engine FORD FESTIVA 1991 Manual PDF

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 122 of 454

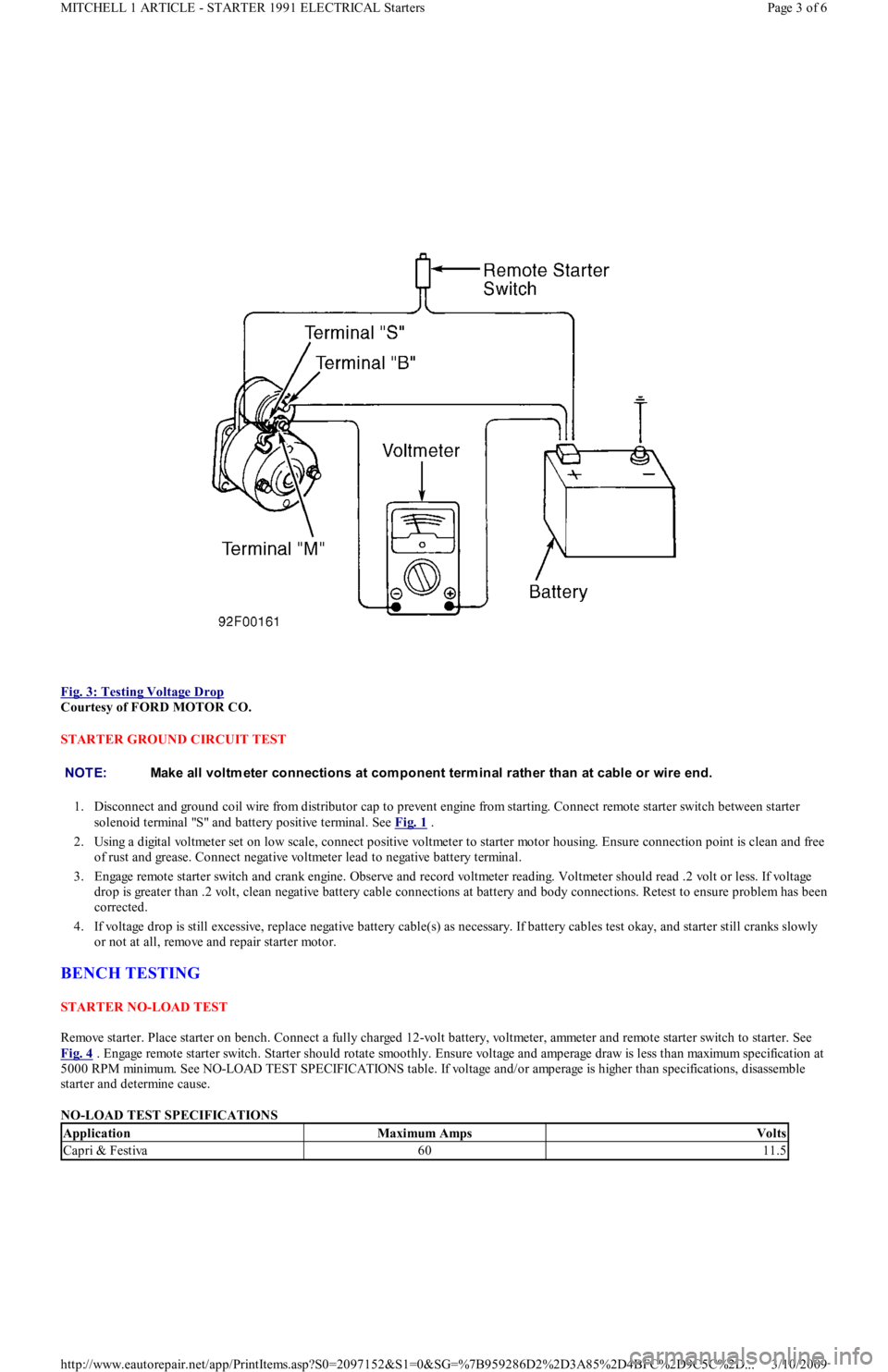

Fig. 3: Testing Voltage Drop

Courtesy of FORD MOTOR CO.

STARTER GROUND CIRCUIT TEST

1. Disconnect and ground coil wire from distributor cap to prevent engine from starting. Connect remote starter switch between starter

solenoid terminal "S" and battery positive terminal. See Fig. 1

.

2. Using a digital voltmeter set on low scale, connect positive voltmeter to starter motor housing. Ensure connection point is clean and free

of rust and grease. Connect negative voltmeter lead to negative battery terminal.

3. Engage remote starter switch and crank engine. Observe and record voltmeter reading. Voltmeter should read .2 volt or less. If voltage

drop is greater than .2 volt, clean negative battery cable connections at battery and body connections. Retest to ensure problem has been

corrected.

4. If voltage drop is still excessive, replace negative battery cable(s) as necessary. If battery cables test okay, and starter still cranks slowly

or not at all, remove and repair starter motor.

BENCH TESTING

STARTER NO-LOAD TEST

Remove starter. Place starter on bench. Connect a fully charged 12-volt battery, voltmeter, ammeter and remote starter switch to starter. See

Fig. 4

. Engage remote starter switch. Starter should rotate smoothly. Ensure voltage and amperage draw is less than maximum specification at

5000 RPM minimum. See NO-LOAD TEST SPECIFICATIONS table. If voltage and/or amperage is higher than specifications, disassemble

starter and determine cause.

NO-LOAD TEST SPECIFICATIONS

NOTE:Make all voltm eter connections at com ponent term inal rather than at cable or wire end.

ApplicationMaximum AmpsVolts

Capri & Festiva6011.5

Page 3 of 6 MITCHELL 1 ARTICLE - STARTER 1991 ELECTRICAL Starters

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 126 of 454

Back To Article

FORD

1.3L 4-Cylinder

MANUFACTURER'S SUGGESTED SCHEDULED MAINTENANCE

For Aspire, the manufacturer recommends the belt be replaced every 60,000 miles on Federal vehicles, and 105,000 miles on California

vehicles. For Festiva, the manufacturer recommends the belt be replaced every 60,000 miles.

REMOVAL & INSTALLATION

TIMING BELT

Removal

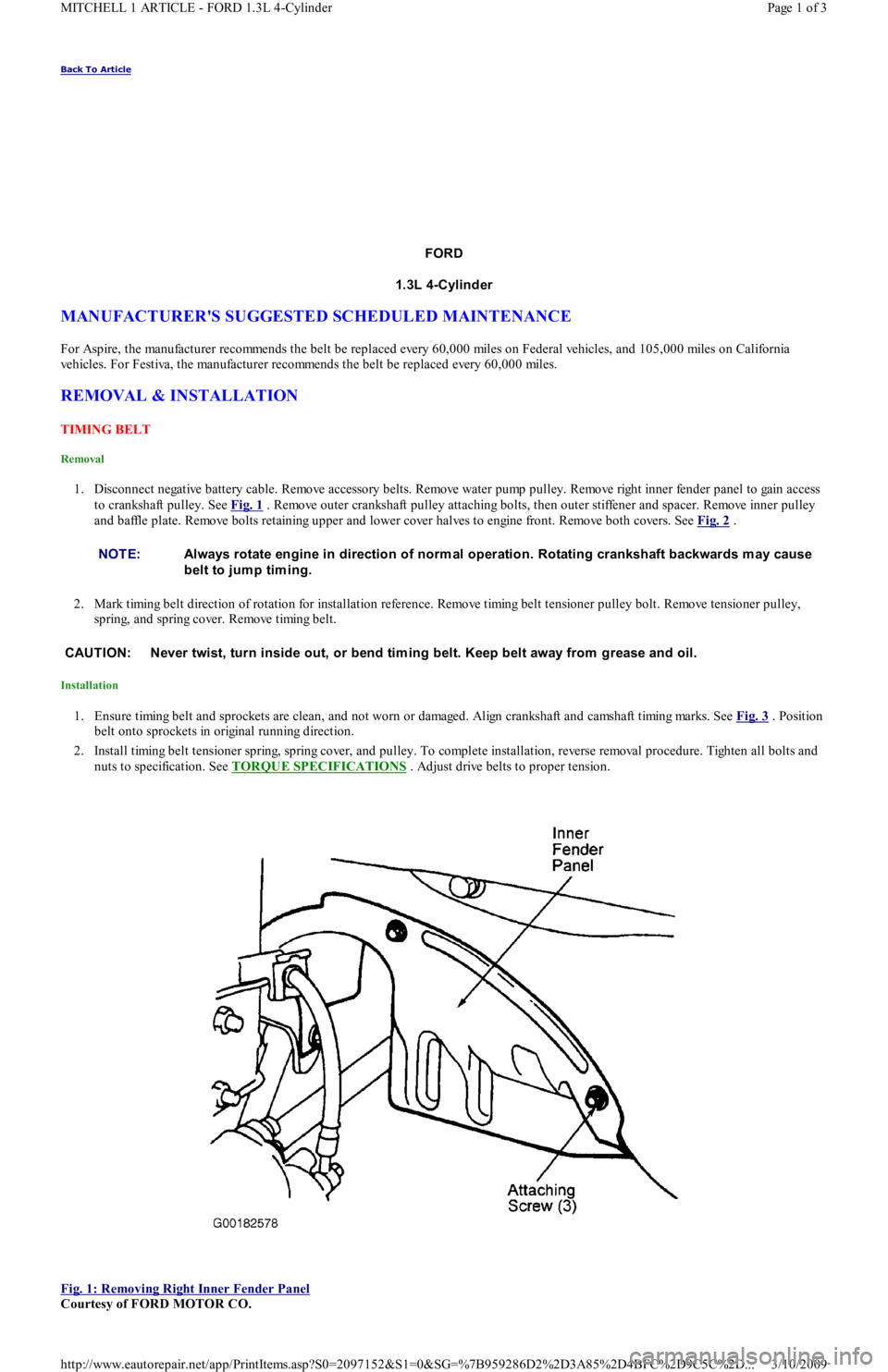

1. Disconnect negative battery cable. Remove accessory belts. Remove water pump pulley. Remove right inner fender panel to gain access

to crankshaft pulley. See Fig. 1

. Remove outer crankshaft pulley attaching bolts, then outer stiffener and spacer. Remove inner pulley

and baffle plate. Remove bolts retaining upper and lower cover halves to engine front. Remove both covers. See Fig. 2

.

2. Mark timing belt direction of rotation for installation reference. Remove timing belt tensioner pulley bolt. Remove tensioner pulley,

spring, and spring cover. Remove timing belt.

Installation

1. Ensure timing belt and sprockets are clean, and not worn or damaged. Align crankshaft and camshaft timing marks. See Fig. 3 . Position

belt onto sprockets in original running direction.

2. Install timing belt tensioner spring, spring cover, and pulley. To complete installation, reverse removal procedure. Tighten all bolts and

nuts to specification. See TORQUE SPECIFICATIONS

. Adjust drive belts to proper tension.

Fig. 1: Removing Right Inner Fender Panel

Courtesy of FORD MOTOR CO. NOTE:Always rotate engine in direction of norm al operation. Rotating crankshaft backwards m ay cause

belt to jum p tim ing.

CAUT ION: Never twist, turn inside out, or bend tim ing belt. Keep belt away from grease and oil.

Page 1 of 3 MITCHELL 1 ARTICLE - FORD 1.3L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 129 of 454

Back To Article

D - ADJUSTMENTS

1991 ENGINE PERFORMANCE Ford/Mercury - On-Vehicle Adjustm ents

ADJUSTMENTS

ENGINE MECHANICAL

Before beginning any on-vehicle adjustments to fuel or ignition systems, ensure engine mechanical condition is okay.

VALVE CLEARANCE

IGNITION TIMING

CAPRI

1. Place automatic transmission in Park or manual transmission in Neutral. Disconnect and plug hoses attached to vacuum diaphragm

assembly on distributor. Connect tachometer and timing light. Turn off all electrical loads.

2. Start engine, and warm it to operating temperature. Ensure idle speed is set to specification, adjusting if necessary. See IDLE SPEED &

MIXTURE . Determine initial timing. See IGNITION TIMING table. If base timing is not correct, loosen distributor mounting bolts

and rotate distributor until marks align. Tighten bolts to 14-18 ft. lbs. (19-25 N.m).

3. Increase engine RPM while observing timing light. Verify ignition timing advances. For Turbo models, go to step 5). For non-Turbo

models, continue with step 4).

4. On non-Turbo models, apply 16 in. Hg vacuum to chamber "A". Verify timing advances by 26-30 degrees. Remove vacuum source from

chamber "A". Apply 8 in. Hg vacuum to chamber "B" while observing timing. Verify timing advances by 3-7 degrees. Stop engine, and

remove test equipment.

5. On Turbo models, apply 20 in. Hg vacuum to advance diaphragm. Verify timing advances by 13-17 degrees. Disconnect vacuum source.

Apply 8 psi (.6 kg/cm

2 ) pressure to advance diaphragm. Verify timing retards by 3-7 degrees. Stop engine, and remove test equipment.

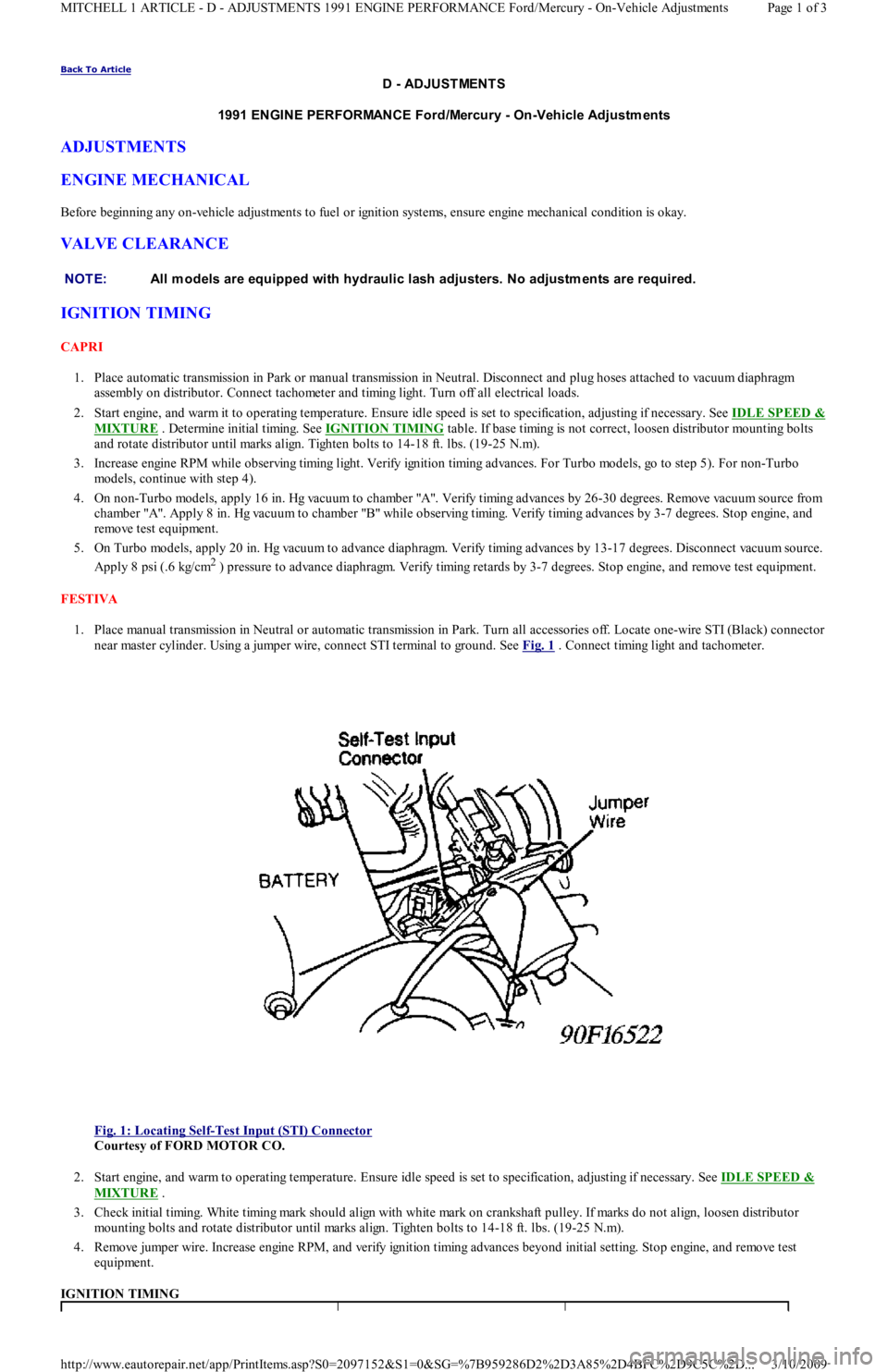

FESTIVA

1. Place manual transmission in Neutral or automatic transmission in Park. Turn all accessories off. Locate one-wire STI (Black) connector

near master cylinder. Using a jumper wire, connect STI terminal to ground. See Fig. 1

. Connect timing light and tachometer.

Fig. 1: Locating Self

-Test Input (STI) Connector

Courtesy of FORD MOTOR CO.

2. Start engine, and warm to operating temperature. Ensure idle speed is set to specification, adjusting if necessary. See IDLE SPEED &

MIXTURE .

3. Check initial timing. White timing mark should align with white mark on crankshaft pulley. If marks do not align, loosen distributor

mounting bolts and rotate distributor until marks align. Tighten bolts to 14-18 ft. lbs. (19-25 N.m).

4. Remove jumper wire. Increase engine RPM, and verify ignition timing advances beyond initial setting. Stop engine, and remove test

equipment.

IGNITION TIMING NOTE:All m odels are equipped with hydraulic lash adjusters. No adjustm ents are required.

Page 1 of 3 MITCHELL 1 ARTICLE - D - ADJUSTMENTS 1991 ENGINE PERFORMANCE Ford/Mercury - On-Vehicle Adjustments

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 130 of 454

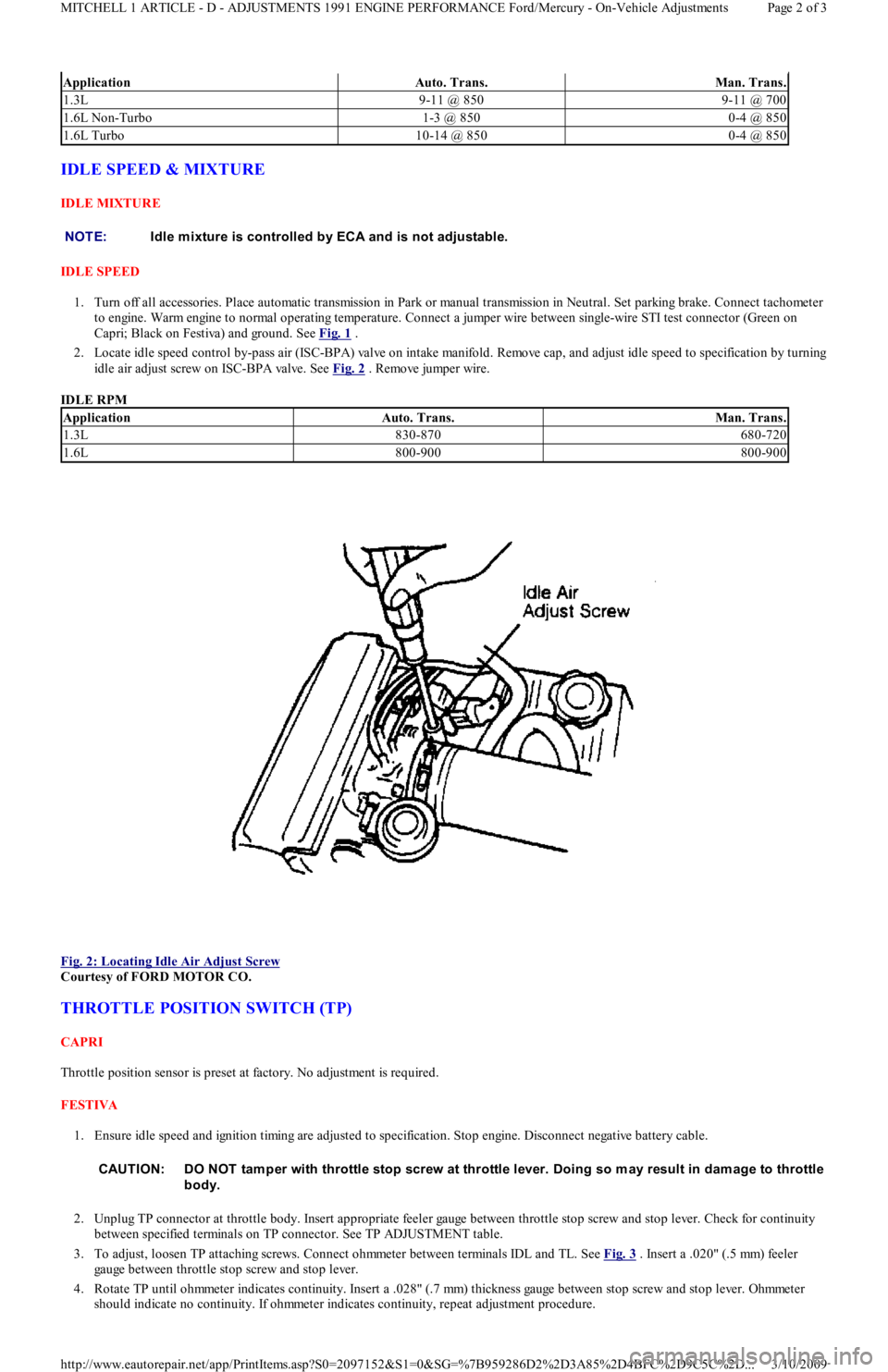

IDLE SPEED & MIXTURE

IDLE MIXTURE

IDLE SPEED

1. Turn off all accessories. Place automatic transmission in Park or manual transmission in Neutral. Set parking brake. Connect tachometer

to engine. Warm engine to normal operating temperature. Connect a jumper wire between single-wire STI test connector (Green on

Capri; Black on Festiva) and ground. See Fig. 1

.

2. Locate idle speed control by-pass air (ISC-BPA) valve on intake manifold. Remove cap, and adjust idle speed to specification by turning

idle air adjust screw on ISC-BPA valve. See Fig. 2

. Remove jumper wire.

IDLE RPM

Fig. 2: Locating Idle Air Adjust Screw

Courtesy of FORD MOTOR CO.

THROTTLE POSITION SWITCH (TP)

CAPRI

Throttle position sensor is preset at factory. No adjustment is required.

FESTIVA

1. Ensure idle speed and ignition timing are adjusted to specification. Stop engine. Disconnect negative battery cable.

2. Unplug TP connector at throttle body. Insert appropriate feeler gauge between throttle stop screw and stop lever. Check for continuity

between specified terminals on TP connector. See TP ADJUSTMENT table.

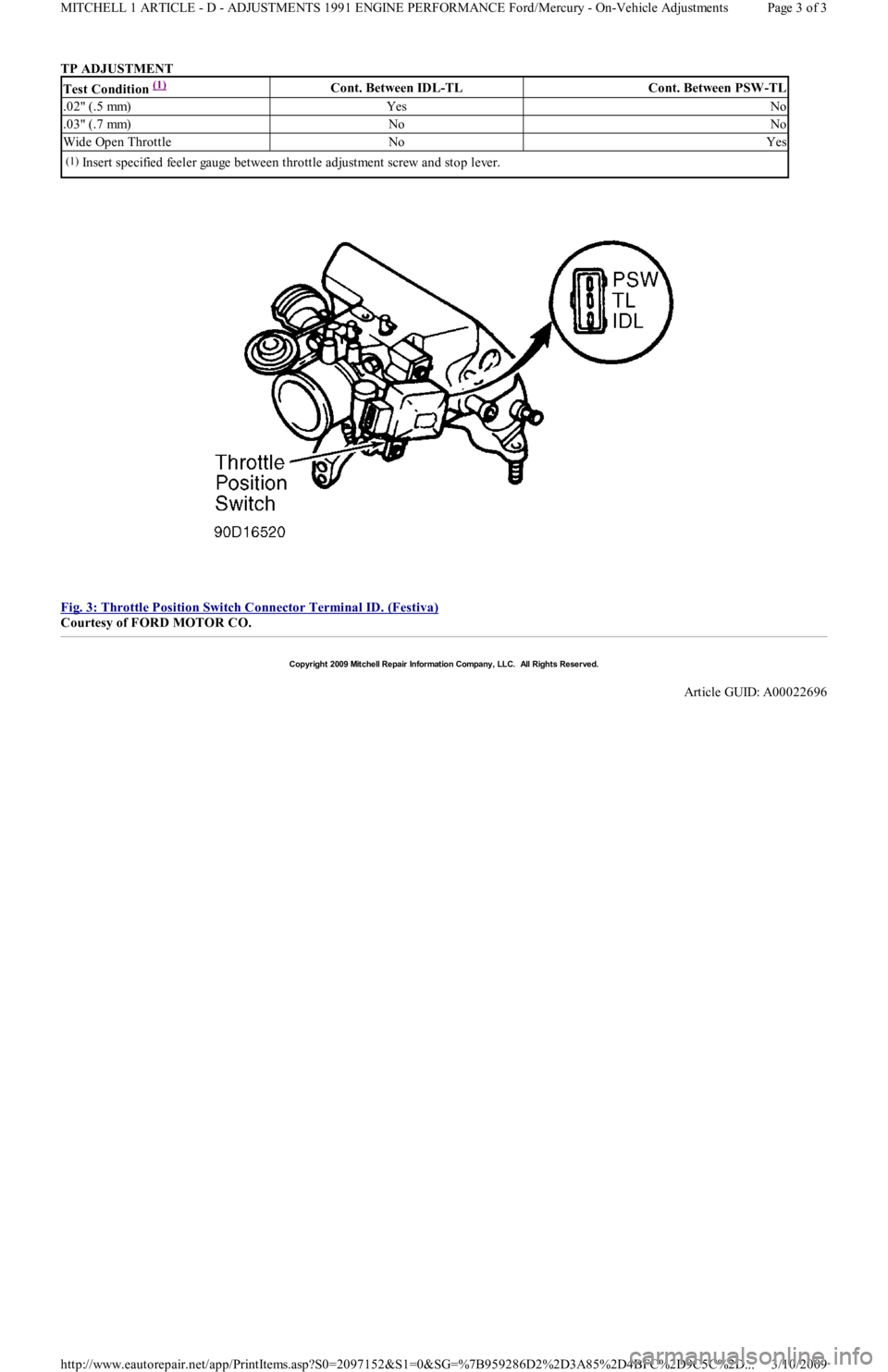

3. To adjust, loosen TP attaching screws. Connect ohmmeter between terminals IDL and TL. See Fig. 3

. Insert a .020" (.5 mm) feeler

gauge between throttle stop screw and stop lever.

4. Rotate TP until ohmmeter indicates continuity. Insert a .028" (.7 mm) thickness gauge between stop screw and stop lever. Ohmmeter

should indicate no continuity. If ohmmeter indicates continuity, repeat adjustment procedure.

ApplicationAuto. Trans.Man. Trans.

1.3L9-11 @ 8509-11 @ 700

1.6L Non-Turbo1-3 @ 8500-4 @ 850

1.6L Turbo10-14 @ 8500-4 @ 850

NOTE:Idle m ixture is controlled by ECA and is not adjustable.

ApplicationAuto. Trans.Man. Trans.

1.3L830-870680-720

1.6L800-900800-900

CAUT ION: DO NOT tam per with throttle stop screw at throttle lever. Doing so m ay result in dam age to throttle

body.

Page 2 of 3 MITCHELL 1 ARTICLE - D - ADJUSTMENTS 1991 ENGINE PERFORMANCE Ford/Mercury - On-Vehicle Adjustments

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 131 of 454

TP ADJUSTMENT

Fig. 3: Throttle Position Switch Connector Terminal ID. (Festiva)

Courtesy of FORD MOTOR CO.

Test Condition (1) Cont. Between IDL-TLCont. Between PSW-TL

.02" (.5 mm)YesNo

.03" (.7 mm)NoNo

Wide Open ThrottleNoYes

(1)Insert specified feeler gauge between throttle adjustment screw and stop lever.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00022696

Page 3 of 3 MITCHELL 1 ARTICLE - D - ADJUSTMENTS 1991 ENGINE PERFORMANCE Ford/Mercury - On-Vehicle Adjustments

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 132 of 454

Back To Article

A - ENGINE/VIN ID

1991 ENGINE PERFORMANCE Ford/Mercury - Introduction

APPLICATION

MODEL COVERAGE

VIN DEFINITION

Numbers preceding the explanations in the legend below refer to the sequence of characters as listed on VIN identification label.

SAMPLE VIN

Digit #: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17.

(VIN) K N J P T O 6 H 9 L 6 1 0 0 0 0 0.

VIN Definition

1-3 - Indicates Nation of Origin.

4 - Indicates Restraint System.

5 - Indicates Carline Code.

6-7 - Indicates Body Type.

8 - Indicates Engine Type.

9 - Indicates Check Digit.

10 - Indicates Model Year.

11 - Indicates Assembly Plant.

12-17 - Vehicle Serial Number.

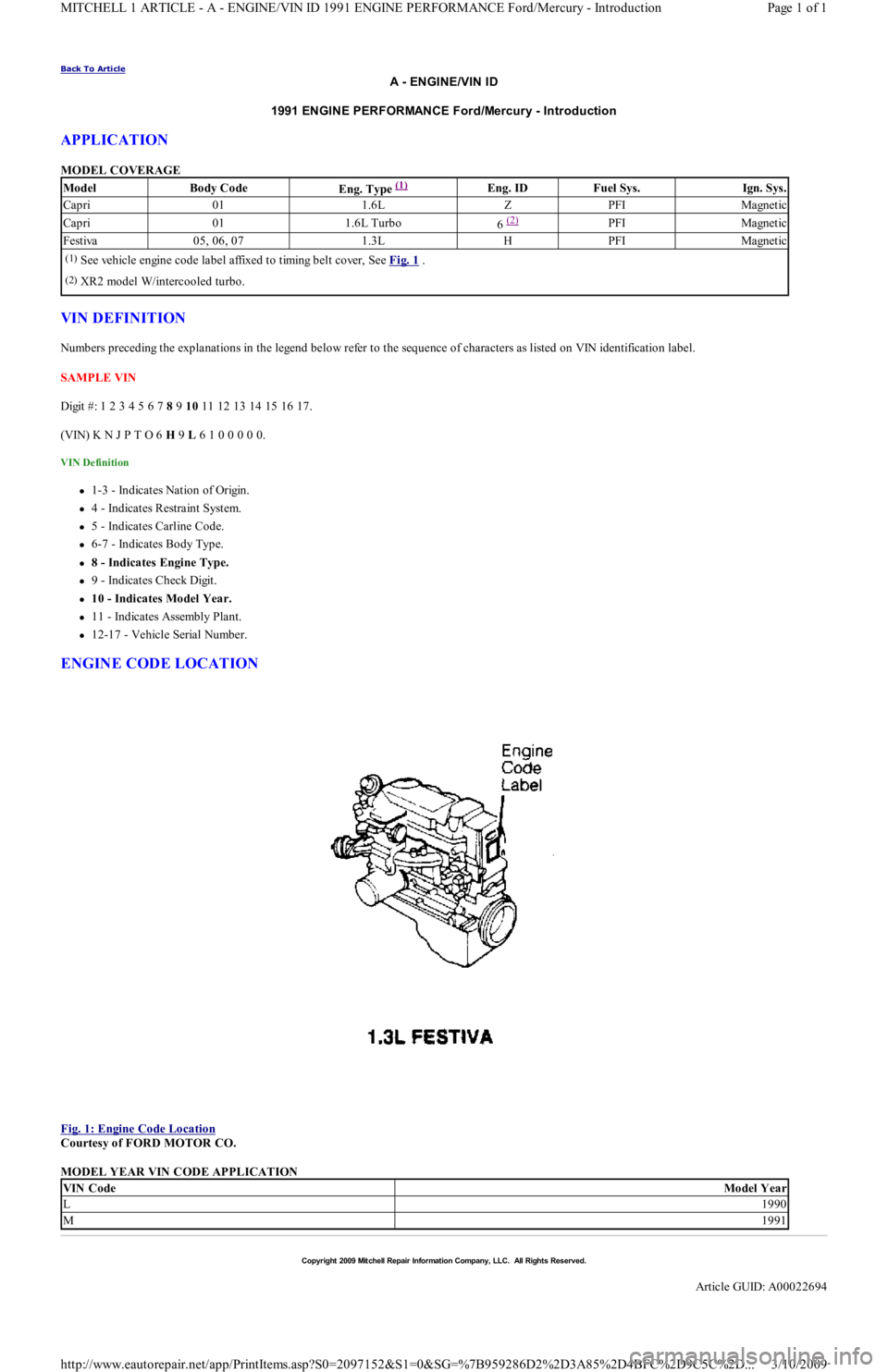

ENGINE CODE LOCATION

Fig. 1: Engine Code Location

Courtesy of FORD MOTOR CO.

MODEL YEAR VIN CODE APPLICATION

ModelBody CodeEng. Type (1) Eng. IDFuel Sys.Ign. Sys.

Capri011.6LZPFIMagnetic

Capri011.6L Turbo6 (2) PFIMagnetic

Festiva05, 06, 071.3LHPFIMagnetic

(1)See vehicle engine code label affixed to timing belt cover, See Fig. 1 .

(2)XR2 model W/intercooled turbo.

VIN CodeModel Year

L1990

M1991

Copyr ight 2009 Mit chell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00022694

Page 1 of 1 MITCHELL 1 ARTICLE - A - ENGINE/VIN ID 1991 ENGINE PERFORMANCE Ford/Mercury - Introduction

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 133 of 454

Back To Article

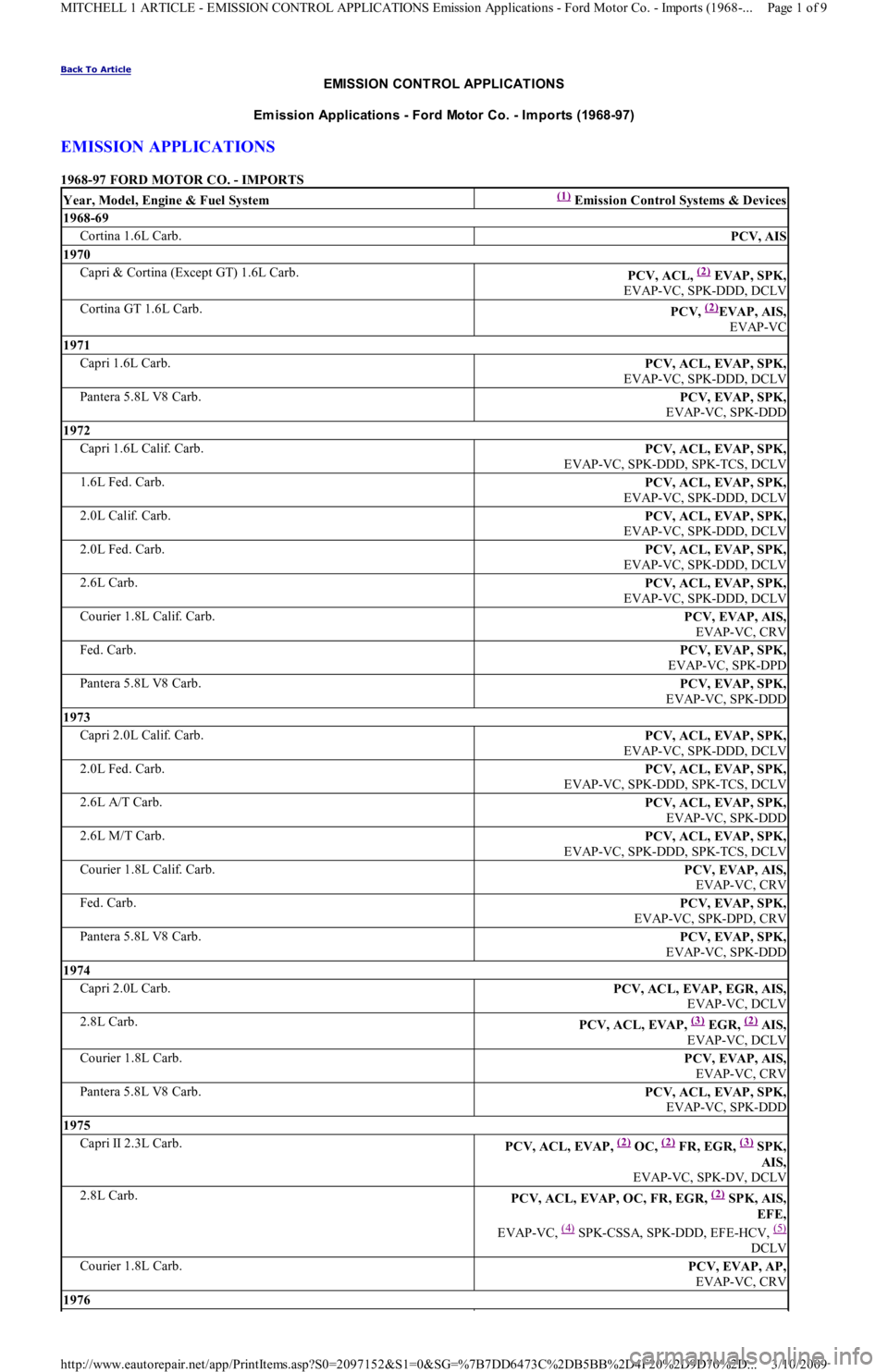

EMISSION CONT ROL APPLICAT IONS

Em ission Applications - Ford Motor Co. - Im ports (1968-97)

EMISSION APPLICATIONS

1968-97 FORD MOTOR CO. - IMPORTS

Year, Model, Engine & Fuel System(1) Emission Control Systems & Devices

1968-69

Cortina 1.6L Carb.PCV, AIS

1970

Capri & Cortina (Except GT) 1.6L Carb.PCV, ACL, (2) EVAP, SPK,

EVAP-VC, SPK-DDD, DCLV

Cortina GT 1.6L Carb.PCV, (2)EVAP, AIS,

EVAP-VC

1971

Capri 1.6L Carb.PCV, ACL, EVAP, SPK,

EVAP-VC, SPK-DDD, DCLV

Pantera 5.8L V8 Carb.PCV, EVAP, SPK,

EVAP-VC, SPK-DDD

1972

Capri 1.6L Calif. Carb.PCV, ACL, EVAP, SPK,

EVAP-VC, SPK-DDD, SPK-TCS, DCLV

1.6L Fed. Carb.PCV, ACL, EVAP, SPK,

EVAP-VC, SPK-DDD, DCLV

2.0L Calif. Carb.PCV, ACL, EVAP, SPK,

EVAP-VC, SPK-DDD, DCLV

2.0L Fed. Carb.PCV, ACL, EVAP, SPK,

EVAP-VC, SPK-DDD, DCLV

2.6L Carb.PCV, ACL, EVAP, SPK,

EVAP-VC, SPK-DDD, DCLV

Courier 1.8L Calif. Carb.PCV, EVAP, AIS,

EVAP-VC, CRV

Fed. Carb.PCV, EVAP, SPK,

EVAP-VC, SPK-DPD

Pantera 5.8L V8 Carb.PCV, EVAP, SPK,

EVAP-VC, SPK-DDD

1973

Capri 2.0L Calif. Carb.PCV, ACL, EVAP, SPK,

EVAP-VC, SPK-DDD, DCLV

2.0L Fed. Carb.PCV, ACL, EVAP, SPK,

EVAP-VC, SPK-DDD, SPK-TCS, DCLV

2.6L A/T Carb.PCV, ACL, EVAP, SPK,

EVAP-VC, SPK-DDD

2.6L M/T Carb.PCV, ACL, EVAP, SPK,

EVAP-VC, SPK-DDD, SPK-TCS, DCLV

Courier 1.8L Calif. Carb.PCV, EVAP, AIS,

EVAP-VC, CRV

Fed. Carb.PCV, EVAP, SPK,

EVAP-VC, SPK-DPD, CRV

Pantera 5.8L V8 Carb.PCV, EVAP, SPK,

EVAP-VC, SPK-DDD

1974

Capri 2.0L Carb.PCV, ACL, EVAP, EGR, AIS,

EVAP-VC, DCLV

2.8L Carb.PCV, ACL, EVAP, (3) EGR, (2) AIS,

EVAP-VC, DCLV

Courier 1.8L Carb.PCV, EVAP, AIS,

EVAP-VC, CRV

Pantera 5.8L V8 Carb.PCV, ACL, EVAP, SPK,

EVAP-VC, SPK-DDD

1975

Capri II 2.3L Carb.PCV, ACL, EVAP, (2) OC, (2) FR, EGR, (3)SPK,

AIS,

EVAP-VC, SPK-DV, DCLV

2.8L Carb.PCV, ACL, EVAP, OC, FR, EGR, (2)SPK, AIS,

EFE,

EVAP-VC,

(4) SPK-CSSA, SPK-DDD, EFE-HCV, (5)

DCLV

Courier 1.8L Carb.PCV, EVAP, AP,

EVAP-VC, CRV

1976

Page 1 of 9 MITCHELL 1 ARTICLE - EMISSION CONTROL APPLICATIONS Emission Applications - Ford Motor Co. - Imports (1968-

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 136 of 454

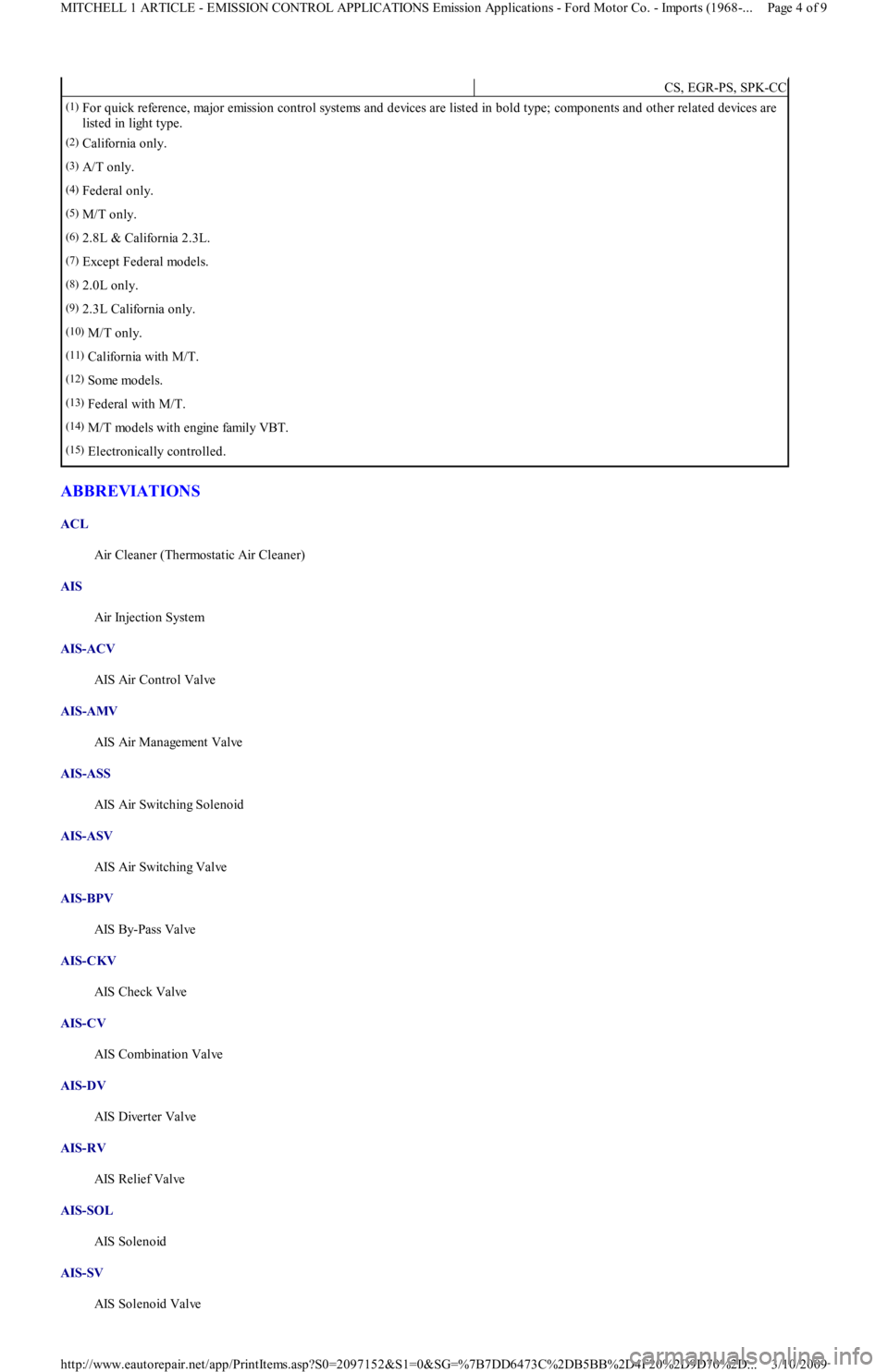

ABBREVIATIONS

ACL

Air Cleaner (Thermostatic Air Cleaner)

AIS

Air Injection System

AIS-ACV

AIS Air Control Valve

AIS-AMV

AIS Air Management Valve

AIS-ASS

AIS Air Switching Solenoid

AIS-ASV

AIS Air Switching Valve

AIS-BPV

AIS By-Pass Valve

AIS-CKV

AIS Check Valve

AIS-CV

AIS Combination Valve

AIS-DV

AIS Diverter Valve

AIS-RV

AIS Relief Valve

AIS-SOL

AIS Solenoid

AIS-SV

AIS Solenoid Valve

CS, EGR-PS, SPK-CC

(1)For quick reference, major emission control systems and devices are listed in bold type; components and other related devices are

listed in light type.

(2)California only.

(3)A/T only.

(4)Federal only.

(5)M/T only.

(6)2.8L & California 2.3L.

(7)Except Federal models.

(8)2.0L only.

(9)2.3L California only.

(10)M/T only.

(11)California with M/T.

(12)Some models.

(13)Federal with M/T.

(14)M/T models with engine family VBT.

(15)Electronically controlled.

Page 4 of 9 MITCHELL 1 ARTICLE - EMISSION CONTROL APPLICATIONS Emission Applications - Ford Motor Co. - Imports (1968-

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 138 of 454

CEC

Computerized Engine Controls

DOHC

Dual Overhead Cam

DPFE

Differential Pressure Feedback EGR Valve

EAIR

Electric Air Injection System

EAIR DV

Electric Air Injection System Diverter Valve

ECM

Electronic Control Module

ECU

Electronic Control Unit

EGR

Exhaust Gas Recirculation

EVRS

EGR Vacuum Regulator Solenoid

EVAP

Fuel Evaporative System

EVAP-AAC

EVAP Auxiliary Air Control

EVAP-BPSV

EVAP By-Pass Solenoid Valve

EVAP-BVSV

EVAP Bimetallic Vacuum Switching Valve

EVAP-CAV

EVAP Canister Air Valve

EVAP-CCV

EVAP Control Canister Close Valve

EVAP-CCVSV

EVAP Control Canister Vent Shut Valve

EVAP-CCVVSV

EVAP Closed Canister Valve Vacuum Switching Valve

EVAP-CDCV

EVAP Canister Drain Cut Valve

EVAP-CKV

EVAP Check Valve

EVAP-CPCS

EVAP Canister Purge Control Solenoid

Page 6 of 9 MITCHELL 1 ARTICLE - EMISSION CONTROL APPLICATIONS Emission Applications - Ford Motor Co. - Imports (1968-

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 142 of 454

Back To Article

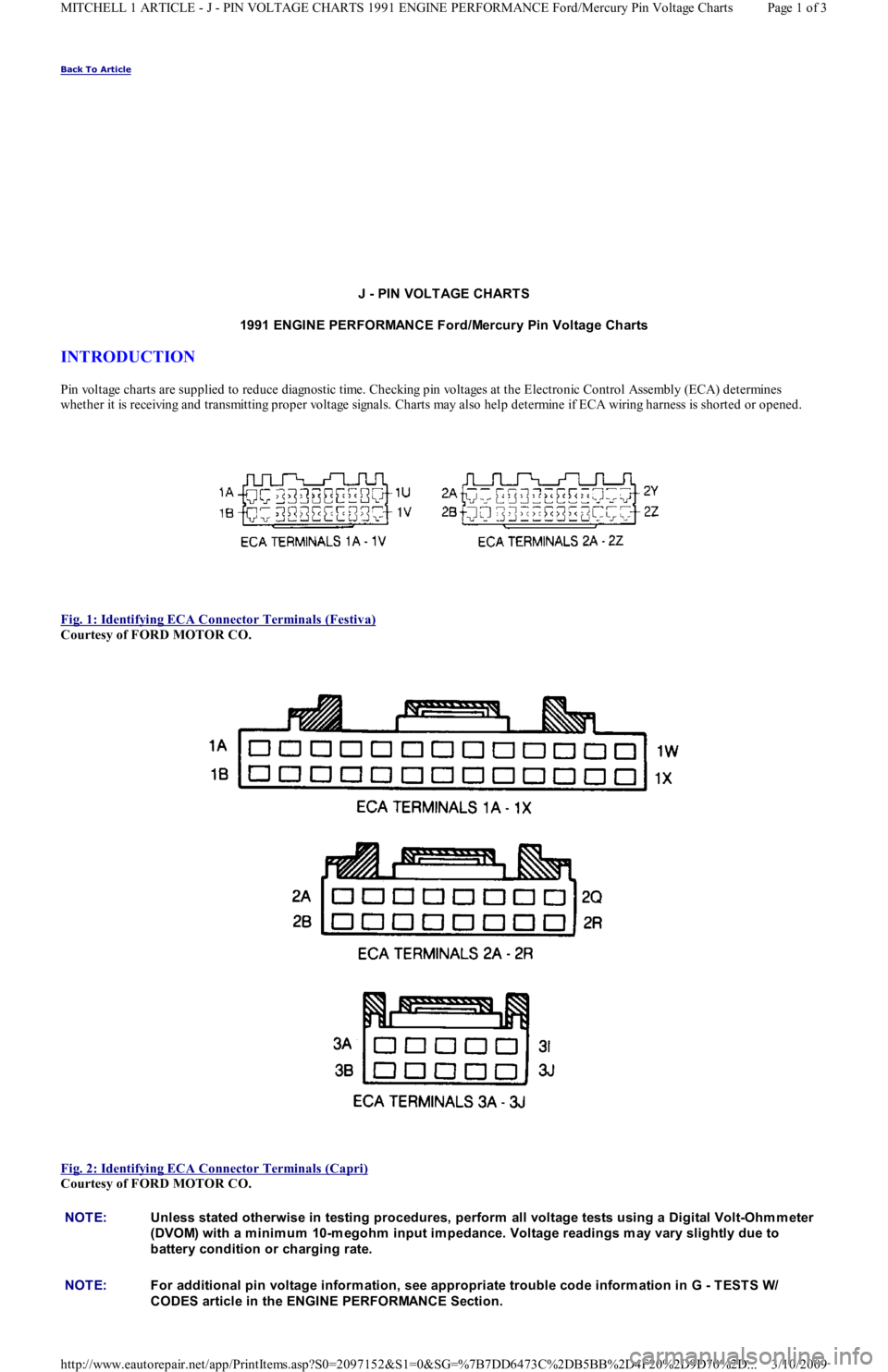

J - PIN VOLT AGE CHART S

1991 ENGINE PERFORMANCE Ford/Mercury Pin Voltage Charts

INTRODUCTION

Pin voltage charts are supplied to reduce diagnostic time. Checking pin voltages at the Electronic Control Assembly (ECA) determin es

whether it is receiving and transmitting proper voltage signals. Charts may also help determine if ECA wiring harness is shorted or opened.

Fig. 1: Identifying ECA Connector Terminals (Festiva)

Courtesy of FORD MOTOR CO.

Fig. 2: Identifying ECA Connector Terminals (Capri)

Courtesy of FORD MOTOR CO.

NOTE:Unless stated otherwise in testing procedures, perform all voltage tests using a Digital Volt-Ohm m eter

(DVOM) with a m inim um 10-m egohm input im pedance. Voltage readings m ay vary slightly due to

battery condition or charging rate.

NOTE:For additional pin voltage inform ation, see appropriate trouble code inform ation in G - T EST S W/

CODES article in the ENGINE PERFORMANCE Section.

Page 1 of 3 MITCHELL 1 ARTICLE - J - PIN VOLTAGE CHARTS 1991 ENGINE PERFORMANCE Ford/Mercury Pin Voltage Charts

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...