FORD FESTIVA 1991 Service Manual

Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 321 of 454

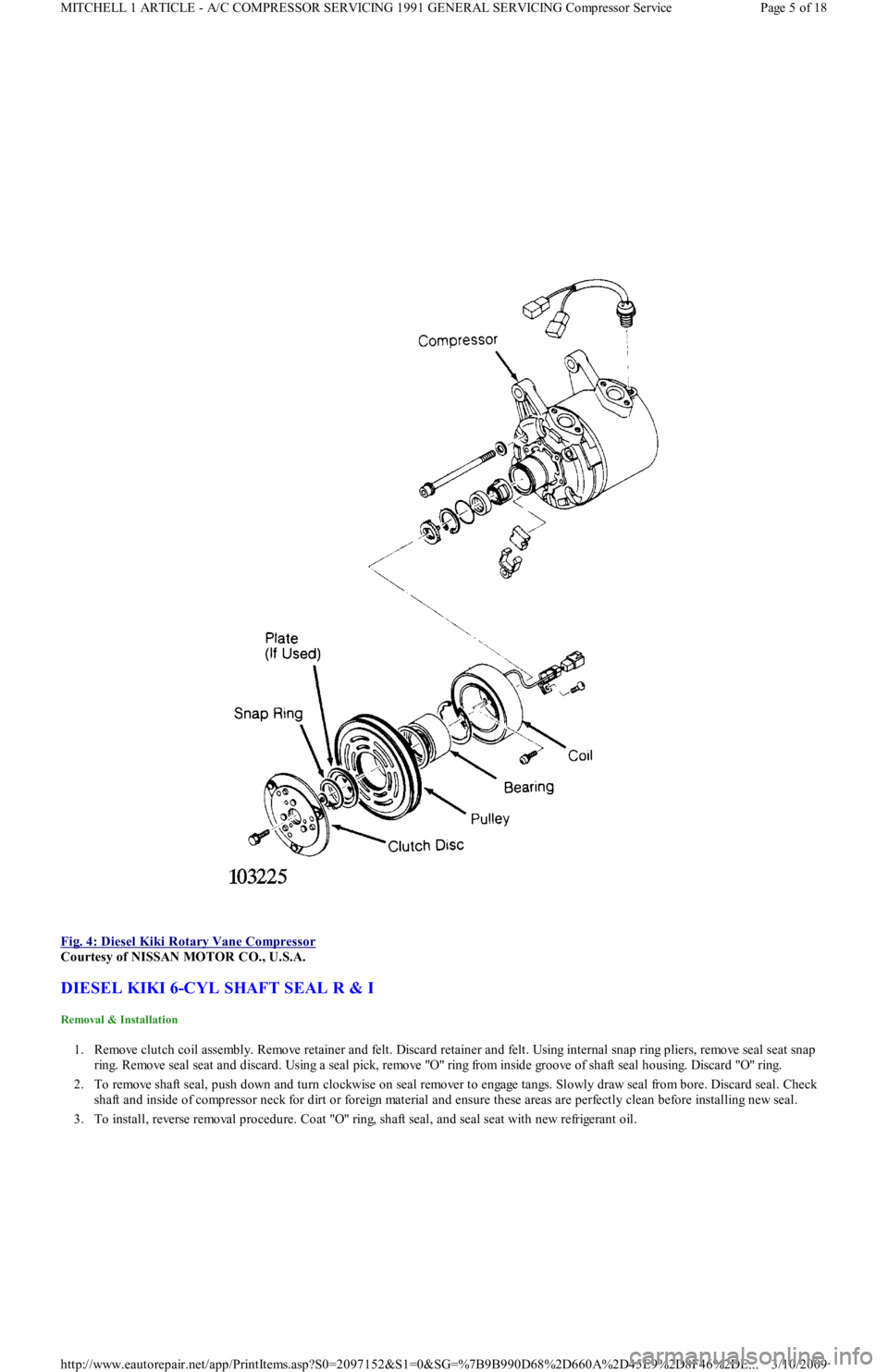

Fig. 4: Diesel Kiki Rotary Vane Compressor

Courtesy of NISSAN MOTOR CO., U.S.A.

DIESEL KIKI 6-CYL SHAFT SEAL R & I

Removal & Installation

1. Remove clutch coil assembly. Remove retainer and felt. Discard retainer and felt. Using internal snap ring pliers, remove seal seat snap

ring. Remove seal seat and discard. Using a seal pick, remove "O" ring from inside groove of shaft seal housing. Discard "O" ring.

2. To remove shaft seal, push down and turn clockwise on seal remover to engage tangs. Slowly draw seal from bore. Discard seal. Check

shaft and inside of compressor neck for dirt or foreign material and ensure these areas are perfectly clean before installing new seal.

3. To install, reverse removal procedure. Coat "O" ring, shaft seal, and seal seat with new refrigerant oil.

Page 5 of 18 MITCHELL 1 ARTICLE - A/C COMPRESSOR SERVICING 1991 GENERAL SERVICING Compressor Service

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 322 of 454

Fig. 5: Diesel Kiki 6

-Cylinder Compressor

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

FORD FX-15 CLUTCH R & I

Removal

1. Using Clutch Holder (00 41 0812 05), remove clutch plate retaining bolt and discard. Using an 8 mm bolt threaded into clutch plate,

remove clutch plate and shim(s). See Fig. 6

.

2. Remove snap ring and pulley assembly. Install Shaft Protector (49 UN01 47) over shaft seal opening. Use a 2-jaw puller to remove

clutch coil from compressor.

Installation

1. Ensure clutch coil mounting surface is clean. Use Coil Installer (49 UN01 046) and 2-jaw puller engaged to rear side of compressor

front mounts to press coil into place.

2. Install pulley assembly. Install pulley assembly snap ring with bevel side of snap ring facing out. Install shim(s) and clutch plate. Install

a NEW clutch plate retaining bolt and tighten to 96-120 INCH lbs. (11-14 N.m).

3. Use a feeler gauge to check clearance between clutch plate and pulley assembly. Clearance should be .018-.033" (.46-.84 mm). If

clearance is incorrect, add or remove shims as necessary.

FORD FX-15 SHAFT SEAL R & I

Removal

1. Using Clutch Holder (000 41 0812 05), remove clutch plate retaining bolt and discard. Using an 8 mm bolt threaded into clutch plate,

remove clutch plate and shim(s). See Fig. 6

.

2. Remove shaft felt seal. Thoroughly clean seal area of compressor. Remove shaft seal retaining snap ring. Position Shaft Seal Remover

(49 UN01 044) over compressor shaft.

3. Push shaft seal remover downward against seal. Ensure end of shaft seal remover is engaged with inside of seal. Rotate shaft seal

remover clockwise to expand remover tip inside seal. Pull shaft seal from compressor.

Installation

1. Lubricate shaft seal protector and shaft seal with refrigerant oil. Install shaft seal on shaft seal protector so lip seal is toward compressor

(large end of shaft seal protector).

2. Install shaft seal protector on compressor shaft. Using shaft seal installer (49 UN01 043), push shaft seal down seal protector until seal

is seated.

3. Remove shaft seal installer and protector. Install a NEW shaft seal retaining snap ring and shaft seal felt. Install shim(s) and clutch plate.

Install a NEW clutch plate retaining bolt and tighten to 91-120 INCH lbs. (11-14 N.m).

4. Use a feeler gauge to check clearance between clutch plate and pulley assembly. Clearance should be .018-.033" (.46-.84 mm). If

clearance is incorrect, add or remove shims as necessary.

Page 6 of 18 MITCHELL 1 ARTICLE - A/C COMPRESSOR SERVICING 1991 GENERAL SERVICING Compressor Service

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 323 of 454

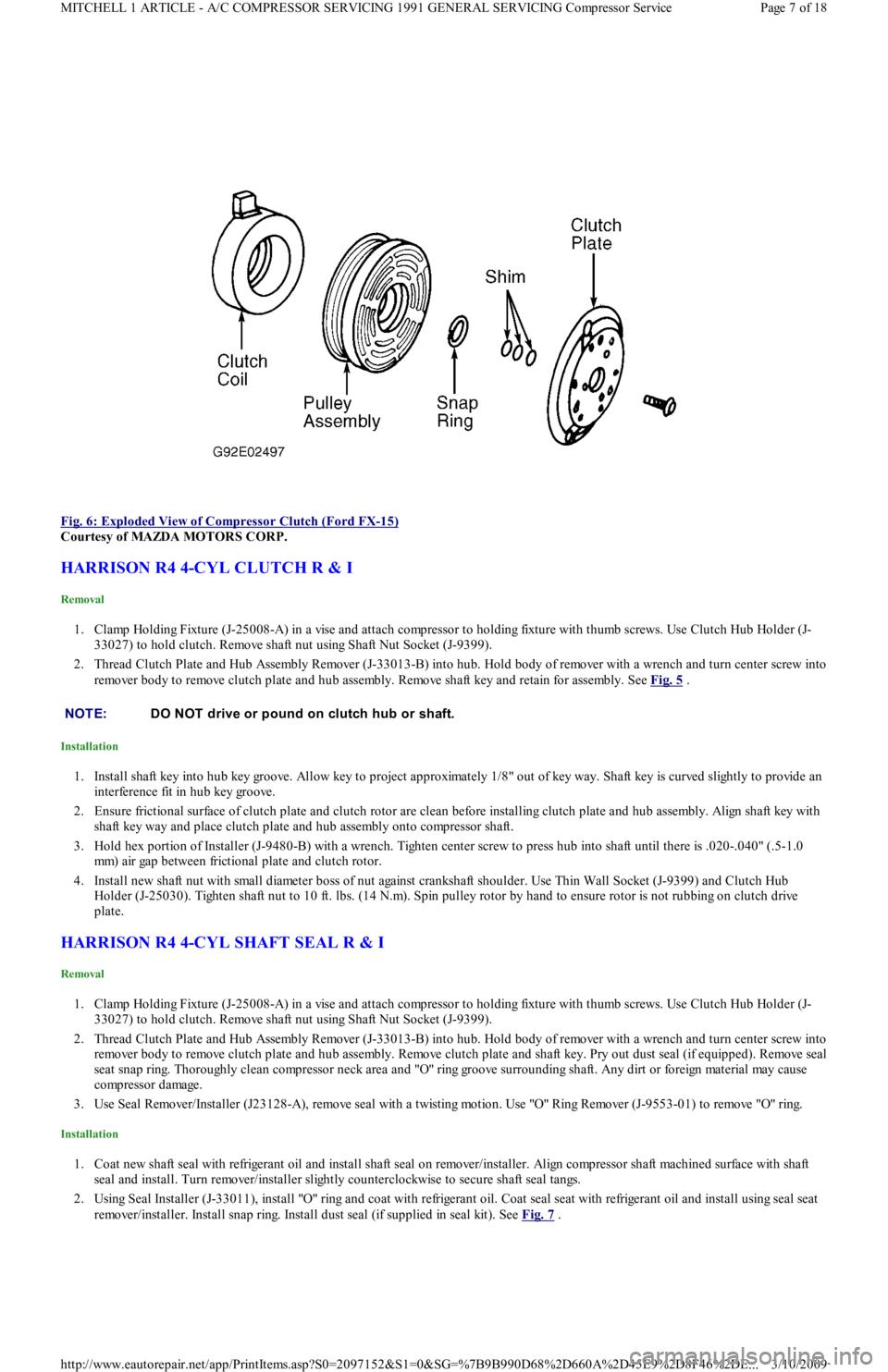

Fig. 6: Exploded View of Compressor Clutch (Ford FX

-15)

Courtesy of MAZDA MOTORS CORP.

HARRISON R4 4-CYL CLUTCH R & I

Removal

1. Clamp Holding Fixture (J-25008-A) in a vise and attach compressor to holding fixture with thumb screws. Use Clutch Hub Holder (J-

33027) to hold clutch. Remove shaft nut using Shaft Nut Socket (J-9399).

2. Thread Clutch Plate and Hub Assembly Remover (J-33013-B) into hub. Hold body of remover with a wrench and turn center screw into

remover body to remove clutch plate and hub assembly. Remove shaft key and retain for assembly. See Fig. 5

.

Installation

1. Install shaft key into hub key groove. Allow key to project approximately 1/8" out of key way. Shaft key is curved slightly to provide an

interference fit in hub key groove.

2. Ensure frictional surface of clutch plate and clutch rotor are clean before installing clutch plate and hub assembly. Align shaft key with

shaft key way and place clutch plate and hub assembly onto compressor shaft.

3. Hold hex portion of Installer (J-9480-B) with a wrench. Tighten center screw to press hub into shaft until there is .020-.040" (.5-1.0

mm) air gap between frictional plate and clutch rotor.

4. Install new shaft nut with small diameter boss of nut against crankshaft shoulder. Use Thin Wall Socket (J-9399) and Clutch Hub

Holder (J-25030). Tighten shaft nut to 10 ft. lbs. (14 N.m). Spin pulley rotor by hand to ensure rotor is not rubbing on clutch drive

plate.

HARRISON R4 4-CYL SHAFT SEAL R & I

Removal

1. Clamp Holding Fixture (J-25008-A) in a vise and attach compressor to holding fixture with thumb screws. Use Clutch Hub Holder (J-

33027) to hold clutch. Remove shaft nut using Shaft Nut Socket (J-9399).

2. Thread Clutch Plate and Hub Assembly Remover (J-33013-B) into hub. Hold body of remover with a wrench and turn center screw into

remover body to remove clutch plate and hub assembly. Remove clutch plate and shaft key. Pry out dust seal (if equipped). Remove seal

seat snap ring. Thoroughly clean compressor neck area and "O" ring groove surrounding shaft. Any dirt or foreign material may cause

compressor damage.

3. Use Seal Remover/Installer (J23128-A), remove seal with a twisting motion. Use "O" Ring Remover (J-9553-01) to remove "O" ring.

Installation

1. Coat new shaft seal with refrigerant oil and install shaft seal on remover/installer. Align compressor shaft machined surface with shaft

seal and install. Turn remover/installer slightly counterclockwise to secure shaft seal tangs.

2. Using Seal Installer (J-33011), install "O" ring and coat with refrigerant oil. Coat seal seat with refrigerant oil and install using seal seat

remover/installer. Install snap ring. Install dust seal (if supplied in seal kit). See Fig. 7

.

NOTE:DO NOT drive or pound on clutch hub or shaft.

Page 7 of 18 MITCHELL 1 ARTICLE - A/C COMPRESSOR SERVICING 1991 GENERAL SERVICING Compressor Service

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 324 of 454

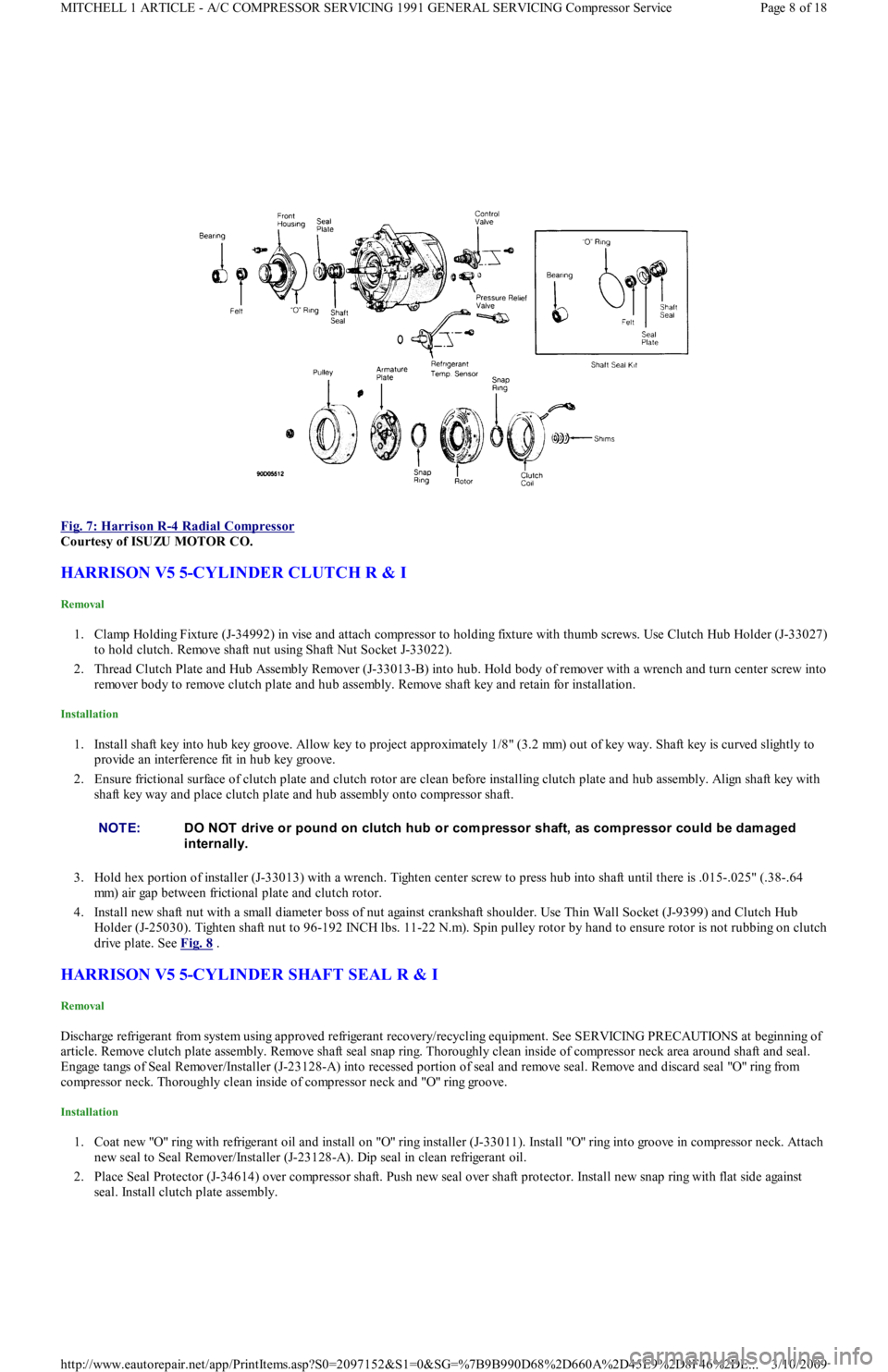

Fig. 7: Harrison R

-4 Radial Compressor

Courtesy of ISUZU MOTOR CO.

HARRISON V5 5-CYLINDER CLUTCH R & I

Removal

1. Clamp Holding Fixture (J-34992) in vise and attach compressor to holding fixture with thumb screws. Use Clutch Hub Holder (J-33027)

to hold clutch. Remove shaft nut using Shaft Nut Socket J-33022).

2. Thread Clutch Plate and Hub Assembly Remover (J-33013-B) into hub. Hold body of remover with a wrench and turn center screw into

remover body to remove clutch plate and hub assembly. Remove shaft key and retain for installation.

Installation

1. Install shaft key into hub key groove. Allow key to project approximately 1/8" (3.2 mm) out of key way. Shaft key is curved slightly to

provide an interference fit in hub key groove.

2. Ensure frictional surface of clutch plate and clutch rotor are clean before installing clutch plate and hub assembly. Align shaft key with

shaft key way and place clutch plate and hub assembly onto compressor shaft.

3. Hold hex portion of installer (J-33013) with a wrench. Tighten center screw to press hub into shaft until there is .015-.025" (.38-.64

mm) air gap between frictional plate and clutch rotor.

4. Install new shaft nut with a small diameter boss of nut against crankshaft shoulder. Use Thin Wall Socket (J-9399) and Clutch Hub

Holder (J-25030). Tighten shaft nut to 96-192 INCH lbs. 11-22 N.m). Spin pulley rotor by hand to ensure rotor is not rubbing on clutch

drive plate. See Fig. 8

.

HARRISON V5 5-CYLINDER SHAFT SEAL R & I

Removal

Discharge refrigerant from system using approved refrigerant recovery/recycling equipment. See SERVICING PRECAUTIONS at beginning of

article. Remove clutch plate assembly. Remove shaft seal snap ring. Thoroughly clean inside of compressor neck area around shaft and seal.

Engage tangs of Seal Remover/Installer (J-23128-A) into recessed portion of seal and remove seal. Remove and discard seal "O" ring from

compressor neck. Thoroughly clean inside of compressor neck and "O" ring groove.

Installation

1. Coat new "O" ring with refrigerant oil and install on "O" ring installer (J-33011). Install "O" ring into groove in compressor neck. Attach

new seal to Seal Remover/Installer (J-23128-A). Dip seal in clean refrigerant oil.

2. Place Seal Protector (J-34614) over compressor shaft. Push new seal over shaft protector. Install new snap ring with flat side against

seal. Install clutch plate assembly.

NOTE:DO NOT drive or pound on clutch hub or com pressor shaft, as com pressor could be dam aged

internally.

Page 8 of 18 MITCHELL 1 ARTICLE - A/C COMPRESSOR SERVICING 1991 GENERAL SERVICING Compressor Service

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 325 of 454

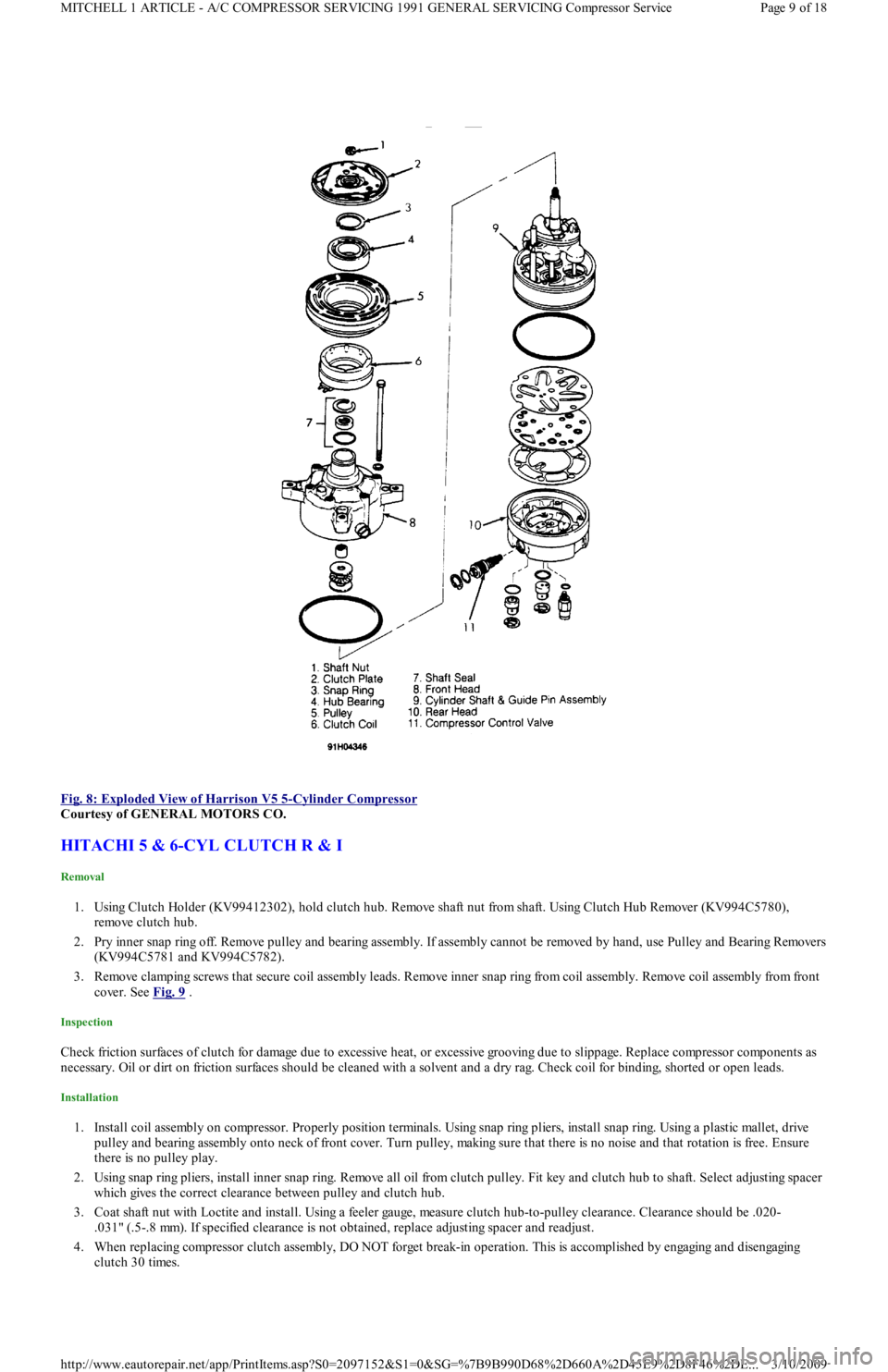

Fig. 8: Exploded View of Harrison V5 5

-Cylinder Compressor

Courtesy of GENERAL MOTORS CO.

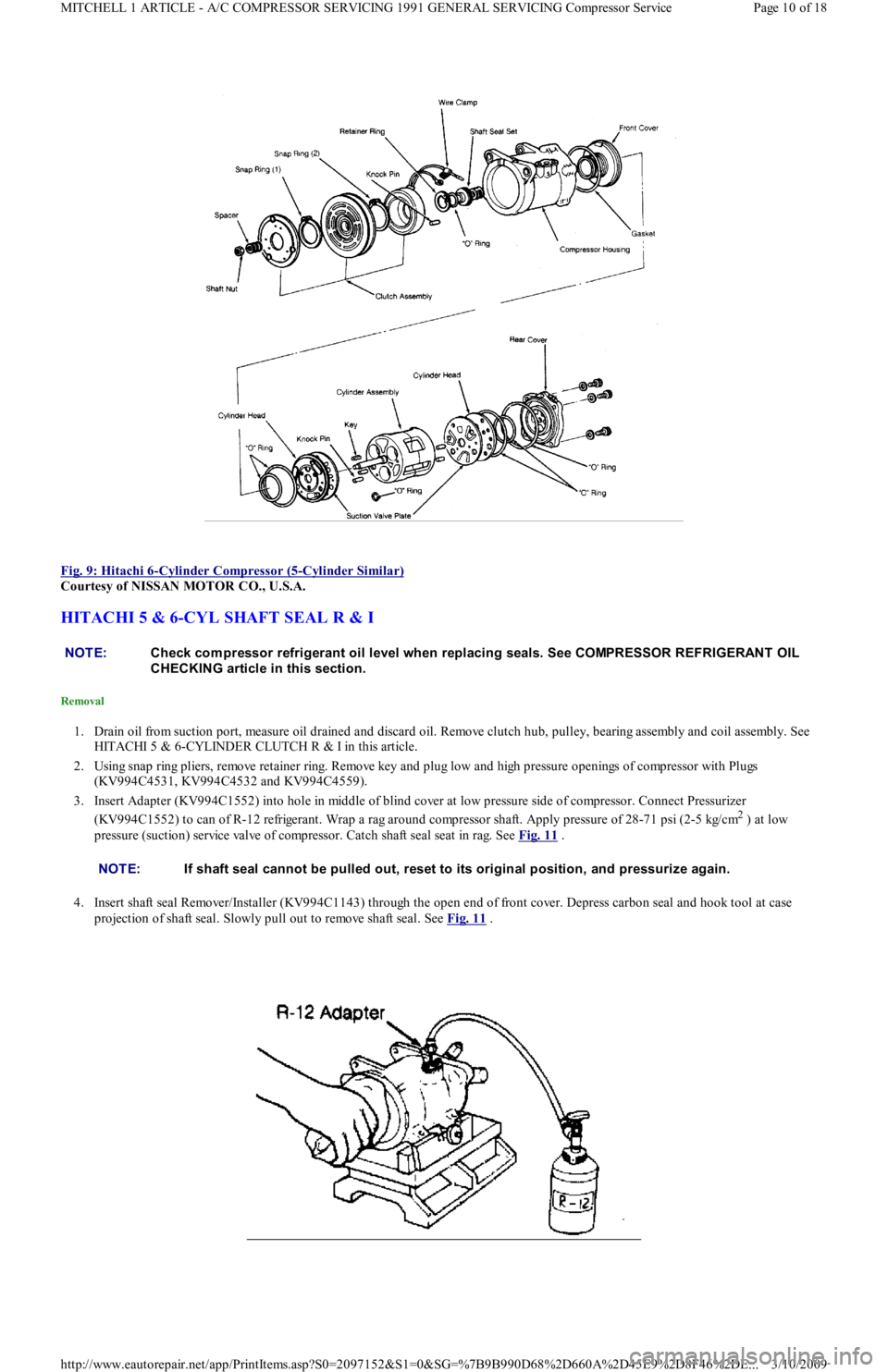

HITACHI 5 & 6-CYL CLUTCH R & I

Removal

1. Using Clutch Holder (KV99412302), hold clutch hub. Remove shaft nut from shaft. Using Clutch Hub Remover (KV994C5780),

remove clutch hub.

2. Pry inner snap ring off. Remove pulley and bearing assembly. If assembly cannot be removed by hand, use Pulley and Bearing Remo vers

(KV994C5781 and KV994C5782).

3. Remove clamping screws that secure coil assembly leads. Remove inner snap ring from coil assembly. Remove coil assembly from fro n t

cover. See Fig. 9

.

Inspection

Check friction surfaces of clutch for damage due to excessive heat, or excessive grooving due to slippage. Replace compressor components as

necessary. Oil or dirt on friction surfaces should be cleaned with a solvent and a dry rag. Check coil for binding, shorted or open leads.

Installation

1. Install coil assembly on compressor. Properly position terminals. Using snap ring pliers, install snap ring. Using a plastic mallet, drive

pulley and bearing assembly onto neck of front cover. Turn pulley, making sure that there is no noise and that rotation is free. Ensure

there is no pulley play.

2. Using snap ring pliers, install inner snap ring. Remove all oil from clutch pulley. Fit key and clutch hub to shaft. Select adjusting spacer

which gives the correct clearance between pulley and clutch hub.

3. Coat shaft nut with Loctite and install. Using a feeler gauge, measure clutch hub-to-pulley clearance. Clearance should be .020-

.031" (.5-.8 mm). If specified clearance is not obtained, replace adjusting spacer and readjust.

4. When replacing compressor clutch assembly, DO NOT forget break-in operation. This is accomplished by engaging and disengaging

clutch 30 times.

Page 9 of 18 MITCHELL 1 ARTICLE - A/C COMPRESSOR SERVICING 1991 GENERAL SERVICING Compressor Service

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 326 of 454

Fig. 9: Hitachi 6

-Cylinder Compressor (5-Cylinder Similar)

Courtesy of NISSAN MOTOR CO., U.S.A.

HITACHI 5 & 6-CYL SHAFT SEAL R & I

Removal

1. Drain oil from suction port, measure oil drained and discard oil. Remove clutch hub, pulley, bearing assembly and coil assembly. See

HITACHI 5 & 6-CYLINDER CLUTCH R & I in this article.

2. Using snap ring pliers, remove retainer ring. Remove key and plug low and high pressure openings of compressor with Plugs

(KV994C4531, KV994C4532 and KV994C4559).

3. Insert Adapter (KV994C1552) into hole in middle of blind cover at low pressure side of compressor. Connect Pressurizer

(KV994C1552) to can of R-12 refrigerant. Wrap a rag around compressor shaft. Apply pressure of 28-71 psi (2-5 kg/cm

2 ) at low

pressure (suction) service valve of compressor. Catch shaft seal seat in rag. See Fig. 11

.

4. Insert shaft seal Remover/Installer (KV994C1143) through the open end of front cover. Depress carbon seal and hook tool at case

projection of shaft seal. Slowly pull out to remove shaft seal. See Fig. 11

.

NOTE:Check com pressor refrigerant oil level when replacing seals. See COMPRESSOR REFRIGERANT OIL

CHECKING article in this section.

NOTE:If shaft seal cannot be pulled out, reset to its original position, and pressurize again.

Page 10 of 18 MITCHELL 1 ARTICLE - A/C COMPRESSOR SERVICING 1991 GENERAL SERVICING Compressor Service

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 327 of 454

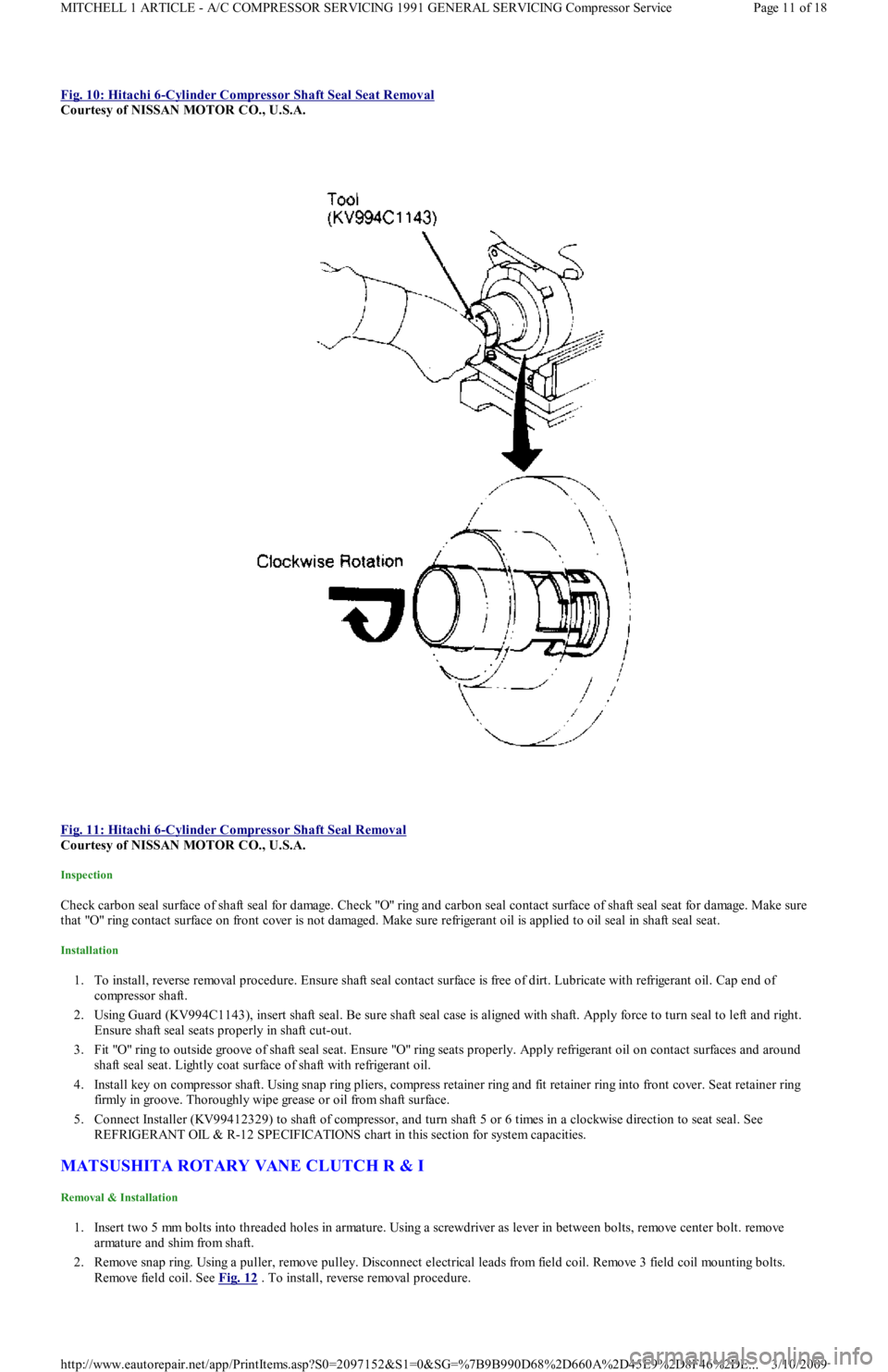

Fig. 10: Hitachi 6-Cylinder Compressor Shaft Seal Seat Removal

Courtesy of NISSAN MOTOR CO., U.S.A.

Fig. 11: Hitachi 6

-Cylinder Compressor Shaft Seal Removal

Courtesy of NISSAN MOTOR CO., U.S.A.

Inspection

Check carbon seal surface of shaft seal for damage. Check "O" ring and carbon seal contact surface of shaft seal seat for damage. Make sure

that "O" ring contact surface on front cover is not damaged. Make sure refrigerant oil is applied to oil seal in shaft seal seat.

Installation

1. To install, reverse removal procedure. Ensure shaft seal contact surface is free of dirt. Lubricate with refrigerant oil. Cap end of

compressor shaft.

2. Using Guard (KV994C1143), insert shaft seal. Be sure shaft seal case is aligned with shaft. Apply force to turn seal to left and right.

Ensure shaft seal seats properly in shaft cut-out.

3. Fit "O" ring to outside groove of shaft seal seat. Ensure "O" ring seats properly. Apply refrigerant oil on contact surfaces and around

shaft seal seat. Lightly coat surface of shaft with refrigerant oil.

4. Install key on compressor shaft. Using snap ring pliers, compress retainer ring and fit retainer ring into front cover. Seat retainer ring

firmly in groove. Thoroughly wipe grease or oil from shaft surface.

5. Connect Installer (KV99412329) to shaft of compressor, and turn shaft 5 or 6 times in a clockwise direction to seat seal. See

REFRIGERANT OIL & R-12 SPECIFICATIONS chart in this section for system capacities.

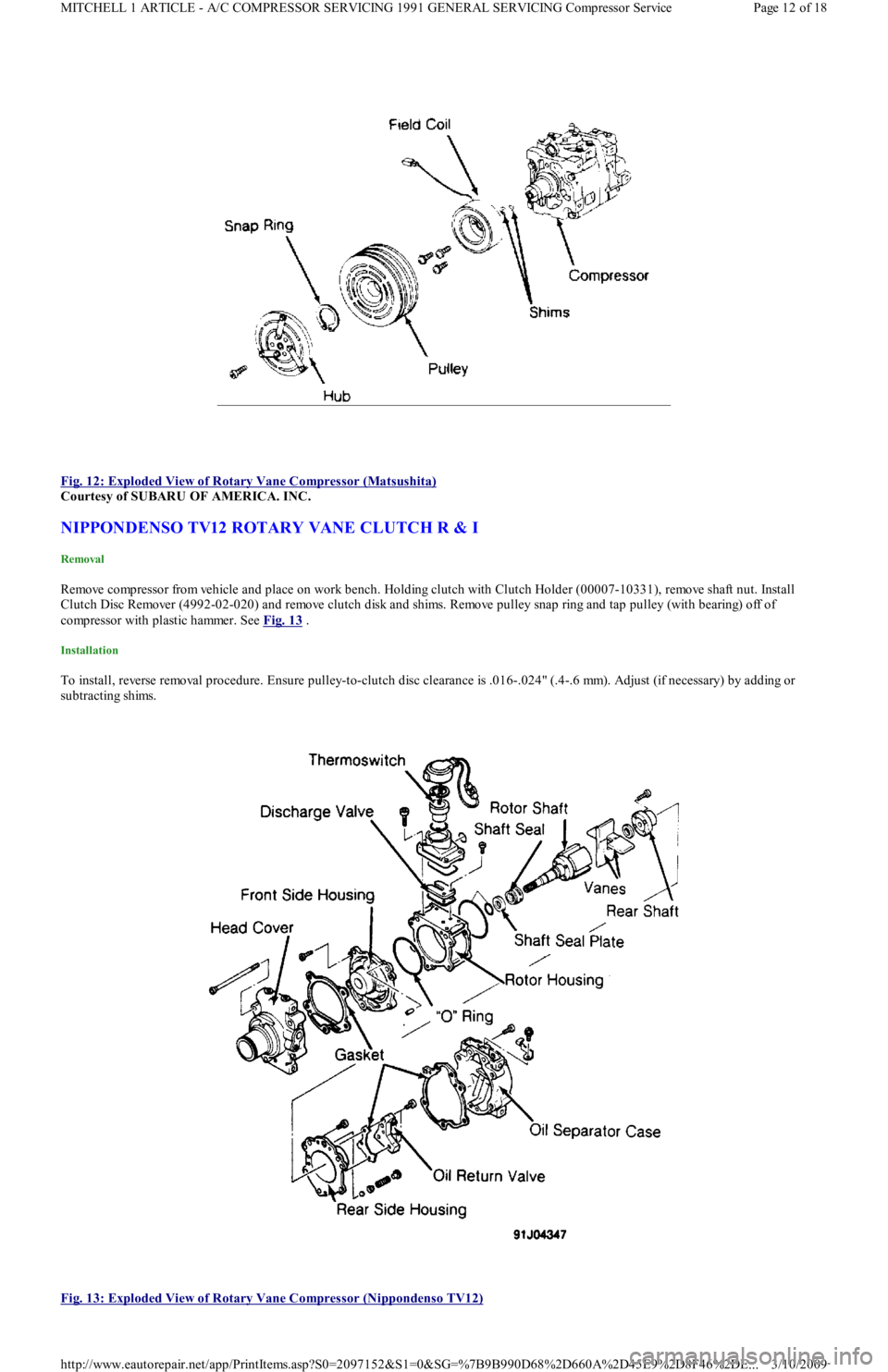

MATSUSHITA ROTARY VANE CLUTCH R & I

Removal & Installation

1. Insert two 5 mm bolts into threaded holes in armature. Using a screwdriver as lever in between bolts, remove center bolt. remove

armature and shim from shaft.

2. Remove snap ring. Using a puller, remove pulley. Disconnect electrical leads from field coil. Remove 3 field coil mounting bolts.

Remove field coil. See Fig. 12

. To install, reverse removal procedure.

Page 11 of 18 MITCHELL 1 ARTICLE - A/C COMPRESSOR SERVICING 1991 GENERAL SERVICING Compressor Service

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 328 of 454

Fig. 12: Exploded View of Rotary Vane Compressor (Matsushita)

Courtesy of SUBARU OF AMERICA. INC.

NIPPONDENSO TV12 ROTARY VANE CLUTCH R & I

Removal

Remove compressor from vehicle and place on work bench. Holding clutch with Clutch Holder (00007-10331), remove shaft nut. Install

Clutch Disc Remover (4992-02-020) and remove clutch disk and shims. Remove pulley snap ring and tap pulley (with bearing) off of

compressor with plastic hammer. See Fig. 13

.

Installation

To install, reverse removal procedure. Ensure pulley-to-clutch disc clearance is .016-.024" (.4-.6 mm). Adjust (if necessary) by adding or

subtracting shims.

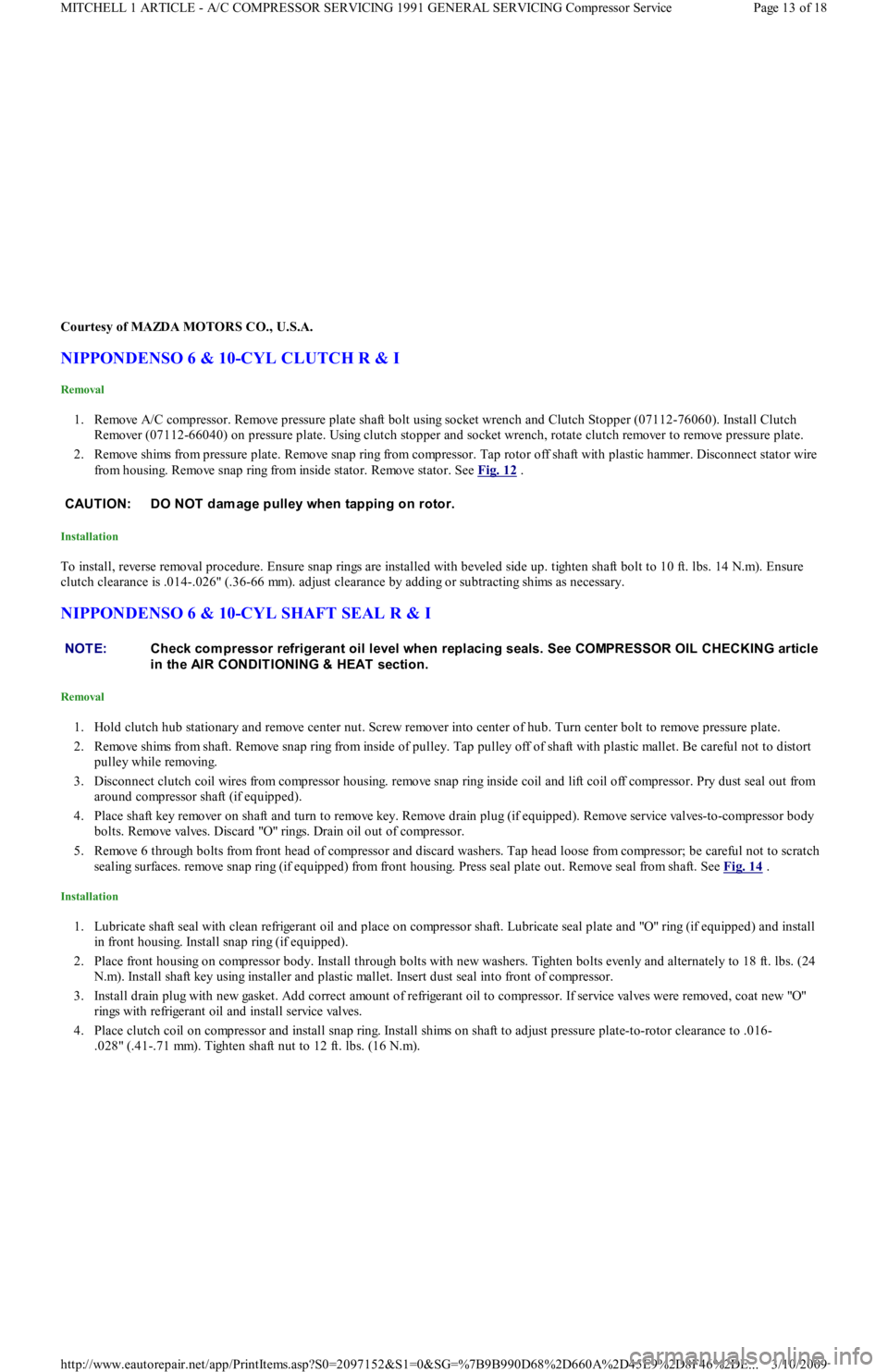

Fig. 13: Exploded View of Rotary Vane Compressor (Nippondenso TV12)

Page 12 of 18 MITCHELL 1 ARTICLE - A/C COMPRESSOR SERVICING 1991 GENERAL SERVICING Compressor Service

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 329 of 454

Courtesy of MAZDA MOTORS CO., U.S.A.

NIPPONDENSO 6 & 10-CYL CLUTCH R & I

Removal

1. Remove A/C compressor. Remove pressure plate shaft bolt using socket wrench and Clutch Stopper (07112-76060). Install Clutch

Remover (07112-66040) on pressure plate. Using clutch stopper and socket wrench, rotate clutch remover to remove pressure plate.

2. Remove shims from pressure plate. Remove snap ring from compressor. Tap rotor off shaft with plastic hammer. Disconnect stator wire

from housing. Remove snap ring from inside stator. Remove stator. See Fig. 12

.

Installation

To install, reverse removal procedure. Ensure snap rings are installed with beveled side up. tighten shaft bolt to 10 ft. lbs. 14 N.m). Ensure

clutch clearance is .014-.026" (.36-66 mm). adjust clearance by adding or subtracting shims as necessary.

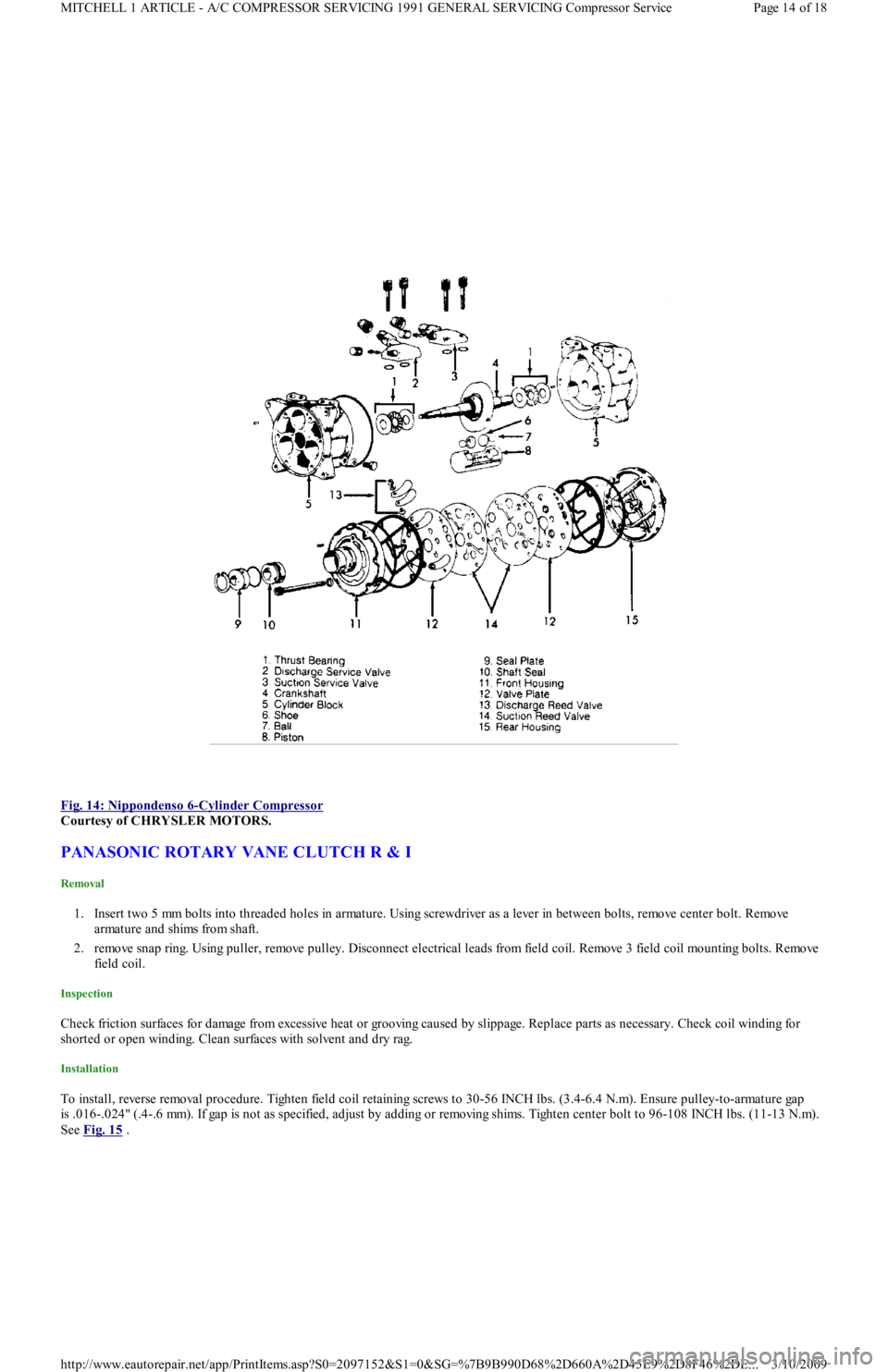

NIPPONDENSO 6 & 10-CYL SHAFT SEAL R & I

Removal

1. Hold clutch hub stationary and remove center nut. Screw remover into center of hub. Turn center bolt to remove pressure plate.

2. Remove shims from shaft. Remove snap ring from inside of pulley. Tap pulley off of shaft with plastic mallet. Be careful not to distort

pulley while removing.

3. Disconnect clutch coil wires from compressor housing. remove snap ring inside coil and lift coil off compressor. Pry dust seal out from

around compressor shaft (if equipped).

4. Place shaft key remover on shaft and turn to remove key. Remove drain plug (if equipped). Remove service valves-to-compressor body

bolts. Remove valves. Discard "O" rings. Drain oil out of compressor.

5. Remove 6 through bolts from front head of compressor and discard washers. Tap head loose from compressor; be careful not to scratch

sealing surfaces. remove snap ring (if equipped) from front housing. Press seal plate out. Remove seal from shaft. See Fig. 14

.

Installation

1. Lubricate shaft seal with clean refrigerant oil and place on compressor shaft. Lubricate seal plate and "O" ring (if equipped) and install

in front housing. Install snap ring (if equipped).

2. Place front housing on compressor body. Install through bolts with new washers. Tighten bolts evenly and alternately to 18 ft. lbs. (24

N.m). Install shaft key using installer and plastic mallet. Insert dust seal into front of compressor.

3. Install drain plug with new gasket. Add correct amount of refrigerant oil to compressor. If service valves were removed, coat n ew "O"

rings with refrigerant oil and install service valves.

4. Place clutch coil on compressor and install snap ring. Install shims on shaft to adjust pressure plate-to-rotor clearance to .016-

.028" (.41-.71 mm). Tighten shaft nut to 12 ft. lbs. (16 N.m). CAUTION: DO NOT dam age pulley when tapping on rotor.

NOTE:Check com pressor refrigerant oil level when replacing seals. See COMPRESSOR OIL CHECKING article

in the AIR CONDIT IONING & HEAT section.

Page 13 of 18 MITCHELL 1 ARTICLE - A/C COMPRESSOR SERVICING 1991 GENERAL SERVICING Compressor Service

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 330 of 454

Fig. 14: Nippondenso 6

-Cylinder Compressor

Courtesy of CHRYSLER MOTORS.

PANASONIC ROTARY VANE CLUTCH R & I

Removal

1. Insert two 5 mm bolts into threaded holes in armature. Using screwdriver as a lever in between bolts, remove center bolt. Remove

armature and shims from shaft.

2. remove snap ring. Using puller, remove pulley. Disconnect electrical leads from field coil. Remove 3 field coil mounting bolts. Remove

field coil.

Inspection

Check friction surfaces for damage from excessive heat or grooving caused by slippage. Replace parts as necessary. Check coil winding for

shorted or open winding. Clean surfaces with solvent and dry rag.

Installation

To install, reverse removal procedure. Tighten field coil retaining screws to 30-56 INCH lbs. (3.4-6.4 N.m). Ensure pulley-to-armature gap

is .016-.024" (.4-.6 mm). If gap is not as specified, adjust by adding or removing shims. Tighten center bolt to 96-108 INCH lbs. (11-13 N.m).

See Fig. 15

.

Page 14 of 18 MITCHELL 1 ARTICLE - A/C COMPRESSOR SERVICING 1991 GENERAL SERVICING Compressor Service

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...