HONDA INTEGRA 1994 4.G Workshop Manual

INTEGRA 1994 4.G

HONDA

HONDA

https://www.carmanualsonline.info/img/13/6067/w960_6067-0.png

HONDA INTEGRA 1994 4.G Workshop Manual

Trending: fuse box diagram, connector identification, rear sub frame, Vacuum, valve lash, spark plugs replace, brake sensor

Page 1191 of 1413

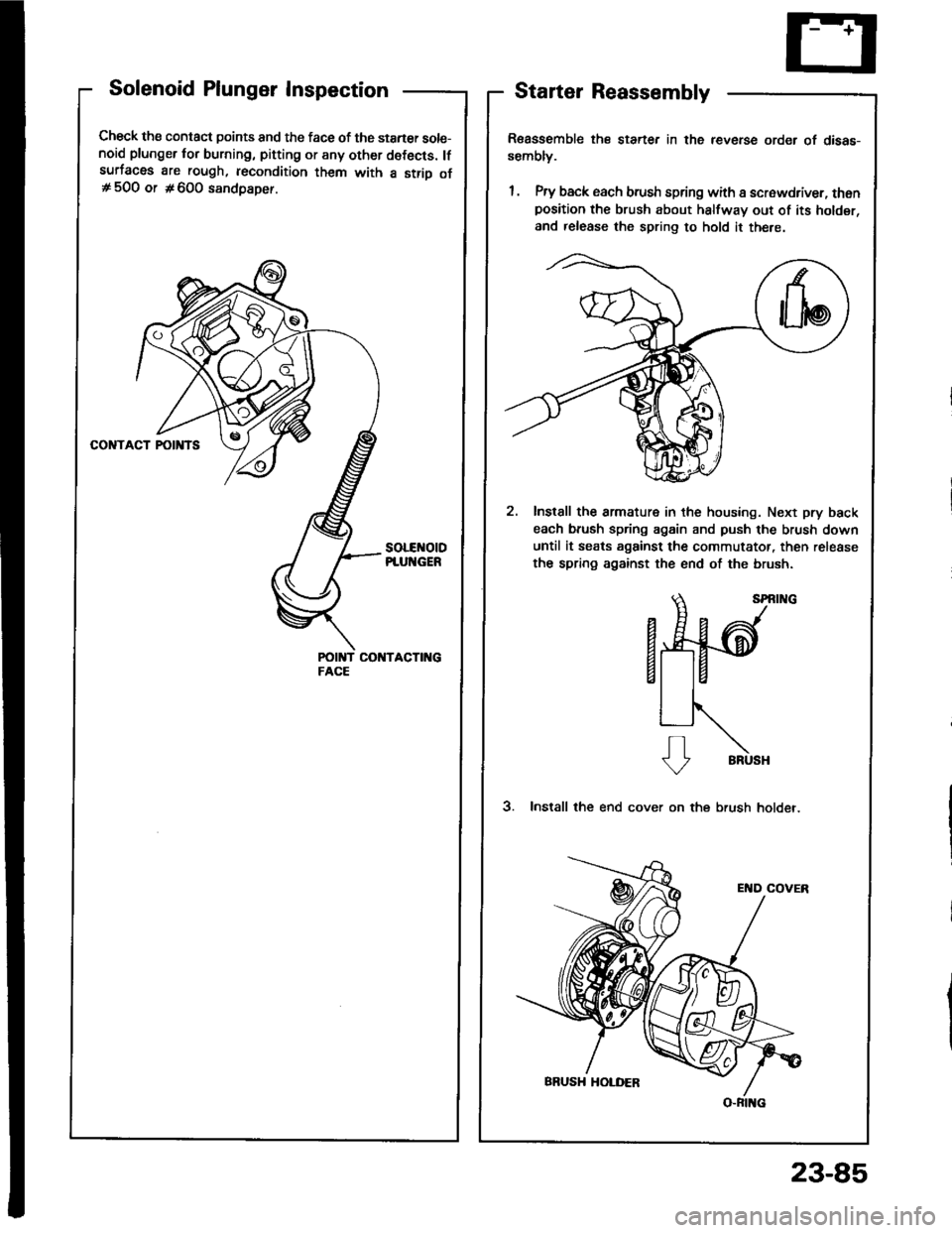

Solenoid Plunger Inspection

Check the contact points and the face of the staner sole-noid plunger for burning, pitting or any other defects. lfsurfacas are rough, recondition them with a strio of# 500 or #600 sandpaper.

soLEr{otDPIUNGER

Starter Reassembly

R€assemble the starter in the reverse order of disas-sembly.

1. Pry back each brush spring with a screwdriver, thonposition the brush about halfway out of its holder,

and release the spring to hold it there.

2. Instsll the armature in the housing. Next pry back

each brush spring again and push the brush down

until it seats against the commutator, then release

the spring against the end of the brush.

a&T&'

s..

V BRUSH

3. Install the end cover on the brush holder.

23-85

Page 1192 of 1413

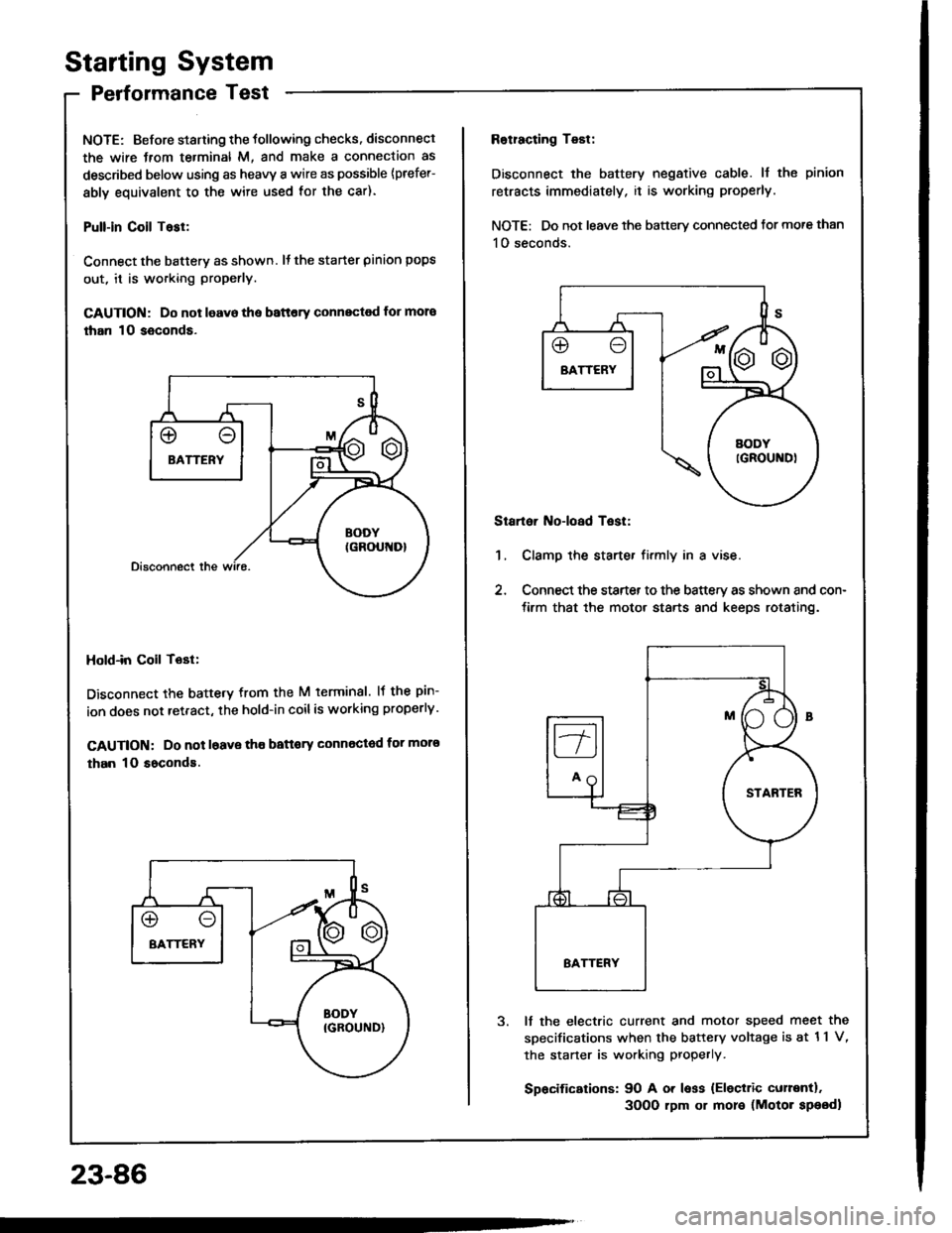

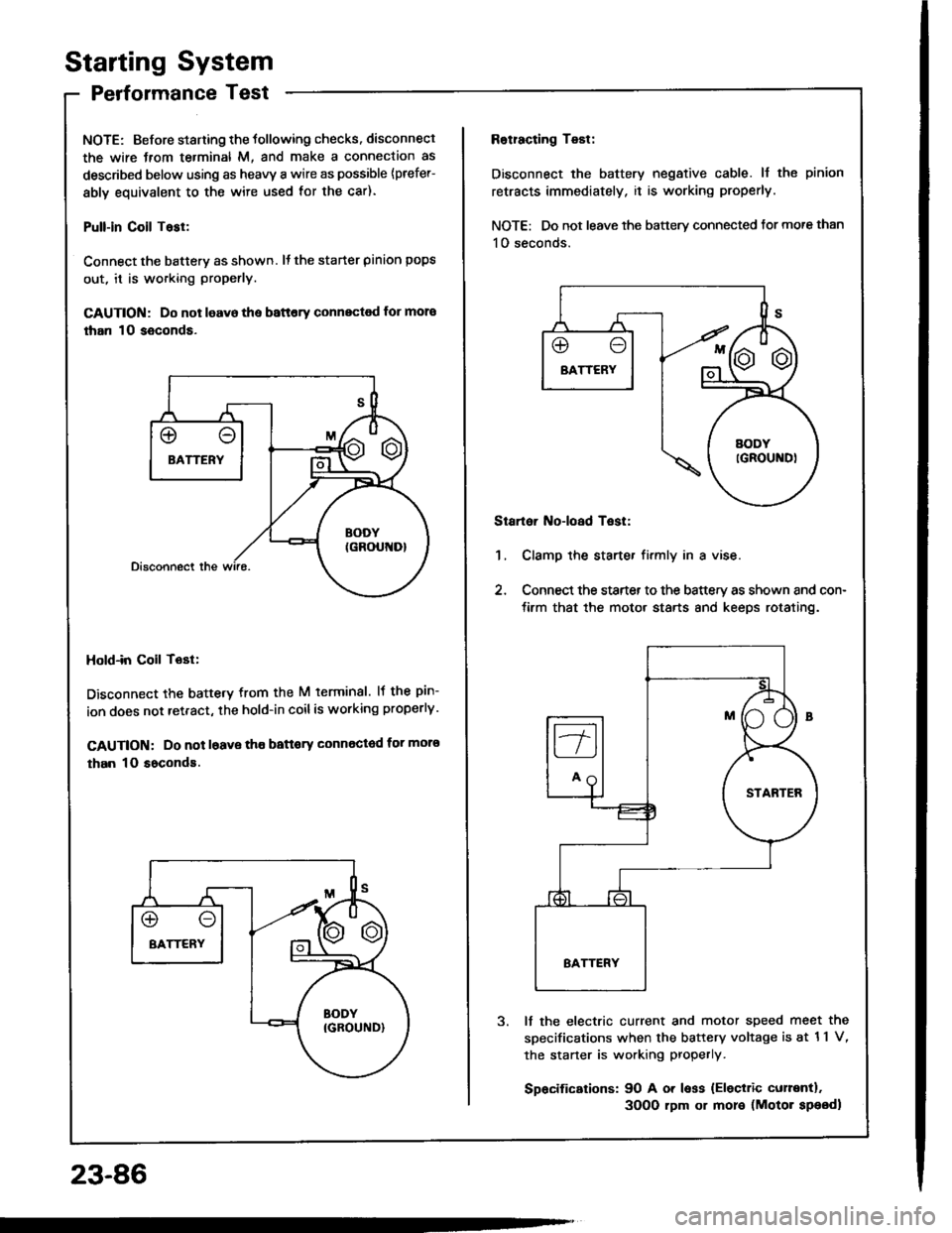

Starting System

Performance Test

NOTE: Before staning the tollowing checks. disconnect

the wire Jrom te.minal M, and make a connection as

described below using as heavy a wire as possible {prefer-

ably equivalent to the wire used for the car).

Pull-in Coil Tasl:

Connect the batterv as shown. It the starter pinion pops

out, it is working properly.

GAUTION: Do not leavo the battery connectod for mora

than 10 seconds.

Hold-in Coil Tost:

Disconnect the battetv from the M terminal. lf the pin-

ion does not retract, the hold-in coilis working properly.

CAUTION: Do not l6ave tho battory Gonnected for moro

than 10 soconds.

23-86

Rotracting Test:

Disconnect the battery negative cable. ll the pinion

retracts immediately, it is working properly.

NOTE: Do not leave the battery connected tor more than

1O seconds.

Startoi Noioad Test:

1, Clamp the starte. firmly in a vise.

2, Connect the starter to the battery as shown and con-

tirm that the motor starts 8nd keeps rotating.

It the electric current and motor speed meet the

sDecifications when the battery voltage is at 11 V,

the staner is working properly.

Spacifications: 90 A or less {Eleciric curentl.

3OO0 rpm or more (Motor speodl

Page 1193 of 1413

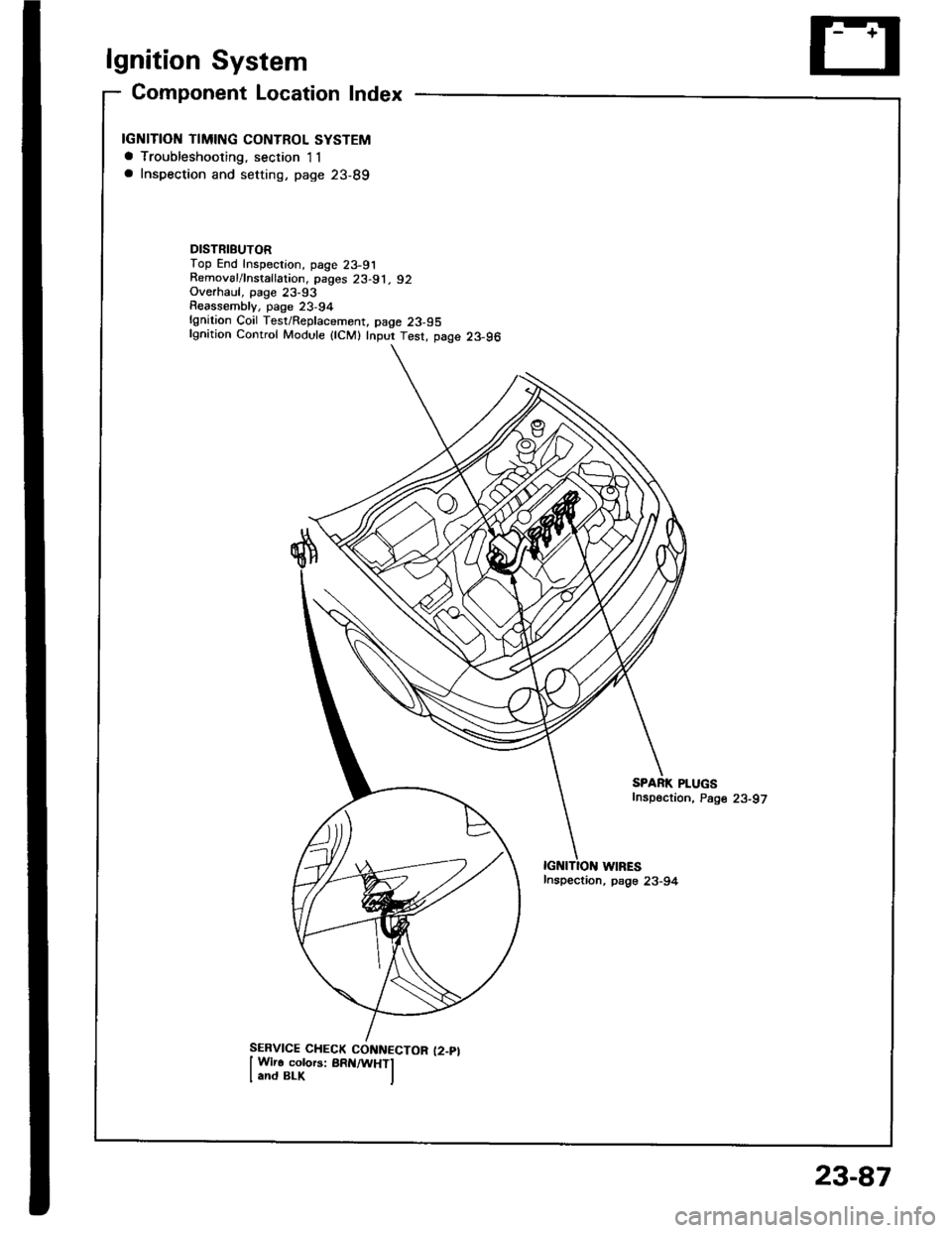

lgnition System

Gomponent Location Index

IGNITION TIMING CONTROL SYSTEMa Troubleshooting, section I1a Inspection and setting, page 23-89

DISTRIBUTORTop End Inspection, page 23-91Removal/lnstallation, pages 23-91, 92Overhaul, page 23-93Reassemblv, page 23,94lgnition Coil Test/Replacement, page 23-95lgnition Control Module {lCM} Inpur Test, page 23-96

WIRESInspection, psge 23-94

SPARK PLUGSfnspection, Page 23-97

23-87

Page 1194 of 1413

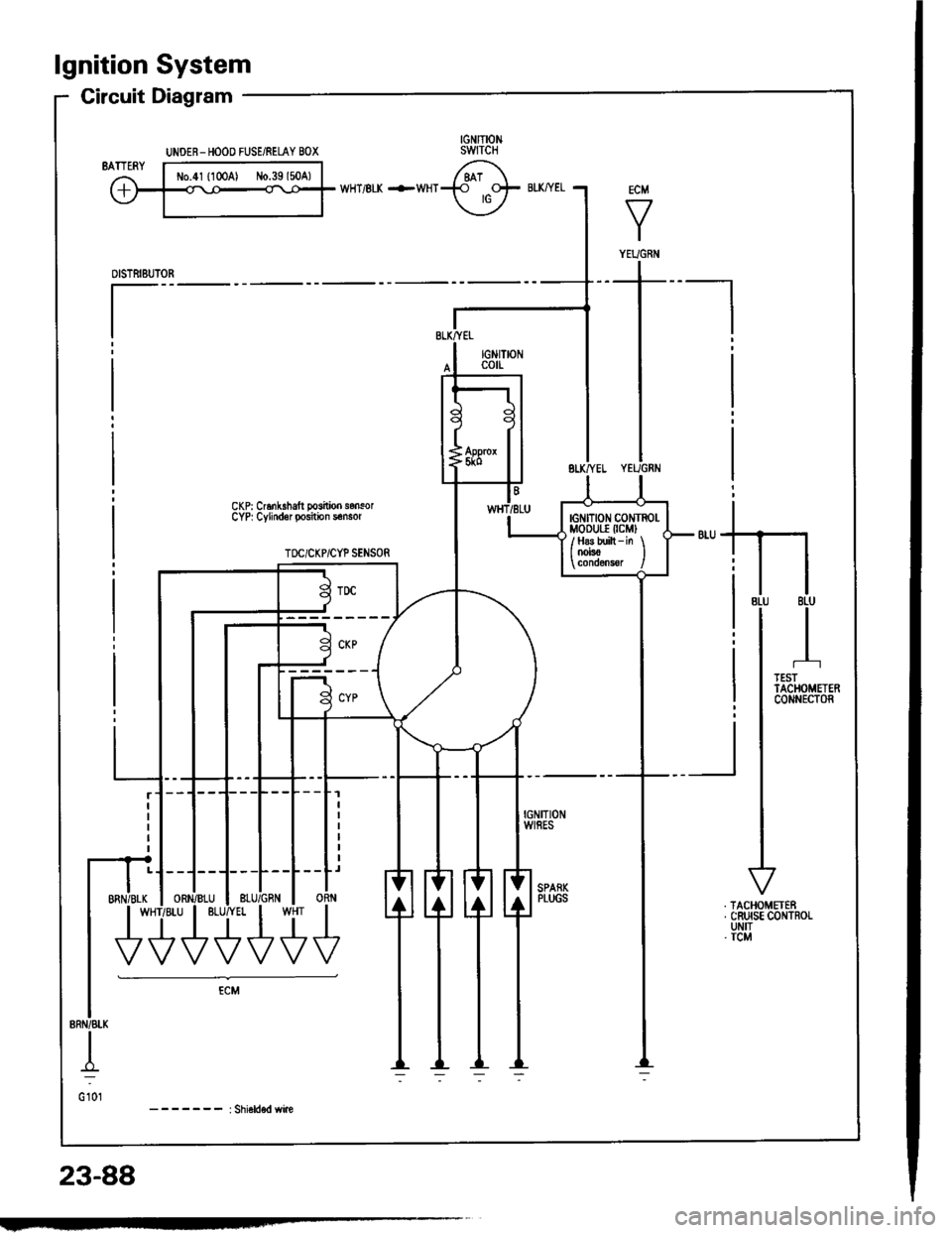

lgnition System

Circuit Diagram

CKP: Cr6nk.halt posilioo sonsorCYP| Cylindor position s€nsor

TOC/CKP/CYP SENSOR

-_r_1=__E

-J---L--L--Lr

ORN

U'+++

UNOER- HOOO FUSE/RELAY BOX

ECM

V

I

YEUGNiI

tG tTtoN c0NTROl-MoDUr.r (cMl

/ H8s built - in \I OOrsO I

23-88

Page 1195 of 1413

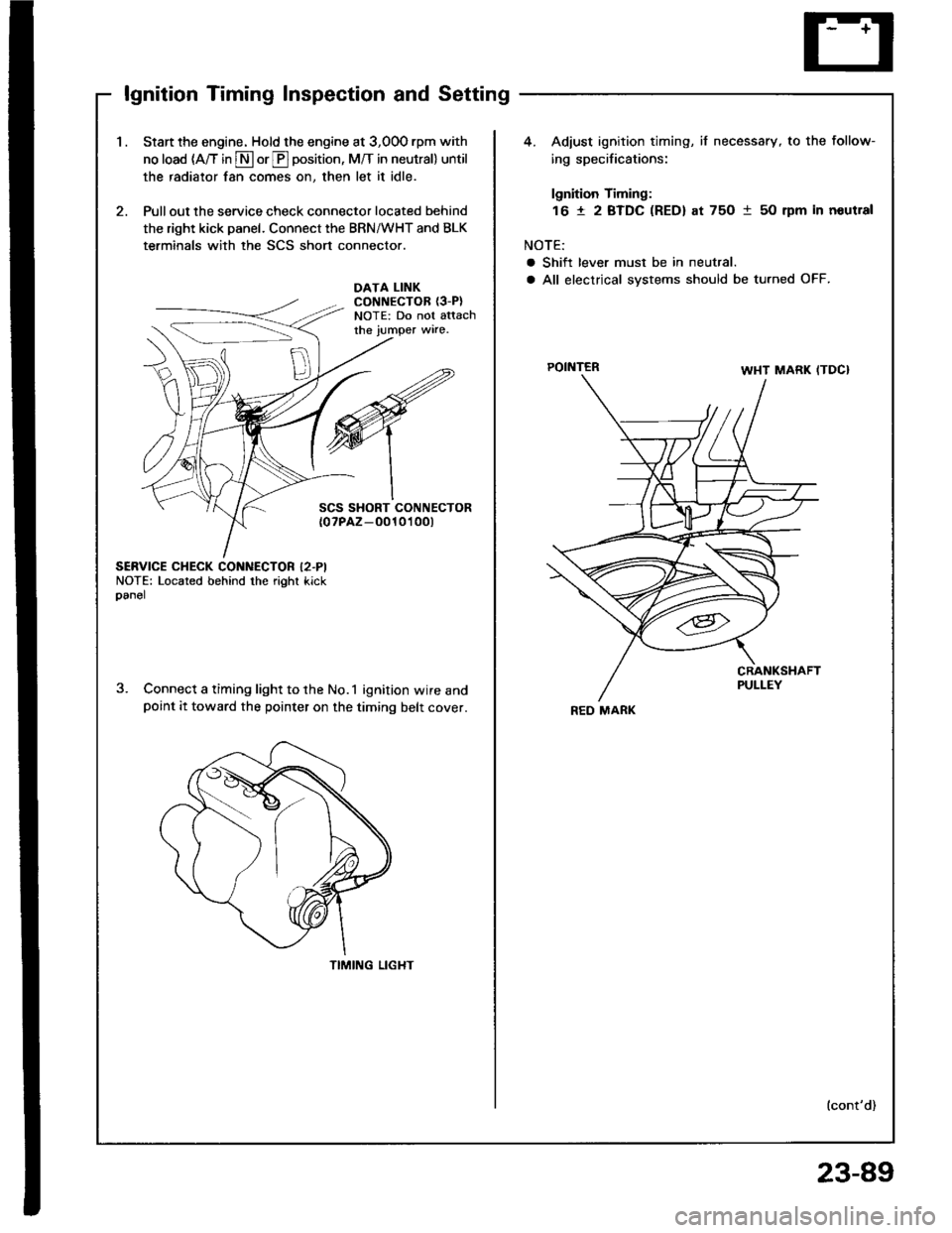

lgnition Timing Inspection and Setting

1.Start the engine. Hold the engine at 3,00O rpm with

no load (A/T in S or E position, M/T in neutral) until

the radiator fan comes on, then let it idle.

Pull out the service check connector located behind

the right kick panel. Connect the BRN/WHT and BLK

terminals with the SCS short connector.

4. Adiust ignition timing, if necessary, to the follow-

ing specifications:

lgnition Timing:

16 t 2 BTDC (RED) at 75O 1 50 rpm in noutral

NOTE:

a Shift lever must be in neutral.

a All electrical systems should be turned OFF.DATA LINKCONNECTOR {3-P}NOTE: Do not attachthe jumper wire.

POINTER

SCS SHORT CONNECTOR{0?PAZ-O010't 00t

SERVICE CHECK CONNECTOR I2.PINOTE: Located behind the right kickoanel

Connect a timing light to the No.1 ignition wire andpoint it toward the pointer on the timing belt cover.

TIMING LIGHT

lcont'd)

REO MARK

23-89

Page 1196 of 1413

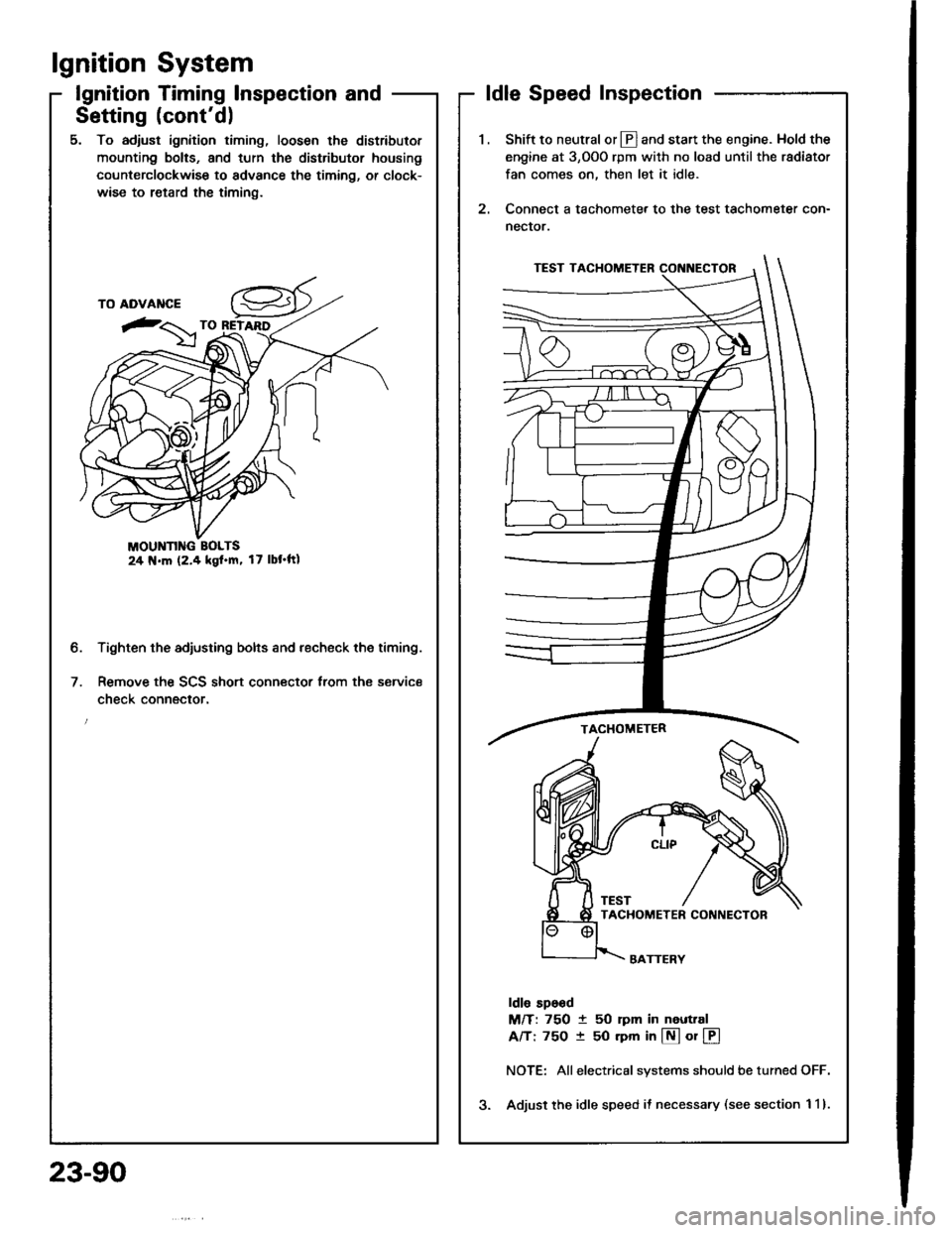

lgnition System

lgnition Timing lnspection and

Setting (cont'd)

5. To adjust ignition timing, loosen the distributor

mounting bolts, and turn the distributor housing

counterclockwise to advance the timing, or clock-

wise to retard the timing.

MOUNN G BOLTS24 N.m (2.4 kgl.m, 17 lbt'ftl

Tighten the adjusting bolts and recheck the timing.

Remove the SCS short connector trom the service

check connector.

2.

ldle Speed Inspection

Shift to neutral or Ll] and start the engine. Hold the

engine at 3,OOO rpm with no load until the radiator

fan comes on, then let it idle.

Connect a tachometer to the test tachometer con-

nector.

ldle sp6od

M/T: 750 t 50 rpm in neuttal

A/T: 75O t 50 rpm in @ or @

NOTE: Allelectrical systems should be turned OFF.

Adjust the idle speed il necessary (see section 1 1).

b.

23-90

Page 1197 of 1413

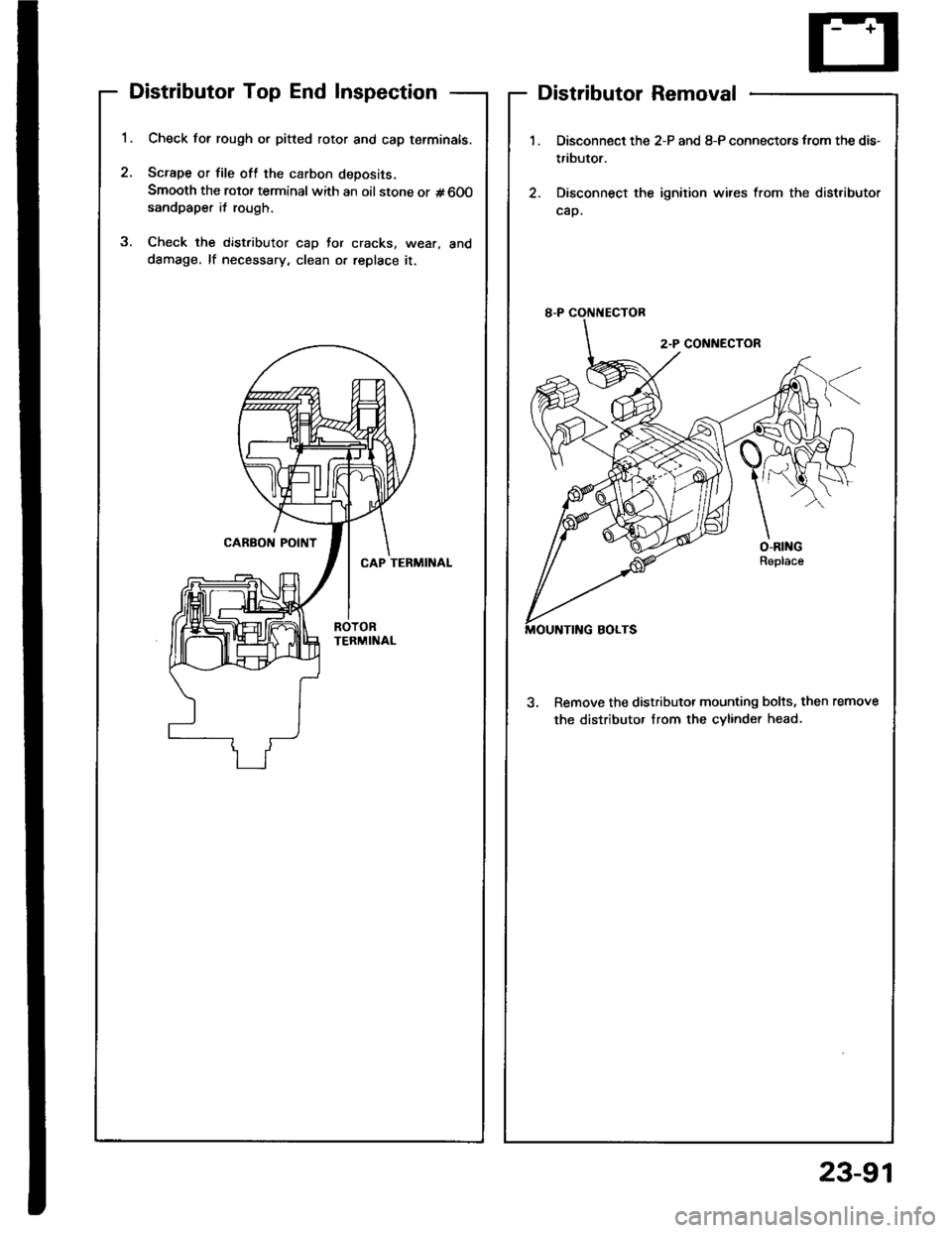

Distributor Top End Inspection

1.

2.

Check for rough or pitted rotor and cap tefminals.

Scrape or file oft the carbon deposits.

Smooth the rotor terminal with an oil stone or #600sandpaper i{ rough.

Check the distributor cap Jor cracks, wear, and

dSmage, lf necessary, clean or replace it.

2

Distributor Removal

1.

2.

Disconnect the 2-P and 8-P connectors from the dis-

tributor.

Disconnect the ignition wires from the distributor

cap.

3. Remove the distributor mounting bolts, then remove

the distributor Irom the cvlinder head.

23-91

Page 1198 of 1413

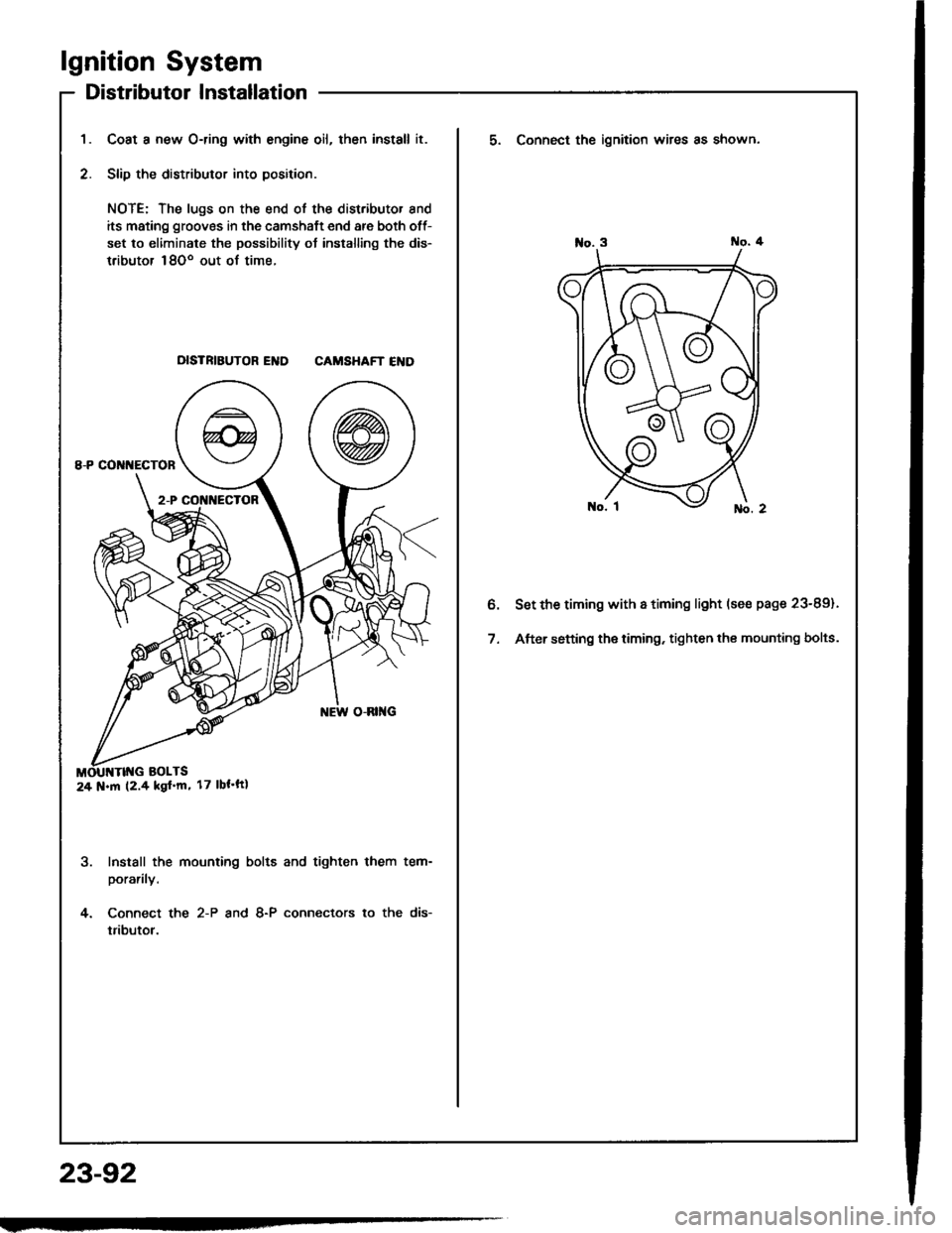

lgnition System

Distributor Installation

Coat a new O-ring with engine oil, then install it.

Slip the distributor into position.

NOTE: The lugs on the end of the distributor and

its mating grooves in the camshaft end are both off-

set to eliminate the possibility ot installing the dis-

tributor 18Oo out of time.

DISTRIBUTOR END CAMSHAFT END

Install the mounting bolts and tighten them tem-

porarily.

Connect the 2-P and 8-P connectors to the dis-

tributor.

24 N.m (2.4 kgf'm' 17 lbt'ft|

23-92

5. Connect the ignition wires as shown.

Set the timing with a timing light (se€ page 23-89).

After setting the timing, tighten the mounting bolts.

Page 1199 of 1413

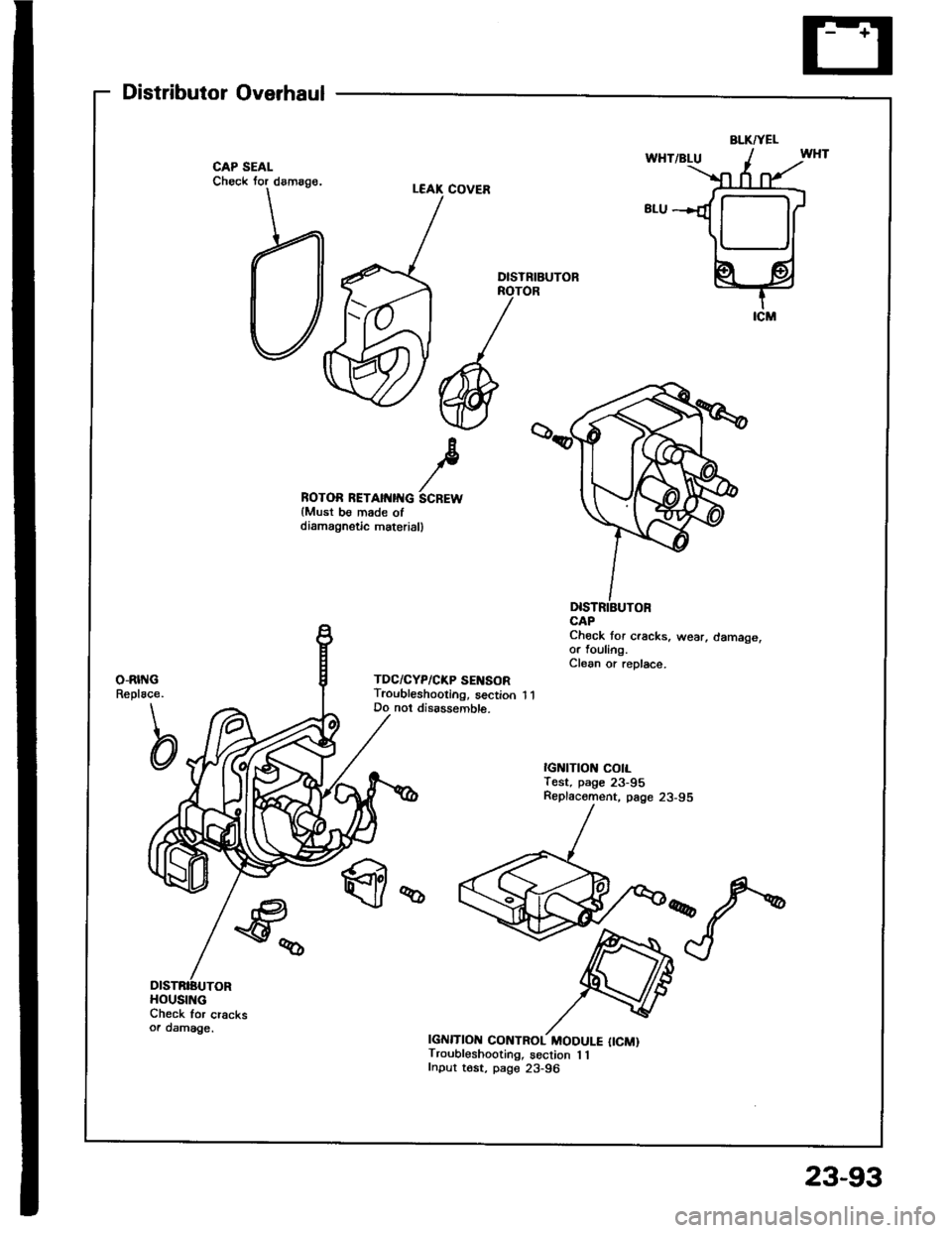

Distributor Overhaul

Check for cracksoa damage.

ROTOR RETAII{IITG SCREWlMust be made ofdiamagnstic materiall

DlsTNIBUTOR

Chock tor cracks, wear, damage,or fouling.Clean or replace.

IGNITION CONTROL MODULE {ICM)Troubleshooting, section 1 1Input tost, page 23-96

BLKTYEL

HOUSING

23-93

Page 1200 of 1413

lgnition System

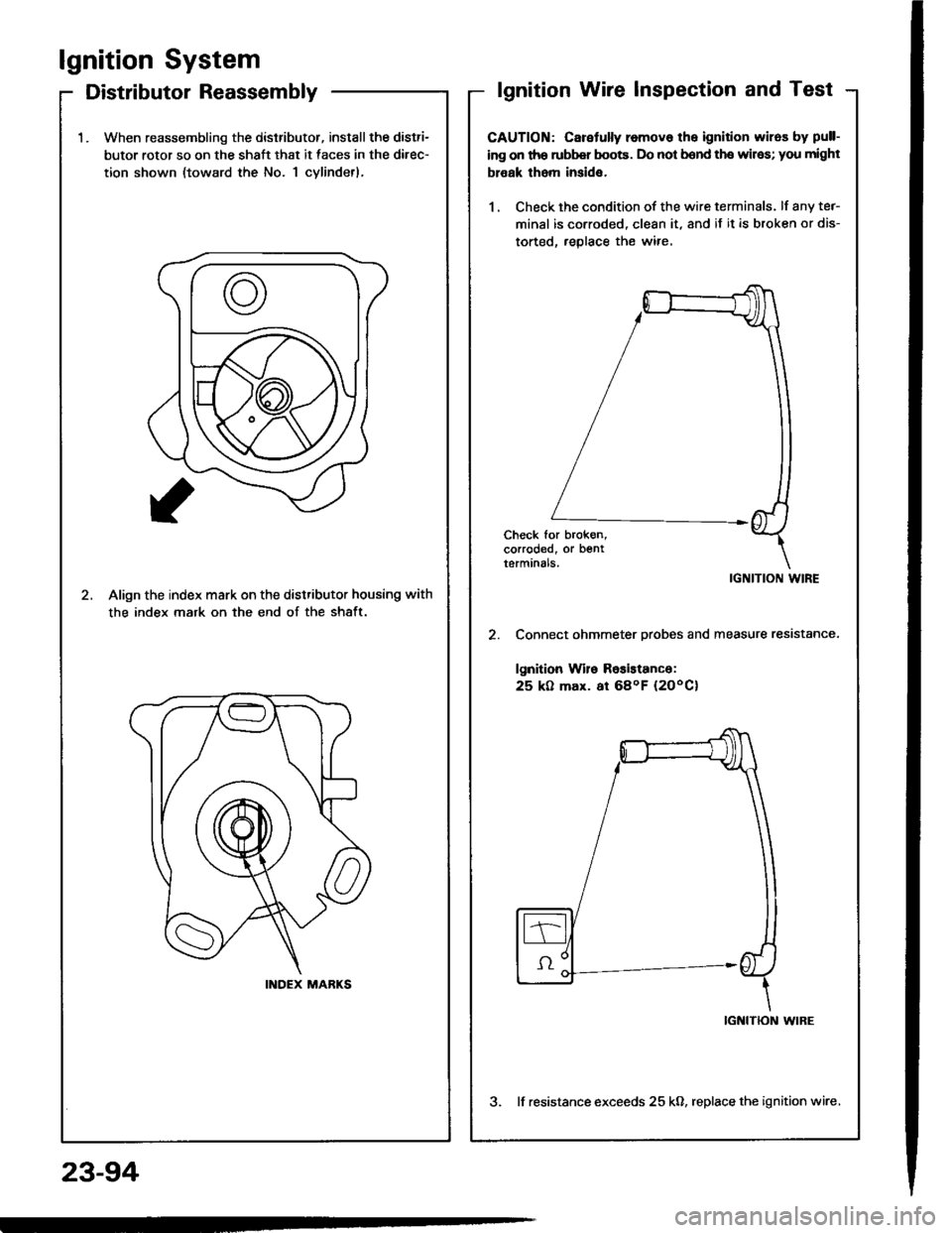

Distributor Reassembly

23-94

1.When reassembling the dislributor, install the distri-

butor rotor so on the shaft that it faces in the direc-

tion shown (toward the No. 1 cylindetl,

2.Align the index mark on the distributor housing with

the index mark on the end of the shaft.

INDEX MARKS

lgnition Wire lnspection and Test

CAUTION: Caretully removo the ignition wiros by pull-

ing on tho rubbq boots. Do not bend the wilos; you might

bl€ak tham inside.

1 . Check the condition of the wire terminals. lf any te.-

minal is corroded, clean it. and if it is broken or dis-

torted. reolace the wire.

IGNITION WIRE

Connect ohmmeter probes and measure resistance.

lgnition Wile Roaistanco:

25 k0 max. at 68oF (2OoCl

2.

IGNITION WIRE

3. lf resistance exceeds 25 kO, replace the ignition wire,

Trending: vehicle speed sensor circuit, hatch trim, rear view mirror, Exhaust, Timing belt, fuse box location, ESP