GEELY MK 2008 Workshop Manual

Manufacturer: GEELY, Model Year: 2008, Model line: MK, Model: GEELY MK 2008Pages: 416, PDF Size: 25.19 MB

Page 311 of 416

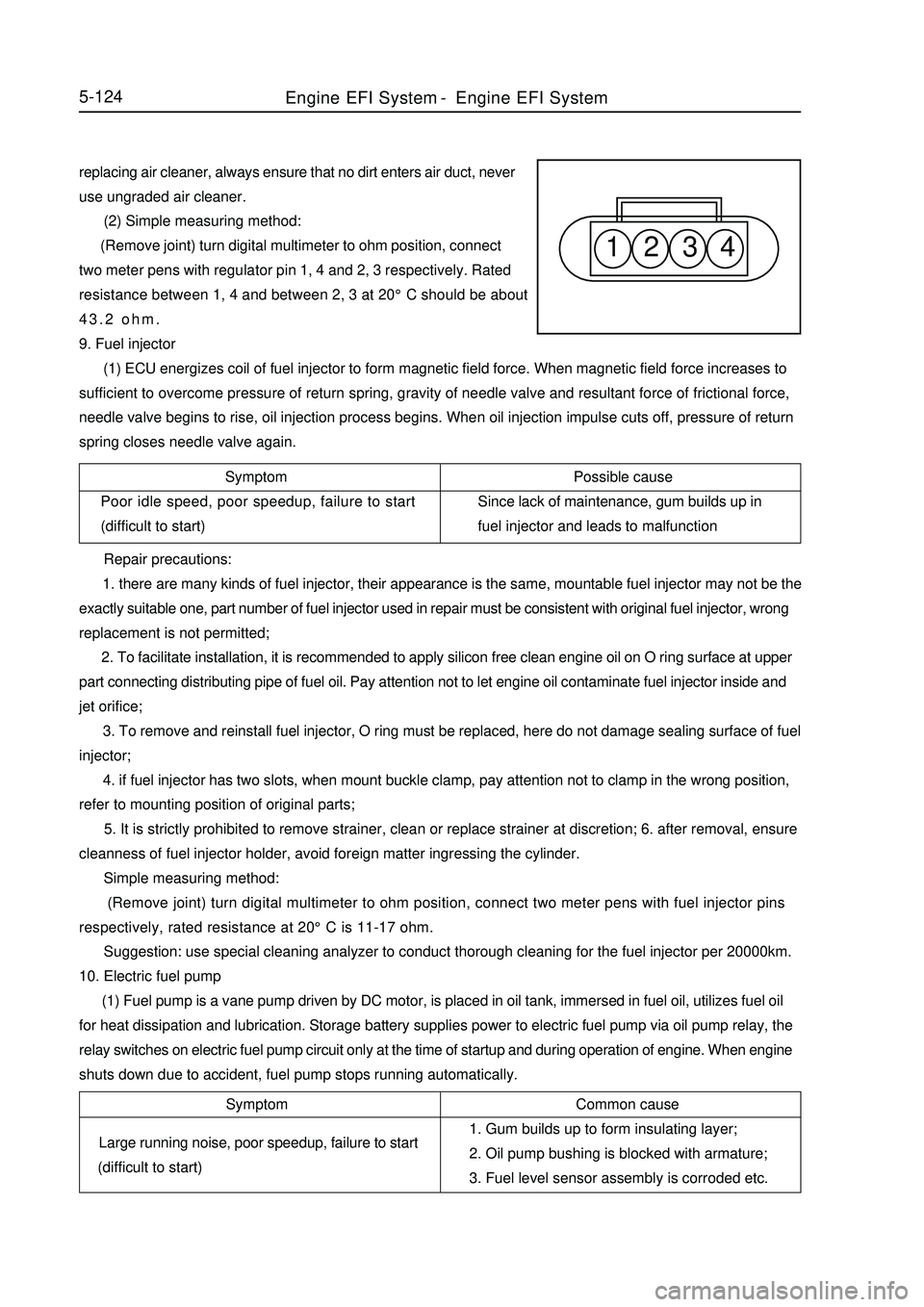

1 2 3 45-124replacing air cleaner, always ensure that no dirt enters air duct, never

use ungraded air cleaner.

(2) Simple measuring method:

(Remove joint) turn digital multimeter to ohm position, connect

two meter pens with regulator pin 1, 4 and 2, 3 respectively. Rated

resistance between 1, 4 and between 2, 3 at 20°C should be about

43.2 ohm.

9. Fuel injector

(1) ECU energizes coil of fuel injector to form magnetic field force. When magnetic field force increases to

sufficient to overcome pressure of return spring, gravity of needle valve and resultant force of frictional force,

needle valve begins to rise, oil injection process begins. When oil injection impulse cuts off, pressure of return

spring closes needle valve again.

Symptom

Poor idle speed, poor speedup, failure to start

(difficult to start)Possible cause

Since lack of maintenance, gum builds up in

fuel injector and leads to malfunction

Repair precautions:

1. there are many kinds of fuel injector, their appearance is the same, mountable fuel injector may not be the

exactly suitable one, part number of fuel injector used in repair must be consistent with original fuel injector, wrong

replacement is not permitted;

2. To facilitate installation, it is recommended to apply silicon free clean engine oil on O ring surface at upper

part connecting distributing pipe of fuel oil. Pay attention not to let engine oil contaminate fuel injector inside and

jet orifice;

3. To remove and reinstall fuel injector, O ring must be replaced, here do not damage sealing surface of fuel

injector;

4. if fuel injector has two slots, when mount buckle clamp, pay attention not to clamp in the wrong position,

refer to mounting position of original parts;

5. It is strictly prohibited to remove strainer, clean or replace strainer at discretion; 6. after removal, ensure

cleanness of fuel injector holder, avoid foreign matter ingressing the cylinder.

Simple measuring method:

(Remove joint) turn digital multimeter to ohm position, connect two meter pens with fuel injector pins

respectively, rated resistance at 20°C is 11-17 ohm.

Suggestion: use special cleaning analyzer to conduct thorough cleaning for the fuel injector per 20000km.

10. Electric fuel pump

(1) Fuel pump is a vane pump driven by DC motor, is placed in oil tank, immersed in fuel oil, utilizes fuel oil

for heat dissipation and lubrication. Storage battery supplies power to electric fuel pump via oil pump relay, the

relay switches on electric fuel pump circuit only at the time of startup and during operation of engine. When engine

shuts down due to accident, fuel pump stops running automatically.Symptom

Large running noise, poor speedup, failure to start

(difficult to start)Common cause

1. Gum builds up to form insulating layer;

2. Oil pump bushing is blocked with armature;

3. Fuel level sensor assembly is corroded etc.Engine EFI System-Engine EFI System

Page 312 of 416

Symptom

Poor idle speed, malfunction etc

Symptom

Fail to start5-125 Repair precautions:

1. according to engine requirement, electric fuel pumps with different flows are available, they have the same

appearance, mountable fuel pump may not be exactly suitable, during repair, part number of fuel pump used must

be consistent with original one, wrong replacement is not permitted;

2. in order to prevent fuel pump from damaging, please do not run it in dry state for a long time;

3. in case fuel pump needs to be replaced, please pay attention to clean fuel tank and pipeline and replace fuel

filter.

(2) Simple measuring method:

(Remove joint) turn digital multimeter to ohm position, connect two meter pens with fuel pump pins

respectively, measure internal resistance, it should not be zero or infinite (namely not in short circuit, open circuit

condition).

(Connect joint) connect fuel pressure gauge on sucker, start up engine, run the engine at idle speed, now fuel

pressure of engine should be about 260kPa; unplug fuel pressure regulator vacuum tube, now fuel pressure should

be about 300KPa.

11. Canister control valve

(1) Canister in fuel evaporation control system adsorbs oil vapor from oil tank until saturated. Electronic

control unit controls opening of canister control valve, fresh air and saturated fuel vapor in canister form

regeneration stream, which is led into engine intake pipe again. Electronic control unit changes duty ratio of pulsing

signal to canister control valve solenoid according to different operating conditions of engine, thus controls flow

of regeneration stream. In addition, this flow is also influenced by pressure difference at both ends.

Possible cause

Entering of foreign matter into valve inside results in

corrosion or poor leak tightness etc

Repair precautions:

1. To install, airflow direction must meet the specification;

2. when black granules inside valve body result in malfunction of control valve, and control valve needs to be

replaced, please check the condition of canister;

3. avoid water, oil etc liquids from entering valve as far as possible during repair;

4. in order to avoid transfer of solid-borne noise, it is recommended to install canister control valve suspending

on the hose or use soft rubber to fix.

(2) Simple measuring method:

(Remove joint) turn digital multimeter to ohm position, connect two meter pens with canister control valve pins

respectively, rated resistance at 20°C is 22 - 30 ohm.

12. Ignition coil

(1) When earthing channel of primary winding is connected, this primary winding is charged. Once ECU cut

off primary winding circuit, charging stops, high voltage is induced in secondary winding at the same time, so spark

plug discharges. Ignition coil ZSK 22 (both ends of 2 secondary windings are connected with a spark plug

respectively, so these two spark plugs ignite simultaneously.

Possible cause

Too heavy current leads to burnout, damaged by external force Repair precautions: it is prohibited to use "short circuit ignition testing method" to test ignition function, soEngine EFI System-

Engine EFI System

Page 313 of 416

Engine ECU5-126as to avoid damaging electronic control unit.

(1) Simple measuring method:

(Remove joint) turn digital multimeter to ohm position, connect two meter pens with primary winding pinsrespectively, rated resistance at 2 0°C is 0. 4-0. 6 ohm for 2X2 type; on secondary winding, 11-15k ohm for 2x2 type.13. Electronic control unit ECU

Possible cause

Electric overload of externally connected

device leads to burnout of components inside

ECU and results in malfunction Symptom

Unsteady idle speed, poor speedup, failure to start, too high

idle, tail gas overproof, difficult to start, malfunction of air

conditioner, malfunction of fuel injector control, flameout

Repair precautions:

1. Don't remove ECU at discretion during repair;

2. ECU may be removed more than 1 minute after removing storage battery head;

3. Store removed ECU properly;

4. It is prohibited to attach any circuit onto connecting wire of ECU.

Simple measuring method:

1. (Connect joint) use engine data K-line to read engine trouble record;

2. (Remove joint) check whether ECU connecting wire is in good condition or not, mainly check whether ECU

power supply grounded circuit is normal or not;

3. Check whether external sensor works normally, whether output signal is credible, whether circuit is in good

condition;

4. Check whether actuator works normally, whether its circuit is in good condition;

5. Finally replace ECU to conduct test.

Judgment principle: "two interchange principle" ---interchange ECU, interchange fault symptom.III. Diagnostic system Description:

When engine ECU detects a trouble, engine trouble warning lamp on instrument will illuminate. In addition,

relevant diagnostic code will be recorded in ECU memory. Connect handheld tester with diagnostic interface on

automobile, read various data from automobile ECU. Connect handheld tester with diagnostic interface. Technical

personnel may also read fault code via blinking of instrument fault warning lamp.Engine EFI System-

Engine EFI System

Page 314 of 416

Flashing way of malfuntion code 17 for O2 sensor (3) Each fault code will blink for three times, interval time is 3s, after blinking for the third times, after an

interval of 3s, next fault code will blink. After blinking of all fault codes is finished, they will blink from begining

again. The following diagram shows engine fault warning lamp blinking mode for oxygen sensor fault code 17.5-127Terminal No. Terminal definition

4 Power supply (-)

7 Bus (signal)

16 Power supply (+)Diagnosis connector Notes: use tester cable to connect handheld tester with diagnostic interface, turn ignition switch to ON position,

operate tester, if tester displays that communication is not possible, the vehicle or tester fails.

Inspection diagnosis

1. Check engine fault warning lamp

(1) When ignition switch is turned to ON position and engine does not run, engine warning lamp on

instrument should illuminate.

(2) When engine runs, engine fault warning lamp should go out. If it still illuminates, diagnostic system

detects system fault or abnormity.

2. Use handheld tester to check diagnostic code

(1) Connect handheld tester according to corresponding pin.

(2) Turn ignition switch to ON position, turn on main switch of handheld tester.

(3) Use handheld tester to detect and check diagnostic code, refer to fault diagnostic code table. (For

operation of handheld tester, see instruction manual of handheld tester)

3. Engine fault warning lamp displays fault code through blinking code, so professional may make fault

judgment in case of emergency.

(1)Turn ignition switch to ON position.

(2) Short signal pin (9#) and negative pole (4#) for more than 2. 5s,then disconnect them,detection fault lamp

on dashboard will blink the faults in fault code according to their occurrence sequence.See from terminal outlet

endConnect in jump way over 2.5s and

disconnect

Diagnosis connectorDiagnosis connectorEngine EFI System-

Engine EFI System

Page 315 of 416

No

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

255-128 4. Eliminate fault code either by diagnosis instrument or manually. Manual operation method, specific

procedure: use engine data K-line (namely 9 # terminal of diagnostic interface) earth twice, earthing time is more

than 2. 5 s at each time.

Fault code tableFaulty part

No fault

Electronic control unit (unit) fault

Knocking control zero test

Knocking sensor

Storage battery voltage

Intake pressure sensor

Throttle position sensor

Idle speed control valve

Coolant temperature sensor

Intake temperature sensor

Engine maximum speed overrun

Fuel injector 1

Fuel injector 2

Fuel injector 3

Fuel injector 4

Fan relay

Oxygen sensor

Air fuel ratio control correction coefficient

? self-learning value 1

? self-learning value 2

? self-learning value 3

Fault caution light

Canister control valve

Air conditioner condenser temperature sensor

Phase sensorFault code

11

34

1

15

38

16

14

61

19

18

33

22

23

24

21

42

17

31

35

36

37

45

25

13

43Fault lamp

OFF

ON

OFF

ON

OFF

ON

ON

ON

ON

ON

OFF

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

ON

OFF

ONFault type

-

2

-

2

2

1

1

1

1

1

2

1

1

1

1

1

1

2

2

2

2

1

1

1

1

Fault type: 1-open circuit 2-signal overrun

No. 18 to 21 in the table refers to air fuel ratio correction coefficient,?=actual air quantity/air need for

combustion, "? self-learning value" is also called learning air fuel ratio control value.Engine EFI System-

Engine EFI System

Page 316 of 416

Chapter 10 On-board Vehicle TelephoneI. Key points for use of Geely hands-free car telephone: 1. Microphone of hands-free car telephone is installed on the back of steering wheel upright column, away from

driver to ensure talking effect. During talking, do not open window, otherwise noisy wind might influence talking

effect.

2. Since there are many kinds of mobile phones in Chinese market, in order to ensure talking effect, please

select interface line corresponding to your mobile phone, otherwise talking effect might be influenced. At present,

Nokia, Motorola, Siemens interface lines are available.

3. To use, insert one end of mobile phone interface line into 8 core RJ 45 stand on automobile panel, connect

the other end to earphone output port of the mobile phone. When mobile phone is not connected, automobile sound

works normally, when mobile phone receive a call, CD becomes quiet automatically, at the same time, loudspeaker

in the vehicle is switched to hands-free telephone output. This hands-free car telephone is provided with response

button at the top of microphone, however, new style of mobile phone does not support manual response function

for the time being, while supports automatic response function, namely it receive the call automatically after

ringing for three times.

4. After talking is finished, automobile sound will return to original state automatically.

5. During daily use, note that contact insertion and withdraw force of mobile phone interface line should not

be too large, so as to avoid damage.

6. Hands-free car telephone has no volume switch, volume of loudspeaker voice may be adjusted by regulating

the volume of handset earphone.II. Circuit diagram5-129On Board Vehicle Telephone-On-board Vehicle TelephonePlease Refer to "MK WIRING DIAGRAM"

Page 317 of 416

III. Troubleshooting:1.Whether power supply is normal or not.

2. Increase mobile phone output volume.

3. Confirm whether mobile phone interface line is correct, (replace

with new mobile phone interface line).

4. When mobile phone works, confirm whether there is relay

closing sound in hands-free telephone box.

5. If there is relay closing sound, check whether anything is wrong

with socket drop-out line.

Adjust mobile phone output volume.

Check receiving signal of mobile phone. No. Symptom Possible cause

1

2

3No voice can be heard from

hands-free telephone

Loudspeaker sound is light

Connection is interruptedOn Board Vehicle Telephone-On-board Vehicle Telephone5-130

Page 318 of 416

Rear Parking Radar System-Rear Parking Radar System5-131Ultrasonic sensor

Ultrasonic sensor

Receiving AmplifierTransmitting Amplifier Receiving AmplifierTransmitting AmplifierPhonetic circuitMCU

Receive, filter and amplifyDisplay

Electric A/D switchChapter 11 Rear Parking Radar SystemI. System principle Reversing radar system mainly adopts ultrasonic ranging technology, utilizes piezoelectric property of

transducer (ultrasonic sensor), excites piezo sheet with voltage with frequency of 40KHZ intermittently, this piezo

sheet is then converted from electric energy to mechanical energy and sent out. When emitted sound wave contacts

object, it will reflect weak sound wave energy to transducer according to sound wave reflection principle, i. e.

convert received weak acoustic vibration signal to electrical signal, after signal amplification processing, it is

transmitted to microprocessor to calculate the distance between vehicle and this object and display the distance.

Then microprocessor determines whether to give caution remind for dangerous object according to varying

degrees.II. Circuit diagramPlease Refer to "MK WIRING DIAGRAM"

Page 319 of 416

III. Fault diagnosis 1. During detection, if there is no sound or display screen does not illuminate, please detect whether polarity

of power supply is connected in a wrong way, whether power cord is connected, whether supply voltage 9V,

whether display joint is inserted properly.

2. If clobber "0.0" or constant ringing occurs, please exit reverse gear, engage reverse gear again. If the

above symptom still exists, it may be deemed that principal machine is damaged, and should be replaced

completely.

3. If certain value is displayed, while there is no evident barrier at right ahead of probe. Prominence on or rear

might be detected (such as license plate, bumper bar etc). please check whether direction axis of the probe is

correct, horizontal axis of the probe should slightly upwarp.

4. When accelerating, the installed display shows irregular disordered frame, circuit interference might occur,

check earth wire of reversing radar.IV. Installation of reversing radar 1. Reversing radar system consists of reversing radar principal machine, reversing radar display screen, wiring

harness, buckle and reversing radar probe etc.Rear Parking Radar System-

Rear Parking Radar System5-132About 500 mm

About 265 mmRear parking radarsensor

Clip

Push Rear bumper bar

Page 320 of 416

Centralized Controller System-

Function Inspectior5-133Chapter 12 Centralized Controller SystemSection 1 Function InspectiorI. Glass frame riser: 1. Glass frame riser may be operated to move within 60s after ignition switch is turned on or off; 60s after

ignition switch is turned off, glass frame riser cannot be operated to move;

2. Manual rise: press corresponding glass frame riser switch rise key, corresponding glass frame riser motor

works, glass frame rises, release rise key, it stops.

3. Manual fall: press corresponding glass frame riser switch fall key (hold time 300ms), corresponding glass

frame riser motor works, glass frame falls, release fall key, it stops.

4. Automatic fall: press corresponding glass frame riser switch fall key (hold time < 300 ms), corresponding

glass frame riser motor works, glass frame falls down to end; or fall down until rise key or fall key is pressed again.

Note:

During automatic fall of glass frame, if corresponding glass frame riser switch fall key is pressed down for more

than 300 ms, glass frame riser is changed to manual fall mode; if corresponding glass frame riser switch rise key

is pressed down for more than 300ms, glass frame riser stops work.

5. Remote window closing:

In case of remote protection, if a key is pressed down for more than 1s, perform glass frame riser automatic

rise action, left front, right front, left rear, right rear in turn.II. Central lock: 1. In case protection is deactivated, use a key to open left front door switch or press internal unlock switch to

open four door fasteners; close left front door switch, close four door fasteners.

2. Remote unlock /lock:

(1) Ignition switch opening

a. Press remote control unlock key to open four door fasteners;

b. Press remote lock key to close four door fasteners;

(2) Turn off ignition switch

a. Press remote unlock key to open four front door fasteners, at the same time turn light flashes once.

b. Press remote lock key to close four door fasteners, at the same time turn light flashes twice.

(3) When door is opened, press remote fastener, turn light will flash for three times, at the same time electric

horn beeps for three times.

(4) If the system is triggered in anti-theft condition, when remote unlock system exits protection state,

directional turn signal will flash for four times, at the same time, electric horn beeps for four times.

3. Automatic lock

When vehicle speed exceeds 30km/h, three doors will be closed.

4. Door lock priority

Central door lock should not act simultaneously with glass frame riser; when they conflict with each other,

central door lock acts with priority, while glass frame riser stops; after central door lock action is finished, glass

frame riser continue its work in previous condition.III. Front womdscreem wiper: After spray water signal is finished, the wiper acts twice.