connector or terminal HONDA INTEGRA 1994 4.G Owners Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 1241 of 1413

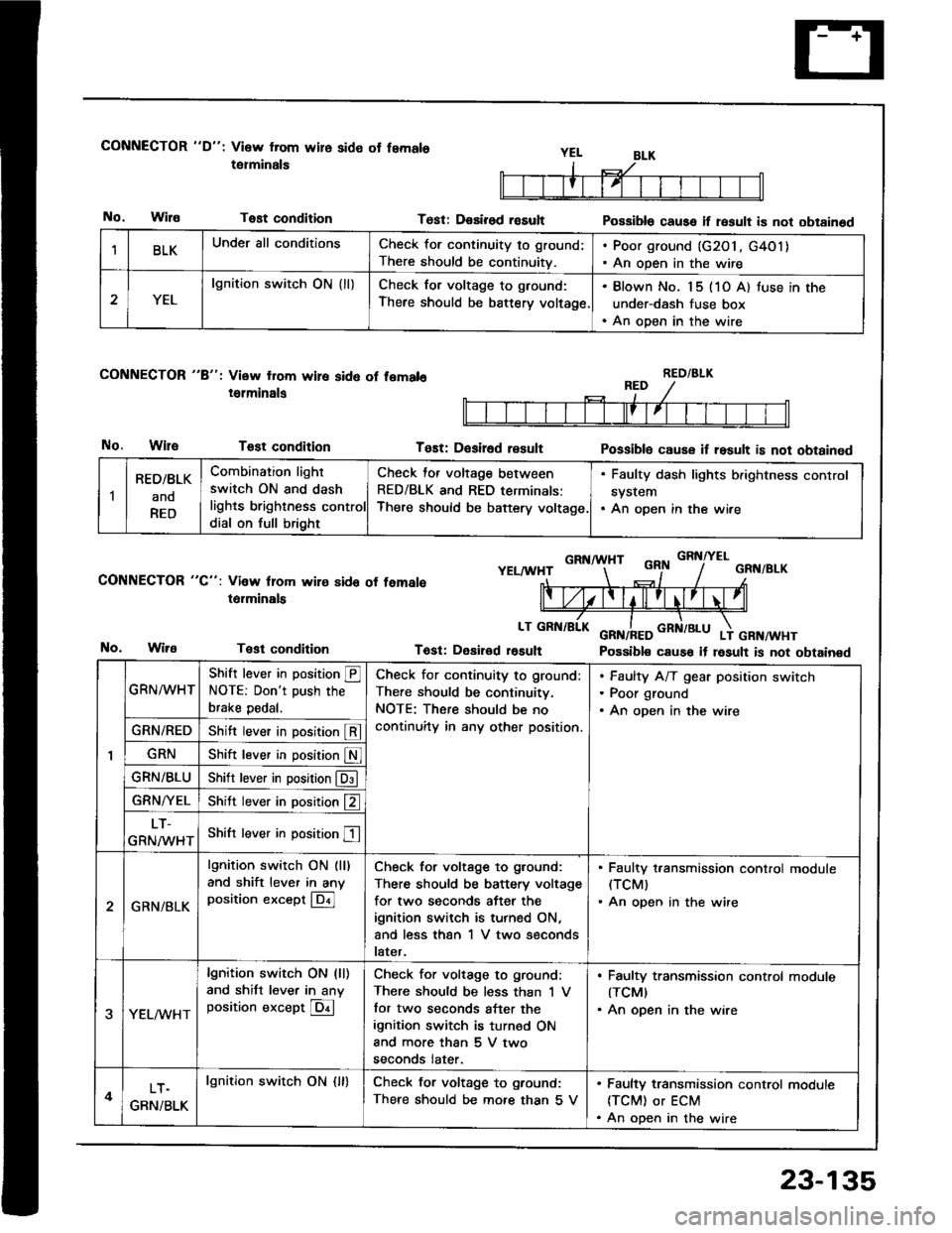

CONNECTOR "D": Visw from wire side ot femals

tetminals

No.WilaTest condition

CONNECTOR "8": View from wire sid6 of fem.l6

i6lminals

No.WileTost condition

CONNECTOR "C": Vi3w lrom wire sido of temale

t6rminals

Test condition

Test: D€sirod rasultPossible cause if result is not obtainod

Tost: D€sir6d resultPossiblo cause if result is not obtained

GRNA HTGRNITELYELAA'HTGRN/BLK

Tost: Desirod r6sult Possible cause it result is not obtainedNo.

BLKUnder all conditionsCheck for continuity to ground:

There should be continuitv.

. Poor ground (G2O1, G4O1). An open in the wire

2YEL

lgnition switch ON { ll}Check for voltage to ground:

There should be battery voltage.

. Blown No. 15 (1O A) tuse in the

under-dash fuse box. An open in the wire

RED/BLK

1

RED/BLK

ano

RED

Combination light

switch ON and dash

lights brighlness control

dial on full bright

Check for voltage between

RED/BLK and RED terminals:

There should be baftery voltage.

. Faulty dash lights b.ightness control

system. An open in the wire

GRN^^/HT

Shift lever in position @NOTE: Don't push the

brake pedal.

Check for continuity to ground:

There should be continuitv.

NOTE: There should be no

continuity in any other position.

Faulty A/T gear position switch

Poor ground

An open in the wire

GRN/REDShift lever in position @

GRNShift lever in position S

GRN/BLUShitr lever in position @

GRN/YELShitt lever in position f2 ]

LT-

GRNMHTShift lever in position E

2GRN/BLK

lgnition switch ON (ll)

and shift lever in anyposition except @

Check for voltage to ground:

There should be battery voltage

for two seconds after the

ignition switch is turned ON,

and less than 1 V two seconds

later.

. Faulty t,ansmission control module(TCM)

. An open in the wire

3YEL/vVHT

lgnition switch ON (ll)

and shitt lever in anyposition except @

Check for voltage to ground:

There should be less than 'l V

tor two seconds after the

ignition switch is turned ON

and more than 5 V two

seconds later.

. Faulty transmission control modute(TCMI

. An open in the wire

4LT.

GRN/BLK

lgnition swirch ON {ll}Check for voltage to ground:

There should be mofe than 5 V

. Faulty transmission control module

ITCM) or ECM. An open in the wire

23-135

Page 1243 of 1413

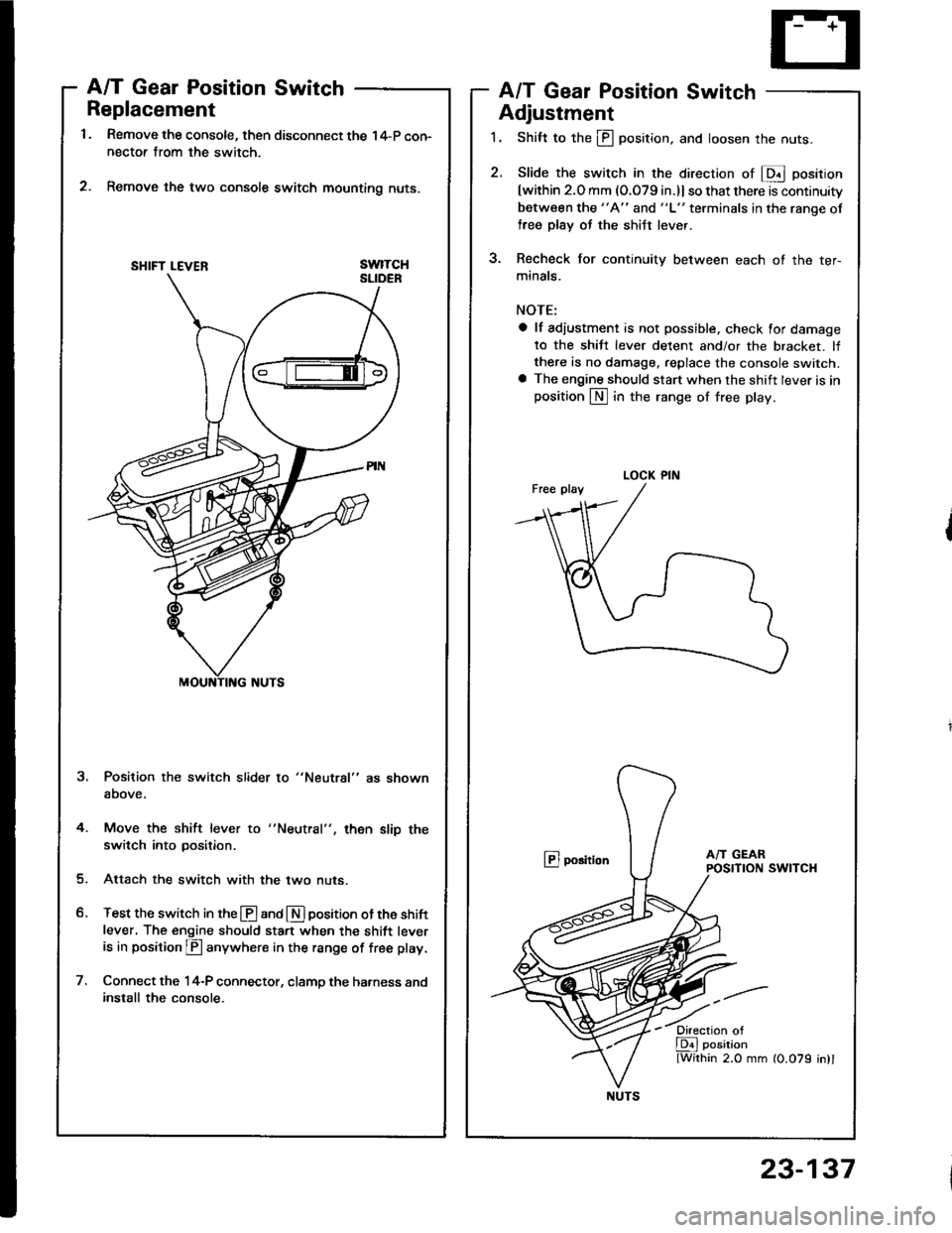

Replacement

Remove the console, then disconnect the 14-P con-nectof from the switch.

Remove the two console switch mounting nuts.

swtTcH

A/T Gear Position SwitchA/T Gear Position Switch

Adjustment

1. Shift to the ill position, and loosen the nuts.

2. Slide the switch in the direcrion of E position

[within 2.O mm (O.079 in.)l so that there is continuity

between the "A" and "L" terminals in the ranqe of

free plsy oJ the shiJt lever.

3. Recheck for continuity between each ot the ter-

minals.

NOTE:

a lf adiustment is not possible. check for damage

to the shiJt lever detent and/or the bracket. lfthere is no damage, replace the console switch.a The engine should start when the shift lever is inposition LN] in the range of free play.

@ porition

Position the switch slider to "Neutral" as shown

above.

4. Move the shift lever to

switch into position.then slip the

Attach the switch with the two nuts.

Test the switch in the @ and E] position ot the shift

lever. The engine should sta.t when the shift leveris in position p anywhere in the range of free play.

Connect the 14-P connector, clamp the harness andinstall the console.

SHIFT LEVER

LOCK PIN

NUTS

23-137

Page 1247 of 1413

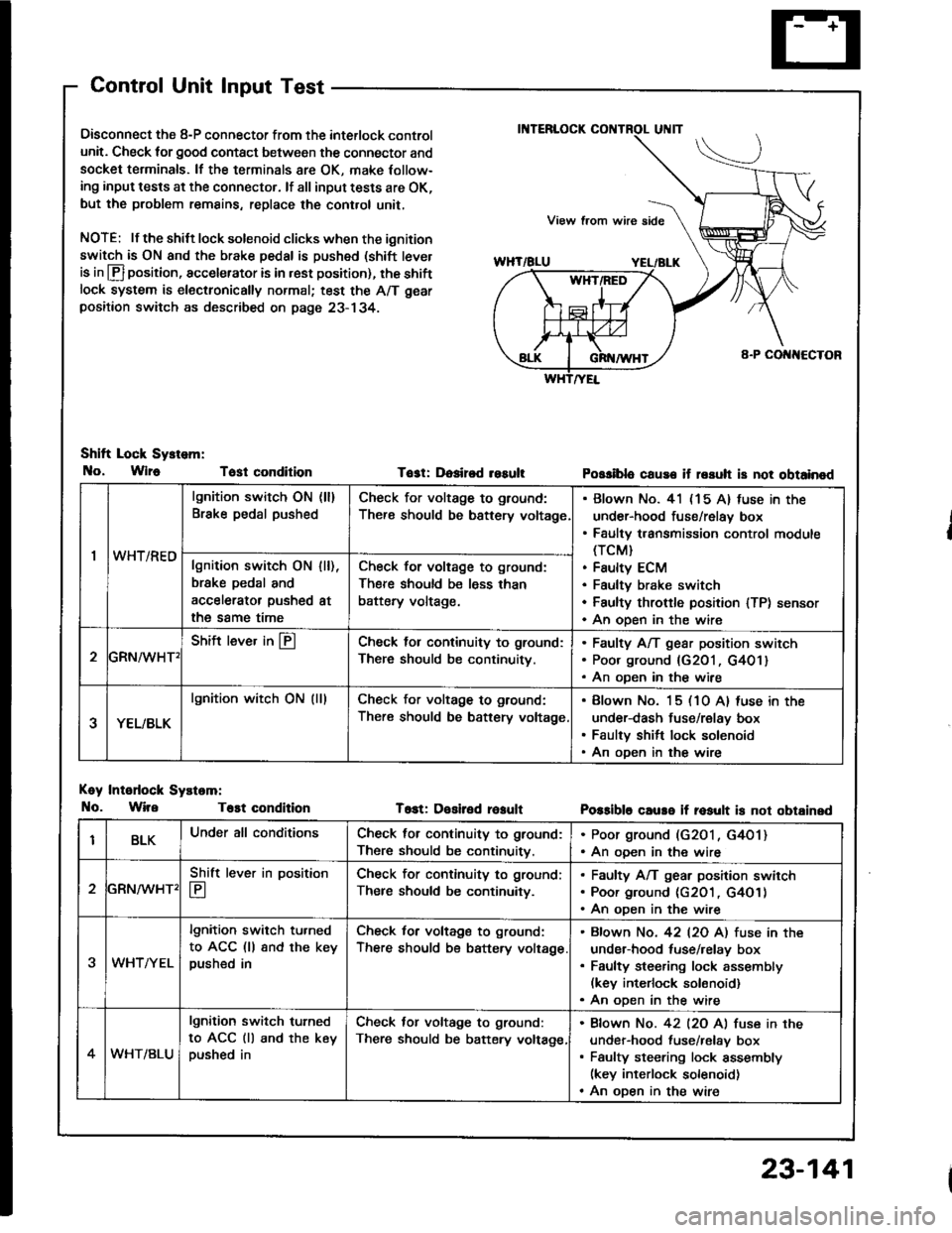

Control Unit Input Test

Oisconnect the 8-P connector from the interlock control

unit. Check for good contact between the connector and

socket terminals. lf the terminals 8re OK, make Iollow-

ing input tests at the connector. lf all input tests are OK,

but the problem remains, replace the cont.ol unit,

NOTE: lf the shilt lock solenoid clicks when the ignition

switch is ON and the brake pedal is pushed (shift tever

is in lfl position, accelerator is in rest position), the shiftlock system is electronically normal; test the A/T gear

positaon switch as described on page 23- 134.

Shift Lock Sy.tem:

No, Wlr6 Tost condition

Koy Intodock Systam:

No. WireT6st condition

Tost: Dosired resultPossiblo cause if rssuh is not obtainod

T6st: Desiled reaultPossible caure if rosult is not obtainsd

'I

lgnition switch ON (ll)

Brake pedal pushedCheck for voltage to ground:

There should be bsttery voltage

Blown No. 41 (15 A) fuse in the

under-hood fuse/relay box

Faulty transmission control module(TCM}

Faulty ECM

Faultv brake switch

Faulty throftle position lTP) sensor

An oDen in the wire

wn t/hEulgnition switch ON

brske pedal and

accelerator pushed

the same time

I [),

at

Check for voltage to ground:

There should be less than

battery voltage.

GRN^/vHT'

Shift lever in @Check lol continuity to ground:

There should be continuity.

Faulty A/T gear position switch

Poor ground {G201, G401}

An oDen in the wire

YEL/BLK

lgnition witch ON (lllCheck for voltage to ground:

There should be battery voltage

Blown No. 15 (10 A) luse in the

under-dash fuse/relay box

Faulty shift lock solenoid

An oDen in the wire

BLKUnder all conditionsCheck for continuity to ground:

There should be continuitv.

. Poor ground (G2O1, G4O1). An ooen in the wire

2

Shift lever in position

E

Check for continuity to ground;

Ther€ should be continuity.

Faulty A/T gear position swirch

Poor ground (c2O1 , G4O1)

An oDen in the wire

3WHTAYEL

lgnition switch tu.ned

to ACC (ll 8nd the keypushed in

Check for voltage to ground:

There should be battery voltage

Bfown No. 42 l2O Al fuse in the

under-hood tuse/relay box

Faulty steering lock assembly(kev interlock solonoid)

An oDen in the wire

4WHT/BLU

lgnition switch turned

to ACC (ll and the keypushed in

Check tor voltage to ground:

There should be batery voltage,

Bfown No. 42 l2O Al fuse in the

under-hood fuse/relav box

Faulty steering lock assembly(key interlock solenoid)

An oDen in the wire

23-141

Page 1248 of 1413

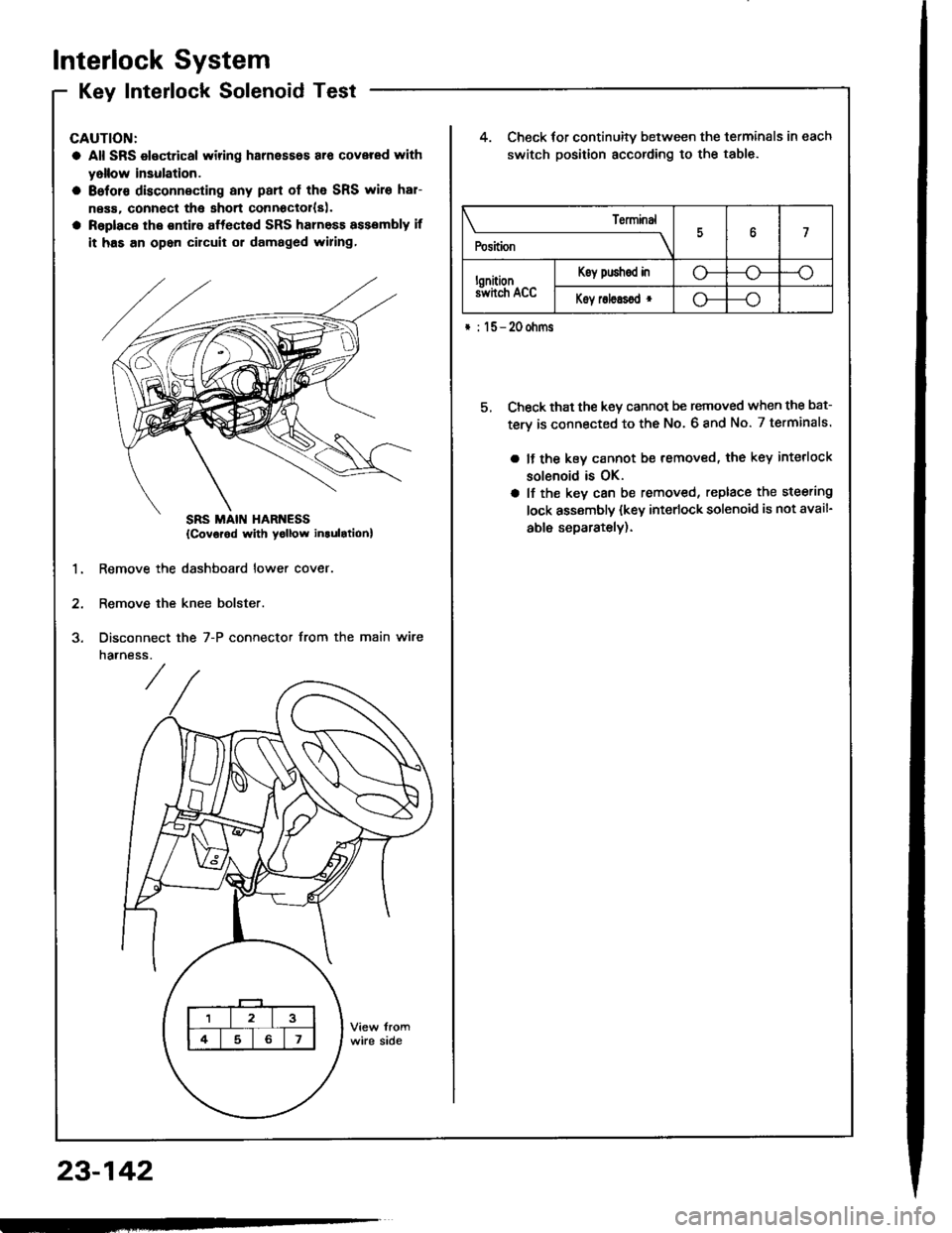

Interlock System

Kev Interlock SolenoidTestKey IntenocK Dorenoro I esr -

CAUTION:

a All SRS electrical wiring harnesses ar€ covered rYith

yollow insulation.

a 8eforc disconnecting any pan of the SRS wire har-

ness. connecl tha short connoclol{s|.

a Raplace the ontire affected SRS harness assembly if

it has an opon circuit or damaged wiring,

4. Check for continuitv between the terminals in each

switch position according to the table.

5, Check that the key cannot be removed when the bat-

tery is connected to the No. 6 8nd No. 7 terminals.

a It the kev cannot be removed, the key interlock

solenoid is OK.

a lf the key can be removed, replace the steering

lock assembly (key interlock solenoid is not avail-

able separately).

1.Remove the dashboard lower cover

Remove the knee bolster.

Disconnect

narness.

the 7-P connector from the main wire

\______________rry

Position7

lonitionS hch Acc

Koy push€d ino---o

Koy roleEsod r--o

* : l5-20ohms

{Covorod with yollow inlulrtionl

23-142

Page 1252 of 1413

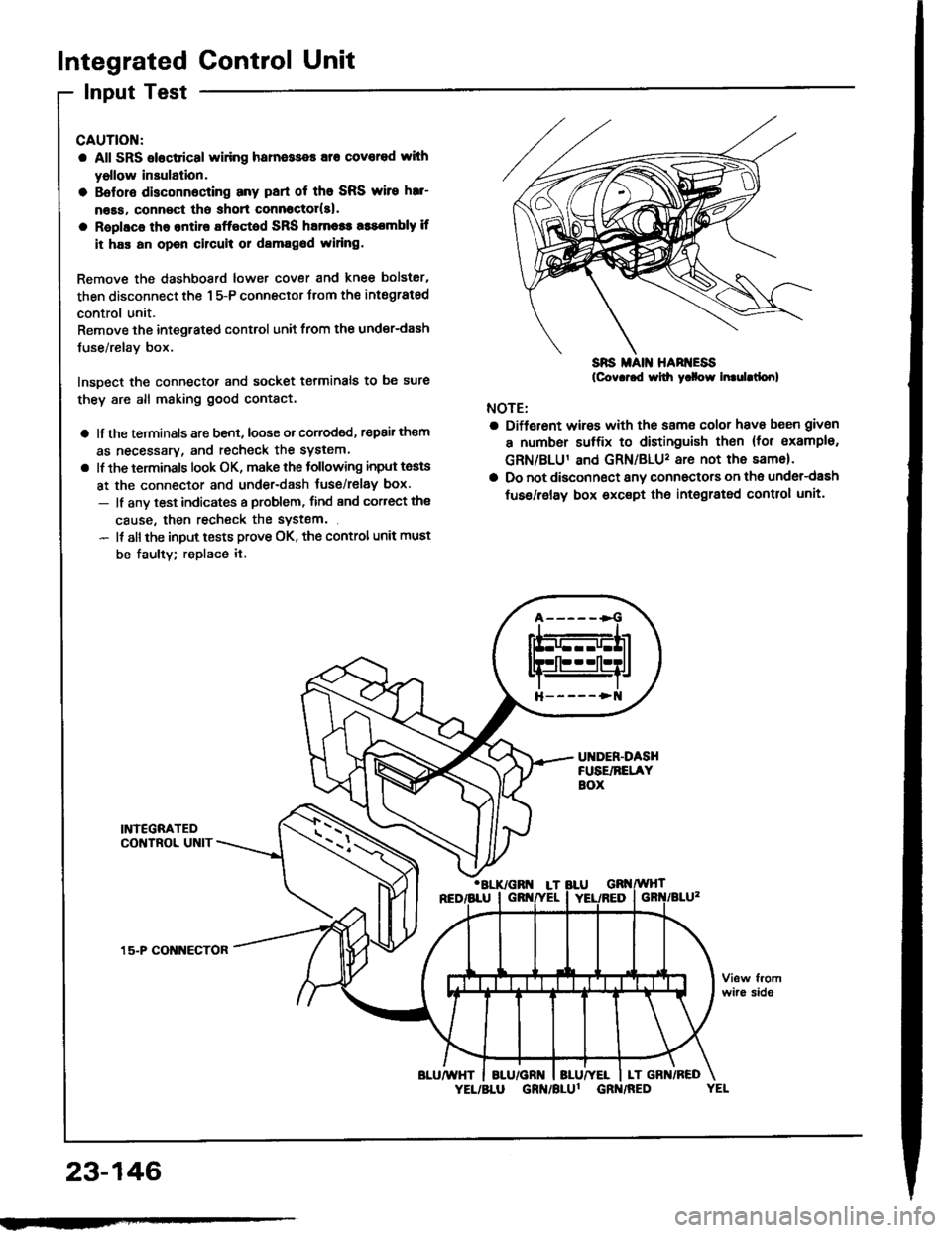

Integrated Control Unit

Input Test

CAUTION:

a All SRS elocttical widng hatness€s ato covored with

yollow insulation.

a Botolo disconnocring any pan ot the SRS wile hal'

ness, conn€ct tho shon connoctor(3l.

a Replaca tho ontlrg affsctod SRS hE noaa assombly if

it has an opon circuit or damag6d wifng.

Remove the dashboSrd lower cover and knee bolstar.

then disconnect the 1 5-P connector Jrom the integratsd

control unit.

Remove the integrated control unit from the under-dash

Juse/relav box.

Inspect the connector and socket tetminals to be sure

they are all making good cont8ct.

a lf the terminals are bent, loose ot corrod€d, repair them

as necessary, and recheck the system

a lf the terminals look OK, make the tollowing input tssts

at the connector and under-dash tuse/relsy box.

- lf any test indicates a problem, find and correct the

cause, then recheck the system.- It all the input tests prove OK, the control unit must

be faulty; replace it.

15.P CONNECTOR

NOTE:

a Diftorent wires with the sam€ color have been given

a number suffix to distinguish th€n {for 6xample,

GRN/BLUI and GRN/BLU'�are not the same).

a Do not disconnect any connectors on tho under-dash

fu8e/relay box except the integratsd contlol unit.

BLU/WHT I BLU/GR]{ I BLU/YEL I LT GB /BED

23-146

SRS MAII{ HARI{ESS

H_____-t{

.BLK/GBI{ LT

YEL/BLU GRN/BLUI GRI{/RED

Page 1256 of 1413

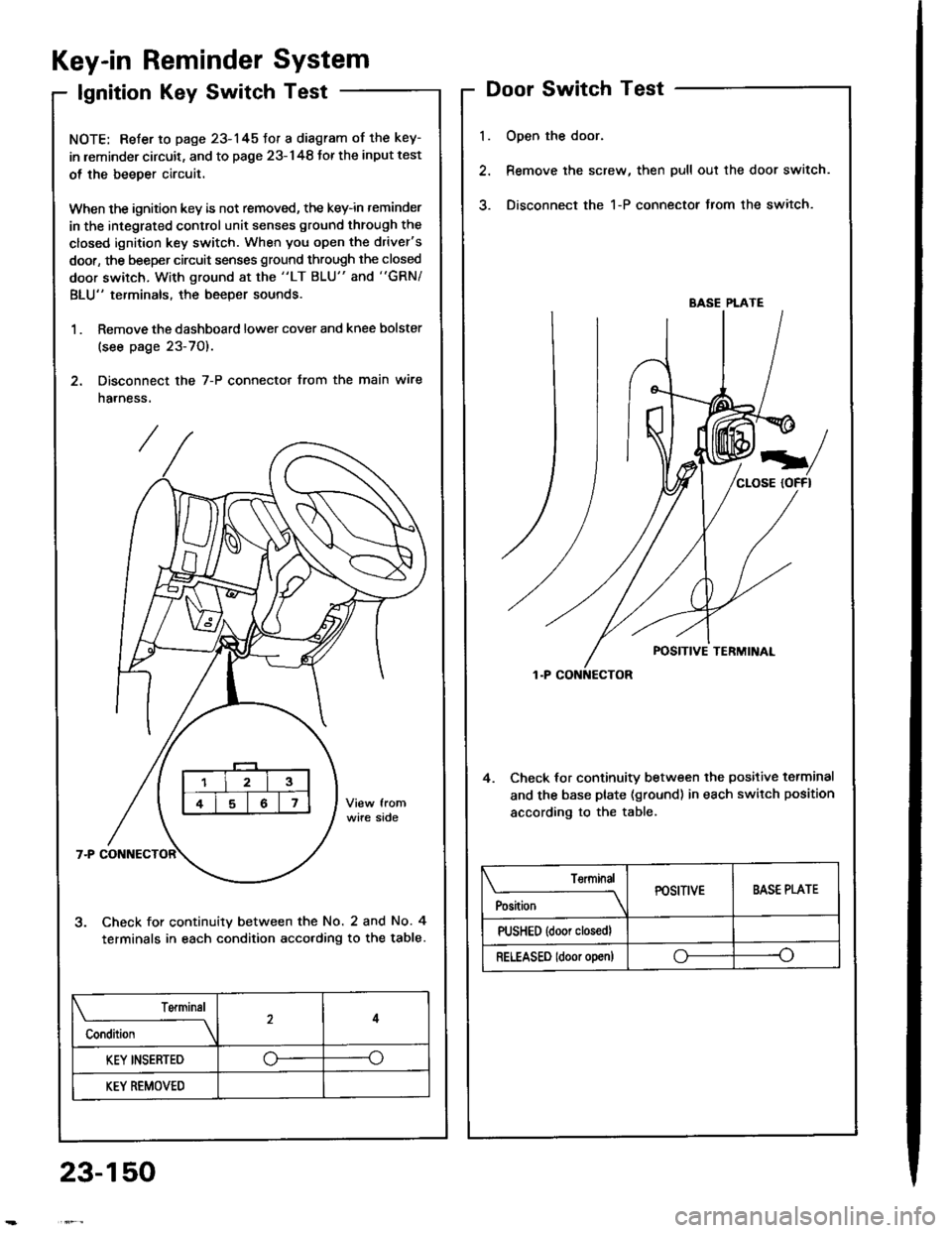

Key-in Reminder System

lgnition Key Switch Test

NOTE: Refer to page 23-145fot a diagram of the key-

in leminder circuit, and to page 23-148 Jor the input test

ol the beeper circuit.

When the ignition key is not removed, the key-in reminder

in the integrated control unit senses ground through the

closed ignition key switch. When you open the driver's

door, the beeper circuit senses ground through the closed

door switch, With ground at the "LT BLU" and "GRN/

BLU" terminals, the beeper sounds.

1 . Remove the dashboard lower cover and knee bolster

(see page 23-70).

2. Disconnect the 7-P connector from the main wire

harness.

Check for continuity between the No. 2 and No. 4

terminals in each condition acco.ding to the table.

l.

Door Switch Test

Open the door.

Remove the screw, then pull out the door switch.

Disconnect the 1-P connector from the switch.

4. Check lor continuity between the positive terminal

and the base plate (ground) in each switch position

according to the table.

BASE PLATE

Position

TerminalPOSITIVEBASE PLATE

PUSHED {door closedl

RELEASED ldoor o!en)oo

Terminal

Condition

4

KEY INSERTED--o

KEY REMOVED

23-150

Page 1257 of 1413

Engine Oil Pressure

Indicator System

Description

NOTE: Reter to page 23-144 tor the circuit diagram otthe engine oil pressure indicator flasher, snd to page

23-148 lor the input test of the flasher circuit.

The low engine oil pressure indicator tight works in twoways. lt will flash continuously following a momentaryloss of oil pressure, or it will go on and stay on with acomplete loss of oil pressure.

When the engine first starts, before oil Dressure risesabove 29.4 kP8 10.3 kgf/cmr, 4.3 psi), current flowsthrough the low engine oil pressure indicator light andthe oil pressure switch to ground. This tests the circuit.

Wilh the engine running, voltage is applied ro the ftash-er circuit of the integrated control unit. With normal oilpressure, the oil pressure switch is open and the low en-gine oil pressure indicator light does not operate. lf theoil pressure switch closes momentarily (more than O.5secondsl, but then opens again, terminal "yEL/RED,'will

sense ground through the switch. The integrated con-trol unit willthen provide and remove ground for th€ lowengine oil pressure indicator light through terminal"YEL/RED". The light will flash on and olf until the igni-tion switch is turned to "OFF".

lf engine oil pressure falls below 29.4 kPa (O.3 kgJ/cmr,4.3 psi) and does not increase, the oil pressure switchwillstsy closed. The low engine oilpressure indicator lightwill go on and stav on.

NOTE; Refer to page 23-122lot the engine oil pressure

switch test.

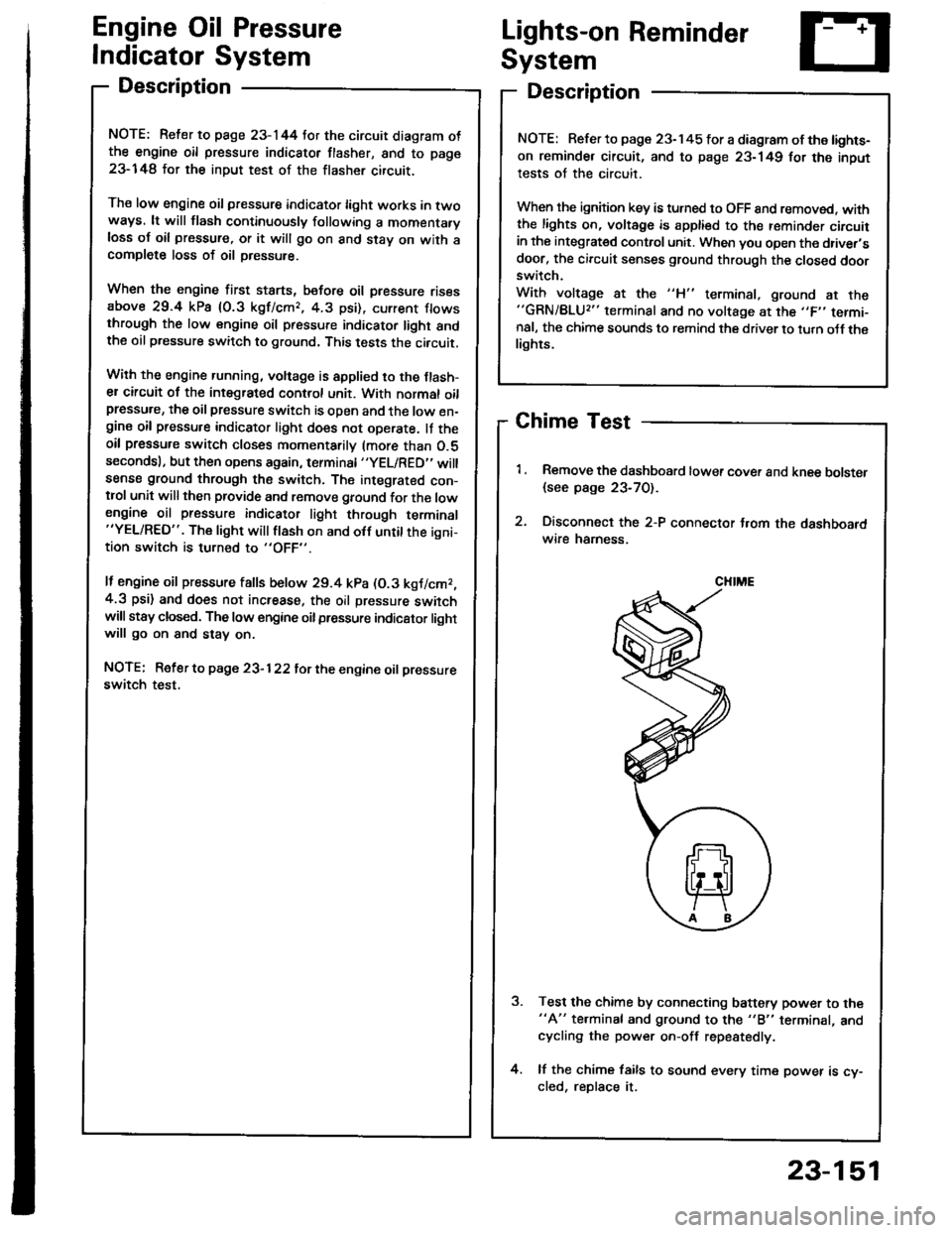

Lights-on Reminder

System

Description

Chime Test

Remove the dashboard lower cover and knee bolster

{see page 23-70).

Disconnect the 2-P connector t.om the dashboardwire hamess.

Test the chime by connecting battery power to the"A" te.minal and ground to the "B" terminal, andcycling the power on-off repestedly.

lf the chime fails to sound every time power is cy-cled, reDlace it.

NOTE: Refer to page 23-145 tor a diagram of the lights-

on reminder circuit, and to page 23-149 for the input

tests of the circuit.

When the ignition key is turned to OFF 8nd removed. withthe lights on, voltage is apptied to the reminder circuitin the integrat€d control unit. When you open the driver,sdoor, the circuit senses ground through the closed doorswitch.

With voltage at the "H" terminal, ground at the"GRN/BLU2" terminal and no voltage at the ,,F,' termi-nal, the chime sounds to remind the driver to turn oJf thelights.

CHIME

23-151

Page 1262 of 1413

Lighting System

Daytime Running Lights Control Unit Input Test (Canada)

CAUTION:

a All SRS eloc{dcal wi ng harn€sses are covelod with

yollow insulation.

a Boforo dbconnocting any psrt of the SRS wir€ h8r-

noss, connoct tho shon connector(s).

a Roplace the entire affected SRS harness assombly it

it has an opon Gilcuit or damagod wifng.

1 . Remove the dashboard lower cover and knee bolster.

2. Disconnect the connectors from the daytime running

lights control unit.

3. Insoect the connectof and socket terminals to be

sure they are all making good contact.

a ll the terminals are bent, loose or coroded, repair

them as necessary. and recheck the system,

a lf the terminals look OK, make the following in-

put tests at the connector,- lf any test indicates a problem, find and cor-

.ect the cause, then recheck the system.- ll allthe input tests prove OK, the control unit

must be taulty; replace if

4-P CONI{ECTOR

WHT/RED

YEL/ALK

8-P CONNECTOR

GRN/RED

WHTA'EL

23-156

View from wire sideVi6w from ware side

RED/GRI{

Page 1264 of 1413

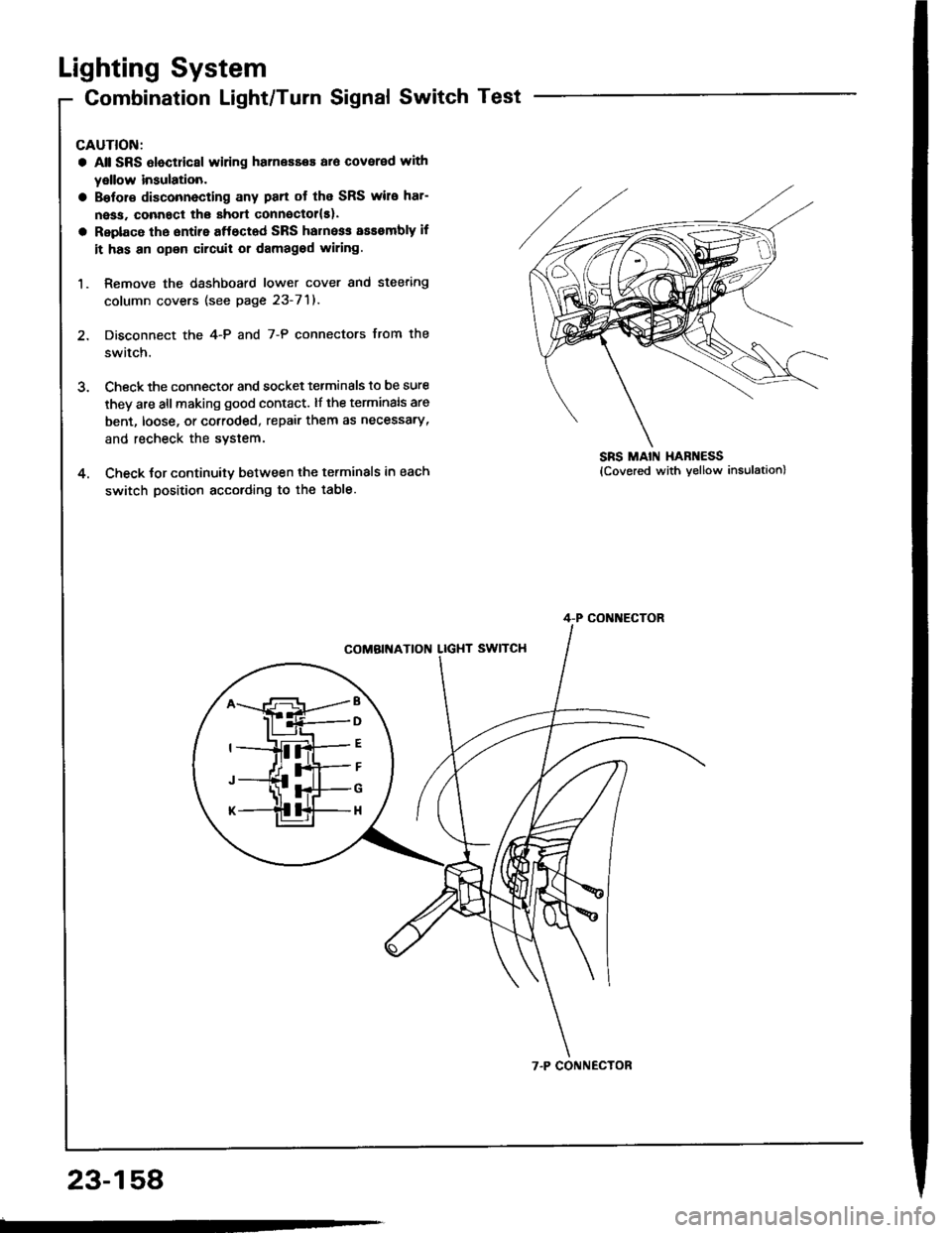

Lighting System

Combination Light/Turn Signal Switch Test

CAUTION:

a Atl SRS Oloctricsl wiring harnesses ar6 covered with

yellow insulation.

a Bslor€ disconnecting any pan ot the SRS wire har-

ness, connact the short connsctollsl.

a Replace the sntire aftectad SRS harne$ assembly if

it has an opon circuit or damagod wiring.

1. Remove the dashboard lower cover and steering

column covers (see page 23-71).

2. Disconnect the 4-P and 7-P connectors from the

switch.

3. Check the connector and socket tetminals to be sure

they are all making good contact. lf the terminals are

bent, loose, or cotroded, repair them as necessary,

and recheck the system.

4. Check tor continuitv between the terminals in each

switch position according to the table.

SRS MAIN HAR ESS

B

D

G

H

4-P CONI{ECTOR

7.P CONNECTOR

23-158

Page 1266 of 1413

Lighting System

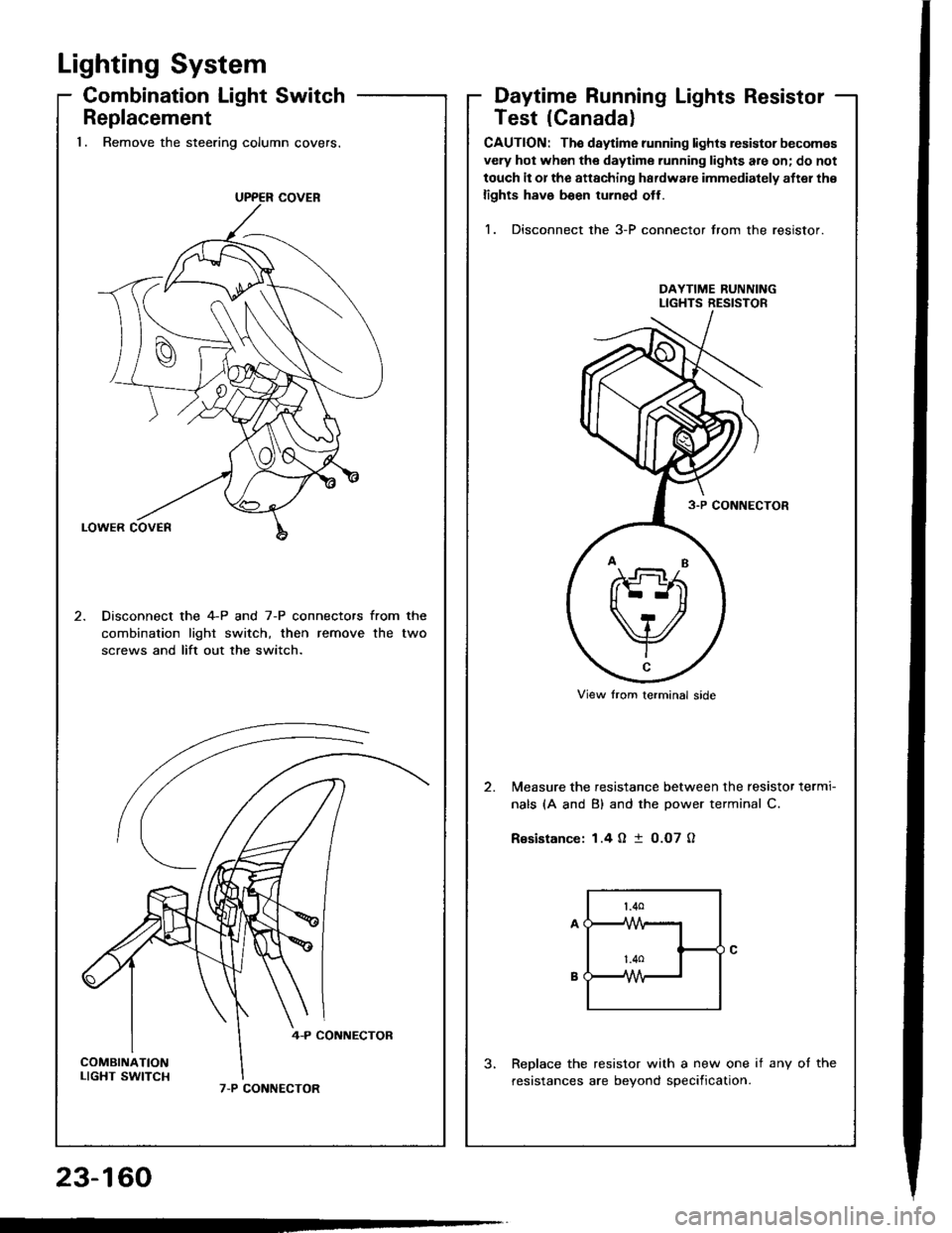

Combination Light Switch

Replacement'1. Remove the steering column covers.

Disconnect the 4-P and 7-P connectors from the

combination lighr switch, then remove the two

screws and lift out the switch.

Daytime Running Lights Resistor

UPP€R COVER

Test lCanada)

CAUTION: The daytime running lights resistor becomas

vely hot when the daytime running lights are on; do not

touch it or the attaching hardware immediately aftel th€

lights h8ve b€en turned otf.

1. Disconnect the 3-P connector from the resistor.

DAYTIME RUNNINGLIGHTS RESISTOR

Measure the resistance between the resistor termi-

nals (A and B) and the Dower terminal C.

R€sistance: 1.4 O I O.O7 O

Replace the resistor with a new one if any ot the

resistances are bevond soecification.

?nd

V-c

View trom lerminal side

23-160