FORD FESTIVA 1991 Service Manual

Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 101 of 454

Back To Article

ENGINE OVERHAUL

1991-92 FORD MOT OR CO. ENGINES 1.3L & 1.6L 4-Cylinder

ENGINE IDENTIFICATION

Engine can be identified by Vehicle Identification Number (VIN) on metal tab attached to instrument panel. Tab is close to windshield on

driver's side and is visible through windshield. VIN has 17 characters. The 8th character identifies engine.

ENGINE IDENTIFICATION CODES

ADJUSTMENTS

VALVE ARRANGEMENT

Firewall Side

In t ake val ves.

Radiator Side

Exhaust valves.

VALVE CLEARANCE ADJUSTMENT

Hydraulic lifters are used. Adjustment is NOT possible nor necessary.

REMOVAL & INSTALLATION

FUEL PRESSURE RELEASE

Remove rear seat. Remove fuel pump access panel. Disconnect fuel pump electrical connector. Start engine and allow to idle until engine dies.

ENGINE

Removal (1.3L)

1. Remove battery and battery tray. Index hood-to-hinge and remove hood. Drain coolant. Drain engine oil and transaxle fluid. Disconnect

vane airflow meter connector, vane airflow meter and hose.

2. Remove oil dipstick, cooling fan and radiator assembly. Disconnect accelerator cable from mounting bracket and throttle lever.

Disconnect speedometer cable at transaxle. Mark and disconnect fuel lines at fuel pump. Plug fuel lines. Remove heater hoses. Remove

brake booster vacuum hose. Disconnect transaxle vacuum hose.

3. Remove charcoal canister hoses from engine. Disconnect engine wiring harness. Remove alternator and brackets. Remove engine ground

strap. Raise vehicle and remove catalytic converter.

4. Disconnect A/C compressor without removing hoses, and set compressor aside. Disconnect distributor wiring at coil. On automatic

transaxle models, remove shift lever-to-manual shaft assembly nut. Remove shift cable from transaxle. Loosen front wheel bolts. Raise

vehicle and remove wheel assemblies.

5. Remove stabilizer mounting nuts and brackets. Remove lower arm clamp bolts and nuts. Pull lower arms downward, separating lower

arms from knuckles. Separate halfshafts and install Differential Plugs (T87C-7025-C) between differential side gears. See FWD AXLE

SHAFTS article in DRIVE AXLES Section.

6. On manual transaxle vehicles, disconnect clutch control cable and shift control cable rod. Remove stabilizer bar from transaxle. Remove

catalytic converter inlet pipe. Support engine assembly with hoist. Remove rear crossmember mount bolts. Remove front and rear engine

mount nuts.

7. Remove crossmember. Lower vehicle and attach engine lift hooks. Remove right engine mount bolt. Remove engine/transaxle assembly.

Remove gusset plates. Remove starter and flywheel cover. Remove torque converter bolts on automatic transaxle. Remove engine-to-

transaxle bolts. Separate transaxle from engine.

Installation (1.3L)

1. Install transaxle to engine in reverse order of removal. Attach hoist to engine/transaxle assembly and position in vehicle. Support engine

in chassis and install engine mount bolts. Raise vehicle and install front engine mount nut. Tighten nuts to specification. See TORQUE

SPECIFICATIONS table at end of article.

2. Position crossmember onto mounts and chassis. Tighten rear nut. Install mount-to-crossmember nuts and tighten. Remove differential

plugs and install halfshafts. To complete installation, reverse removal procedure. Tighten all bolts/nuts to specifications. Fill all fluid NOTE:For engine repair procedures not covered in this article, see ENGINE OVERHAUL PROCEDURES

-

GENERAL INFORMATION

article in the GENERAL INFORMAT ION section.

ApplicationVIN Code

Festiva

1.3L SOHC PFIH

Capri

1.6L DOHC PFIZ

1.6L DOHC PFI TURBO6

NOTE:When rem oving engine m ounts, m ark and note location and position to ensure proper installation.

Engine and transaxle are rem oved as an assem bly.

Page 1 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 102 of 454

levels to proper level.

Removal (1.6L & 1.6L Turbo)

1. Relieve fuel pressure and discharge air conditioning system (if equipped). See FUEL PRESSURE RELEASE under REMOVAL &

INSTALLATION. Disconnect and remove battery, battery tray and battery tray support bracket.

2. Release wiring harness retaining straps from battery support tray. Disconnect windshield washer supply hose between fluid reservoir and

hood. Mark hinge locations and remove hood.

3. Disconnect intake air tube and wiring to ignition coil and vane airflow meter. Remove air cleaner/vane airflow meter assembly. Remove

air cleaner assembly support brackets. Disconnect intercooler hoses from turbocharger (if equipped).

4. Drain engine coolant and remove radiator. Disconnect accelerator cable, and remove retaining bracket from cam cover. Position cable to

one side.

5. Disconnect and plug fuel lines at fuel filter and pressure regulator. Disconnect power brake booster manifold vacuum hose from

manifold. Disconnect heater hoses at heater core tubes. Label and remove vacuum hoses located at throttle body.

6. For manual transaxle turbocharged vehicles, disconnect clutch cable and remove support bracket and cable from transmission. On non-

turbo vehicles, disconnect clutch slave hydraulic line. For automatic transaxle, remove transaxle cooler lines.

7. Disconnect starter wiring at starter. Remove harness from locating strap on bracket. Disconnect alternator wiring. Disconnect wiring

from engine coolant sensors located on rear of engine block. Remove ground connection at bracket on thermostat cover. Disconnect O2

sensor wire, main wiring harness connector, TPS connector (turbocharged only), knock sensor connector, distributor wiring and

transaxle wiring. Disconnect ground wire and strap at front of engine, and reinstall lifting eye.

8. Remove engine oil dipstick and retaining clip. Remove power steering pump from mounting bracket. Remove power steering pump

mounting bracket. With hoses attached, position pump aside. Remove upper air conditioning compressor retaining bolts (if equipped).

9. Raise vehicle on hoist. Drain engine oil and cooling system. On vehicles with air conditioning, remove lower air conditioning

compressor mounting bolts, and position compressor out of way.

10. Remove front wheels and tires. Remove front ball joints-to-ste e r in g kn u c kl e s r e t a in in g b o l t s. R e mo ve sp l a sh gu a r d s. Dr a in t ransmission

oil and remove half shafts from differential. Remove front exhaust pipe bracket located on lower side of engine. Disconnect front

exhaust pipe from exhaust manifold, or turbocharger (if equipped).

11. Remove frame support bar-to-engine support bolt. Loosen right control arm bolt and, pivot support bar downward. Disengage rubber

exhaust hangers located directly behind catalytic converter. Allow exhaust system to hang down 6 inches, and support system with

mechanic's wire. Unbolt shift linkage and stabilizer bar at transaxle. Remove nuts from front and rear engine mounts, and lower vehicle.

12. Attach chains onto lift eyes at ends of cylinder head, and support engine with hoist. Remove RH engine mount through bolt. Raise

engine off mounts and slightly pivot engine/transaxle assembly. Disconnect oil pressure sensor and route starter/alternator wiring

harness from engine. Carefully lift engine/transaxle assembly, turn assembly while raising to clear brake master cylinder, shift linkage

universal joint, radiator support and air conditioning lines (if equipped).

13. Remove intake manifold support bracket. Remove gusset plate(s) (if equipped). Remove starter. Remove transaxle-to-engine retaining

bolts. Identify bolts to ensure correct installation. Separate transaxle from engine. On manual transaxle, remove pressure plate, clutch

disc and flywheel. On automatic transaxle, remove flexplate.

Installation (1.6L & 1.6L Turbo)

1. Install transaxle to engine in reverse order of removal. Attach hoist to engine/transaxle assembly and position assembly in vehicle.

Before engine contacts mounts, route starter, alternator and oil pressure sensor wiring, and connect oil pressure sensor. Lower engine

until front mount seats on crossmember. Install through bolt on RH engine mount. DO NOT tighten bolt.

2. Remove hoist. Raise vehicle and support with jackstands. Align rear engine mount to crossmember, and install retaining nuts to front

and rear engine mounts. Tighten nuts to specification. See TORQUE SPECIFICATIONS

table at end of article.

3. On manual transaxles, connect shift coupling and stabilizer. Tighten to specification. On automatic transaxles, connect shift linkage and

oil cooler lines. Tighten linkage retaining bolt, shift cable pivot and oil cooler hose clamps to specification. Connect front exhaust pipe

to manifold (or turbocharger). Install exhaust pipe to support bracket. Tighten bolts to specification. Tighten manifold (or turbocharger)

to specification. Attach rubber exhaust hangers. Position cross brace. Tighten retaining nut and bolt and right control arm front bolt.

4. Install drive axles. Install ball joint retaining bolts and tighten to specification. Mount A/C Compressor to engine (if equipped). Tighten

lower retaining bolts to specification. Install splash guards. Install tire and wheel assemblies. Tighten retaining nuts to specification.

5. Lower vehicle. Install upper A/C compressor retaining bolts (if equipped). Tighten bolts to specification. Tighten RH engine mo u n t

through bolt to specification. Connect alternator wiring.

6. Position power steering pump bracket on stud. Lower pump into engine compartment. Install power steering pump bracket retaining

bolts and nut. Tighten to specification. Install power steering pump and belt. Tighten adjustment nut and pivot bolt to specification.

7. Install engine oil dipstick and retaining clip. Install ground strap and ground wire to cylinder head. Install clutch cable (if equipped).

Connect clutch hydraulic line if equipped with manual transaxle or naturally aspirated. Connect transmission electrical connectors.

Connect fuel lines to fuel filter and pressure regulator. Install intake air tube to throttle body.

8. Install intercooler hoses on turbocharged models. Install air cleaner assembly brackets. Install air cleaner assembly with airflow meter

attached. Install intake air tube. Install coil and airflow meter connectors. Connect coolant crankcase and air bypass hoses. Install

vacuum hoses as noted in disassembly.

9. Connect accelerator cable. Install retaining bracket. Install power brake booster hose. Remove speedometer cable from transaxle. Fill

transaxle to specification. See CAPACITIES in SERVICE & ADJUSTMENT SPECIFICATIONS article. Install speedometer cable.

Connect speedometer cable connector. Fill engine oil to capacity.

10. Install radiator/fan assembly. Tighten bracket retaining bolts to specification. Connect coolant hoses and fan electrical connector. Fill

coolant to specification.

11. Install hood and connect washer hose. Install battery tray support, battery tray, battery and battery hold-down. Connect battery

terminal. Evacuate and charge air conditioning system (if equipped). Road test vehicle and inspect for leaks.

INTAKE MANIFOLD

Removal (1.3L)

CAUT ION: DO NOT allow com pressor to hang by hoses. T ie up com pressor with m echanic's wire.

Page 2 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 103 of 454

Disconnect negative battery cable. Drain cooling system. Remove air cleaner. Remove intake manifold bracket. Disconnect throttle cable.

Mark and disconnect vacuum hoses, fuel hoses and wiring. Remove intake manifold bolts. Remove intake manifold and gasket.

Installation (1.3L)

Clean all gasket mating surfaces. Ensure surface is free of burrs, scratches and cracks. Replace all gaskets. Position gasket and manifold to

cylinder head. Install bolts and tighten to specification. To complete installation, reverse removal procedure.

Removal (1.6L)

1. Disconnect negative battery terminal. Relieve fuel pressure. See FUEL PRESSURE RELEASE under REMOVAL &

INSTALLATION. Drain cooling system. Disconnect intercooler tube and/or air intake tube. Disconnect air by-pass hoses. Disconnect

main engine harness electrical connection and TPS connector. Disconnect vacuum hoses from throttle body.

2. Disconnect fuel lines from fuel filter and pressure regulator. Disconnect throttle cable. Disconnect hoses from By-pass Air Control valve

( B AC ) . R e mo ve B AC va l ve r e t a in in g n u t a n d b o l t . R e mo ve in t a ke manifold retaining nuts and bolts from support bracket and cylinder

head. Remove intake manifold and throttle body assembly.

Installation (1.6L)

1. Install new intake manifold gasket, ensuring coolant passage openings align with openings in cylinder head and manifold. Install intake

manifold. Tighten retaining nut and bolts and support bracket bolts to specification. See TORQUE SPECIFICATIONS

table at end of

article.

2. Install BAC valve and connect air hoses. Connect throttle cable. Connect fuel lines to fuel filters and pressure regulator. Connect main

engine harness connector and TPS connector. Connect vacuum lines to throttle body. Install intake air tube. Connect intercooler tube

and/or intake air tube. Connect air by-pass hoses. Fill cooling system. Connect negative battery terminal. Start engine and check for

fluid leaks and correct operation.

EXHAUST MANIFOLD

Removal (1.3L)

1. Raise vehicle. Remove catalytic converter inlet pipe at exhaust manifold. Remove pulse air tube nuts at inlet pipe. Remove inlet pipe

support bracket bolts. Lower vehicle. Remove air intake duct. Remove exhaust manifold heat shroud bolts and remove shroud.

2. Disconnect oxygen sensor connector. Remove exhaust manifold nuts and remove exhaust manifold. Remove gasket from inlet pipe and

cylinder head.

Installation

Position new gasket on cylinder head and inlet pipe. Install exhaust manifold and nuts. Tighten nuts to specification. See, at end of article,

TORQUE SPECIFICATIONS

table. To complete installation, reverse removal procedure. Tighten all bolts and nuts to specification.

Removal (1.6L Non-Turbo)

Remove intake air tube. Remove front exhaust pipe to exhaust manifold retaining nuts. Remove exhaust support bracket (if equipped). Remove

heat shield. Disconnect O2 sensor electrical connector. Remove exhaust manifold.

Installation (1.6L Non-Turbo)

Install exhaust manifold gaskets. Install heavier gasket first. Install exhaust manifold and tighten retaining nuts to specification. See TORQUE

SPECIFICATIONS table at end of article. Connect O2 sensor electrical connector. Install manifold heat shield. Install intake air tube.

Connect front exhaust pipe to intake manifold and tighten retaining nuts to specification. Install exhaust support bracket, if removed, and

tighten engine mount bolt to specification. Start engine and check for leaks.

Removal (1.6L Turbo)

1. Disconnect negative battery cable. Drain cooling system. Remove throttle body air intake tube. Disconnect intercooler hose from

turbocharger assembly and position both intercooler hoses out of the way. Remove O2 sensor connector from its retaining clip, and

disconnect O2 sensor. Remove lower heat shield and then upper heat shield. Remove turbocharger side heat shield.

2. Remove power steering pump (leave hoses attached) and lay aside. Disconnect lower radiator hose from water pump. Position power

steering pump to access mounting bracket retaining bolts and nut. Remove both bolts and one nut, and remove bracket from engine.

Remove 2 screws retaining air cleaner duct tube, loosen clamp at turbocharger and position duct tube out of the way. Disconnect

coolant return hose at turbocharger. Remove bolt and brass sealing washers from oil supply line at engine block.

3. Raise vehicle. Remove retaining nuts and washers from exhaust pipe flange. Remove 2 bolts retaining exhaust hangers to engine block.

Slide off two rubber exhaust hangers at catalytic converter. Pull exhaust pipe downward and to LH side of vehicle. Disconnect oil return

hose at turbocharger. Disconnect coolant return hose at turbocharger. Remove 2 retaining bolts from turbocharger support bracket.

Remove 2 bolts retaining coolant by-pass tube outlet to water pump. Lower vehicle.

4. Loosen retaining clamp bolt on coolant by-pass tube at rear of cylinder head. Remove 11 retaining nuts from exhaust manifold. Pull

coolant by-pass tube bracket from exhaust stud, and position tube out of way. Grasp manifold, pull off studs and move assembly slightly

to RH side of engine compartment to clear cooling fan, and remove assembly from vehicle.

5. Working on bench, remove 4 nuts retaining turbocharger to exhaust manifold, separate assembly and discard gasket.

Installation (1.6L Turbo)

NOTE:Feed O2 sensor wire and guide through upper heat shield.

NOTE:When reinstalling turbocharger, thoroughly rem ove all gaskets and sealant. Use new gaskets. Add .85

oz. (25 cc) of engine oil in the oil passage of the turbocharger.

Page 3 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 104 of 454

1. Position new gasket on exhaust manifold, and install turbocharger onto studs. Install 4 retaining nuts and tighten to specification. See

TORQUE SPECIFICATIONS

table at end of article.

2. Remove oil supply line from turbocharger. Position new (2-piece) exhaust gasket on cylinder head with heavy gasket installed first .

Carefully position turbocharger assembly in engine compartment and slide exhaust manifold on studs. Position heater tube bracket onto

exhaust stud. Install 11 retaining nuts onto exhaust manifold and tighten to specification. See TORQUE SPECIFICATIONS

table at

end of article. Tighten heater tube clamp bolt securely.

3. Raise vehicle. Position new gasket and install 2 retaining bolts on heater tube outlet. Install 2 retaining bolts into turbocharger support

bracket and tighten bolts to specification.

4. Connect coolant return hose. Connect oil return hose and secure with clamp. Position exhaust pipe onto turbocharger, and start nuts

and washers. Install 2 retaining bolts on exhaust hanger at engine. Slide on 2 rubber exhaust hangers at catalytic converter. Tighten

exhaust pipe retaining nuts to specification. Lower vehicle.

5. Install retaining bolt and brass washers on oil supply line, carefully position oil line into vehicle and hand-start bolt into engine block.

Connect and finger tighten oil line to turbocharger. Tighten oil line bolt and oil supply line on turbocharger to specification.

6. Connect coolant supply hose. Position air cleaner duct tube on turbocharger and tighten clamp. Install 2 screws retaining air cleaner

duct tube. Position power steering pump bracket on engine, and install 2 retaining bolts and one retaining nut. Tighten to specification.

Position power steering pump on mounting bracket, and install though bolt and adjuster. Connect lower radiator hose. Install power

steering belt. Position upper heat shield and install 2 retaining bolts finger tight.

7. Position lower heat shield and install three retaining bolts finger tight. Tighten all heat shield bolts to specification. Connect O2 sensor

and install connector into its retaining clip. See TORQUE SPECIFICATIONS

table at end of article. Position intercooler hose on

turbocharger and secure with clamp. Install throttle body air intake tube. Connect negative battery cable. Refill cooling system.

CYLINDER HEAD

Removal (1.3L)

1. Disconnect battery ground cable. Mark and disconnect fuel lines at fuel pump. Remove accessory belts, water pump pulley, crankshaft

pulley, timing belt covers, timing belt tensioner, timing belt, valve cover and exhaust and intake manifolds. Drain cooling system.

2. Mark and remove electrical connectors and vacuum hoses. Remove spark plug wires from spark plugs, and remove spark plugs. Remove

distributor cap. Disconnect vacuum hoses and distributor wiring.

3. Index distributor-to-mount position and remove hold-down bolt. Remove distributor assembly. Remove engine ground strap. Remove

front and rear engine lifting hooks. Remove upper radiator hose, by-pass hose and bracket.

4. Remove bolts retaining rocker arm shaft. Remove rocker arm assemblies. Remove cylinder head bolts. Remove head and gasket.

Inspection (1.3L)

1. Thoroughly clean and check gasket mating surface of cylinder head and block. Check cylinder for cracks, nicks, burrs or damage. Using

a straightedge and feeler gauge, check warpage over entire gasket area. Ensure cylinder head and/or block warpage does not

exceed .006" (.15 mm).

2. If warpage exceeds .006" (.15 mm), machine cylinder head and/or block gasket surface. Maximum machining allowed is .008" (.20 mm).

If more machining is required, replace block and/or cylinder head.

Installation (1.3L)

1. Place new head gasket properly on block. Carefully place cylinder head in position on block. Install head bolts. Tighten bolts in

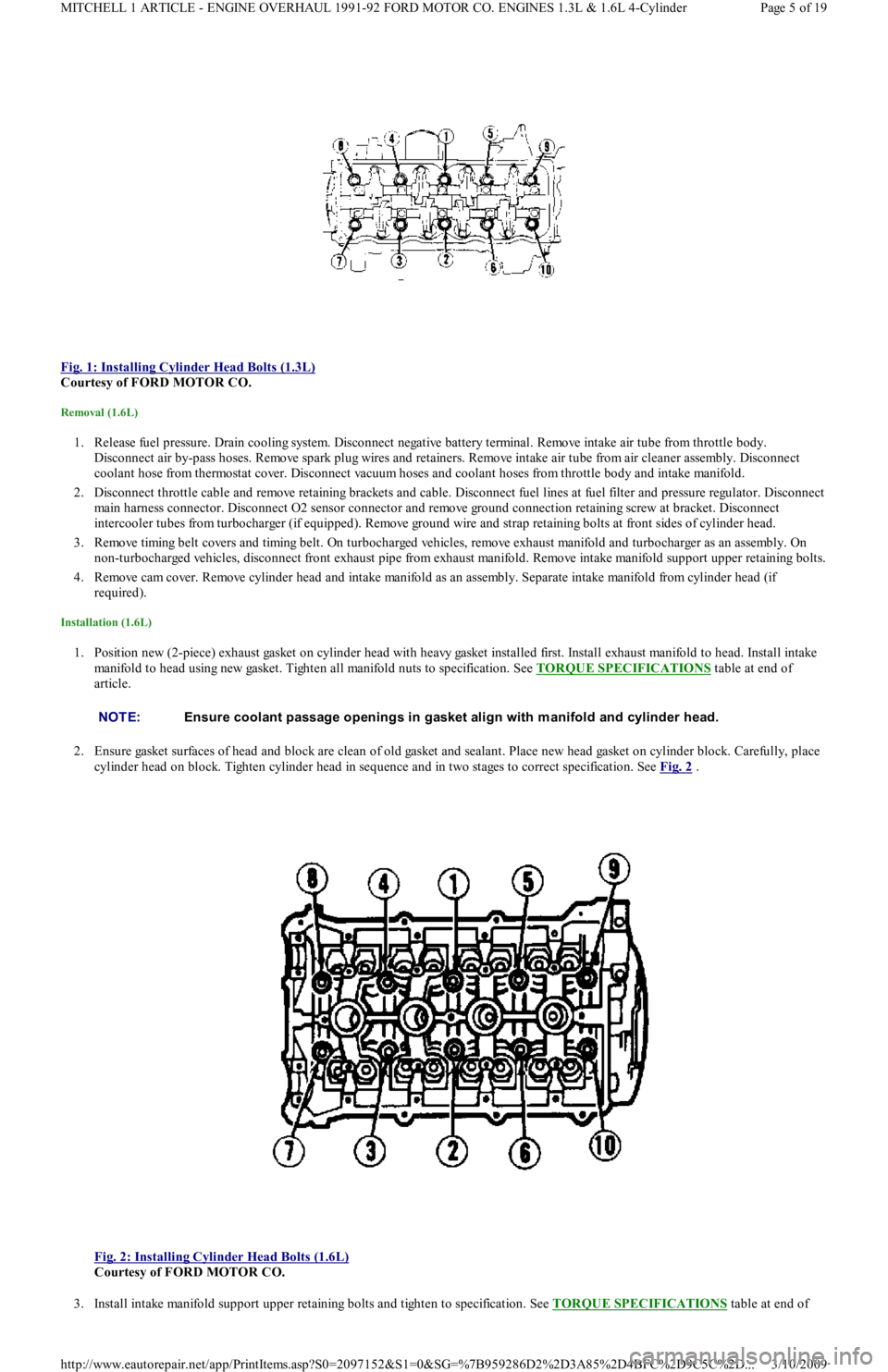

sequence and in 2 steps. See Fig. 1

.

2. While tightening rocker arm shaft, slide shaft springs away from retaining bolt to prevent pinching springs. Tighten rocker arm shaft bolts

in sequence and to specification. See Fig. 5

. To complete installation, reverse removal procedure. Tighten all bolts/nuts to

specification. Fill all fluids to proper levels. NOTE:T urbocharger-to-exhaust m anifold m ounting nuts are of special quality. Ensure correct nuts are

used.

NOTE:Ensure one brass washer is positioned on each side of oil line fitting.

NOTE:Feed O2 sensor wire through upper heat shield. Install wire retainer under LH bolt.

NOTE:If turbocharger was replaced: Disconnect ignition coil, crank engine for 20 seconds, connect ignition

coil, start engine and run at idle for 30 seconds and check for leaks.

NOTE:If original tim ing belt is being reused, m ark direction of rotation for installation reference.

Page 4 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 105 of 454

Fig. 1: Installing Cylinder Head Bolts (1.3L)

Courtesy of FORD MOTOR CO.

Removal (1.6L)

1. Release fuel pressure. Drain cooling system. Disconnect negative battery terminal. Remove intake air tube from throttle body.

Disconnect air by-pass hoses. Remove spark plug wires and retainers. Remove intake air tube from air cleaner assembly. Disconnect

coolant hose from thermostat cover. Disconnect vacuum hoses and coolant hoses from throttle body and intake manifold.

2. Disconnect throttle cable and remove retaining brackets and cable. Disconnect fuel lines at fuel filter and pressure regulator. Disconnect

main harness connector. Disconnect O2 sensor connector and remove ground connection retaining screw at bracket. Disconnect

intercooler tubes from turbocharger (if equipped). Remove ground wire and strap retaining bolts at front sides of cylinder head.

3. Remove timing belt covers and timing belt. On turbocharged vehicles, remove exhaust manifold and turbocharger as an assembly. On

non-turbocharged vehicles, disconnect front exhaust pipe from exhaust manifold. Remove intake manifold support upper retaining bolts.

4. Remove cam cover. Remove cylinder head and intake manifold as an assembly. Separate intake manifold from cylinder head (if

required).

Installation (1.6L)

1. Position new (2-piece) exhaust gasket on cylinder head with heavy gasket installed first. Install exhaust manifold to head. Install intake

manifold to head using new gasket. Tighten all manifold nuts to specification. See TORQUE SPECIFICATIONS

table at end of

article.

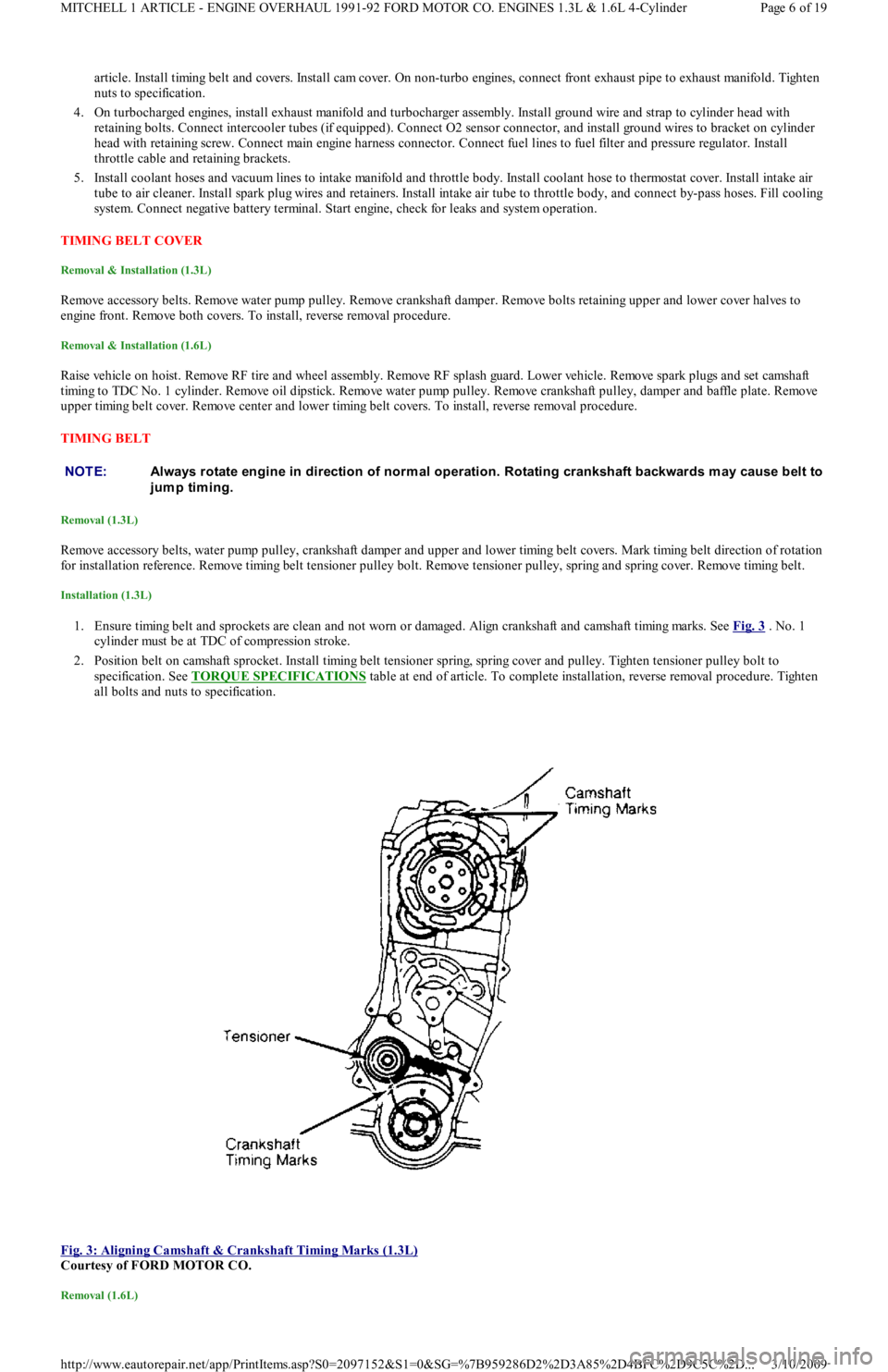

2. Ensure gasket surfaces of head and block are clean of old gasket and sealant. Place new head gasket on cylinder block. Carefully, place

cylinder head on block. Tighten cylinder head in sequence and in two stages to correct specification. See Fig. 2

.

Fig. 2: Installing Cylinder Head Bolts (1.6L)

Courtesy of FORD MOTOR CO.

3. Install intake manifold support upper retaining bolts and tighten to specification. See TORQUE SPECIFICATIONS

table at end of

NOTE:Ensure coolant passage openings in gasket align with m anifold and cylinder head.

Page 5 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 106 of 454

article. Install timing belt and covers. Install cam cover. On non-turbo engines, connect front exhaust pipe to exhaust manifold. Tighten

nuts to specification.

4. On turbocharged engines, install exhaust manifold and turbocharger assembly. Install ground wire and strap to cylinder head with

retaining bolts. Connect intercooler tubes (if equipped). Connect O2 sensor connector, and install ground wires to bracket on cylinder

head with retaining screw. Connect main engine harness connector. Connect fuel lines to fuel filter and pressure regulator. Install

throttle cable and retaining brackets.

5. Install coolant hoses and vacuum lines to intake manifold and throttle body. Install coolant hose to thermostat cover. Install intake air

tube to air cleaner. Install spark plug wires and retainers. Install intake air tube to throttle body, and connect by-pass hoses. Fill cooling

system. Connect negative battery terminal. Start engine, check for leaks and system operation.

TIMING BELT COVER

Removal & Installation (1.3L)

Remove accessory belts. Remove water pump pulley. Remove crankshaft damper. Remove bolts retaining upper and lower cover halves to

engine front. Remove both covers. To install, reverse removal procedure.

Removal & Installation (1.6L)

Raise vehicle on hoist. Remove RF tire and wheel assembly. Remove RF splash guard. Lower vehicle. Remove spark plugs and set camsh aft

timing to TDC No. 1 cylinder. Remove oil dipstick. Remove water pump pulley. Remove crankshaft pulley, damper and baffle plate. Remove

upper timing belt cover. Remove center and lower timing belt covers. To install, reverse removal procedure.

TIMING BELT

Removal (1.3L)

Remove accessory belts, water pump pulley, crankshaft damper and upper and lower timing belt covers. Mark timing belt direction of rotation

for installation reference. Remove timing belt tensioner pulley bolt. Remove tensioner pulley, spring and spring cover. Remove timing belt.

Installation (1.3L)

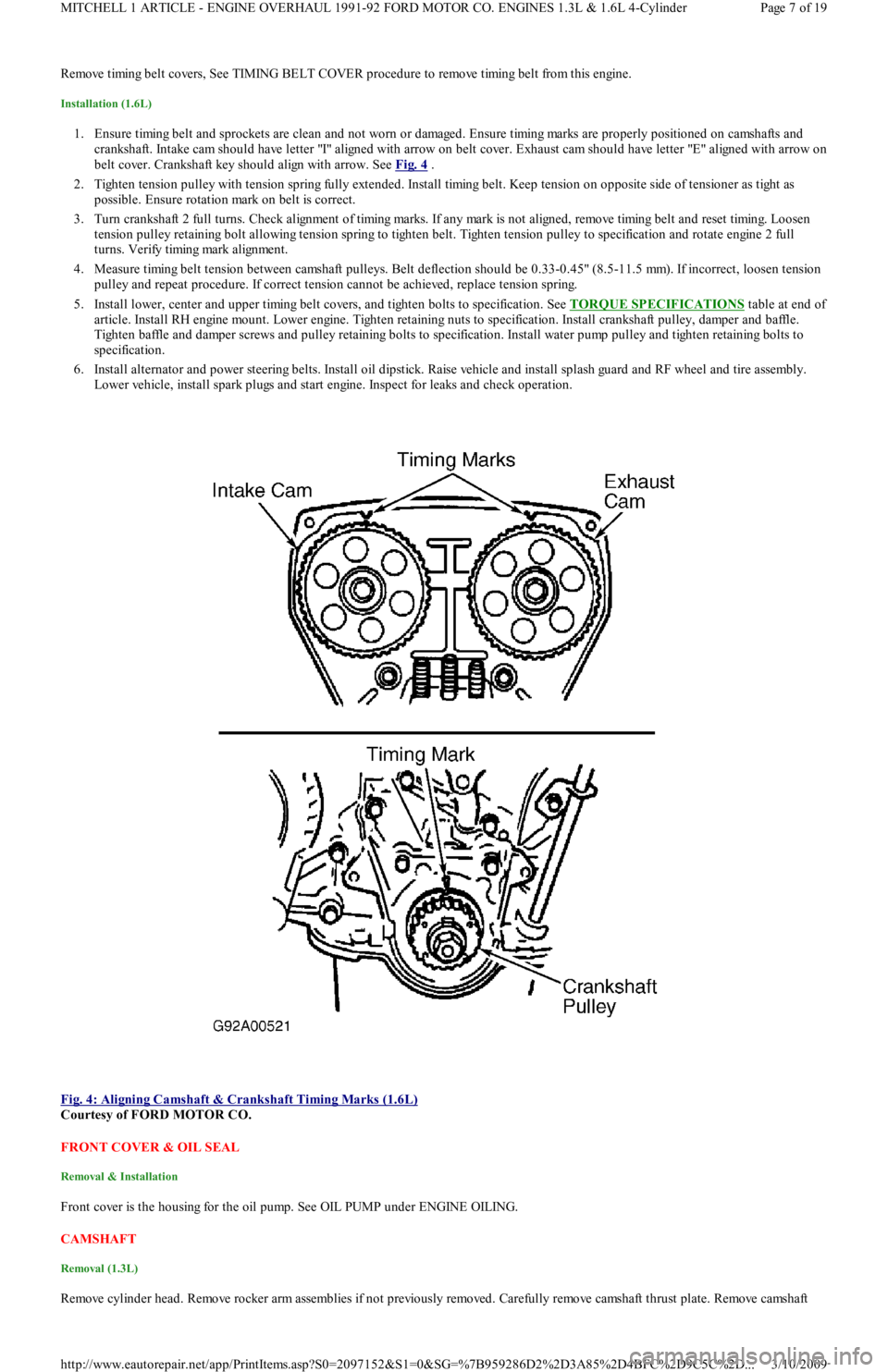

1. Ensure timing belt and sprockets are clean and not worn or damaged. Align crankshaft and camshaft timing marks. See Fig. 3 . No. 1

cylinder must be at TDC of compression stroke.

2. Position belt on camshaft sprocket. Install timing belt tensioner spring, spring cover and pulley. Tighten tensioner pulley bolt to

specification. See TORQUE SPECIFICATIONS

table at end of article. To complete installation, reverse removal procedure. Tighten

all bolts and nuts to specification.

Fig. 3: Aligning Camshaft & Crankshaft Timing Marks (1.3L)

Courtesy of FORD MOTOR CO.

Removal (1.6L)

NOTE:Always rotate engine in direction of norm al operation. Rotating crankshaft backwards m ay cause belt to

jump timing.

Page 6 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 107 of 454

Remove timing belt covers, See TIMING BELT COVER procedure to remove timing belt from this engine.

Installation (1.6L)

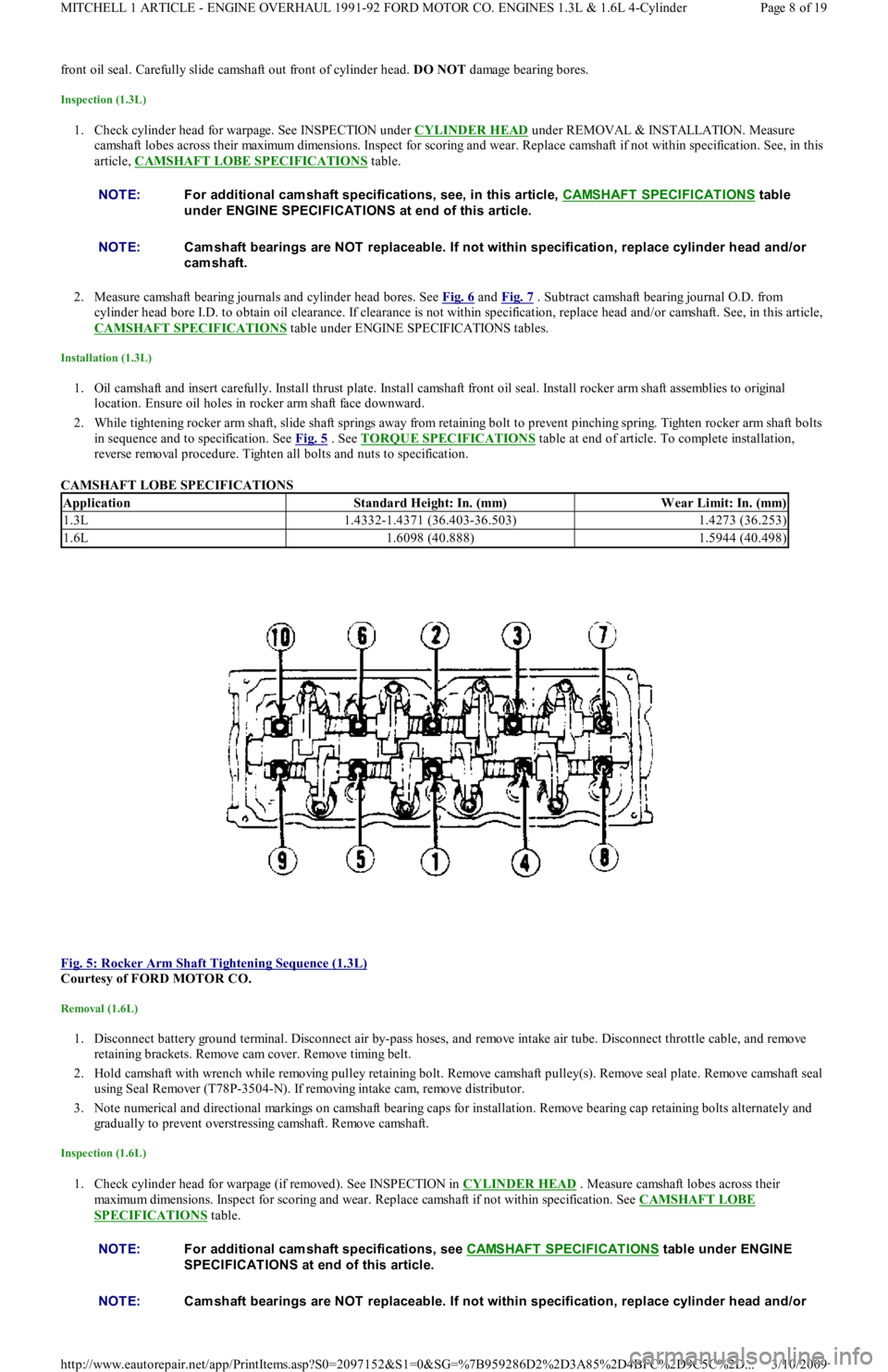

1. Ensure timing belt and sprockets are clean and not worn or damaged. Ensure timing marks are properly positioned on camshafts and

crankshaft. Intake cam should have letter "I" aligned with arrow on belt cover. Exhaust cam should have letter "E" aligned with arrow on

belt cover. Crankshaft key should align with arrow. See Fig. 4

.

2. Tighten tension pulley with tension spring fully extended. Install timing belt. Keep tension on opposite side of tensioner as tight as

possible. Ensure rotation mark on belt is correct.

3. Turn crankshaft 2 full turns. Check alignment of timing marks. If any mark is not aligned, remove timing belt and reset timing. Lo o se n

tension pulley retaining bolt allowing tension spring to tighten belt. Tighten tension pulley to specification and rotate engine 2 full

turns. Verify timing mark alignment.

4. Measure timing belt tension between camshaft pulleys. Belt deflection should be 0.33-0.45" (8.5-11.5 mm). If incorrect, loosen tension

pulley and repeat procedure. If correct tension cannot be achieved, replace tension spring.

5. Install lower, center and upper timing belt covers, and tighten bolts to specification. See TORQUE SPECIFICATIONS

table at end of

article. Install RH engine mount. Lower engine. Tighten retaining nuts to specification. Install crankshaft pulley, damper and baffle.

Tighten baffle and damper screws and pulley retaining bolts to specification. Install water pump pulley and tighten retaining bolts to

specification.

6. Install alternator and power steering belts. Install oil dipstick. Raise vehicle and install splash guard and RF wheel and tire assembly.

Lower vehicle, install spark plugs and start engine. Inspect for leaks and check operation.

Fig. 4: Aligning Camshaft & Crankshaft Timing Marks (1.6L)

Courtesy of FORD MOTOR CO.

FRONT COVER & OIL SEAL

Removal & Installation

Front cover is the housing for the oil pump. See OIL PUMP under ENGINE OILING.

CAMSHAFT

Removal (1.3L)

Remove cylinder head. Remove rocker arm assemblies if not previously removed. Carefully remove camshaft thrust plate. Remove camsh aft

Page 7 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 108 of 454

front oil seal. Carefully slide camshaft out front of cylinder head. DO NOT d a ma ge b e a r in g b o r e s.

Inspection (1.3L)

1. Check cylinder head for warpage. See INSPECTION under CYLINDER HEAD under REMOVAL & INSTALLATION. Measure

camshaft lobes across their maximum dimensions. Inspect for scoring and wear. Replace camshaft if not within specification. See, in this

article, CAMSHAFT LOBE SPECIFICATIONS

table.

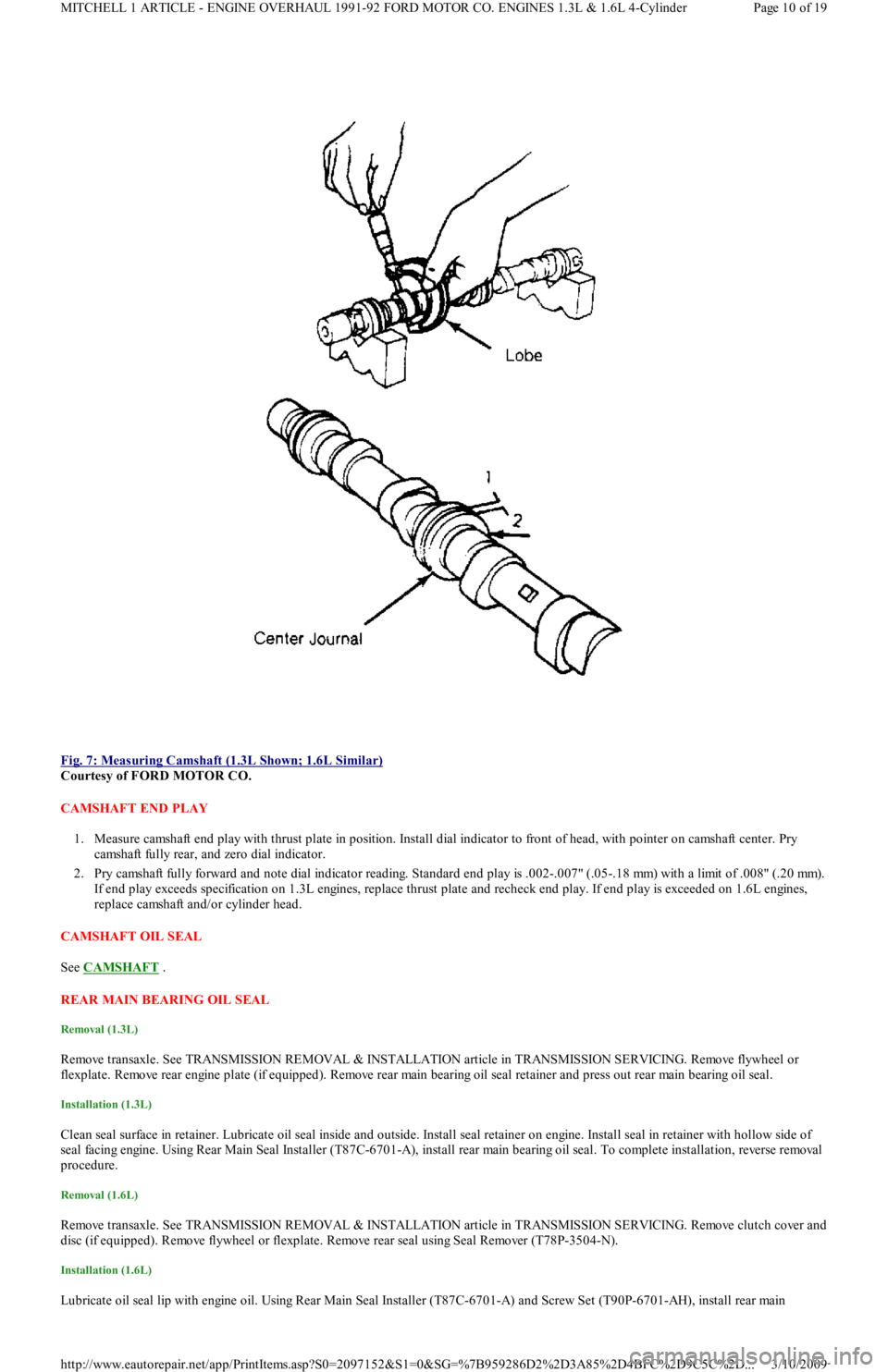

2. Measure camshaft bearing journals and cylinder head bores. See Fig. 6

and Fig. 7 . Subtract camshaft bearing journal O.D. from

cylinder head bore I.D. to obtain oil clearance. If clearance is not within specification, replace head and/or camshaft. See, in this article,

CAMSHAFT SPECIFICATIONS

table under ENGINE SPECIFICATIONS tables.

Installation (1.3L)

1. Oil camshaft and insert carefully. Install thrust plate. Install camshaft front oil seal. Install rocker arm shaft assemblies to original

location. Ensure oil holes in rocker arm shaft face downward.

2. While tightening rocker arm shaft, slide shaft springs away from retaining bolt to prevent pinching spring. Tighten rocker arm shaft bolts

in sequence and to specification. See Fig. 5

. See TORQUE SPECIFICATIONS table at end of article. To complete installation,

reverse removal procedure. Tighten all bolts and nuts to specification.

CAMSHAFT LOBE SPECIFICATIONS

Fig. 5: Rocker Arm Shaft Tightening Sequence (1.3L)

Courtesy of FORD MOTOR CO.

Removal (1.6L)

1. Disconnect battery ground terminal. Disconnect air by-pass hoses, and remove intake air tube. Disconnect throttle cable, and remove

ret ain in g b racket s. Remo ve cam co ver. Remo ve t imin g b el t .

2. Hold camshaft with wrench while removing pulley retaining bolt. Remove camshaft pulley(s). Remove seal plate. Remove camshaft seal

using Seal Remover (T78P-3504-N). If removing intake cam, remove distributor.

3. Note numerical and directional markings on camshaft bearing caps for installation. Remove bearing cap retaining bolts alternately and

gradually to prevent overstressing camshaft. Remove camshaft.

Inspection (1.6L)

1. Check cylinder head for warpage (if removed). See INSPECTION in CYLINDER HEAD . Measure camshaft lobes across their

maximum dimensions. Inspect for scoring and wear. Replace camshaft if not within specification. See CAMSHAFT LOBE

SPECIFICATIONS table. NOTE:For additional cam shaft specifications, see, in this article, CAMSHAFT SPECIFICAT IONS

table

under ENGINE SPECIFICATIONS at end of this article.

NOTE:Cam shaft bearings are NOT replaceable. If not within specification, replace cylinder head and/or

cam shaft.

ApplicationStandard Height: In. (mm)W ear Limit: In. (mm)

1.3L1.4332-1.4371 (36.403-36.503)1.4273 (36.253)

1.6L1.6098 (40.888)1.5944 (40.498)

NOTE:For additional cam shaft specifications, see CAMSHAFT SPECIFICAT IONS table under ENGINE

SPECIFICAT IONS at end of this article.

NOTE:Cam shaft bearings are NOT replaceable. If not within specification, replace cylinder head and/or

Page 8 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 109 of 454

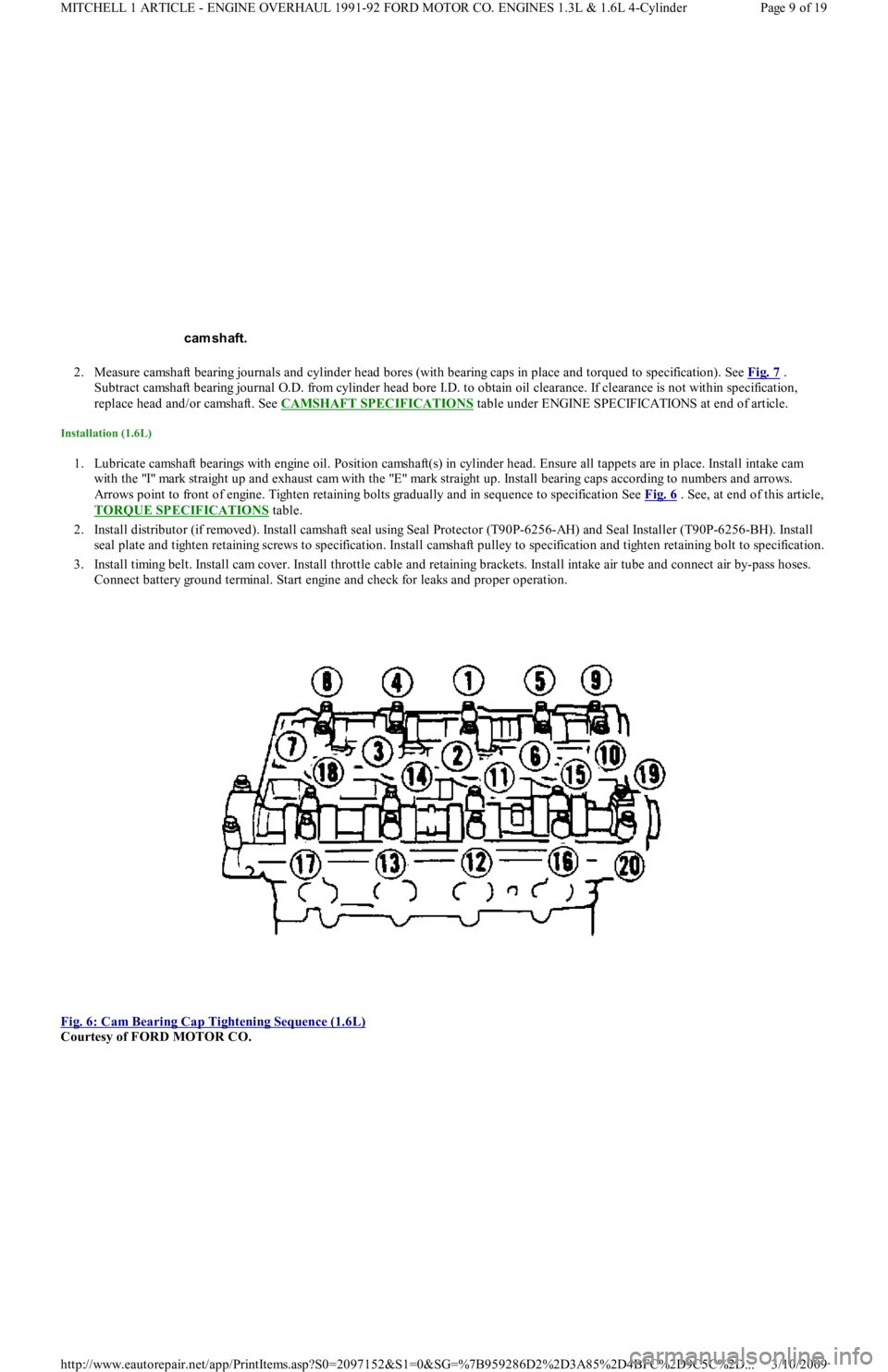

2. Measure camshaft bearing journals and cylinder head bores (with bearing caps in place and torqued to specification). See Fig. 7 .

Subtract camshaft bearing journal O.D. from cylinder head bore I.D. to obtain oil clearance. If clearance is not within specification,

replace head and/or camshaft. See CAMSHAFT SPECIFICATIONS

table under ENGINE SPECIFICATIONS at end of article.

Installation (1.6L)

1. Lubricate camshaft bearings with engine oil. Position camshaft(s) in cylinder head. Ensure all tappets are in place. Install intake cam

with the "I" mark straight up and exhaust cam with the "E" mark straight up. Install bearing caps according to numbers and arrows.

Arrows point to front of engine. Tighten retaining bolts gradually and in sequence to specification See Fig. 6

. See, at end of this article,

TORQUE SPECIFICATIONS

table.

2. Install distributor (if removed). Install camshaft seal using Seal Protector (T90P-6256-AH) and Seal Installer (T90P-6256-BH). Install

seal plate and tighten retaining screws to specification. Install camshaft pulley to specification and tighten retaining bolt to specification.

3. Install timing belt. Install cam cover. Install throttle cable and retaining brackets. Install intake air tube and connect air by-pass hoses.

Connect battery ground terminal. Start engine and check for leaks and proper operation.

Fig. 6: Cam Bearing Cap Tightening Sequence (1.6L)

Courtesy of FORD MOTOR CO. cam shaft.

Page 9 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 110 of 454

Fig. 7: Measuring Camshaft (1.3L Shown; 1.6L Similar)

Courtesy of FORD MOTOR CO.

CAMSHAFT END PLAY

1. Measure camshaft end play with thrust plate in position. Install dial indicator to front of head, with pointer on camshaft center. Pry

camshaft fully rear, and zero dial indicator.

2. Pry camshaft fully forward and note dial indicator reading. Standard end play is .002-.007" (.05-.18 mm) with a limit of .008" (.2 0 mm).

If end play exceeds specification on 1.3L engines, replace thrust plate and recheck end play. If end play is exceeded on 1.6L engines,

replace camshaft and/or cylinder head.

CAMSHAFT OIL SEAL

See CAMSHAFT

.

REAR MAIN BEARING OIL SEAL

Removal (1.3L)

Remove transaxle. See TRANSMISSION REMOVAL & INSTALLATION article in TRANSMISSION SERVICING. Remove flywheel or

flexplate. Remove rear engine plate (if equipped). Remove rear main bearing oil seal retainer and press out rear main bearing oil seal.

Installation (1.3L)

Clean seal surface in retainer. Lubricate oil seal inside and outside. Install seal retainer on engine. Install seal in retainer with hollow side of

seal facing engine. Using Rear Main Seal Installer (T87C-6701-A), install rear main bearing oil seal. To complete installation, reverse removal

procedure.

Removal (1.6L)

Remove transaxle. See TRANSMISSION REMOVAL & INSTALLATION article in TRANSMISSION SERVICING. Remove clutch cover and

disc (if equipped). Remove flywheel or flexplate. Remove rear seal using Seal Remover (T78P-3504-N).

Installation (1.6L)

Lubricate oil seal lip with engine oil. Using Rear Main Seal Installer (T87C-6701-A) and Screw Set (T90P-6701-AH), install rear main

Page 10 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...