lock FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 97 of 413

03-02-21

Suspension

03-02-21

8. Place a box wrench over the

lower end of the ball joint remover

tool, and position the tool as in Fig.

13.

The tool should seat firmly against

the ends of both studs, and not

against the stud nuts.

9. Turn the wrench until both studs

are under tension, and then, tap the

spindle with a hammer near the studs

to loosen them from the spindle. Do

not loosen

the

studs with tool pressure

alone.

10.

Place a jack under the outer

end of the lower arm, and raise the

arm several inches. Remove both ball

stud nuts, and remove t^e spindle.

Installation

1.

Position the new spindle onto the

upper and lower ball joint studs, in-

stall the stud nuts and tighten the nuts

to specifications. Continue to tighten

both nuts until the cotter pin holes

line up with the slots, then install new

cotter pines.

2.

Connect the spindle connecting

rod to the spindle arm. Install the re-

taining nut and tighten the nut to

specification. Continue to tighten the

nut until the cotter pin hole lines up

with the slot, then install a new cotter

pin.

3.

Install the gasket and splash

shield on the spindle. Tighten the at-

taching bolts to specifications.

4.

Install the hub and rotor on the

spindle.

5.

Install the caliper to the spindle

and tighten the attaching bolts to spe-

cifications. Check for the correct flex-

ible hose routing (Part 2-2).

6. Install the wheel and tire and ad-

just the wheel bearings (Part 3-12).

7.

Lubricate the steering stop on

the lower arm and the mating flat on

the spindle with the specified lubri-

cant.

8. Remove the safety stands, lower

the car and check camber, caster and

toe-in.

FRONT SHOCK ABSORBER

REPLACEMENT

FORD, MERCURY,

METEOR, THUNDERBIRD,

CONTINENTAL MARK III

1.

Remove the nut, washer, and

bushing from the shock absorber

upper end.

2.

Raise the vehicle on a hoist and

install safety stands.

3.

Remove 2 bolts attaching the

shock absorber to the lower arm and

remove the shock absorber.

4.

Place a washer and bushing on

the shock absorber top stud and posi-

tion the shock absorber inside the

front spring. Install the 2 lower at-

taching bolts and torque them to spe-

cifications.

5.

Remove the safety stands and

lower the vehicle.

6. Place a bushing and washer on

the shock absorber top stud and in-

stall the attaching nut. Torque it to

specification.

COUGAR, FAIRLANE,

FALCON, MONTEGO,

MUSTANG

Removal

1. Raise the hood and remove 3

shock absorber upper mounting

bracket-to-spring tower attaching

nuts.

2.

Raise the front of the vehicle and

place safety stands under the lower

arms.

3.

Remove 2 shock absorber lower

attaching nuts and washers.

4.

Lift the shock absorber and

upper bracket from the spring tower

(Fig. 26) and remove the bracket from

the shock absorber.

Installation

1. Install the upper mounting

bracket on the shock absorber and

torque to specification.

2.

Position the shock absorber and

upper mounting bracket in the spring

tower, making sure the shock absor-

ber lower studs are in the pivot plate

holes.

3.

Install the 2 washers and attach-

ing nuts on the shock absorber lower

studs and torque to specification.

4.

Install the 3 shock absorber

upper mounting bracket-to-spring

tower attaching nuts and torque to

specification. Then, remove the safety

stands and lower the vehicle.

LINCOLN CONTINENTAL

Removal

1.

Remove the stud nut at the

upper eye of the shock absorber. Re-

move the upper eye stud bracket to

crossmember attaching bolt and re-

move the stud bracket. Refer to Fig.

22.

2.

Remove the bolts which attach

the shock absorber to the suspension

lower arm. Lower, and remove the

shock absorber.

3.

Examine the shock absorber unit

and rubber bushings. Replace parts

that are defective, deteriorated, or

worn.

Installation

1. Fully extend the shock absorber

and position it inside the coil spring.

Connect the lower end of the shock

absorber to the suspension lower arm.

Torque the attaching nuts to specifica-

tion.

2.

Insert the upper bracket stud

through the bushing in the shock ab-

sorber upper eye. Install the stud

bracket to crossmember attaching

bolt. Do not tighten the bolt: at this

time.

3.

Install the upper eye bracket

stud nut. Torque the nut to specifica-

tion.

4.

Torque the stud bracket- to-

crossmember attaching bolt to specifi-

cation.

The

shock absorber upper

eye

stud

nut

must

be

tightened

to com-

press

the

rubber bushing before

the

stud bracket

is

bolted

to the

crossmember;

otherwise,

the

upper

at-

tachment could

be

loose

and

noisy.

REAR SHOCK ABSORBER

REPLACEMENT

FORD, MERCURY,

METEOR, THUNDERBIRD,

CONTINENTAL MARK 1(11

1.

Raise the vehicle on a hoist.

2.

Remove the shock absorber at-

taching nut, washer and insulator

from the upper stud at the upper side

of the spring upper seat. Compress the

shock absorber to clear the hole in the

spring seat, and remove the inner in-

sulator and washer from the upper at-

taching stud.

3.

Remove the self-locking attach-

ing nut, and disconnect the shock ab-

sorber lower stud from the mounting

bracket on the rear axle housing (Fig.

4).

4.

Expel all air by performing step

3 On Vehicle Tests in Part 3-1.

5.

Place the inner washer and insu-

lator on the upper attaching stud, and

position the shock absorber so that

the upper attaching stud enters the

hole in the spring upper seat. While

holding the shock absorber in this po-

sition, install the outer insulator andprocarmanuals.com

Page 98 of 413

03-02-22

Suspension

03-02-22

washer and the nut on the upper stud

from the upper side of the spring

upper seat. Torque the nut to specifi-

cations.

6. Extend the shock absorber and

locate the lower stud in the hole in

mounting bracket on the rear axle

housing. Install a new self-locking at-

taching nut and torque to specifica-

tion.

MUSTANG AND COUGAR

Removal

1.

Disconnect the shock absorber

from the spring clip plate (Fig. 30).

2.

Remove the shock absorber ac-

cess cover from the luggage compart-

ment (Fig. 28).-(On convertible mod-

els,

remove the rear seat and seat

back to reach the access cover.)

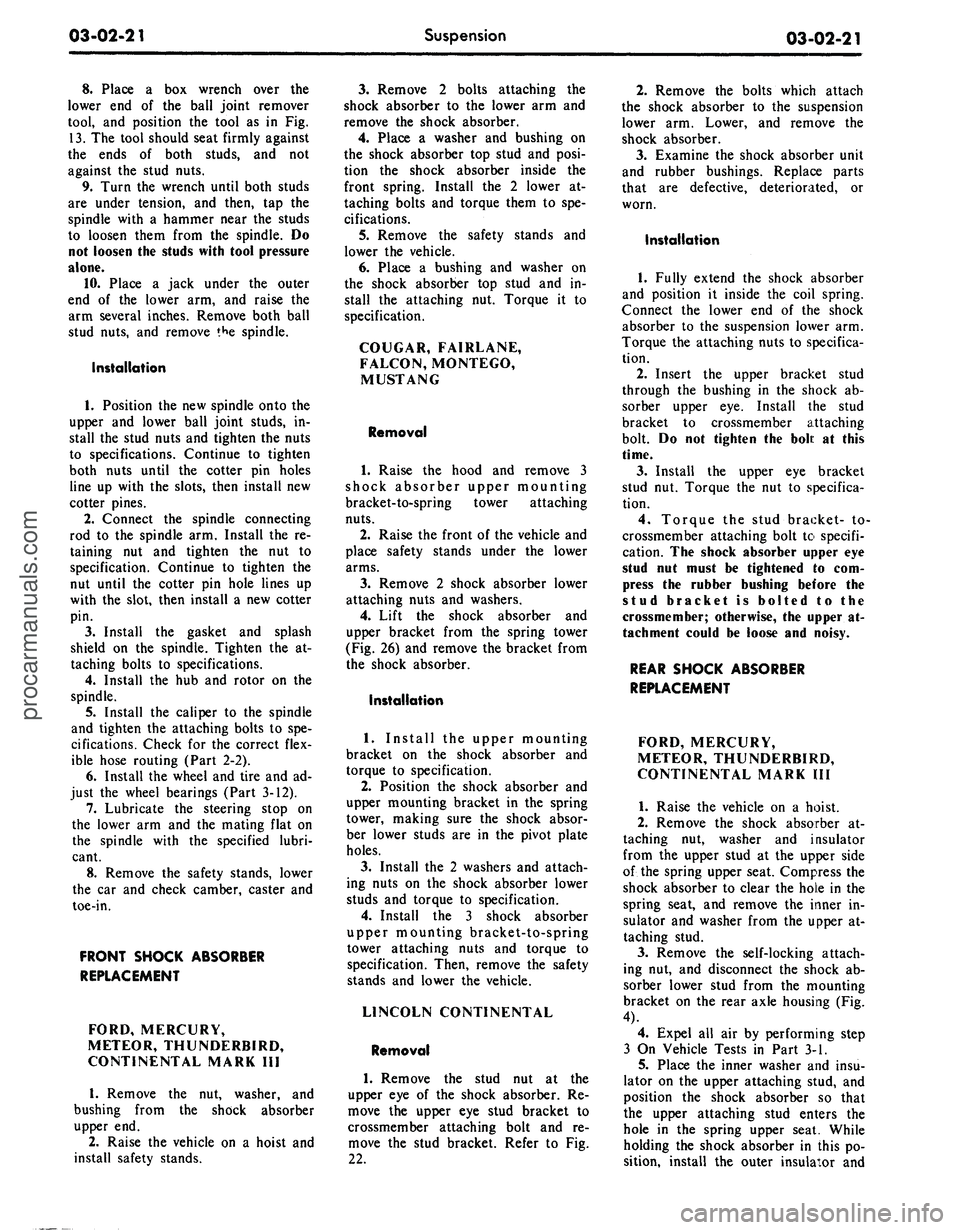

SHOCK ABSORBER ACCESS COVER

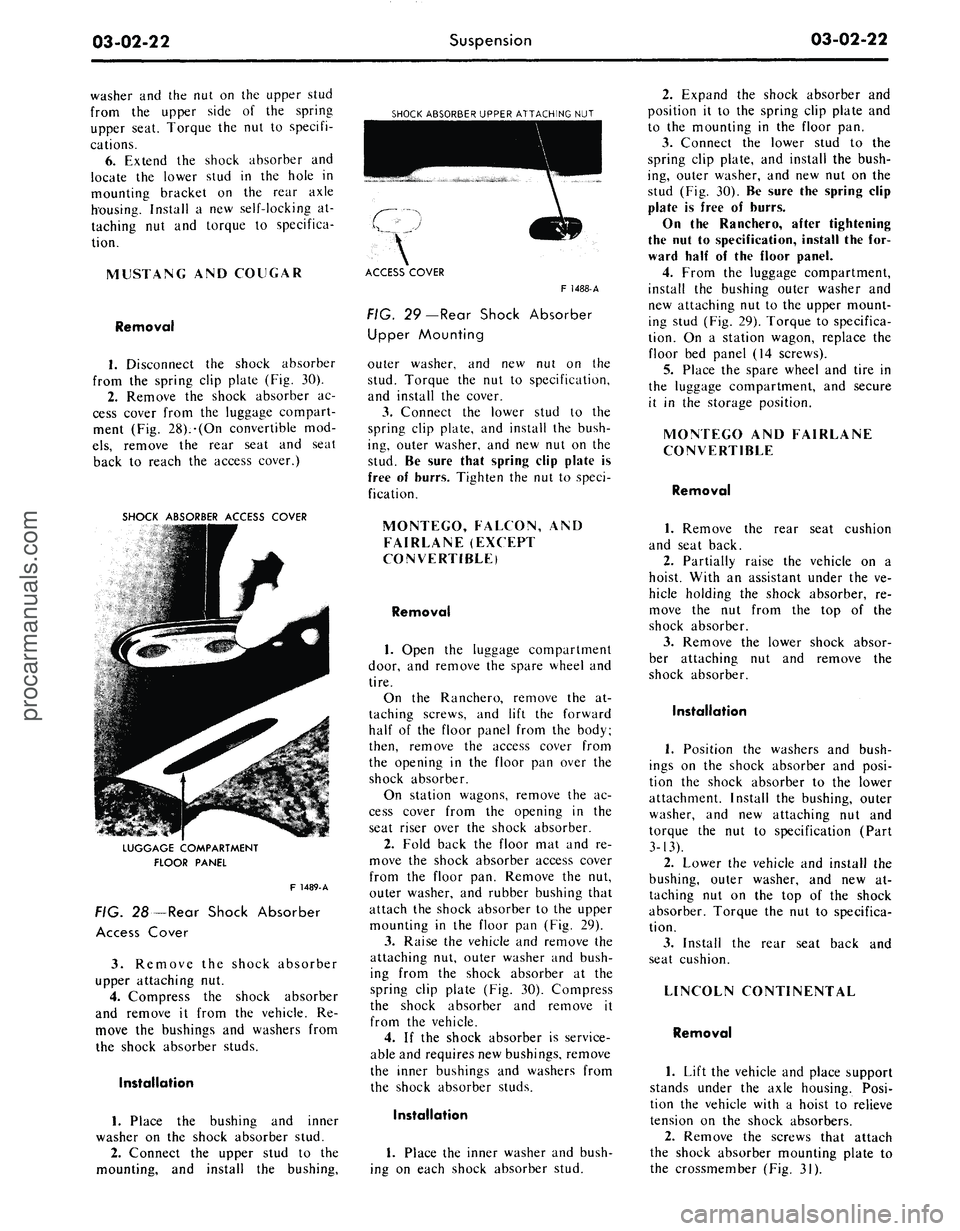

SHOCK ABSORBER UPPER ATTACHING NUT

LUGGAGE COMPARTMENT

FLOOR PANEL

F 1489-A

FIG. 28—Rear Shock Absorber

Access Cover

3.

Remove the shock absorber

upper attaching nut.

4.

Compress the shock absorber

and remove it from the vehicle. Re-

move the bushings and washers from

the shock absorber studs.

Installation

1.

Place the bushing and inner

washer on the shock absorber stud.

2.

Connect the upper stud to the

mounting, and install the bushing,

ACCESS COVER

F 1488-A

FIG. 29—Rear Shock Absorber

Upper Mounting

outer washer, and new nut on the

stud. Torque the nut to specification,

and install the cover.

3.

Connect the lower stud to the

spring clip plate, and install the bush-

ing, outer washer, and new nut on the

stud. Be sure that spring clip plate is

free of burrs. Tighten the nut to speci-

fication.

MONTEGO, FALCON, AND

FAIRLANE (EXCEPT

CONVERTIBLE)

Removal

1.

Open the luggage compartment

door, and remove the spare wheel and

tire.

On the Ranchero, remove the at-

taching screws, and lift the forward

half of the floor panel from the body;

then, remove the access cover from

the opening in the floor pan over the

shock absorber.

On station wagons, remove the ac-

cess cover from the opening in the

seat riser over the shock absorber.

2.

Fold back the floor mat and re-

move the shock absorber access cover

from the floor pan. Remove the nut,

outer washer, and rubber bushing that

attach the shock absorber to the upper

mounting in the floor pan (Fig. 29).

3.

Raise the vehicle and remove the

attaching nut, outer washer and bush-

ing from the shock absorber at the

spring clip plate (Fig. 30). Compress

the shock absorber and remove it

from the vehicle.

4.

If the shock absorber is service-

able and requires new bushings, remove

the inner bushings and washers from

the shock absorber studs.

Installation

1.

Place the inner washer and bush-

ing on each shock absorber stud.

2.

Expand the shock absorber and

position it to the spring clip plate and

to the mounting in the floor pan.

3.

Connect the lower stud to the

spring clip plate, and install the bush-

ing, outer washer, and new nut on the

stud (Fig. 30). Be sure the spring clip

plate is free of burrs.

On the Ranchero, after tightening

the nut to specification, install the for-

ward half of the floor panel.

4.

From the luggage compartment,

install the bushing outer washer and

new attaching nut to the upper mount-

ing stud (Fig. 29). Torque to specifica-

tion. On a station wagon, replace the

floor bed panel (14 screws).

5.

Place the spare wheel and tire in

the luggage compartment, and secure

it in the storage position.

MONTEGO AND FAIRLANE

CONVERTIBLE

Removal

1.

Remove the rear seat cushion

and seat back.

2.

Partially raise the vehicle on a

hoist. With an assistant under the ve-

hicle holding the shock absorber, re-

move the nut from the top of the

shock absorber.

3.

Remove the lower shock absor-

ber attaching nut and remove the

shock absorber.

Installation

1.

Position the washers and bush-

ings on the shock absorber and posi-

tion the shock absorber to the lower

attachment. Install the bushing, outer

washer, and new attaching nut and

torque the nut to specification (Part

3-13).

2.

Lower the vehicle and install the

bushing, outer washer, and new at-

taching nut on the top of the shock

absorber. Torque the nut to specifica-

tion.

3.

Install the rear seat back and

seat cushion.

LINCOLN CONTINENTAL

Removal

1.

Lift the vehicle and place support

stands under the axle housing. Posi-

tion the vehicle with a hoist to relieve

tension on the shock absorbers.

2.

Remove the screws that attach

the shock absorber mounting plate to

the crossmember (Fig. 31).procarmanuals.com

Page 100 of 413

03-02-24

Suspension

03-02-24

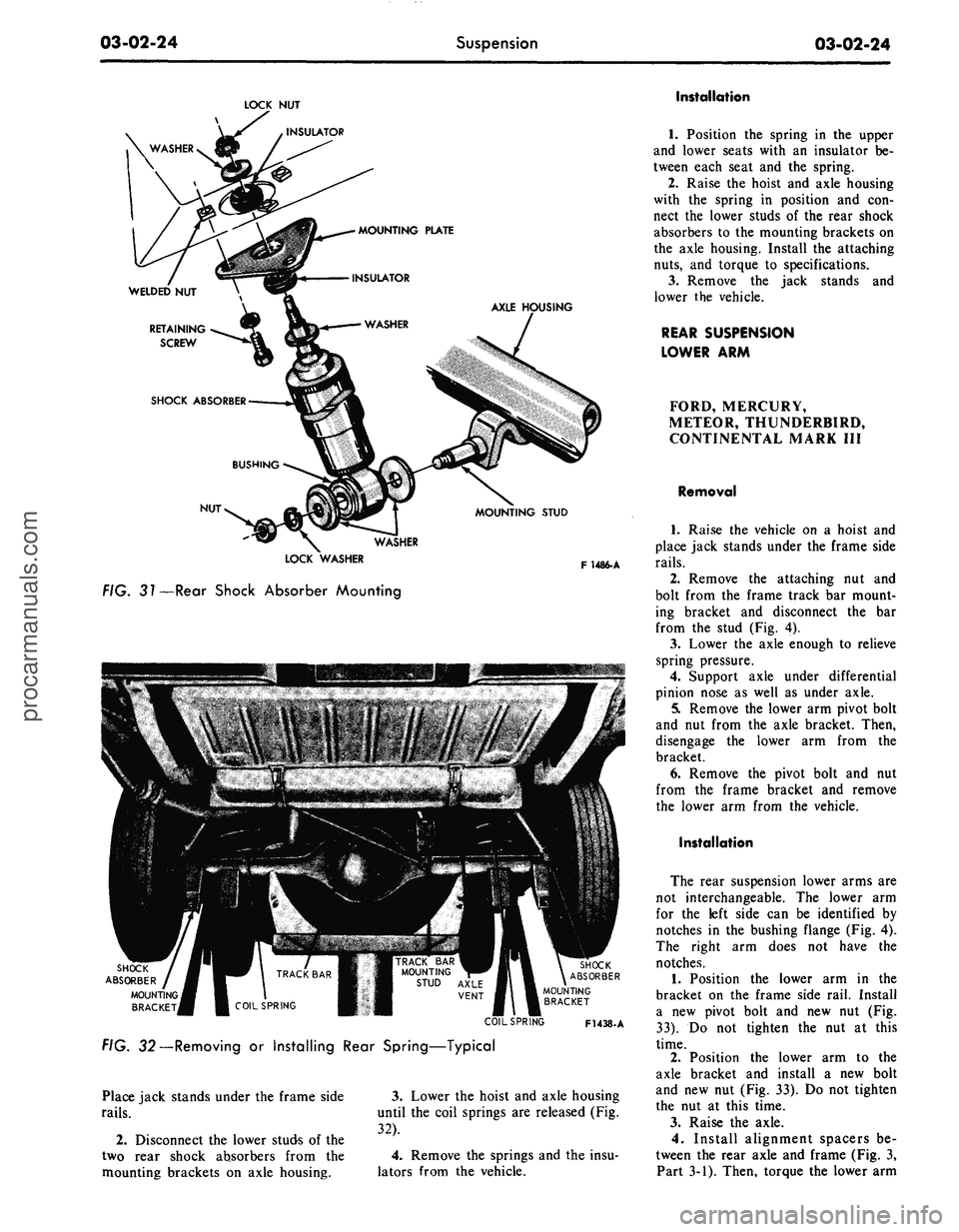

LOCK NUT

INSULATOR

NG

NUT

MOUNTING STUD

WASHER

LOCK WASHER

FIG. 31—Rear Shock Absorber Mounting

F1486-A

TRACK BAR

MOUNTING

STUD AXLE

VENT

SHOCK

ABSORBER

MOUNTING

BRACKET

SHOCK

ABSORBER

MOUNTING

BRACKET

V-V.

FIG. 32—Removing or Installing Rear Spring—Typical

COIL SPRING

F1438-A

Place jack stands under the frame side

rails.

2.

Disconnect the lower studs of the

two rear shock absorbers from the

mounting brackets on axle housing.

3.

Lower the hoist and axle housing

until the coil springs are released (Fig.

32).

4.

Remove the springs and the insu-

lators from the vehicle.

Installation

1.

Position the spring in the upper

and lower seats with an insulator be-

tween each seat and the spring.

2.

Raise the hoist and axle housing

with the spring in position and con-

nect the lower studs of the rear shock

absorbers to the mounting brackets on

the axle housing. Install the attaching

nuts,

and torque to specifications.

3.

Remove the jack stands and

lower the vehicle.

REAR SUSPENSION

LOWER ARM

FORD, MERCURY,

METEOR, THUNDERBIRD,

CONTINENTAL MARK III

Removal

1.

Raise the vehicle on a hoist and

place jack stands under the frame side

rails.

2.

Remove the attaching nut and

bolt from the frame track bar mount-

ing bracket and disconnect the bar

from the stud (Fig. 4).

3.

Lower the axle enough to relieve

spring pressure.

4.

Support axle under differential

pinion nose as well as under axle.

5.

Remove the lower arm pivot bolt

and nut from the axle bracket. Then,

disengage the lower arm from the

bracket.

6. Remove the pivot bolt and nut

from the frame bracket and remove

the lower arm from the vehicle.

Installation

The rear suspension lower arms are

not interchangeable. The lower arm

for the left side can be identified by

notches in the bushing flange (Fig. 4).

The right arm does not have the

notches.

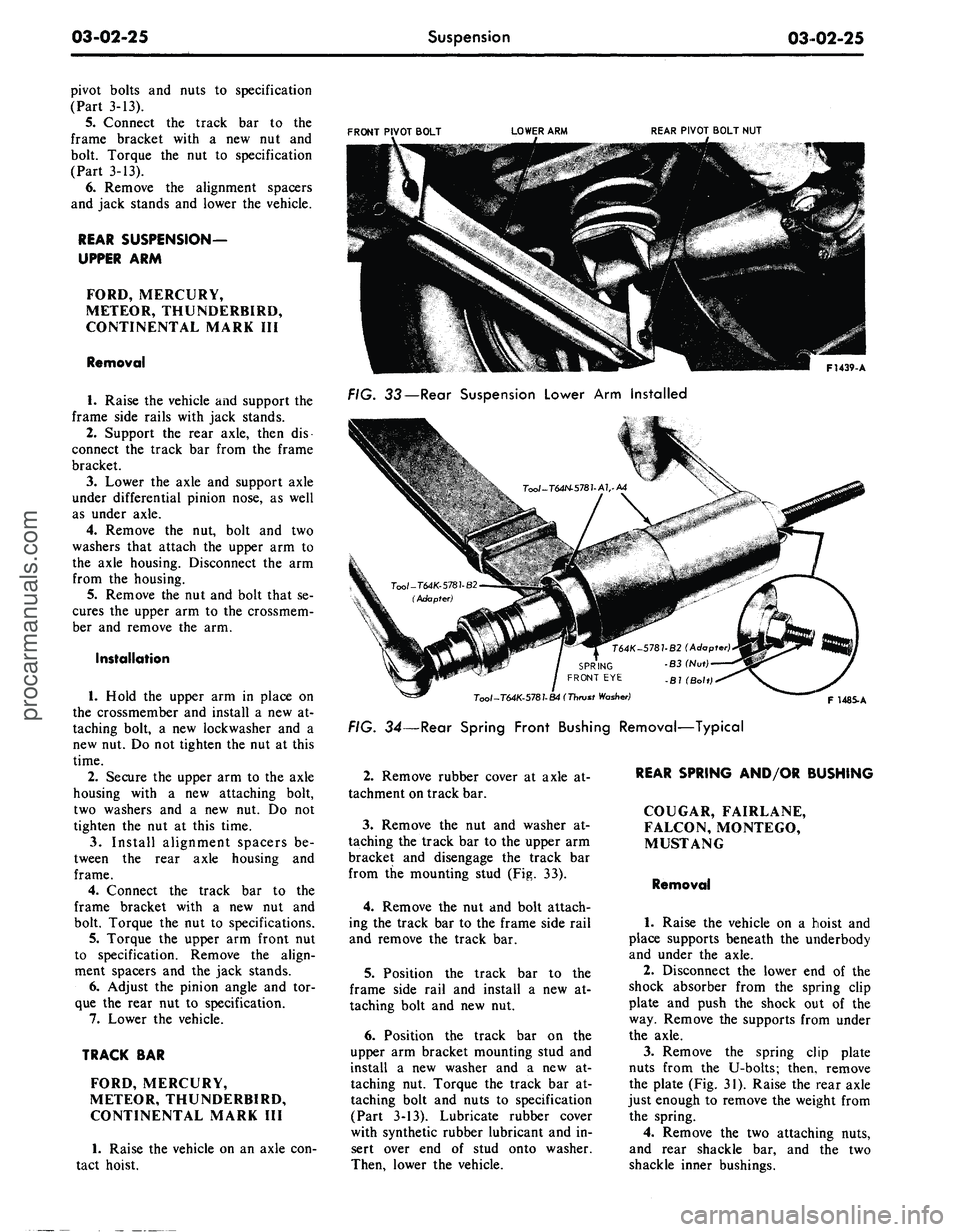

1.

Position the lower arm in the

bracket on the frame side rail. Install

a new pivot bolt and new nut (Fig.

33).

Do not tighten the nut at this

time.

2.

Position the lower arm to the

axle bracket and install a new bolt

and new nut (Fig. 33). Do not tighten

the nut at this time.

3.

Raise the axle.

4.

Install alignment spacers be-

tween the rear axle and frame (Fig. 3,

Part 3-1). Then, torque the lower armprocarmanuals.com

Page 101 of 413

03-02-25

Suspension

03-02-25

pivot bolts and nuts to specification

(Part 3-13).

5.

Connect the track bar to the

frame bracket with a new nut and

bolt. Torque the nut to specification

(Part 3-13).

6. Remove the alignment spacers

and jack stands and lower the vehicle.

REAR SUSPENSION-

UPPER ARM

FORD, MERCURY,

METEOR, THUNDERBIRD,

CONTINENTAL MARK HI

Removal

1.

Raise the vehicle and support the

frame side rails with jack stands.

2.

Support the rear axle, then dis

connect the track bar from the frame

bracket.

3.

Lower the axle and support axle

under differential pinion nose, as well

as under axle.

4.

Remove the nut, bolt and two

washers that attach the upper arm to

the axle housing. Disconnect the arm

from the housing.

5.

Remove the nut and bolt that se-

cures the upper arm to the crossmem-

ber and remove the arm.

Installation

1.

Hold the upper arm in place on

the crossmember and install a new at-

taching bolt, a new lockwasher and a

new nut. Do not tighten the nut at this

time.

2.

Secure the upper arm to the axle

housing with a new attaching bolt,

two washers and a new nut. Do not

tighten the nut at this time.

3.

Install alignment spacers be-

tween the rear axle housing and

frame.

4.

Connect the track bar to the

frame bracket with a new nut and

bolt. Torque the nut to specifications.

5.

Torque the upper arm front nut

to specification. Remove the align-

ment spacers and the jack stands.

6. Adjust the pinion angle and tor-

que the rear nut to specification.

7.

Lower the vehicle.

TRACK BAR

FORD, MERCURY,

METEOR, THUNDERBIRD,

CONTINENTAL MARK HI

1.

Raise the vehicle on an axle con-

tact hoist.

FRONT PIVOT BOLT

LOWER ARM

REAR PIVOT BOLT NUT

F1439-A

FIG. 33—Rear Suspension Lower Arm Installed

Tool-T64K-5781-B4 (Thrust

Washer)

FIG. 34—Rear Spring Front Bushing Removal—Typical

F 1485. A

2.

Remove rubber cover at axle at-

tachment on track bar.

3.

Remove the nut and washer at-

taching the track bar to the upper arm

bracket and disengage the track bar

from the mounting stud (Fig. 33).

4.

Remove the nut and bolt attach-

ing the track bar to the frame side rail

and remove the track bar.

5.

Position the track bar to the

frame side rail and install a new at-

taching bolt and new nut.

6. Position the track bar on the

upper arm bracket mounting stud and

install a new washer and a new at-

taching nut. Torque the track bar at-

taching bolt and nuts to specification

(Part 3-13). Lubricate rubber cover

with synthetic rubber lubricant and in-

sert over end of stud onto washer.

Then, lower the vehicle.

REAR SPRING AND/OR BUSHING

COUGAR, FAIRLANE,

FALCON, MONTEGO,

MUSTANG

Removal

1.

Raise the vehicle on a hoist and

place supports beneath the underbody

and under the axle.

2.

Disconnect the lower end of the

shock absorber from the spring clip

plate and push the shock out of the

way. Remove the supports from under

the axle.

3.

Remove the spring clip plate

nuts from the U-bolts; then, remove

the plate (Fig. 31). Raise the rear axle

just enough to remove the weight from

the spring.

4.

Remove the two attaching nuts,

and rear shackle bar, and the two

shackle inner bushings.procarmanuals.com

Page 102 of 413

03-02-26

Suspension

03-02-26

T64K-578 7-B2 (Adapter)

-83 (Nut)

(Bolt)

SPRING FRONT

EYE

Tool-T64K-5781-B2 (Adapter)

BUSHING

F 1484-A

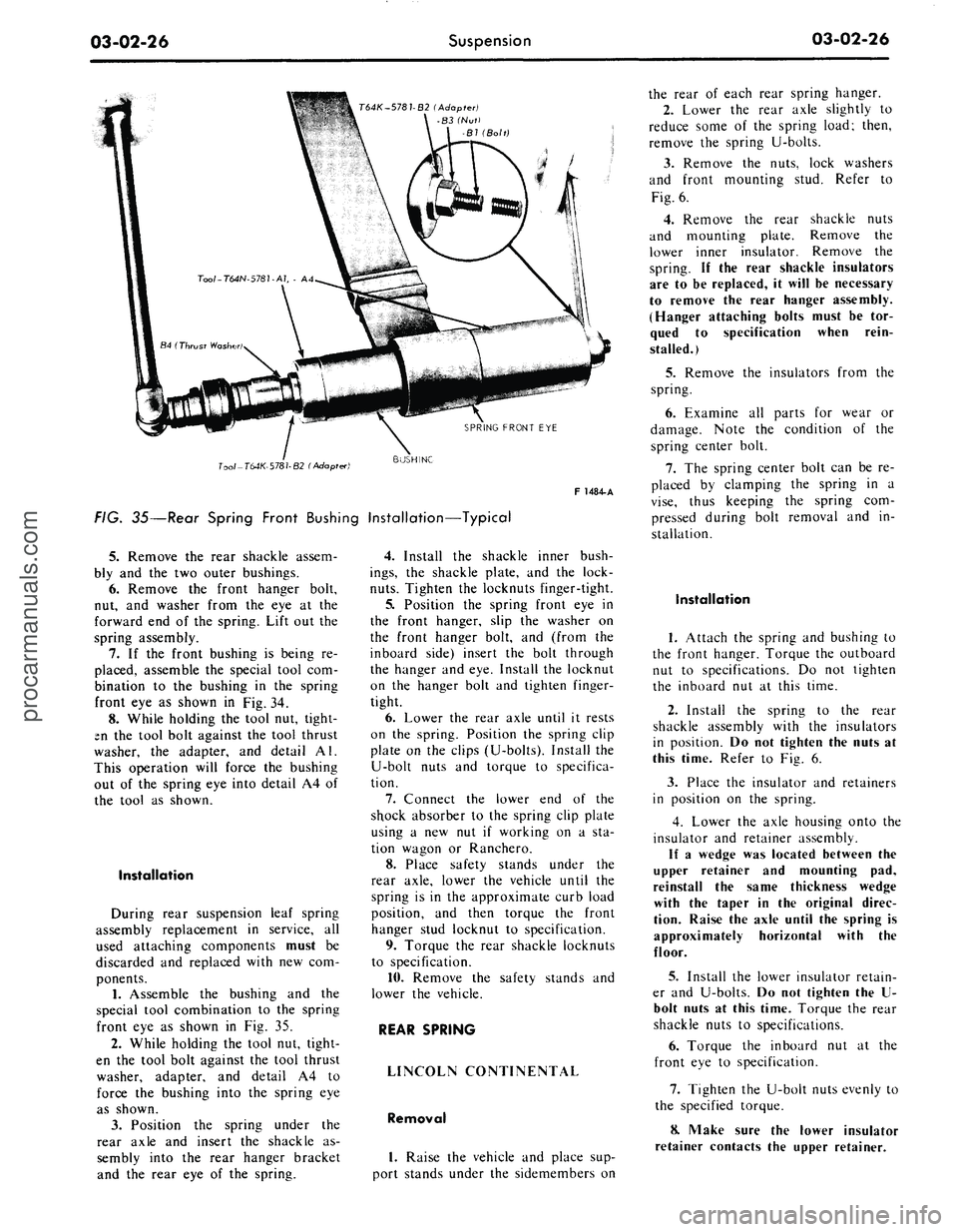

FIG. 35—Rear Spring Front Bushing Installation—Typical

5.

Remove

the

rear shackle assem-

bly

and the two

outer bushings.

6. Remove

the

front hanger bolt,

nut,

and

washer from

the eye at the

forward

end of the

spring. Lift

out the

spring assembly.

7.

If the

front bushing

is

being

re-

placed, assemble

the

special tool

com-

bination

to the

bushing

in the

spring

front

eye as

shown

in

Fig.

34.

8. While holding

the

tool

nut,

tight-

en

the

tool bolt against

the

tool thrust

washer,

the

adapter,

and

detail

Al.

This operation will force

the

bushing

out

of the

spring

eye

into detail

A4 of

the tool

as

shown.

Installation

During rear suspension leaf spring

assembly replacement

in

service,

all

used attaching components must

be

discarded

and

replaced with

new com-

ponents.

1.

Assemble

the

bushing

and the

special tool combination

to the

spring

front

eye as

shown

in Fig. 35.

2.

While holding

the

tool

nut,

tight-

en

the

tool bolt against

the

tool thrust

washer, adapter,

and

detail

A4 to

force

the

bushing into

the

spring

eye

as shown.

3.

Position

the

spring under

the

rear axle

and

insert

the

shackle

as-

sembly into

the

rear hanger bracket

and

the

rear

eye of the

spring.

4.

Install

the

shackle inner bush-

ings,

the

shackle plate,

and the

lock-

nuts.

Tighten

the

locknuts finger-tight.

5.

Position

the

spring front

eye in

the front hanger, slip

the

washer

on

the front hanger bolt,

and

(from

the

inboard side) insert

the

bolt through

the hanger

and

eye. Install

the

locknut

on

the

hanger bolt

and

tighten finger-

tight.

6. Lower

the

rear axle until

it

rests

on

the

spring. Position

the

spring clip

plate

on the

clips (U-bolts). Install

the

U-bolt nuts

and

torque

to

specifica-

tion.

7.

Connect

the

lower

end of the

shock absorber

to the

spring clip plate

using

a new nut if

working

on a sta-

tion wagon

or

Ranchero.

8. Place safety stands under

the

rear axle, lower

the

vehicle until

the

spring

is in the

approximate curb load

position,

and

then torque

the

front

hanger stud locknut

to

specification.

9. Torque

the

rear shackle locknuts

to specification.

10.

Remove

the

safety stands

and

lower

the

vehicle.

REAR SPRING

LINCOLN CONTINENTAL

Removal

1.

Raise

the

vehicle

and

place

sup-

port stands under

the

sidemembers

on

the rear

of

each rear spring hanger.

2.

Lower

the

rear axle slightly

to

reduce some

of the

spring load; then,

remove

the

spring U-bolts.

3.

Remove

the

nuts, lock washers

and front mounting stud. Refer

to

Fig.

6.

4.

Remove

the

rear shackle nuts

and mounting plate. Remove

the

lower inner insulator. Remove

the

spring.

If the

rear shackle insulators

are

to be

replaced,

it

will

be

necessary

to remove

the

rear hanger assembly.

(Hanger attaching bolts must

be tor-

qued

to

specification when rein-

stalled.)

5.

Remove

the

insulators from

the

spring.

6. Examine

all

parts

for

wear

or

damage. Note

the

condition

of the

spring center bolt.

7.

The

spring center bolt

can be re-

placed

by

clamping

the

spring

in a

vise,

thus keeping

the

spring

com-

pressed during bolt removal

and in-

stallation.

Installation

1.

Attach

the

spring

and

bushing

to

the front hanger. Torque

the

outboard

nut

to

specifications.

Do not

tighten

the inboard

nut at

this time.

2.

Install

the

spring

to the

rear

shackle assembly with

the

insulators

in position.

Do not

tighten

the

nuts

at

this time. Refer

to Fig. 6.

3.

Place

the

insulator

and

retainers

in position

on the

spring.

4.

Lower

the

axle housing onto

the

insulator

and

retainer assembly.

If

a

wedge

was

located between

the

upper retainer

and

mounting

pad,

reinstall

the

same thickness wedge

with

the

taper

in the

original direc-

tion. Raise

the

axle until

the

spring

is

approximately horizontal with

the

floor.

5.

Install

the

lower insulator retain-

er

and

U-bolts.

Do not

tighten

the U-

bolt nuts

at

this time. Torque

the

rear

shackle nuts

to

specifications.

6. Torque

the

inboard

nut at the

front

eye to

specification.

7.

Tighten

the

U-bolt nuts evenly

to

the specified torque.

8. Make sure

the

lower insulator

retainer contacts

the

upper retainer.procarmanuals.com

Page 104 of 413

03-02-28

Suspension

03-02-28

used, these components should

be re-

placed

on the

bench.

Do not wash the ball joint with sol-

vent.

The

solvent

may

attack parts

within the joint.

BUSHING AND INNER

SHAFT REPLACEMENT

LINCOLN CONTINENTAL

Always replace both upper

arm

bushings,

if

either bushing

is

worn

or

damaged. Install only

new

bushings

when replacing

the

inner shaft. Refer

to Section

3 for

the upper arm remov-

al procedure.

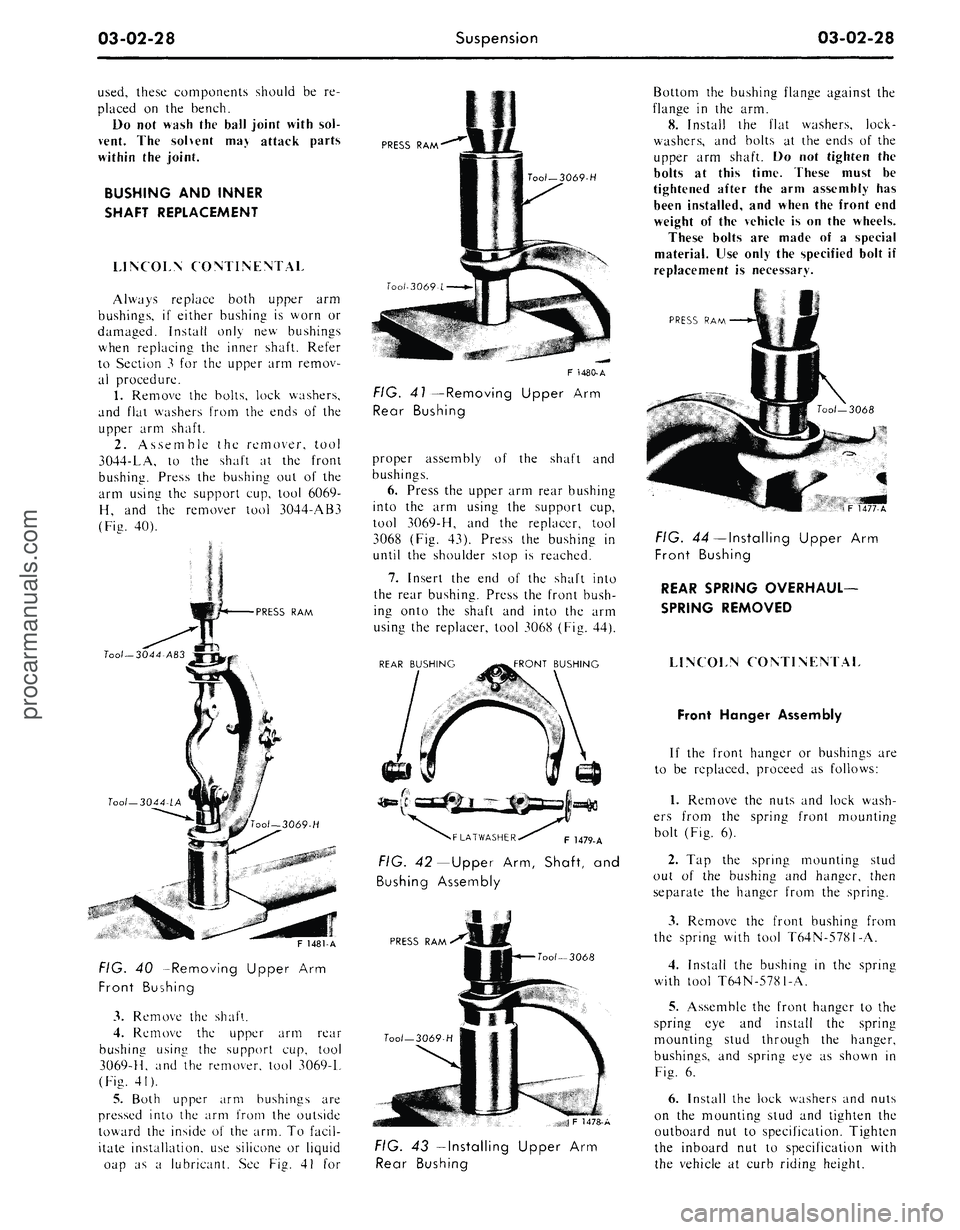

1.

Remove

the

bolts, lock washers,

and flat washers from the ends

of

the

upper arm shaft.

2.

Assemble

the

remover, tool

3044-LA,

to the

shaft

at the

front

bushing. Press

the

bushing

out of the

arm using

the

support cup, tool 6069-

H,

and the

remover tool 3044-AB3

(Fig. 40).

PRESS RAM

FIG.

40

—Removing Upper

Arm

Front Bushing

3.

Remove

the

shaft.

4.

Remove

the

upper

arm

rear

bushing using

the

support

cup,

tool

3069-H, and

the

remover, tool 3069-L

(Fig. 41).

5.

Both upper

arm

bushings

are

pressed into the arm from the outside

toward the inside

of

the arm. To facil-

itate installation, use silicone

or

liquid

oap

as a

lubricant.

See

Fig.

41 for

PRESS RAM

Tool-3069-H

F 1480-A

FIG. 41—Removing Upper

Arm

Rear Bushing

proper assembly

of the

shaft

and

bushings.

6. Press the upper arm rear bushing

into

the arm

using

the

support cup,

tool 3069-H,

and the

replacer, tool

3068 (Fig. 43). Press

the

bushing

in

until

the

shoulder stop

is

reached.

7.

Insert

the end of the

shaft into

the rear bushing. Press the front bush-

ing onto

the

shaft

and

into

the arm

using the replacer, tool 3068 (Fig. 44).

REAR BUSHING

FRONT BUSHING

F 1479-A

FIG. 42— Upper Arm, Shaft,

and

Bushing Assembly

PRESS RAM

Tool— 3068

JF 1478-A

Bottom the bushing flange against the

flange

in the

arm.

8. Install

the

flat washers, lock-

washers,

and

bolts

at

the ends

of

the

upper

arm

shaft.

Do not

tighten

the

bolts

at

this time. These must

be

tightened after

the

arm assembly

has

been installed, and when the front end

weight

of

the vehicle

is

on the wheels.

These bolts

are

made

of a

special

material. Use only the specified bolt

if

replacement

is

necessary.

PRESS

RAM

FIG. 43—Installing Upper

Arm

Rear Bushing

FIG. 44—Installing Upper

Arm

Front Bushing

REAR SPRING OVERHAUL-

SPRING REMOVED

LINCOLN CONTINENTAL

Front Hanger Assembly

If

the

front hanger

or

bushings

are

to

be

replaced, proceed

as

follows:

1.

Remove

the

nuts and lock wash-

ers from

the

spring front mounting

bolt (Fig.

6).

2.

Tap the

spring mounting stud

out

of the

bushing

and

hanger, then

separate

the

hanger from

the

spring.

3.

Remove

the

front bushing from

the spring with tool T64N-5781-A.

4.

Install

the

bushing

in the

spring

with tool T64N-5781-A.

5.

Assemble the front hanger

to

the

spring

eye and

install

the

spring

mounting stud through

the

hanger,

bushings,

and

spring eye

as

shown

in

Fig.

6.

6. Install the lock washers and nuts

on

the

mounting stud

and

tighten

the

outboard

nut to

specification. Tighten

the inboard

nut to

specification with

the vehicle

at

curb riding height.procarmanuals.com

Page 114 of 413

03-05-01

Steering Columns And Linkage

03-05-01

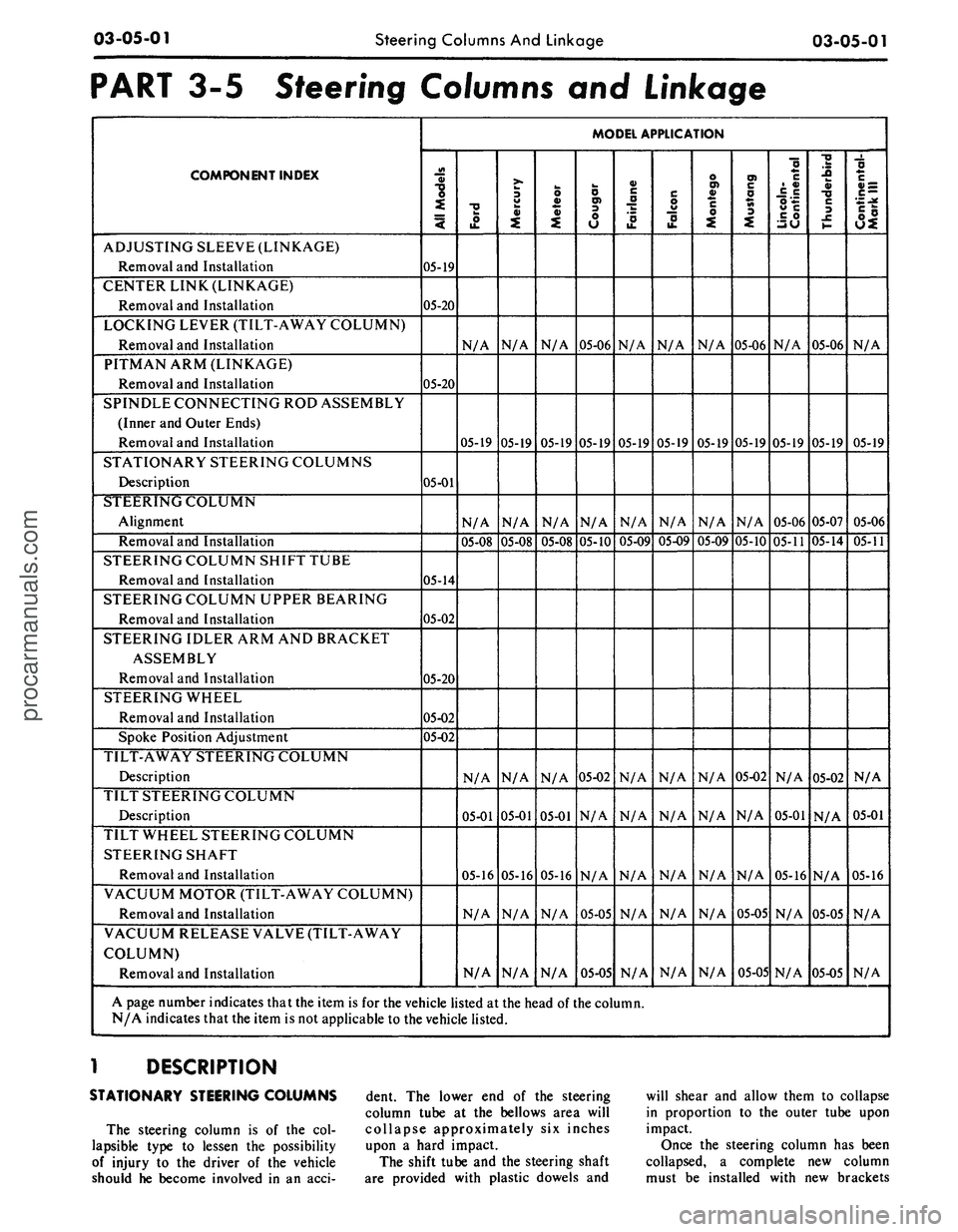

PART 3-5 Steering

Columns

and Linkage

COMPONENT INDEX

ADJUSTING SLEEVE (LINKAGE)

Removal and Installation

CENTER LINK (LINKAGE)

Removal and Installation

LOCKING LEVER (TILT-AWAY COLUMN)

Removal and Installation

PITMAN ARM (LINKAGE)

Removal and Installation

SPINDLE CONNECTING ROD ASSEMBLY

(Inner and Outer Ends)

Removal and Installation

STATIONARY STEERING COLUMNS

Description

STEERING COLUMN

Alignment

Removal and Installation

STEERING COLUMN SHIFT TUBE

Removal and Installation

STEERING COLUMN UPPER BEARING

Removal and Installation

STEERING IDLER ARM AND BRACKET

ASSEMBLY

Removal and Installation

STEERING WHEEL

Removal and Installation

Spoke Position Adjustment

TILT-AWAY STEERING COLUMN

Description

TILT STEERING COLUMN

Description

TILT WHEEL STEERING COLUMN

STEERING SHAFT

Removal and Installation

VACUUM MOTOR (TILT-AWAY COLUMN)

Removal and Installation

VACUUM RELEASE VALVE (TILT-AWAY

COLUMN)

Removal and Installation

MODEL APPLICATION

All

Models

05-19

05-20

05-20

05-01

05-14

05-02

05-20

05-02

05-02

Ford

N/A

05-19

N/A

05-08

N/A

05-01

05-16

N/A

N/A

Mercury

N/A

05-19

N/A

05-08

N/A

05-01

05-16

N/A

N/A

Meteor

N/A

05-19

N/A

05-08

N/A

05-01

05-16

N/A

N/A

Cougar

05-06

05-19

N/A

05-10

05-02

N/A

N/A

05-05

05-05

Fairlane

N/A

05-19

N/A

05-09

N/A

N/A

N/A

N/A

N/A

Falcon

N/A

05-19

N/A

05-09

N/A

N/A

N/A

N/A

N/A

Montego

N/A

05-19

N/A

05-09

N/A

N/A

N/A

N/A

N/A

Mustang

05-06

05-19

N/A

05-10

05-02

N/A

N/A

05-05

05-05

Lincoln-

Continental

N/A

05-19

05-06

05-11

N/A

05-01

05-16

N/A

N/A

Thunderbird

05-06

05-19

05-07

05-14

05-02

N/A

N/A

05-05

05-05

Continental-

Mark

III

N/A

05-19

05-06

05-11

N/A

05-01

05-16

N/A

N/A

A page number indicates that the item is for the vehicle listed at the head of the column.

N/A indicates that the item is not applicable to the vehicle listed.

1 DESCRIPTION

STATIONARY STEERING COLUMNS

The steering column is of the col-

lapsible type to lessen the possibility

of injury to the driver of the vehicle

should he become involved in an acci-

dent. The lower end of the steering

column tube at the bellows area will

collapse approximately six inches

upon a hard impact.

The shift tube and the steering shaft

are provided with plastic dowels and

will shear and allow them to collapse

in proportion to the outer tube upon

impact.

Once the steering column has been

collapsed, a complete new column

must be installed with new brackets

procarmanuals.com

Page 115 of 413

03-05-02

Steering Columns

And

Linkage

03-05-02

which also will shear away during

im-

pact.

TILT STEERING COLUMNS

The steering column

is of the col-

lapsible type

to

lessen

the

possibility

of injury

to the

driver

of the

vehicle

should

he

become involved

in an

acci-

dent.

The

lower

end of the

steering

column tube

at the

bellows area will

collapse approximately

six

inches

upon

a

hard impact.

The shift tube

and the

steering shaft

are provided with plastic dowels

and

will shear

and

allow them

to

collapse

in proportion

to the

outer tube upon

impact.

Once

the

steering column

has

been

collapsed,

a

complete

new

column

must

be

installed.

The tilt column features nine driv-

ing positions (four

up and

four down

from

a

center position).

The

.column

also features

a

turn signal switch with

a lane-changer position turn indicating

position

and

emergency warning flash-

er control.

TILT-AWAY STEERING COLUMNS

The tilt-away steering column

fea-

tures nine driving positions (four

up

and four down from

a

center position)

and

a

tilt-away position that

is

auto-

matically accomplished

on

Mustang

and Cougar models when

the

ignition

key

is

turned

to the

OFF

position

and

the left door

is

opened.

On

Thunder-

bird models,

the

tilt-away occurs when

the shift lever

is

placed

in

PARK

and

the driverns door

is

opened.

The steering column

is of the col-

lapsible type

to

lessen

the

possibility

of injury

to the

driver

of the

vehicle

should

he

become involved

in an

acci-

dent.

The

lower

end of the

steering

column tube

at the

bellows area will

collapse approximately

six

inches

upon

a

hard impact.

The shift tube

and the

steering shaft

are provided with plastic dowels

and

will shear

and

allow them

to

collapse

in proportion

to the

outer tube upon

impact.

Once

the

steering column

has

been

collapsed,

a

complete

new

column

must

be

installed along with mounting

brackets which will also shear away

during impact.

IN-VEHICLE ADJUSTMENTS

AND

REPAIRS

STEERING WHEEL SPOKE

POSITION ADJUSTMENT

When

the

steering gear

is on the

high point,

the

front wheels should

be

in

the

straight-ahead position

and the

steering wheel spokes should

be in

their normal position with

the

Pitman

arm pointing directly forward.

If the

spokes

are not in

their normal posi-

tion, they

can be

adjusted without

dis-

turbing

the

toe-in adjustment (Part

3-1).

STEERING WHEEL

REPLACEMENT

1.

Disconnect

the

negative cable

from

the

battery.

2.

Working from

the

underside

of

the steering wheel spoke, remove

the

crash

pad

attaching screws. Lift

the

crash

pad

from

the

wheel.

(On

Conti-

nental Mark

III

models,

pry out the

crash

pad

insert

and

remove

the two

screws that secure

the

crash

pad. Re-

move

the

crash

pad. On

models

equipped with steering wheel mounted

speed controls, refer

to

Group

16 for

removal instructions). Remove

the

horn ring

(if so

equipped)

by

turning

it counterclockwise.

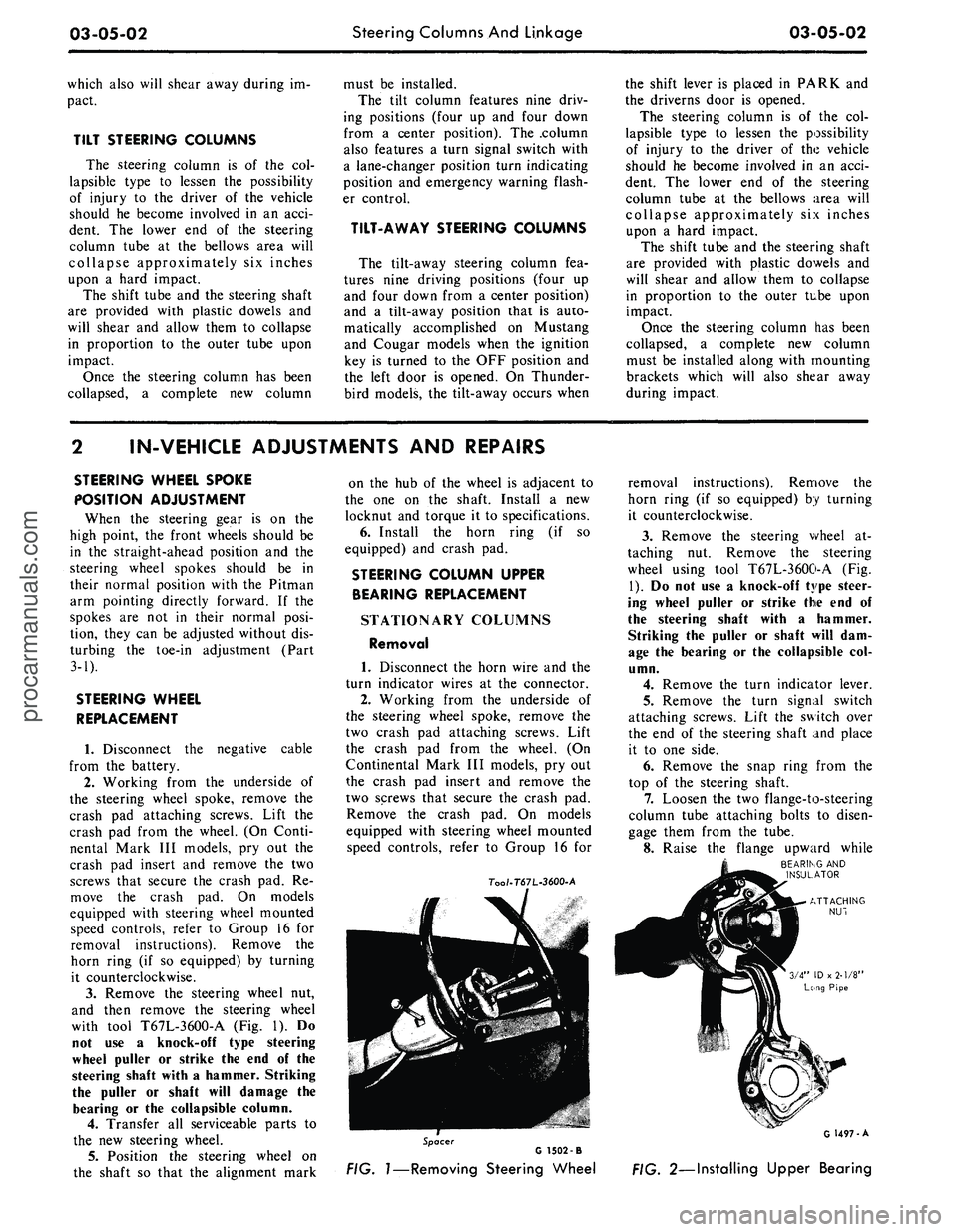

3.

Remove

the

steering wheel

nut,

and then remove

the

steering wheel

with tool T67L-3600-A

(Fig. 1). Do

not

use a

knock-off type steering

wheel puller

or

strike

the end of the

steering shaft with

a

hammer. Striking

the puller

or

shaft will damage

the

bearing

or the

collapsible column.

4.

Transfer

all

serviceable parts

to

the

new

steering wheel.

5.

Position

the

steering wheel

on

the shaft

so

that

the

alignment mark

on

the hub of the

wheel

is

adjacent

to

the

one on the

shaft. Install

a new

locknut

and

torque

it to

specifications.

6. Install

the

horn ring

(if so

equipped)

and

crash

pad.

STEERING COLUMN UPPER

BEARING REPLACEMENT

STATIONARY COLUMNS

Removal

1. Disconnect

the

horn wire

and the

turn indicator wires

at the

connector.

2.

Working from

the

underside

of

the steering wheel spoke, remove

the

two crash

pad

attaching screws. Lift

the crash

pad

from

the

wheel.

(On

Continental Mark

III

models,

pry out

the crash

pad

insert

and

remove

the

two screws that secure

the

crash

pad.

Remove

the

crash

pad. On

models

equipped with steering wheel mounted

speed controls, refer

to

Group

16 for

7oo/-T67L-3600-A

removal instructions). Remove

the

horn ring

(if so

equipped)

by

turning

it counterclockwise.

3.

Remove

the

steering wheel

at-

taching

nut.

Remove

the

steering

wheel using tool T67L-3600-A

(Fig.

1).

Do not use a

knock-off type steer-

ing wheel puller

or

strike

the end of

the steering shaft with

a

hammer.

Striking

the

puller

or

shaft will

dam-

age

the

bearing

or the

collapsible

col-

umn.

4.

Remove

the

turn indicator lever.

5.

Remove

the

turn signal switch

attaching screws. Lift

the

switch over

the

end of the

steering shaft

and

place

it

to one

side.

6. Remove

the

snap ring from

the

top

of the

steering shaft.

7.

Loosen

the two

flange-to-steering

column tube attaching bolts

to

disen-

gage them from

the

tube.

8. Raise

the

flange upward while

BEARING

AND

INSULATOR

Spacer

G 1502 -B

FIG.

1—Removing

Steering Wheel

G 1497-A

FIG. 2—Installing Upper Bearingprocarmanuals.com

Page 116 of 413

03-05-03

Steering Columns And Linkage

03-05-03

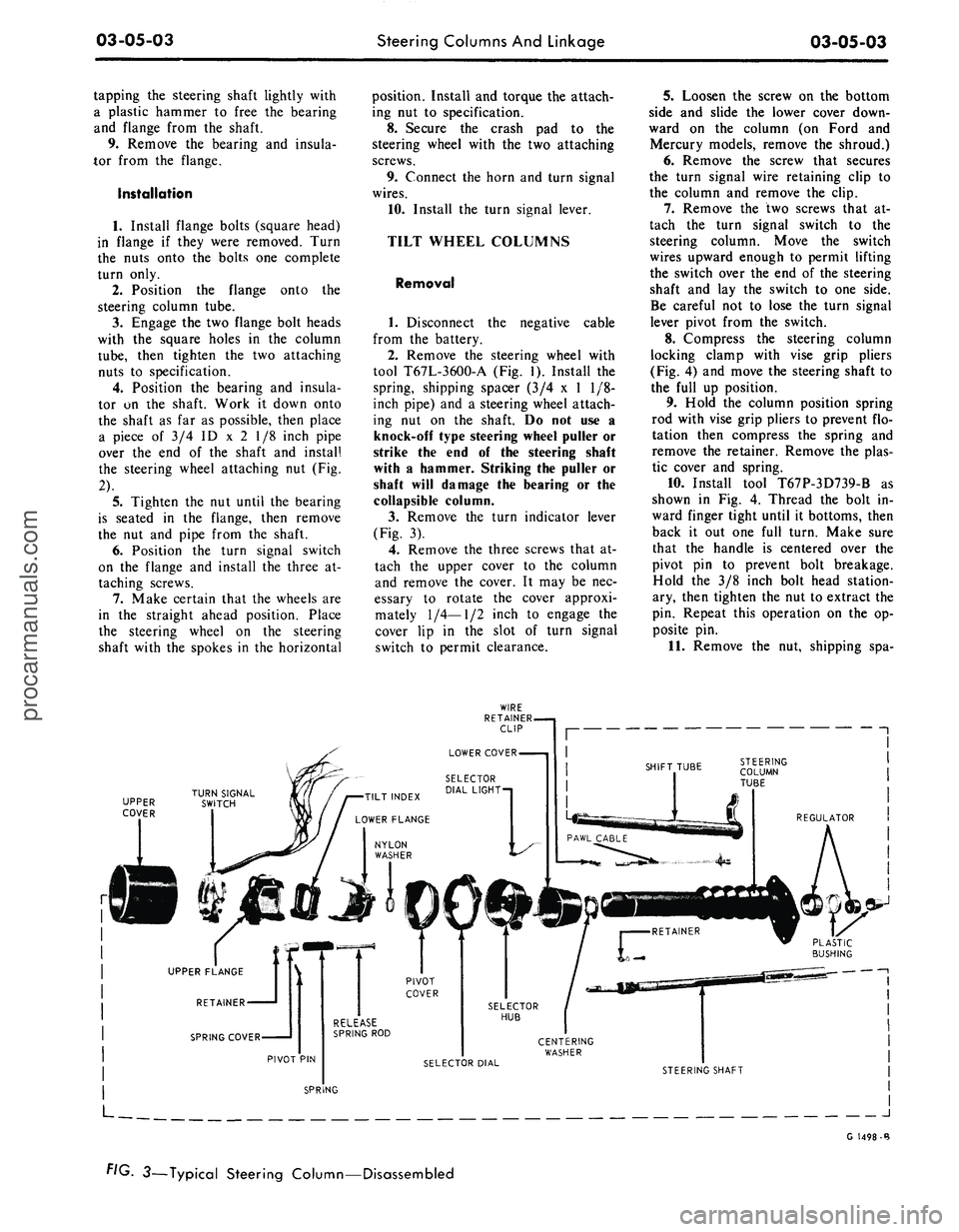

tapping the steering shaft lightly with

a plastic hammer to free the bearing

and flange from the shaft.

9. Remove the bearing and insula-

tor from the flange.

Installation

1.

Install flange bolts (square head)

in flange if they were removed. Turn

the nuts onto the bolts one complete

turn only.

2.

Position the flange onto the

steering column tube.

3.

Engage the two flange bolt heads

with the square holes in the column

tube,

then tighten the two attaching

nuts to specification.

4.

Position the bearing and insula-

tor on the shaft. Work it down onto

the shaft as far as possible, then place

a piece of 3/4 ID x 2 1/8 inch pipe

over the end of the shaft and install

the steering wheel attaching nut (Fig.

2).

5.

Tighten the nut until the bearing

is seated in the flange, then remove

the nut and pipe from the shaft.

6. Position the turn signal switch

on the flange and install the three at-

taching screws.

7.

Make certain that the wheels are

in the straight ahead position. Place

the steering wheel on the steering

shaft with the spokes in the horizontal

position. Install and torque the attach-

ing nut to specification.

8. Secure the crash pad to the

steering wheel with the two attaching

screws.

9. Connect the horn and turn signal

wires.

10.

Install the turn signal lever.

TILT WHEEL COLUMNS

Removal

1.

Disconnect the negative cable

from the battery.

2.

Remove the steering wheel with

tool T67L-3600-A (Fig. 1). Install the

spring, shipping spacer (3/4 x 1 1/8-

inch pipe) and a steering wheel attach-

ing nut on the shaft. Do not use a

knock-off type steering wheel puller or

strike the end of the steering shaft

with a hammer. Striking the puller or

shaft will damage the bearing or the

collapsible column.

3.

Remove the turn indicator lever

(Fig. 3).

4.

Remove the three screws that at-

tach the upper cover to the column

and remove the cover. It may be nec-

essary to rotate the cover approxi-

mately

1/4—1/2

inch to engage the

cover lip in the slot of turn signal

switch to permit clearance.

5.

Loosen the screw on the bottom

side and slide the lower cover down-

ward on the column (on Ford and

Mercury models, remove the shroud.)

6. Remove the screw that secures

the turn signal wire retaining clip to

the column and remove the clip.

7.

Remove the two screws that at-

tach the turn signal switch to the

steering column. Move the switch

wires upward enough to permit lifting

the switch over the end of the steering

shaft and lay the switch to one side.

Be careful not to lose the turn signal

lever pivot from the switch.

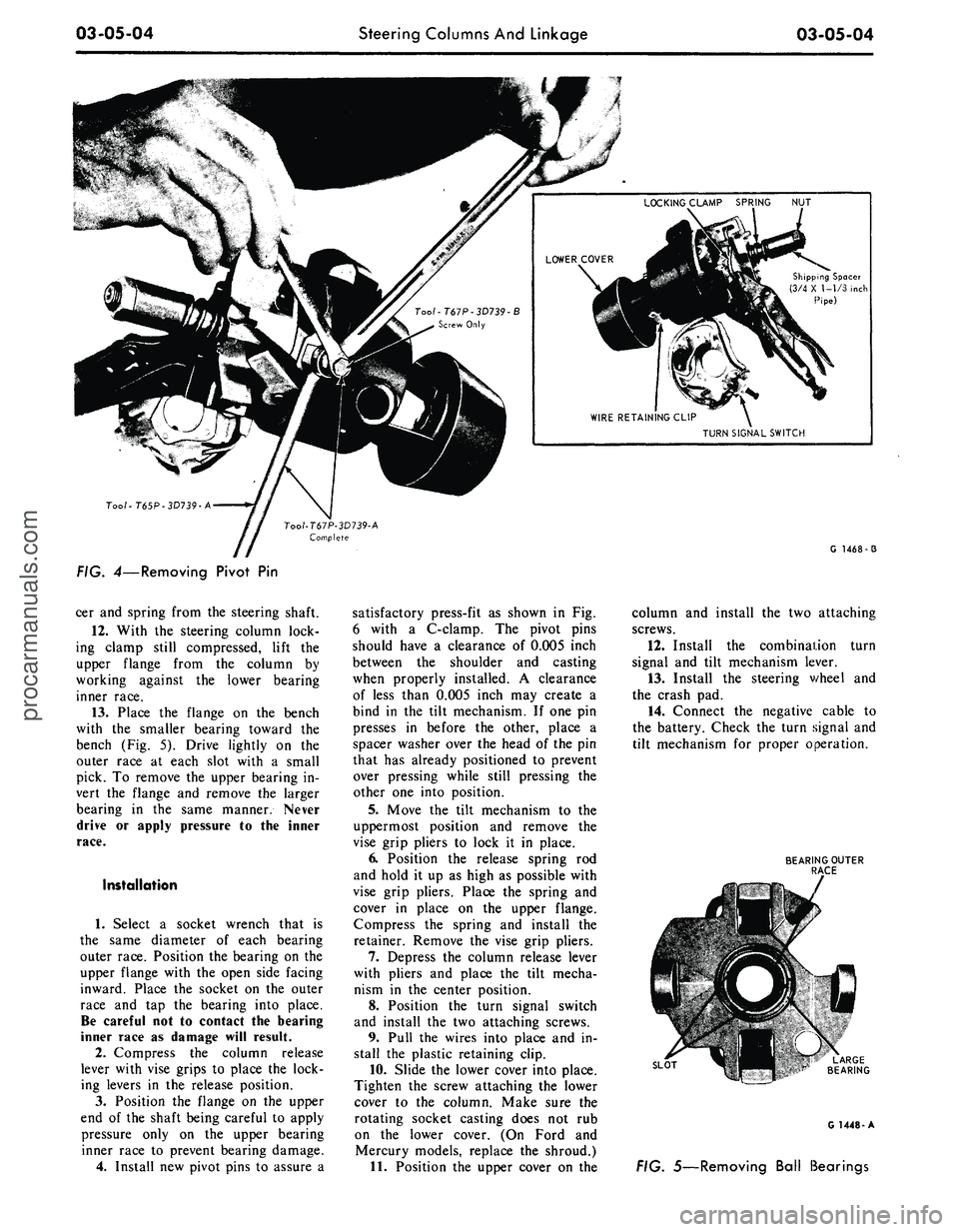

8. Compress the steering column

locking clamp with vise grip pliers

(Fig. 4) and move the steering shaft to

the full up position.

9. Hold the column position spring

rod with vise grip pliers to prevent flo-

tation then compress the spring and

remove the retainer. Remove the plas-

tic cover and spring.

10.

Install tool T67P-3D739-B as

shown in Fig. 4. Thread the bolt in-

ward finger tight until it bottoms, then

back it out one full turn. Make sure

that the handle is centered over the

pivot pin to prevent bolt breakage.

Hold the 3/8 inch bolt head station-

ary, then tighten the nut to extract the

pin. Repeat this operation on the op-

posite pin.

11.

Remove the nut, shipping spa-

UPPER

COVER

J

G 1498-B

FIG. 3—Typical Steering Column—Disassembledprocarmanuals.com

Page 117 of 413

03-05-04

Steering Columns And Linkage

03-05-04

Shipping Spacer

(3/4 X 1-1/3 inch

Pipe)

TURN SIGNAL SWITCH

Too/-T65P-3D739-A

G 1468-3

FIG. 4—Removing Pivot

Pin

cer and spring from the steering shaft.

12.

With

the

steering column lock-

ing clamp still compressed, lift

the

upper flange from

the

column

by

working against

the

lower bearing

inner race.

13.

Place

the

flange

on the

bench

with

the

smaller bearing toward

the

bench (Fig.

5).

Drive lightly

on the

outer race

at

each slot with

a

small

pick.

To

remove the upper bearing in-

vert

the

flange

and

remove

the

larger

bearing

in the

same manner. Never

drive

or

apply pressure

to the

inner

race.

Installation

1.

Select

a

socket wrench that

is

the same diameter

of

each bearing

outer race. Position the bearing on the

upper flange with the open side facing

inward. Place

the

socket

on the

outer

race

and tap the

bearing into place.

Be careful not

to

contact

the

bearing

inner race

as

damage will result.

2.

Compress

the

column release

lever with vise grips

to

place the lock-

ing levers

in the

release position.

3.

Position

the

flange

on the

upper

end

of

the shaft being careful

to

apply

pressure only

on the

upper bearing

inner race

to

prevent bearing damage.

4.

Install new pivot pins

to

assure

a

satisfactory press-fit

as

shown

in Fig.

6 with

a

C-clamp.

The

pivot pins

should have

a

clearance

of

0.005 inch

between

the

shoulder

and

casting

when properly installed.

A

clearance

of less than 0.005 inch may create

a

bind

in the

tilt mechanism.

If

one pin

presses

in

before

the

other, place

a

spacer washer over the head

of

the pin

that has already positioned

to

prevent

over pressing while still pressing

the

other one into position.

5.

Move

the

tilt mechanism

to the

uppermost position

and

remove

the

vise grip pliers

to

lock

it in

place.

6. Position

the

release spring

rod

and hold

it

up

as

high

as

possible with

vise grip pliers. Place

the

spring

and

cover

in

place

on the

upper flange.

Compress

the

spring

and

install

the

retainer. Remove the vise grip pliers.

7.

Depress

the

column release lever

with pliers

and

place

the

tilt mecha-

nism

in the

center position.

8. Position

the

turn signal switch

and install

the

two attaching screws.

9. Pull

the

wires into place and

in-

stall

the

plastic retaining clip.

10.

Slide the lower cover into place.

Tighten

the

screw attaching the lower

cover

to the

column. Make sure

the

rotating socket casting does

not rub

on

the

lower cover.

(On

Ford

and

Mercury models, replace

the

shroud.)

11.

Position the upper cover

on the

column

and

install

the

two attaching

screws.

12.

Install

the

combination turn

signal

and

tilt mechanism lever.

13.

Install

the

steering v/heel

and

the crash pad.

14.

Connect

the

negative cable

to

the battery. Check the turn signal and

tilt mechanism

for

proper operation.

BEARING OUTER

RACE

SLOT

G 1448-A

FIG. 5—Removing Ball Bearingsprocarmanuals.com