FORD FESTIVA 1991 Manual Online

Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 81 of 454

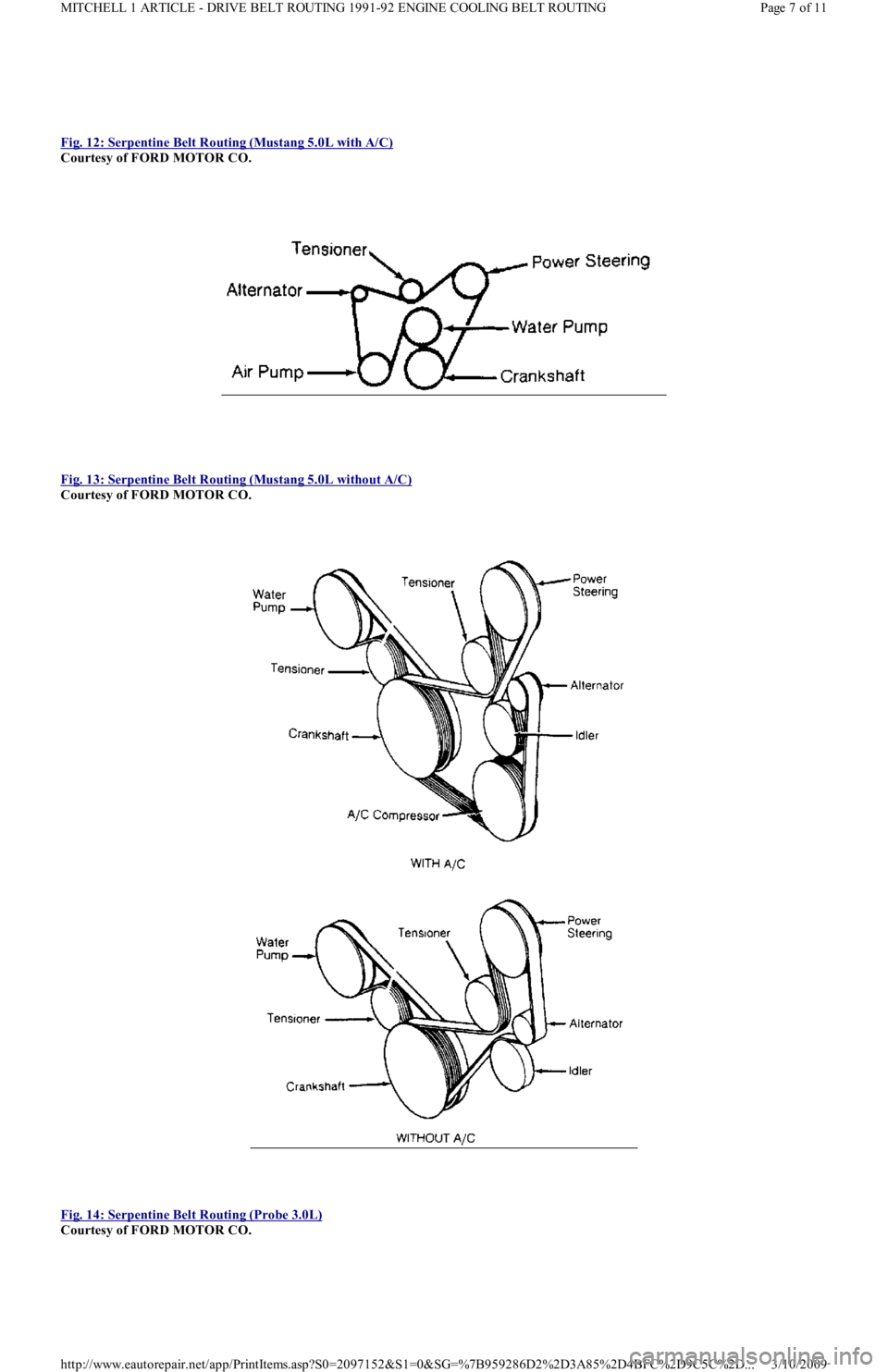

Fig. 12: Serpentine Belt Routing (Mustang 5.0L with A/C)

Courtesy of FORD MOTOR CO.

Fig. 13: Serpentine Belt Routing (Mustang 5.0L without A/C)

Courtesy of FORD MOTOR CO.

Fig. 14: Serpentine Belt Routing (Probe 3.0L)

Courtesy of FORD MOTOR CO.

Page 7 of 11 MITCHELL 1 ARTICLE - DRIVE BELT ROUTING 1991-92 ENGINE COOLING BELT ROUTING

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 82 of 454

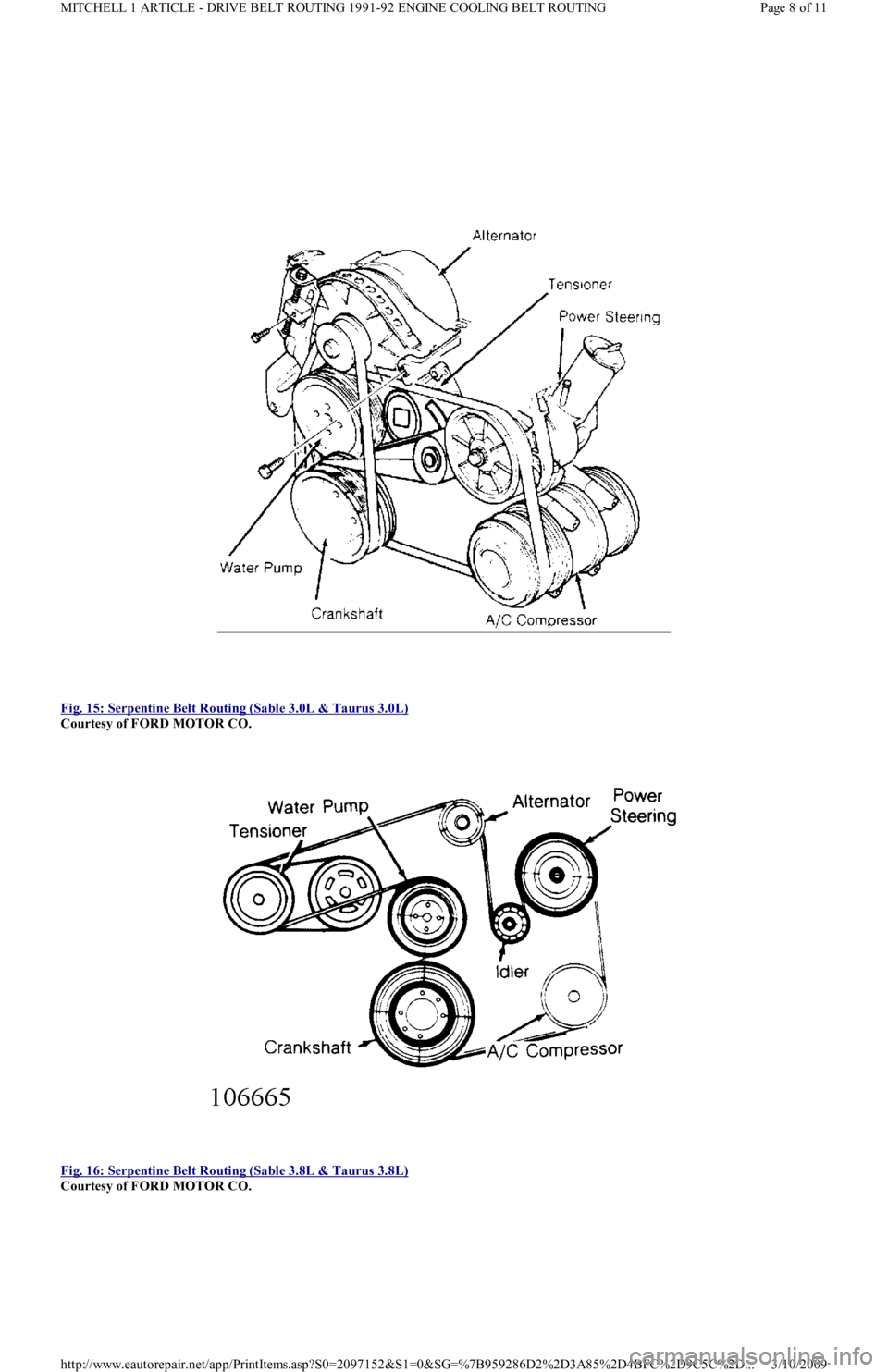

Fig. 15: Serpentine Belt Routing (Sable 3.0L & Taurus 3.0L)

Courtesy of FORD MOTOR CO.

Fig. 16: Serpentine Belt Routing (Sable 3.8L & Taurus 3.8L)

Courtesy of FORD MOTOR CO.

Page 8 of 11 MITCHELL 1 ARTICLE - DRIVE BELT ROUTING 1991-92 ENGINE COOLING BELT ROUTING

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 83 of 454

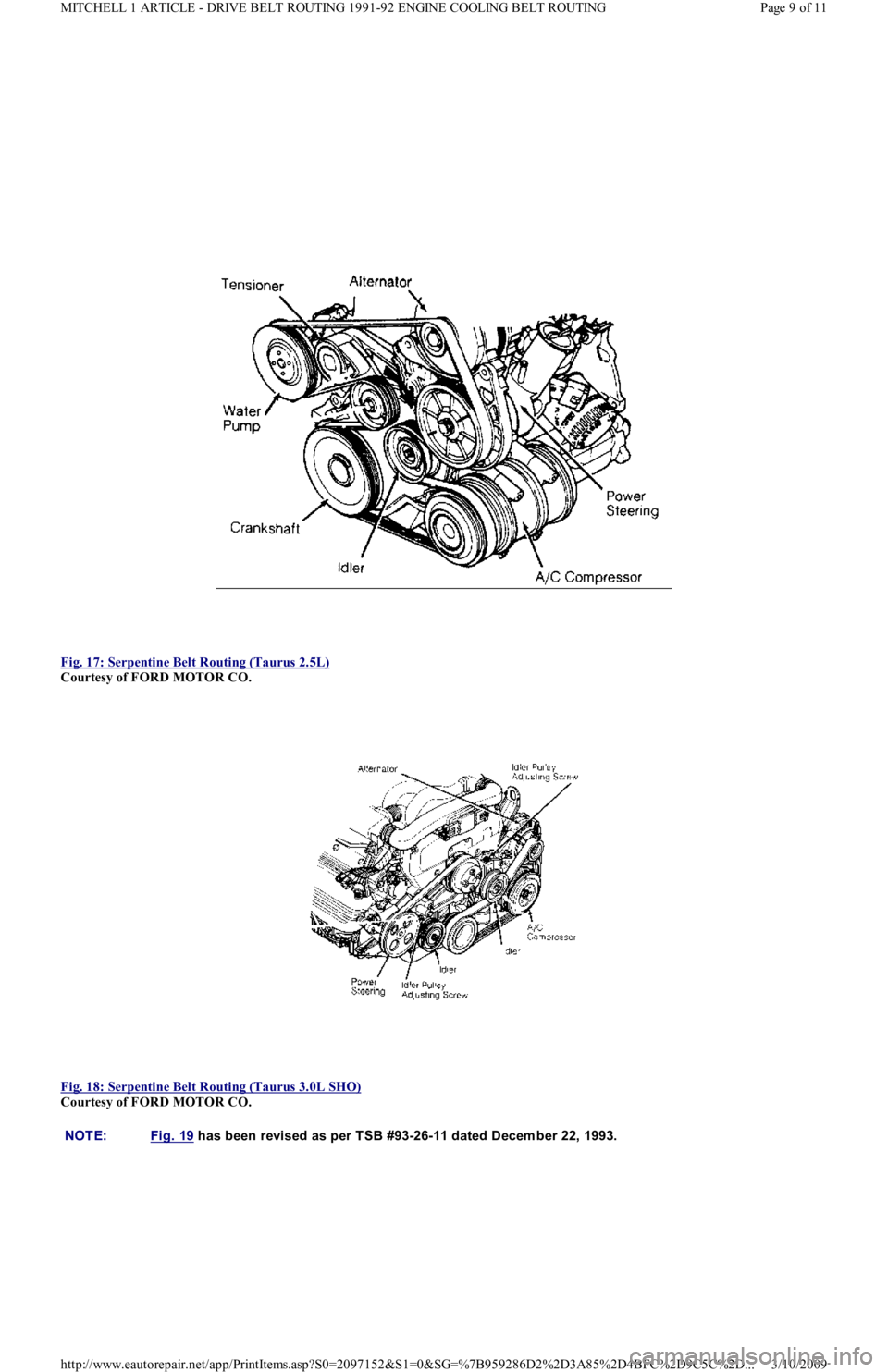

Fig. 17: Serpentine Belt Routing (Taurus 2.5L)

Courtesy of FORD MOTOR CO.

Fig. 18: Serpentine Belt Routing (Taurus 3.0L SHO)

Courtesy of FORD MOTOR CO.

NOTE: Fig. 19 has been revised as per T SB #93-26-11 dated Decem ber 22, 1993.

Page 9 of 11 MITCHELL 1 ARTICLE - DRIVE BELT ROUTING 1991-92 ENGINE COOLING BELT ROUTING

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 84 of 454

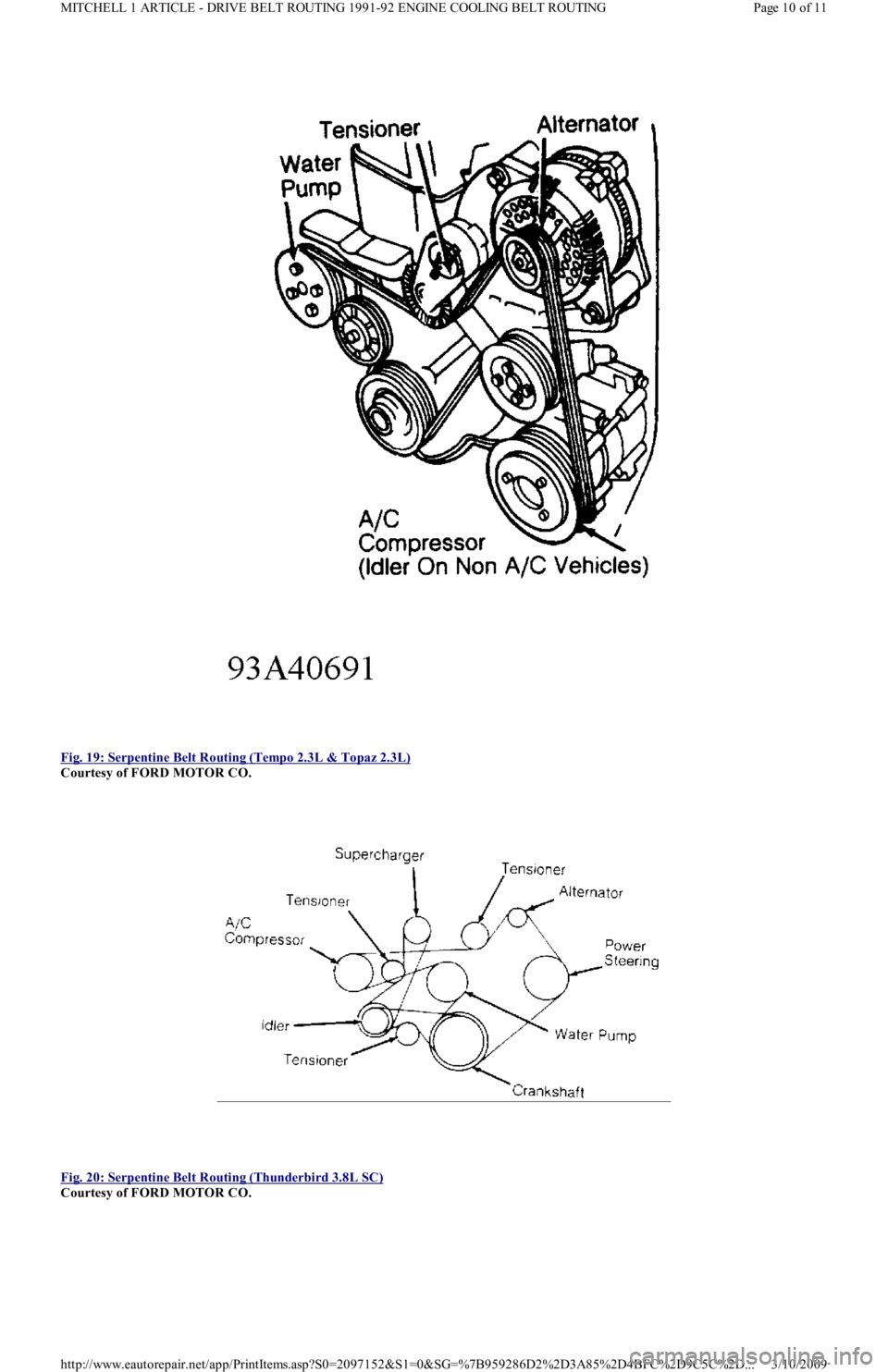

Fig. 19: Serpentine Belt Routing (Tempo 2.3L & Topaz 2.3L)

Courtesy of FORD MOTOR CO.

Fig. 20: Serpentine Belt Routing (Thunderbird 3.8L SC)

Courtesy of FORD MOTOR CO.

Page 10 of 11 MITCHELL 1 ARTICLE - DRIVE BELT ROUTING 1991-92 ENGINE COOLING BELT ROUTING

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 85 of 454

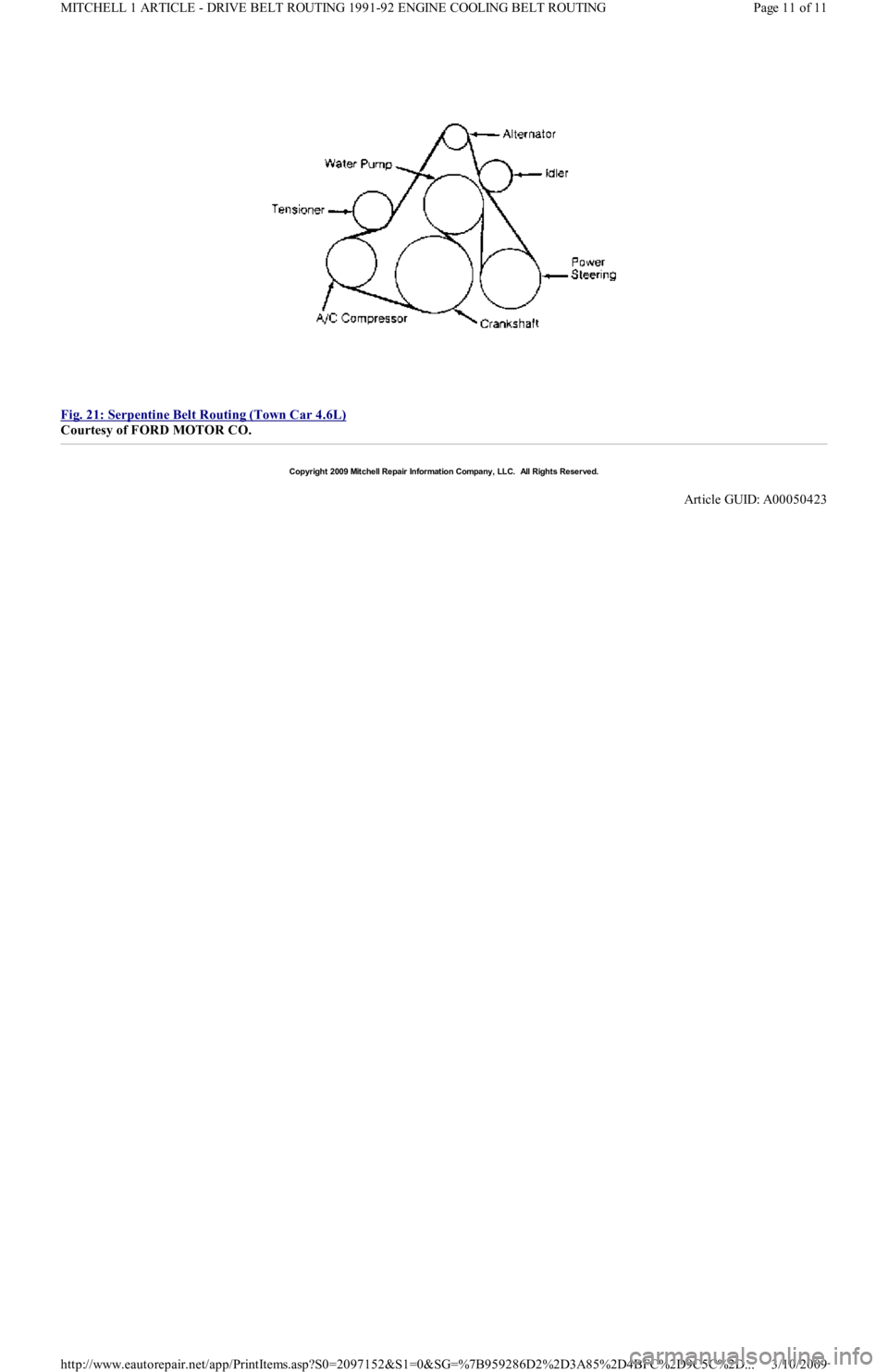

Fig. 21: Serpentine Belt Routing (Town Car 4.6L)

Courtesy of FORD MOTOR CO.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00050423

Page 11 of 11 MITCHELL 1 ARTICLE - DRIVE BELT ROUTING 1991-92 ENGINE COOLING BELT ROUTING

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 86 of 454

Back To Article

ENGINE COOLING FAN

1990-92 ENGINE COOLING Ford Motor Co. Engine Cooling Fans

DESCRIPTION

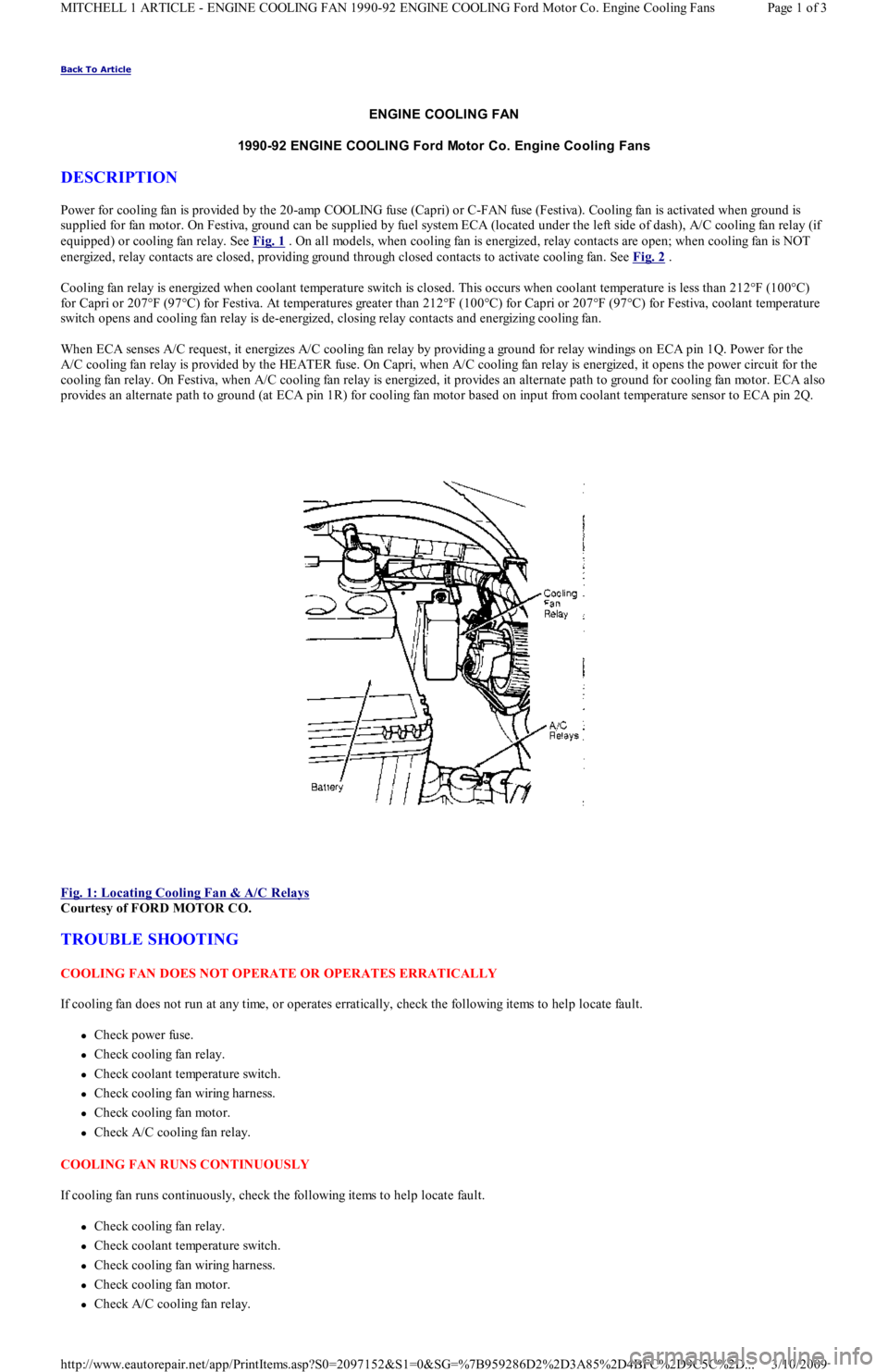

Power for cooling fan is provided by the 20-amp COOLING fuse (Capri) or C-FAN fuse (Festiva). Cooling fan is activated when ground is

supplied for fan motor. On Festiva, ground can be supplied by fuel system ECA (located under the left side of dash), A/C cooling fan relay (if

equipped) or cooling fan relay. See Fig. 1

. On all models, when cooling fan is energized, relay contacts are open; when cooling fan is NOT

energized, relay contacts are closed, providing ground through closed contacts to activate cooling fan. See Fig. 2

.

Cooling fan relay is energized when coolant temperature switch is closed. This occurs when coolant temperature is less than 212°F (1 00 °C)

for Capri or 207°F (97°C) for Festiva. At temperatures greater than 212°F (100°C) for Capri or 207°F (97°C) for Festiva, coolant temperature

switch opens and cooling fan relay is de-energized, closing relay contacts and energizing cooling fan.

When ECA senses A/C request, it energizes A/C cooling fan relay by providing a ground for relay windings on ECA pin 1Q. Power for the

A/C cooling fan relay is provided by the HEATER fuse. On Capri, when A/C cooling fan relay is energized, it opens the power circuit for the

cooling fan relay. On Festiva, when A/C cooling fan relay is energized, it provides an alternate path to ground for cooling fan mo t o r. E CA al so

provides an alternate path to ground (at ECA pin 1R) for cooling fan motor based on input from coolant temperature sensor to ECA pin 2Q.

Fig. 1: Locating Cooling Fan & A/C Relays

Courtesy of FORD MOTOR CO.

TROUBLE SHOOTING

COOLING FAN DOES NOT OPERATE OR OPERATES ERRATICALLY

If cooling fan does not run at any time, or operates erratically, check the following items to help locate fault.

Check power fuse.

Check cooling fan relay.

Check coolant temperature switch.

Check cooling fan wiring harness.

Check cooling fan motor.

Check A/C cooling fan relay.

COOLING FAN RUNS CONTINUOUSLY

If cooling fan runs continuously, check the following items to help locate fault.

Check cooling fan relay.

Check coolant temperature switch.

Check cooling fan wiring harness.

Check cooling fan motor.

Check A/C cooling fan relay.

Page 1 of 3 MITCHELL 1 ARTICLE - ENGINE COOLING FAN 1990-92 ENGINE COOLING Ford Motor Co. Engine Cooling Fans

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 87 of 454

COOLING FAN DOES NOT RUN WITH A/C ON

If cooling fan does not run with A/C on, check the following items to help isolate fault.

Check A/C cooling fan relay.

Check cooling fan wiring harness.

TESTING

VOLTAGE SUPPLY TEST

Disconnect cooling fan motor connector. Turn ignition on. Check for voltage at Yellow wire terminal of connector. If voltage is NOT present,

check for blown 20-amp COOLING fuse (Capri) or C-FAN fuse (Festiva) or open in Yellow wire between cooling fan and fuse.

Disconnect cooling fan relay connector. Cooling fan relay is located in the left front corner of engine compartment. Turn ignition on. Check

for voltage at Yellow (Capri) or Black/Yellow (Festiva) wire terminal of connector. If voltage is NOT present, check for blown 30-amp

HEATER fuse on Capri or 10-amp METER fuse on Festiva or open in Black/Yellow wire between cooling fan relay and fuse.

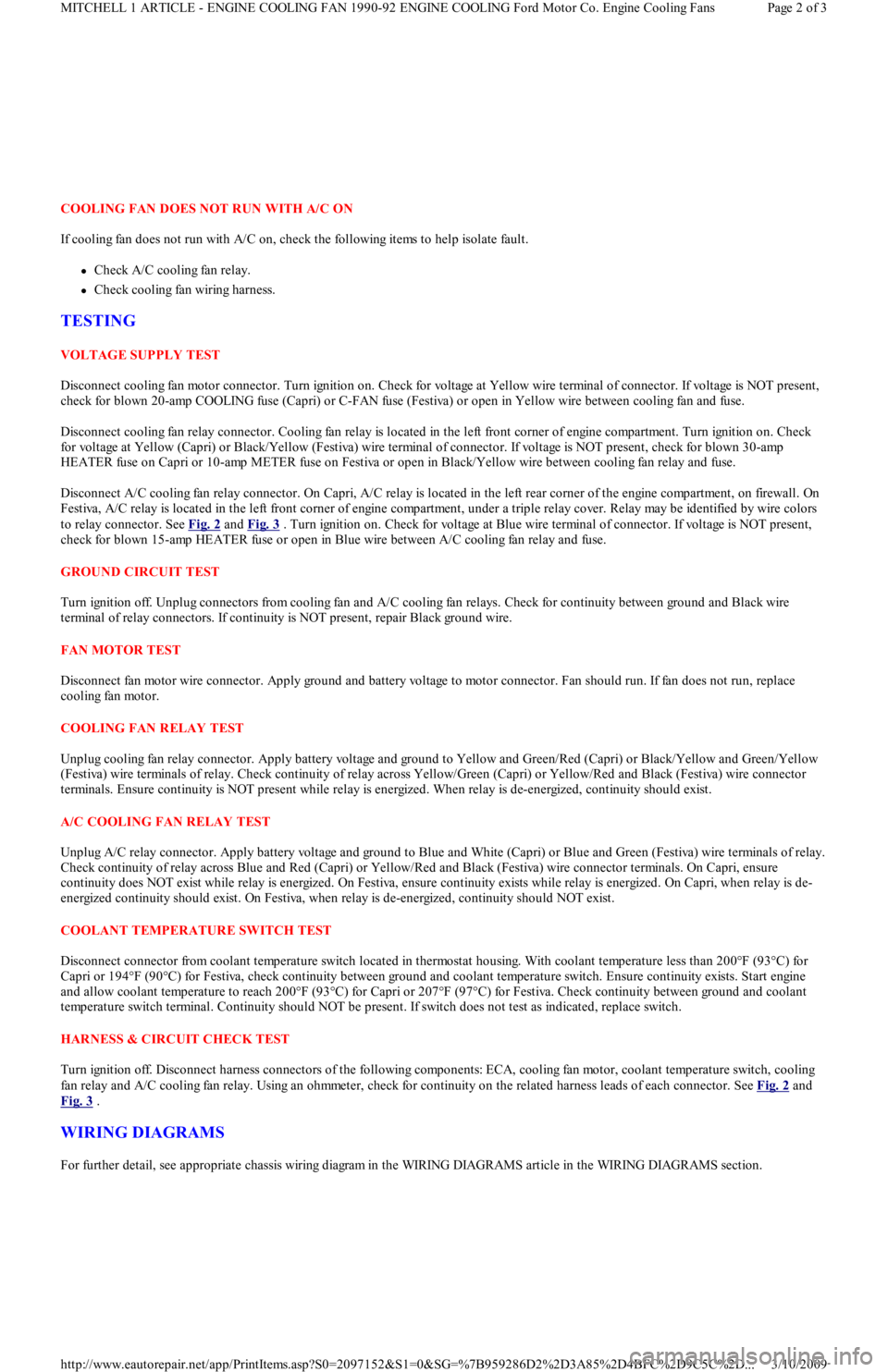

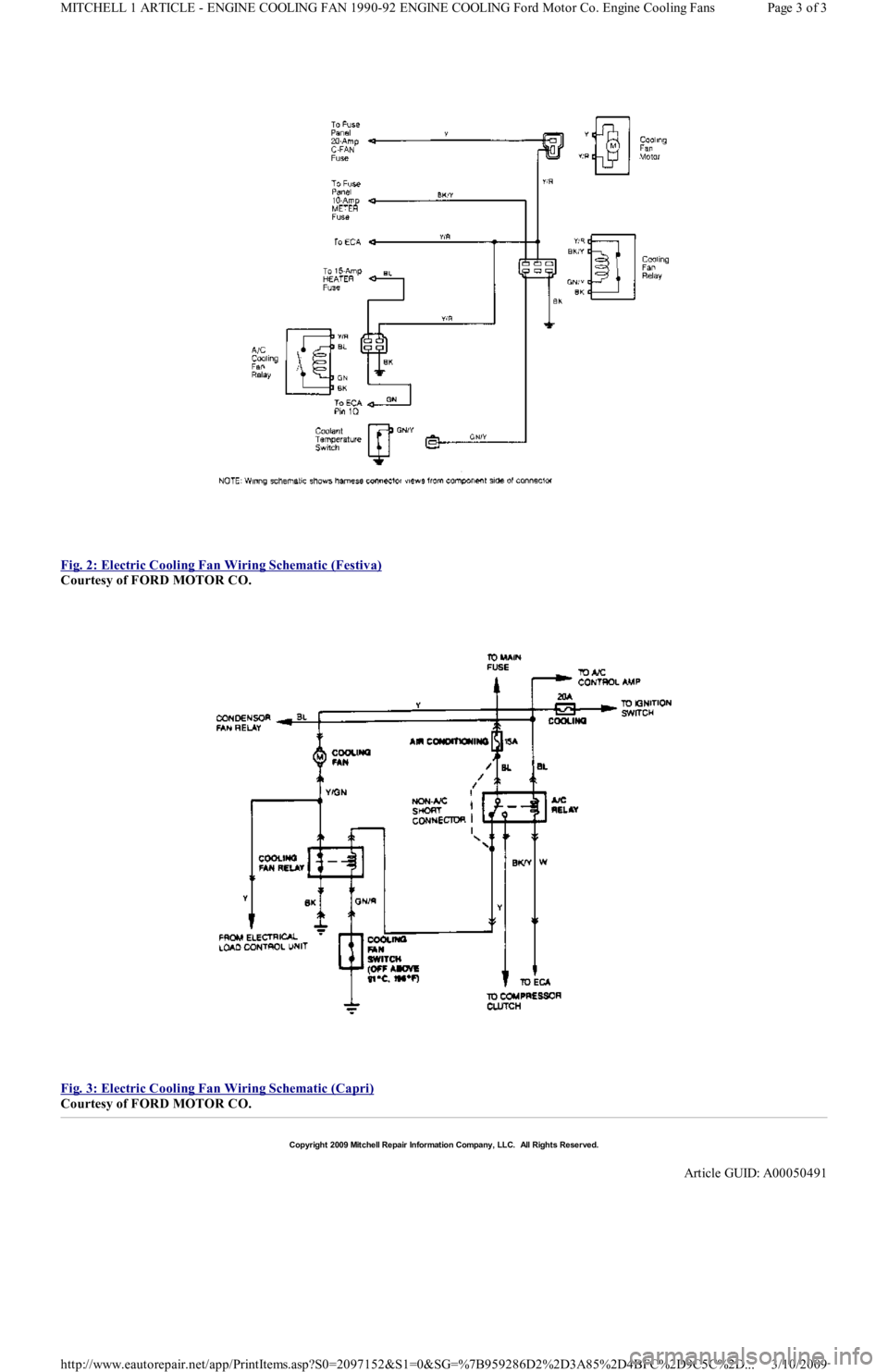

Disconnect A/C cooling fan relay connector. On Capri, A/C relay is located in the left rear corner of the engine compartment, on firewall. On

Festiva, A/C relay is located in the left front corner of engine compartment, under a triple relay cover. Relay may be identified by wire colors

to relay connector. See Fig. 2

and Fig. 3 . Turn ignition on. Check for voltage at Blue wire terminal of connector. If voltage is NOT present,

check for blown 15-amp HEATER fuse or open in Blue wire between A/C cooling fan relay and fuse.

GROUND CIRCUIT TEST

Turn ignition off. Unplug connectors from cooling fan and A/C cooling fan relays. Check for continuity between ground and Black wire

terminal of relay connectors. If continuity is NOT present, repair Black ground wire.

FAN MOTOR TEST

Disconnect fan motor wire connector. Apply ground and battery voltage to motor connector. Fan should run. If fan does not run, replace

cooling fan motor.

COOLING FAN RELAY TEST

Unplug cooling fan relay connector. Apply battery voltage and ground to Yellow and Green/Red (Capri) or Black/Yellow and Green/Yellow

(Festiva) wire terminals of relay. Check continuity of relay across Yellow/Green (Capri) or Yellow/Red and Black (Festiva) wire connector

terminals. Ensure continuity is NOT present while relay is energized. When relay is de-energized, continuity should exist.

A/C COOLING FAN RELAY TEST

Unplug A/C relay connector. Apply battery voltage and ground to Blue and White (Capri) or Blue and Green (Festiva) wire terminals of relay.

Check continuity of relay across Blue and Red (Capri) or Yellow/Red and Black (Festiva) wire connector terminals. On Capri, ensure

continuity does NOT exist while relay is energized. On Festiva, ensure continuity exists while relay is energized. On Capri, when relay is de-

energized continuity should exist. On Festiva, when relay is de-energized, continuity should NOT exist.

COOLANT TEMPERATURE SWITCH TEST

Disconnect connector from coolant temperature switch located in thermostat housing. With coolant temperature less than 200°F (93°C) for

Capri or 194°F (90°C) for Festiva, check continuity between ground and coolant temperature switch. Ensure continuity exists. Start engine

and allow coolant temperature to reach 200°F (93°C) for Capri or 207°F (97°C) for Festiva. Check continuity between ground and coolant

temperature switch terminal. Continuity should NOT be present. If switch does not test as indicated, replace switch.

HARNESS & CIRCUIT CHECK TEST

Turn ignition off. Disconnect harness connectors of the following components: ECA, cooling fan motor, coolant temperature switch, cooling

fan relay and A/C cooling fan relay. Using an ohmmeter, check for continuity on the related harness leads of each connector. See Fig. 2

and

Fig. 3

.

WIRING DIAGRAMS

For further detail, see appropriate chassis wiring diagram in the WIRING DIAGRAMS article in the WIRING DIAGRAMS section.

Page 2 of 3 MITCHELL 1 ARTICLE - ENGINE COOLING FAN 1990-92 ENGINE COOLING Ford Motor Co. Engine Cooling Fans

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 88 of 454

Fig. 2: Electric Cooling Fan Wiring Schematic (Festiva)

Courtesy of FORD MOTOR CO.

Fig. 3: Electric Cooling Fan Wiring Schematic (Capri)

Courtesy of FORD MOTOR CO.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00050491

Page 3 of 3 MITCHELL 1 ARTICLE - ENGINE COOLING FAN 1990-92 ENGINE COOLING Ford Motor Co. Engine Cooling Fans

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 89 of 454

Back To Article

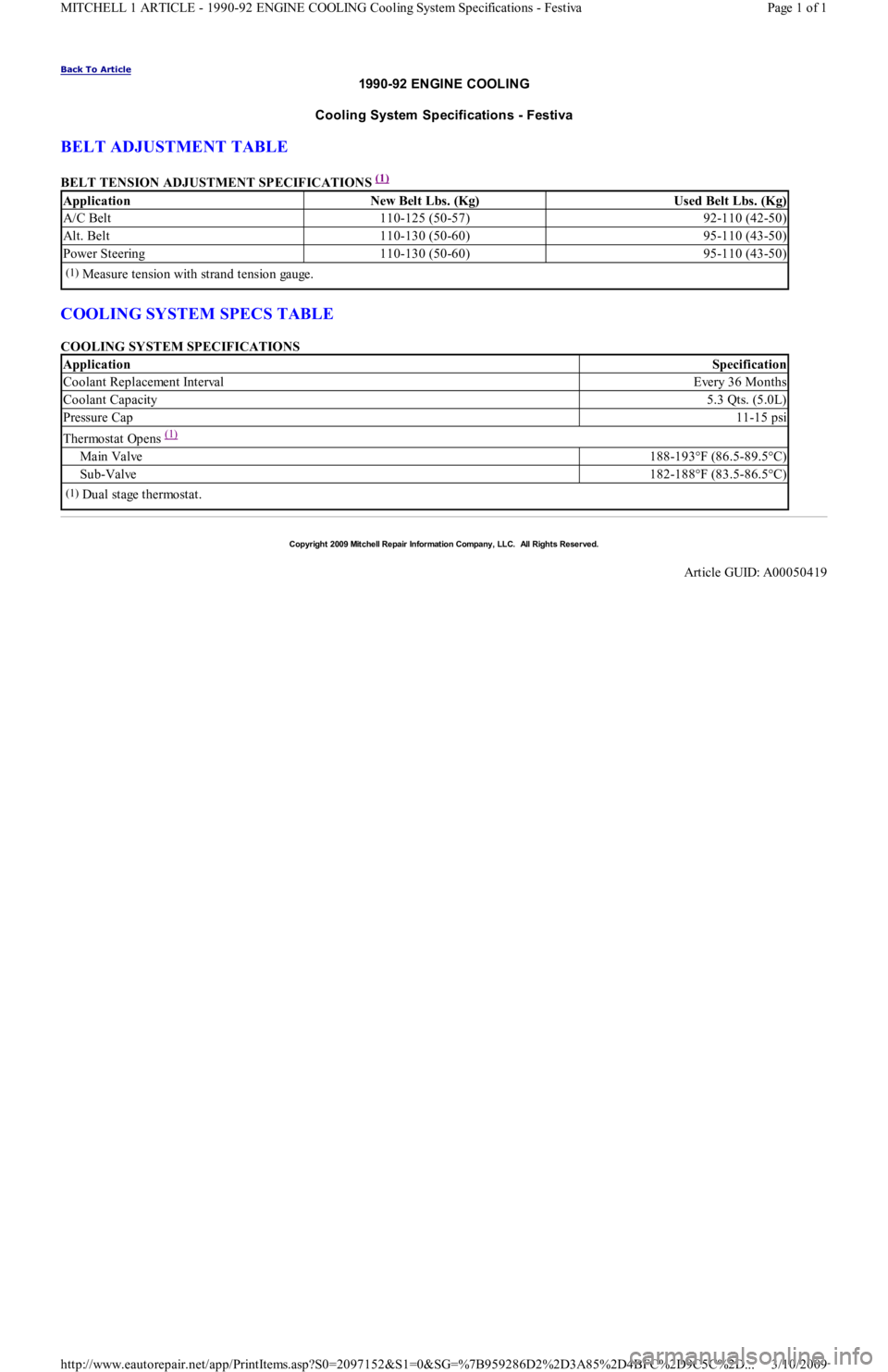

1990-92 ENGINE COOLING

Cooling System Specifications - Festiva

BELT ADJUSTMENT TABLE

BELT TENSION ADJUSTMENT SPECIFICATIONS (1)

COOLING SYSTEM SPECS TABLE

COOLING SYSTEM SPECIFICATIONS

ApplicationNew Belt Lbs. (Kg)Used Belt Lbs. (Kg)

A/C Belt110-125 (50-57)92-110 (42-50)

Alt. Belt110-130 (50-60)95-110 (43-50)

Power Steering110-130 (50-60)95-110 (43-50)

(1)Measure tension with strand tension gauge.

ApplicationSpecification

Coolant Replacement IntervalEvery 36 Months

Coolant Capacity5.3 Qts. (5.0L)

Pressure Cap11-15 psi

Thermostat Opens (1)

Main Valve188-193°F (86.5-89.5°C)

Sub-Valve182-188°F (83.5-86.5°C)

(1)Dual stage thermostat.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00050419

Page 1 of 1 MITCHELL 1 ARTICLE - 1990-92 ENGINE COOLING Cooling System Specifications - Festiva

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 90 of 454

Back To Article

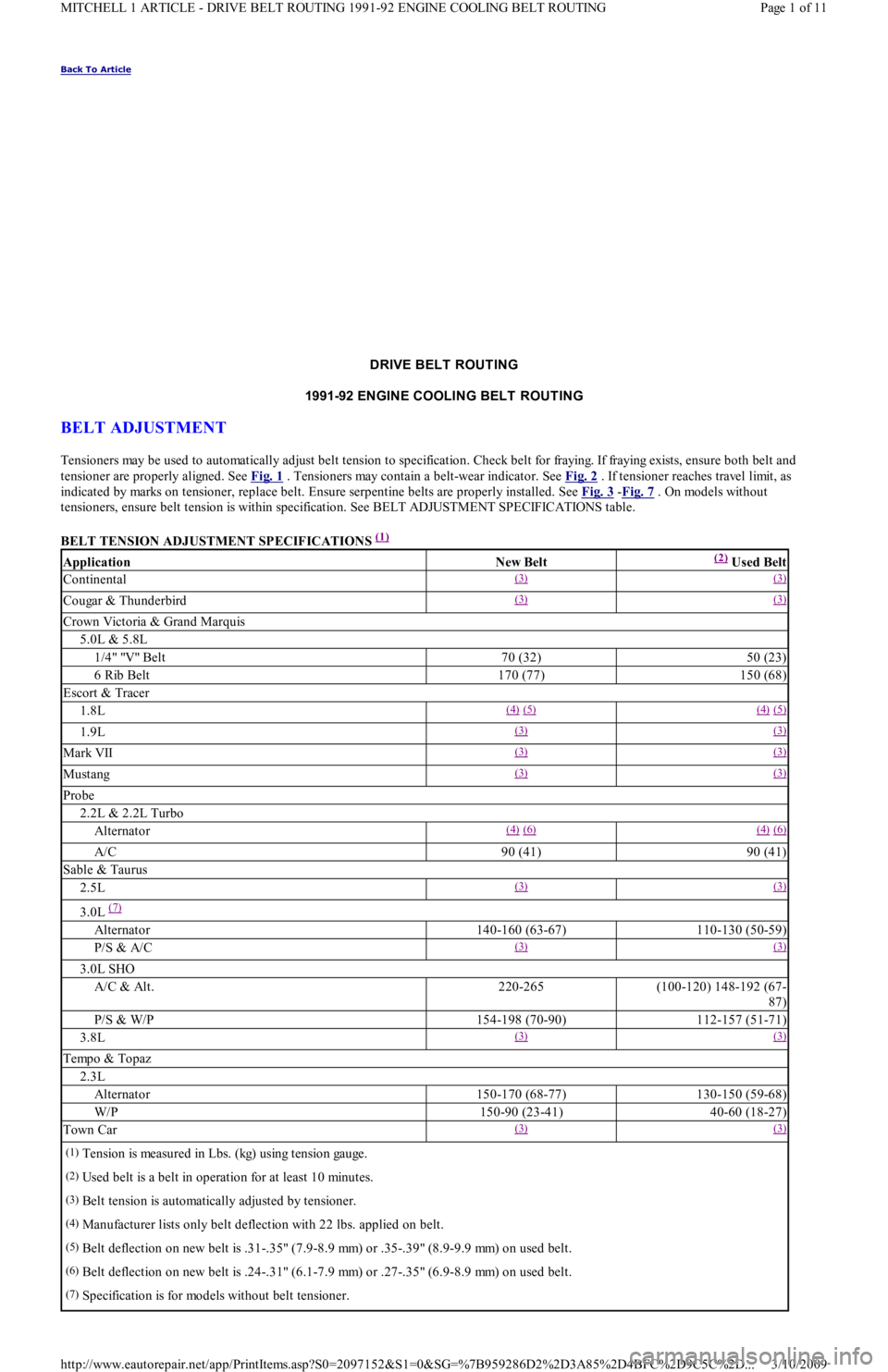

DRIVE BELT ROUTING

1991-92 ENGINE COOLING BELT ROUT ING

BELT ADJUSTMENT

Tensioners may be used to automatically adjust belt tension to specification. Check belt for fraying. If fraying exists, ensure both belt and

tensioner are properly aligned. See Fig. 1

. Tensioners may contain a belt-wear indicator. See Fig. 2 . If tensioner reaches travel limit, as

indicated by marks on tensioner, replace belt. Ensure serpentine belts are properly installed. See Fig. 3

-Fig. 7 . On models without

tensioners, ensure belt tension is within specification. See BELT ADJUSTMENT SPECIFICATIONS table.

BELT TENSION ADJUSTMENT SPECIFICATIONS

(1)

ApplicationNew Belt(2) Used Belt

Continental(3) (3)

Cougar & Thunderbird(3) (3)

Crown Victoria & Grand Marquis

5.0L & 5.8L

1/4" "V" Belt70 (32)50 (23)

6 Rib Belt170 (77)150 (68)

Escort & Tracer

1.8L(4) (5) (4) (5)

1.9L(3) (3)

Mark VII(3) (3)

Mustang(3) (3)

Probe

2.2L & 2.2L Turbo

Alternator(4) (6) (4) (6)

A/C90 (41)90 (41)

Sable & Taurus

2.5L(3) (3)

3.0L (7)

Alternator140-160 (63-67)110-130 (50-59)

P/S & A/C(3) (3)

3.0L SHO

A/C & Alt.220-265(100-120) 148-192 (67-

87)

P/S & W/P154-198 (70-90)112-157 (51-71)

3.8L(3) (3)

Tempo & Topaz

2.3L

Alternator150-170 (68-77)130-150 (59-68)

W/P150-90 (23-41)40-60 (18-27)

Town Car(3) (3)

(1)Tension is measured in Lbs. (kg) using tension gauge.

(2)Used belt is a belt in operation for at least 10 minutes.

(3)Belt tension is automatically adjusted by tensioner.

(4)Manufacturer lists only belt deflection with 22 lbs. applied on belt.

(5)Belt deflection on new belt is .31-.35" (7.9-8.9 mm) or .35-.39" (8.9-9.9 mm) on used belt.

(6)Belt deflection on new belt is .24-.31" (6.1-7.9 mm) or .27-.35" (6.9-8.9 mm) on used belt.

(7)Specification is for models without belt tensioner.

Page 1 of 11 MITCHELL 1 ARTICLE - DRIVE BELT ROUTING 1991-92 ENGINE COOLING BELT ROUTING

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...