clock FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 390 of 413

07-04-21

C-6 Automatic Transmission

07-04-21

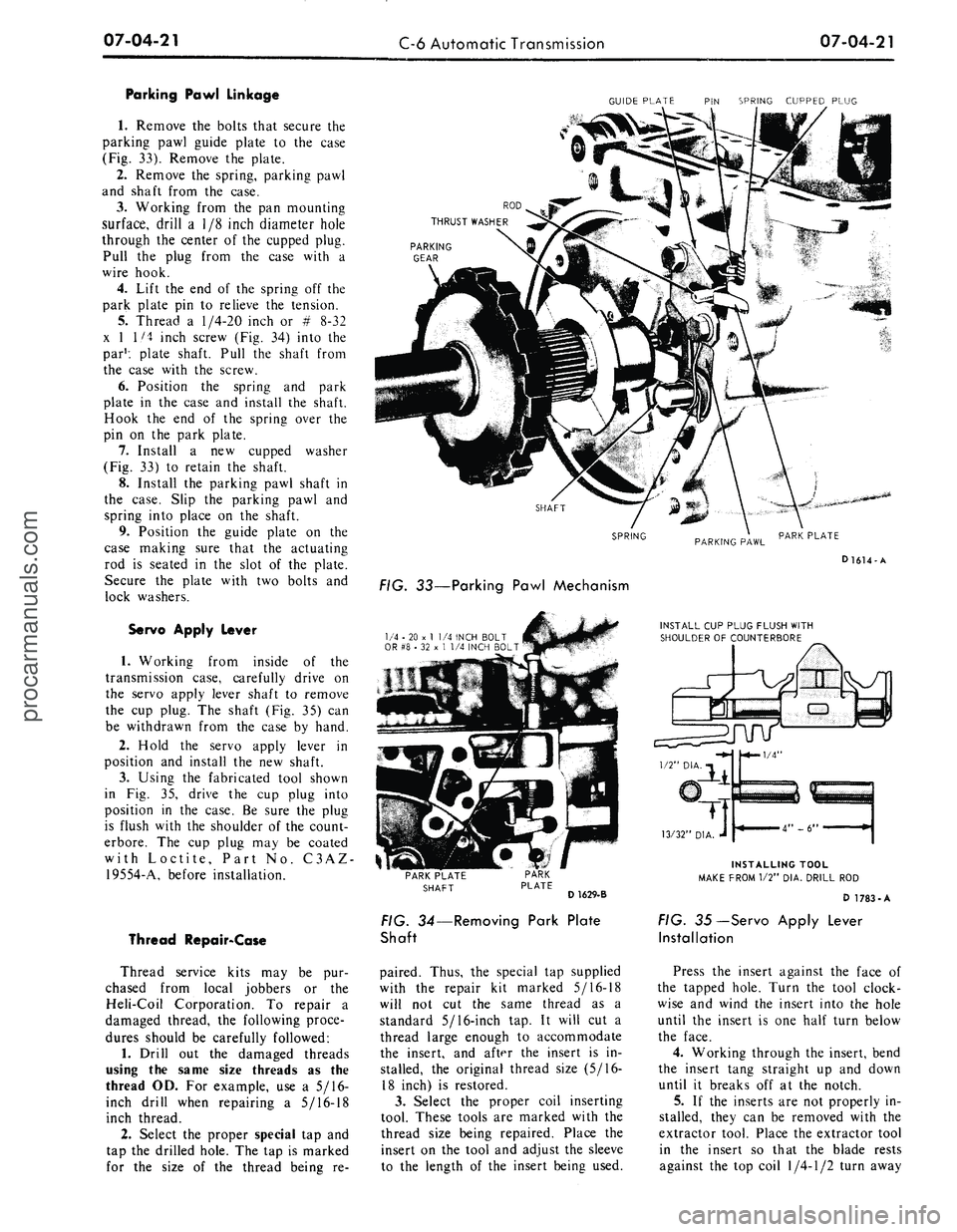

Parking Pawl Linkage

1.

Remove the bolts that secure the

parking pawl guide plate to the case

(Fig. 33). Remove the plate.

2.

Remove the spring, parking pawl

and shaft from the case.

3.

Working from the pan mounting

surface, drill a 1/8 inch diameter hole

through the center of the cupped plug.

Pull the plug from the case with a

wire hook.

4.

Lift the end of the spring off the

park plate pin to relieve the tension.

5.

Thread a

1/4-20

inch or # 8-32

x 1 1/4 inch screw (Fig. 34) into the

par1: plate shaft. Pull the shaft from

the case with the screw.

6. Position the spring and park

plate in the case and install the shaft.

Hook the end of the spring over the

pin on the park plate.

7.

Install a new cupped washer

(Fig. 33) to retain the shaft.

8. Install the parking pawl shaft in

the case. Slip the parking pawl and

spring into place on the shaft.

9. Position the guide plate on the

case making sure that the actuating

rod is seated in the slot of the plate.

Secure the plate with two bolts and

lock washers.

Servo Apply Lever

1.

Working from inside of the

transmission case, carefully drive on

the servo apply lever shaft to remove

the cup plug. The shaft (Fig. 35) can

be withdrawn from the case by hand.

2.

Hold the servo apply lever in

position and install the new shaft.

3.

Using the fabricated tool shown

in Fig. 35, drive the cup plug into

position in the case. Be sure the plug

is flush with the shoulder of the count-

erbore. The cup plug may be coated

with Loctite, Part No. C3AZ-

19554-A, before installation.

Thread Repair-Case

Thread service kits may be pur-

chased from local jobbers or the

Heli-Coil Corporation. To repair a

damaged thread, the following proce-

dures should be carefully followed:

1.

Drill out the damaged threads

using the same size threads as the

thread OD. For example, use a 5/16-

inch drill when repairing a 5/16-18

inch thread.

2.

Select the proper special tap and

tap the drilled hole. The tap is marked

for the size of the thread being re-

GUIDE PLATE PIN SPRING CUPPED PLUG

PARKING

GEAR

SHAFT

SPRING

PARKING PAWL

PARK PLATE

D1614-A

FIG. 33—Parking Pawl Mechanism

1/4 - 20 x

1

1/4 INCH BOLT

OR #8 • 32 x 1 1/4 INCH BOLT

INSTALL CUP PLUG FLUSH WITH

SHOULDER OF COUNTERBORE

PARK PLATE

SHAFT

D 1629-B

FIG. 34—Removing Park Plate

Shaft

paired. Thus, the special tap supplied

with the repair kit marked 5/16-18

will not cut the same thread as a

standard 5/16-inch tap. It will cut a

thread large enough to accommodate

the insert, and after the insert is in-

stalled, the original thread size (5/16-

18 inch) is restored.

3.

Select the proper coil inserting

tool. These tools are marked with the

thread size being repaired. Place the

insert on the tool and adjust the sleeve

to the length of the insert being used.

INSTALLING TOOL

MAKE FROM 1/2" DIA. DRILL ROD

D 1783-A

FIG. 35—Servo Apply Lever

Installation

Press the insert against the face of

the tapped hole. Turn the tool clock-

wise and wind the insert into the hole

until the insert is one half turn below

the face.

4.

Working through the insert, bend

the insert tang straight up and down

until it breaks off at the notch.

5.

If the inserts are not properly in-

stalled, they can be removed with the

extractor tool. Place the extractor tool

in the insert so that the blade rests

against the top coil

1/4-1/2

turn awayprocarmanuals.com

Page 391 of 413

07-04-22

C-6 Automatic Transmission

07-04-22

LOWER VALVE

BODY

7A101

UPPER VALVE

BODY

7A092

PLATE

7C056

PLATE

7D259

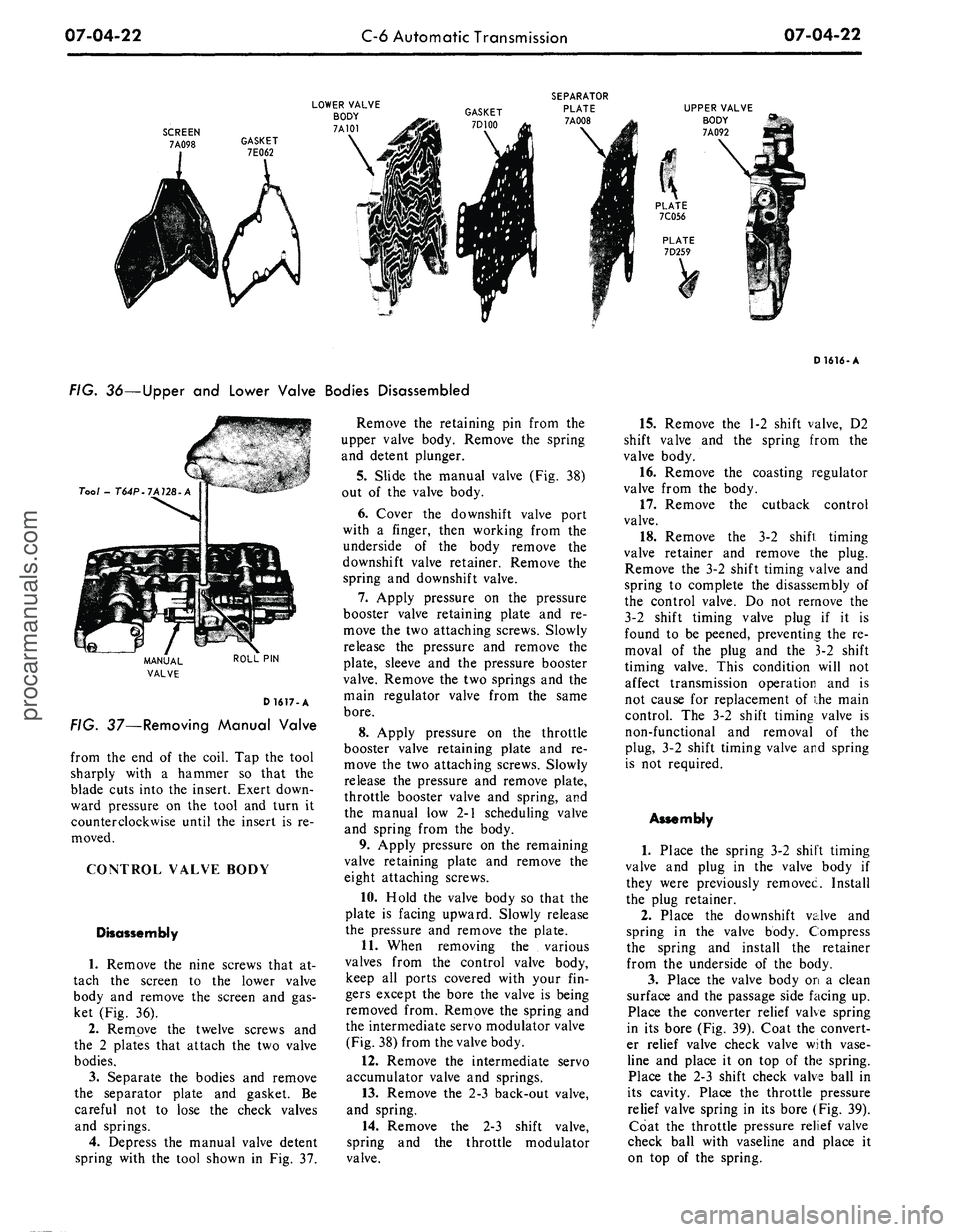

FIG. 36—Upper and Lower Valve Bodies Disassembled

Tool - T64P.7A128-A

ROLL PIN

D 1617-A

FIG. 37—Removing Manual Valve

from the end of the coil. Tap the tool

sharply with a hammer so that the

blade cuts into the insert. Exert down-

ward pressure on the tool and turn it

counterclockwise until the insert is re-

moved.

CONTROL VALVE BODY

Disassembly

1.

Remove the nine screws that at-

tach the screen to the lower valve

body and remove the screen and gas-

ket (Fig. 36).

2.

Remove the twelve screws and

the 2 plates that attach the two valve

bodies.

3.

Separate the bodies and remove

the separator plate and gasket. Be

careful not to lose the check valves

and springs.

4.

Depress the manual valve detent

spring with the tool shown in Fig. 37.

Remove the retaining pin from the

upper valve body. Remove the spring

and detent plunger.

5.

Slide the manual valve (Fig. 38)

out of the valve body.

6. Cover the downshift valve port

with a finger, then working from the

underside of the body remove the

downshift valve retainer. Remove the

spring and downshift valve.

7.

Apply pressure on the pressure

booster valve retaining plate and re-

move the two attaching screws. Slowly

release the pressure and remove the

plate, sleeve and the pressure booster

valve. Remove the two springs and the

main regulator valve from the same

bore.

8. Apply pressure on the throttle

booster valve retaining plate and re-

move the two attaching screws. Slowly

release the pressure and remove plate,

throttle booster valve and spring, and

the manual low 2-1 scheduling valve

and spring from the body.

9. Apply pressure on the remaining

valve retaining plate and remove the

eight attaching screws.

10.

Hold the valve body so that the

plate is facing upward. Slowly release

the pressure and remove the plate.

11.

When removing the various

valves from the control valve body,

keep all ports covered with your fin-

gers except the bore the valve is being

removed from. Remove the spring and

the intermediate servo modulator valve

(Fig. 38) from the valve body.

12.

Remove the intermediate servo

accumulator valve and springs.

13.

Remove the 2-3 back-out valve,

and spring.

14.

Remove the 2-3 shift valve,

spring and the throttle modulator

valve.

D1616-A

15.

Remove the 1-2 shift valve, D2

shift valve and the spring from the

valve body.

16.

Remove the coasting regulator

valve from the body.

17.

Remove the cutback control

valve.

18.

Remove the 3-2 shift timing

valve retainer and remove the plug.

Remove the 3-2 shift timing valve and

spring to complete the disassembly of

the control valve. Do not remove the

3-2 shift timing valve plug if it is

found to be peened, preventing the re-

moval of the plug and the 3-2 shift

timing valve. This condition will not

affect transmission operation and is

not cause for replacement of the main

control. The 3-2 shift timing valve is

non-functional and removal of the

plug, 3-2 shift timing valve and spring

is not required.

Assembly

1.

Place the spring 3-2 shift timing

valve and plug in the valve body if

they were previously removed. Install

the plug retainer.

2.

Place the downshift valve and

spring in the valve body. Compress

the spring and install the retainer

from the underside of the body.

3.

Place the valve body on a clean

surface and the passage side facing up.

Place the converter relief valve spring

in its bore (Fig. 39). Coat the convert-

er relief valve check valve with vase-

line and place it on top of the spring.

Place the 2-3 shift check valve ball in

its cavity. Place the throttle pressure

relief valve spring in its bore (Fig. 39).

Coat the throttle pressure relief valve

check ball with vaseline and place it

on top of the spring.procarmanuals.com

Page 397 of 413

07-04-28

C-6 Automatic Transmission

07-04-28

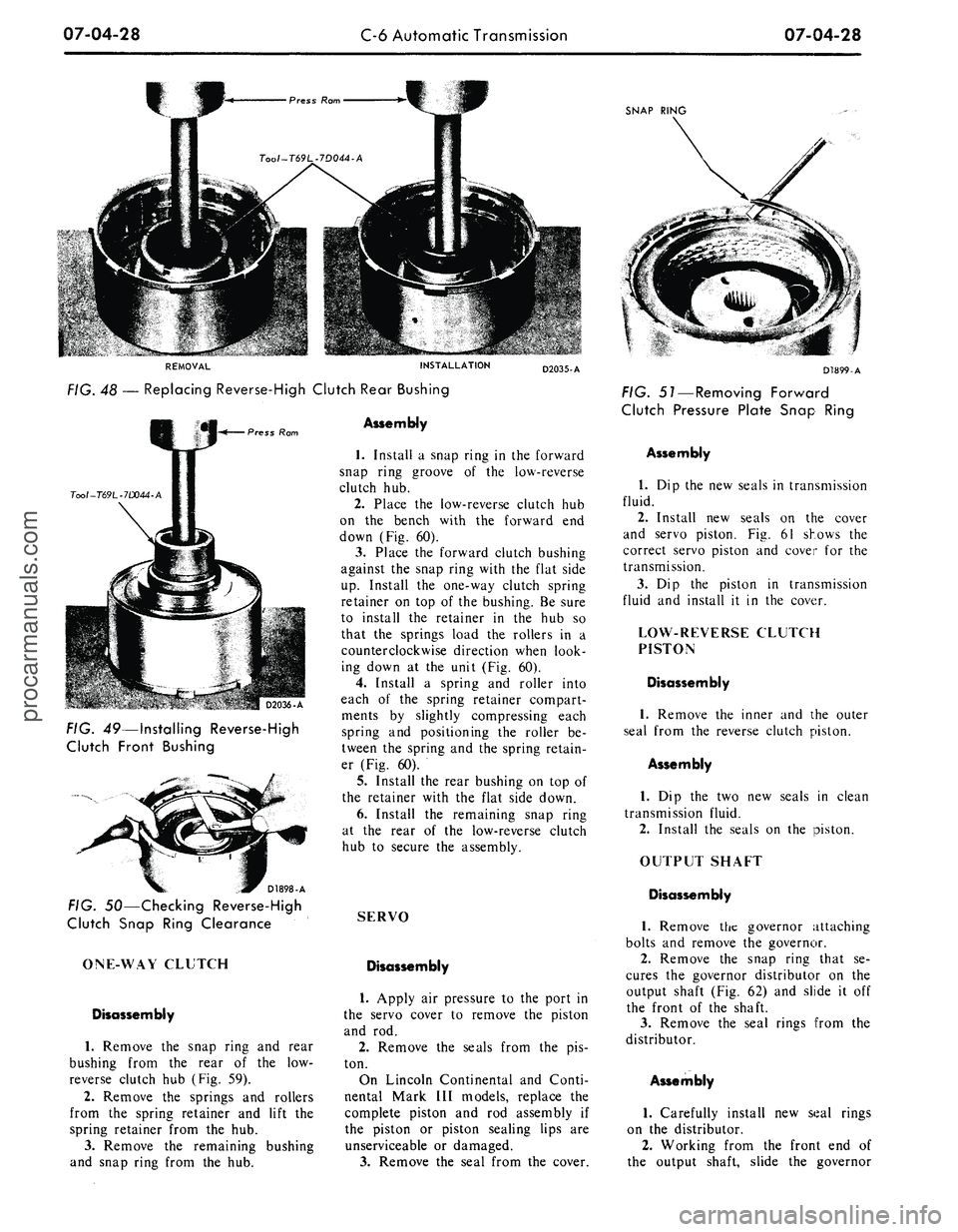

SNAP RING

REMOVAL INSTALLATION

FIG. 48 — Replacing Reverse-High Clutch Rear Bushing

D2035-A

Press Ram

Tool-T69L-7D044-A

D2036-A

FIG. 49—Installing Reverse-High

Clutch Front Bushing

D1898-A

FIG. 50—Checking Reverse-High

Clutch Snap Ring Clearance

ONE-WAY CLUTCH

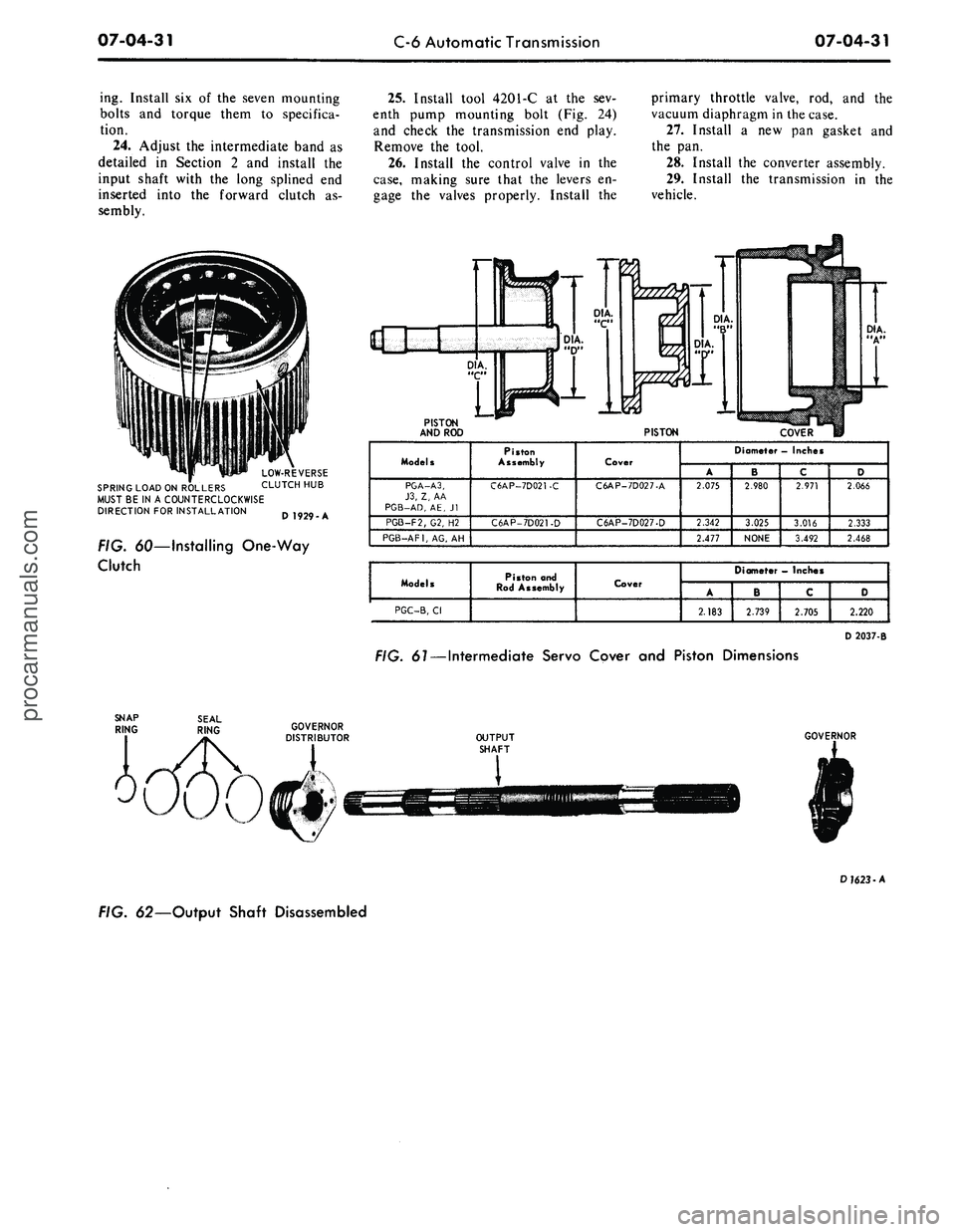

Disassembly

1.

Remove the snap ring and rear

bushing from the rear of the low-

reverse clutch hub (Fig. 59).

2.

Remove the springs and rollers

from the spring retainer and lift the

spring retainer from the hub.

3.

Remove the remaining bushing

and snap ring from the hub.

Assembly

1.

Install a snap ring in the forward

snap ring groove of the low-reverse

clutch hub.

2.

Place the low-reverse clutch hub

on the bench with the forward end

down (Fig. 60).

3.

Place the forward clutch bushing

against the snap ring with the flat side

up.

Install the one-way clutch spring

retainer on top of the bushing. Be sure

to install the retainer in the hub so

that the springs load the rollers in a

counterclockwise direction when look-

ing down at the unit (Fig. 60).

4.

Install a spring and roller into

each of the spring retainer compart-

ments by slightly compressing each

spring and positioning the roller be-

tween the spring and the spring retain-

er (Fig. 60).

5.

Install the rear bushing on top of

the retainer with the flat side down.

6. Install the remaining snap ring

at the rear of the low-reverse clutch

hub to secure the assembly.

SERVO

Disassembly

1.

Apply air pressure to the port in

the servo cover to remove the piston

and rod.

2.

Remove the seals from the pis-

ton.

On Lincoln Continental and Conti-

nental Mark III models, replace the

complete piston and rod assembly if

the piston or piston sealing lips are

unserviceable or damaged.

3.

Remove the seal from the cover.

D1899-A

FIG. 51—Removing Forward

Clutch Pressure Plate Snap Ring

Assembly

1.

Dip the new seals in transmission

fluid.

2.

Install new seals on the cover

and servo piston. Fig. 61 shows the

correct servo piston and cover for the

transmission.

3.

Dip the piston in transmission

fluid and install it in the cover.

LOW-REVERSE CLUTCH

PISTON

Disassembly

1.

Remove the inner and the outer

seal from the reverse clutch piston.

Assembly

1.

Dip the two new seals in clean

transmission fluid.

2.

Install the seals on the piston.

OUTPUT SHAFT

Disassembly

1.

Remove the governor attaching

bolts and remove the governor.

2.

Remove the snap ring that se-

cures the governor distributor on the

output shaft (Fig. 62) and slide it off

the front of the shaft.

3.

Remove the seal rings from the

distributor.

Assembly

1.

Carefully install new seal rings

on the distributor.

2.

Working from the front end of

the output shaft, slide the governorprocarmanuals.com

Page 398 of 413

07-04-29

C-6 Automatic Transmission

07-04-29

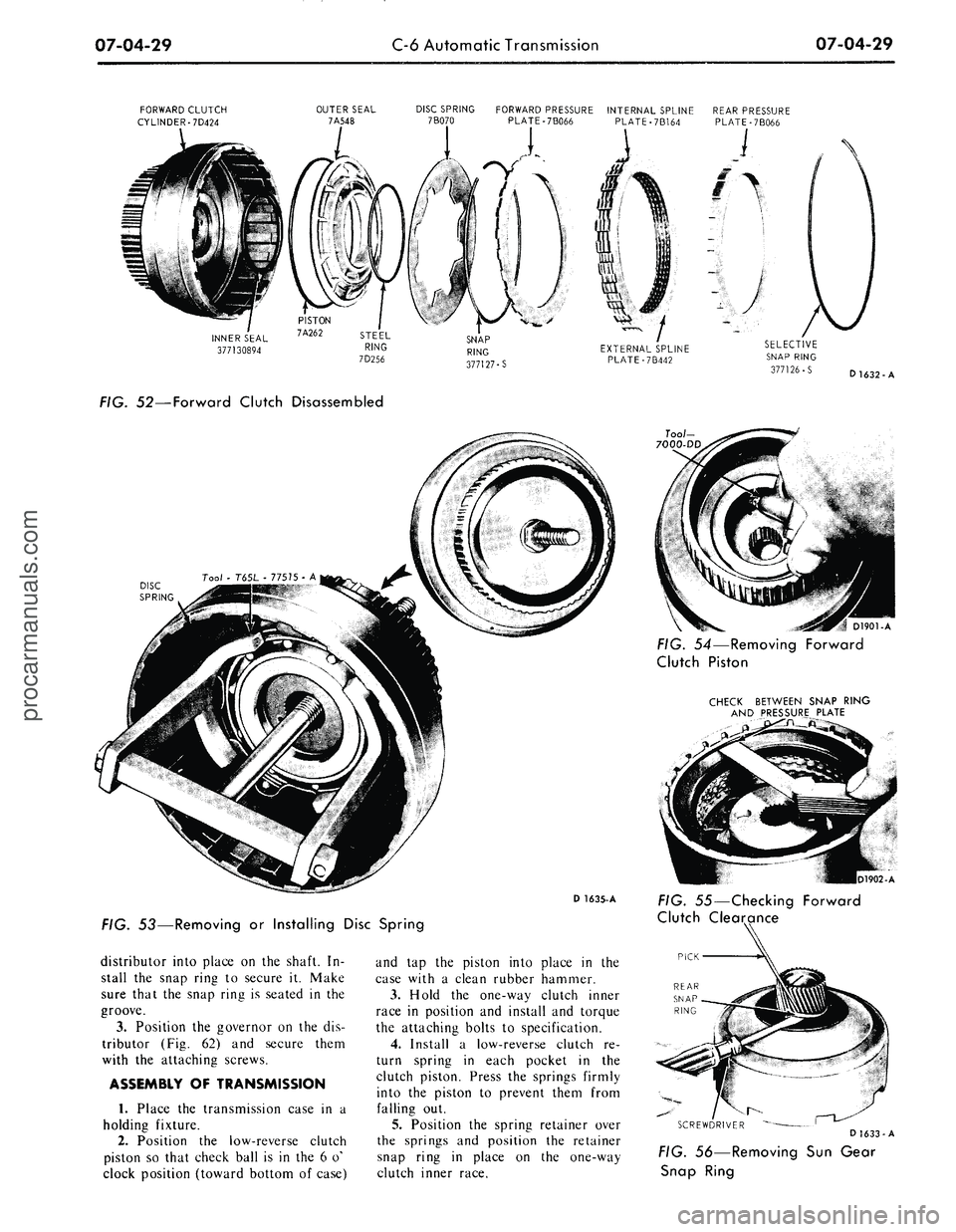

FORWARD CLUTCH

CYLINDER-7D424

OUTER SEAL

7A548

DISC SPRING FORWARD PRESSURE INTERNAL SPLINE REAR PRESSURE

7B070

PLATE-7B066

PLATE-7B164 PLATE-7B066

INNER SEAL

377130894

PISTON

7A262 STEEL

RING

7D256

SNAP

RING

377127-S

FIG. 52—Forward Clutch Disassembled

DISC

SPRING

EXTERNAL SPLINE

PLATE-7B442

7oo/-

7000-DD

SELECTIVE

SNAP RING

377126-S

D 1635-A

FIG. 53—Removing or Installing Disc Spring

distributor into place on the shaft. In-

stall the snap ring to secure it. Make

sure that the snap ring is seated in the

groove.

3.

Position the governor on the dis-

tributor (Fig. 62) and secure them

with the attaching screws.

ASSEMBLY OF TRANSMISSION

1.

Place the transmission case in a

holding fixture.

2.

Position the low-reverse clutch

piston so that check ball is in the 6 o'

clock position (toward bottom of case)

and tap the piston into place in the

case with a clean rubber hammer.

3.

Hold the one-way clutch inner

race in position and install and torque

the attaching bolts to specification.

4.

Install a low-reverse clutch re-

turn spring in each pocket in the

clutch piston. Press the springs firmly

into the piston to prevent them from

falling out.

5.

Position the spring retainer over

the springs and position the retainer

snap ring in place on the one-way

clutch inner race.

D1632-A

D1901-A

FIG. 54—Removing Forward

Clutch Piston

CHECK BETWEEN SNAP RING

AND PRESSURE PLATE

1902-A

FIG. 55—Checking Forward

Clutch Clearance

PICK

SCREWDRIVER

D 1633-A

FIG. 56—Removing Sun Gear

Snap Ringprocarmanuals.com

Page 399 of 413

07-04-30

C-6 Automatic Transmission

07-04-30

6. Install the compressing tool

shown in Fig. 29 and compress the

springs just enough to install the low-

reverse clutch piston retainer snap

ring.

7.

Install the snap ring, then re-

move the compressing tool.

8. Place the transmission case on

the bench with the front end facing

downward.

9. Position the parking gear thrust

washer and the gear on the case (Fig.

33).

Do not restake the thrust washer.

10.

Position the oil distributor and

tubes in place on the rear of the case.

Install and torque the attaching bolts

to specification.

11.

Install the output shaft, and

governor as an assembly.

12.

Place a new gasket on the rear

of the transmission case. Position the

extension housing on the case and in-

stall the attaching bolts. Torque the

attaching bolts to specification.

13.

Place the case in the holding

fixture.

14.

Align the low-reverse clutch hub

and one-way clutch with the inner

race at the rear of the case. Rotate

the low-reverse clutch hub clockwise

while applying pressure to seat it on

the inner race.

15.

Install the low-reverse clutch

plates,

starting with a steel plate and

following with friction and steel plates

alternately. Retain them with vaseline.

Refer to the Specifications Section for

the number of plates required. If new

composition plates are being used,

soak them in clean transmission fluid

for fifteen minutes before installation.

Install the pressure plate and the snap

ring. Test the operation of the low-

reverse clutch by applying air pressure

at the clutch pressure apply hole in

the case.

16.

Install the reverse planet ring

gear thrust washer and the ring gear

and hub assembly. Insert the snap

ring in the groove in the output shaft.

17.

Assemble the front and rear

thrust washers onto the reverse planet

assembly; retain with vasoline. Insert

the assembly into the ring gear and

install the snap ring.

18.

Set the reverse-high clutch on

the bench, with the front end facing

down. Install the thrust washer on the

rear end of the reverse-high clutch as-

sembly. Retain the thrust washer with

vaseline and insert the splined end of

forward clutch into the open end of

the reverse-high clutch so that the

splines engage the direct clutch fric-

tion plates (Fig. 43).

19.

Install the thrust washer and re-

tain it with vaseline, on the front end

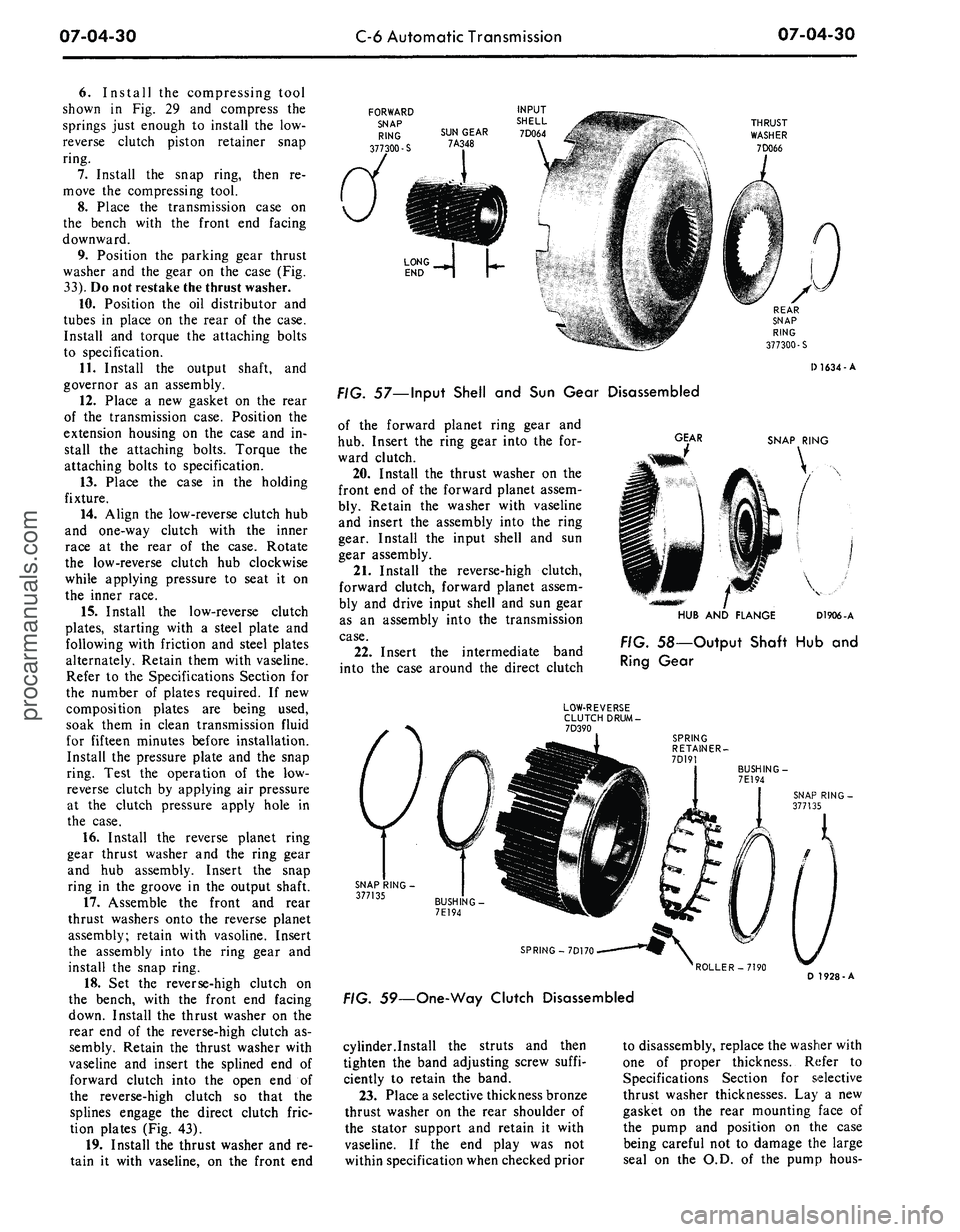

FORWARD

SNAP

RING

377300-S

SUN

GEAR

7A348

•

INPUT

SHELL

7D064

\

THRUST

WASHER

7D066

-IT

REAR

SNAP

RING

377300-S

I)

1634-A

57—Input Shell and Sun Gear Disassembled

of the forward planet ring gear and

hub.

Insert the ring gear into the for-

ward clutch.

20.

Install the thrust washer on the

front end of the forward planet assem-

bly. Retain the washer with vaseline

and insert the assembly into the ring

gear. Install the input shell and sun

gear assembly.

21.

Install the reverse-high clutch,

forward clutch, forward planet assem-

bly and drive input shell and sun gear

as an assembly into the transmission

case.

22.

Insert the intermediate band

into the case around the direct clutch

GEAR

SNAP RING

HUB AND FLANGE

D1906-A

FIG. 58—Output Shaft Hub and

Ring Gear

LOW-REVERSE

CLUTCH

DRUM-

7D390

SPRING

RETAINER-

7D191

BUSHING

-

7E194

SPRING

-

7D170

ROLLER-7190

D 1928-A

FIG. 59—One-Way Clutch Disassembled

cylinder.Install the struts and then

tighten the band adjusting screw suffi-

ciently to retain the band.

23.

Place a selective thickness bronze

thrust washer on the rear shoulder of

the stator support and retain it with

vaseline. If the end play was not

within specification when checked prior

to disassembly, replace the washer with

one of proper thickness. Refer to

Specifications Section for selective

thrust washer thicknesses. Lay a new

gasket on the rear mounting face of

the pump and position on the case

being careful not to damage the large

seal on the O.D. of the pump hous-procarmanuals.com

Page 400 of 413

07-04-31

C-6 Automatic Transmission

07-04-31

ing. Install six of the seven mounting

bolts and torque them to specifica-

tion.

24.

Adjust the intermediate band as

detailed in Section 2 and install the

input shaft with the long splined end

inserted into the forward clutch as-

sembly.

LOW-REVERSE

SPRING LOAD ON ROLLERS CLUTCH HUB

MUST BE IN A COUNTERCLOCKWISE

DIRECTION FOR INSTALLATION Q 192O A

FIG. 60—Installing One-Way

Clutch

25.

Install tool 4201-C at the sev-

enth pump mounting bolt (Fig. 24)

and check the transmission end play.

Remove the tool.

26.

Install the control valve in the

case,

making sure that the levers en-

gage the valves properly. Install the

primary throttle valve, rod, and the

vacuum diaphragm in the case.

27.

Install a new pan gasket and

the pan.

28.

Install the converter assembly.

29.

Install the transmission in the

vehicle.

PISTON

AND ROD

PISTON

COVER

Models

PGA-A3,

J3,

Z, AA

PGB-AD,

AE, Jl

PGB-F2/G2, H2

PGB-AF1,

AG, AH

Piston

Assembly

C6AP-7D021-C

C6AP-7D021-D

Cover

C6AP-7D027-A

C6AP-7D027-D

Diameter - Inches

A

2.075

2.342

2.477

' B

2.980

3.025

NONE

c

2.971

3.016

3.492

D

2.066

2.333

2.468

Models

PGC-B,

Cl

Piston and

Rod Assembly

Cover

Diameter

—

Inches

A

2.183

B

2.739

C

2.705

D

2.220

D 2037-B

FIG.

61

— Intermediate Servo Cover and Piston Dimensions

OUTPUT

SHAFT

GOVERNOR

D

1623

-A

FIG. 62—Output Shaft Disassembledprocarmanuals.com