

routed

correctly.

If not,

the

engine

may

overheat

due to the

water

pump

ro

tating

in the

wrong

direction.

Refer

to

Group

7 -

Cooling

System

for

correct

engine

belt

routing.

The

correct

belt

with

the

correct

length

must

be

used

(3) Position drive belt over all pulleys except wa

ter pump pulley.

(4) Attach a 3/8 inch rachet to tensioner.

(5) Rotate ratchet and belt tensioner counterclock

wise.

Place belt over water pump pulley. Let ten sioner rotate back into place. Remove ratchet. Be

sure belt is properly seated on all pulleys.

(6) Connect negative cable to battery.

GENERATOR

REPLACEMENT—DIESEL

ENGINE

(1) Remove negative cable from battery.

(2) Remove generator drive belt. See Group 7 -

Cooling System, for instructions. (3) Remove B+ terminal nut, 2 field terminal

nuts,

ground, and harness hold down nuts (Fig. 6).

Remove wire connectors. (4) Remove upper mounting bolt and nut (Fig. 7). (5) Remove lower mounting bolt.

(6) Remove generator from the vehicle.

(7) To install generator, first tighten lower mount

ing bolt to 43 Nun (32 ft. lbs.). Tighten upper bolt to

24 Nun (18 ft. lbs.).

Fig.

7

Remove

or Install Generator

Mounting

Bolts

Page 350 of 1502

•

BATTERY/STARTER/GENERATOR

SERVICE

8B - 9

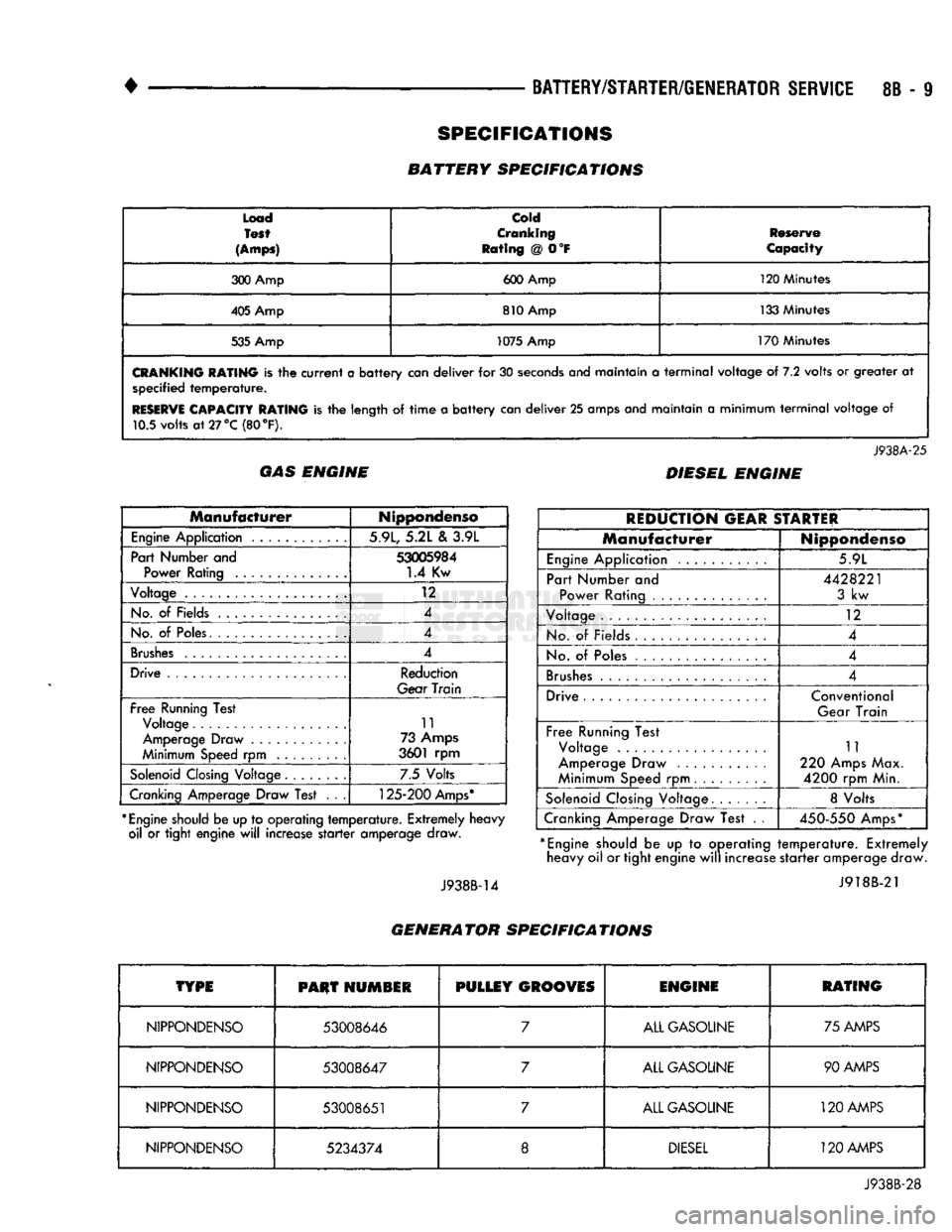

Load

Test

(Amps)

cold

Cranking

Rating

@ 0°F

Reserve

Capacity

300 Amp 600 Amp 120 Minutes

405 Amp 810 Amp 133 Minutes

535 Amp 1075 Amp

170 Minutes

CRANKING

RATING

is the

current

a

battery

can

deliver

for 30

seconds

anej

maintain

a

terminal

voltage

of 7.2

volts

or

greater

at

specified

temperature.

RESERVE

CAPACITY RATING

is the

length

of

time

a

battery

can

deliver

25

amps and maintain

a

minimum

terminal

voltage

of

10.5 volts

at

27 °C (80

°F).

J938A-25

GAS ENGINE DIESEL ENGINE

Manufacturer

Nippondenso

Engine

Application 5.9L, 5.2L

&

3.9L

Part Number and

53005984

Power Rating

1.4

Kw

Voltage

12

No.

of

Fields 4

No.

of

Poles. 4

Brushes

4

Drive Reduction

Gear

Train

Free

Running Test Voltage 11

Amperage Draw 73 Amps

Minimum Speed

rpm

3601

rpm

Solenoid

Closing Voltage 7.5 Volts

Cranking Amperage Draw Test

. . .

125-200

Amps*

*

Engine

should be up to operating

temperature.

Extremely heavy oil

or

tight engine

will

increase

starter

amperage draw.

J938B-14

REDUCTION

GEAR

STARTER

Manufacturer

Nippondenso

Engine

Application 5.9L

Part Number

and

Power Rating

4428221

3

kw

Voltage

12

No.

of

Fields

4

No.

of

Poles 4

Brushes

4

Drive Conventional

Gear Train

Free

Running Test Voltage

Amperage Draw

Minimum Speed

rpm

11

220 Amps Max.

4200

rpm Min.

Solenoid

Closing Voltage 8 Volts

Cranking Amperage Draw Test

. .

450-550

Amps*

*

Engine

should

be up to

operating

temperature.

Extremely heavy oil or tight engine

will

increase

starter

amperage draw.

J918B-21

GENERATOR SPECIFICATIONS

TYPE

PHUT

HUMSIR

PULLEY

GROOVES

ENGINE

RATING

NIPPONDENSO

53008646

7

ALL GASOLINE 75 AMPS

NIPPONDENSO

53008647

7

ALL GASOLINE 90 AMPS

NIPPONDENSO

53008651

7

ALL GASOLINE

120

AMPS

NIPPONDENSO

5234374

8

DIESEL

120 AMPS

J938B-28

SPECIFICATIONS

BATTERY SPECIFICATIONS