lock FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 174 of 413

03-12-03

Wheels And Tires

03-12-03

DISC BRAKES

1.

Raise the vehicle until the wheel

and tire clear the floor.

2.

Pry off the wheel cover and re-

move the grease cap (Fig. 2) from the

hub.

3.

Wipe the excess grease from the

end of the spindle, and remove the ad-

justing nut cotter pin and nut lock.

4.

Loosen the bearing adjusting nut

three turns. Then, rock the wheel,

hub,

and rotor assembly in and out

several times to push the shoe and lin-

ings away from the rotor.

5.

While rotating the wheel, hub,

and rotor assembly, torque the adjust-

ing nut to 17-25 ft-lbs to seat the

bearings (Fig. 4).

6. Back the adjusting nut off one

half turn. Then, retighten the adjust-

ing nut to 10-15 in-lbs with a torque

wrench or finger tight.

7.

Locate the nut lock on the ad-

justing nut so that the castellations on

the lock are aligned with the cotter

pin hole in the spindle.

8. Install a new cotter pin, and

bend the ends of the cotter pin around

the castellated flange of the nut lock.

9. Check the front wheel rotation.

If the wheel rotates properly, install

the grease cap and the hub cap or

wheel cover. If the wheel still rotates

roughly or noisily, clean or replace the

bearings and cups as required.

10.

Before driving the vehicle,

pump the brake pedal several times to

obtain normal brake lining to rotor

clearance and restore normal brake

pedal travel.

BALANCING LIFE

GUARD TIRE

Tires fitted with the Life Guard

Safety Spare are balanced in the same

manner as conventional tires. If an ex-

cessive out of balance condition exists

the following procedure can be used to

correct the condition:

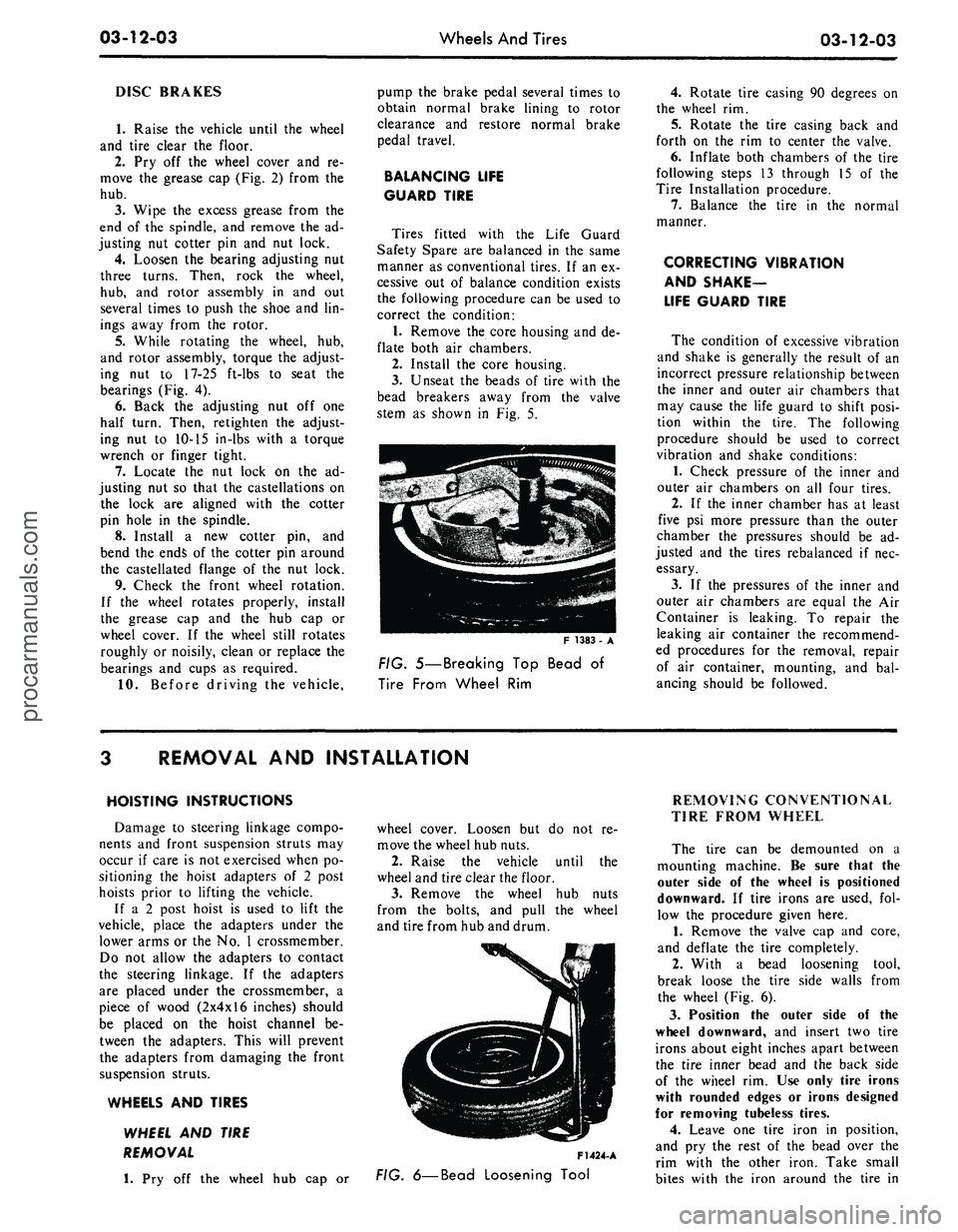

1.

Remove the core housing and de-

flate both air chambers.

2.

Install the core housing.

3.

Unseat the beads of tire with the

bead breakers away from the valve

stem as shown in Fig. 5.

F 1383

FIG. 5—Breaking Top Bead of

Tire From Wheel Rim

4.

Rotate tire casing 90 degrees on

the wheel rim.

5.

Rotate the tire casing back and

forth on the rim to center the valve.

6. Inflate both chambers of the tire

following steps 13 through 15 of the

Tire Installation procedure.

7.

Balance the tire in the normal

manner.

CORRECTING VIBRATION

AND SHAKE-

LIFE GUARD TIRE

The condition of excessive vibration

and shake is generally the result of an

incorrect pressure relationship between

the inner and outer air chambers that

may cause the life guard to shift posi-

tion within the tire. The following

procedure should be used to correct

vibration and shake conditions:

1.

Check pressure of the inner and

outer air chambers on all four tires.

2.

If the inner chamber has at least

five psi more pressure than the outer

chamber the pressures should be ad-

justed and the tires rebalanced if nec-

essary.

3.

If the pressures of the inner and

outer air chambers are equal the Air

Container is leaking. To repair the

leaking air container the recommend-

ed procedures for the removal, repair

of air container, mounting, and bal-

ancing should be followed.

REMOVAL AND INSTALLATION

HOISTING INSTRUCTIONS

Damage to steering linkage compo-

nents and front suspension struts may

occur if care is not exercised when po-

sitioning the hoist adapters of 2 post

hoists prior to lifting the vehicle.

If a 2 post hoist is used to lift the

vehicle, place the adapters under the

lower arms or the No. 1 crossmember.

Do not allow the adapters to contact

the steering linkage. If the adapters

are placed under the crossmember, a

piece of wood (2x4x16 inches) should

be placed on the hoist channel be-

tween the adapters. This will prevent

the adapters from damaging the front

suspension struts.

WHEELS AND TIRES

WHEEL AND TIRE

REMOVAL

1.

Pry off the wheel hub cap or

wheel cover. Loosen but do not re-

move the wheel hub nuts.

2.

Raise the vehicle until the

wheel and tire clear the floor.

3.

Remove the wheel hub nuts

from the bolts, and pull the wheel

and tire from hub and drum.

F1424-

A

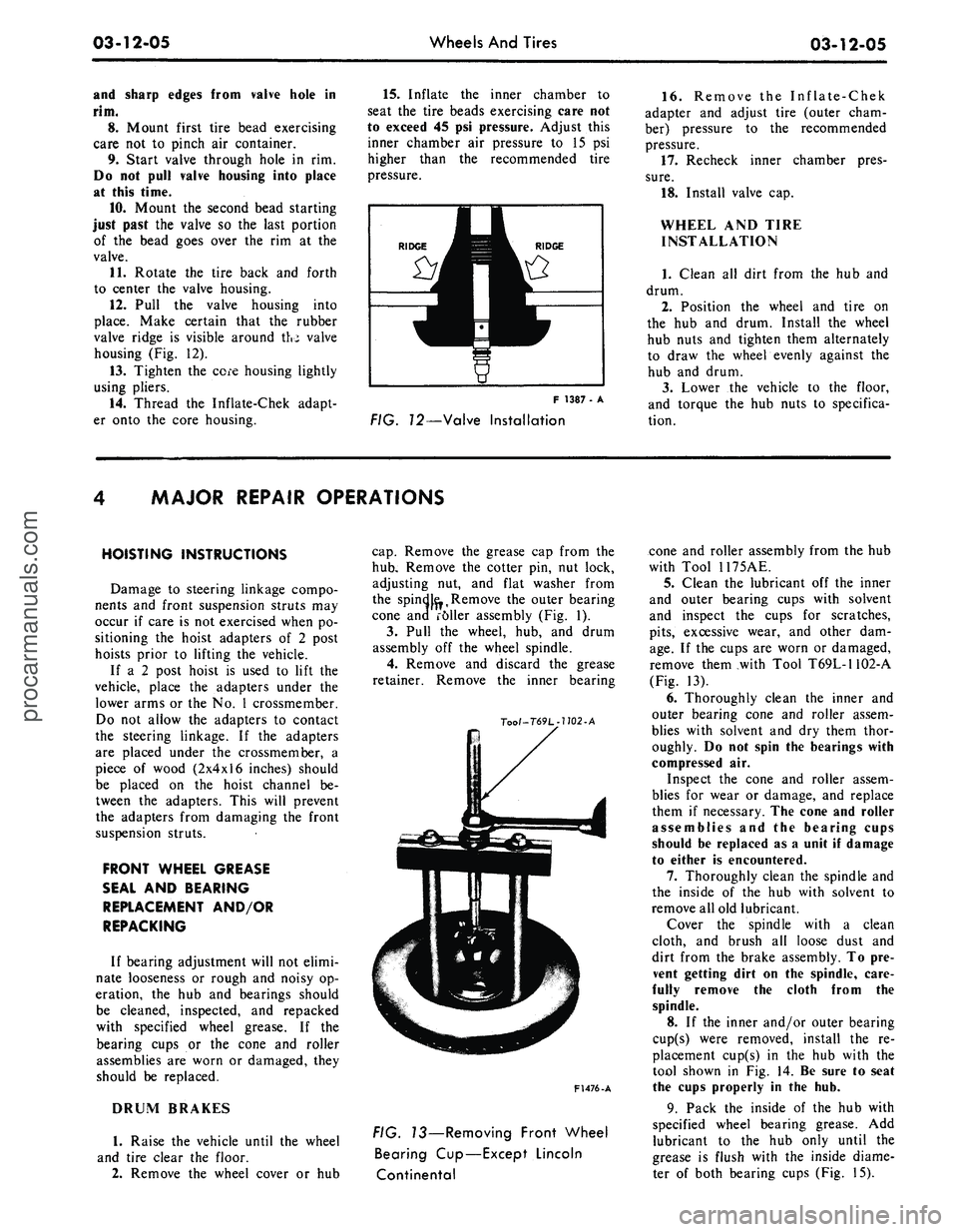

FIG.

6—Bead

Loosening Tool

REMOVING CONVENTIONAL

TIRE FROM WHEEL

The tire can be demounted on a

mounting machine. Be sure that the

outer side of the wheel is positioned

downward. If tire irons are used, fol-

low the procedure given here.

1.

Remove the valve cap and core,

and deflate the tire completely.

2.

With a bead loosening tool,

break loose the tire side walls from

the wheel (Fig. 6).

3.

Position the outer side of the

wheel downward, and insert two tire

irons about eight inches apart between

the tire inner bead and the back side

of the wheel rim. Use only tire irons

with rounded edges or irons designed

for removing tubeless tires.

4.

Leave one tire iron in position,

and pry the rest of the bead over the

rim with the other iron. Take small

bites with the iron around the tire inprocarmanuals.com

Page 176 of 413

03-12-05

Wheels

And

Tires

03-12-05

and sharp edges from valve hole

in

rim.

8. Mount first tire bead exercising

care

not to

pinch

air

container.

9. Start valve through hole

in rim.

Do

not

pull valve housing into place

at this time.

10.

Mount

the

second bead starting

just past

the

valve

so the

last portion

of

the

bead goes over

the rim at the

valve.

11.

Rotate

the

tire back

and

forth

to center

the

valve housing.

12.

Pull

the

valve housing into

place. Make certain that

the

rubber

valve ridge

is

visible around

thi

valve

housing

(Fig.

12).

13.

Tighten

the

core housing lightly

using pliers.

14.

Thread

the

Inflate-Chek adapt-

er onto

the

core housing.

15.

Inflate

the

inner chamber

to

seat

the

tire beads exercising care

not

to exceed

45 psi

pressure. Adjust this

inner chamber

air

pressure

to 15 psi

higher than

the

recommended tire

pressure.

F 1387

- A

FIG. 12—Valve Installation

16.

Remove

the

Inflate-Chek

adapter

and

adjust tire (outer cham-

ber) pressure

to the

recommended

pressure.

17.

Recheck inner chamber pres-

sure.

18.

Install valve

cap.

WHEEL

AND

TIRE

INSTALLATION

1.

Clean

all

dirt from

the hub and

drum.

2.

Position

the

wheel

and

tire

on

the

hub and

drum. Install

the

wheel

hub nuts

and

tighten them alternately

to draw

the

wheel evenly against

the

hub

and

drum.

3.

Lower

the

vehicle

to the

floor,

and torque

the hub

nuts

to

specifica-

tion.

MAJOR REPAIR OPERATIONS

HOISTING INSTRUCTIONS

Damage

to

steering linkage compo-

nents

and

front suspension struts

may

occur

if

care

is

not

exercised when

po-

sitioning

the

hoist adapters

of 2

post

hoists prior

to

lifting

the

vehicle.

If

a 2

post hoist

is

used

to

lift

the

vehicle, place

the

adapters under

the

lower arms

or the

No.

1

crossmember.

Do

not

allow

the

adapters

to

contact

the steering linkage.

If the

adapters

are placed under

the

crossmember,

a

piece

of

wood (2x4x16 inches) should

be placed

on the

hoist channel

be-

tween

the

adapters. This will prevent

the adapters from damaging

the

front

suspension struts.

FRONT WHEEL GREASE

SEAL

AND

BEARING

REPLACEMENT AND/OR

REPACKING

If bearing adjustment will

not

elimi-

nate looseness

or

rough

and

noisy

op-

eration,

the hub and

bearings should

be cleaned, inspected,

and

repacked

with specified wheel grease.

If the

bearing cups

or the

cone

and

roller

assemblies

are

worn

or

damaged, they

should

be

replaced.

DRUM BRAKES

1.

Raise

the

vehicle until

the

wheel

and tire clear

the

floor.

2.

Remove

the

wheel cover

or hub

cap.

Remove

the

grease

cap

from

the

hub.

Remove

the

cotter

pin,

nut

lock,

adjusting

nut, and

flat washer from

the spindjej, Remove

the

outer bearing

cone

and

roller assembly

(Fig.

1).

3.

Pull

the

wheel,

hub, and

drum

assembly

off the

wheel spindle.

4.

Remove

and

discard

the

grease

retainer. Remove

the

inner bearing

Too/-T69L-J102-A

F1476-A

FIG. 13—Removing Front Wheel

Bearing Cup—Except Lincoln

Continental

cone

and

roller assembly from

the hub

with Tool 1175AE.

5.

Clean

the

lubricant

off the

inner

and outer bearing cups with solvent

and inspect

the

cups

for

scratches,

pits,

excessive wear,

and

other

dam-

age.

If

the

cups

are

worn

or

damaged,

remove them with Tool T69L-1102-A

(Fig.

13).

6. Thoroughly clean

the

inner

and

outer bearing cone

and

roller assem-

blies with solvent

and dry

them thor-

oughly.

Do not

spin

the

bearings with

compressed

air.

Inspect

the

cone

and

roller assem-

blies

for

wear

or

damage,

and

replace

them

if

necessary.

The

cone

and

roller

assemblies

and the

bearing cups

should

be

replaced

as a

unit

if

damage

to either

is

encountered.

7. Thoroughly clean

the

spindle

and

the inside

of the hub

with solvent

to

remove

all old

lubricant.

Cover

the

spindle with

a

clean

cloth,

and

brush

all

loose dust

and

dirt from

the

brake assembly.

To

pre-

vent getting dirt

on the

spindle, care-

fully remove

the

cloth from

the

spindle.

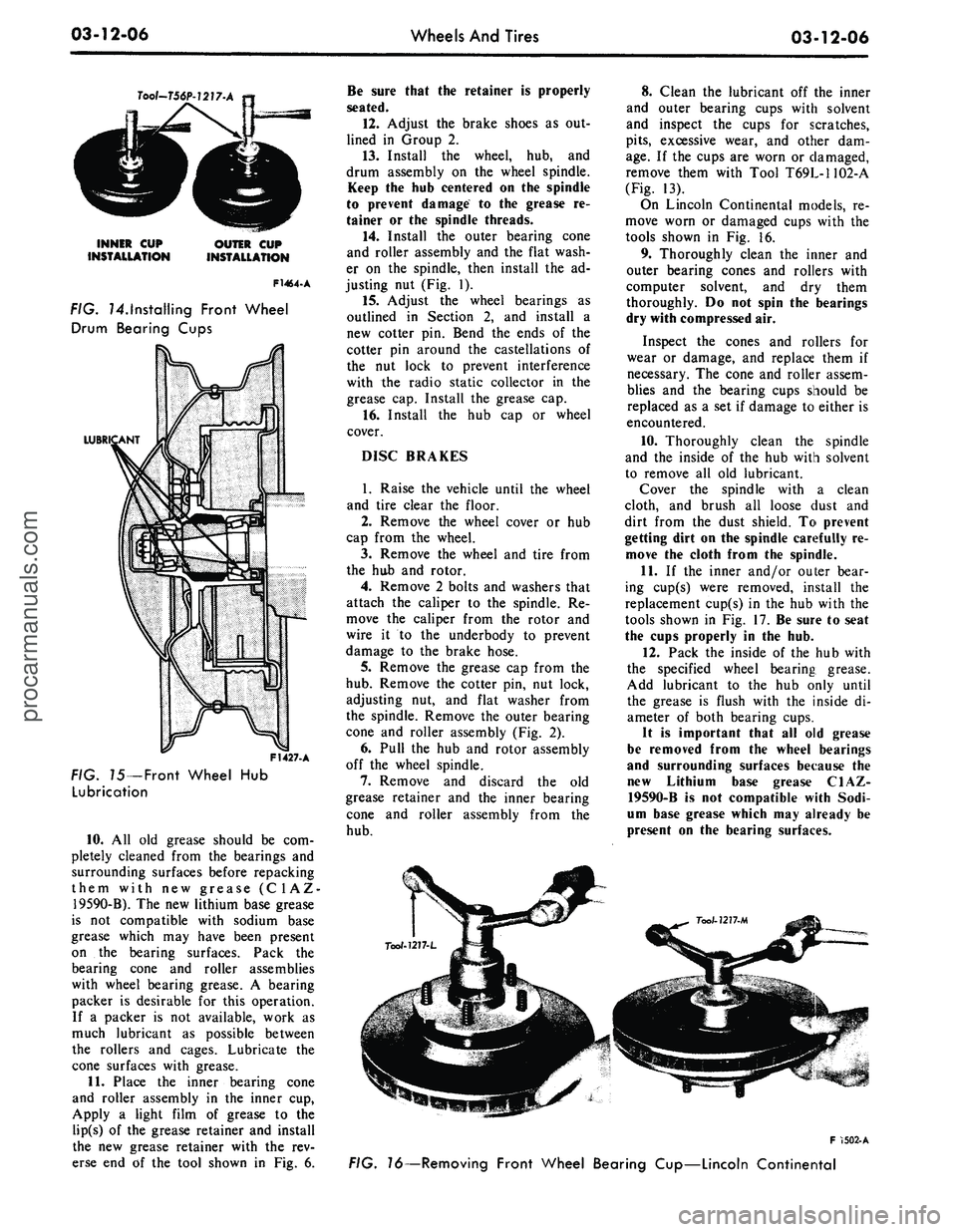

8.

If the

inner and/or outer bearing

cup(s) were removed, install

the re-

placement cup(s)

in the hub

with

the

tool shown

in Fig.

14.

Be

sure

to

seat

the cups properly

in the hub.

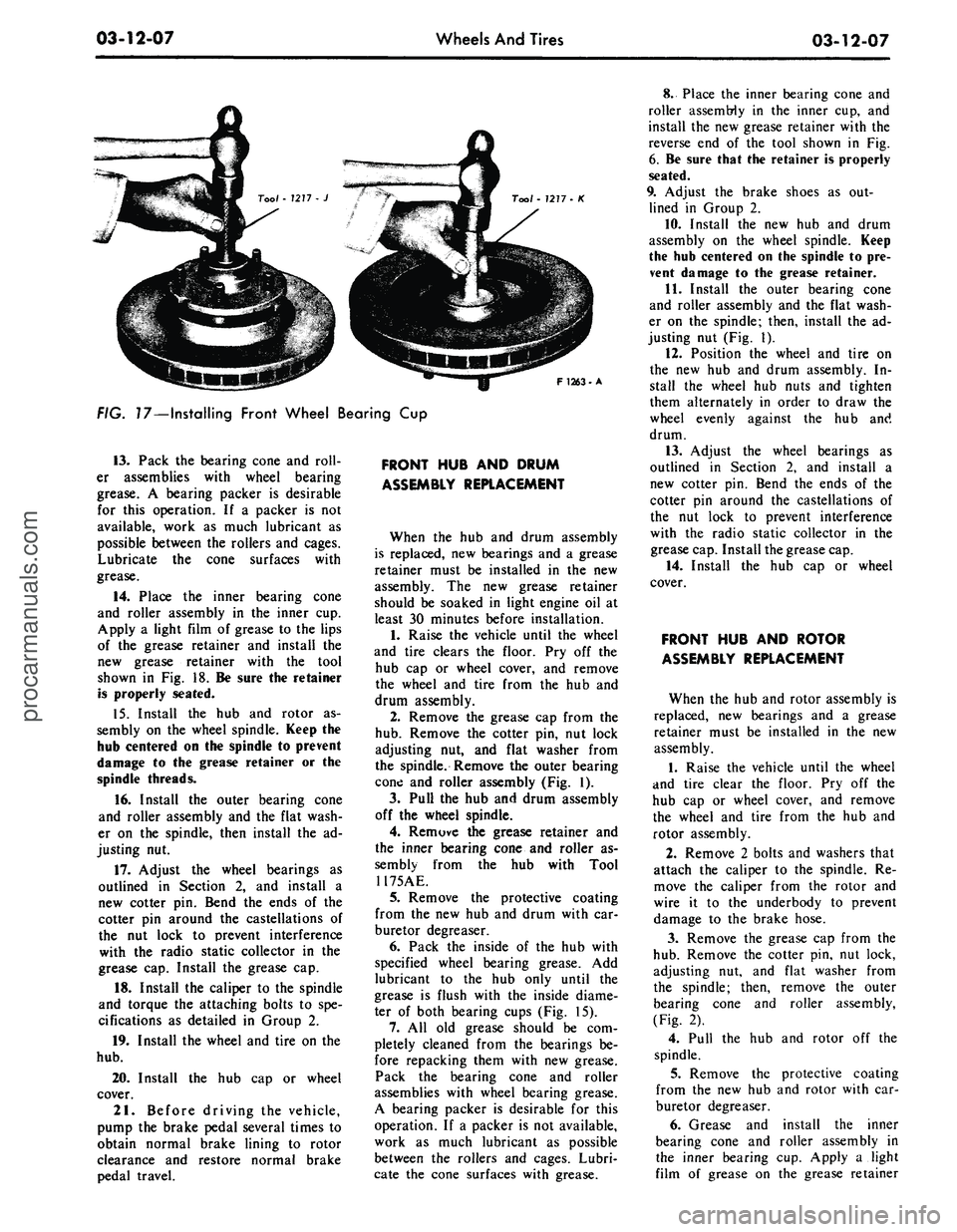

9. Pack

the

inside

of the hub

with

specified wheel bearing grease.

Add

lubricant

to the hub

only until

the

grease

is

flush with

the

inside diame-

ter

of

both bearing cups

(Fig.

15).procarmanuals.com

Page 177 of 413

03-12-06

Wheels And Tires

03-12-06

Tool-T56P-1217-A

INNER CUP

INSTALLATION

OUTER CUP

INSTALLATION

F1464-A

FIG. ^.Installing Front Wheel

Drum Bearing Cups

LUBR

F1427. A

FIG. 75—Front Wheel Hub

Lubrication

10.

All old grease should be com-

pletely cleaned from the bearings and

surrounding surfaces before repacking

them with new grease (C1AZ-

19590-B). The new lithium base grease

is not compatible with sodium base

grease which may have been present

on the bearing surfaces. Pack the

bearing cone and roller assemblies

with wheel bearing grease. A bearing

packer is desirable for this operation.

If a packer is not available, work as

much lubricant as possible between

the rollers and cages. Lubricate the

cone surfaces with grease.

11.

Place the inner bearing cone

and roller assembly in the inner cup,

Apply a light film of grease to the

lip(s) of the grease retainer and install

the new grease retainer with the rev-

erse end of the tool shown in Fig. 6.

Be sure that the retainer is properly

seated.

12.

Adjust the brake shoes as out-

lined in Group 2.

13.

Install the wheel, hub, and

drum assembly on the wheel spindle.

Keep the hub centered on the spindle

to prevent damage to the grease re-

tainer or the spindle threads.

14.

Install the outer bearing cone

and roller assembly and the flat wash-

er on the spindle, then install the ad-

justing nut (Fig. 1).

15.

Adjust the wheel bearings as

outlined in Section 2, and install a

new cotter pin. Bend the ends of the

cotter pin around the castellations of

the nut lock to prevent interference

with the radio static collector in the

grease cap. Install the grease cap.

16.

Install the hub cap or wheel

cover.

DISC BRAKES

1.

Raise the vehicle until the wheel

and tire clear the floor.

2.

Remove the wheel cover or hub

cap from the wheel.

3.

Remove the wheel and tire from

the hub and rotor.

4.

Remove 2 bolts and washers that

attach the caliper to the spindle. Re-

move the caliper from the rotor and

wire it to the underbody to prevent

damage to the brake hose.

5.

Remove the grease cap from the

hub.

Remove the cotter pin, nut lock,

adjusting nut, and flat washer from

the spindle. Remove the outer bearing

cone and roller assembly (Fig. 2).

6. Pull the hub and rotor assembly

off the wheel spindle.

7.

Remove and discard the old

grease retainer and the inner bearing

cone and roller assembly from the

hub.

8. Clean the lubricant off the inner

and outer bearing cups with solvent

and inspect the cups for scratches,

pits,

excessive wear, and other dam-

age.

If the cups are worn or damaged,

remove them with Tool T69L-1102-A

(Fig. 13).

On Lincoln Continental models, re-

move worn or damaged cups with the

tools shown in Fig. 16.

9. Thoroughly clean the inner and

outer bearing cones and rollers with

computer solvent, and dry them

thoroughly. Do not spin the bearings

dry with compressed air.

Inspect the cones and rollers for

wear or damage, and replace them if

necessary. The cone and roller assem-

blies and the bearing cups should be

replaced as a set if damage to either is

encountered.

10.

Thoroughly clean the spindle

and the inside of the hub with solvent

to remove all old lubricant.

Cover the spindle with a clean

cloth, and brush all loose dust and

dirt from the dust shield. To prevent

getting dirt on the spindle carefully re-

move the cloth from the spindle.

11.

If the inner and/or outer bear-

ing cup(s) were removed, install the

replacement cup(s) in the hub with the

tools shown in Fig. 17. Be sure to seat

the cups properly in the hub.

12.

Pack the inside of the hub with

the specified wheel bearing grease.

Add lubricant to the hub only until

the grease is flush with the inside di-

ameter of both bearing cups.

It is important that all old grease

be removed from the wheel bearings

and surrounding surfaces because the

new Lithium base grease C1AZ-

19590-B is not compatible with Sodi-

um base grease which may already be

present on the bearing surfaces.

F 1502-A

FIG. 16—Removing Front Wheel Bearing Cup—Lincoln Continentalprocarmanuals.com

Page 178 of 413

03-12-07

Wheels And Tires

03-12-07

Tool - 7277- K

F 1263-A

FIG. 17—Installing Front Wheel Bearing Cup

13.

Pack the bearing cone and roll-

er assemblies with wheel bearing

grease. A bearing packer is desirable

for this operation. If a packer is not

available, work as much lubricant as

possible between the rollers and cages.

Lubricate the cone surfaces with

grease.

14.

Place the inner bearing cone

and roller assembly in the inner cup.

Apply a light film of grease to the lips

of the grease retainer and install the

new grease retainer with the tool

shown in Fig. 18. Be sure the retainer

is properly seated.

15.

Install the hub and rotor as-

sembly on the wheel spindle. Keep the

hub centered on the spindle to prevent

damage to the grease retainer or the

spindle threads.

16.

Install the outer bearing cone

and roller assembly and the flat wash-

er on the spindle, then install the ad-

justing nut.

17.

Adjust the wheel bearings as

outlined in Section 2, and install a

new cotter pin. Bend the ends of the

cotter pin around the castellations of

the nut lock to prevent interference

with the radio static collector in the

grease cap. Install the grease cap.

18.

Install the caliper to the spindle

and torque the attaching bolts to spe-

cifications as detailed in Group 2.

19.

Install the wheel and tire on the

hub.

20.

Install the hub cap or wheel

cover.

21.

Before driving the vehicle,

pump the brake pedal several times to

obtain normal brake lining to rotor

clearance and restore normal brake

pedal travel.

FRONT HUB AND DRUM

ASSEMBLY REPLACEMENT

When the hub and drum assembly

is replaced, new bearings and a grease

retainer must be installed in the new

assembly. The new grease retainer

should be soaked in light engine oil at

least 30 minutes before installation.

1.

Raise the vehicle until the wheel

and tire clears the floor. Pry off the

hub cap or wheel cover, and remove

the wheel and tire from the hub and

drum assembly.

2.

Remove the grease cap from the

hub.

Remove the cotter pin, nut lock

adjusting nut, and flat washer from

the spindle. Remove the outer bearing

cone and roller assembly (Fig. 1).

3.

Pull the hub and drum assembly

off the wheel spindle.

4.

Remuve the grease retainer and

the inner bearing cone and roller as-

sembly from the hub with Tool

1175AE.

5.

Remove the protective coating

from the new hub and drum with car-

buretor degreaser.

6. Pack the inside of the hub with

specified wheel bearing grease. Add

lubricant to the hub only until the

grease is flush with the inside diame-

ter of both bearing cups (Fig. 15).

7.

All old grease should be com-

pletely cleaned from the bearings be-

fore repacking them with new grease.

Pack the bearing cone and roller

assemblies with wheel bearing grease.

A bearing packer is desirable for this

operation. If a packer is not available,

work as much lubricant as possible

between the rollers and cages. Lubri-

cate the cone surfaces with grease.

8. Place the inner bearing cone and

roller assembly in the inner cup, and

install the new grease retainer with the

reverse end of the tool shown in Fig.

6. Be sure that the retainer is properly

seated.

9. Adjust the brake shoes as out-

lined in Group 2.

10.

Install the new hub and drum

assembly on the wheel spindle. Keep

the hub centered on the spindle to pre-

vent damage to the grease retainer.

11.

Install the outer bearing cone

and roller assembly and the flat wash-

er on the spindle; then, install the ad-

justing nut (Fig. 1).

12.

Position the wheel and tire on

the new hub and drum assembly. In-

stall the wheel hub nuts and tighten

them alternately in order to draw the

wheel evenly against the hub and

drum.

13.

Adjust the wheel bearings as

outlined in Section 2, and install a

new cotter pin. Bend the ends of the

cotter pin around the castellations of

the nut lock to prevent interference

with the radio static collector in the

grease cap. Install the grease cap.

14.

Install the hub cap or wheel

cover.

FRONT HUB AND ROTOR

ASSEMBLY REPLACEMENT

When the hub and rotor assembly is

replaced, new bearings and a grease

retainer must be installed in the new

assembly.

1.

Raise the vehicle until the wheel

and tire clear the floor. Pry off the

hub cap or wheel cover, and remove

the wheel and tire from the hub and

rotor assembly.

2.

Remove 2 bolts and washers that

attach the caliper to the spindle. Re-

move the caliper from the rotor and

wire it to the underbody to prevent

damage to the brake hose.

3.

Remove the grease cap from the

hub.

Remove the cotter pin, nut lock,

adjusting nut, and flat washer from

the spindle; then, remove the outer

bearing cone and roller assembly,

(Fig. 2).

4.

Pull the hub and rotor off the

spindle.

5.

Remove the protective coating

from the new hub and rotor with car-

buretor degreaser.

6. Grease and install the inner

bearing cone and roller assembly in

the inner bearing cup. Apply a light

film of grease on the grease retainerprocarmanuals.com

Page 179 of 413

03-12-08

Wheels And Tires

03-12-08

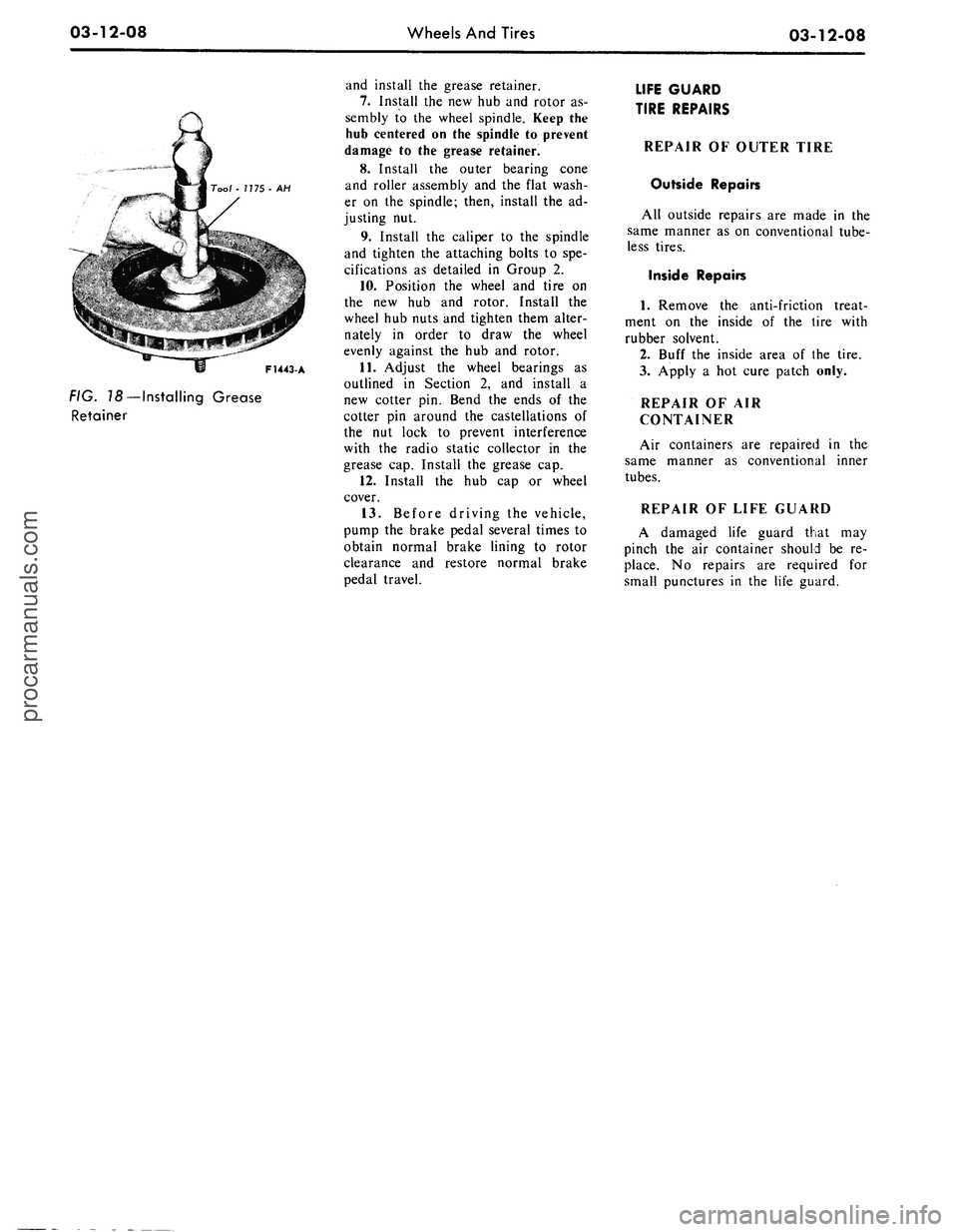

Tool -

7

775 - AH

F1443-A

FIG.

18

— Installing Grease

Retainer

and install the grease retainer.

7.

Install the new hub and rotor as-

sembly to the wheel spindle. Keep the

hub centered on the spindle to prevent

damage to the grease retainer.

8. Install the outer bearing cone

and roller assembly and the flat wash-

er on the spindle; then, install the ad-

justing nut.

9. Install the caliper to the spindle

and tighten the attaching bolts to spe-

cifications as detailed in Group 2.

10.

Position the wheel and tire on

the new hub and rotor. Install the

wheel hub nuts and tighten them alter-

nately in order to draw the wheel

evenly against the hub and rotor.

11.

Adjust the wheel bearings as

outlined in Section 2, and install a

new cotter pin. Bend the ends of the

cotter pin around the castellations of

the nut lock to prevent interference

with the radio static collector in the

grease cap. Install the grease cap.

12.

Install the hub cap or wheel

cover.

13.

Before driving the vehicle,

pump the brake pedal several times to

obtain normal brake lining to rotor

clearance and restore normal brake

pedal travel.

LIFE GUARD

TIRE REPAIRS

REPAIR OF OUTER TIRE

Outside Repairs

All outside repairs are made in the

same manner as on conventional tube-

less tires.

Inside Repairs

1.

Remove the anti-friction treat-

ment on the inside of the tire with

rubber solvent.

2.

Buff the inside area of the tire.

3.

Apply a hot cure patch only.

REPAIR OF AIR

CONTAINER

Air containers are repaired in the

same manner as conventional inner

tubes.

REPAIR OF LIFE GUARD

A damaged life guard that may

pinch the air container should be re-

place. No repairs are required for

small punctures in the life guard.procarmanuals.com

Page 181 of 413

03-13-02

Specifications

03-13-02

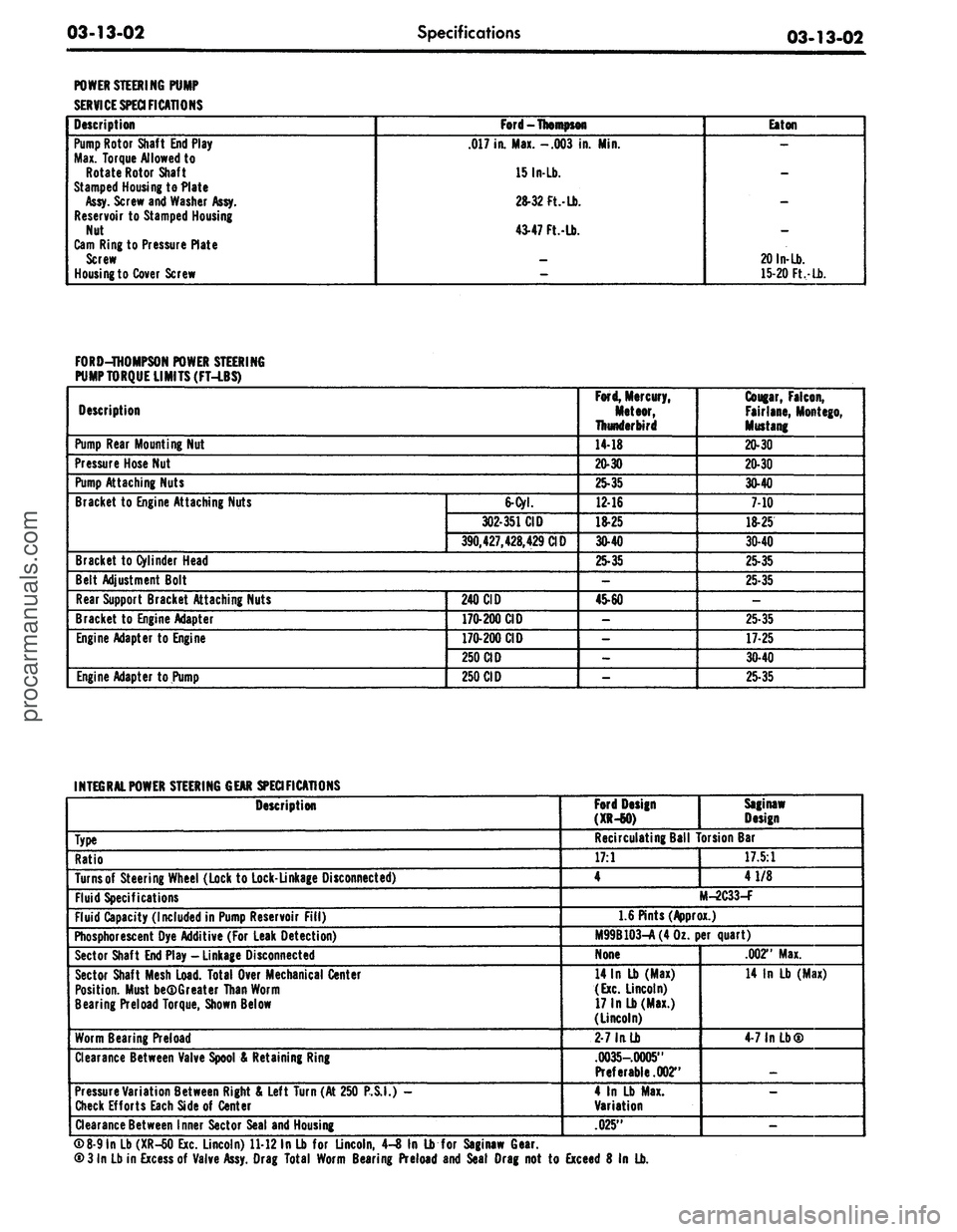

POWER STEERING PUMP

SERVICE

SPECIFICATIONS

Description

Pump Rotor Shaft End Play

Max. Torque Allowed

to

Rotate Rotor Shaft

Stamped Housing to Plate

Assy. Screw and Washer Assy.

Reservoir

to

Stamped Housing

Nut

Cam Ring to Pressure Plate

Screw

Housing to Cover Screw

Ford-Thompson

.017 in. Max.-.003 in. Min.

15 In-Lb.

28-32 Ft.-Lb.

43-47 Ft.-Lb.

_

-

Eaton

—

_

-

—

20 In-Lb.

15-20 Ft,-Lb.

FORD-THOMPSON POWER STEERING

PUMP

TORQUE

LIMITS (FT-LBS)

Description

Pump Rear Mounting Nut

Pressure Hose Nut

Pump Attaching Nuts

Bracket

to

Engine Attaching Nuts

6-Cyl.

302-351 CID

390,427,428,429 CID

Bracket

to

Cylinder Head

Belt Adjustment Bolt

Rear Support Bracket Attaching Nuts

Bracket

to

Engine Adapter

Engine Adapter

to

Engine

Engine Adapter

to

Pump

240 CID

170-200 CID

170-200 CID

250 CID

250 CID

Ford,

Mercury,

Meteor,

Thunderbird

14-18

20-30

25-35

1216

18-25

30-40

25-35

-

45-60

-

-

-

-

Cougar, Falcon,

Fairlane, Montego,

Mustang

20-30

20-30

30-40

7-10

18-25

30-40

25-35

25-35

-

25-35

17-25

30-40

25-35

INTEGRAL

POWER

STEERING GEAR SPECIFICATIONS

Description

Type

Ratio

Turns of Steering Wheel (Lock

to

Lock-Linkage Disconnected)

Fluid Specifications

Fluid Capacity (Included in Pump Reservoir Fill)

Phosphorescent Dye Additive (For Leak Detection)

Sector Shaft End Play -Linkage Disconnected

Sector Shaft Mesh Load. Total Over Mechanical Center

Position.

Must beCDGreater Than Worm

Bearing Preload Torque, Shown Below

Worm Bearing Preload

Clearance Between Valve Spool

&

Retaining Ring

Pressure Variation Between Right

&

Left Turn (At 250

P.S.I.)

-

Check Efforts Each Side

of

Center

Clearance Between Inner Sector Seal and Housing

Ford Design

(XR-«0)

Saginaw

Design

Recirculating Ball Torsion Bar

17:1

4

17.5:1

41/8

M-2C33-F

1.6 Pints (Approx.)

M99B103-A(4 0z. per quart)

None

14 In Lb (Max)

(Exc. Lincoln)

17

In

Lb (Max.)

(Lincoln)

2-7 la

U)

.0035-.0005"

Preferable .002"

4

In

Lb Max.

Variation

.025"

.002"

Max.

14

In

Lb (Max)

4-7 In Lb®

_

—

-

©8-9 In Lb (XR-50 Exc. Lincoln) 11-12 In Lb

for

Uncoln,

4-8 In

Lb

for

Saginaw Gear.

® 3 In Lb in Excess of Valve Assy. Drag Total Worm Bearing Preload and Seal Drag

not to

Exceed

8 In

Lb.procarmanuals.com

Page 182 of 413

03-13-03

Specifications

03-13-03

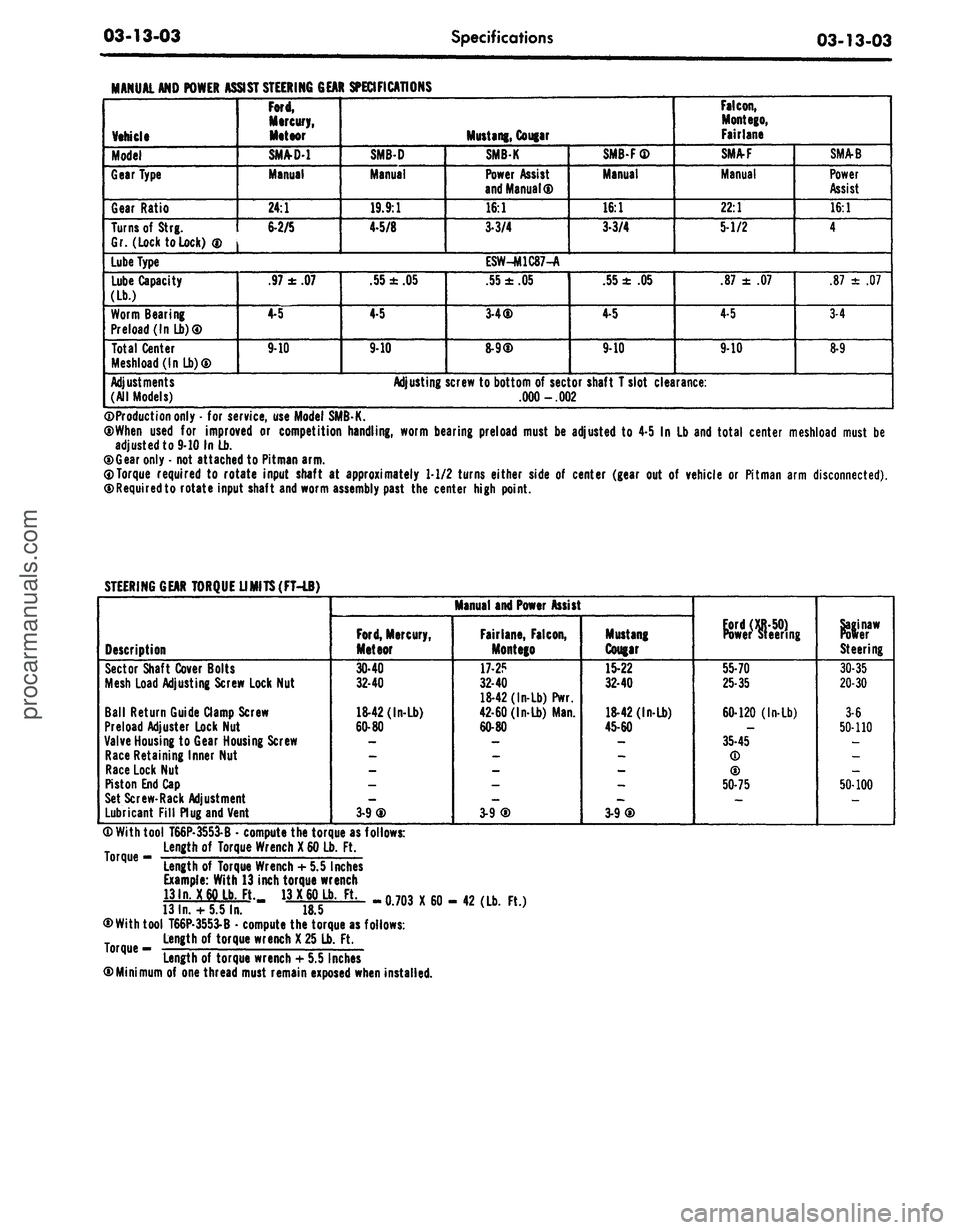

MANUAL AND POWER

Vehicle

Model

Gear Type

Gear Ratio

Turns of

Strg.

Gr. (Lock to Lock)

®

Lube Type

Lube Capacity

(Lb.)

Worm Bearing

Preload (In Lb)®

Total Center

Meshload(lnLb)®

Adjustments

(All Models)

ASSIST STEERING GEAR SPECIFICATIONS

Ford,

Mercury,

Meteor

SM/VD-1

Manual

24:1

6-2/5

.97

±

.07

4-5

9-10

SMB-D

Manual

19.9:1

4-5/8

.55

±

.05

4-5

9-10

Adjusting

Mustang, Cougar

SMBK

Power Assist

and Manual®

16:1

3-3/4

ESW-M1C87-A

.55

±

.05

3-4®

8-9®

screw to bottom

of

sector

.000 -.002

SMB-F®

Manual

16:1

3-3/4

.55

±

.05

4-5

9-10

shaft T slot clearance:

Falcon,

Mont ego,

Fairlane

SMA-F

Manual

22:1

5-1/2

.87

±

.07

4-5

9-10

SMA-B

Power

Assist

16:1

4

.87

±

.07

3-4

8-9

©Production only

-

for service, use Model SMB-K.

®When used

for

improved

or

competition handling, worm bearing preload must

be

adjusted

to

4-5

In

Lb and total center meshload must

be

adjusted to 9-10 In Lb.

®Gear only

-

not attached to Pitman arm.

0Torque required

to

rotate input shaft

at

approximately 1-1/2 turns either side

of

center (gear

out of

vehicle

or

Pitman arm disconnected).

©Requiredto rotate input shaft and worm assembly past

the

center high point.

STEERING GEAR TORQUE UMITS(FT-LB)

Description

Sector Shaft Cover Bolts

Mesh Load Adjusting Screw Lock Nut

Ball Return Guide Clamp Screw

Preload Adjuster Lock Nut

Valve Housing

to

Gear Housing Screw

Race Retaining Inner Nut

Race Lock Nut

Piston End Cap

Set Screw-Rack Adjustment

Lubricant Fill Plug and Vent

Manual and Power Assist

Ford,

Mercury,

Meteor

30-40

32-40

18-42 (In-Lb)

60-80

3-9®

Fairlane, Falcon,

Montego

17-2?

32-40

18-42 (In-Lb) Pwr.

42-60 (In-Lb) Man.

60-80

3-9®

Mustang

Cougar

15-22

32-40

18-42 (In-Lb)

45-60

3-9®

Power steering

55-70

25-35

60-120 (In-Lb)

35-45

(D

®

50-75

Steering

30-35

20-30

3-6

50-110

50-100

® With tool T66P-3553-B

•

compute the torque as follows:

Length

of

Torque Wrench

X

60 Lb.

Ft.

°rque

"

Length

of

Torque Wrench

+

5.5 Inches

Example: With 13 inch torque wrench

13ln.

X

60 Lb. Ft. 13

X

60 Lb.

Ft.

13

In.

+

5.5 In.

18.5

®With tool T66P-3553-B

•

compute the torque as follows:

Length

of

torque wrench

X

25 Lb.

Ft.

Length of torque wrench

+

5.5 Inches

©Minimum

of

one thread must remain exposed when installed.

-0.703 X60- 42 (Lb.

Ft.)procarmanuals.com

Page 183 of 413

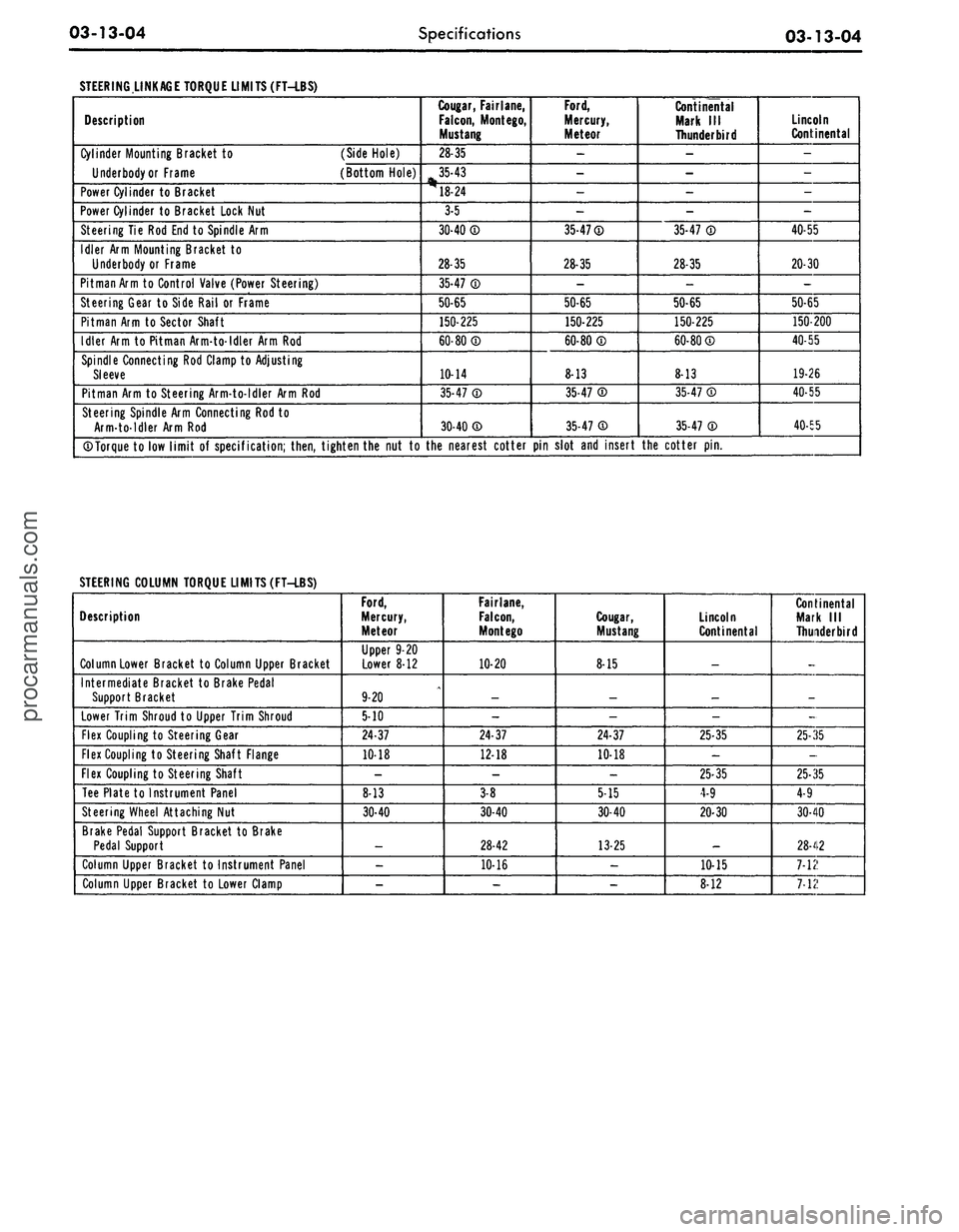

03-13-04

Specifications

03-13-04

STEERING LINKAGE TORQUE LIMITS (FT-LBS)

Description

Cylinder Mounting Bracket

to

(Side Hole)

Underbodyor Frame (Bottom Hole)

Power Cylinder

to

Bracket

Power Cylinder

to

Bracket Lock

Nut

Steering

Tie Rod End to

Spindle

Arm

Idler

Arm

Mounting Bracket

to

Underbody

or

Frame

Pitman Arm

to

Control Valve (Power Steering)

Steering Gear

to

Side Rail

or

Frame

Pitman

Arm to

Sector Shaft

Idler

Arm to

Pitman Arm-to-ldler

Arm Rod

Spindle Connecting

Rod

Clamp

to

Adjusting

Sleeve

Pitman

Arm to

Steering Arm-to-ldler

Arm Rod

Steering Spindle

Arm

Connecting

Rod to

Arm-to-ldler

Arm Rod

Cougar, Fairlane,

Falcon,

Mont

ego,

Mustang

28-35

35-43

18-24

3-5

30-40

©

28-35

35-47

©

50-65

150-225

60-80®

10-14

35-47

©

30-40

©

Ford,

Mercury,

Meteor

-

-

-

-

35-47®

28-35

-

50-65

150-225

60-80

®

8-13

35-47

©

35-47

®

Continental

Mark

III

Thunder bird

-

-

-

-

35-47

©

28-35

-

50-65

150-225

60-80

©

8-13

35-47

©

35-47

©

Lincoln

Continental

-

-

-

-

40-55

20-30

-

50-65

150-200

40-55

19-26

40-55

40-55

CD

Torque

to low

limit

of

specification;

then,

tighten

the nut to the

nearest cotter

pin

slot

and

insert

the

cotter

pin.

STEERING COLUMN TORQUE LIMITS (FT-LBS)

Description

Column Lower Bracket

to

Column Upper Bracket

Intermediate Bracket

to

Brake Pedal

Support Bracket

Lower Trim Shroud

to

Upper Trim Shroud

Flex Coupling

to

Steering Gear

Flex Coupling

to

Steering Shaft Flange

Flex Coupling

to

Steering Shaft

Tee Plate

to

Instrument Panel

Steering Wheel Attaching

Nut

Brake Pedal Support Bracket

to

Brake

Pedal Support

Column Upper Bracket

to

Instrument Panel

Column Upper Bracket

to

Lower Clamp

Ford,

Mercury,

Meteor

Upper

9-20

Lower

8-12

9-20

5-10

24-37

10-18

-

8-13

30-40

_

-

-

Fairlane,

Falcon,

Mont

ego

10-20

_

-

24-37

12-18

-

3-8

30-40

28-42

10-16

-

Cougar,

Mustang

8-15

_

-

24-37

10-18

-

5-15

30-40

13-25

-

-

Lincoln

Continental

_

_

-

25-35

-

25-35

4-9

20-30

_

10-15

8-12

Continental

Mark

III

Thunder bird

_

_

-

25-35

-

25-35

4-9

30-40

28-42

7-12

7-1?procarmanuals.com

Page 184 of 413

03-13-05

Specifications

03-13-05

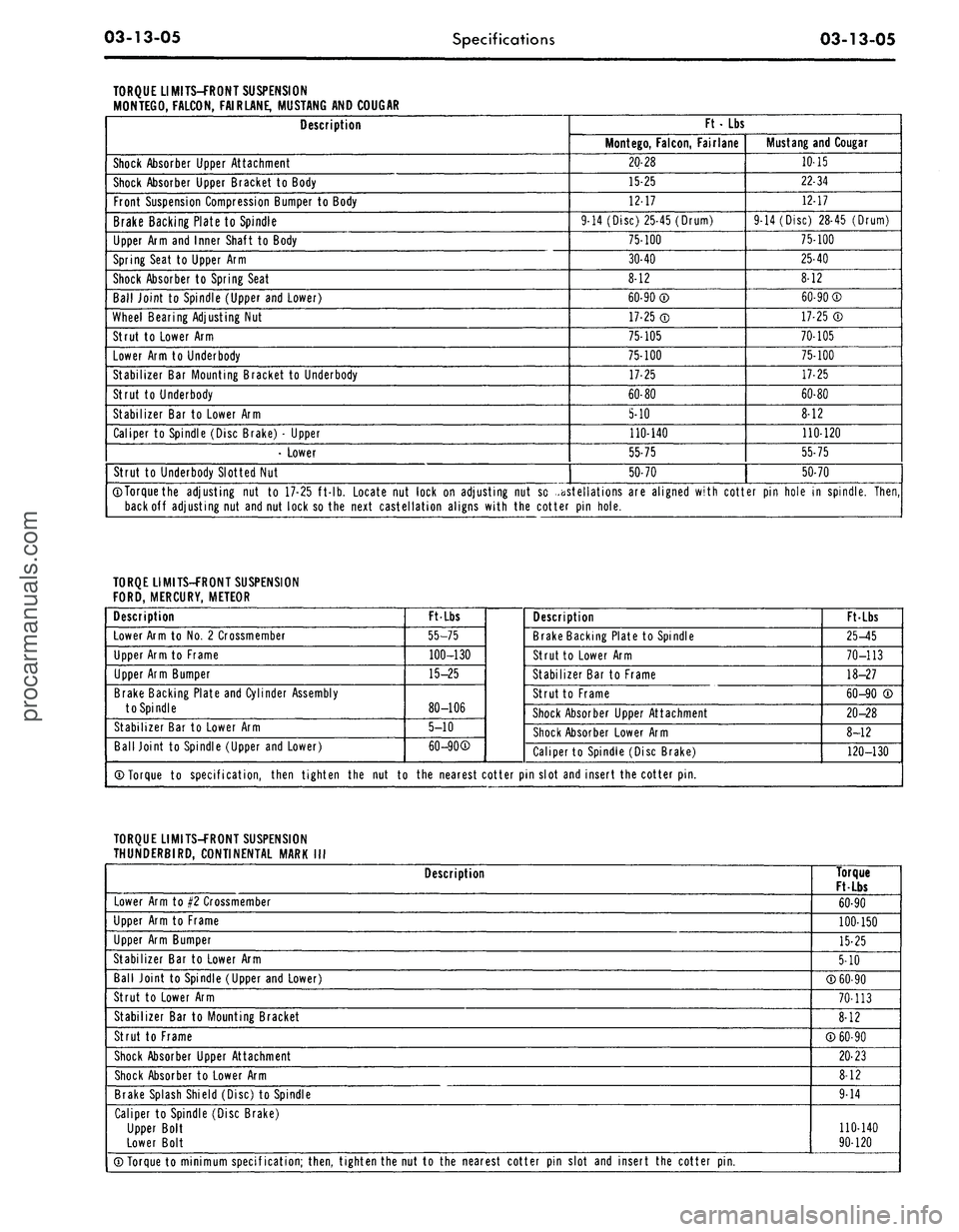

TORQUE LIMITS-FRONT SUSPENSION

MONTEGO, FALCON,

FAIR

LANE,

MUSTANG AND COUGAR

Description

Shock Absorber Upper Attachment

Shock Absorber Upper Bracket to Body

Front Suspension Compression Bumper to Body

Brake Backing Plate to Spindle

Upper Arm and Inner Shaft to Body

Spring Seat to Upper Arm

Shock Absorber to Spring Seat

Ball Joint to Spindle (Upper and Lower)

Wheel Bearing Adjusting Nut

Strut to Lower Arm

Lower Arm to Underbody

Stabilizer Bar Mounting Bracket to Underbody

Strut to Underbody

Stabilizer Bar to Lower Arm

Caliper to Spindle (Disc Brake) • Upper

- Lower

Strut to Underbody Slotted Nut

Ft • Lbs

Montego, Falcon, Fairlane

20-28

15-25

12-17

9-14 (Disc) 25-45 (Drum)

75-100

30-40

8-12

60-90 ©

17-25 ©

75-105

75-100

17-25

60-80

5-10

110-140

55-75

Mustang and Cougar

10-15

22-34

12-17

9-14 (Disc) 28-45 (Drum)

75-100

25-40

8-12

60-90 ©

17-25 ©

70-105

75-100

17-25

60-80

8-12

110-120

55-75

50-70 | 50-70

©Torquethe adjusting nut to 17-25 ft-lb. Locate nut lock on adjusting nut so ,ctstellations are aligned with cotter pin hole in spindle. Then,

backoff adjusting nut and nut lock so the next castellation aligns with the cotter pin hole.

TORQE LIMITS-fRONT SUSPENSION

FORD,

MERCURY, METEOR

Description

Lower Arm to No. 2 Crossmember

Upper Arm to Frame

Upper Arm Bumper

Brake Backing Plate and Cylinder Assembly

to Spindle

Stabilizer Bar to Lower Arm

Ball Joint to Spindle (Upper and Lower)

Ft Lbs

55-75

100-130

15-25

80-106

5-10

60-90®

Description

Brake Backing Plate to Spindle

Strut to Lower Arm

Stabilizer Bar to Frame

Strut to Frame

Shock Absorber Upper Attachment

Shock Absorber Lower Arm

Caliper to Spindle (Disc Brake)

Ft-Lbs

25-45

70-113

18-27

60-90 ©

20-28

8 12

120-130

©Torque to specification, then tighten the nut to the nearest cotter pin slot and insert the cotter pin.

TORQUE LIMITS-FRONT SUSPENSION

THUNDERBIRD, CONTINENTAL MARK

Description

Lower Arm to #2 Crossmember

Upper Arm to Frame

Upper Arm Bumper

Stabilizer Bar to Lower Arm

Ball Joint to Spindle (Upper and Lower)

Strut to Lower Arm

Stabilizer Bar to Mounting Bracket

Strut to Frame

Shock Absorber Upper Attachment

Shock Absorber to Lower Arm

Brake Splash Shield (Disc) to Spindle

Caliper to Spindle (Disc Brake)

Upper Bolt

Lower Bolt

Torque

Ft-Lbs

60-90

100-150

15-25

5-10

©60-90

70-113

8-12

©60-90

20-23

8-12

9-14

110-140

90-120

©Torque to minimum specification;

then,

tighten the nut to the nearest cotter pin slot and insert the cotter pin.procarmanuals.com

Page 187 of 413

03-13-08

Specifications

03-13-08

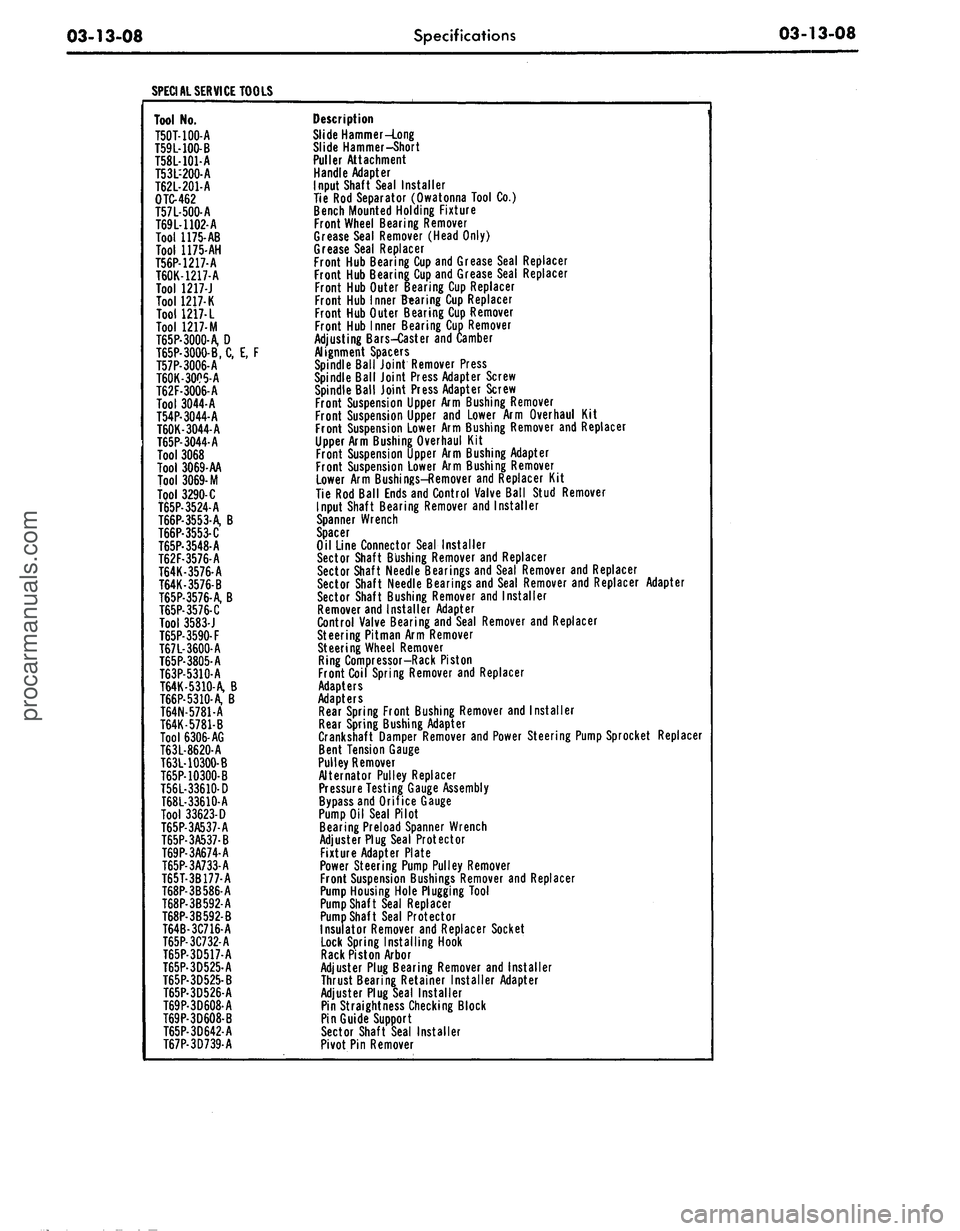

SPECIAL SERVICE TOOLS

Tool No.

T50T-100-A

T59L-100-B

T58L-101-A

T53L-200-A

T62L-201-A

OTC-462

T57L-500-A

T69L-1102-A

Tool 1175-AB

Tool 1175-AH

T56P-1217-A

T60K-1217-A

Tool 1217-J

Tool 1217-K

Tool

1217- L

Tool 1217-M

T65P-3000-A, D

T65P-3000-B, C, E, F

T57P-3006-A

T60K-3005-A

T62F-3006-A

Tool 3044-A

T54P-3044-A

T60K-3044-A

T65P-3044-A

Tool 3068

Tool 3069-AA

Tool

3069-

M

Tool 3290-C

T65P-3524-A

T66P-3553-A, B

T66P-3553-C

T65P-3548-A

T62F-3576-A

T64K-3576-A

T64K-3576-B

T65P-3576-A, B

T65P-3576-C

Tool 3583-J

T65P-3590-F

T67L-3600-A

T65P-3805-A

T63P-5310-A

T64K-5310-A, B

T66P-5310-A, B

T64N-5781-A

T64K-5781-B

Tool 6306-AG

T63L-8620-A

T63L-10300-B

T65P-10300-B

T56L-33610-D

T68L-33610-A

Tool 33623-D

T65P-3A537-A

T65P-3A537-B

T69P-3A674-A

T65P-3A733-A

T65T-3B177-A

T68P-3B586-A

T68P-3B592-A

T68P-3B592-B

T64B-3C716-A

T65P-3C732-A

T65P-3D517-A

T65P-3D525-A

T65P-3D525-B

T65P-3D526-A

T69P-3D608-A

T69P-3D608-B

T65P-3D642-A

T67P-3D739-A

Description

Slide Hammer-Long

Slide Hammer-Short

Puller Attachment

Handle Adapter

Input Shaft Seal Installer

Tie Rod Separator (Owatonna Tool Co.)

Bench Mounted Holding Fixture

Front Wheel Bearing Remover

Grease Seal Remover (Head Only)

Grease Seal Replacer

Front Hub Bearing Cup and Grease Seal Replacer

Front Hub Bearing Cup and Grease Seal Replacer

Front Hub Outer Bearing Cup Replacer

Front Hub Inner Bearing Cup Replacer

Front Hub Outer Bearing Cup Remover

Front Hub Inner Bearing Cup Remover

Adjusting Bars-Caster and Camber

Alignment Spacers

Spindle Ball Joint Remover Press

Spindle Ball Joint Press Adapter Screw

Spindle Ball Joint Press Adapter Screw

Front Suspension Upper Arm Bushing Remover

Front Suspension Upper and Lower Arm Overhaul Kit

Front Suspension Lower Arm Bushing Remover and Replacer

Upper Arm Bushing Overhaul Kit

Front Suspension Upper Arm Bushing Adapter

Front Suspension Lower Arm Bushing Remover

Lower Arm Bushings-Remover and Replacer Kit

Tie Rod Ball Ends and Control Valve Ball Stud Remover

Input Shaft Bearing Remover and Installer

Spanner Wrench

Spacer

Oil Line Connector Seal Installer

Sector Shaft Bushing Remover and Replacer

Sector Shaft Needle Bearings and Seal Remover and Replacer

Sector Shaft Needle Bearings and Seal Remover and Replacer Adapter

Sector Shaft Bushing Remover and Installer

Remover and Installer Adapter

Control Valve Bearing and Seal Remover and Replacer

Steering Pitman Arm Remover

Steering Wheel Remover

Ring Compressor-Rack Piston

Front Coil Spring Remover and Replacer

Adapters

Adapters

Rear Spring Front Bushing Remover and Installer

Rear Spring Bushing Adapter

Crankshaft Damper Remover and Power Steering Pump Sprocket Replacer

Bent Tension Gauge

Pulley Remover

Alternator Pulley Replacer

Pressure Testing Gauge Assembly

Bypass and Orifice Gauge

Pump Oil Seal Pilot

Bearing Preload Spanner Wrench

Adjuster Plug Seal Protector

Fixture Adapter Plate

Power Steering Pump Pulley Remover

Front Suspension Bushings Remover and Replacer

Pump Housing Hole Plugging Tool

Pump Shaft Seal Replacer

Pump Shaft Seal Protector

Insulator Remover and Replacer Socket

Lock Spring Installing Hook

Rack Piston Arbor

Adjuster Plug Bearing Remover and Installer

Thrust Bearing Retainer Installer Adapter

Adjuster Plug Seal Installer

Pin Straightness Checking Block

Pin Guide Support

Sector Shaft Seal Installer

Pivot Pin Removerprocarmanuals.com