technical specifications FIAT STILO 2006 1.G Owners Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2006, Model line: STILO, Model: FIAT STILO 2006 1.GPages: 274, PDF Size: 4.76 MB

Page 175 of 274

174

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

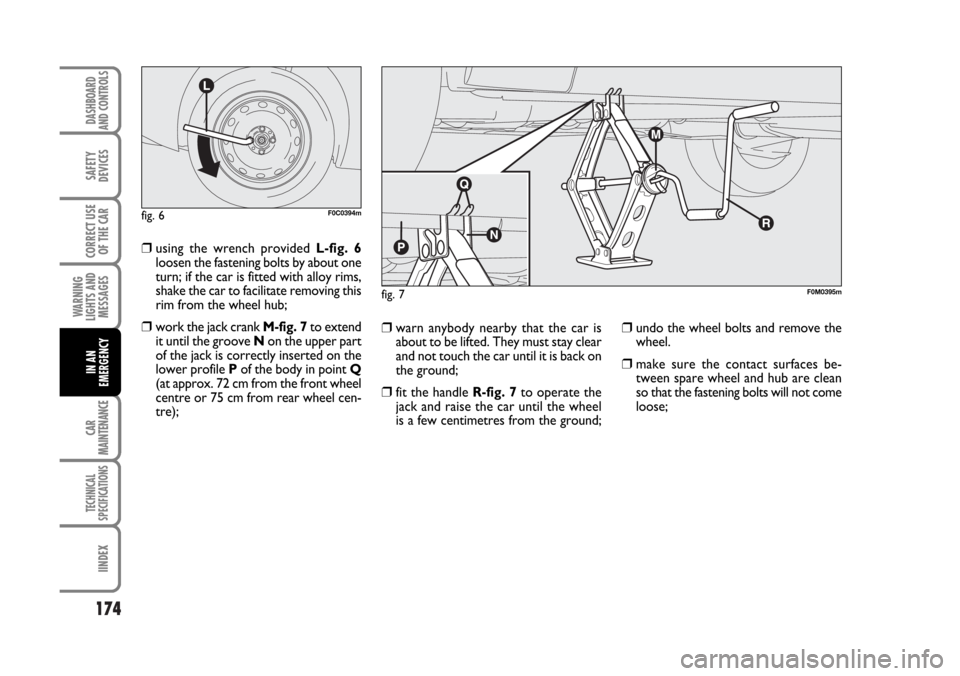

❒using the wrench provided L-fig. 6

loosen the fastening bolts by about one

turn; if the car is fitted with alloy rims,

shake the car to facilitate removing this

rim from the wheel hub;

❒work the jack crank M-fig. 7to extend

it until the groove Non the upper part

of the jack is correctly inserted on the

lower profile Pof the body in point Q

(at approx. 72 cm from the front wheel

centre or 75 cm from rear wheel cen-

tre);❒undo the wheel bolts and remove the

wheel.

❒make sure the contact surfaces be-

tween spare wheel and hub are clean

so that the fastening bolts will not come

loose;

fig. 6F0C0394m

fig. 7F0M0395m

❒warn anybody nearby that the car is

about to be lifted. They must stay clear

and not touch the car until it is back on

the ground;

❒fit the handle R-fig. 7to operate the

jack and raise the car until the wheel

is a few centimetres from the ground;

Page 176 of 274

175

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

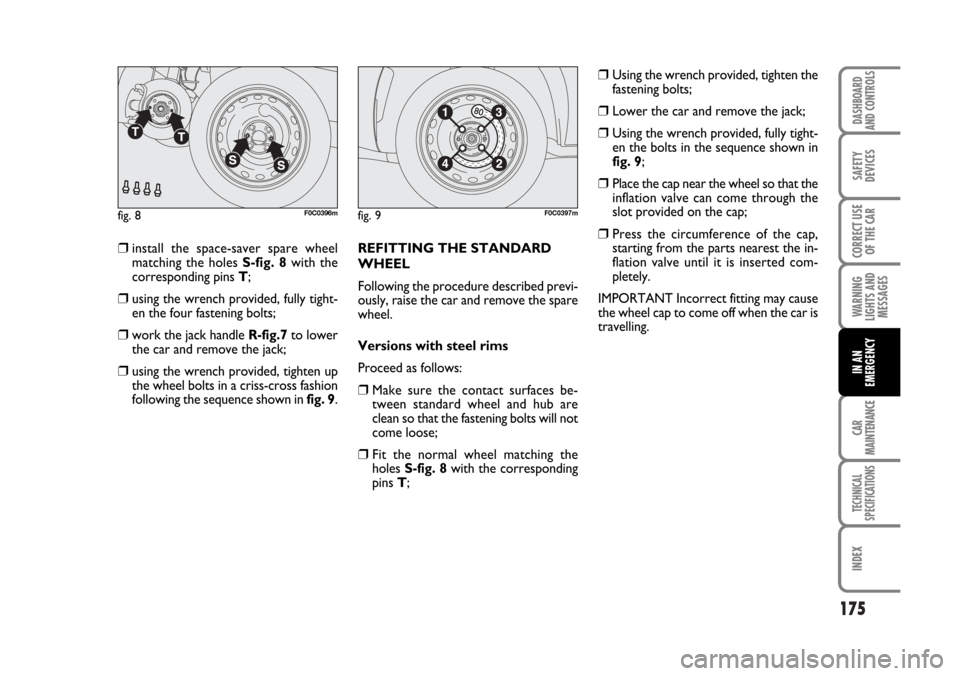

❒install the space-saver spare wheel

matching the holes S-fig. 8with the

corresponding pins T;

❒using the wrench provided, fully tight-

en the four fastening bolts;

❒work the jack handle R-fig.7to lower

the car and remove the jack;

❒using the wrench provided, tighten up

the wheel bolts in a criss-cross fashion

following the sequence shown in fig. 9.REFITTING THE STANDARD

WHEEL

Following the procedure described previ-

ously, raise the car and remove the spare

wheel.

Versions with steel rims

Proceed as follows:

❒Make sure the contact surfaces be-

tween standard wheel and hub are

clean so that the fastening bolts will not

come loose;

❒Fit the normal wheel matching the

holes S-fig. 8with the corresponding

pins T;

❒Using the wrench provided, tighten the

fastening bolts;

❒Lower the car and remove the jack;

❒Using the wrench provided, fully tight-

en the bolts in the sequence shown in

fig. 9;

❒Place the cap near the wheel so that the

inflation valve can come through the

slot provided on the cap;

❒Press the circumference of the cap,

starting from the parts nearest the in-

flation valve until it is inserted com-

pletely.

IMPORTANT Incorrect fitting may cause

the wheel cap to come off when the car is

travelling.

fig. 8F0C0396mfig. 9F0C0397m

Page 177 of 274

176

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

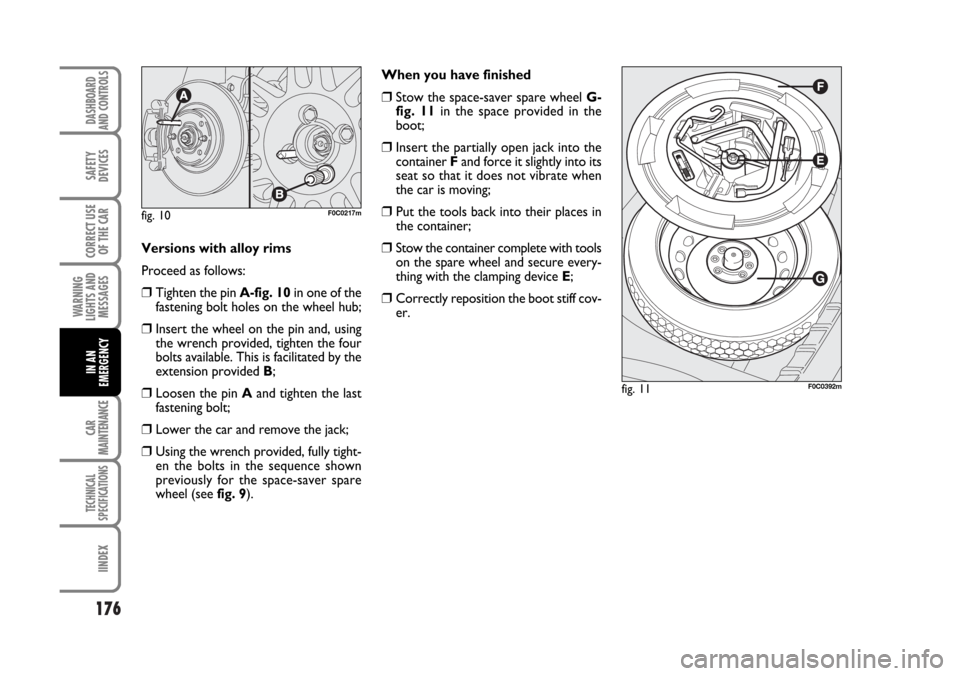

Versions with alloy rims

Proceed as follows:

❒Tighten the pin A-fig. 10in one of the

fastening bolt holes on the wheel hub;

❒Insert the wheel on the pin and, using

the wrench provided, tighten the four

bolts available. This is facilitated by the

extension provided B;

❒Loosen the pin Aand tighten the last

fastening bolt;

❒Lower the car and remove the jack;

❒Using the wrench provided, fully tight-

en the bolts in the sequence shown

previously for the space-saver spare

wheel (see fig. 9).When you have finished

❒Stow the space-saver spare wheel G-

fig. 11in the space provided in the

boot;

❒Insert the partially open jack into the

container Fand force it slightly into its

seat so that it does not vibrate when

the car is moving;

❒ Put the tools back into their places in

the container;

❒Stow the container complete with tools

on the spare wheel and secure every-

thing with the clamping device E;

❒Correctly reposition the boot stiff cov-

er.

fig. 10F0C0217m

fig. 11F0C0392m

Page 178 of 274

177

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

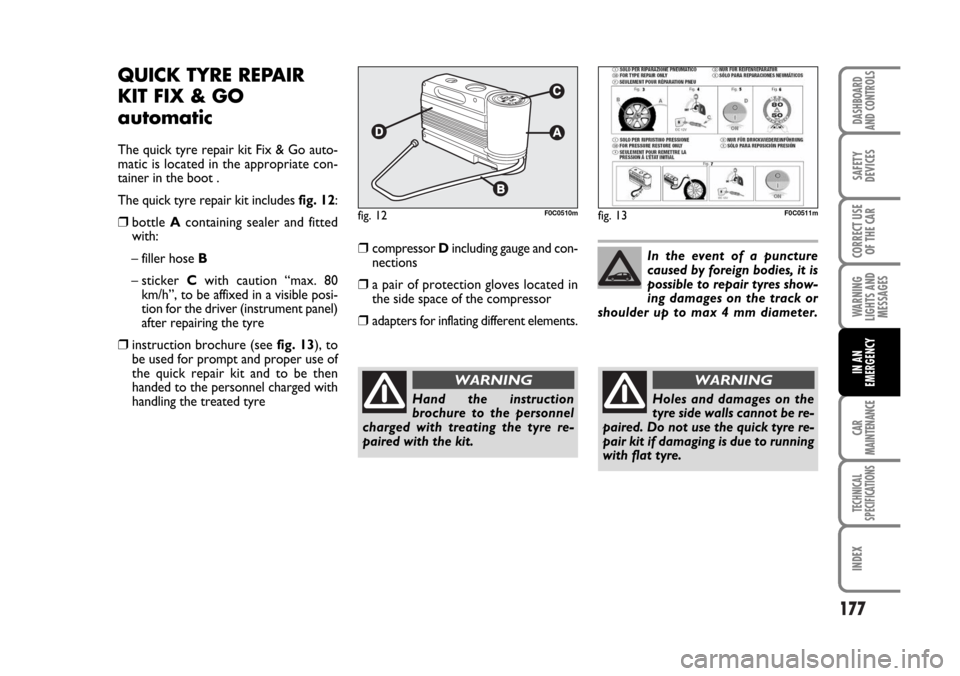

QUICK TYRE REPAIR

KIT FIX & GO

automatic

The quick tyre repair kit Fix & Go auto-

matic is located in the appropriate con-

tainer in the boot .

The quick tyre repair kit includes fig. 12:

❒bottle A containing sealer and fitted

with:

– filler hose B

– sticker Cwith caution “max. 80

km/h”, to be affixed in a visible posi-

tion for the driver (instrument panel)

after repairing the tyre

❒instruction brochure (see fig. 13), to

be used for prompt and proper use of

the quick repair kit and to be then

handed to the personnel charged with

handling the treated tyre

fig. 12F0C0510mfig. 13F0C0511m

Hand the instruction

brochure to the personnel

charged with treating the tyre re-

paired with the kit.

WARNING

In the event of a puncture

caused by foreign bodies, it is

possible to repair tyres show-

ing damages on the track or

shoulder up to max 4 mm diameter.

Holes and damages on the

tyre side walls cannot be re-

paired. Do not use the quick tyre re-

pair kit if damaging is due to running

with flat tyre.

WARNING

❒compressor Dincluding gauge and con-

nections

❒a pair of protection gloves located in

the side space of the compressor

❒adapters for inflating different elements.

Page 179 of 274

178

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

IT SHOULD BE NOTICED THAT:

The sealing fluid of the quick tyre repair

kit is effective with external temperatures

between –20 °C and +50 °C. INFLATING PROCEDURE

The compressor shall not be

operated for more than 20

minutes. Risk of overheating!. Tyres

repaired with the quick tyre repair kit

shall be used temporarily only.

WARNING

The cylinder contains ethyl-

ene glycol. The cylinder con-

tains latex: it can cause allergic re-

actions. It is harmful if ingested or in-

haled and irritant for the eyes and in

case of contact. In case of contact

rinse immediately with water and

take off contaminated clothes. If

swallowed, do not induce vomit, rinse

out the mouth, drink a lot of water

and call the doctor immediately.

Keep away from children. This prod-

uct must not be used by asthmatics.

Do not inhale vapours. Call the doc-

tor immediately in case of allergic re-

actions. Keep the cylinder in the

space provided for the purpose and

far from heat. The sealing fluid has

limited life. Replace the cylinder if

sealer has run out.

WARNING

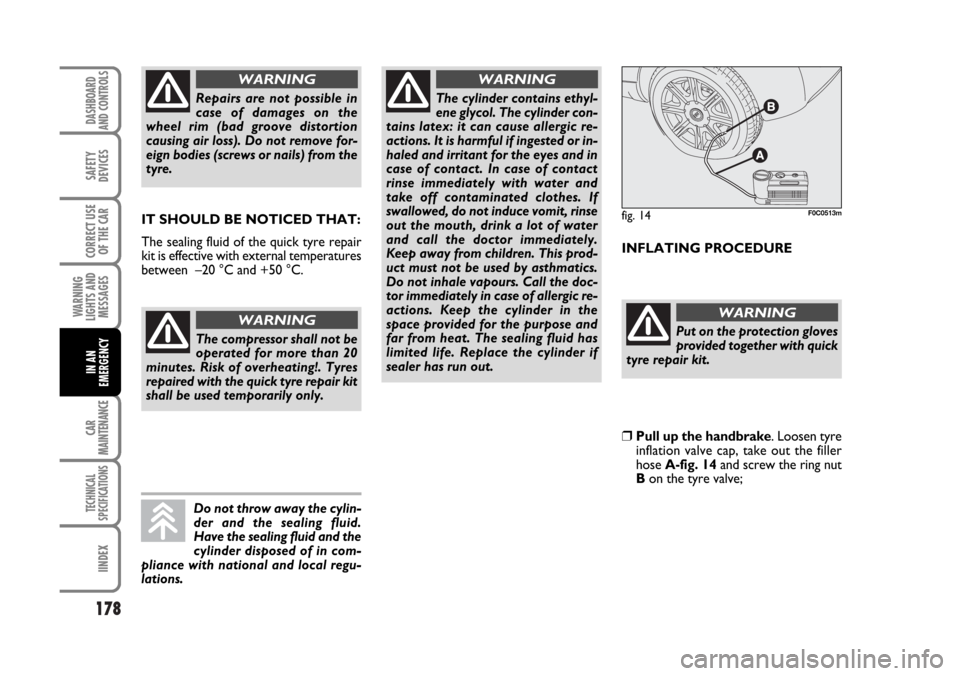

fig. 14F0C0513m

Put on the protection gloves

provided together with quick

tyre repair kit.

WARNING

❒Pull up the handbrake. Loosen tyre

inflation valve cap, take out the filler

hose A-fig. 14and screw the ring nut

Bon the tyre valve;

Repairs are not possible in

case of damages on the

wheel rim (bad groove distortion

causing air loss). Do not remove for-

eign bodies (screws or nails) from the

tyre.

WARNING

Do not throw away the cylin-

der and the sealing fluid.

Have the sealing fluid and the

cylinder disposed of in com-

pliance with national and local regu-

lations.

Page 180 of 274

179

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

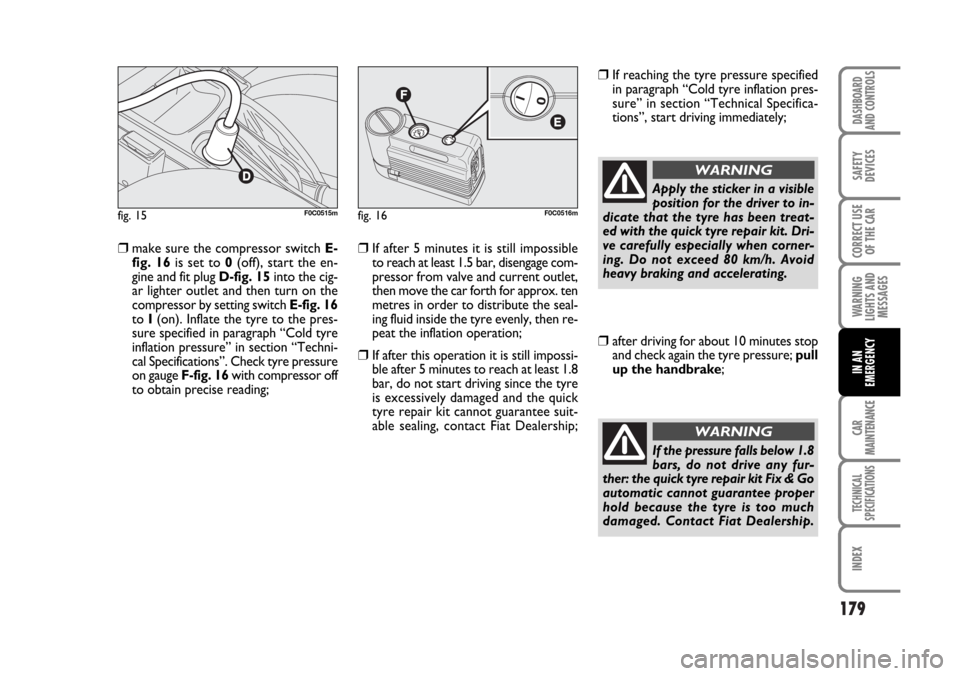

❒make sure the compressor switch E-

fig. 16is set to 0(off), start the en-

gine and fit plug D-fig. 15into the cig-

ar lighter outlet and then turn on the

compressor by setting switch E-fig. 16

to I(on). Inflate the tyre to the pres-

sure specified in paragraph “Cold tyre

inflation pressure” in section “Techni-

cal Specifications”. Check tyre pressure

on gauge F-fig. 16with compressor off

to obtain precise reading; ❒If after 5 minutes it is still impossible

to reach at least 1.5 bar, disengage com-

pressor from valve and current outlet,

then move the car forth for approx. ten

metres in order to distribute the seal-

ing fluid inside the tyre evenly, then re-

peat the inflation operation;

❒If after this operation it is still impossi-

ble after 5 minutes to reach at least 1.8

bar, do not start driving since the tyre

is excessively damaged and the quick

tyre repair kit cannot guarantee suit-

able sealing, contact Fiat Dealership;

fig. 15F0C0515mfig. 16F0C0516m

Apply the sticker in a visible

position for the driver to in-

dicate that the tyre has been treat-

ed with the quick tyre repair kit. Dri-

ve carefully especially when corner-

ing. Do not exceed 80 km/h. Avoid

heavy braking and accelerating.

WARNING

❒after driving for about 10 minutes stop

and check again the tyre pressure; pull

up the handbrake;

If the pressure falls below 1.8

bars, do not drive any fur-

ther: the quick tyre repair kit Fix & Go

automatic cannot guarantee proper

hold because the tyre is too much

damaged. Contact Fiat Dealership.

WARNING

❒If reaching the tyre pressure specified

in paragraph “Cold tyre inflation pres-

sure” in section “Technical Specifica-

tions”, start driving immediately;

Page 181 of 274

180

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

❒if at least 1.8 bar pressure is read, re-

store proper pressure (with engine

running and handbrake on) and restart;

❒drive with the utmost care to the near-

est Fiat Dealership.

It is of vital importance to

communicate that the tyre

has been repaired using the quick tyre

repair kit. Hand the instruction

brochure to the personnel charged

with treating the tyre repaired with

the kit.

WARNING

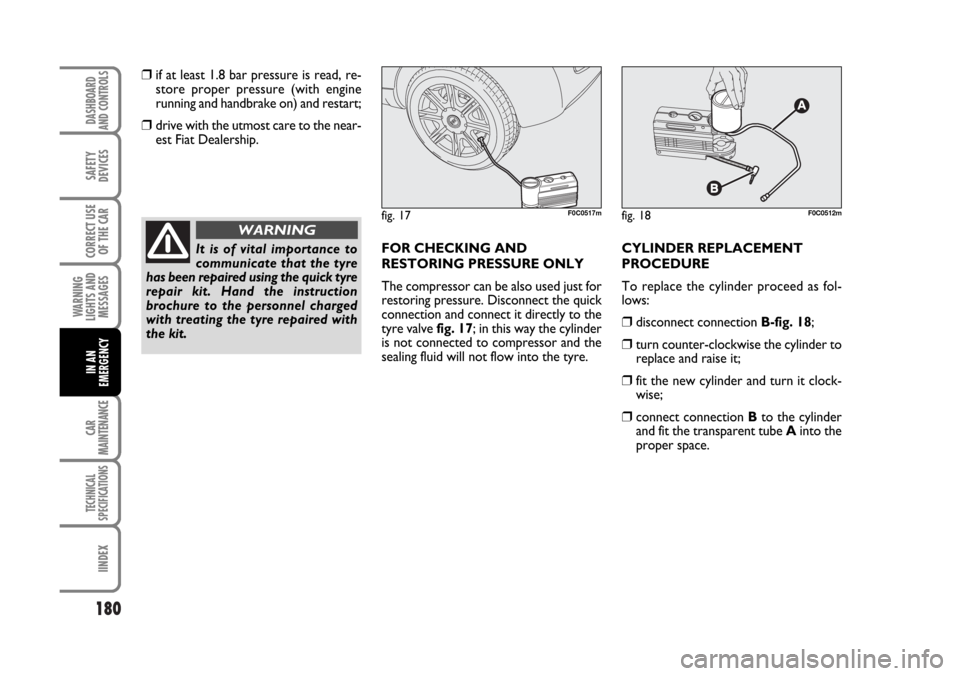

FOR CHECKING AND

RESTORING PRESSURE ONLY

The compressor can be also used just for

restoring pressure. Disconnect the quick

connection and connect it directly to the

tyre valve fig. 17; in this way the cylinder

is not connected to compressor and the

sealing fluid will not flow into the tyre. CYLINDER REPLACEMENT

PROCEDURE

To replace the cylinder proceed as fol-

lows:

❒disconnect connection B-fig. 18;

❒turn counter-clockwise the cylinder to

replace and raise it;

❒fit the new cylinder and turn it clock-

wise;

❒connect connection Bto the cylinder

and fit the transparent tube Ainto the

proper space.

fig. 17F0C0517mfig. 18F0C0512m

Page 182 of 274

181

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

WHEN NEEDING TO

CHANGE A BULB

GENERAL INSTRUCTIONS

❒When a light is not working, check that

the corresponding fuse is intact before

changing a bulb. For the location of fus-

es, refer to the paragraph “If a fuse

blows” in this section;

❒ Before changing a bulb check the con-

tacts for oxidation;

❒Burnt bulbs must be replaced by oth-

ers of the same type and power;

❒ Always check the height of the head-

light beam after changing a bulb.Halogen bulbs must be han-

dled touching only the metal-

lic part. If the transparent bulb

is touched with the fingers, its

lighting intensity is reduced and life of

the bulb may be compromised. If

touched accidentally, rub the bulb with

a cloth moistened with alcohol and al-

low to dry.

Modifications or repairs to

the electrical system (elec-

tronic control units) carried out in-

correctly and without bearing the fea-

tures of the system in mind can cause

malfunctions with the risk of fire.

WARNING

Halogen bulbs contain pres-

surised gas which, if broken,

may cause small fragments of glass to

be projected outwards.

WARNING

Due to high voltage, the bulb

of (Xenon) gas-discharge

headlights must only be replaced by

experts: danger of death! Contact Fi-

at Dealership.

WARNING

IMPORTANT The headlight inner surface

may be lightly misted over: this is not a

fault but a natural fact due to low tem-

perature and the level of air humidity. It

will disappear as soon the headlights are

turned on. The presence of drops inside

the headlights means water infiltration,

therefore contact Fiat Dealership.

Page 183 of 274

182

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

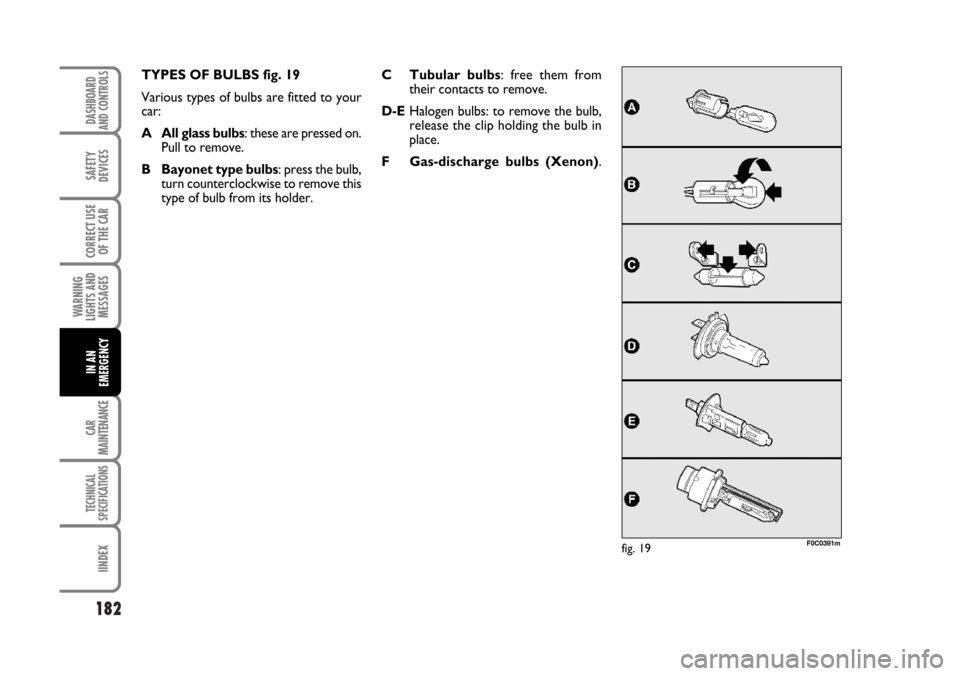

TYPES OF BULBS fig. 19

Various types of bulbs are fitted to your

car:

A All glass bulbs: these are pressed on.

Pull to remove.

B Bayonet type bulbs: press the bulb,

turn counterclockwise to remove this

type of bulb from its holder.

F0C0391m

C Tubular bulbs: free them from

their contacts to remove.

D-EHalogen bulbs: to remove the bulb,

release the clip holding the bulb in

place.

F Gas-discharge bulbs (Xenon).

fig. 19

Page 184 of 274

183

WARNING

LIGHTS AND

MESSAGES

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

E

D

D

F

A

E

B

A

B

B

B

B

B

B

B

A

B

B

A

C

A

C

C

C

A

CH1

H7

H7

D2R

W5W

H1

PY21W

WY5W

P21W

W5W

P4/21W

P21/5W

P21W

R5W

P21W

W2,3W

P21W

P21W

W5W

C5W

W5W

C5W

C10W

C5W

W5W

C5W55W

55W

55W

35W

5W

55W

21W

5W

21W

5W

4W/21W

21W/5W

21W

5W

21W

2,3W

21W

21W

5W

5W

5W

5W

10W

5W

5W

5W

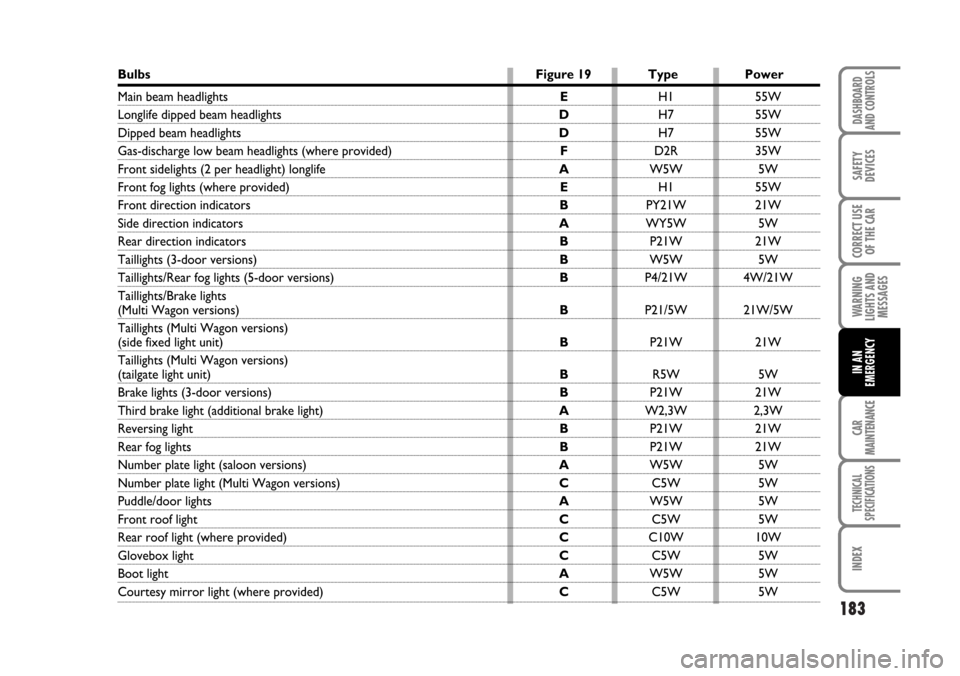

Bulbs Figure 19 Type Power

Main beam headlights

Longlife dipped beam headlights

Dipped beam headlights

Gas-discharge low beam headlights (where provided)

Front sidelights (2 per headlight) longlife

Front fog lights (where provided)

Front direction indicators

Side direction indicators

Rear direction indicators

Taillights (3-door versions)

Taillights/Rear fog lights (5-door versions)

Taillights/Brake lights

(Multi Wagon versions)

Taillights (Multi Wagon versions)

(side fixed light unit)

Taillights (Multi Wagon versions)

(tailgate light unit)

Brake lights (3-door versions)

Third brake light (additional brake light)

Reversing light

Rear fog lights

Number plate light (saloon versions)

Number plate light (Multi Wagon versions)

Puddle/door lights

Front roof light

Rear roof light (where provided)

Glovebox light

Boot light

Courtesy mirror light (where provided)