DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 921 of 1502

14

- 102

FUEL

SYSTEM

—

•

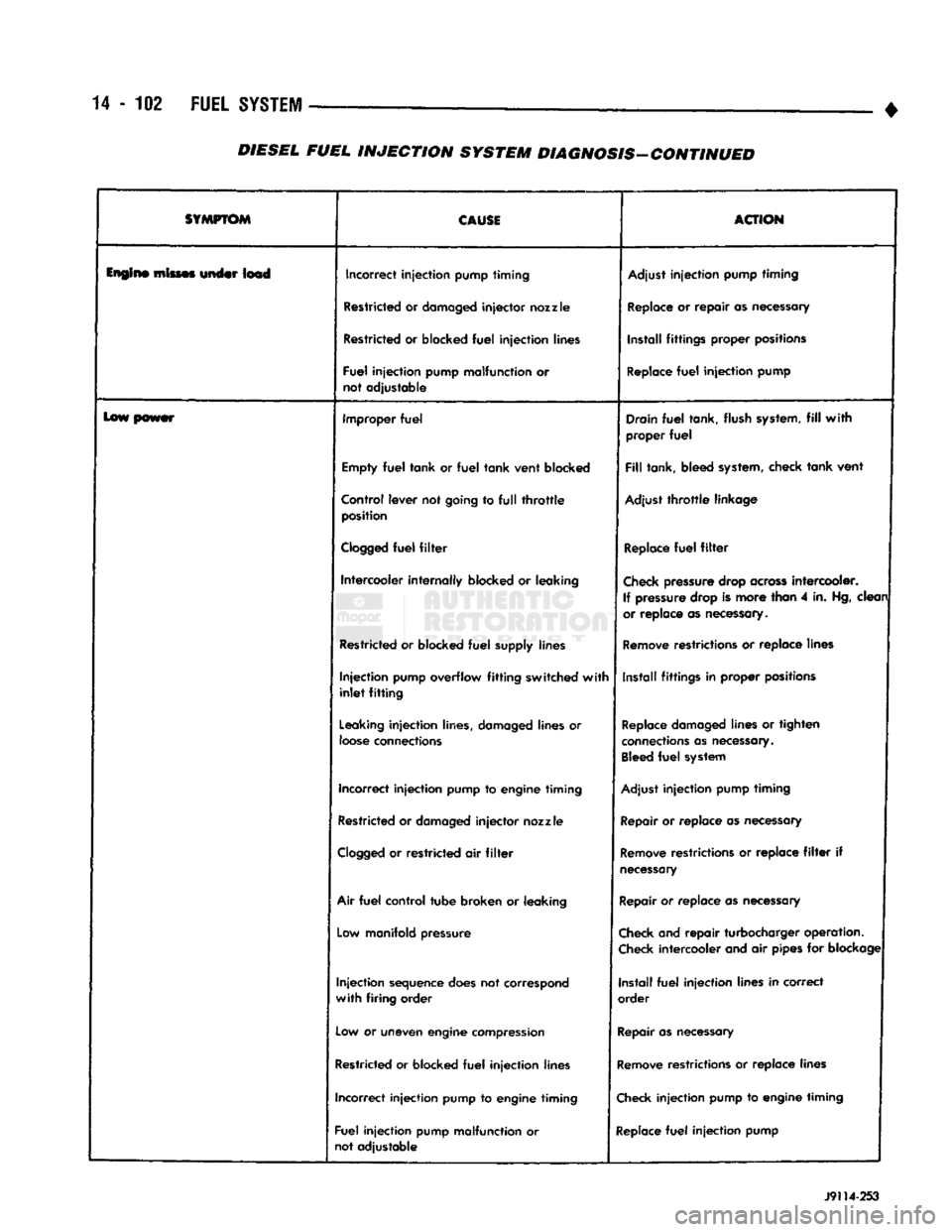

SYMPTOM

CAUSI

ACTION

lupin*

mimes under Im4 Incorrect

injection

pump

timing

Adjust

injection

pump

timing

Restricted

or

damaged

injector

nozzle

Replace

or

repair

as

necessary

Restricted

or

blocked

fuel

injection

lines Install

fittings

proper positions

Fuel

Injection

pump malfunction

or

not adjustable

Replace

fuel

injection

pump

lew power Improper

fuel

Drain

fuel

tank, flush

system,

fill

with

proper

fuel

Empty

fuel

tank or

fuel

tank vent blocked

Fill

tank, bleed

system,

check tank vent

Control lever not going

to full throttle

position Adjust

throttle

linkage

Clogged

fuel

filter

Replace

fuel

filter

Intercooler

internally

blocked

or

leaking

Check

pressure

drop

across

intercooler.

If

pressure

drop is more than

4

in.

Hg,

clean

or replace

as

necessary.

Restricted

or

blocked

fuel

supply lines

Remove

restrictions

or

replace lines

Injection

pump overflow

fitting

switched

with

inlet

fitting

Install

fittings

in

proper positions

Leaking

injection

lines, damaged lines

or

loose

connections

Replace

damaged

lines

or

tighten

connections

as

necessary.

Bleed

fuel

system

Incorrect

injection

pump

to

engine

timing

Adjust

injection

pump

timing

Restricted or

damaged

injector

nozzle

Repair

or replace as

necessary

Clogged

or

restricted

air filter

Remove

restrictions

or

replace

filter if

necessary

Air

fuel

control

tube broken

or

leaking

Repair

or replace

as

necessary

Low

manifold pressure

Check

and repair turbocharger operation.

Check

intercooler and

air

pipes

for

blockage

Injection

sequence

does

not correspond

with

firing

order Install

fuel

injection

lines in correct

order

Low

or

uneven

engine

compression

Repair

as

necessary

Restricted or blocked

fuel

injection

lines

Remove

restrictions

or

replace lines

Incorrect

injection

pump

to

engine

timing

Check

injection

pump

to

engine

timing

Fuel

injection

pump malfunction

or

not adjustable

Replace

fuel

injection

pump J9114-253

DIESEL

FUEL

INJECTION

SYSTEM

DIAGNOSIS-CONTINUED

Page 922 of 1502

FUEL

SYSTEM

14-103

DIESEL FUEL

INJECTION

SYSTEM DIAGNOSIS-CONTINUED

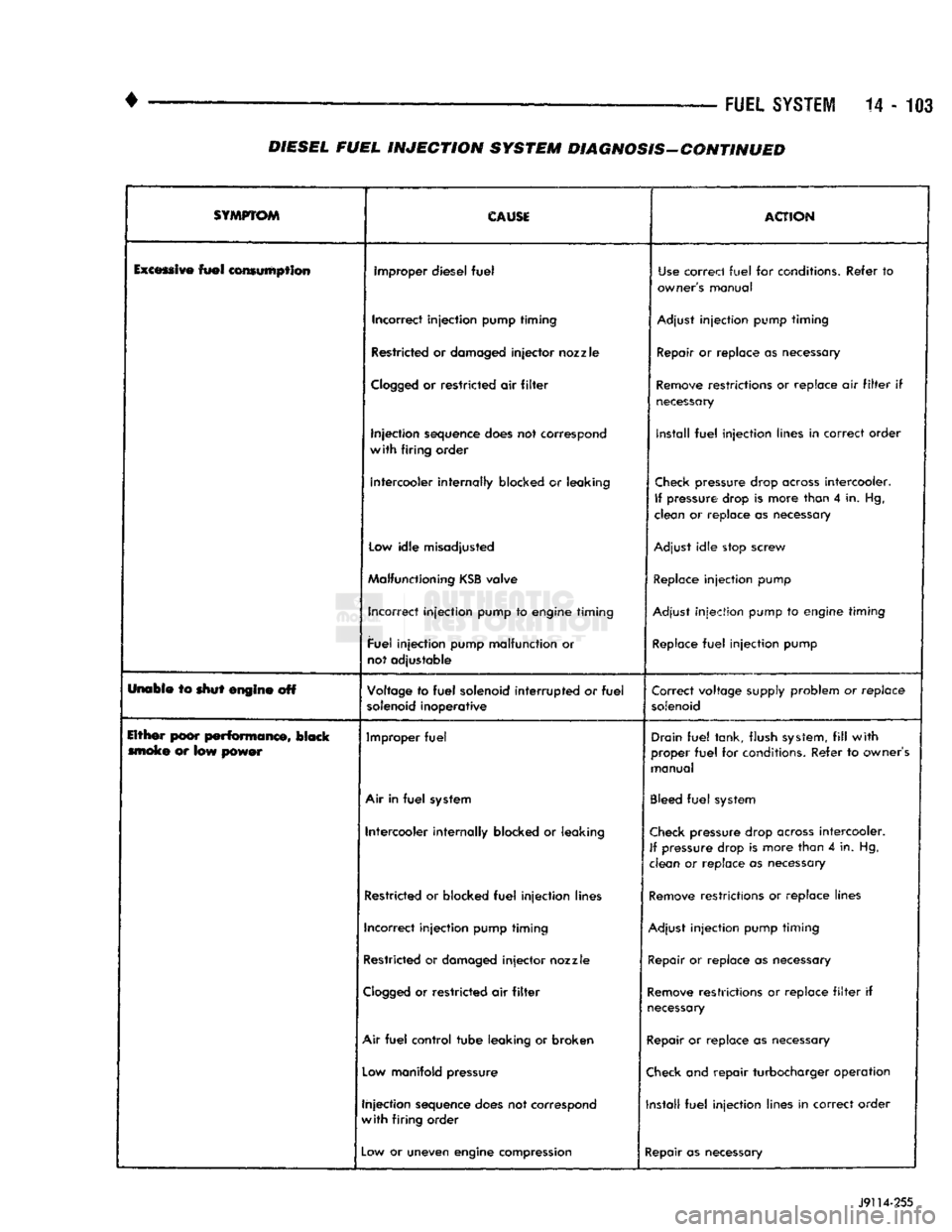

SYMPTOM

CAUSE

ACTION

Excessive

fuel

consumption improper diesel

fuel

Use

correct

fuel

for conditions. Refer

to

owner's manual

Incorrect injection pump timing

Adjust

injection pump timing

Restricted or damaged

injector

nozzle Repair or replace as necessary

Clogged

or

restricted air

filter

Remove

restrictions or replace air

filter

if

necessary

Injection sequence does not correspond

with

firing order install

fuel

injection lines in correct order

Intercooler internally blocked

or

leaking

Check

pressure drop

across

intercooler.

If

pressure drop

is

more than

4

in. Hg,

clean or replace as necessary

Low

idle misadjusted

Adjust

idle stop screw

Malfunctioning

KSB

valve

Replace

injection pump

Incorrect injection pump to engine timing

Adjust

injection pump to engine timing

Fuel injection pump malfunction or

not adjustable

Replace

fuel

injection pump

Unabie to shut engine off Voltage to

fuel

solenoid

interrupted

or

fuel

solenoid

inoperative Correct voltage supply problem or

replace

solenoid

Either poor

performance,

black moke

or

low power Improper

fuel

Drain

fuel

tank, flush

system,

fill

with

proper

fuel

for conditions. Refer to owner's

manual

Air

in

fuel

system

Bleed

fuel

system

Intercooler internally blocked

or

leaking

Check

pressure drop

across

intercooler.

If

pressure drop is more than

4

in. Hg,

clean

or

replace

as

necessary

Restricted or blocked

fuel

injection lines

Remove

restrictions or replace lines

Incorrect injection pump timing

Adjust

injection pump timing

Restricted or damaged

injector

nozzle

Repair

or replace as necessary

Clogged

or restricted air

filter

Remove

restrictions or replace

filter

if

necessary

Air

fuel

control tube leaking or broken Repair or replace as necessary

Low

manifold pressure

Check

and repair turbocharger operation

Injection sequence does not correspond

with

firing order Install

fuel

injection lines in correct order

—

Low

or uneven engine compression

Repair as necessary

J9114-255

Page 923 of 1502

14-104

FUEL

SYSTEM

• DIESEL FUEL INJECTION SYSTEM DIAGNOSIS-CONTINUED

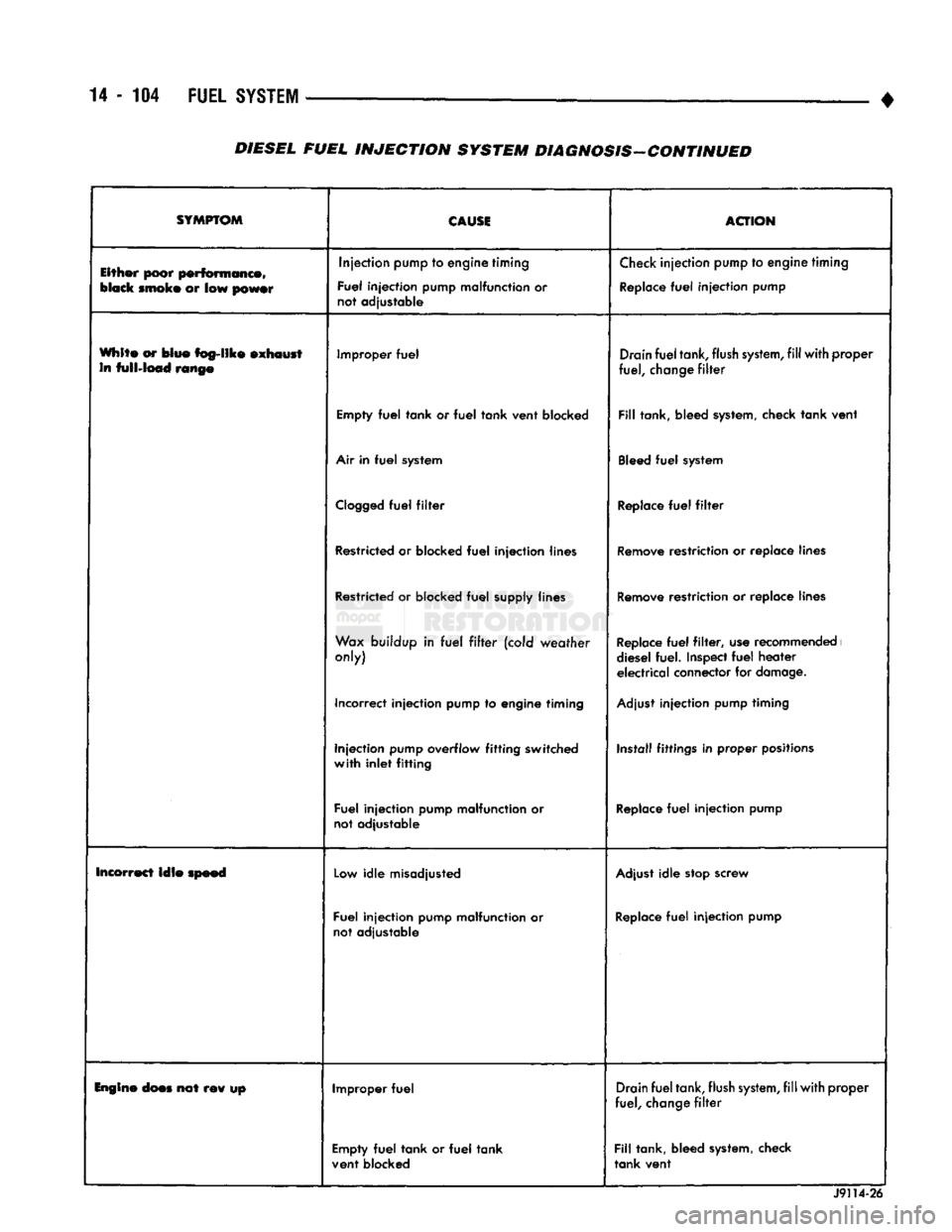

SYMPTOM

CAUSE

ACTION

Either poor performance,

black

smoke

or low

power

Injection

pump

to engine timing

Fuel injection pump malfunction or

not adjustable

Check

injection

pump

to

engine

timing

Replace

fuel

injection pump

White or blue fog-like exhaust in full-load range Improper

fuel

Drain

fuel

tank,

flush

system,

fill

with proper

fuel,

change

filter

Empty

fuel

tank or

fuel

tank vent blocked

Fill

tank, bleed

system,

check tank vent

Air

in

fuel

system

Bleed

fuel

system

Clogged

fuel

filter

Replace

fuel

filter

Restricted

or blocked

fuel

injection lines

Remove

restriction or replace lines

Restricted

or blocked

fuel

supply lines

Remove

restriction or replace lines

Wax

buildup in

fuel

filter

(cold weather

only)

Replace

fuel

filter,

use

recommended

i

diesel fuel.

Inspect

fuel

heater electrical connector for

damage.

Incorrect injection pump to engine timing

Adjust

injection pump timing

Injection pump overflow fitting switched

with inlet fitting Install fittings in

proper

positions

Fuel injection pump malfunction or

not adjustable

Replace

fuel

injection pump

Incorrect lale speed

Low

idle misadjusted

Adjust

idle

stop

screw

Fuel injection pump malfunction or

not adjustable

Replace

fuel

injection pump

Engine

does

not rev up Improper

fuel

Drain

fuel

tank,

flush

system,

fill

with proper

fuel,

change

filter

Empty

fuel

tank or

fuel

tank

vent blocked

Fill

tank, bleed

system,

check

tank vent J9114-26

Page 924 of 1502

•

FUEL

SYSTEM

14-105 DIESEL FUEL INJECTION SYSTEM DIAGNOSIS-CONTINUED

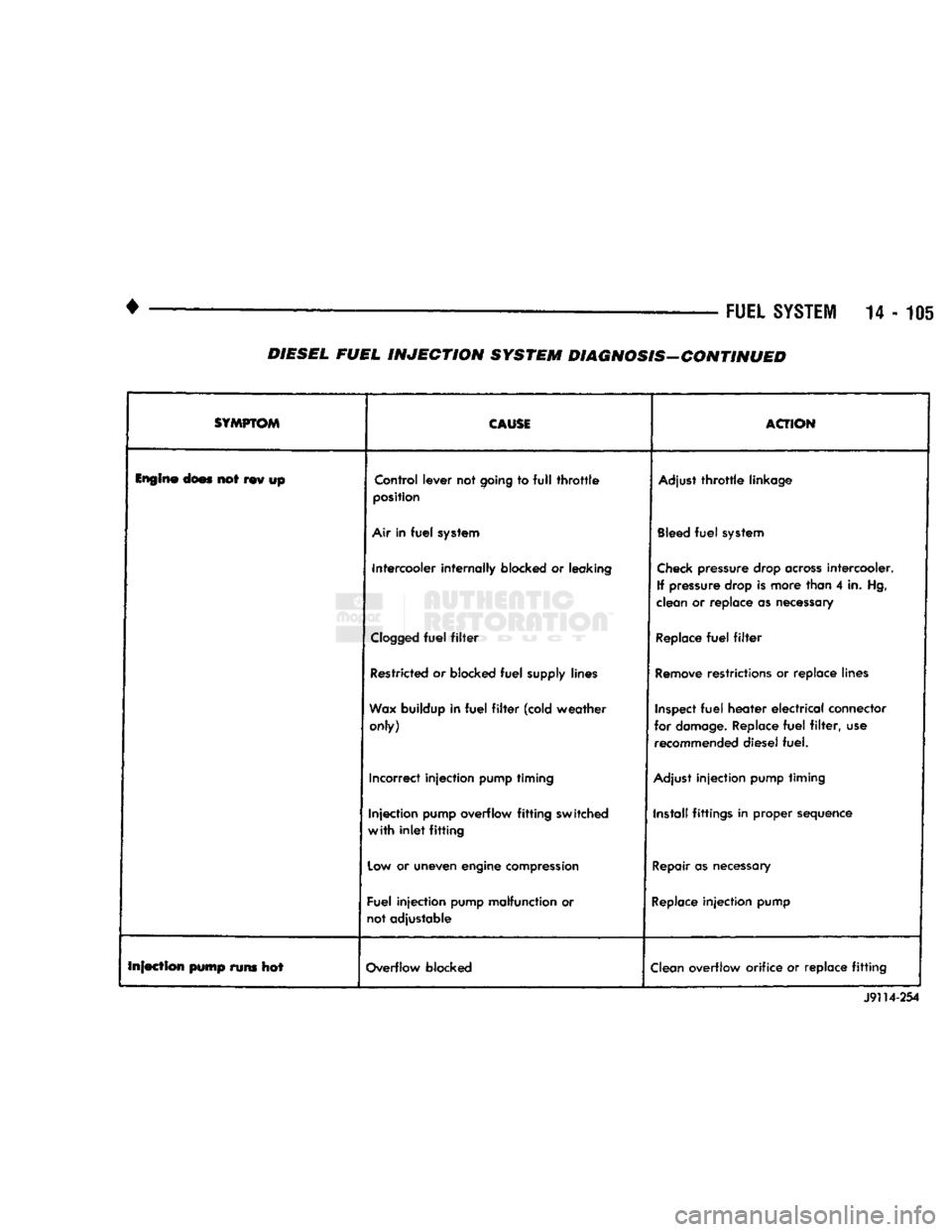

SYMPTOM

CAUSE

ACTION

Engine

does not rev up Control lever not

going

to

full

throttle

position

Adjust

throttle

linkage

Air

in

fuel

system

Bleed

fuel

system

Intercooler internally blocked or leaking

Check

pressure drop

across

intercooler.

If pressure drop is more than 4 in. Hg,

clean or replace as necessary

Clogged

fuel

filter

Replace

fuel

filter

Restricted or blocked

fuel

supply lines

Remove

restrictions or replace lines

Wax

buildup in

fuel

filter

(cold weather only)

Inspect

fuel

heater

electrical

connector

for

damage.

Replace

fuel

filter,

use recommended diesel fuel.

Incorrect injection pump timing

Adjust

injection pump timing

Injection pump overflow

fitting

switched

with

inlet

fitting

Install fittings in proper sequence

Low

or uneven engine

compression

Repair

as

necessary

Fuel injection pump malfunction or

not adjustable

Replace

injection pump

Infection pump runs hot Overflow blocked

Clean

overflow orifice or replace

fitting

J9114-254

Page 925 of 1502

14

- 106

FUEL SYSTEi

DIESEL FUEL

INJECTION-SERVICE

PROCEDURES

INDEX

page

Air Bleed Procedure

106

Air Fuel Control Tube

107

Air Intake Heater

107

Engine

Speed

Sensor

108

Fuel Drain Manifold

109

Fuel Heater

. 110

Fuel

Injection

Pump

110

Fuel

Injection

Pump Supply Line

114

Fuel

Injectors

114

AIR BLEED PROCEDURE

A certain amount

of air

becomes trapped

in the

fuel system when fuel system components

are

ser

viced

or

replaced. Bleed

the

system after fuel system service according

to the

following procedures.

WARNING:

DO NOT

BLEED

AIR

FROM

THE

FUEL

SYSTEM

OF

A

HOT

ENGINE.

DO

NOT

ALLOW FUEL

TO SPRAY ONTO

THE

EXHAUST MANIFOLD WHEN BLEEDING

AIR

FROM

THE

FUEL SYSTEM.

MANUAL BLEEDING

Some

air

enters

the

fuel system when

the

filters

or

injection pump supply line

are

changed. This small

amount

of air is

vented automatically from

the

injec

tion pump through

the

fuel drain manifold. This

is if

the filter

was

changed according

to

instructions.

The system will have

to be

bleed manually

if:

•

The

fuel filter

is not

filled before installation

•

Injection pump

is

replaced

•

High pressure fuel line connections

are

loosened

or

lines replaced

•

Initial engine start-up

or

start-up after

an ex

tended period

of no

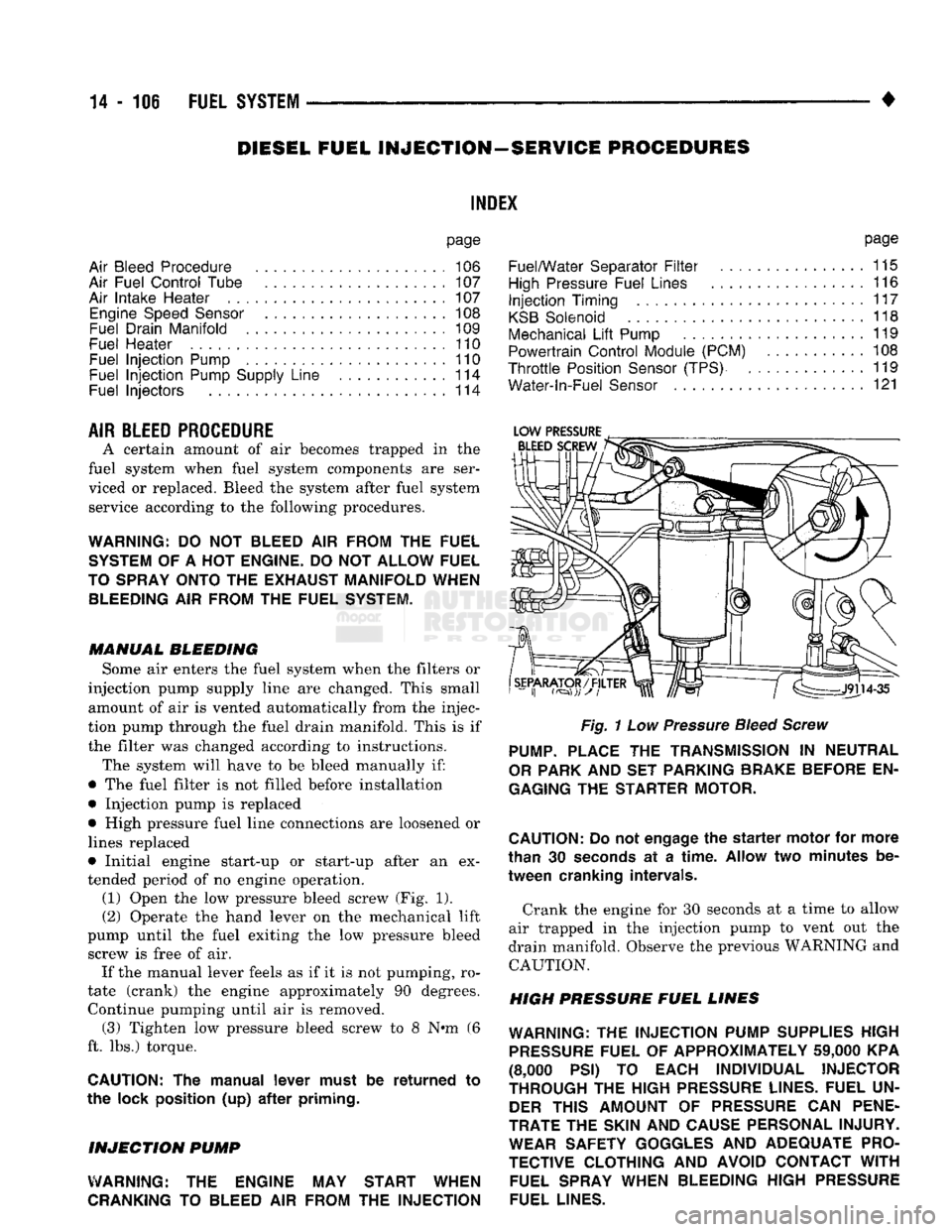

engine operation. (1) Open

the low

pressure bleed screw

(Fig. 1).

(2) Operate

the

hand lever

on the

mechanical lift

pump until

the

fuel exiting

the low

pressure bleed screw

is

free

of air.

If

the

manual lever feels

as if it is not

pumping,

ro

tate (crank)

the

engine approximately

90

degrees. Continue pumping until

air is

removed. (3) Tighten

low

pressure bleed screw

to 8 N»m (6

ft.

lbs.)

torque.

CAUTION:

The

manual lever must

be

returned

to

the lock position

(up) after

priming.

INJECTION

PUMP

WARNING:

THE

ENGINE

MAY

START WHEN

CRANKING

TO

BLEED

AIR

FROM

THE

INJECTION

page

Fuel/Water Separator

Filter

................

115

High

Pressure Fuel Lines

116

Injection

Timing

117

KSB

Solenoid

118

Mechanical

Lift

Pump

119

Powertrain Control Module (PCM)

108

Throttle

Position

Sensor

(TPS)

119

Water-ln-Fuel

Sensor

121

Fig.

1

Low

Pressure

Bleed Screw

PUMP.

PLACE

THE

TRANSMISSION

IN

NEUTRAL

OR

PARK

AND SET

PARKING BRAKE BEFORE

EN

GAGING

THE

STARTER MOTOR.

CAUTION:

Do

not

engage

the

starter

motor

for

more

than

30

seconds

at a

time.

Allow

two

minutes

be

tween cranking intervals.

Crank

the

engine

for 30

seconds

at a

time

to

allow

air trapped

in the

injection pump

to

vent

out the

drain manifold. Observe

the

previous WARNING

and

CAUTION.

HIGH PRESSURE FUEL LINES

WARNING:

THE

INJECTION PUMP SUPPLIES HIGH

PRESSURE

FUEL

OF

APPROXIMATELY

59,000

KPA

(8,000

PSI) TO

EACH INDIVIDUAL INJECTOR

THROUGH

THE

HIGH

PRESSURE

LINES. FUEL

UN

DER

THIS AMOUNT

OF

PRESSURE

CAN

PENE

TRATE

THE

SKIN

AND

CAUSE PERSONAL INJURY. WEAR SAFETY GOGGLES

AND

ADEQUATE PRO

TECTIVE CLOTHING

AND

AVOID CONTACT

WITH

FUEL SPRAY WHEN BLEEDING HIGH

PRESSURE

FUEL LINES.

Page 926 of 1502

•

FUEL SYSTEM 14 - 107

WARNING;

DO NOT

BLEED

AIR

FROM

THE

FUEL

SYSTEM

OF A HOT

ENGINE.

DO NOT

ALLOW FUEL

TO SPRAY ONTO

THE

EXHAUST MANIFOLD WHEN

BLEEDING

AIR

FROM

THE

FUEL SYSTEM.

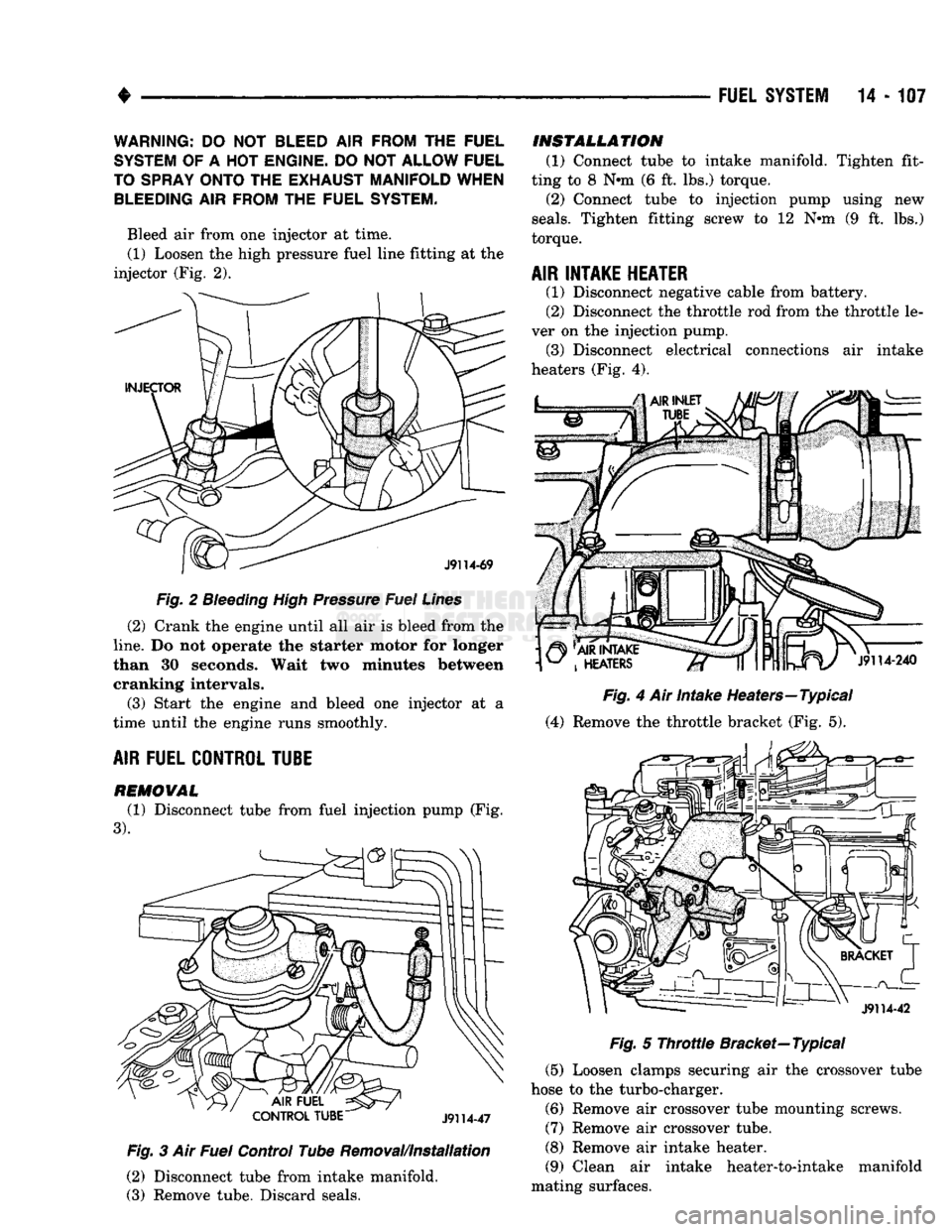

Bleed air from one injector at time. (1) Loosen the high pressure fuel line fitting at the

injector (Fig. 2).

Fig.

2

Bleeding

High Pressure Fuel Lines

(2) Crank the engine until all air is bleed from the

line.

Do not operate the starter motor for longer

than 30 seconds. Wait two minutes between cranking intervals.

(3) Start the engine and bleed one injector at a

time until the engine runs smoothly.

AIR

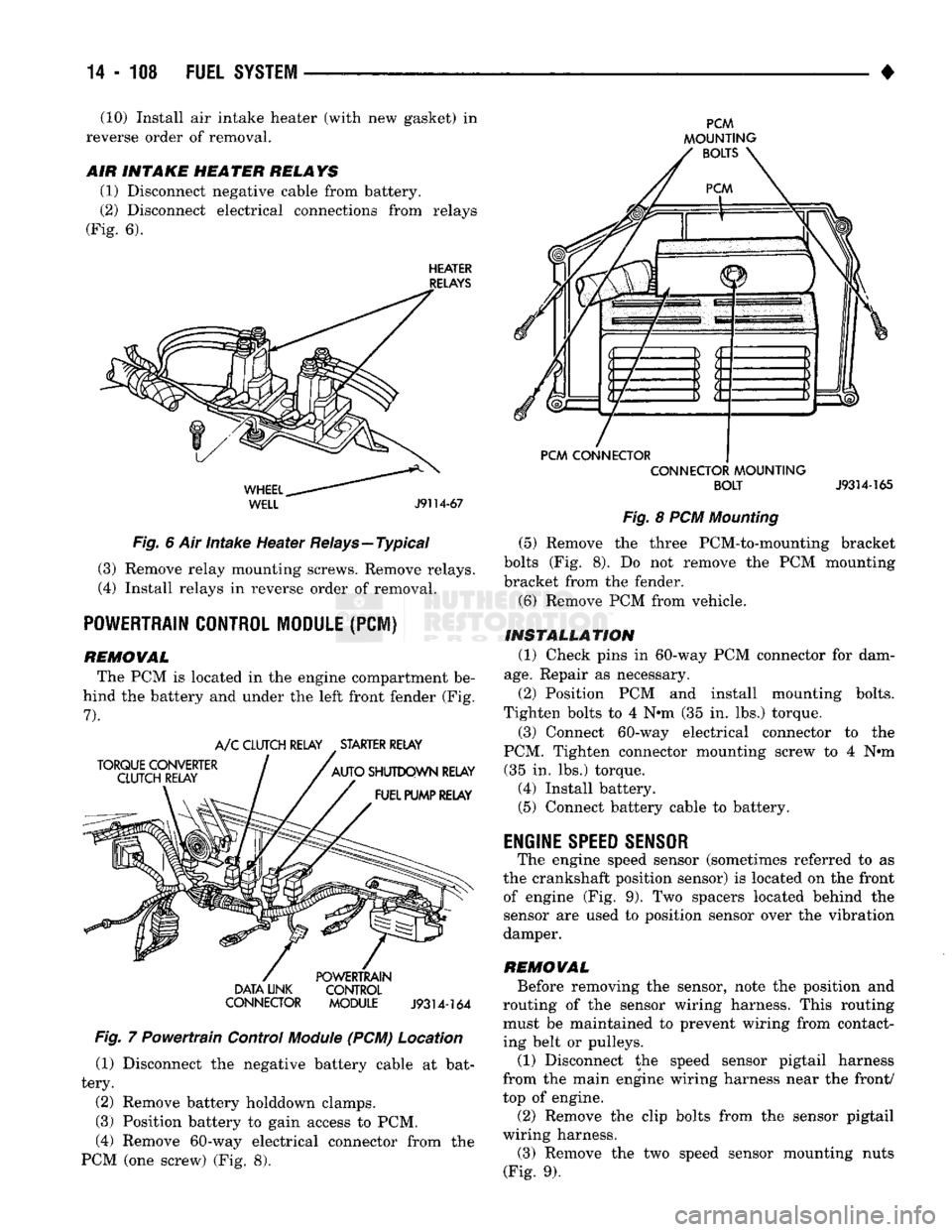

FUEL CONTROL TUBE

REMOWAL

(1) Disconnect tube from fuel injection pump (Fig.

3). Fig.

3 Air

Fuel

Control Tube Removal/Installation

(2) Disconnect tube from intake manifold.

(3) Remove tube. Discard seals.

INSTALLATION

(1) Connect tube to intake manifold. Tighten fit

ting to 8 Nnn (6 ft. lbs.) torque. (2) Connect tube to injection pump using new

seals.

Tighten fitting screw to 12 Nnn (9 ft. lbs.)

torque.

AIR INTAKE HEATER

(1) Disconnect negative cable from battery.

(2) Disconnect the throttle rod from the throttle le

ver on the injection pump. (3) Disconnect electrical connections air intake

heaters (Fig. 4).

Fig.

4 Air Intake Heaters—Typical

(4) Remove the throttle bracket (Fig. 5).

Fig.

5

Throttle

Bracket—Typical

(5) Loosen clamps securing air the crossover tube

hose to the turbo-charger.

(6) Remove air crossover tube mounting screws.

(7) Remove air crossover tube.

(8) Remove air intake heater.

(9) Clean air intake heater-to-intake manifold

mating surfaces.

Page 927 of 1502

(10) Install air intake heater (with new gasket) in

reverse order of removal.

AIR

INTAKE

HE

A TER

RELA YS

(1) Disconnect negative cable from battery.

(2) Disconnect electrical connections from relays

(Fig. 6).

HEATER

RELAYS

WHEEL..

WELL

J9114-67

Fig. 6 Air intake Heater Relays—Typical (3) Remove relay mounting screws. Remove relays.

(4) Install relays in reverse order of removal.

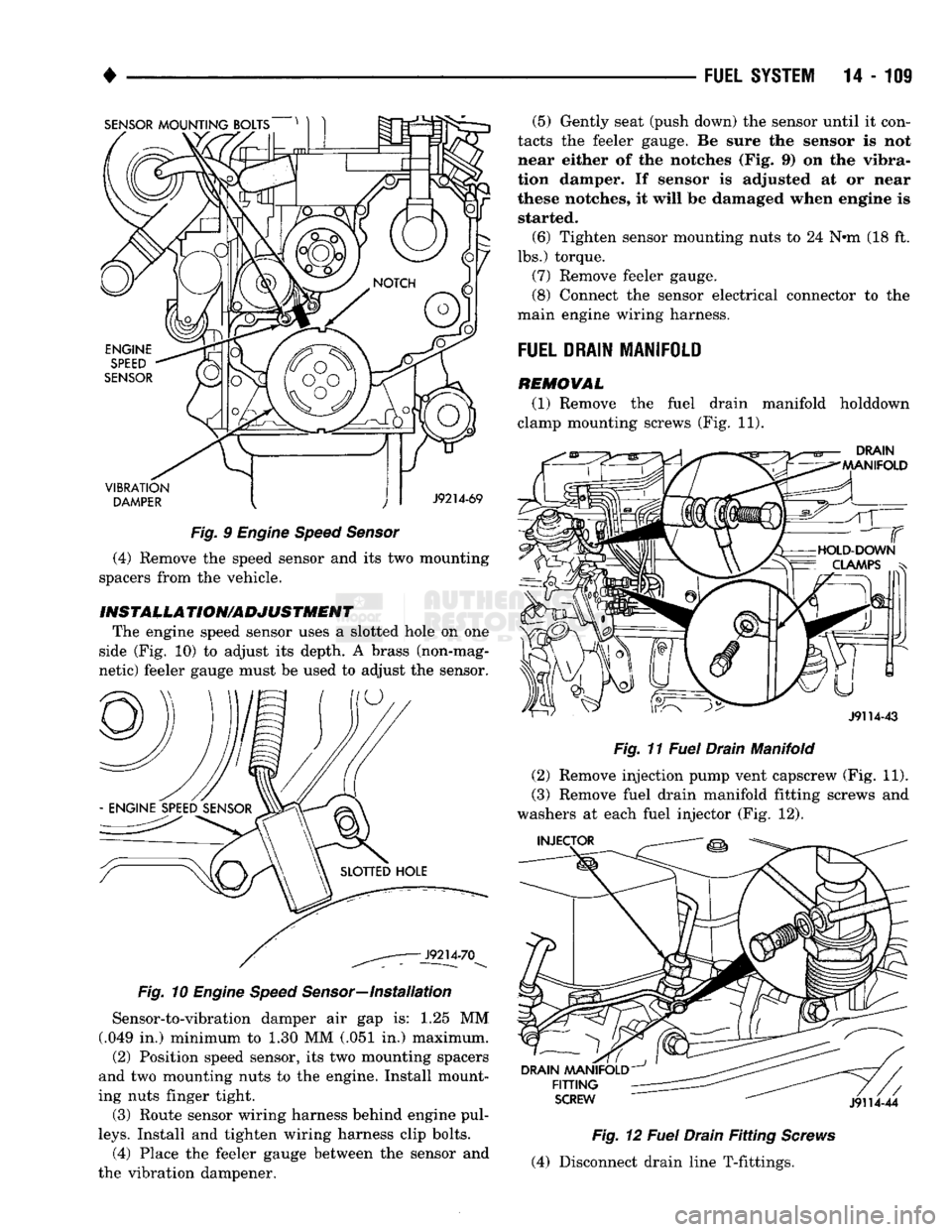

POWERTRAIN CONTROL MODULE

(PCI)

REMOWAL The PCM is located in the engine compartment be

hind the battery and under the left front fender (Fig.

7).

TORQUE CONVERTER

CLUTCH RELAY A/C CLUTCH RELAY STARTER RELAY

AUTO SHUTDOWN RELAY FUEL PUMP RELAY DATA LINK

CONNECTOR POWERTRAIN

CONTROL

MODULE

J9314-164

Fig. 7 Powertrain Control

Module

(PCM) Location (1) Disconnect the negative battery cable at bat

tery.

(2) Remove battery holddown clamps.

(3) Position battery to gain access to PCM,

(4) Remove 60-way electrical connector from the

PCM (one screw) (Fig. 8).

PCM

MOUNTING BOLTS

PCM CONNECTOR CONNECTOR MOUNTING

BOLT

J9314-165

Fig. 8 PCM Mounting (5) Remove the three PCM-to-mounting bracket

bolts (Fig. 8). Do not remove the PCM mounting

bracket from the fender.

(6) Remove PCM from vehicle.

INSTALLATION (1) Check pins in 60-way PCM connector for dam

age.

Repair as necessary.

(2) Position PCM and install mounting bolts.

Tighten bolts to 4 N*m (35 in. lbs.) torque.

(3) Connect 60-way electrical connector to the

PCM. Tighten connector mounting screw to 4 N#m (35 in. lbs.) torque. (4) Install battery. (5) Connect battery cable to battery.

ENGINE

SPEED SENSOR

The engine speed sensor (sometimes referred to as

the crankshaft position sensor) is located on the front of engine (Fig. 9). Two spacers located behind the

sensor are used to position sensor over the vibration

damper.

REMOWAL Before removing the sensor, note the position and

routing of the sensor wiring harness. This routing must be maintained to prevent wiring from contact

ing belt or pulleys.

(1) Disconnect the speed sensor pigtail harness

from the main engine wiring harness near the front/

top of engine.

(2) Remove the clip bolts from the sensor pigtail

wiring harness. (3) Remove the two speed sensor mounting nuts

(Fig. 9).

Page 928 of 1502

SENSOR

MOUNTING BOLTS

VIBRATION

DAMPER

J9214-69

Fig.

9

Engine Speed Sensor

(4) Remove the speed sensor and its two mounting

spacers from the vehicle.

INST

ALL A

TION/ADJUSTMENT

The engine speed sensor uses a slotted hole on one

side (Fig. 10) to adjust its depth. A brass (non-mag

netic) feeler gauge must be used to adjust the sensor.

Fig.

10

Engine Speed

Sensor—Installation

Sensor-to-vibration damper air gap is: 1.25 MM

(.049 in.) minimum to 1.30 MM (.051 in.) maximum.

(2) Position speed sensor, its two mounting spacers

and two mounting nuts to the engine. Install mount

ing nuts finger tight.

(3) Route sensor wiring harness behind engine pul

leys.

Install and tighten wiring harness clip bolts. (4) Place the feeler gauge between the sensor and

the vibration dampener. (5) Gently seat (push down) the sensor until it con

tacts the feeler gauge. Be sure the sensor is not

near either of the notches (Fig. 9) on the vibra

tion damper. If sensor is adjusted at or near

these notches, it will be damaged when engine is started.

(6) Tighten sensor mounting nuts to 24 N#m (18 ft.

lbs.) torque.

(7) Remove feeler gauge.

(8) Connect the sensor electrical connector to the

main engine wiring harness.

FUEL

DRAIN

MANIFOLD

REMOVAL

(1) Remove the fuel drain manifold holddown

clamp mounting screws (Fig. 11).

DRAIN

MANIFOLD

J9114-43

Fig.

11

Fuel

Drain Manifold

(2) Remove injection pump vent capscrew (Fig. 11).

(3) Remove fuel drain manifold fitting screws and

washers at each fuel injector (Fig. 12).

INJECTOR

DRAIN

MANIFOLD

FITTING

SCREW

J9114-44

Fig.

12

Fuel

Drain

Fitting

Screws

(4) Disconnect drain line T-fittings.

Page 929 of 1502

14

- 110

FUEL SYSTEM

SENSOR

J9114-39

Fig.

13 Fuel/Water Separator

Filter

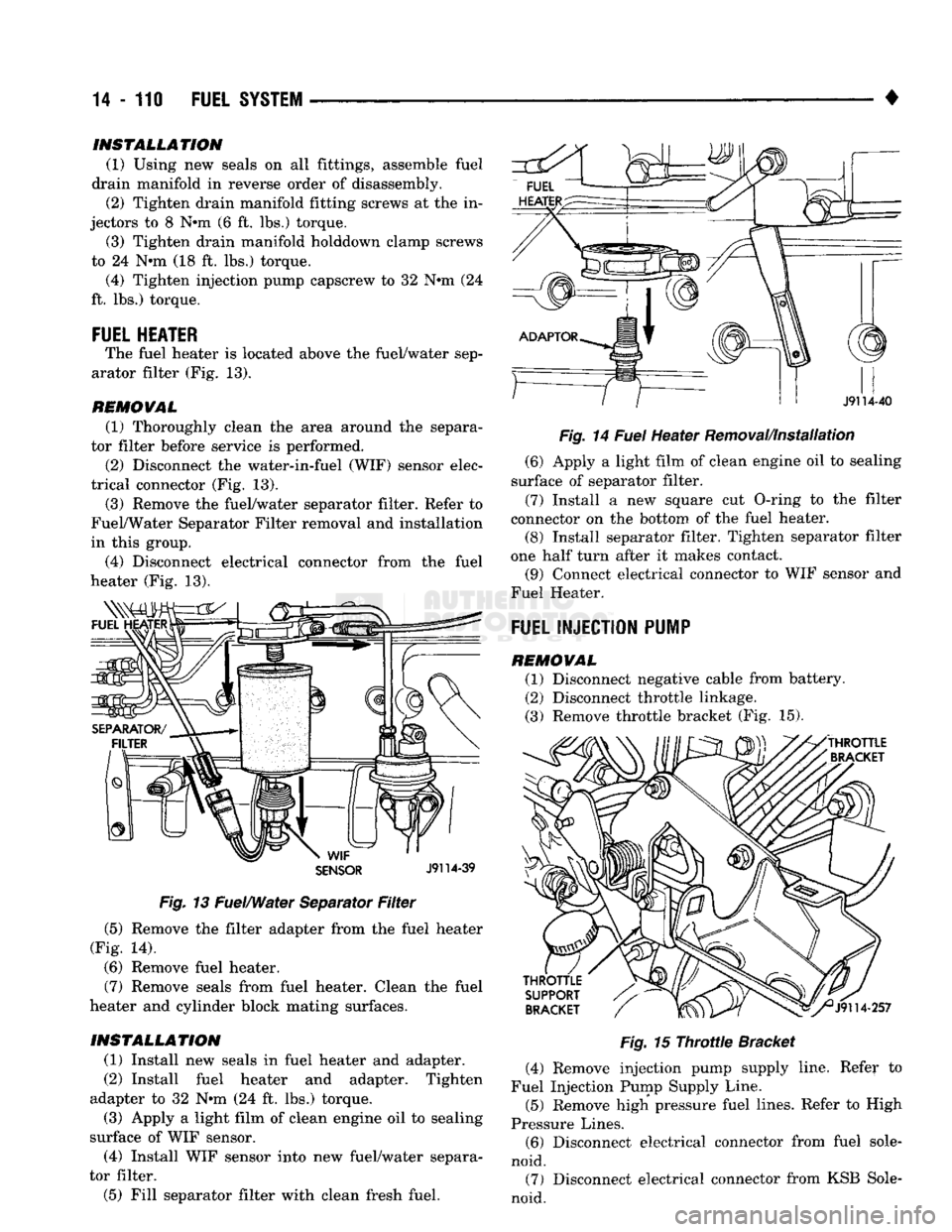

(5) Remove the filter adapter from the fuel heater

(Fig. 14).

(6) Remove fuel heater.

(7) Remove seals from fuel heater. Clean the fuel

heater and cylinder block mating surfaces.

INSTALLATION

(1) Install new seals in fuel heater and adapter.

(2) Install fuel heater and adapter. Tighten

adapter to 32 Nrn (24 ft. lbs.) torque. (3) Apply a light film of clean engine oil to sealing

surface of WIF sensor.

(4) Install WIF sensor into new fuel/water separa

tor filter.

(5) Fill separator filter with clean fresh fuel. •

Fig.

14

Fuel

Heater Removal/Installation (6) Apply a light film of clean engine oil to sealing

surface of separator filter.

(7) Install a new square cut O-ring to the filter

connector on the bottom of the fuel heater. (8) Install separator filter. Tighten separator filter

one half turn after it makes contact. (9) Connect electrical connector to WIF sensor and

Fuel Heater.

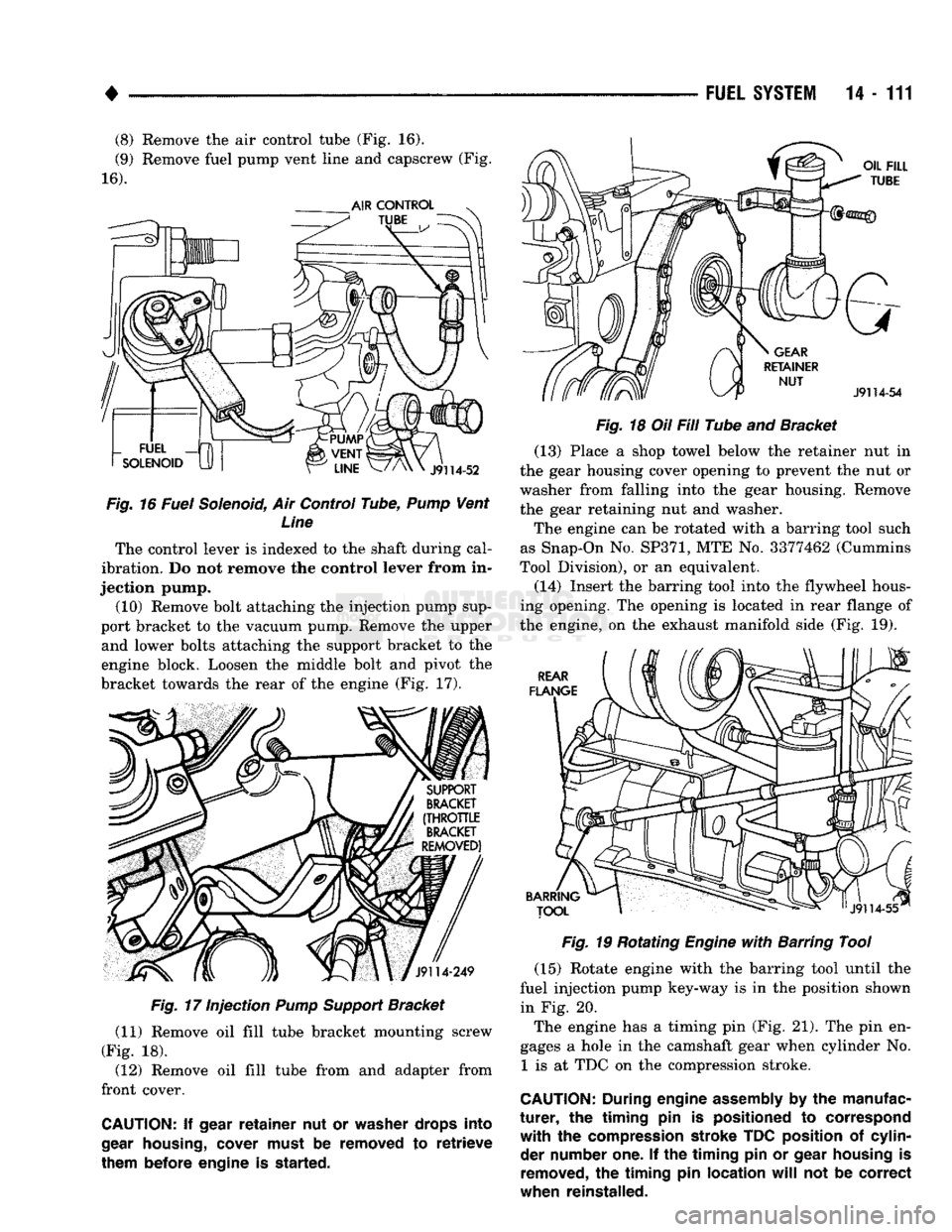

FUEL INJECTION PUMP

REMOVAL (1) Disconnect negative cable from battery.

(2) Disconnect throttle linkage.

(3) Remove throttle bracket (Fig. 15).

Fig.

15

Throttle

Bracket

(4) Remove injection pump supply line. Refer to

Fuel Injection Pump Supply Line.

(5) Remove high pressure fuel lines. Refer to High

Pressure Lines. (6) Disconnect electrical connector from fuel sole

noid. (7) Disconnect electrical connector from KSB Sole

noid.

INSTALLATION

(1) Using new seals on all fittings, assemble fuel

drain manifold in reverse order of disassembly. (2) Tighten drain manifold fitting screws at the in

jectors to 8 N#m (6 ft. lbs.) torque. (3) Tighten drain manifold holddown clamp screws

to 24 N*m (18 ft. lbs.) torque. (4) Tighten injection pump capscrew to 32 N#m (24

ft. lbs.) torque.

FUEL HEATER

The fuel heater is located above the fuel/water sep

arator filter (Fig. 13).

REMOVAL

(1) Thoroughly clean the area around the separa

tor filter before service is performed.

(2) Disconnect the water-in-fuel (WIF) sensor elec

trical connector (Fig. 13). (3) Remove the fuel/water separator filter. Refer to

Fuel/Water Separator Filter removal and installation

in this group.

(4) Disconnect electrical connector from the fuel

heater (Fig. 13).

Page 930 of 1502

•

(8) Remove the air control tube (Fig. 16).

(9) Remove fuel pump vent line and capscrew (Fig.

16).

Fig.

16 Fuel Solenoid, Air Control Tube,

Pump

Vent Line

The control lever is indexed to the shaft during cal

ibration. Do not remove the control lever from in

jection pump. (10) Remove bolt attaching the injection pump sup

port bracket to the vacuum pump. Remove the upper and lower bolts attaching the support bracket to the

engine block. Loosen the middle bolt and pivot the

bracket towards the rear of the engine (Fig. 17).

Fig.

17 Injection

Pump

Support

Bracket

(11) Remove oil fill tube bracket mounting screw

(Fig. 18). (12) Remove oil fill tube from and adapter from

front cover.

CAUTION:

If

gear

retainer

nut or

washer drops into

gear

housing,

cover must

be

removed

to

retrieve

them before engine

is

started. FUEL

SYSTEM

14-111

Fig.

18 Oil Fill Tube and Bracket (13) Place a shop towel below the retainer nut in

the gear housing cover opening to prevent the nut or

washer from falling into the gear housing. Remove

the gear retaining nut and washer.

The engine can be rotated with a barring tool such

as Snap-On No.

SP371,

MTE No. 3377462 (Cummins

Tool Division), or an equivalent.

(14) Insert the barring tool into the flywheel hous

ing opening. The opening is located in rear flange of

the engine, on the exhaust manifold side (Fig. 19).

Fig.

19 Rotating

Engine

with

Barring Tool

(15) Rotate engine with the barring tool until the

fuel injection pump key-way is in the position shown in Fig. 20.

The engine has a timing pin (Fig. 21). The pin en

gages a hole in the camshaft gear when cylinder No. 1 is at TDC on the compression stroke.

CAUTION:

During

engine

assembly

by the

manufac

turer,

the

timing

pin is

positioned

to

correspond

with

the

compression stroke TDC position

of

cylin der number one.

If the

timing

pin or

gear housing

is

removed,

the

timing

pin

location

will

not be

correct

when reinstalled.