lock FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 753 of 1226

Engine Cooling - 1.3L Duratec-8V

(Rocam)llI25L Duratec-1 6V (Sigma)llI4L

303-03A-I I Duratec-1 6V (Sigma)/lI6L Duratec-I 6V (Sigma) 303-03A-1 I

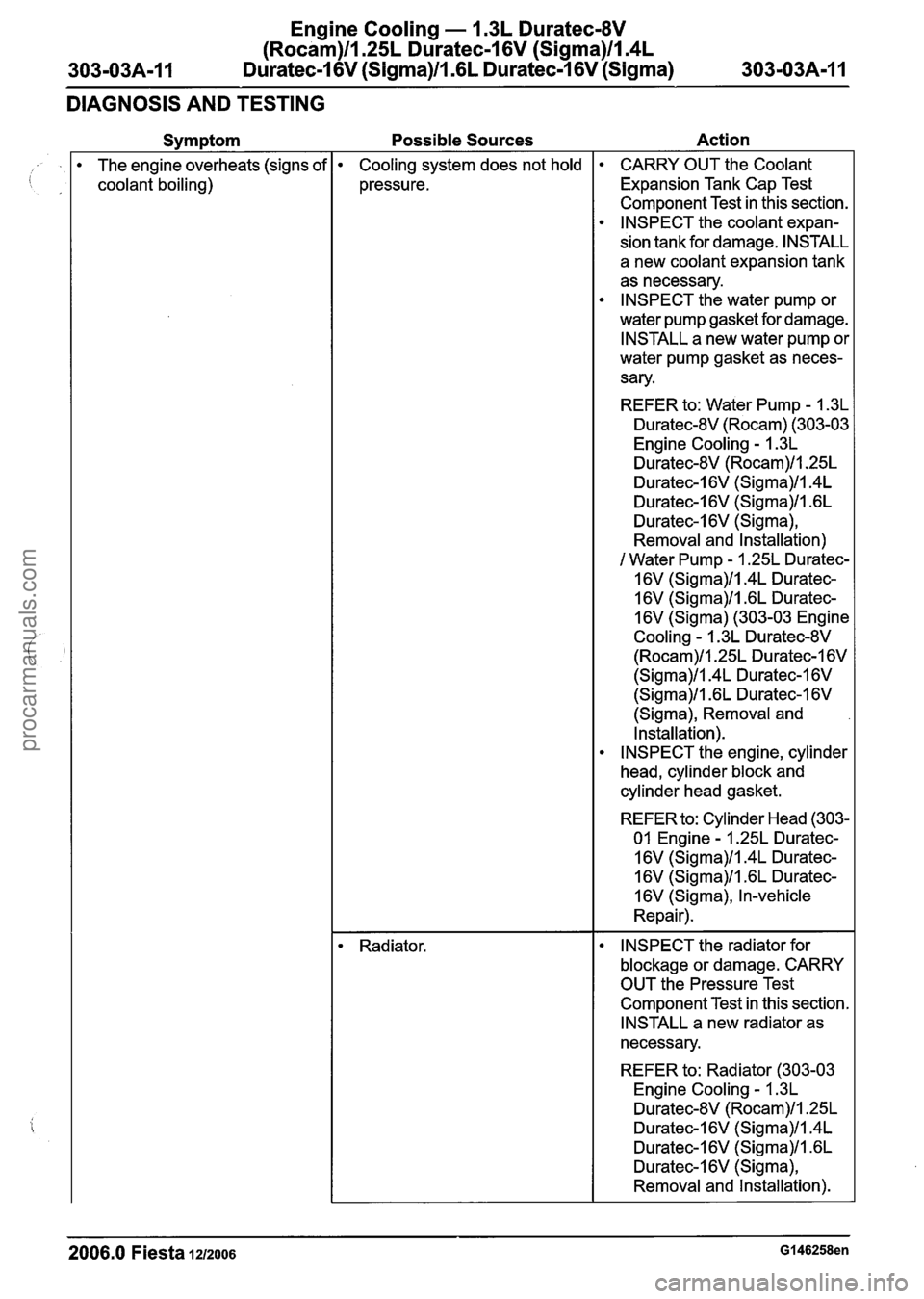

DIAGNOSIS AND TESTING

Symptom

The engine overheats (signs of

coolant boiling)

Possible Sources Action

Cooling system does not hold

pressure.

Radiator. CARRY

OUT the Coolant

Expansion Tank Cap Test

Component Test in this section.

INSPECT the coolant expan-

sion tank for damage. INSTALL

a new coolant expansion tank

as necessary.

INSPECT the water pump or

water pump gasket for damage.

INSTALL a new water pump or

water pump gasket as neces-

sary.

REFER to: Water Pump

- 1.3L

Duratec-8V (Rocam) (303-03

Engine Cooling

- 1.3L

Duratec-8V (Rocam)/l.25L

Duratec-I 6V (Sigma)/l.4L

Duratec-1 6V (Sigma)/l .6L

Duratec-I 6V (Sigma),

Removal and Installation)

/ Water Pump - 1.25L Duratec-

16V

(Sigma)ll.4L Duratec-

16V

(Sigma)/l .6L Duratec-

16V (Sigma) (303-03 Engine

Cooling

- 1.3L Duratec-8V

(Rocam)/l.25L Duratec-1 6V

(Sigma)ll.4L Duratec-1 6V

(Sigma)ll .6L Duratec-1 6V

(Sigma), Removal and

Installation).

INSPECT the engine, cylinder

head, cylinder block and

cylinder head gasket.

REFER to: Cylinder Head (303-

01 Engine

- 1.25L Duratec-

16V

(Sigma)/l.4L Duratec-

1 6V

(Sigma)/l .6L Duratec-

16V (Sigma), In-vehicle

Repair).

INSPECT the radiator for

blockage or damage. CARRY

OUT the Pressure Test

Component Test in this section.

INSTALL a new radiator as

necessary.

REFER to: Radiator (303-03

Engine Cooling

- 1.3L

Duratec-8V (Rocam)ll.25L

Duratec-I 6V (Sigma)/l.4L

Duratec-1 6V (Sigma)/l .6L

Duratec-I 6V (Sigma),

Removal and Installation).

2006.0 Fiesta 1212006 GI 46258en

procarmanuals.com

Page 757 of 1226

Engine Cooling - 1.3L Duratec-8V

(Rocam)llI25L Duratec-1 6V (Sigma)llI4L

303-03A-I 5 Duratec-1 6V (Sigma)/l .6L Duratec-1 6V (Sigma) 303-0344-15

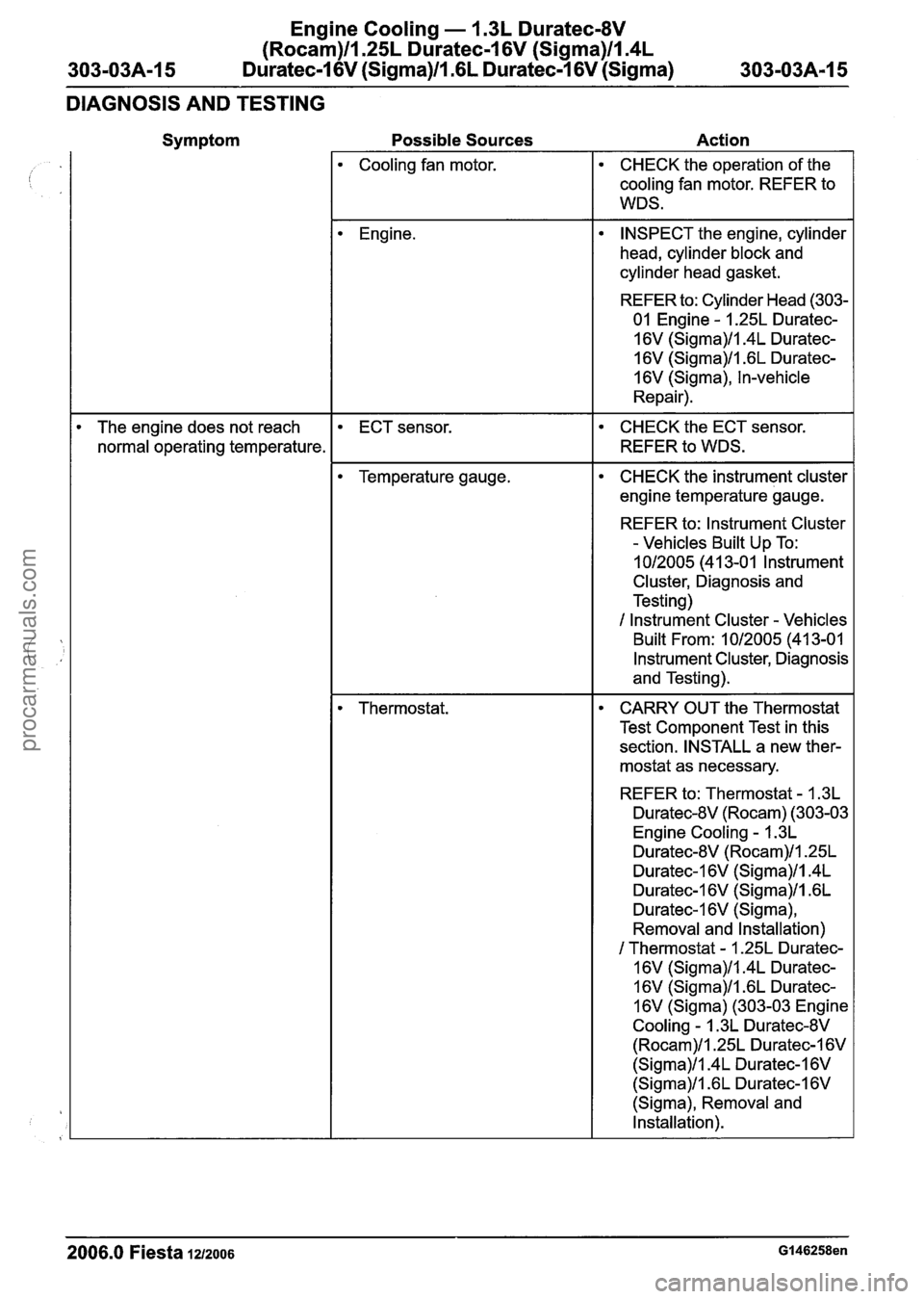

DIAGNOSIS AND TESTING

Symptom Possible Sources Action

Cooling fan motor. CHECK the operation of the

cooling fan motor. REFER to

WDS.

Engine. INSPECT

the engine, cylinder

head, cylinder block and

cylinder head gasket.

REFER to: Cylinder Head (303-

01 Engine - 1.25L Duratec-

16V (Sigma)/l.4L Duratec-

16V (Sigma)/l.GL Duratec-

16V (Sigma), In-vehicle

Repair).

, The engine does not reach

normal operating temperature. ECT sensor. CHECK the ECT sensor.

I REFER to WDS.

Temperature gauge. CHECK

the instrument cluster

engine temperature gauge.

REFER to: lnstrument Cluster

- Vehicles Built Up To:

1012005 (41 3-01 lnstrument

Cluster, Diagnosis and

Testing)

I lnstrument Cluster - Vehicles

Built From:

1012005 (41 3-01

lnstrument Cluster, Diagnosis

and Testing).

Thermostat. CARRY OUT the Thermostat

Test Component Test in this

section. INSTALL a new ther-

mostat as necessary.

REFER to: Thermostat

- I .3L

Duratec-8V

(Rocam) (303-03

Engine Cooling

- 1.3L

Duratec-8V (Rocam)ll.25L

Duratec-16V (Sigma)/l.4L

Duratec-1 6V (Sigma)ll .6L

Duratec-16V (Sigma),

Removal and Installation)

I Thermostat - 1.25L Duratec-

16V (Sigma)/l.4L Duratec-

16V (Sigma)ll .6L Duratec-

16V (Sigma) (303-03 Engine

Cooling

- 1.3L Duratec-8V

(Rocam)ll.25L Duratec-1 6V

(Sigma)ll.4L Duratec-1 6V

(Sigma)/l .6L Duratec-I 6V

(Sigma), Removal and

Installation).

2006.0 Fiesta 1212oo6 GI 46258en

procarmanuals.com

Page 758 of 1226

Engine Cooling - 1.3L Duratec-8V

(Rocam)ll.25L Duratec-I 6V (Sigma)ll.4L

303-03A-16 Duratec-1 6V (Sigma)/l .6L Duratec-1 6V (Sigma) 303-03A-16

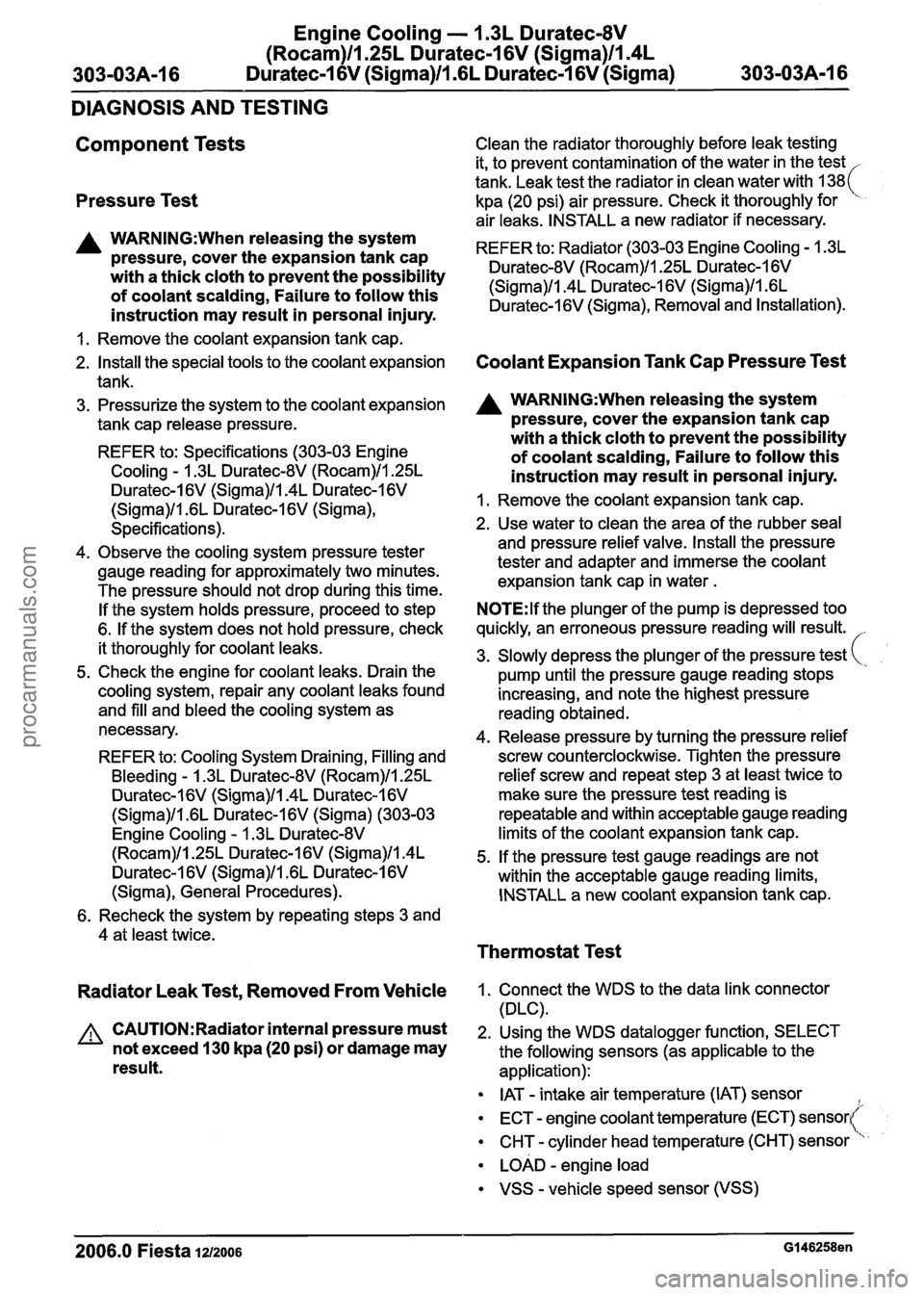

DIAGNOSIS AND TESTING

Component Tests

Pressure Test

A WARNING:When releasing the system

pressure, cover the expansion tank cap

with a thick cloth to prevent the possibility

of coolant scalding, Failure to follow this

instruction may result in personal injury.

1. Remove the coolant expansion tank cap.

2.

Install the special tools to the coolant expansion

tank.

3. Pressurize the system to the

coolant expansion

tank cap

release pressure.

REFER to: Specifications (303-03 Engine

Cooling - 1.3L Duratec-8V (Rocam)/l.25L

Duratec-I 6V (Sigma)/l.4L Duratec-1 6V

(Sigma)/l .6L Duratec-1 6V (Sigma),

Specifications).

4. Observe the

cooling system pressure tester

gauge reading for

approximately two minutes.

The pressure

should not drop during this time.

If the system holds pressure, proceed to step

6.

If the system does not hold pressure, check

it

thoroughly for coolant leaks.

5. Check the engine for coolant leaks. Drain the

cooling system, repair any coolant leaks found

and

fill and bleed the cooling system as

necessary.

REFER to:

Cooling System Draining, Filling and

Bleeding - 1.3L Duratec-8V (Rocam)/l.25L

Duratec-I 6V (Sigma)/l.4L Duratec-1 6V

(Sigma)/l .6L Duratec-1 6V (Sigma) (303-03

Engine

Cooling - 1.3L Duratec-8V

(Rocam)/l.25L Duratec-1 6V (Sigma)/l.4L

Duratec-1 6V (Sigma)/l .6L Duratec-1 6V

(Sigma), General Procedures).

Clean the radiator thoroughly before leak testing

it, to prevent contamination of the water in the test

tank. Leak test the radiator in

clean water with 138(

kpa (20 psi) air pressure. Check it thoroughly for

air

leaks. INSTALL a new radiator if necessary.

REFER to: Radiator (303-03 Engine

Cooling - 1.3L

Duratec-8V (Rocam)/l.25L Duratec-I 6V

(Sigma)/l.4L Duratec-I 6V (Sigma)ll .6L

Duratec-I 6V (Sigma), Removal and Installation).

Coolant Expansion Tank Cap Pressure Test

A WARNING:When releasing the system

pressure, cover the expansion tank cap

with a thick cloth to prevent the possibility

of coolant scalding, Failure to follow this

instruction may result in personal injury.

1. Remove the coolant expansion tank cap.

2. Use water to clean the area of the rubber seal

and pressure relief valve. Install the pressure

tester and adapter and immerse the

coolant

expansion tank cap in water .

N0TE:lf the plunger of the pump is depressed too

quickly, an erroneous pressure reading will result. l-

3. Slowly depress the plunger of the pressure test

pump until the pressure gauge reading stops

increasing, and note the highest pressure

reading obtained.

4.

Release pressure by turning the pressure relief

screw counterclockwise. Tighten the pressure

relief screw and repeat step 3 at least twice to

make sure the pressure test reading is

repeatable and within acceptable gauge reading

limits of the coolant expansion tank cap.

5.

If the pressure test gauge readings are not

within the

acceptable gauge reading limits,

INSTALL a new coolant expansion tank cap.

6. Recheck the system by repeating steps 3 and

4 at least twice.

Thermostat Test

Radiator Leak Test, Removed From Vehicle

A CAUTI0N:Radiator internal pressure must

not exceed

130 kpa (20 psi) or damage may

result.

1. Connect the WDS to the data link connector

(DLC).

2. Using the WDS

datalogger function, SELECT

the

following sensors (as applicable to the

application):

IAT - intake air temperature (IAT) sensor

ECT

- engine coolant temperature (ECT) sensort

CHT - cylinder head temperature (CHT) sensori

LOAD - engine load

VSS - vehicle speed sensor (VSS)

2006.0 Fiesta 1212006 GI 46258en

procarmanuals.com

Page 768 of 1226

Engine Cooling - 1.3L Duratec-8V

(Rocam)llI25L Duratec-1 6V (Sigma)llI4L

3-03A-26 Duratec-I 6V (Sigma)llm6L Duratec-1 6V (Sigma) 303-03A-26

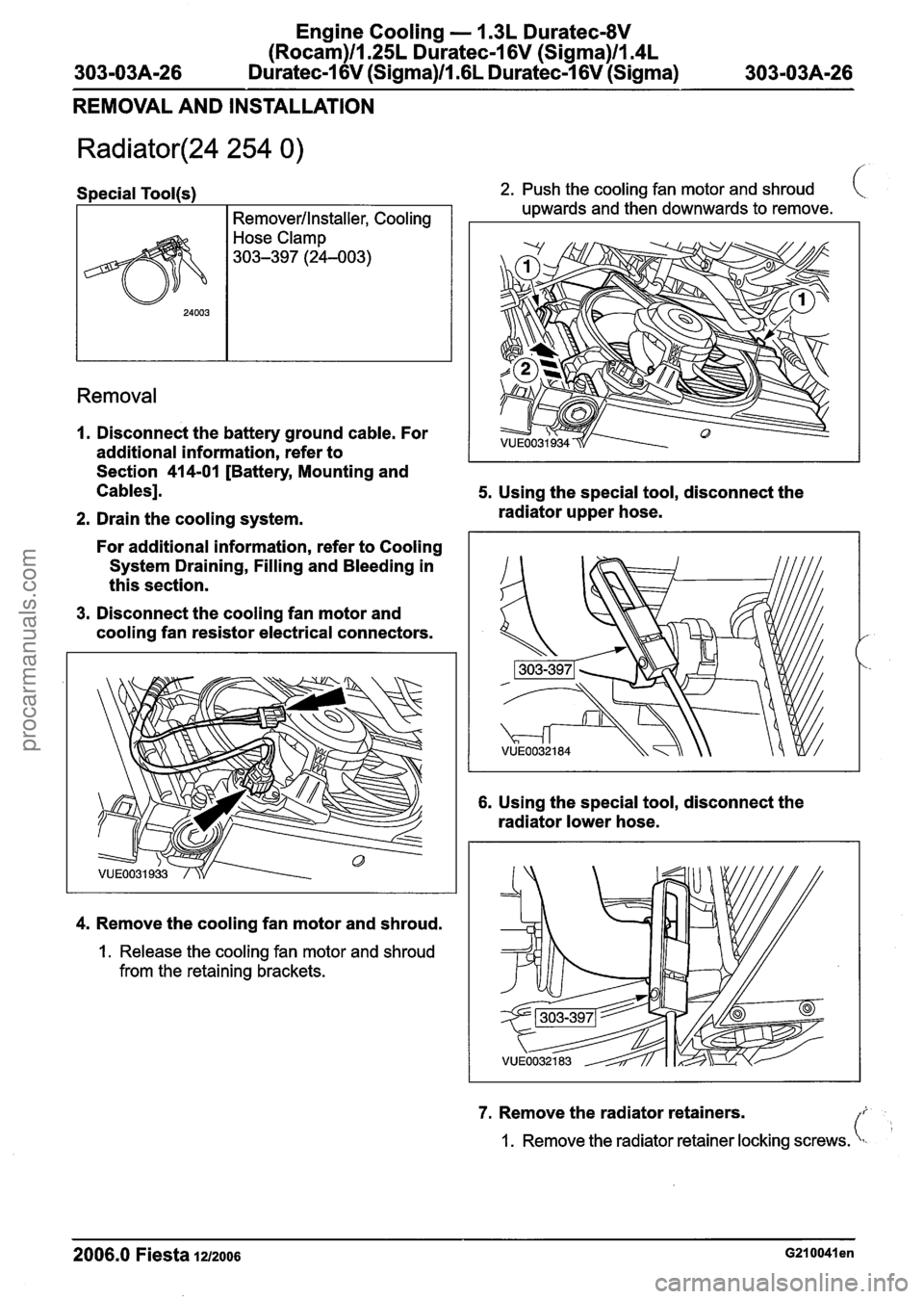

REMOVAL AND INSTALLATION

Radiator(24 254 0) /'

Special Tool@)

I I Remover/lnstaller, Cooling I

2. Push the cooling fan motor and shroud (.

upwards and then downwards to remove.

24003

Removal

Hose Clamp

303-397 (24-003)

1. Disconnect the battery ground cable. For

additional information, refer to

Section 414-01 [Battery, Mounting and

Cables].

5. Using the special tool, disconnect the

2. Drain the cooling system. radiator

upper hose.

For additional information, refer to Cooling

System Draining, Filling and Bleeding in

this section.

3. Disconnect the cooling fan motor and

cooling fan resistor electrical connectors.

4. Remove the cooling fan motor and shroud.

I. Release the cooling fan motor and shroud

from the retaining brackets.

6. Using the special tool, disconnect the

radiator lower hose.

7. Remove the radiator retainers.

1. Remove the radiator retainer locking screws.

2006.0 Fiesta 1212006 ~210041 en

procarmanuals.com

Page 775 of 1226

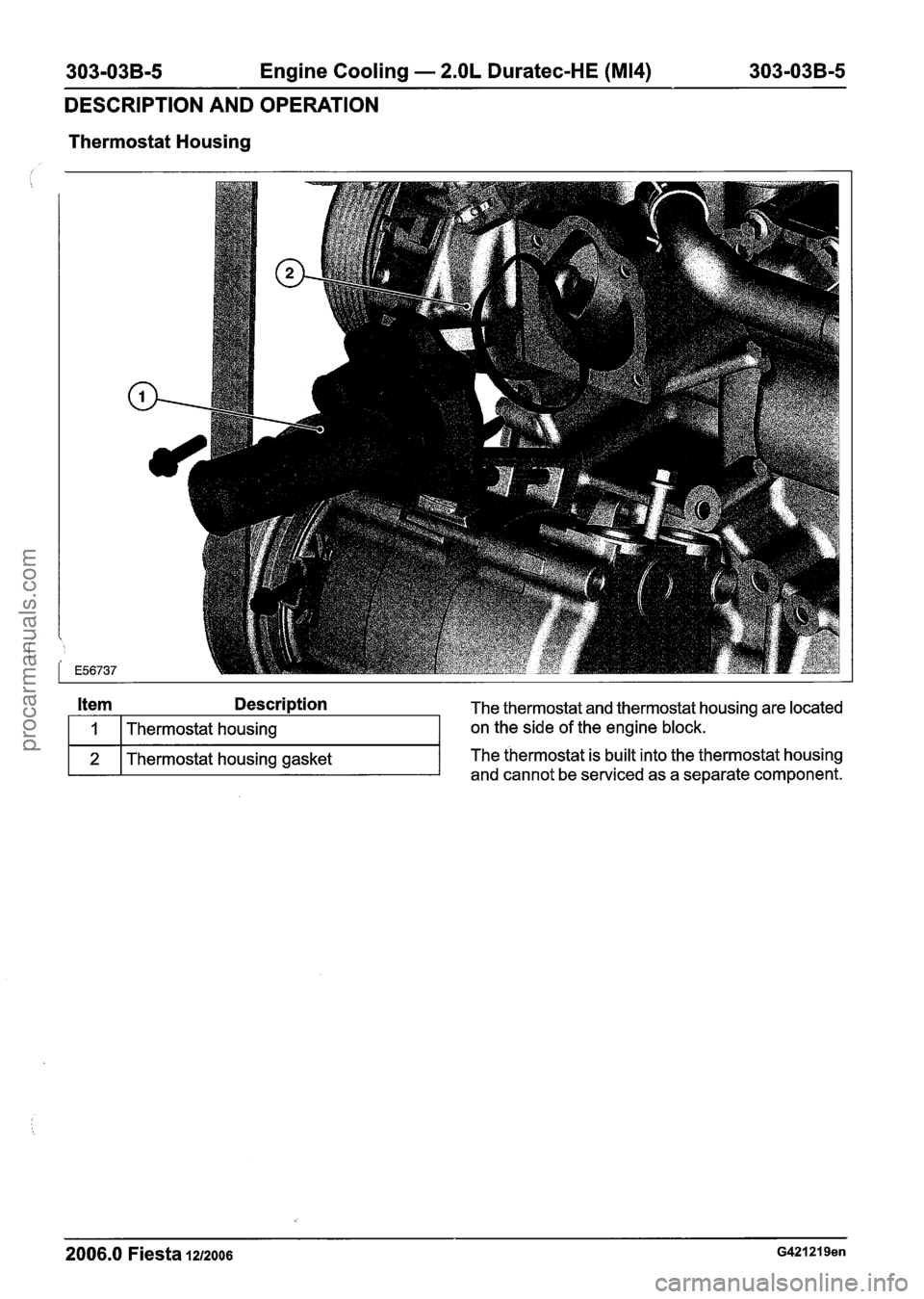

303-03B-5 Engine Cooling - 2.OL Duratec-HE (M14) 303-03B-5

DESCRIPTION AND OPERATION

Thermostat Housing

Item Description The thermostat and thermostat housing are located

2006.0 Fiesta 1212006 G421219en

I 1 I Thermostat housing

2

on the side of the engine block.

and cannot be serviced as a separate component.

Thermostat housing gasket

The thermostat

is built into the thermostat housing

procarmanuals.com

Page 777 of 1226

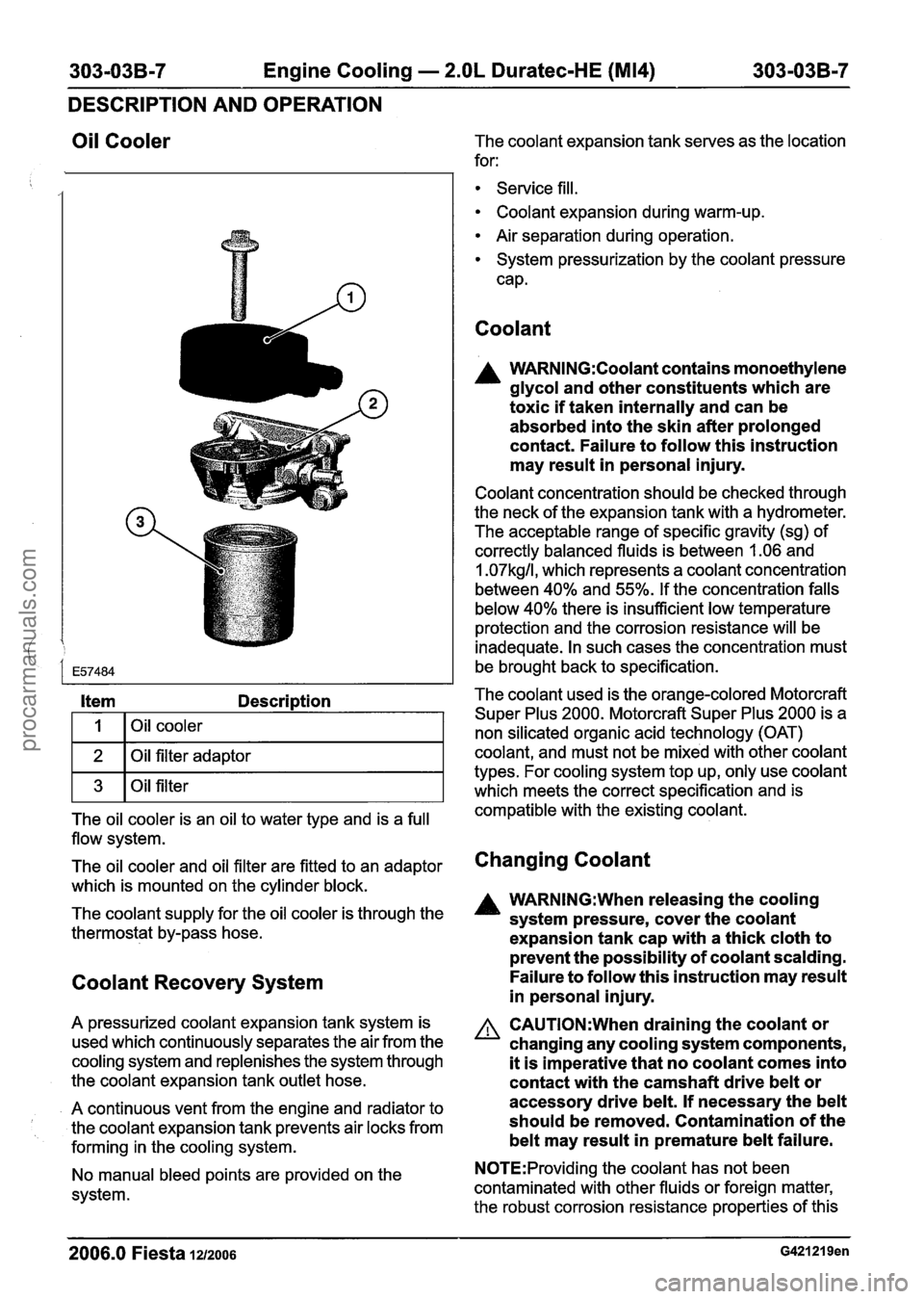

303-03B-7 Engine Cooling - 2.OL Duratec-HE (M14) 303-03B-7

DESCRIPTION AND OPERATION

Oil Cooler

Item Description

I I I Oil cooler I

1 2 1 Oil filter adaptor I

1 3 1 Oil filter I

The oil cooler is an oil to water type and is a full

flow system.

The oil cooler and oil filter are fitted to an adaptor

which is mounted on the cylinder block.

The coolant supply for the oil cooler is through the

thermostat by-pass hose.

Coolant Recovery System

A pressurized coolant expansion tank system is

used which continuously separates the air from the

cooling system and replenishes the system through

the coolant expansion tank outlet hose.

A continuous vent from the engine and radiator to

I the coolant expansion tank prevents air locks from

forming in the cooling system.

No manual bleed points are provided on the

system. The coolant expansion tank serves

as the location

for:

Service fill.

Coolant expansion during warm-up.

Air separation during operation.

System pressurization by the coolant pressure

cap.

Coolant

A WARN1NG:Coolant contains monoethylene

glycol and other constituents which are

toxic if taken internally and can be

absorbed into the skin after prolonged

contact. Failure to follow this instruction

may result in personal injury.

Coolant concentration should be checked through

the neck of the expansion tank with a hydrometer.

The acceptable range of specific gravity (sg) of

correctly balanced fluids is between

1.06 and

1.07kg/l, which represents a coolant concentration

between 40% and 55%. If the concentration falls

below 40% there is insufficient low temperature

protection and the corrosion resistance will be

inadequate. In such cases the concentration must

be brought back to specification.

The coolant used is the orange-colored Motorcraft

Super Plus 2000. Motorcraft Super Plus 2000 is a

non silicated organic acid technology (OAT)

coolant, and must not be mixed with other coolant

types. For cooling system top up, only use coolant

which meets the correct specification and is

compatible with the existing coolant.

Changing Coolant

A WARN1NG:When releasing the cooling

system pressure, cover the coolant

expansion tank cap with a thick cloth to

prevent the possibility of coolant scalding.

Failure to follow this instruction may result

in personal injury.

A CAUTI0N:When draining the coolant or

changing any cooling system components,

it is imperative that no coolant comes into

contact with the camshaft drive belt or

accessory drive belt. If necessary the belt

should be removed. Contamination of the

belt may result in premature belt failure.

N0TE:Providing the coolant has not been

contaminated with other fluids or foreign matter,

the robust corrosion resistance properties of this

2006.0 Fiesta 1212006 G421219en

procarmanuals.com

Page 780 of 1226

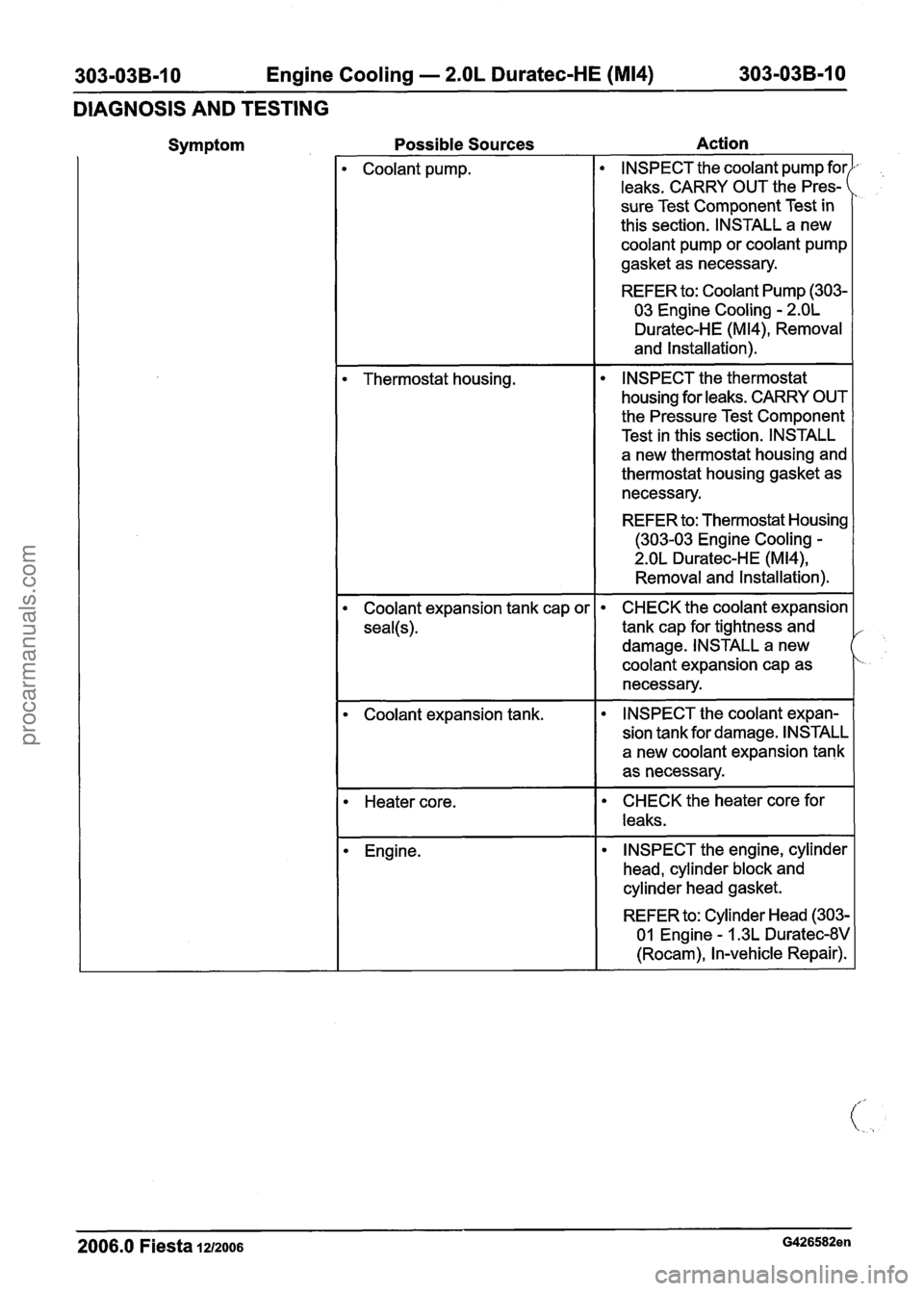

Engine Cooling - 2.OL Duratec-HE (M14)

DIAGNOSIS AND TESTING

Symptom Possible Sources Action

Coolant

pump.

Thermostat housing.

Coolant expansion tank cap or

seal(s).

- -

Coolant expansion tank.

Heater core.

Engine. INSPECT the

coolant pump

leaks. CARRY OUT the Pres-

sure Test Component Test in

this section. INSTALL a new

gasket as necessary.

REFER to: Coolant Pump (303-

03 Engine Cooling

- 2.OL

Duratec-HE (M14), Removal

and Installation).

INSPECT the thermostat

housing for leaks. CARRY OUT

the Pressure Test Component

Test in this section. INSTALL

a new thermostat housing and

thermostat housing gasket as

necessary.

REFER to: Thermostat Housing

(303-03 Engine Cooling

-

2.OL Duratec-HE (M14),

Removal and Installation).

CHECK the coolant expansion

tank cap for tightness and

damage. INSTALL a new

coolant expansion cap as

necessary.

INSPECT the coolant expan-

sion tank for damage. INSTALL

a new coolant expansion tank

as necessary.

CHECK the heater core for

leaks.

INSPECT the engine, cylinder

head, cylinder block and

cylinder head gasket.

REFER to: Cylinder Head (303-

01 Engine

- 1.3L Duratec-8V

(Rocam), In-vehicle Repair).

2006.0 Fiesta lu2006 G426582en

procarmanuals.com

Page 781 of 1226

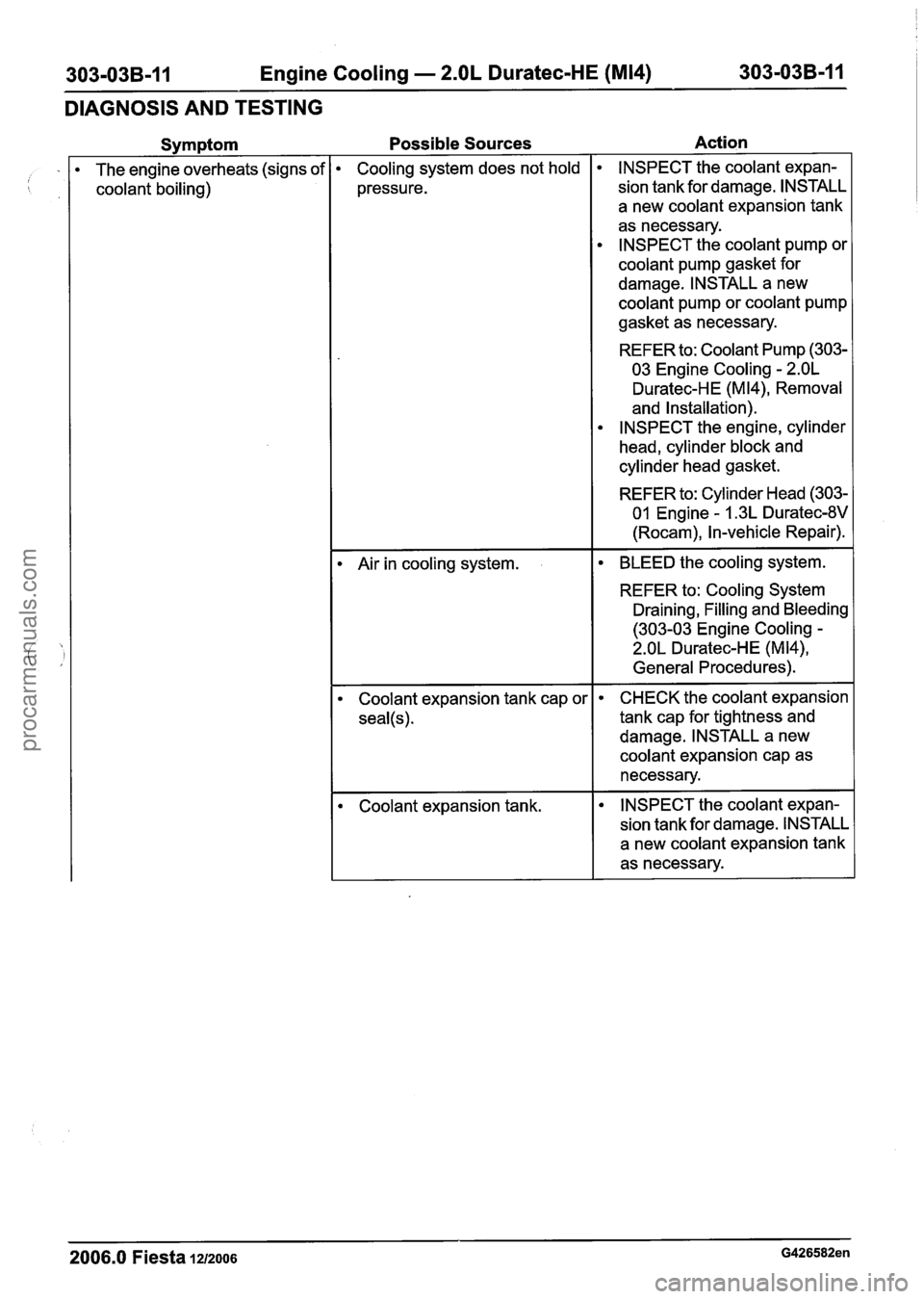

303-03B-11 Engine Cooling - 2.OL Duratec-HE (M14) 303-03B-1 I

DIAGNOSIS AND TESTING

Symptom

The engine overheats (signs of

coolant boiling)

Possible Sources Action

Cooling system does not hold

pressure. INSPECT

the coolant expan-

sion tank for damage. INSTALL

a new coolant expansion tank

as necessary. INSPECT the coolant pump or

coolant pump gasket for

damage. INSTALL a new

coolant pump or coolant pump

gasket as necessary.

REFER to: Coolant Pump (303-

03 Engine Cooling

- 2.OL

Duratec-HE (M14), Removal

and Installation).

INSPECT the engine, cylinder

head, cylinder block and

cylinder head gasket.

REFER to: Cylinder Head (303-

01 Engine - 1.3L Duratec-8V

(Rocam), In-vehicle Repair). -

Air in cooling system. BLEED the cooling system.

REFER to: Cooling System

Draining, Filling and Bleeding

(303-03 Engine Cooling

-

2.OL Duratec-HE (M14),

General Procedures).

Coolant expansion tank cap or

seal(s).

CHECK the coolant expansion

tank cap for tightness and damage. INSTALL a new

coolant expansion cap as

necessary.

Coolant expansion tank. INSPECT

the coolant expan-

sion tank for damage. INSTALL

a new coolant expansion tank

as necessary.

2006.0 Fiesta 1212006 G426582en

procarmanuals.com

Page 783 of 1226

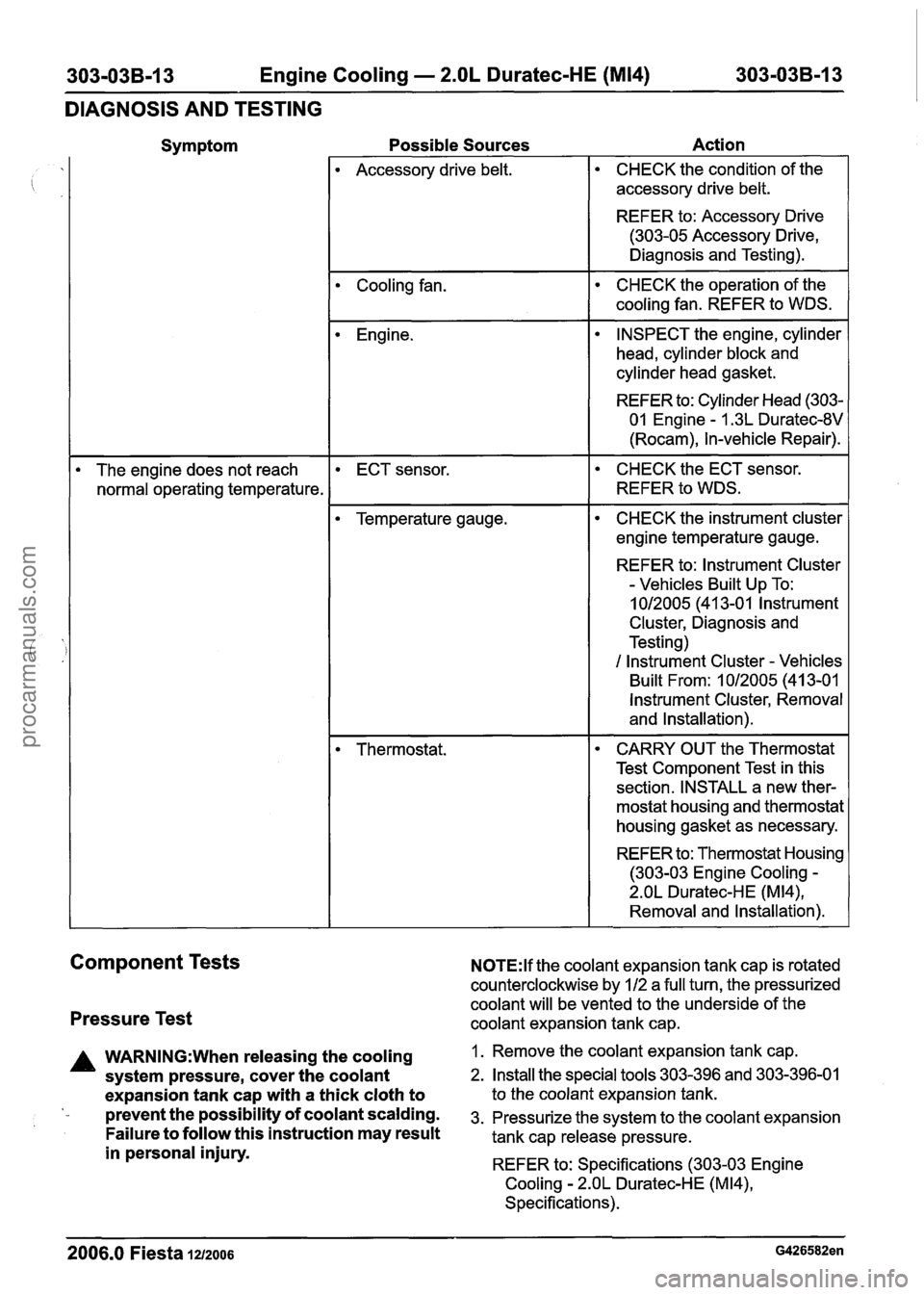

Engine Cooling - 2.OL Duratec-HE (M14)

DIAGNOSIS AND TESTING

Symptom Possible Sources

Action

I Accessory drive belt. CHECK the condition of the

accessory drive belt.

REFER to: Accessory Drive

(303-05 Accessory Drive,

Diagnosis and Testing).

Cooling fan.

CHECK the operation of the

I cooling fan. REFER to WDS.

Engine. INSPECT the engine, cylinder

head, cylinder block and

cylinder head gasket.

REFER to: Cylinder Head

(303-

01 Engine - I .3L Duratec-8V

(Rocam), I n-vehicle Repair).

The engine does not reach

normal operating temperature. CHECK the ECT sensor.

I REFER to WDS.

Temperature gauge. CHECK the instrument cluster

engine temperature gauge.

REFER to: lnstrument Cluster

- Vehicles Built Up To:

1012005 (41 3-01 lnstrument

Cluster, Diagnosis and

Testing)

I lnstrument Cluster - Vehicles

Built From:

1012005 (41 3-01

lnstrument Cluster, Removal

and Installation).

Thermostat. CARRY OUT the Thermostat

Test Component Test in this

section. INSTALL a new ther-

mostat housing and thermostat

housing gasket as necessary.

REFER to: Thermostat Housing (303-03 Engine Cooling

-

2.OL Duratec-HE (M14),

Removal and Installation).

Component Tests

Pressure Test

A WARNING:When releasing the cooling

system pressure, cover the coolant

expansion tank cap with a thick cloth to

- prevent the possibility of coolant scalding.

Failure to follow this instruction may result

in personal injury.

N0TE:lf the coolant expansion tank cap is rotated

counterclockwise by 1 12 a full turn, the pressurized

coolant will be vented to the underside of the

coolant expansion tank cap.

1. Remove the coolant expansion tank cap.

2. Install the special tools 303-396 and 303-396-01

to the coolant expansion tank.

3. Pressurize the system to the coolant expansion

tank cap release pressure.

REFER to: Specifications (303-03 Engine

Cooling

- 2.OL Duratec-HE (M14),

Specifications).

2006.0 Fiesta 1212006 G426582en

procarmanuals.com

Page 784 of 1226

303-03B-14 Engine Cooling - 2.OL Duratec-HE (M14) 303-03B-14

DIAGNOSIS AND TESTING

4. Observe the cooling system pressure tester make sure the pressure test reading

is

gauge reading for approximately two minutes. repeatable

and within acceptable gauge reading

The pressure should not drop during this time. limits of

the coolant expansion tank cap.

( If the system holds Pressure, proceed to Step 5. If the pressure test gauge readings are not 7. If the system does not hold pressure, check

within the acceptable gauge reading limits,

it thoroughly for coolant leaks.

INSTALL a new coolant expansion tank cap.

5. Check the engine for coolant leaks. Drain the

cooling system, repair any coolant leaks found

and fill and bleed the cooling system as

Thermostat Test

necessaw.

REFER to: Cooling System Draining, Filling and

Bleeding (303-03 Engine Cooling

- 2.OL

Duratec-HE (M14), General Procedures).

.Recheck the system by repeating Steps 3 and

4 at least twice.

Radiator Leak Test, Removed From Vehicle

CAUTI0N:Radiator internal pressure must

not exceed

130 kpa (20 psi) or damage may

result.

Clean the radiator thoroughly before leak testing

it, to prevent contamination of the water in the test

tank. Leak test the radiator in clean water with 138

kpa (20 psi) air pressure. Check it thoroughly for

air leaks. INSTALL a new radiator if necessary.

REFER to: Radiator (303-03 Engine Cooling

- 2.OL

Duratec-HE (M14), Removal and Installation).

Coolant Expansion Tank Cap Pressure Test

A WARNING:When releasing the system

pressure, cover the expansion tank cap

with a thick cloth to prevent the possibility

of coolant scalding, Failure to follow this

instruction may result in personal injury.

1. Remove the coolant expansion tank cap.

2. Use water to clean the area of the rubber seal

and pressure relief valve. Install the pressure

tester and adapter and immerse the coolant

-

expansion tank cap in water.

N0TE:lf the plunger of the pump is depressed too

quickly, an erroneous pressure reading will result.

3. Slowly depress the plunger of the pressure test

pump until the pressure gauge reading stops

increasing, and note the highest pressure

reading obtained.

4. Release pressure by turning the pressure relief

screw counterclockwise. Tighten the pressure

relief screw and repeat step 3 at least twice to

I. Connect the WDS to the data link connector

(DLC).

2. Using the WDS datalogger function, SELECT

the following sensors (as applicable to the

application):

IAT

- intake air temperature (IAT) sensor

ECT

- engine coolant temperature (ECT) sensor

CHT

- cylinder head temperature (CHT) sensor

LOAD

- engine load

VSS

- vehicle speed sensor (VSS)

RPM

- engine speed

DSRPM

- desired engine speed

The IAT sensor output is useful if the engine being

tested is cold or after an over-night cold soak. The

ECT sensor or CHT sensor and the IAT sensor

(

should either indicate the same value or be within

1 to 2 degrees Celsius of each other.

The ECT sensor output is important to display as

it indicates the engine warm-up and opening

temperature for the thermostat. It will initially

indicate a slightly higher reading just before the

thermostat opens and then drops back before

settling to a near flat line output (see graphic

below).

Item Description 1'. .

) A 1 Thermostat opens I\

B Thermostat settles into a cyclic open and

I I closure pattern

2006.0 Fiesta 1212006 G426582en

procarmanuals.com