lock FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 40 of 413

02-02-21

Brake System

02-02-21

INSTALLATION

CLUTCH ASSIST

SPRING

MASTER CYLINDER

2140

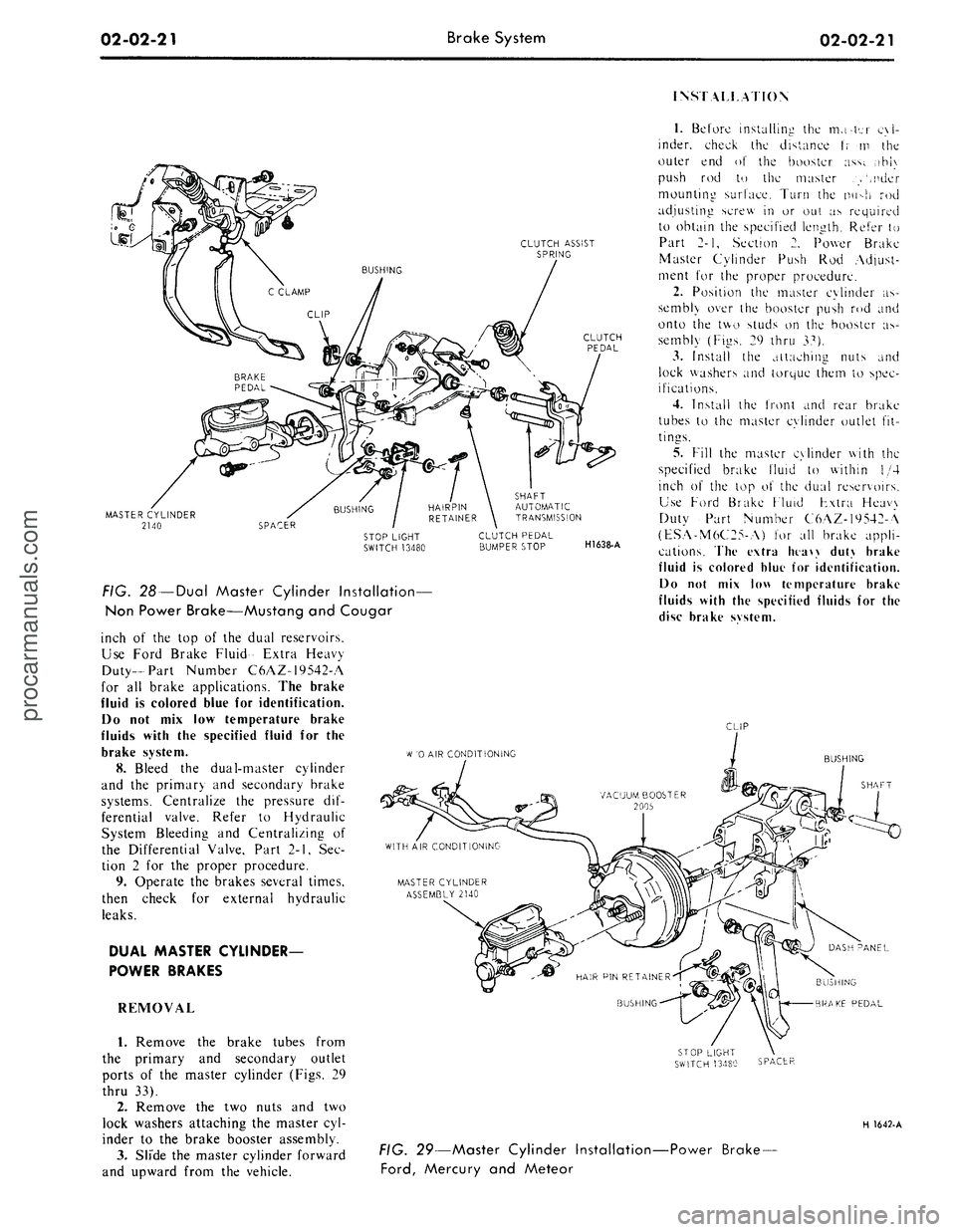

FIG. 28 —Dual Master Cylinder Installation—

Non Power Brake—Mustang and Cougar

inch of the top of the dual reservoirs.

Use Ford Brake Fluid- Extra Heavy

Duty-Part Number C6AZ-19542-A

for all brake applications. The brake

fluid is colored blue for identification.

Do not mix low temperature brake

fluids with the specified fluid for the

brake system.

8. Bleed the dual-master cylinder

and the primary and secondary brake

systems. Centralize the pressure dif-

ferential valve. Refer to Hydraulic

System Bleeding and Centralizing of

the Differential Valve, Part 2-1, Sec-

tion 2 for the proper procedure.

9. Operate the brakes several times,

then check for external hydraulic

leaks.

DUAL MASTER CYLINDER-

POWER BRAKES

REMOVAL

1.

Remove the brake tubes from

the primary and secondary outlet

ports of the master cylinder (Figs. 29

thru 33).

2.

Remove the two nuts and two

lock washers attaching the master cyl-

inder to the brake booster assembly.

3.

Slide the master cylinder forward

and upward from the vehicle.

SHAFT

AUTOMATIC

TRANSMISSION

CLUTCH PEDAL

BUMPER STOP

H1638-A

1.

Before installing the mater cyl-

inder, check the distance t; m the

outer end of the booster ass;. ,ihi\

push rod to the master .>',nder

mounting surface. Turn the nu->h rod

adjusting screw in or out as required

to obtain the specified length. Refer to

Part 2-1, Section 2. Power Brake

Master Cylinder Push Rod Adjust-

ment for the proper procedure.

2.

Position the master cylinder as-

sembly over the booster push rod and

onto the two studs on the booster as-

sembly (Figs. 29 thru 37).

3.

Install the attaching nuts and

lock washers and torque them to spec-

ifications.

4.

Install the front and rear brake

tubes to the master cylinder outlet fit-

tings.

5.

Fill the master cylinder with the

specified brake fluid to within 1/4

inch of the top o\ the dual reservoirs.

Use Ford Brake Fluid Fxtra Heavy

Duty Part Number C6AZ-19542-A

(ESA-M6C25-A) for all brake appli-

cations. The extra htaw duty brake

fluid is colored blue for identification.

Do not mix low temperature brake

fluids with the specified fluids for the

disc brake svstem.

CLIP

W

'0 AIR CONDITIONING

BUSHING

SHAFT

BUSHING

BRAKE PEDAL

SPACER

H 1642-A

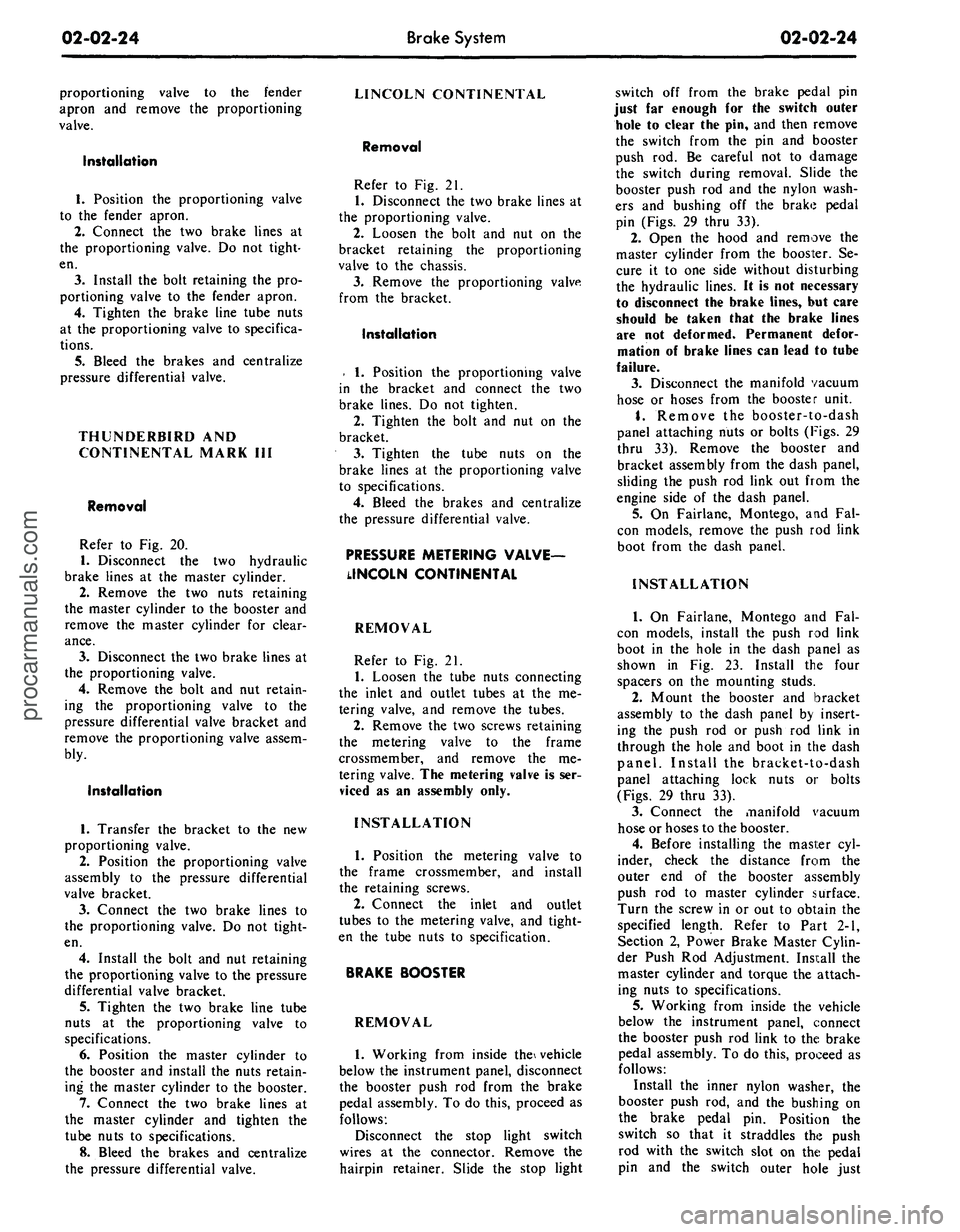

FIG. 29—Master Cylinder Installation-

Ford,

Mercury and Meteor

-Power Brake-procarmanuals.com

Page 43 of 413

02-02-24

Brake

System

02-02-24

proportioning valve to the fender

apron and remove the proportioning

valve.

Installation

1.

Position the proportioning valve

to the fender apron.

2.

Connect the two brake lines at

the proportioning valve. Do not tight-

en.

3.

Install the bolt retaining the pro-

portioning valve to the fender apron.

4.

Tighten the brake line tube nuts

at the proportioning valve to specifica-

tions.

5.

Bleed the brakes and centralize

pressure differential valve.

THUNDERBIRD AND

CONTINENTAL MARK III

Removal

Refer to Fig. 20.

1.

Disconnect the two hydraulic

brake lines at the master cylinder.

2.

Remove the two nuts retaining

the master cylinder to the booster and

remove the master cylinder for clear-

ance.

3.

Disconnect the two brake lines at

the proportioning valve.

4.

Remove the bolt and nut retain-

ing the proportioning valve to the

pressure differential valve bracket and

remove the proportioning valve assem-

bly.

Installation

1.

Transfer the bracket to the new

proportioning valve.

2.

Position the proportioning valve

assembly to the pressure differential

valve bracket.

3.

Connect the two brake lines to

the proportioning valve. Do not tight-

en.

4.

Install the bolt and nut retaining

the proportioning valve to the pressure

differential valve bracket.

5.

Tighten the two brake line tube

nuts at the proportioning valve to

specifications.

6. Position the master cylinder to

the booster and install the nuts retain-

ing the master cylinder to the booster.

7.

Connect the two brake lines at

the master cylinder and tighten the

tube nuts to specifications.

8. Bleed the brakes and centralize

the pressure differential valve.

LINCOLN CONTINENTAL

Removal

Refer to Fig. 21.

1.

Disconnect the two brake lines at

the proportioning valve.

2.

Loosen the bolt and nut on the

bracket retaining the proportioning

valve to the chassis.

3.

Remove the proportioning valve

from the bracket.

Installation

- 1. Position the proportioning valve

in the bracket and connect the two

brake lines. Do not tighten.

2.

Tighten the bolt and nut on the

bracket.

3.

Tighten the tube nuts on the

brake lines at the proportioning valve

to specifications.

4.

Bleed the brakes and centralize

the pressure differential valve.

PRESSURE METERING VALVE—

LINCOLN CONTINENTAL

REMOVAL

Refer to Fig. 21.

1.

Loosen the tube nuts connecting

the inlet and outlet tubes at the me-

tering valve, and remove the tubes.

2.

Remove the two screws retaining

the metering valve to the frame

crossmember, and remove the me-

tering valve. The metering valve is ser-

viced as an assembly only.

INSTALLATION

1.

Position the metering valve to

the frame crossmember, and install

the retaining screws.

2.

Connect the inlet and outlet

tubes to the metering valve, and tight-

en the tube nuts to specification.

BRAKE BOOSTER

REMOVAL

1.

Working from inside the\ vehicle

below the instrument panel, disconnect

the booster push rod from the brake

pedal assembly. To do this, proceed as

follows:

Disconnect the stop light switch

wires at the connector. Remove the

hairpin retainer. Slide the stop light

switch off from the brake pedal pin

just far enough for the switch outer

hole to clear the pin, and then remove

the switch from the pin and booster

push rod. Be careful not to damage

the switch during removal. Slide the

booster push rod and the nylon wash-

ers and bushing off the brake pedal

pin (Figs. 29 thru 33).

2.

Open the hood and remove the

master cylinder from the booster. Se-

cure it to one side without disturbing

the hydraulic lines. It is not necessary

to disconnect the brake lines, but care

should be taken that the brake lines

are not deformed. Permanent defor-

mation of brake lines can lead to tube

failure.

3.

Disconnect the manifold vacuum

hose or hoses from the booster unit.

4.

Remove the booster-to-dash

panel attaching nuts or bolts (Figs. 29

thru 33). Remove the booster and

bracket assembly from the dash panel,

sliding the push rod link out from the

engine side of the dash panel.

5.

On Fairlane, Montego, and Fal-

con models, remove the push rod link

boot from the dash panel.

INSTALLATION

1.

On Fairlane, Montego and Fal-

con models, install the push rod link

boot in the hole in the dash panel as

shown in Fig. 23. Install the four

spacers on the mounting studs.

2.

Mount the booster and bracket

assembly to the dash panel by insert-

ing the push rod or push rod link in

through the hole and boot in the dash

panel. Install the bracket-to-dash

panel attaching lock nuts or bolts

(Figs.

29 thru 33).

3.

Connect the manifold vacuum

hose or hoses to the booster.

4.

Before installing the master cyl-

inder, check the distance from the

outer end of the booster assembly

push rod to master cylinder surface.

Turn the screw in or out to obtain the

specified length. Refer to Part 2-1,

Section 2, Power Brake Master Cylin-

der Push Rod Adjustment. Install the

master cylinder and torque the attach-

ing nuts to specifications.

5.

Working from inside the vehicle

below the instrument panel, connect

the booster push rod link to the brake

pedal assembly. To do this, proceed as

follows:

Install the inner nylon washer, the

booster push rod, and the bushing on

the brake pedal pin. Position the

switch so that it straddles the push

rod with the switch slot on the pedal

pin and the switch outer hole justprocarmanuals.com

Page 44 of 413

02-02-25

Brake System

02-02-25

clearing the pin. Slide the switch com-

pletely onto the pin, and install the

nylon washer as shown in Figs. 29

thru 33. Be careful not to bend or de-

form the switch. Secure these parts to

the pin with the hairpin retainer. Con-

nect the stop light switch wires to the

connector, and install the wires in the

retaining clip.

BRAKE PEDAL

FORD, MERCURY

AND METEOR

Removal

1.

Disconnect the stop light switch

wires at the connector.

2.

Remove the hairpin retainer.

Slide the stop light switch off the

brake pedal pin just far enough for

the switch outer hole to clear the pin,

and then lift the switch straight up-

ward from the pin. Be careful not to

damage the switch during removal.

Slide the master cylinder or booster

push rod and the nylon washers and

bushing off the brake pedal pin (Figs.

26 and 29).

3.

Remove the hairpin type retainer

and washer from the brake pedal

shaft, then remove the shaft, the brake

pedal and the bushings from the pedal

support bracket.

Installation

1.

Apply a coating of SAE 10 En-

gine oil to the bushings and locate

bushings in their proper places on the

pedal assembly and pedal support

bracket (Figs. 26 and 29).

2.

Position the brake pedal assem-

bly to the support bracket, then install

the pedal shaft through the support

bracket and brake pedal assembly. In-

stall the retainer.

3.

Install the inner nylon washer,

the master cylinder or booster push

rod, and the bushing on the brake

pedal pin. Position the switch so that

it straddles the push rod with the

switch slot on the pedal pin and the

switch outer hole just clearing the pin.

Slide the switch completely onto the

pin, and install the nylon washer as

shown in Figs. 26 and 29. Be careful

not to bend or deform the switch. Se-

cure these parts to the pin with the

hairpin retainer.

4.

Connect the stop light switch

wires to the connector, and install the

wires in the retaining clip.

5.

Check the Brake Pedal Free

Height and Travel Measurements,

Part 2-1, Section 1.

FAIRLANE, MONTEGO AND

FALCON—MANUAL-SHIFT

TRANSMISSION

Removal

1.

Remove the clutch pedal assist

spring.

2.

Disconnect the clutch pedal-

to-equalizer rod at the clutch pedal by

removing the retainer and bushing.

3.

Disconnect the stop light switch

wires at the connector.

4.

Remove the switch retainer, and

slide the stop light switch off the

brake pedal pin just far enough for

the switch outer hole to clear the pin.

Then lower the switch away from the

pin.

5. Slide the master cylinder or

booster push rod and the nylon wash-

ers and bushing off from the brake

pedal pin (Figs. 27 and 30).

6. Remove the self-locking pin and

washer from the clutch and brake

pedal shaft, then remove the clutch

pedal and shaft assembly, the brake

pedal assembly, and the bushings from

the pedal support bracket (Figs. 27

and 30).

Installation

1.

Apply a coating of SAE 10 en-

gine oil to the bushings and locate all

bushings in their proper places on the

clutch and brake pedal assemblies.

2.

Position the brake pedal to the

support bracket, then install the clutch

pedal and shaft assembly through the

support bracket and brake pedal as-

sembly. Install the spring clip (Figs.

27 and 30).

3.

Install the clutch pedal assist

spring.

4.

Connect the clutch pedal-

to-equalizer rod to the clutch pedal

assembly with the bushing and the

spring clip retainer. Apply SAE 10

engine oil to the bushing.

5.

Install the inner nylon washer,

the master cylinder or booster push

rod, and the bushing on the brake

pedal pin. Position the switch so that

it straddles the push rod with the

switch slot on the pedal pin and the

switch outer hole just clearing the pin.

Slide the switch completely onto the

pin, and install the outer nylon washer

as shown in Figs. 27 and 30. Secure

these parts to the pin with the

self-

locking pin.

6. Connect the stop light switch

wires to the connector, and install the

wires to the retaining clip.

7.

Adjust the clutch pedal free play

(Group 5) to specification, if required.

8. Check the Brake Pedal Free

Height and Travel Measurements

(Part 2-1, Section 1).

MUSTANG AND COUGAR—

MANUAL-SHIFT

TRANSMISSION

Removal

1.

Disconnect the battery ground

cable from the battery.

2.

Remove the steering column.

Refer to Part 3-4, Section 2 for pro-

cedure.

3.

On non-power brakes, remove

the two cap screws retaining the mas-

ter cylinder to the dash panel and re-

move the two cap screws retaining the

brake pedal support bracket to the

dash panel. On power brakes remove

the two cap screws retaining the

booster to the dash panel.

4.

Working inside the vehicle, se-

cure the clutch pedal against the

bumper stop with a small C-clamp as

shown in Figs. 28 and 31.

5.

Disconnect the clutch pedal-

to-equalizer rod at the clutch pedal by

removing the retainer and bushing.

6. Disconnect the stop light switch

wires at the connector.

7.

Remove the switch retainer and

slide the stop light switch off the

brake pedal pin just far enough for

the switch outer hole to clear the pin.

Then lower the switch away from the

pin.

Remove the master cylinder or

booster push rod, bushing and nylon

washer from the brake pedal pin.

8. Remove the screw retaining the

pedal support bracket to the top inner

cowl bracket (Figs. 28 and 31).

9. Remove the two sheet metal

screws retaining the pedal support

bracket to the dash panel. On power

brakes remove the nuts from the

brake booster studs.

10.

Remove the two screws retain-

ing the pedal support bracket to the

upper cowl brace and lower the pedal

support bracket away from the steer-

ing column studs.

11.

Remove the pedal support

bracket assembly from the vehicle.

12.

Position the pedal and support

bracket assembly in a vise.

13.

Remove the C-clamp to release

the clutch pedal from its bumper stop

and pivot the pedal away from the

bumper.procarmanuals.com

Page 45 of 413

02-02-26

Brake System

02-02-26

14.

Remove the clutch pedal assist

spring.

15.

On non-power brakes, remove

the retainer clip from the clutch and

brake pedal shaft, then remove the

clutch pedal and shaft assembly, the

brake pedal assembly, and the bush-

ings from the pedal support bracket.

On power brakes, remove the retainer

nut from the brake pedal shaft then

remove the pedal shaft, the brake

pedal assembly and the bushings from

the pedal support bracket.

Installation

1. Apply a coating of SAE 10 en-

gine oil to the bushings and locate all

bushings in their proper places on the

clutch and brake pedal assemblies.

2.

On non-power brakes, position

the brake pedal to the pedal support

bracket, then install the clutch pedal

and shaft assembly through the sup-

port bracket and brake pedal assem-

bly. On power brakes position the

brake pedal to the pedal support

bracket, then install the pedal shaft

and nut.

3.

Install the clutch pedal assist

spring and pivot the clutch pedal

against its bumper stop. Secure the

pedal to the stop with a small C-

clamp as shown in Figs. 28 and 31.

4.

Position the pedal support

bracket assembly to the dash panel,

and to the steering column retainer

studs.

5.

Align the pedal support bracket

holes with the holes in the dash panel

and install the two attaching sheet

metal screws. On power brakes install

the nuts on the brake booster studs.

6. Install the two cap screws at-

taching the pedal support bracket to

the upper cowl bracket.

7. Install the cap screw attaching

the pedal support bracket to the top

inner cowl bracket (Figs. 28 and 31).

8. Install the inner nylon washer,

the master cylinder push rod, and the

bushing on the brake pedal pin. Posi-

tion the stop light switch so that it

straddles the push rod with the switch

slot on the pedal pin and the switch

outer hole just clearing the pin. Slide

the switch completely onto the pin,

and install the outer nylon washer as

shown in Figs. 28 and 31. Secure

these parts to the pin with the

self-

locking retainer.

9. Connect the stop light switch

wires to the connector.

10.

Connect the clutch pedal-

to-equalizer rod to the clutch pedal

assembly with the bushing and the

spring clip retainer. Apply SAE 10

engine oil to the bushing. Remove the

C-clamp from the clutch pedal.

11.

Working from the engine side

of the dash panel, on non-power

brakes, install the two cap screws at-

taching the pedal support bracket to

the dash panel. Then install the two

screws attaching the master cylinder

to the dash panel. On power brakes

install the cap screws retaining the

brake booster to the dash panel.

12.

Install the steering column.

Refer to Part 3-4, Section 2 for pro-

cedure.

13.

Adjust the clutch pedal free

play (Group 5) to specification, if re-

quired.

14.

Check the Brake Pedal Free

Height and Travel Measurements

(Part 2-1, Section 1).

15.

Connect the ground cable to the

battery.

FAIRLANE, MONTEGO,

FALCON, MUSTANG

AND COUGAR-

AUTOMATIC TRANSMISSION

Removal

1. Disconnect the stop light switch

wires at the connector.

2.

Remove the self-locking pin and

slide the stop light switch off the

brake pedal pin just far enough for

the switch outer hole to clear the pin.

Then lower the switch away from the

pin. Slide the master cylinder or

booster push rod and the nylon wash-

ers and bushing off from the brake

pedal pin (Figs. 27, 28, 30 and 31).

3.

On all vehicles except Mustang

and Cougar with power brakes, re-

move the self-locking pin and washer

from the brake pedal shaft, then re-

move the shaft, the brake pedal as-

sembly and the bushings from the

pedal support bracket. On Mustang

and Cougar vehicles with power

brakes, remove the locknut and bolt

from the pedal. Remove the pedal as-

sembly from the support bracket (Fig.

3).

Installation

1. Apply a coating of SAE 10 en-

gine oil to the bushings and locate all

the bushings in their proper places on

the pedal assembly and pedal support

bracket (Figs. 27, 28, 30 and 31).

2.

Position the brake pedal assem-

bly to the support bracket, then install

the pedal shaft or bolt through the

support bracket and brake pedal as-

sembly. Install the retainer or locknut.

3.

Install the inner nylon washer,

the master cylinder or booster push

rod, and the bushing on the brake

pedal pin. Position the switch so that

it straddles the push rod with the

switch slot on the pedal pin, and the

switch outer hole just clearing the pin.

Slide the switch completely onto the

pin, and install the outer nylon washer

as shown in Figs. 27, 28, 30 and 31.

Secure these parts to the pin with the

self-locking pin.

4.

Connect the stop light switch

wires to the connector, and install the

wires in the retaining clip.

Check the Brake Pedal Free Height

and Travel Measurements, Part 2,

Section 1.

THUNDERBIRD

AND

CONTINENTAL MARK

III

Removal

1.

Loosen the booster mounting

nuts.

2.

Disconnect the stop light switch

wires at the connector.

3.

Remove the hairpin retainer.

Slide the stop light switch off from

the brake pedal pin just far enough

for

the

switch outer hole

to

clear

the

pin,

and then lift the switch straight

upward from the pin. Slide the master

cylinder push rod and the nylon wash-

ers and bushing off from the brake

pedal pin (Fig. 32).

4.

Remove the pivot bolt and nut

that holds the pedal to the pedal sup-

port bracket. Remove the brake pedal

assembly from the pedal support

bracket, and remove the bushings.

Installation

1. Apply a coating of SAE 10 en-

gine oil to the bushings and locate all

the bushings in their proper places on

the pedal assembly (Fig. 32).

2.

Install the brake pedal assembly

and bushings to the support bracket,

and then install the pivot bolt through

the support bracket and brake pedal

assembly. Install the pivot bolt nut

and torque to specifications.

3.

Install the inner nylon washer,

the master cylinder push rod, and the

bushing on the brake pedal pin. Posi-

tion the switch so that it straddles the

push rod with the switch slot on the

pedal pin and the switch outer hole

just clearing the pin. Slide the switch

completely onto the pin, install the

outer nylon washer as shown in Fig.

32.

Secure these parts to the pin with

the hairpin retainer.procarmanuals.com

Page 47 of 413

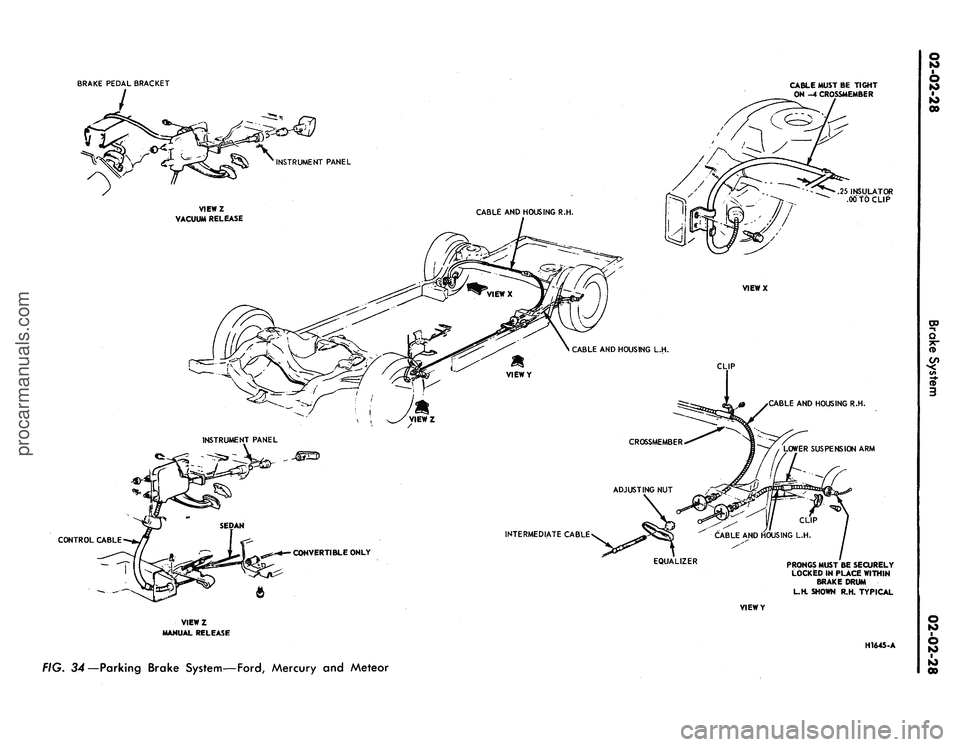

BRAKE PEDAL BRACKET

CABLE MUST BE TIGHT

ON -4 CROSSMEMBER

INSTRUMENT PANEL

VIEWZ

VACUUM RELEASE

INSTRUMENT PANEL

CONTROL CABLE

CABLE AND HOUSING R.H.

.25 INSULATOR

.00 TO CLIP

VIEWX

CABLE AND HOUSING L.H.

CLIP

CROSSMEMBER

CABLE AND HOUSING R.H.

LOWER SUSPENSION ARM

INTERMEDIATE CABLE

CONVERTIBLE ONLY

EQUALIZER

VIEWY

VIEWZ

MANUAL RELEASE

PRONGS MUST BE SECURELY

LOCKED IN PLACE WITHIN

BRAKE DRUM

L.H. SHOWN R.H. TYPICAL

H1645-A

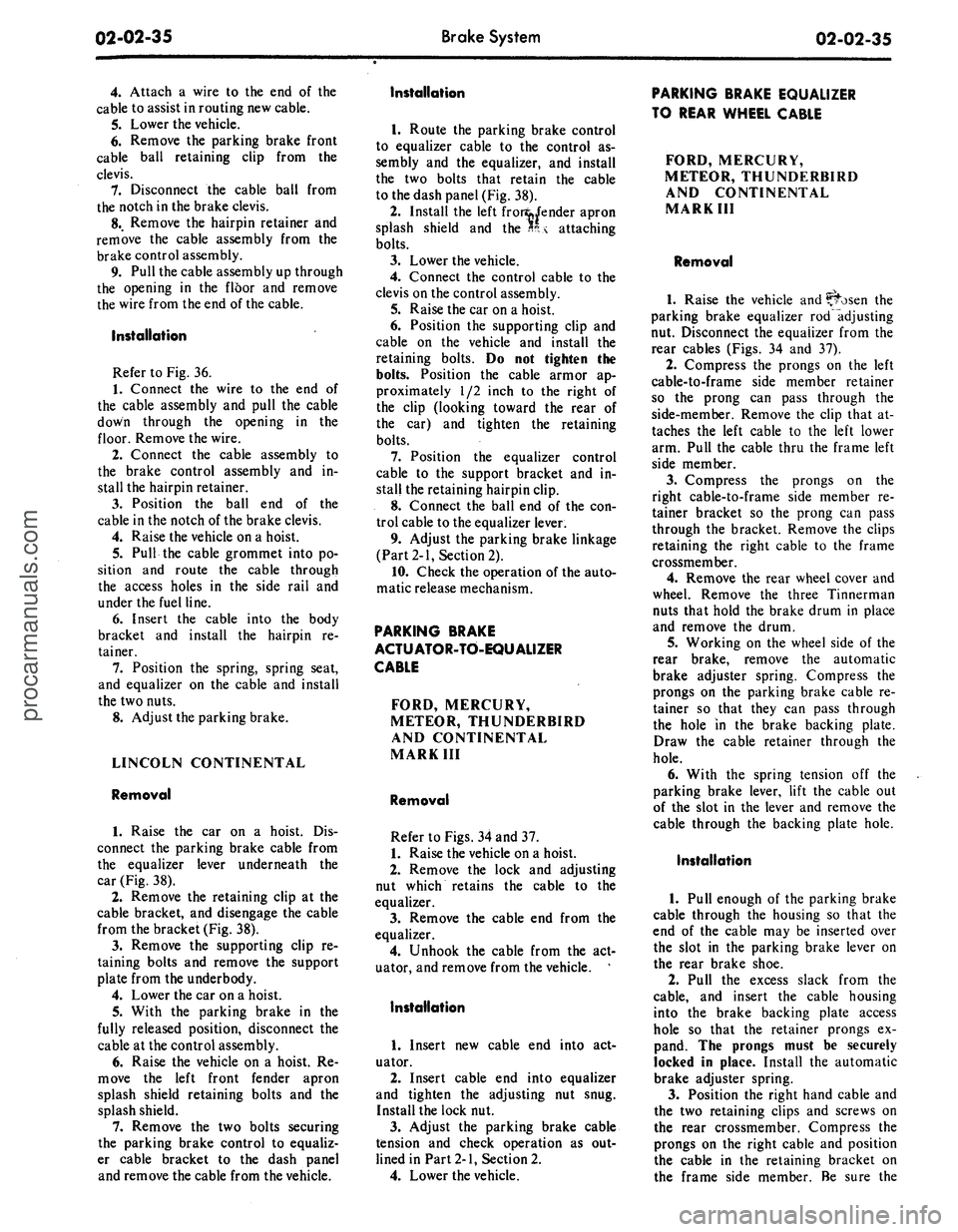

FIG. 34—Parking Brake System—Ford, Mercury and Meteorprocarmanuals.com

Page 50 of 413

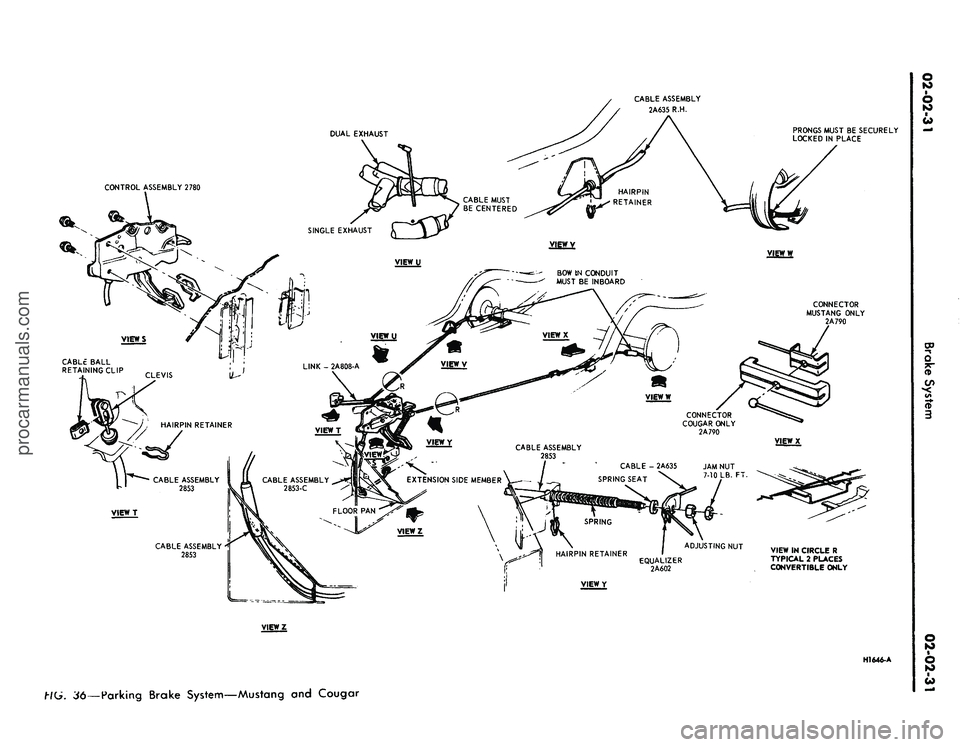

CABLE ASSEMBLY

2A635 R.H.

DUAL EXHAUST

PRONGS MUST BE SECURELY

LOCKED IN PLACE

EXTENSION SIDE MEMBER

EQUALIZER

2A602

VIEW IN CIRCLE R

TYPICAL 2 PLACES

CONVERTIBLE ONLY

VIEWY

VIEWZ

HI646-A

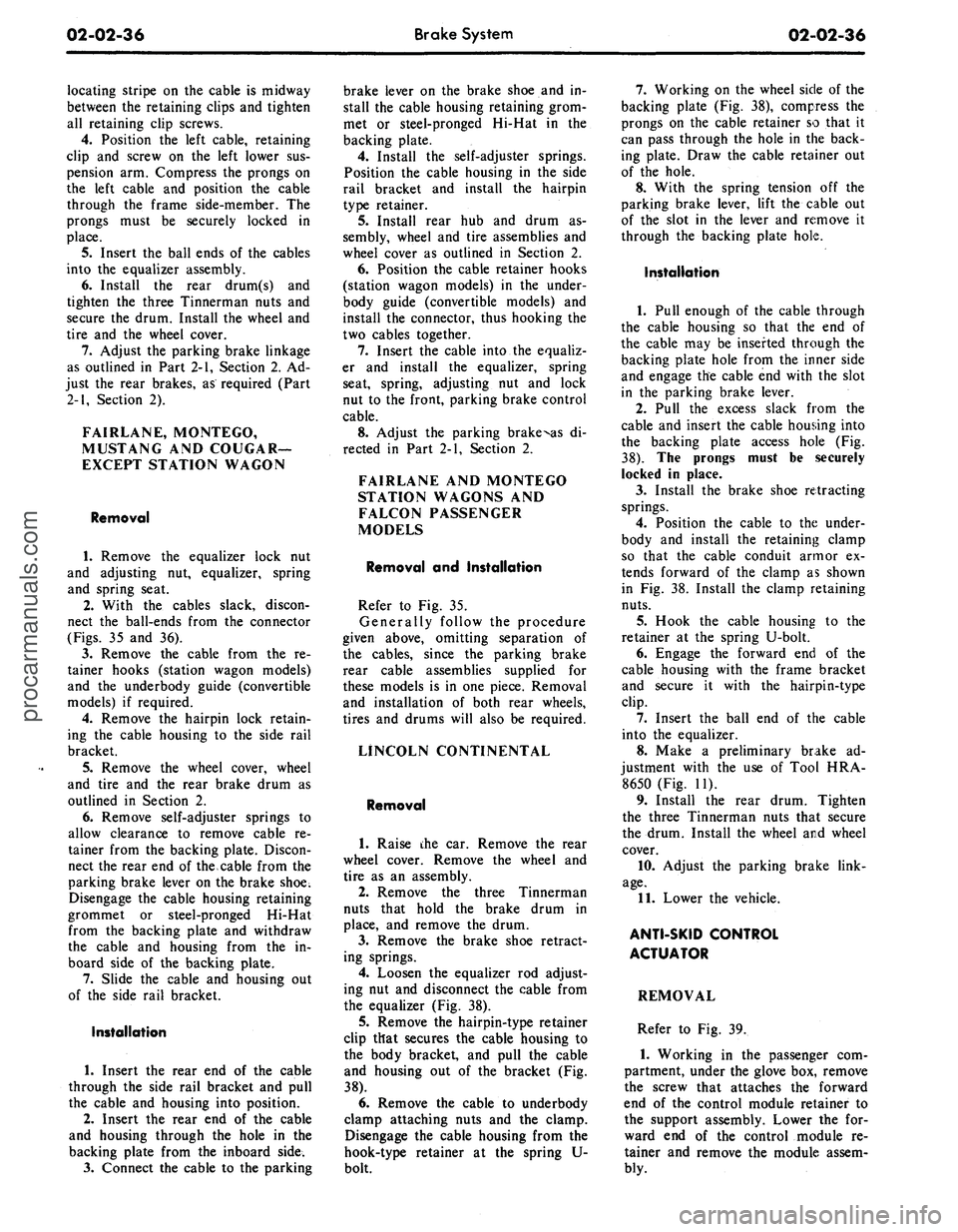

36—Parking Brake System—Mustang and Cougarprocarmanuals.com

Page 51 of 413

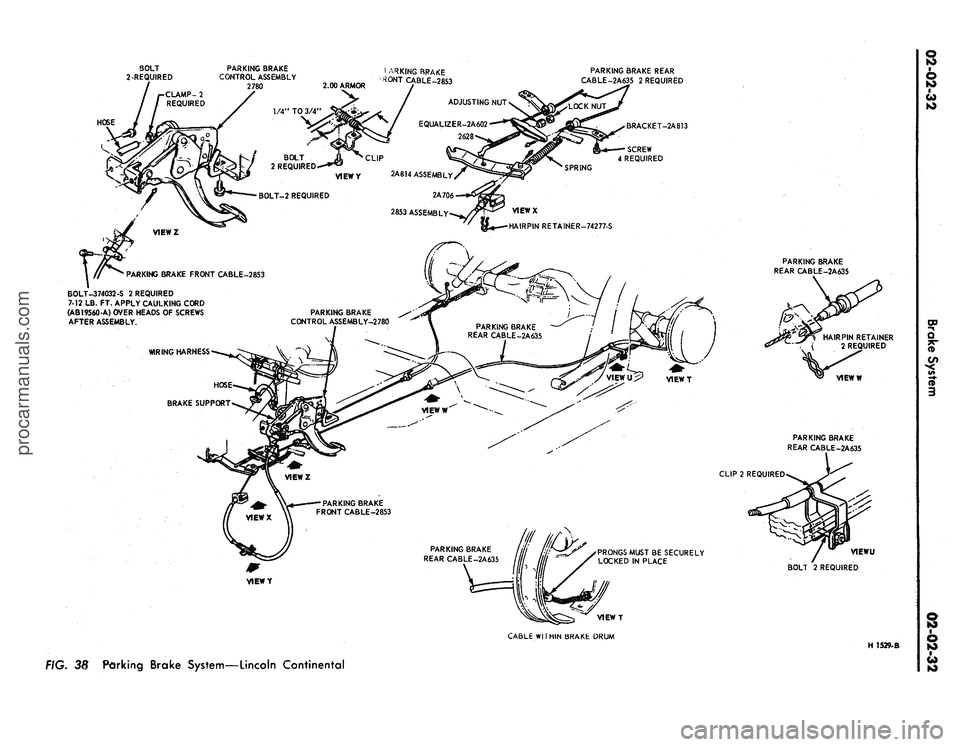

BOLT

2-REQUIRED

PARKING BRAKE

CONTROL ASSEMBLY

2780

2.00 ARMOR

I

A RKING

RRAKE

HONT CABLE-2853

ADJUSTING NUT

EQUALIZER-2A602

2628

CLIP

VIEWY 2A814 ASSEMBLY

BOLT-2 REQUIRED 2A706

2853 ASSEMBLY

PARKING BRAKE REAR

CABLE-2A635 2 REQUIRED

BRACKET-2A813

SCREW

4 REQUIRED

VIEWZ

8~-

VIEWX

HAIRPIN RETAINER-74277-S

PARKING BRAKE FRONT CABLE-2853

BOLT-374032-S 2 REQUIRED

7-12 LB. FT. APPLY CAULKING CORD

(AB19560-A) OVER HEADS OF SCREWS

AFTER ASSEMBLY.

WIRING HARNESS

HOSE

BRAKE SUPPORT

PARKING BRAKE

REAR CABLE-2A635

PARKING BRAKE

REAR CABLE-2A635

PARKING BRAKE

REAR CABLE-2A635

HAIRPIN RETAINER

( 2 REQUIRED

V1EWW

PARKING BRAKE

REAR CABLE-2A635

CLIP 2 REQUIRED

PRONGS MUST BE SECURELY

LOCKED IN PLACE

VtEWU

BOLT 2 REQUIRED

VIEWY

VIEWT

CABLE WllHIN BRAKE DRUM

H 1529-B

FIG. 38

Parking Brake System—Lincoln Continentalprocarmanuals.com

Page 52 of 413

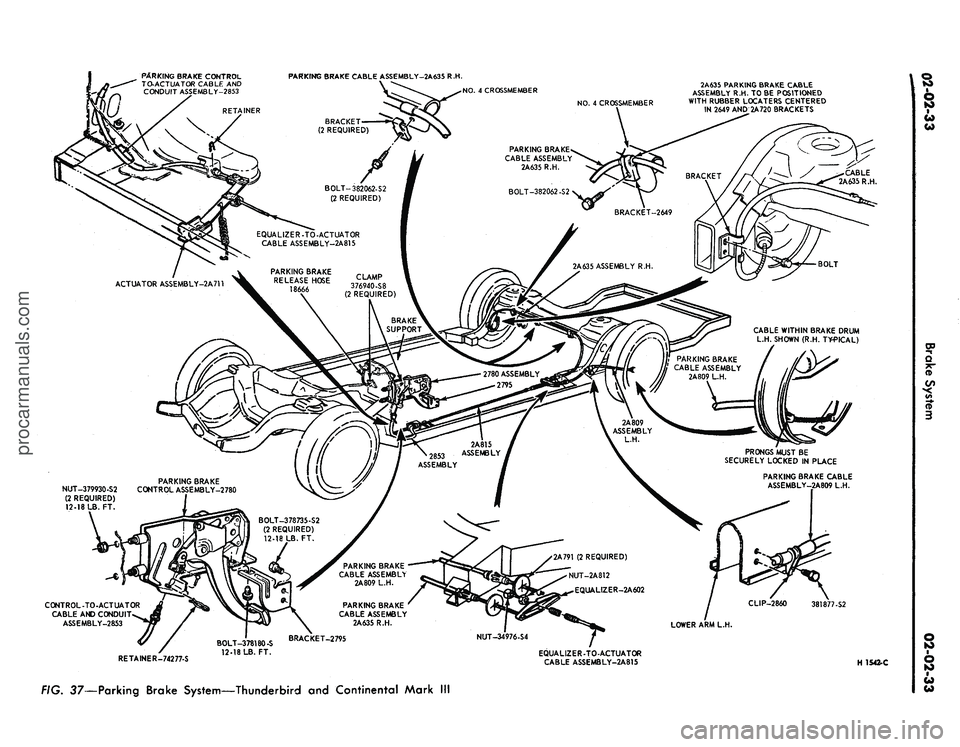

PARKING BRAKE CONTROL

TO-ACTUATOR CABLE AND

CONDUIT ASSEMBLY-2853

PARKING BRAKE CABLE ASSEMBLY-2A635 R.H.

2A635 PARKING BRAKE CABLE

ASSEMBLY R.H. TO BE POSITIONED

WITH RUBBER LOCATERS CENTERED

IN 2649 AND

2A 720

BRACKETS

NO.

4 CROSSMEMBER

NO.

4 CROSSMEMBER

BRACKET

(2 REQUIRED)

PARKING BRAKE

CABLE ASSEMBLY

2A635 R.H.

BOLT-382062-S2

(2 REQUIRED)

EQUALIZER.TO-ACTUATOR

CABLE ASSEMBLY-2A815

2A635 ASSEMBLY R.H.

ACTUATOR ASSEMBLY-2A7U

CABLE WITHIN BRAKE DRUM

L.H. SHOWN (R.H. TYPICAL)

PARKING BRAKE

CABLE ASSEMBLY

2A809 UH.

2780 ASSEMBLY

2795

2A809

ASSEMBLY

L.H.

PRONGS MUST BE

SECURELY LOCKED IN PLACE

PARKING BRAKE CABLE

ASSEMBLY-2A809 L.H.

PARKING BRAKE

CONTROL ASSEMBLY-2780

BOLT-378735-S2

(2 REQUIRED)

LB.

FT.

2A791 (2 REQUIRED)

PARKING BRAKE

CABLE ASSEMBLY

2A809 L.H.

NUT-2A812

EQUALIZER-2A602

PARKING BRAKE

CABLE ASSEMBLY

2A635 R.H.

NUT-379930-S2

(2 REQUIRED)

12-18 LB. FT.

CONTROL-TO-ACTUATOR

CABLE AND CONDUIT

ASSEMBLY-2853

381877-S2

RETAINER-74277-S

BOLT-378180-S

12-18 LB. FT.

EQUALIZER.TO-ACTUATOR

CABLE ASSEMBLY-2A815

H1542-C

FIG. 37—Parking Brake System—Thunderbird and Continental Mark IIIprocarmanuals.com

Page 54 of 413

02-02-35

Brake System

02-02-35

4.

Attach a wire to the end of the

cable to assist in routing new cable.

5.

Lower the vehicle.

6. Remove the parking brake front

cable ball retaining clip from the

clevis.

7.

Disconnect the cable ball from

the notch in the brake clevis.

8.. Remove the hairpin retainer and

remove the cable assembly from the

brake control assembly.

9. Pull the cable assembly up through

the opening in the floor and remove

the wire from the end of the cable.

Installation

Refer to Fig. 36.

1.

Connect the wire to the end of

the cable assembly and pull the cable

down through the opening in the

floor. Remove the wire.

2.

Connect the cable assembly to

the brake control assembly and in-

stall the hairpin retainer.

3.

Position the ball end of the

cable in the notch of the brake clevis.

4.

Raise the vehicle on a hoist.

5.

Pull the cable grommet into po-

sition and route the cable through

the access holes in the side rail and

under the fuel line.

6. Insert the cable into the body

bracket and install the hairpin re-

tainer.

7.

Position the spring, spring seat,

and equalizer on the cable and install

the two nuts.

8. Adjust the parking brake.

LINCOLN CONTINENTAL

Removal

1.

Raise the car on a hoist. Dis-

connect the parking brake cable from

the equalizer lever underneath the

car (Fig. 38).

2.

Remove the retaining clip at the

cable bracket, and disengage the cable

from the bracket (Fig. 38).

3.

Remove the supporting clip re-

taining bolts and remove the support

plate from the underbody.

4.

Lower the car on a hoist.

5.

With the parking brake in the

fully released position, disconnect the

cable at the control assembly.

6. Raise the vehicle on a hoist. Re-

move the left front fender apron

splash shield retaining bolts and the

splash shield.

7.

Remove the two bolts securing

the parking brake control to equaliz-

er cable bracket to the dash panel

and remove the cable from the vehicle.

Installation

1.

Route the parking brake control

to equalizer cable to the control as-

sembly and the equalizer, and install

the two bolts that retain the cable

to the dash panel (Fig. 38).

2.

Install the left fror%/ender apron

splash shield and the ^u attaching

bolts.

3.

Lower the vehicle.

4.

Connect the control cable to the

clevis on the control assembly.

5.

Raise the car on a hoist.

6. Position the supporting clip and

cable on the vehicle and install the

retaining bolts. Do not tighten the

bolts.

Position the cable armor ap-

proximately 1/2 inch to the right of

the clip (looking toward the rear of

the car) and tighten the retaining

bolts.

7.

Position the equalizer control

cable to the support bracket and in-

stall the retaining hairpin clip.

8. Connect the ball end of the con-

trol cable to the equalizer lever.

9. Adjust the parking brake linkage

(Part

2-1,

Section 2).

10.

Check the operation of the auto-

matic release mechanism.

PARKING BRAKE

ACTUATOR-TO-EQUALIZER

CABLE

FORD, MERCURY,

METEOR, THUNDERBIRD

AND CONTINENTAL

MARK III

Removal

Refer to Figs. 34 and 37.

1.

Raise the vehicle on a hoist.

2.

Remove the lock and adjusting

nut which retains the cable to the

equalizer.

3.

Remove the cable end from the

equalizer.

4.

Unhook the cable from the act-

uator, and remove from the vehicle. *

Installation

1.

Insert new cable end into act-

uator.

2.

Insert cable end into equalizer

and tighten the adjusting nut snug.

Install the lock nut.

3.

Adjust the parking brake cable

tension and check operation as out-

lined in Part

2-1,

Section 2.

4.

Lower the vehicle.

PARKING BRAKE EQUALIZER

TO REAR WHEEL CABLE

FORD, MERCURY,

METEOR, THUNDERBIRD

AND CONTINENTAL

MARK III

Removal

1.

Raise the vehicle and tffosen the

parking brake equalizer rod" adjusting

nut. Disconnect the equalizer from the

rear cables (Figs. 34 and 37).

2.

Compress the prongs on the left

cable-to-frame side member retainer

so the prong can pass through the

side-member. Remove the clip that at-

taches the left cable to the left lower

arm. Pull the cable thru the frame left

side member.

3.

Compress the prongs on the

right cable-to-frame side member re-

tainer bracket so the prong can pass

through the bracket. Remove the clips

retaining the right cable to the frame

crossmember.

4.

Remove the rear wheel cover and

wheel. Remove the three Tinnerman

nuts that hold the brake drum in place

and remove the drum.

5.

Working on the wheel side of the

rear brake, remove the automatic

brake adjuster spring. Compress the

prongs on the parking brake cable re-

tainer so that they can pass through

the hole in the brake backing plate.

Draw the cable retainer through the

hole.

6. With the spring tension off the

parking brake lever, lift the cable out

of the slot in the lever and remove the

cable through the backing plate hole.

Installation

1.

Pull enough of the parking brake

cable through the housing so that the

end of the cable may be inserted over

the slot in the parking brake lever on

the rear brake shoe.

2.

Pull the excess slack from the

cable, and insert the cable housing

into the brake backing plate access

hole so that the retainer prongs ex-

pand. The prongs must be securely

locked in place. Install the automatic

brake adjuster spring.

3.

Position the right hand cable and

the two retaining clips and screws on

the rear crossmember. Compress the

prongs on the right cable and position

the cable in the retaining bracket on

the frame side member. Be sure theprocarmanuals.com

Page 55 of 413

02-02-36

Brake System

02-02-36

locating stripe on the cable is midway

between the retaining clips and tighten

all retaining clip screws.

4.

Position the left cable, retaining

clip and screw on the left lower sus-

pension arm. Compress the prongs on

the left cable and position the cable

through the frame side-member. The

prongs must be securely locked in

place.

5.

Insert the ball ends of the cables

into the equalizer assembly.

6. Install the rear drum(s) and

tighten the three Tinnerman nuts and

secure the drum. Install the wheel and

tire and the wheel cover.

7.

Adjust the parking brake linkage

as outlined in Part 2-1, Section 2. Ad-

just the rear brakes, as required (Part

2-1,

Section 2).

FAIRLANE, MONTEGO,

MUSTANG AND COUGAR—

EXCEPT STATION WAGON

Removal

1.

Remove the equalizer lock nut

and adjusting nut, equalizer, spring

and spring seat.

2.

With the cables slack, discon-

nect the ball-ends from the connector

(Figs.

35 and 36).

3.

Remove the cable from the re-

tainer hooks (station wagon models)

and the underbody guide (convertible

models) if required.

4.

Remove the hairpin lock retain-

ing the cable housing to the side rail

bracket.

5.

Remove the wheel cover, wheel

and tire and the rear brake drum as

outlined in Section 2.

6. Remove self-adjuster springs to

allow clearance to remove cable re-

tainer from the backing plate. Discon-

nect the rear end of the cable from the

parking brake lever on the brake shoe.

Disengage the cable housing retaining

grommet or steel-pronged Hi-Hat

from the backing plate and withdraw

the cable and housing from the in-

board side of the backing plate.

7.

Slide the cable and housing out

of the side rail bracket.

Installation

1.

Insert the rear end of the cable

through the side rail bracket and pull

the cable and housing into position.

2.

Insert the rear end of the cable

and housing through the hole in the

backing plate from the inboard side.

3.

Connect the cable to the parking

brake lever on the brake shoe and in-

stall the cable housing retaining grom-

met or steel-pronged Hi-Hat in the

backing plate.

4.

Install the self-adjuster springs.

Position the cable housing in the side

rail bracket and install the hairpin

type retainer.

5.

Install rear hub and drum as-

sembly, wheel and tire assemblies and

wheel cover as outlined in Section 2.

6. Position the cable retainer hooks

(station wagon models) in the under-

body guide (convertible models) and

install the connector, thus hooking the

two cables together.

7.

Insert the cable into the equaliz-

er and install the equalizer, spring

seat, spring, adjusting nut and lock

nut to the front, parking brake control

cable.

8. Adjust the parking brake^as di-

rected in Part 2-1, Section 2.

FAIRLANE AND MONTEGO

STATION WAGONS AND

FALCON PASSENGER

MODELS

Removal and Installation

Refer to Fig. 35.

Generally follow the procedure

given above, omitting separation of

the cables, since the parking brake

rear cable assemblies supplied for

these models is in one piece. Removal

and installation of both rear wheels,

tires and drums will also be required.

LINCOLN CONTINENTAL

Removal

1.

Raise the car. Remove the rear

wheel cover. Remove the wheel and

tire as an assembly.

2.

Remove the three Tinnerman

nuts that hold the brake drum in

place, and remove the drum.

3.

Remove the brake shoe retract-

ing springs.

4.

Loosen the equalizer rod adjust-

ing nut and disconnect the cable from

the equalizer (Fig. 38).

5.

Remove the hairpin-type retainer

clip that secures the cable housing to

the body bracket, and pull the cable

and housing out of the bracket (Fig.

38).

6. Remove the cable to underbody

clamp attaching nuts and the clamp.

Disengage the cable housing from the

hook-type retainer at the spring U-

bolt.

7.

Working on the wheel side of the

backing plate (Fig. 38), compress the

prongs on the cable retainer so that it

can pass through the hole in the back-

ing plate. Draw the cable retainer out

of the hole.

8. With the spring tension off the

parking brake lever, lift the cable out

of the slot in the lever and remove it

through the backing plate hols.

Installation

1.

Pull enough of the cable through

the cable housing so that the end of

the cable may be inserted through the

backing plate hole from the inner side

and engage the cable end with the slot

in the parking brake lever.

2.

Pull the excess slack from the

cable and insert the cable housing into

the backing plate access hole (Fig.

38).

The prongs must be securely

locked in place.

3.

Install the brake shoe retracting

springs.

4.

Position the cable to the under-

body and install the retaining clamp

so that the cable conduit armor ex-

tends forward of the clamp as shown

in Fig. 38. Install the clamp retaining

nuts.

5.

Hook the cable housing to the

retainer at the spring U-bolt.

6. Engage the forward end of the

cable housing with the frame bracket

and secure it with the hairpin-type

clip.

7.

Insert the ball end of the cable

into the equalizer.

8. Make a preliminary brake ad-

justment with the use of Tool HRA-

8650 (Fig. 11).

9. Install the rear drum. Tighten

the three Tinnerman nuts that secure

the drum. Install the wheel and wheel

cover.

10.

Adjust the parking brake link-

age.

11.

Lower the vehicle.

ANTI-SKID CONTROL

ACTUATOR

REMOVAL

Refer to Fig. 39.

1.

Working in the passenger com-

partment, under the glove box, remove

the screw that attaches the forward

end of the control module retainer to

the support assembly. Lower the for-

ward end of the control module re-

tainer and remove the module assem-

bly.procarmanuals.com