steering FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 70 of 413

03-01-05

Suspension — Steering, Wheels And Tires — General Service

03-01-05

type of equipment is used, follow the

installation and inspection instructions

provided by the equipment manufactu-

rer.

CASTER

Check the caster angle at each front

wheel.

The caster is the forward or rear-

ward tilt of the top of the wheel

spindle (Fig. 12). If the spindle tilts to

the rear, caster is positive. If the

spindle tilts to the front, caster is neg-

ative. The correct caster angle, or tilt,

is specified in Part 3-13.

On Mustang, Cougar, Fairlane,

Falcon and Montego vehicles, the

maximum caster difference for check-

ing purposes must not exceed one de-

gree.

If setting is necessary, then the

maximum difference must not exceed

1/2 degree. On all other vehicles, the

maximum caster difference must never

exceed 1/2 degree.

CAMBER

Check the camber angle at each

front wheel.

Camber is the amount the front

wheels are tilted at the top (Fig. 12).

If a wheel tilts outward, camber is

positive. If a wheel tilts inward, cam-

ber is negative. The correct camber

angle, or outward (positive) tilt is

specified in Part 3-13.

On Mustang, Cougar, Fairlane,

Falcon and Montego vehicles, the

maximum camber difference for

checking purposes must not exceed

one degree. If setting is necessary,

then the maximum difference must

not exceed 1/2 degree. On all other

vehicles, the maximum camber differ-

ence must never exceed 1/2 degree.

TOE-IN

Alignment height spacers should not

be used to check and adjust toe-in.

Toe-in should only be checked and ad-

justed after the caster and camber

have been adjusted to specifications.

Check the toe-in with the front

wheels in the straight-ahead position.

Run the engine so that the power

steering control valve will be in the

center (neutral) position (if so

equipped). Measure the distance be-

tween the extreme front and also be-

tween the extreme rear of both front

wheels. The difference between these

two distances is the toe-in or toe-out.

Correct toe-in, or inward pointing

of both front wheels at the front is

specified in Part 3-13.

FRONT WHEEL

TURNING ANGLE

When the inside wheel is turned 20

degrees, the turning angle of the out-

side wheel should be as specified in

Part 3-13. The turning angle cannot

be adjusted directly, because it is a re-

sult of the combination of caster,

camber, and toe-in adjustments and

should, therefore, be measured only

after these adjustments have been

made. If the turning angle does not

measure to specifications, check the

spindle or other suspension parts for a

bent condition.

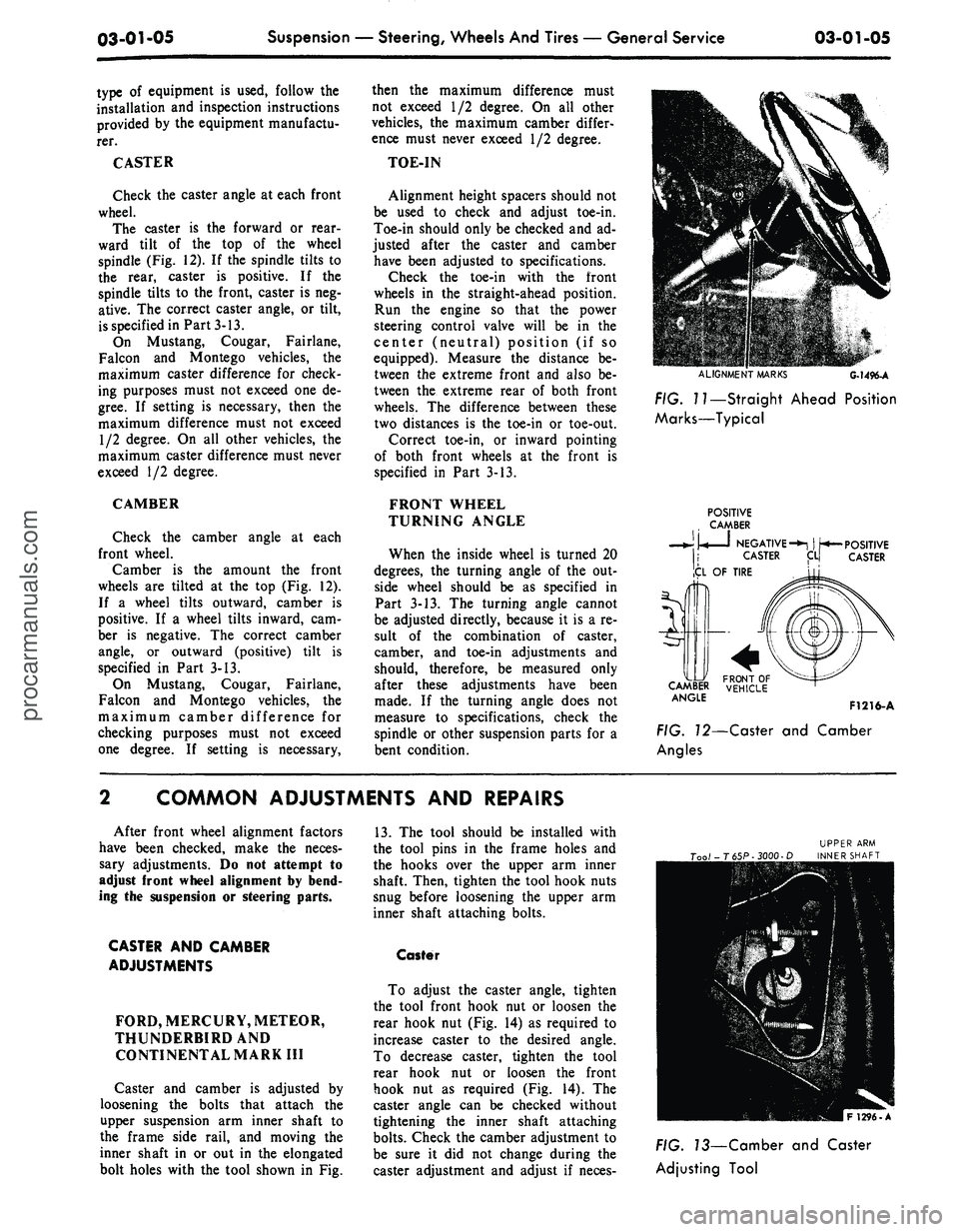

ALIGNMENT

MARKS

G-1496-A

FIG. I?—Straight Ahead Position

Marks—Typical

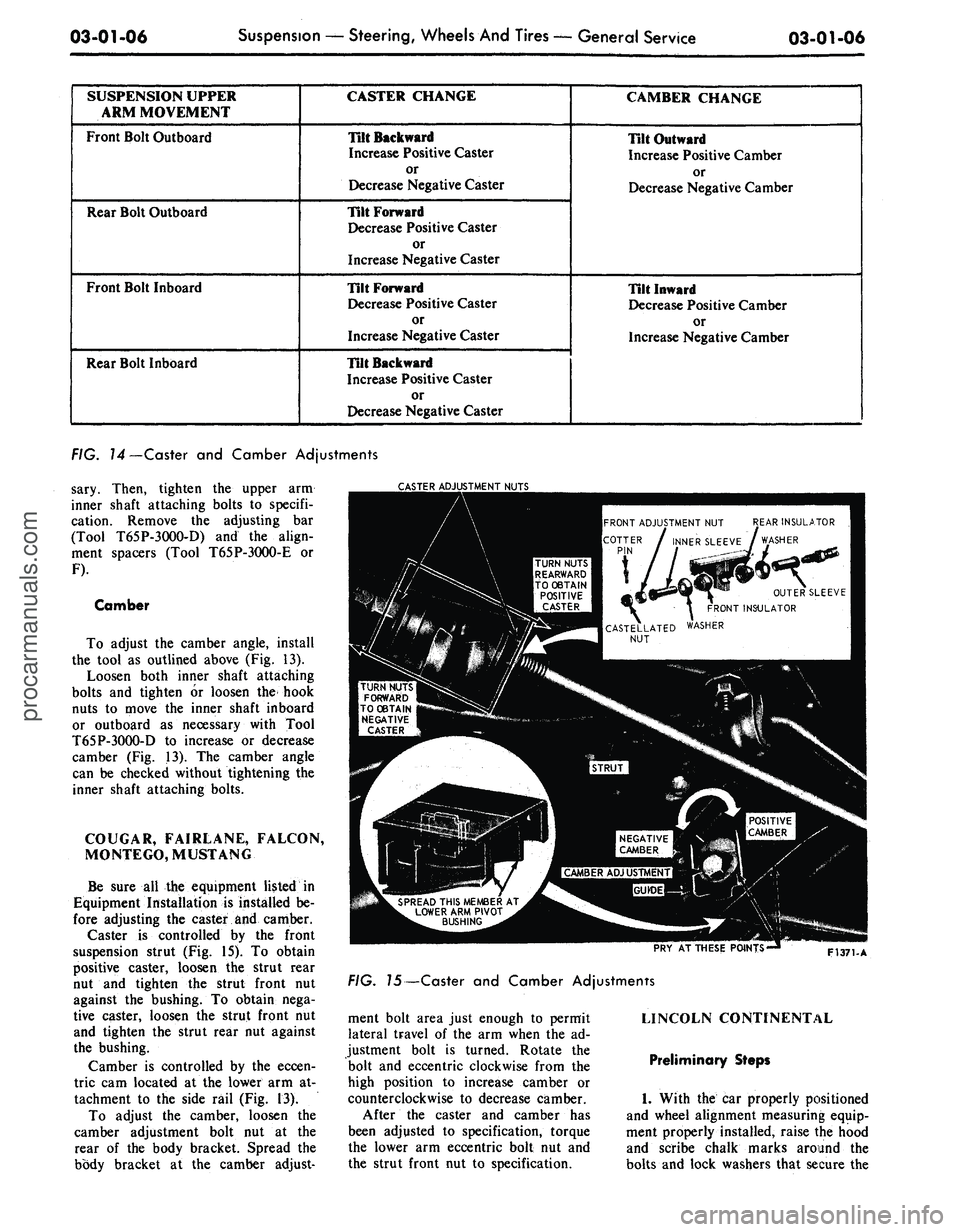

POSITIVE

CAMBER

• •

NEGATIVE-*!

| ^*—

CASTER

ICL

OF TIRE

POSITIVE

CASTER

5r\

CA&U

ANGlE

F1216-A

FIG. 72—Caster and Camber

Angles

COMMON ADJUSTMENTS AND REPAIRS

After front wheel alignment factors

have been checked, make the neces-

sary adjustments. Do not attempt to

adjust front wheel alignment by bend-

ing the suspension or steering parts.

CASTER AND CAMBER

ADJUSTMENTS

FORD, MERCURY, METEOR,

THUNDERBIRDAND

CONTINENTAL MARK III

Caster and camber is adjusted by

loosening the bolts that attach the

upper suspension arm inner shaft to

the frame side rail, and moving the

inner shaft in or out in the elongated

bolt holes with the tool shown in Fig.

13.

The tool should be installed with

the tool pins in the frame holes and

the hooks over the upper arm inner

shaft. Then, tighten the tool hook nuts

snug before loosening the upper arm

inner shaft attaching bolts.

Caster

To adjust the caster angle, tighten

the tool front hook nut or loosen the

rear hook nut (Fig. 14) as required to

increase caster to the desired angle.

To decrease caster, tighten the tool

rear hook nut or loosen the front

hook nut as required (Fig. 14). The

caster angle can be checked without

tightening the inner shaft attaching

bolts.

Check the camber adjustment to

be sure it did not change during the

caster adjustment and adjust if neces-

FIG. 73—Camber and Caster

Adjusting Toolprocarmanuals.com

Page 71 of 413

03-01-06

Suspension — Steering, Wheels And Tires — General Service

03-01-06

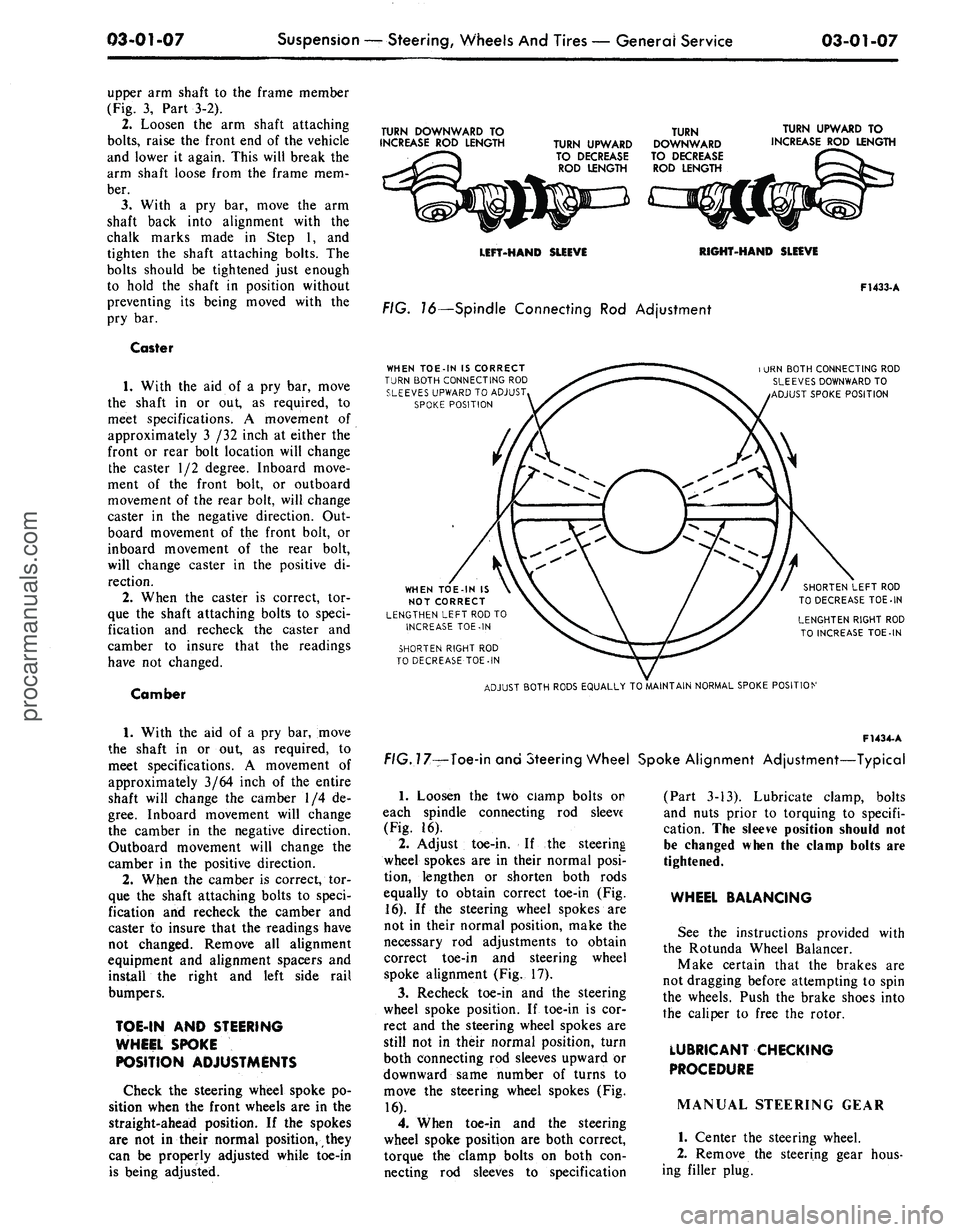

SUSPENSION UPPER

ARM MOVEMENT

Front Bolt Outboard

Rear Bolt Outboard

Front Bolt Inboard

Rear Bolt Inboard

CASTER CHANGE

Tilt Backward

Increase Positive Caster

or

Decrease Negative Caster

Tilt Forward

Decrease Positive Caster

or

Increase Negative Caster

Tilt Forward

Decrease Positive Caster

or

Increase Negative Caster

Tilt Backward

Increase Positive Caster

or

Decrease Negative Caster

CAMBER CHANGE

Tilt Outward

Increase Positive Camber

or

Decrease Negative Camber

Tilt Inward

Decrease Positive Camber

or

Increase Negative Camber

FIG. 14—Caster and Camber Adjustments

sary. Then, tighten the upper arm

inner shaft attaching bolts to specifi-

cation. Remove the adjusting bar

(Tool T65P-3OOO-D) and the align-

ment spacers (Tool T65P-3O00-E or

F).

Camber

To adjust the camber angle, install

the tool as outlined above (Fig. 13).

Loosen both inner shaft attaching

bolts and tighten or loosen the hook

nuts to move the inner shaft inboard

or outboard as necessary with Tool

T65P-3OOO-D to increase or decrease

camber (Fig. 13). The camber angle

can be checked without tightening the

inner shaft attaching bolts.

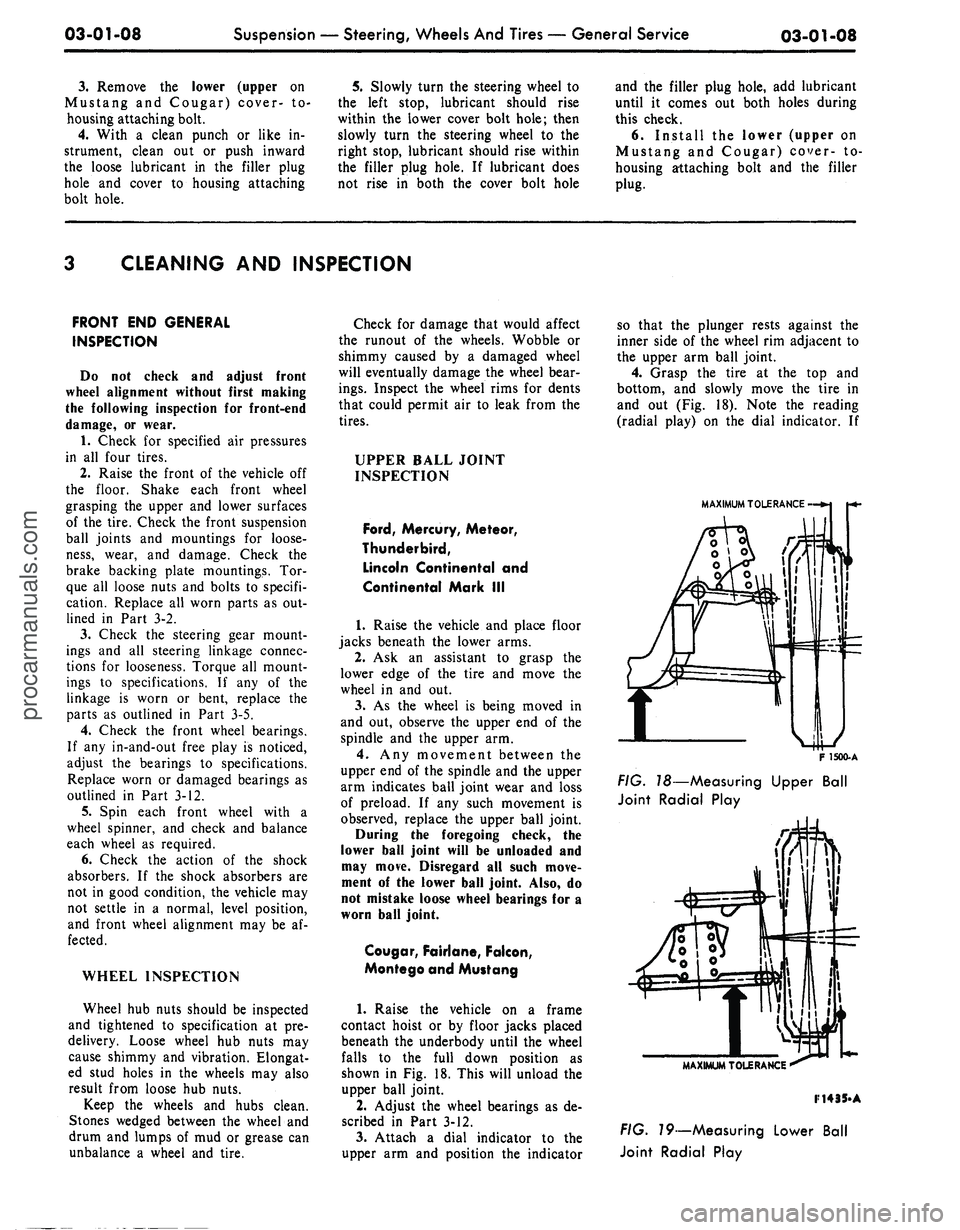

COUGAR, FAIRLANE, FALCON,

MONTEGO, MUSTANG

Be sure all the equipment listed in

Equipment Installation is installed be-

fore adjusting the caster and camber.

Caster is controlled by the front

suspension strut (Fig. 15). To obtain

positive caster, loosen the strut rear

nut and tighten the strut front nut

against the bushing. To obtain nega-

tive caster, loosen the strut front nut

and tighten the strut rear nut against

the bushing.

Camber is controlled by the eccen-

tric cam located at the lower arm at-

tachment to the side rail (Fig. 13).

To adjust the camber, loosen the

camber adjustment bolt nut at the

rear of the body bracket. Spread the

body bracket at the camber adjust-

TER ADJUSTMENT NUTS

EAR INSULATOR

WASHER

FRONT ADJUSTMENT NUT

INNER SLEEVE

TURN NUTS

REARWARD

TO OBTAIN

POSITIVE

CASTER

OUTER SLEEVE

RONT INSULATOR

WASHER

CASTELLATED

NUT

TURN NUTS

FORWARD

TO OBTAIN

NEGATIVE

CASTER

NEGATIVE

CAMBER

SPREAD THIS MEMBER AT

LOWER ARM PIVOT

BUSHING

PRY AT THESE POINTS'

F1371-A

FIG. J5—Caster and Camber Adjustments

ment bolt area just enough to permit

lateral travel of the arm when the ad-

justment bolt is turned. Rotate the

bolt and eccentric clockwise from the

high position to increase camber or

counterclockwise to decrease camber.

After the caster and camber has

been adjusted to specification, torque

the lower arm eccentric bolt nut and

the strut front nut to specification.

LINCOLN CONTINENTAL

Preliminary Steps

1.

With the car properly positioned

and wheel alignment measuring equip-

ment properly installed, raise the hood

and scribe chalk marks around the

bolts and lock washers that secure theprocarmanuals.com

Page 72 of 413

03-01-07

Suspension — Steering, Wheels And Tires — General Service

03-01-07

upper arm shaft to the frame member

(Fig. 3, Part 3-2).

2.

Loosen the arm shaft attaching

bolts,

raise the front end of the vehicle

and lower it again. This will break the

arm shaft loose from the frame mem-

ber.

3.

With a pry bar, move the arm

shaft back into alignment with the

chalk marks made in Step 1, and

tighten the shaft attaching bolts. The

bolts should be tightened just enough

to hold the shaft in position without

preventing its being moved with the

pry bar.

Caster

1.

With the aid of a pry bar, move

the shaft in or out, as required, to

meet specifications. A movement of

approximately 3 /32 inch at either the

front or rear bolt location will change

the caster 1/2 degree. Inboard move-

ment of the front bolt, or outboard

movement of the rear bolt, will change

caster in the negative direction. Out-

board movement of the front bolt, or

inboard movement of the rear bolt,

will change caster in the positive di-

rection.

2.

When the caster is correct, tor-

que the shaft attaching bolts to speci-

fication and recheck the caster and

camber to insure that the readings

have not changed.

Camber

TURN DOWNWARD TO

INCREASE ROD LENGTH

TURN UPWARD

TO DECREASE

ROD LENGTH

TURN

DOWNWARD

TO DECREASE

ROD LENGTH

TURN UPWARD TO

INCREASE ROD LENGTH

LEFT-HAND SLEEVE

RIGHT-HAND SLEEVE

FIG. 16—Spindle Connecting Rod Adjustment

WHEN TOE-IN IS CORRECT

TURN BOTH CONNECTING ROD

SLEEVES UPWARD TO ADJUST

SPOKE POSITION

F1433-A

i URN BOTH CONNECTING ROD

SLEEVES DOWNWARD TO

ADJUST SPOKE POSITION

WHEN TOE-IN IS

NOT CORRECT

LENGTHEN LEFT ROD TO

INCREASE TOE-IN

SHORTEN RIGHT ROD

TO DECREASE TOE-IN

SHORTEN LEFT ROD

TO DECREASE TOE-IN

LENGHTEN RIGHT ROD

TO INCREASE TOE-IN

ADJUST BOTH RODS EQUALLY TO MAINTAIN NORMAL SPOKE POSITION

1.

With the aid of a pry bar, move

the shaft in or out, as required, to

meet specifications. A movement of

approximately 3/64 inch of the entire

shaft will change the camber 1/4 de-

gree.

Inboard movement will change

the camber in the negative direction.

Outboard movement will change the

camber in the positive direction.

2.

When the camber is correct, tor-

que the shaft attaching bolts to speci-

fication and recheck the camber and

caster to insure that the readings have

not changed. Remove all alignment

equipment and alignment spacers and

install the right and left side rail

bumpers.

TOE-IN AND STEERING

WHEEL SPOKE

POSITION ADJUSTMENTS

Check the steering wheel spoke po-

sition when the front wheels are in the

straight-ahead position. If the spokes

are not in their normal position, they

can be properly adjusted while toe-in

is being adjusted.

F1434-

A

f/G.77—Toe-in and Steering Wheel Spoke Alignment Adjustment—Typical

1.

Loosen the two ciamp bolts or

each spindle connecting rod sleeve

(Fig. 16).

2.

Adjust toe-in. If the steering

wheel spokes are in their normal posi-

tion, lengthen or shorten both rods

equally to obtain correct toe-in (Fig.

16).

If the steering wheel spokes are

not in their normal position, make the

necessary rod adjustments to obtain

correct toe-in and steering wheel

spoke alignment (Fig. 17).

3.

Recheck toe-in and the steering

wheel spoke position. If toe-in is cor-

rect and the steering wheel spokes are

still not in their normal position, turn

both connecting rod sleeves upward or

downward same number of turns to

move the steering wheel spokes (Fig.

16).

4.

When toe-in and the steering

wheel spoke position are both correct,

torque the clamp bolts on both con-

necting rod sleeves to specification

(Part 3-13). Lubricate clamp, bolts

and nuts prior to torquing to specifi-

cation. The sleeve position should not

be changed when the clamp bolts are

tightened.

WHEEL BALANCING

See the instructions provided with

the Rotunda Wheel Balancer.

Make certain that the brakes are

not dragging before attempting to spin

the wheels. Push the brake shoes into

the caliper to free the rotor.

LUBRICANT CHECKING

PROCEDURE

MANUAL STEERING GEAR

1.

Center the steering wheel.

2.

Remove the steering gear hous-

ing filler plug.procarmanuals.com

Page 73 of 413

03-01-08

Suspension

—

Steering,

Wheels

And

Tires

—

General Service

03-01-08

3.

Remove the lower (upper on

Mustang and Cougar) cover- to-

housing attaching bolt.

4.

With a clean punch or like in-

strument, clean out or push inward

the loose lubricant in the filler plug

hole and cover to housing attaching

bolt hole.

5.

Slowly turn the steering wheel to

the left stop, lubricant should rise

within the lower cover bolt hole; then

slowly turn the steering wheel to the

right stop, lubricant should rise within

the filler plug hole. If lubricant does

not rise in both the cover bolt hole

and the filler plug hole, add lubricant

until it comes out both holes during

this check.

6. Install the lower (upper on

Mustang and Cougar) cover- to-

housing attaching bolt and the filler

plug.

CLEANING

AND

INSPECTION

FRONT

END

GENERAL

INSPECTION

Do not check and adjust front

wheel alignment without first making

the following inspection for front-end

damage, or wear.

1.

Check for specified air pressures

in all four tires.

2.

Raise the front of the vehicle off

the floor. Shake each front wheel

grasping the upper and lower surfaces

of the tire. Check the front suspension

ball joints and mountings for loose-

ness,

wear, and damage. Check the

brake backing plate mountings. Tor-

que all loose nuts and bolts to specifi-

cation. Replace all worn parts as out-

lined in Part 3-2.

3.

Check the steering gear mount-

ings and all steering linkage connec-

tions for looseness. Torque all mount-

ings to specifications. If any of the

linkage is worn or bent, replace the

parts as outlined in Part 3-5.

4.

Check the front wheel bearings.

If any in-and-out free play is noticed,

adjust the bearings to specifications.

Replace worn or damaged bearings as

outlined in Part 3-12.

5.

Spin each front wheel with a

wheel spinner, and check and balance

each wheel as required.

6. Check the action of the shock

absorbers. If the shock absorbers are

not in good condition, the vehicle may

not settle in a normal, level position,

and front wheel alignment may be af-

fected.

WHEEL INSPECTION

Wheel hub nuts should be inspected

and tightened to specification at pre-

delivery. Loose wheel hub nuts may

cause shimmy and vibration. Elongat-

ed stud holes in the wheels may also

result from loose hub nuts.

Keep the wheels and hubs clean.

Stones wedged between the wheel and

drum and lumps of mud or grease can

unbalance a wheel and tire.

Check for damage that would affect

the runout of the wheels. Wobble or

shimmy caused by a damaged wheel

will eventually damage the wheel bear-

ings.

Inspect the wheel rims for dents

that could permit air to leak from the

tires.

UPPER BALL JOINT

INSPECTION

Ford,

Mercury,

Meteor,

Thunderbird,

Lincoln Continental

and

Continental Mark

III

1.

Raise the vehicle and place floor

jacks beneath the lower arms.

2.

Ask an assistant to grasp the

lower edge of the tire and move the

wheel in and out.

3.

As the wheel is being moved in

and out, observe the upper end of the

spindle and the upper arm.

4.

Any movement between the

upper end of the spindle and the upper

arm indicates ball joint wear and loss

of preload. If any such movement is

observed, replace the upper ball joint.

During

the

foregoing

check,

the

lower ball joint will

be

unloaded

and

may

move.

Disregard

all

such

move-

ment

of the

lower ball

joint.

Also,

do

not mistake loose wheel bearings

for a

worn ball

joint.

Cougar,

Fairlane,

Falcon,

Montego

and

Mustang

1.

Raise the vehicle on a frame

contact hoist or by floor jacks placed

beneath the underbody until the wheel

falls to the full down position as

shown in Fig. 18. This will unload the

upper ball joint.

2.

Adjust the wheel bearings as de-

scribed in Part 3-12.

3.

Attach a dial indicator to the

upper arm and position the indicator

so that the plunger rests against the

inner side of the wheel rim adjacent to

the upper arm ball joint.

4.

Grasp the tire at the top and

bottom, and slowly move the tire in

and out (Fig. 18). Note the reading

(radial play) on the dial indicator. If

MAXIMUM TOLERANCE

F

1500-A

FIG.

T8—Measuring Upper Ball

Joint Radial Play

MAXIMUM TOLERANCE

F14

35-A

FIG.

79—Measuring Lower Ball

Joint Radial Playprocarmanuals.com

Page 74 of 413

03-01-09

Suspension — Steering, Wheels And Tires — General Service

03-01-09

the reading exceeds specifications

(Part 3-13), replace the upper ball

joint.

LOWER BALL JOINT

INSPECTION

Ford,

Mercury, Meteor,

Thunderbird, Lincoln Continental

and Continental Mark III

1.

Raise the vehicle and place

jacks under the lower arms as shown

in Fig. 12. This will unload the lower

ball joints.

2.

Adjust the wheel bearings as des-

cribed in Part 3-12.

3.

Attach a dial indicator to the

lower arm and position the indicator

so that the plunger rests against the

inner side of the wheel rim adjacent to

the lower ball joint.

4.

Grasp the tire at the top and

bottom and slowly move the tire in

and out (Fig. 19). Note the reading

(radial play) on the dial indicator. If

the reading exceeds specifications

(Part 3-13), replace the lower ball

joint.

Cougar, Fairlane, Falcon,

Montego, Mustang

1.

Raise the vehicle on a frame

contact hoist or by floor jacks placed

beneath the underbody until the wheel

falls to the full down position.

2.

Ask an assistant to grasp the

lower edge of the tire and move the

wheel in and out.

3.

As the wheel is being moved in

and out, observe the lower end of the

spindle and the lower arm.

4.

Any movement between the

lower end of the spindle and the lower

arm indicates ball joint wear and loss

of preload. If any such movement is

observed, replace the lower arm.

During the foregoing check, the

upper ball joint will be unloaded and

may move. Disregard all such move-

ment of the upper ball joint. Also, do

not mistake loose wheel bearings for a

worn ball joint.

POWER STEERING GEAR

CLEANING

Disassembly and assembly of the

steering gear and. the sub-assemblies

must be made on a clean workbench.

As in repairing any hydraulically op-

erated unit, cleanliness is of utmost

importance. The bench, tools, and

parts must be kept clean at all times.

Thoroughly clean the exterior of the

unit with a suitable solvent and, when

necessary drain as much of the hy-

draulic fluid as possible. Handle all

parts very carefully to avoid nicks,

burrs,

scratches and dirt, which could

make the parts unfit for use.

Do not clean, wash or soak seals in

cleaning solvent.

INSPECTION

1.

Check the sector shaft contact

surface in the cover for wear. If worn,

replace the cover.

2.

Inspect the input shaft bearing

for cracked races and the balls for

looseness, wear, pitting, end play or

other damage. Check the fit of the

bearing on the input shaft. Replace

the bearing, if required.

3.

Inspect the valve housing for

wear, scoring or burrs.

4.

Inspect the tube seats in the

pressure and return ports in the valve

body for nicks, etc. If necessary, re-

move and replace.

5.

Check the sector shaft contact

surface in the housing for wear. If

worn, replace the bushing or the hous-

ing.

6. Check all fluid passages for ob-

struction or leakage.

7.

Inspect the steering gear housing

for cracks, stripped threads, and mat-

ing surfaces for burrs. Inspect the pis-

ton bore of the housing for scoring or

wear. If necessary, replace the hous-

ing.

8. Check the input shaft bearing

after installation to be sure that it ro-

tates freely.

9. If the valve spool is not free in

the valve housing, check for burrs at

the outward edges of the working

lands in the housing and remove with

a hard stone. Check the valve spool

for burrs and if burrs are found, stone

the valve in a radial direction only.

Check for freedom of the valve again.

10.

Check the piston rack teeth and

sector shaft teeth for nicks and burrs.

FLUSHING THE POWER

STEERING SYSTEM—ALL EXCEPT

LINCOLN CONTINENTAL AND

CONTINENTAL MARK III

Should it be necessary to replace an

inoperative power steering pump, the

need for flushing the steering system

is required when installing the new

pump.

1.

Remove the power steering pump

and remove the pulley as outlined in

Part 3-10.

2.

Install the pulley on a new

pump. Install the pump and connect

only the pressure hose to the pump

(Part 3-10).

3.

Place the fluid return line in a

suitable container and plug the reser-

voir return pipe.

4.

Fill the reservoir with lubricant

(C1AZ-19582-A).

5.

Disconnect the coil wire to pre-

vent the engine from starting and raise

the front wheels off the ground.

6. While approximately two quarts

of steering gear fluid are being poured

into the reservoir, turn the engine over

using the ignition key, at the same

time cycle the steering wheel from

stop to stop.

7.

As soon as all of the lubricant

has been poured in, turn off the igni-

tion key, and attach the coil wire.

8. Remove the plug from the reser-

voir return pipe, and attach the return

hose to the reservoir.

9. Check the reservoir fluid level; if

low, add fluid to the proper level. Do

not overfill.

10.

Lower the vehicle.

11.

Start the engine and cycle the

steering from stop to stop to expel

any trapped air from the system.

POWER STEERING PUMP—ALL

EXCEPT LINCOLN

CONTINENTAL AND

CONTINENTAL MARK III

CLEANING

Wash all parts (except seals) in a

Naptha or Chlorinated-type solvent

and dry with compressed air.

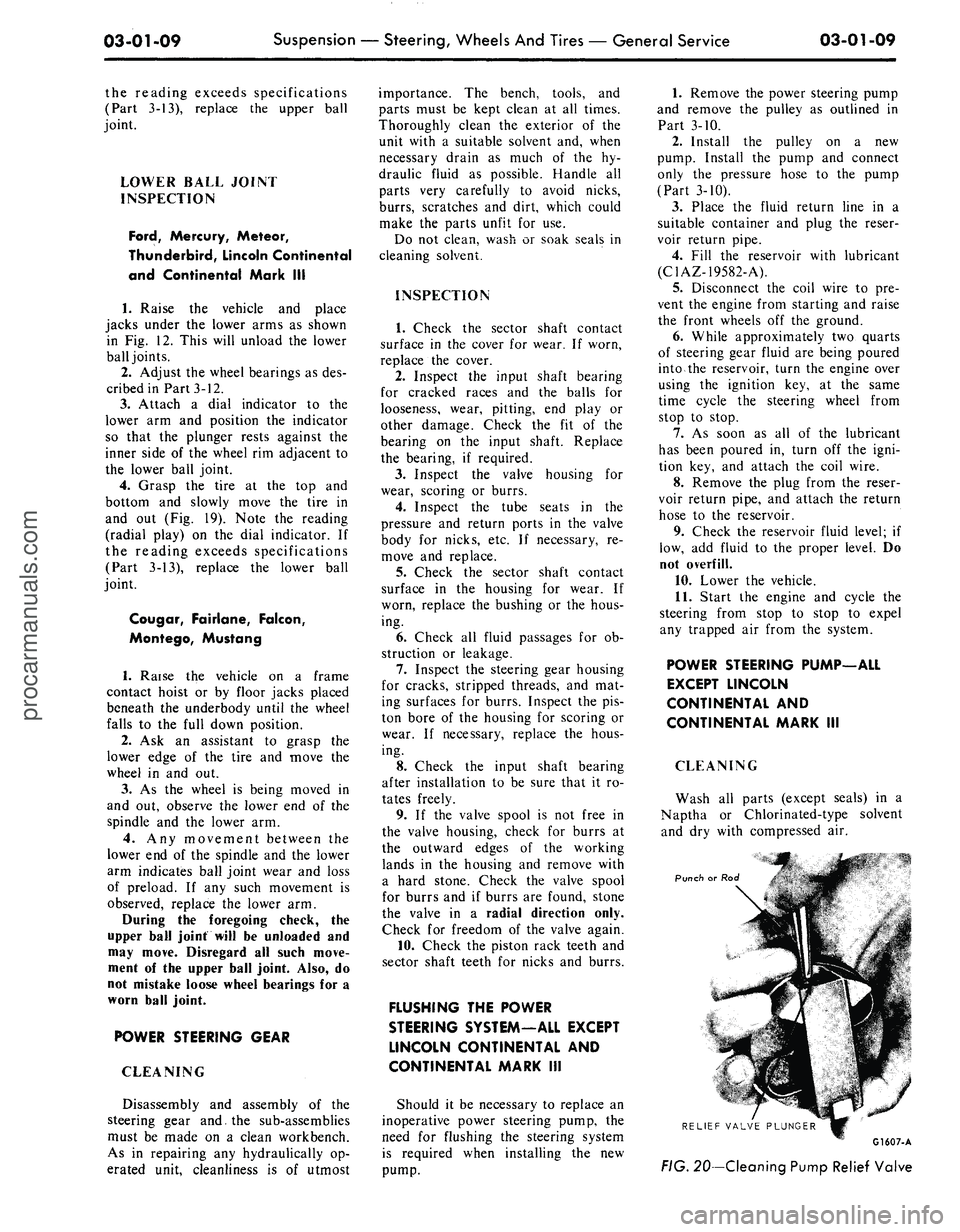

Punch or Rod

RELIEF VALVE PLUNGER

G1607-A

FIG.

20—Cleaning Pump Relief Valveprocarmanuals.com

Page 75 of 413

03-01-10

Suspension — Steering, Wheels And Tires — General Service

03-01-10

The following procedure should be

followed when cleaning the relief valve

which is a part of the pump valve as-

sembly.

1.

Using a punch or rod of suitable

diameter, apply an even pressure in a

straight line to the tip of the relief

valve pin (Fig. 20). Depress the valve

two or three times to exhaust the oil

which is trapped in the assembly. Do

not hammer on the valve pin or hous-

ing.

2.

Submerge the assembly in a con-

tainer of clean solvent. Again applying

an even pressure to the tip of the relief

valve pin, (a sudden strong force could

push the pin through the relief valve

spool) move the valve in and out sev-

eral times, thereby thoroughly flushing

the assembly. Pressure created within

the valve bore when the valve is moved

inward should force the cleaning fluid

out through the sensing orifice. If this

does not occur, the sensing orifice

should be cleaned with a piece of wire.

The valve must move freely and even-

ly. If the pin is bent or damaged, or if

the valve binds, the pump valve must

be replaced.

INSPECTION

The following describes the compo-

nents of the power steering pump

which must be replaced regardless of

condition and how to determine when

other components should be replaced.

The outlet fitting hex nut may be

reused if the corners of the hex are

not rounded. The housing bolts may

be reused if the threads are not dam-

aged.

All gaskets and seals must be re-

placed with new components except

the rotor shaft seal which should be

reused unless it was leaking.

The reservoir assembly may be

reused if the reservoir seal and gasket

areas are not damaged (dents, scratch-

es,

etc.). The soldered joints of the re-

turn and fill tubes must not be loose

or bent. Be sure to check for a broken

baffle.

The housing or housing assembly

may be reused if there is no damage

(scratches, etc.) at reservoir gasket,

outlet fitting or cover seal areas.

If the outlet fitting is damaged, the

pump housing must be replaced. The

pressure plate springs may be reused

providing they are not bent, broken or

have not taken a set.

Do not reuse the retainer end plate

if it is burred or damaged. The upper

pressure plate may be reused if there

is no scoring on the wear surface. It is

acceptable to polish the phosphate

coating.

The rotor and cam assembly can be

reused if there is no wear other than

the removal of the phosphate coating

on the cam contour. Do not disas-

semble the rotor and cam assembly.

Push the rotor part way out the cam

insert taking care not to let the slip-

pers and springs fall out. Check the

cam ID for scoring and burning.

Check the rotor faces and OD for

scoring and chipping. Do not attempt

to repair or refinish the lower and

upper pressure plates, cam or rotor

assembly. When wear or burning is

encountered, replace, them with new

components.

Install a new rotor and cam assem-

bly if the slippers are worn. Replace

the springs if they are bent or broken.

Polishing the phosphate coating of the

slipper sealing surface is permissable.

The rotor shaft can be reused if the

front and rear thrust faces, the bush-

ing diameter and the shaft seal diame-

ter are not excessively worn or scored.

The housing plate and bushing as-

sembly may be reused if all of the

threaded holes are not damaged

beyond repair and the bushing diame-

ter is not scored or worn .0005 inch

over the maximum dimension of .6897

inch. Threaded holes can be repaired

by drilling out the damaged threads

and installing a helicoil insert. If the

bushing is scored or excessively worn,

a new plate and bushing assembly

must be installed.

With Tool T69P-3D608-A (using a

dial indicator) check the squareness of

the fixed dowel pin in the plate (Fig.

21).

The pin must be square with the

adjacent surface within .001 inch per

inch through a 180 degree arch.

A bent or broken dowel pin can be

replaced as follows:

1.

Hold the plate assembly in a

horizontal position and grip at least

an inch of the dowel pin in a vise. Tap

the plate with a plastic or a rubber

hammer to pull the pin from the

plate.

2.

Insert the support guide (Tool

T69P-3D608-B) over a dowel pin (Fig.

22) and press the pin into the plate to

a height of 1.68 inch (See Fig. 23).

The support guide tool will serve as a

stop guide. Be careful not to bend the

new dowel pin during installation.

3.

Again use Tool T69P-3D608-A

(with a dial indicaator) to check the

dowel pin squareness as outlined

above.

POWER STEERING PUMP

INSPECTION—LINCOLN

CONTINENTAL AND

CONTINENTAL MARK III

1.

Wash all parts in clean solvent

and dry them with clean cloths or

compressed air.

2.

Inspect the rotor shaft for wear,

scoring, nicks, or burrs. Replace the

shaft if it is damaged or if the inner

keyway is damaged.

Tool

T69P-3D608-B

G1609-A

FIG. 22—Dowel Pin Insertion

Tool

T69P-3D608-A

G1608-A

FIG. 21—Dowel Pin Squareness

Check

FIG. 23 — Replacing Dowel Pinprocarmanuals.com

Page 76 of 413

03-01-11

Suspension — Steering, Wheels And Tires — General Service

03-01-11

3.

Inspect the rotor, rollers, cam

ring, pressure plate, cover, and bush-

ing in the pressure plate for wear or

scoring. If damaged, replacement of

the pump (less housing) is required.

4.

Make sure the inner faces of the

cover and the housing are free of

paint, nicks, or burrs. Check all fluid

passages for restrictions.

5.

Inspect the valving surfaces

(areas where the rotor and rollers con-

tact) for wear or scoring. Replace the

pressure plate or the cover if worn or

scored. Inspect the bushing in the

pressure plate for wear or scoring, and

replace the plate if necessary.

6. Inspect the control valve for

scores, nicks, or burred edges. Re-

place the valve if damaged. Do not dis-

assemble the valve. Check the valve

for free movement in the housing

bore.

7.

Inspect the tube seat in the hous-

ing. If damaged, remove it with an

E-Z-Out and install a new seat.

SHOCK ABSORBER CHECKS

All vehicles are equipped with hy-

draulic shock absorbers of the direct-

acting type and are nonadjustable and

nonrefillable. They cannot be repaired.

Before replacing a shock absorber,

check the action of the shock absor-

bers as follows:

ON VEHICLE TESTS

1.

Check the shock absorber to be

sure it is securely and properly in-

stalled. Check the shock absorber in-

sulators for damage and wear.

Replace any defective insulators and

tighten attachments to the specified

torque (on a shock absorber which in-

corporates integral insulators, replace

the shock absorbers).

2.

Inspect the shock absorber for

evidence of fluid leakage. A light film

of fluid is permissible. Be sure any

fluid observed is not from sources

other than the shock absorber.

Replace the shock absorber if leak-

age is severe.

3.

Disconnect the lower end of the

shock absorber. Extend and compress

the shock absorber as fast as possible,

using as much travel as possible.

Action should become smooth and

uniform throughout each stroke.

Higher resistance on extension than

on compression is a normal condition.

Faint swish noises are also normal.

Remove the shock absorber for a

bench test if action is erratic. If the

action is smooth, but the shock absor-

bers are suspected of being weak fol-

low step 4:

4.

Repeat step 3 on the mating

shock absorber installed on the oppo-

site side of the vehicle, and compare

results of both tests. If the action is

similar, it is unlikely that either shock

absorber is defective. Reconnect both

shock absorbers.

Replace the shock absorber having

the lower resistance. Ensure that the

part number of the replacement is the

same as that of the original shock ab-

sorber. The replacement shock absor-

ber resistance will appear to be higher

than either original due to initial fric-

tion of the rod seal.

BENCH TEST

With the shock absorber right side

up (as installed in vehicle), extend it

fully. Then turn the shock absorber

upside down and fully compress it.

Repeat this procedure at least three

times to ensure that any entrapped air

has been expelled. Now place the

shock absorber right side up in a vise,

and hand stroke the shock absorber as

described in On Vehicle Tests, step 3.

If action is not now smooth and uni-

form, install a new shock absorber.procarmanuals.com

Page 84 of 413

03-02-08

Suspension

03-02-08

IN-VEHICLE ADJUSTMENTS AND REPAIRS

HOISTING INSTRUCTIONS

Damage to steering linkage compo-

nents and front suspension struts may

occur if care is not exercised when po-

sitioning the hoist adapters of 2 post

hoists prior to lifting the vehicle.

If a 2 post hoist is used to lift the

vehicle, place the adapters under the

lower arms or the No. 1 crossmember.

Do not allow the adapters to contact

the steering linkage. If the adapters

are placed under the crossmember, a

piece of wood (2 x 4 x 16 inches)

should be placed on the hoist channel

between the adapters. This will pre-

vent the adapters from damaging the

front suspension struts.

UPPER BALL JOINT

REPLACEMENT

FORD, MERCURY,

METEOR, THUNDERBIRD,

CONTINENTAL MARK III

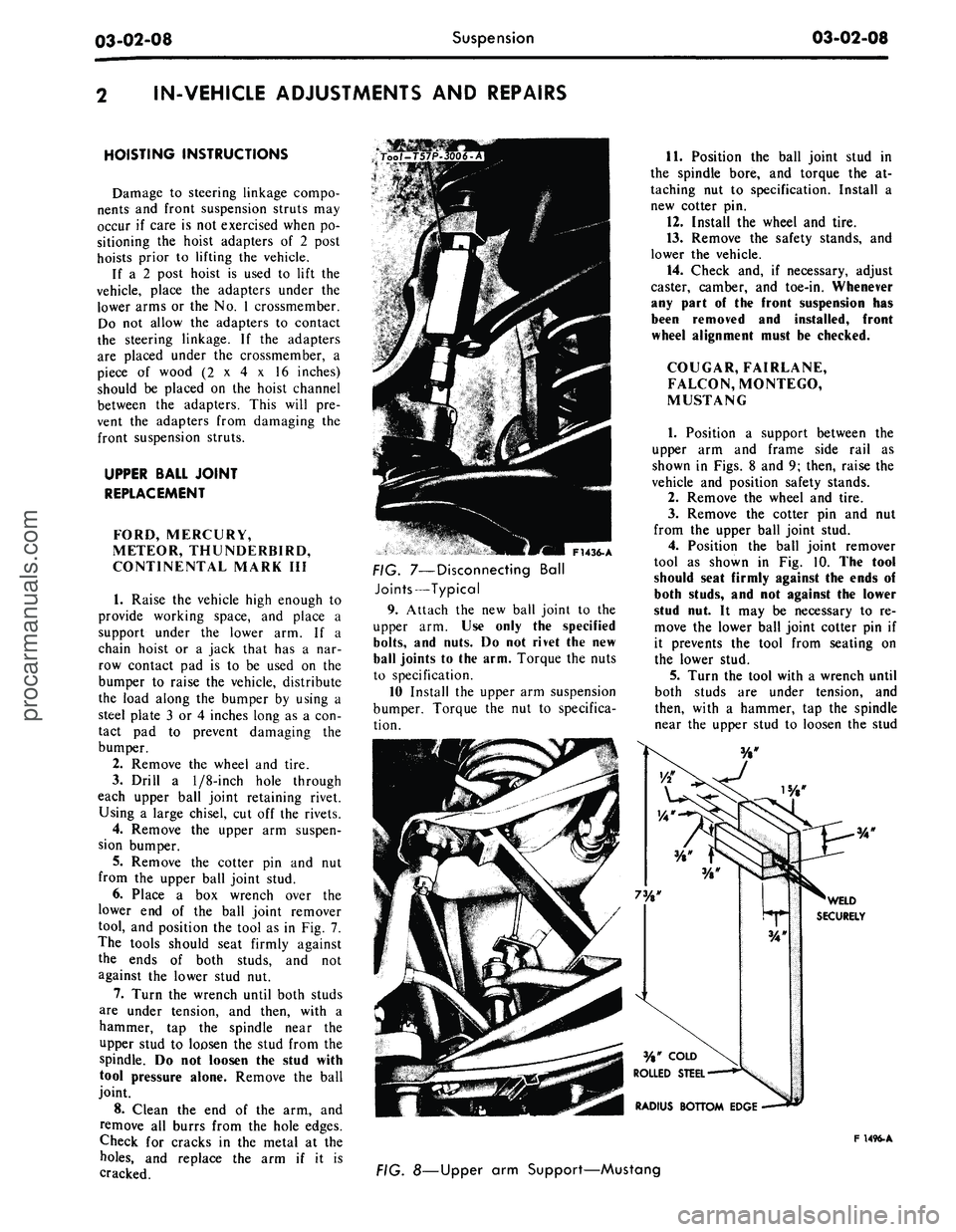

1.

Raise the vehicle high enough to

provide working space, and place a

support under the lower arm. If a

chain hoist or a jack that has a nar-

row contact pad is to be used on the

bumper to raise the vehicle, distribute

the load along the bumper by using a

steel plate 3 or 4 inches long as a con-

tact pad to prevent damaging the

bumper.

2.

Remove the wheel and tire.

3.

Drill a

1/8-inch

hole through

each upper ball joint retaining rivet.

Using a large chisel, cut off the rivets.

4.

Remove the upper arm suspen-

sion bumper.

5.

Remove the cotter pin and nut

from the upper ball joint stud.

6. Place a box wrench over the

lower end of the ball joint remover

tool, and position the tool as in Fig. 7.

The tools should seat firmly against

the ends of both studs, and not

against the lower stud nut.

7.

Turn the wrench until both studs

are under tension, and then, with a

hammer, tap the spindle near the

upper stud to loosen the stud from the

spindle. Do not loosen the stud with

tool pressure alone. Remove the ball

joint.

8. Clean the end of the arm, and

remove all burrs from the hole edges.

Check for cracks in the metal at the

holes,

and replace the arm if it is

cracked.

F1436-A

FIG. 7—Disconnecting Ball

Joints—Typical

9. Attach the new ball joint to the

upper arm. Use only the specified

bolts,

and nuts. Do not rivet the new

ball joints to the arm. Torque the nuts

to specification.

10 Install the upper arm suspension

bumper. Torque the nut to specifica-

tion.

11.

Position the ball joint stud in

the spindle bore, and torque the at-

taching nut to specification. Install a

new cotter pin.

12.

Install the wheel and tire.

13.

Remove the safety stands, and

lower the vehicle.

14.

Check and, if necessary, adjust

caster, camber, and toe-in. Whenever

any part of the front suspension has

been removed and installed, front

wheel alignment must be checked.

COUGAR, FAIRLANE,

FALCON, MONTEGO,

MUSTANG

1.

Position a support between the

upper arm and frame side rail as

shown in Figs. 8 and 9; then, raise the

vehicle and position safety stands.

2.

Remove the wheel and tire.

3.

Remove the cotter pin and nut

from the upper ball joint stud.

4.

Position the ball joint remover

tool as shown in Fig. 10. The tool

should seat firmly against the ends of

both studs, and not against the lower

stud nut. It may be necessary to re-

move the lower ball joint cotter pin if

it prevents the tool from seating on

the lower stud.

5.

Turn the tool with a wrench until

both studs are under tension, and

then, with a hammer, tap the spindle

near the upper stud to loosen the stud

F 1496-A

FIG. 8—Upper arm Support—Mustangprocarmanuals.com

Page 88 of 413

03-02-12

Suspension

03-02-12

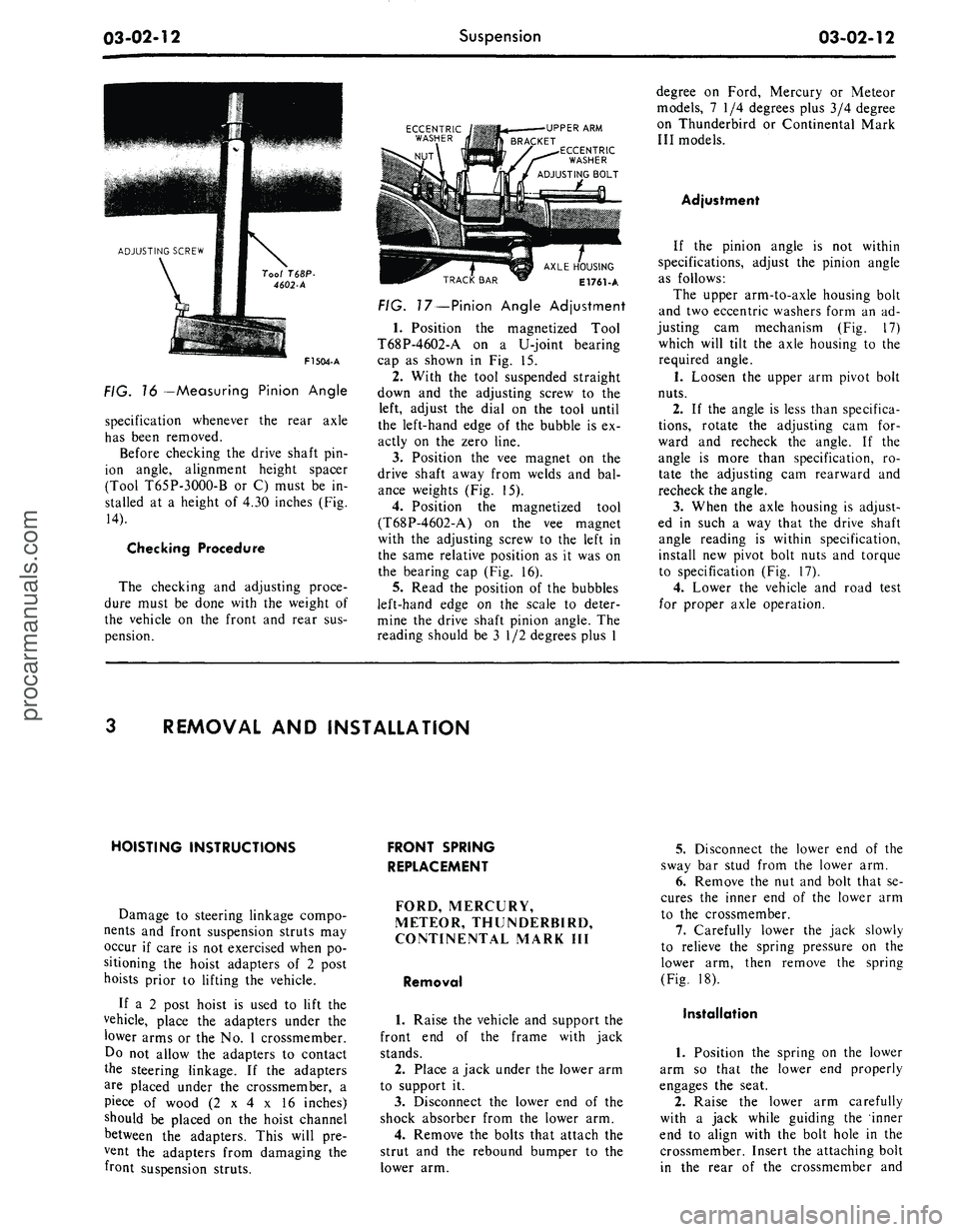

ECCENTRIC

WASHER

F1504-A

FIG. 76 —Measuring Pinion Angle

specification whenever the rear axle

has been removed.

Before checking the drive shaft pin-

ion angle, alignment height spacer

(Tool T65P-3OOO-B or C) must be in-

stalled at a height of 4.30 inches (Fig.

14).

Checking Procedure

The checking and adjusting proce-

dure must be done with the weight of

the vehicle on the front and rear sus-

pension.

UPPER ARM

KET

ECCENTRIC

WASHER

AXLE HOUSING

E1761-A

FIG.

17

—

Pinion

Angle Adjustment

1.

Position the magnetized Tool

T68P-4602-A on a U-joint bearing

cap as shown in Fig. 15.

2.

With the tool suspended straight

down and the adjusting screw to the

left, adjust the dial on the tool until

the left-hand edge of the bubble is ex-

actly on the zero line.

3.

Position the vee magnet on the

drive shaft away from welds and bal-

ance weights (Fig. 15).

4.

Position the magnetized tool

(T68P-4602-A) on the vee magnet

with the adjusting screw to the left in

the same relative position as it was on

the bearing cap (Fig. 16).

5.

Read the position of the bubbles

left-hand edge on the scale to deter-

mine the drive shaft pinion angle. The

reading should be 3 1/2 degrees plus 1

degree on Ford, Mercury or Meteor

models, 7 1/4 degrees plus 3/4 degree

on Thunderbird or Continental Mark

III models.

Adjustment

If the pinion angle is not within

specifications, adjust the pinion angle

as follows:

The upper arm-to-axle housing bolt

and two eccentric washers form an ad-

justing cam mechanism (Fig. 17)

which will tilt the axle housing to the

required angle.

1.

Loosen the upper arm pivot bolt

nuts.

2.

If the angle is less than specifica-

tions,

rotate the adjusting cam for-

ward and recheck the angle. If the

angle is more than specification, ro-

tate the adjusting cam rearward and

recheck the angle.

3.

When the axle housing is adjust-

ed in such a way that the drive shaft

angle reading is within specification,

install new pivot bolt nuts and torque

to specification (Fig. 17).

4.

Lower the vehicle and road test

for proper axle operation.

REMOVAL AND INSTALLATION

HOISTING INSTRUCTIONS

Damage to steering linkage compo-

nents and front suspension struts may

occur if care is not exercised when po-

sitioning the hoist adapters of 2 post

hoists prior to lifting the vehicle.

If a 2 post hoist is used to lift the

vehicle, place the adapters under the

lower arms or the No. 1 crossmember.

Do not allow the adapters to contact

the steering linkage. If the adapters

are placed under the crossmember, a

piece of wood (2 x 4 x 16 inches)

should be placed on the hoist channel

between the adapters. This will pre-

vent the adapters from damaging the

front suspension struts.

FRONT SPRING

REPLACEMENT

FORD, MERCURY,

METEOR, THUNDERBIRD,

CONTINENTAL MARK HI

Removal

1.

Raise the vehicle and support the

front end of the frame with jack

stands.

2.

Place a jack under the lower arm

to support it.

3.

Disconnect the lower end of the

shock absorber from the lower arm.

4.

Remove the bolts that attach the

strut and the rebound bumper to the

lower arm.

5.

Disconnect the lower end of the

sway bar stud from the lower arm.

6. Remove the nut and bolt that se-

cures the inner end of the lower arm

to the crossmember.

7.

Carefully lower the jack slowly

to relieve the spring pressure on the

lower arm, then remove the spring

(Fig. 18).

Installation

1.

Position the spring on the lower

arm so that the lower end properly

engages the seat.

2.

Raise the lower arm carefully

with a jack while guiding the inner

end to align with the bolt hole in the

crossmember. Insert the attaching bolt

in the rear of the crossmember andprocarmanuals.com

Page 95 of 413

03-02-19

Suspension

03-02-19

6. Raise the upper arm to free the

ball joint stud from the spindle. Wire

the upper end of the spindle to the un-

derbody to prevent damage to the

brake hose.

7.

Mark the position of the upper

arm shaft on the underbody member

to facilitate making caster and camber

adjustments after installation of the

upper arm.

8. Remove the suspension upper

arm-to-underbody attaching bolts,

lock washers, and attaching nuts.

Then, remove the upper arm.

Installation

1.

Position the upper arm shaft on

the underbody member. Line up the

shaft with the marks made before re-

moval of the arm.

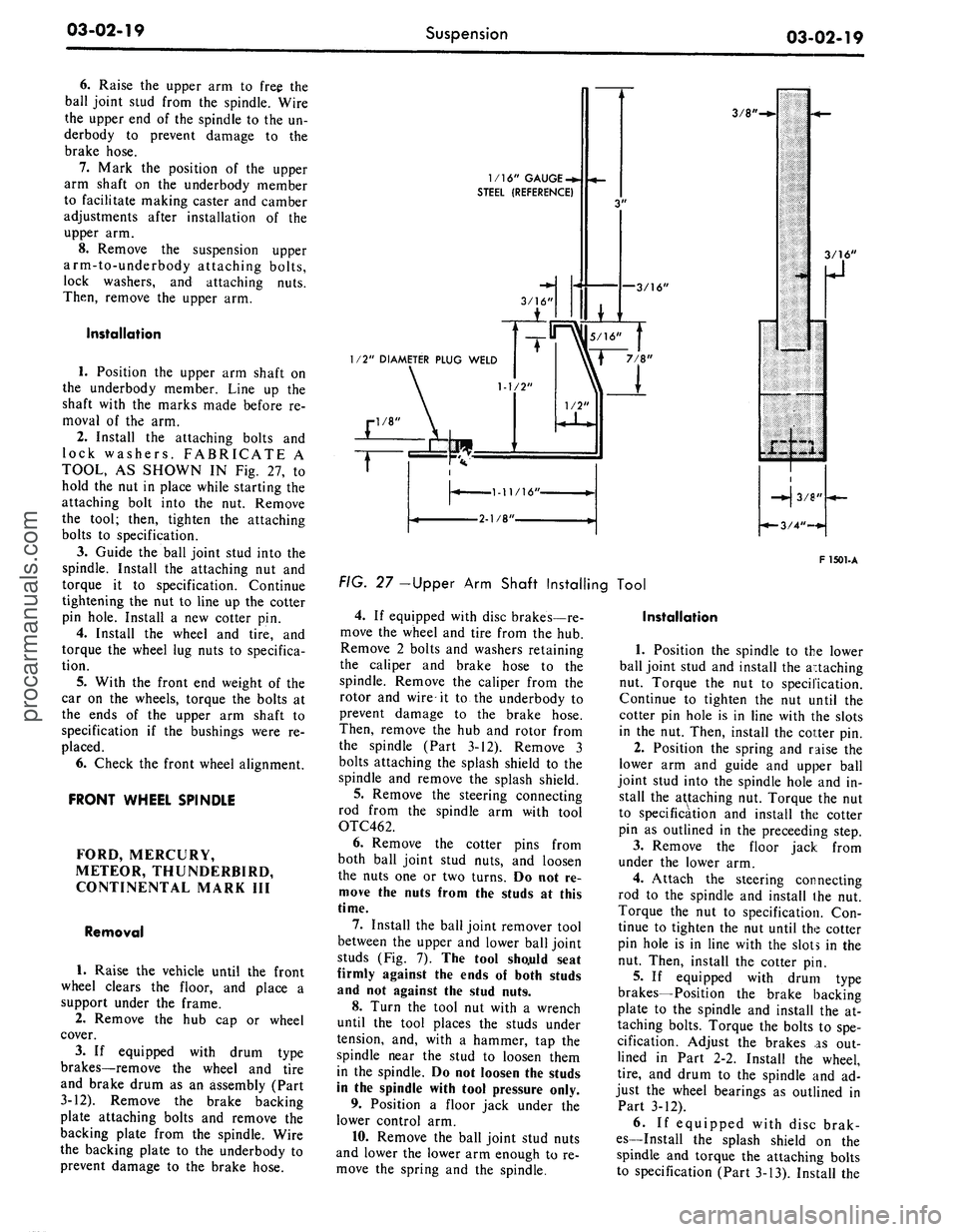

2.

Install the attaching bolts and

lock washers. FABRICATE A

TOOL, AS SHOWN IN Fig. 27, to

hold the nut in place while starting the

attaching bolt into the nut. Remove

the tool; then, tighten the attaching

bolts to specification.

3.

Guide the ball joint stud into the

spindle. Install the attaching nut and

torque it to specification. Continue

tightening the nut to line up the cotter

pin hole. Install a new cotter pin.

4.

Install the wheel and tire, and

torque the wheel lug nuts to specifica-

tion.

5.

With the front end weight of the

car on the wheels, torque the bolts at

the ends of the upper arm shaft to

specification if the bushings were re-

placed.

6. Check the front wheel alignment.

FRONT WHEEL SPINDLE

FORD, MERCURY,

METEOR, THUNDERBIRD,

CONTINENTAL MARK III

Removal

1.

Raise the vehicle until the front

wheel clears the floor, and place a

support under the frame.

2.

Remove the hub cap or wheel

cover.

3.

If equipped with drum type

brakes—remove the wheel and tire

and brake drum as an assembly (Part

3-12). Remove the brake backing

plate attaching bolts and remove the

backing plate from the spindle. Wire

the backing plate to the underbody to

prevent damage to the brake hose.

1/16" GAUGE

-*.

STEEL (REFERENCE)

—3/16'

3/8'

1/2" DIAMETER PLUG WELD

F 1501-A

FIG. 27 -Upper Arm Shaft Installing Tool

4.

If equipped with disc brakes—re-

move the wheel and tire from the hub.

Remove 2 bolts and washers retaining

the caliper and brake hose to the

spindle. Remove the caliper from the

rotor and wire it to the underbody to

prevent damage to the brake hose.

Then, remove the hub and rotor from

the spindle (Part 3-12). Remove 3

bolts attaching the splash shield to the

spindle and remove the splash shield.

5.

Remove the steering connecting

rod from the spindle arm with tool

OTC462.

6. Remove the cotter pins from

both ball joint stud nuts, and loosen

the nuts one or two turns. Do not re-

move the nuts from the studs at this

time.

7.

Install the ball joint remover tool

between the upper and lower ball joint

studs (Fig. 7). The tool sho.uld seat

firmly against the ends of both studs

and not against the stud nuts.

8. Turn the tool nut with a wrench

until the tool places the studs under

tension, and, with a hammer, tap the

spindle near the stud to loosen them

in the spindle. Do not loosen the studs

in the spindle with tool pressure only.

9. Position a floor jack under the

lower control arm.

10.

Remove the ball joint stud nuts

and lower the lower arm enough to re-

move the spring and the spindle.

Installation

1.

Position the spindle to the lower

ball joint stud and install the attaching

nut. Torque the nut to specification.

Continue to tighten the nut until the

cotter pin hole is in line with the slots

in the nut. Then, install the cotter pin.

2.

Position the spring and raise the

lower arm and guide and upper ball

joint stud into the spindle hole and in-

stall the attaching nut. Torque the nut

to specification and install the cotter

pin as outlined in the preceeding step.

3.

Remove the floor jack from

under the lower arm.

4.

Attach the steering connecting

rod to the spindle and install the nut.

Torque the nut to specification. Con-

tinue to tighten the nut until the cotter

pin hole is in line with the slots in the

nut. Then, install the cotter pin.

5.

If equipped with drum type

brakes—Position the brake backing

plate to the spindle and install the at-

taching bolts. Torque the bolts to spe-

cification. Adjust the brakes as out-

lined in Part 2-2. Install the wheel,

tire,

and drum to the spindle and ad-

just the wheel bearings as outlined in

Part 3-12).

6. If equipped with disc brak-

es—Install the splash shield on the

spindle and torque the attaching bolts

to specification (Part 3-13). Install theprocarmanuals.com