HONDA INTEGRA 1994 4.G Workshop Manual

Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 411 of 1413

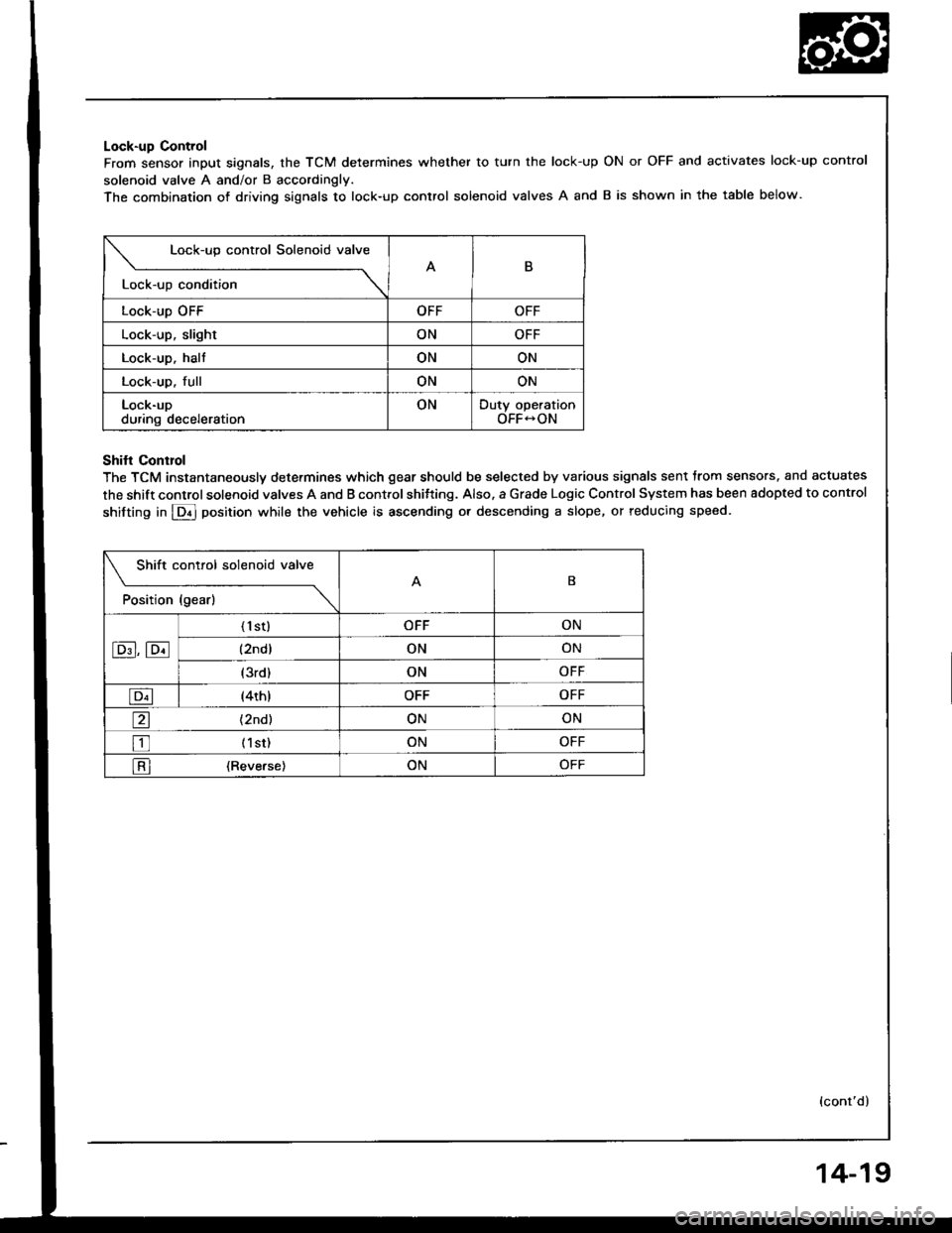

Lock-up Control

From sensor input signals, the TCM determines whether to turn the lock-up

solenoid valve A and/or B accordingly.

The combination of driving siqnals to lock-up control solenoid valves A and

ON or OFF and activates lock-up control

B is shown in the table below.

Lock-up control Solenoid valve

B

Lock-up condition \

Lock-up OFFOFFOFF

Lock-up, slightONOFF

Lock-up. haltONON

Lock-up. fullONON

Lock-upduring decelerationONDuty operationOFF-ON

Shifl Conrrol

The TCM instantaneously determines which gear should be selected by various signals sent trom sensors. and actuates

the shift control solenoid valves A and B control shitting. Also. a Grade Logic Control System has been adopted to control

shifting in E] position while the vehicle is ascending or descending a slope, or reducing speed.

Shift control solenoid valve

t"*b" ,t"-l

------\B

E,E

('l st)OFFON

(2ndlONON

(3rd)ONOFF

E(4th)OFFOFF

a(2nd)ONON

tr (lst)ONOFF

l-Rl {Reverse)ONOFF

(cont'd)

14-19

Page 412 of 1413

Description

Electronic Control System (cont'd)

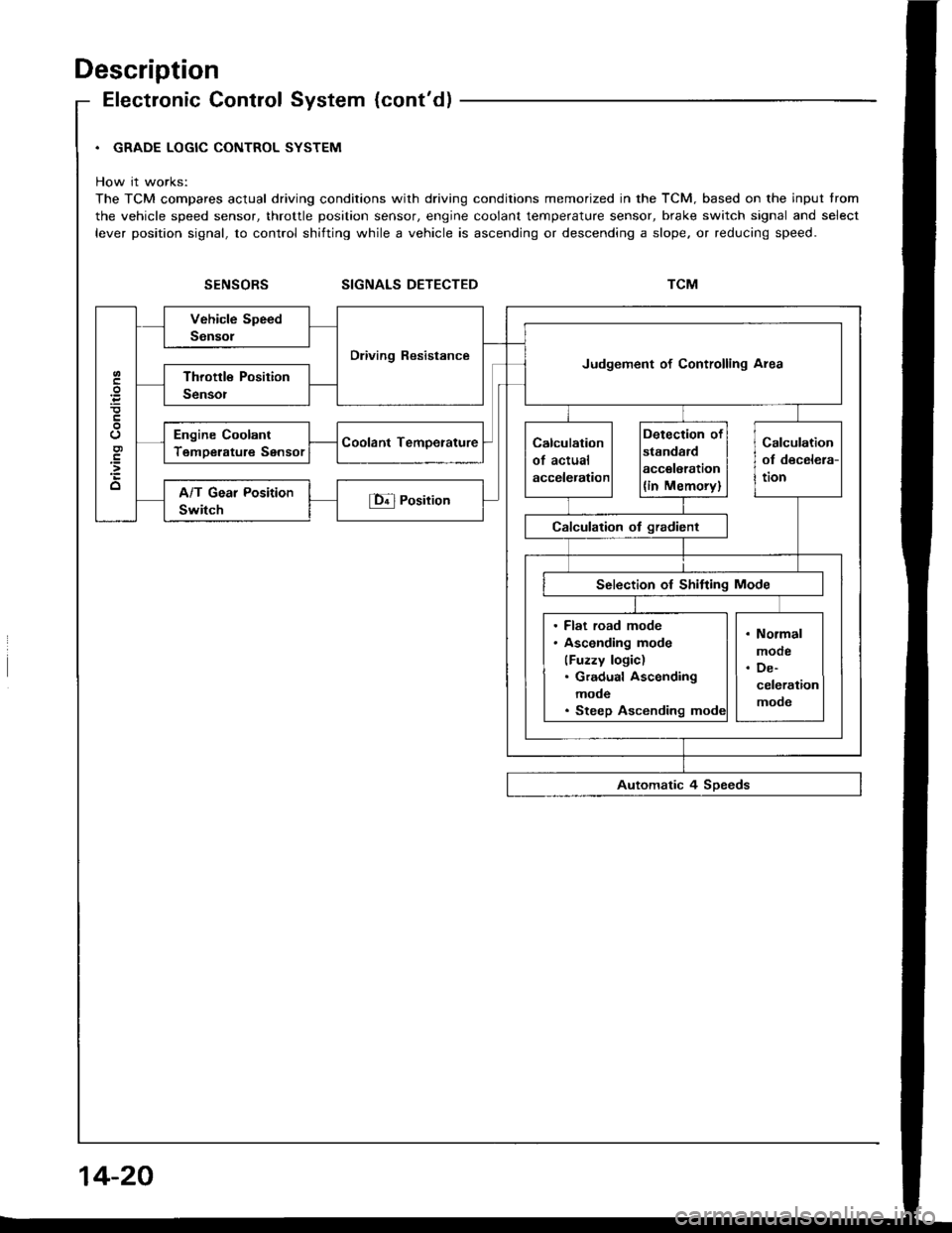

. GRADE LOGIC CONTROL SYSTEM

How it works:

The TCM compares actual driving conditions with driving conditions memorized in the TCM. based on the input trom

the vehicle speed sensor, throttle position sensor, engine coolant temperature sensor, brake switch signal and select

lever position signal, to control shifting while a vehicle is ascending or descending a slope. or reducing speed.

SIGNALS DETECTED

Dliving ResistanceJudgement of Controlling Area

Engine Coolant

TemDerature Sensor

. Flat road mode. Asconding mode

(Fuzzy logic). Gradual Ascending

mode. Steep Ascending

14-20

Page 413 of 1413

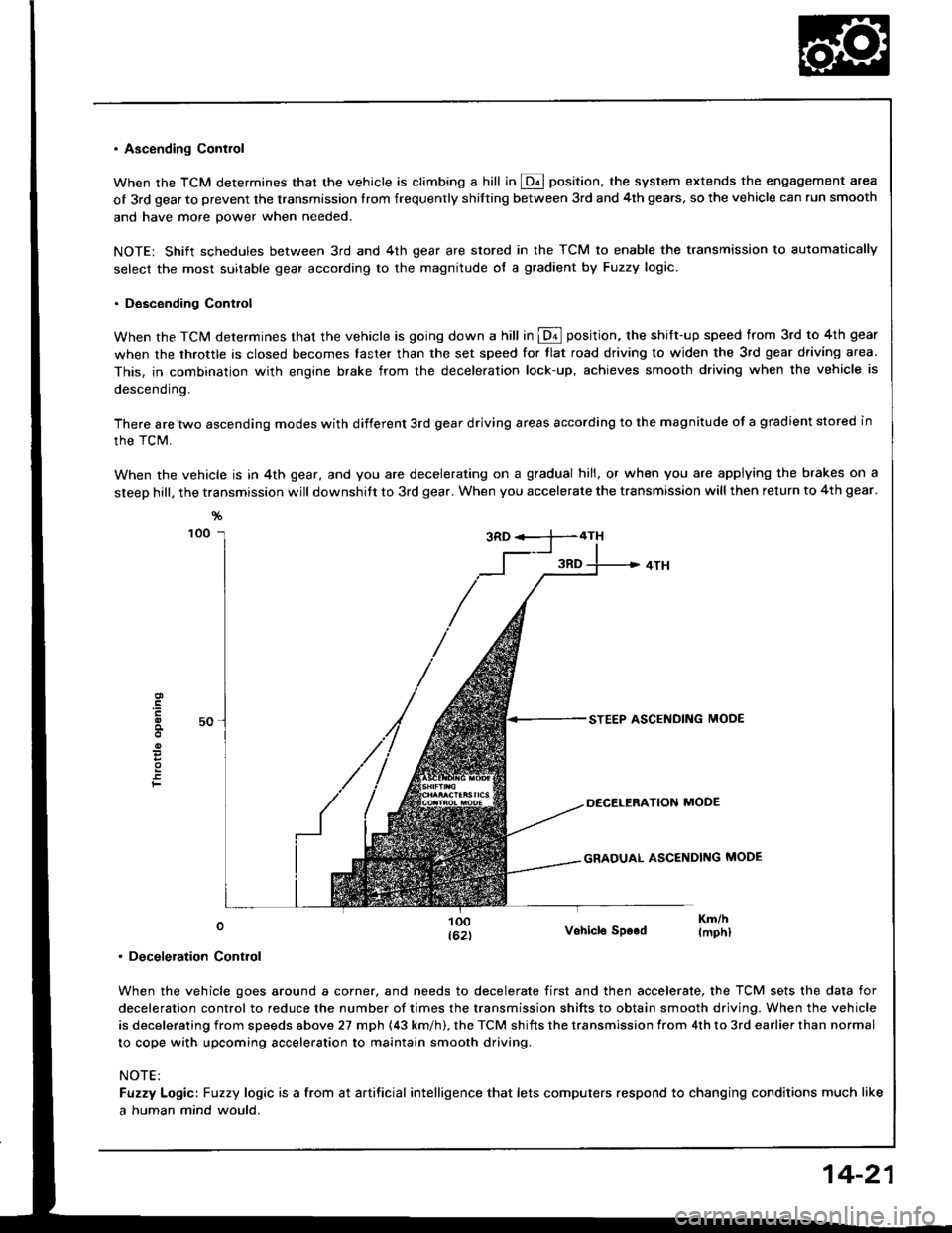

. Ascending Contlol

When the TCM determines that the vehicle is climbing a hill in @ position, the system extends the engagement area

of 3rd gear to prevent the transmission Irom frequenrly shitting between 3rd and 4th gears, so the vehicle can run smooth

and have more power when needed.

NOTE: Shift schedules between 3rd and 4th gear are stored in the TCM to enable the transmission to automatically

select the most suitable gear according to the magnitude of a gradient by Fuzzy logic.

. Descending Control

When the TCM determines that the vehicle is going down a hill in @ position. the shift-up speed from 3rd to 4th gear

when the throttle is closed becomes taster than the set speed for tlat road driving to widen the 3rd gear driving area.

This, in combination with engine brake from the deceleration lock-up, achieves smooth driving when the vehicle is

descending.

There are two ascending modes with different 3rd gear driving areas according to the magnitude of a gradient stored in

the TCM.

When the vehicle is in 4th gear, and you are decelerating on a gradual hill, or when you are applying the brakes on a

steep hill, the transmission will downshitt to 3rd gear. When you accelerate the transmission will then return to 4th gear.

F

0

. Deceleration Control

Vohicle SDood

When the vehicle goes around a corner, and needs to decelerate first and then accelerate, the TCM sets the data for

deceleration control to reduce the number of times the transmission shifts to obtain smooth driving. When the vehicle

is decelerating from speeds above 27 mph (43 km/h). the TCM shifts the transmission from 4th to 3rd earlier than normal

to cope with upcoming acceleration to maintain smooth driving.

NOTE:

Fuzzy Logic: Fuzzy logic is a from at artificial intelligence that lets computers respond to changing conditions much like

a human mind would.

14-21

Page 414 of 1413

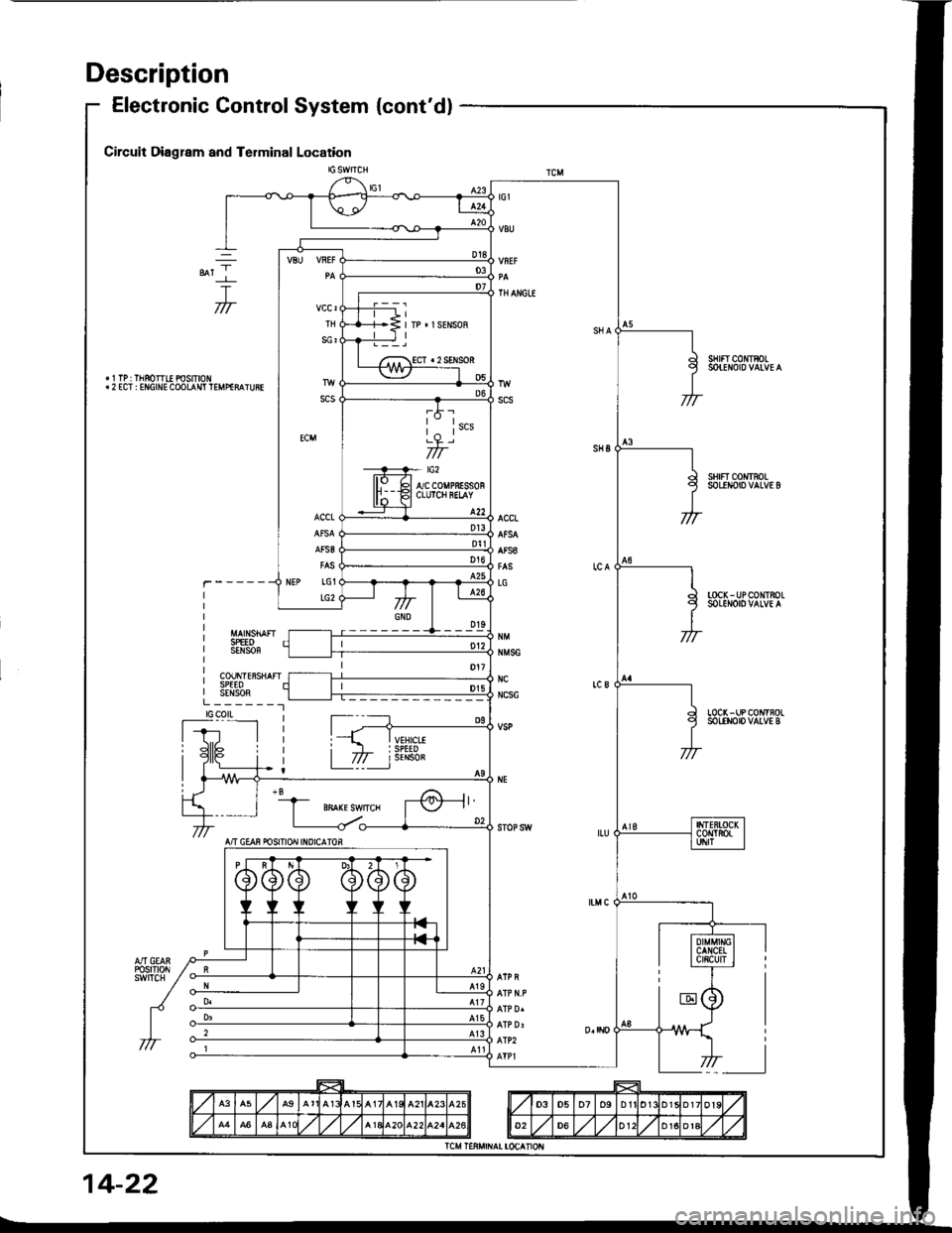

Description

Electronic Control System {cont'dl

TH

SCI

scs

ECM

ACCL

AFSB

NEP LG1

LG2

*t-l

T777

sHtfT c0mRoL

SHFT COI{rFOLSOLINOIO VALVE B

TOCK-UPCONTROLSOLENOIOVALVE A

SPEEOSENSOF

COUNTE8SHAFISPEEOSENSORL_______.1tGcotLLOC( - UP CONTROLSOLENOIO VALVE B

f-r,'__lI Jll6 i

A/T CEAN POSITION INDICATOR

14-22

Page 415 of 1413

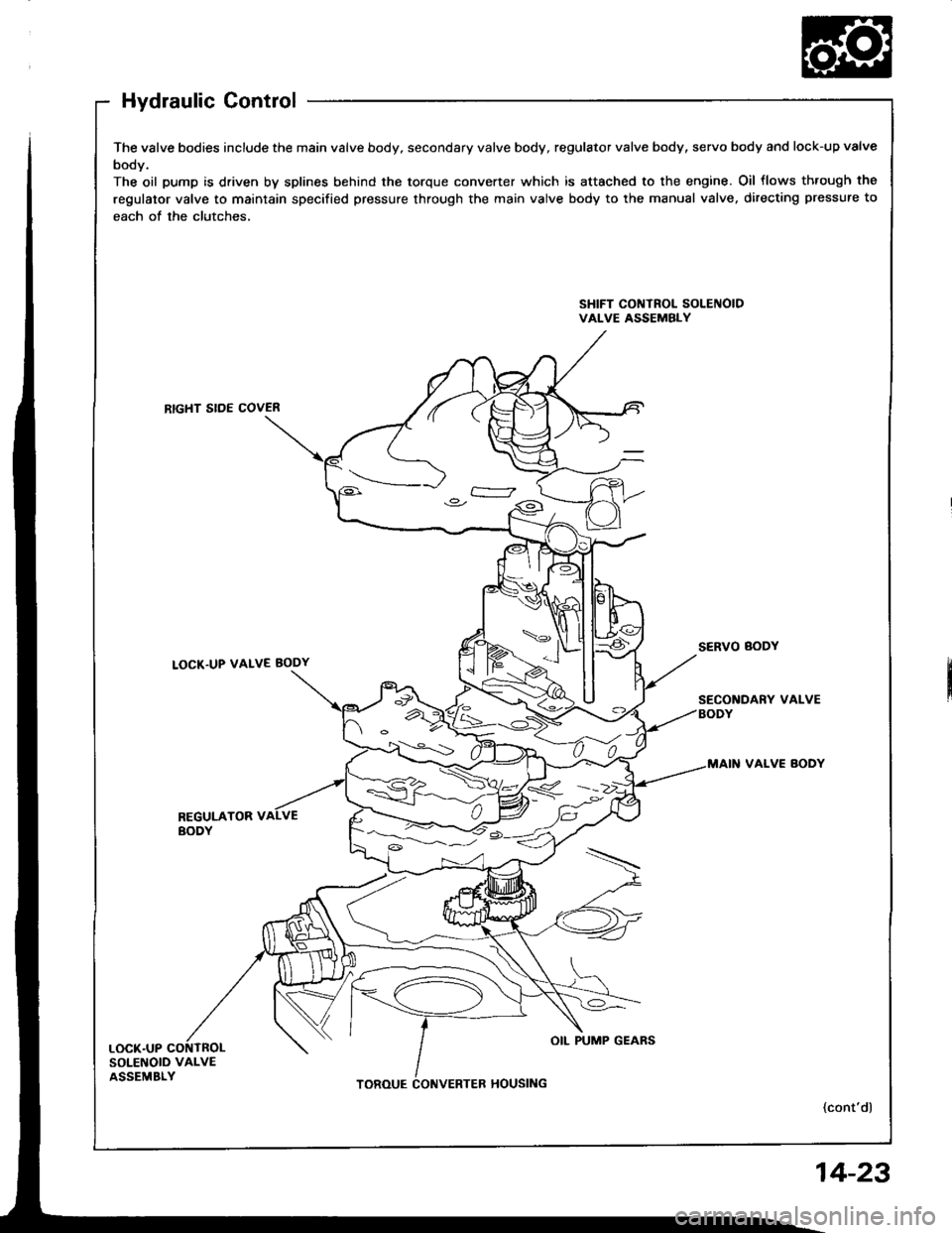

Hydraulic Control

The valve bodies include the main valve body, secondary valve body, regulator valve body, servo body and lock-up valve

body.

The oil pump is driven by splines behind the torque converter which is attached to the engine. Oil flows th.ough the

regulator valve to maintain specified pressure through the main valve body to the manual valve, directing pressure to

each of the clutches,

SHIFT CONTROL SOLEIIOIDVALVE ASSEMBLY

RTGHT SIDE COVER

LOCK.UP VALVE BODY

VALVE BODY

REGULATOR VBODY

SOLENOID VALVEASSEMBLY

4<.__i: )o.-

OIL PUMP GEARS

14-23

Page 416 of 1413

Description

Hydraulic Control (cont'dl

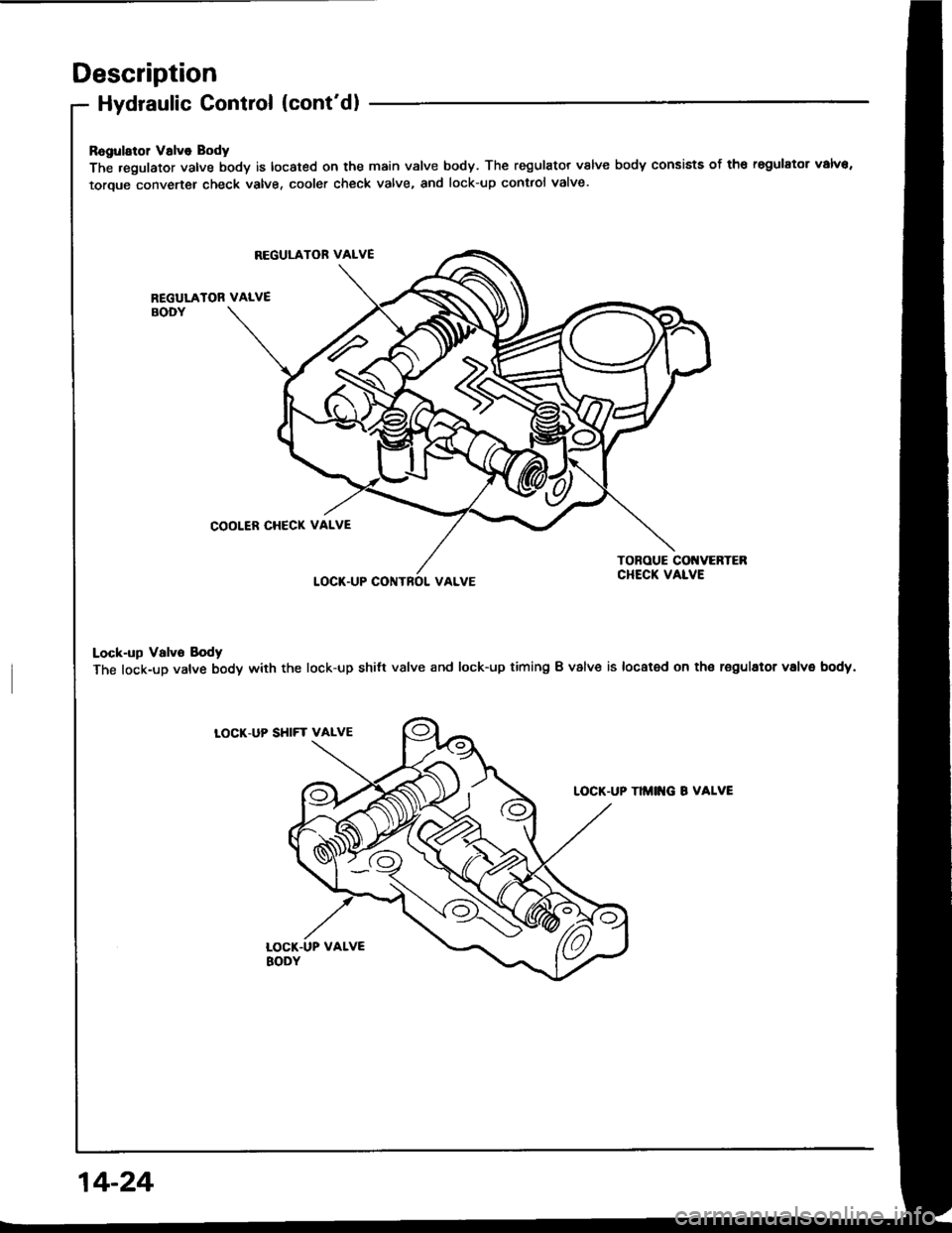

Ragularol Valve Body

The .egulator valve body is located on the main valve body. The regulator valve body consists of th€ regulator valva,

toroue converter check valve, cooler check valve, and lock-up contlol valve.

REGULATOR VALVE

REGULATOR VALVEBODY

COOLER CHECK VALVE

LOCT.UP CONTROI. VALVE

TONOUE COI{VERTEBCHECK VALVE

Lock-up Valvo Body

The lock-up valve body with the lock-up shilt valve and lock-up timing B valve is located on th€ regulator volvs body.

LOCK.UP SHIFT VALVE

TIMITG B VALVE

14-24

Page 417 of 1413

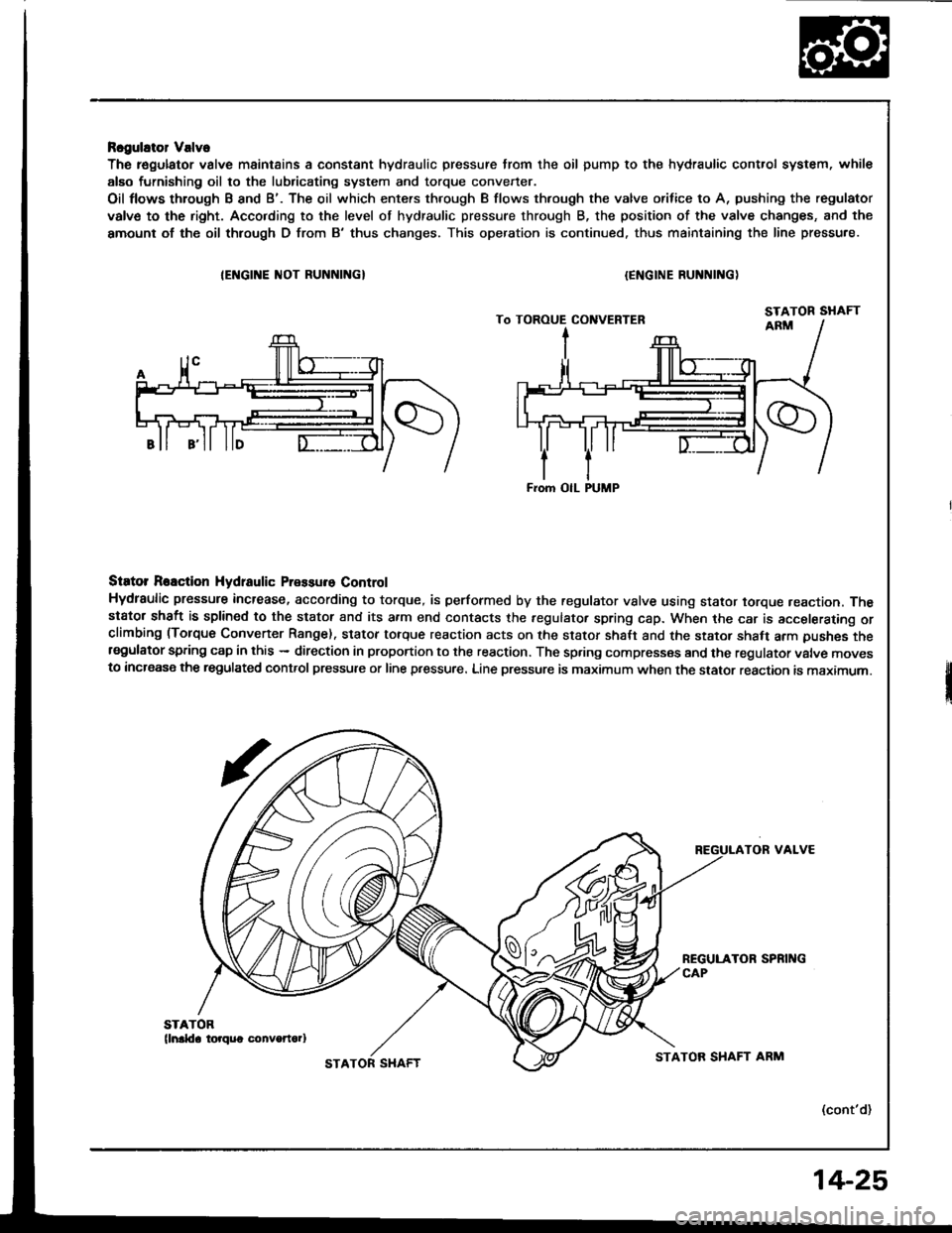

Rcgulator Valve

The r€gulator valve maintains a constant hydraulic pressure from the oil pump to the hydraulic control system, whil€

alEo furnishing oil to the lubricating system and torque convener.

Oil flows through B and B'. The oil which enters through B flows thfough the valve orifice to A, pushing the regulator

valve to the right. Acco.ding to the level of hydraulic pressure through B, the position of the valve changes, and the

amount of the oil thlough D from B'thus changes. This operation is continued. thus maintaining the line pressure.

IEI{GINE ]IIOT RUNNINGI{ENGINE RUNNING)

Siator Reaction Hydtaulic Pressure Control

Hydraulic pressure increase, according to torque, is performed by the regulator vslve using stator torque reaction. Thestator shaft is splined to the stator and its a.m end contacts the fegulator spring cap. When the car is accelerating orclimbing (Torque Convener Range). stator torque reaction acts on the stator shalt and the stator shaft arm pushes thersgulator spring cap in this - direction in proportion to the reaction. The spring compresses and the regulator valve movesto increase the regulated control pressure or line pressure. Line pressure is maximum when the stator reaction is maximum.

TOR VALVE

(cont'd)

From OIL PUMP

STATOR SHAFTSTATOR SHAFT ARM

14-25

Page 418 of 1413

Description

Hydraulic Control (cont'dl

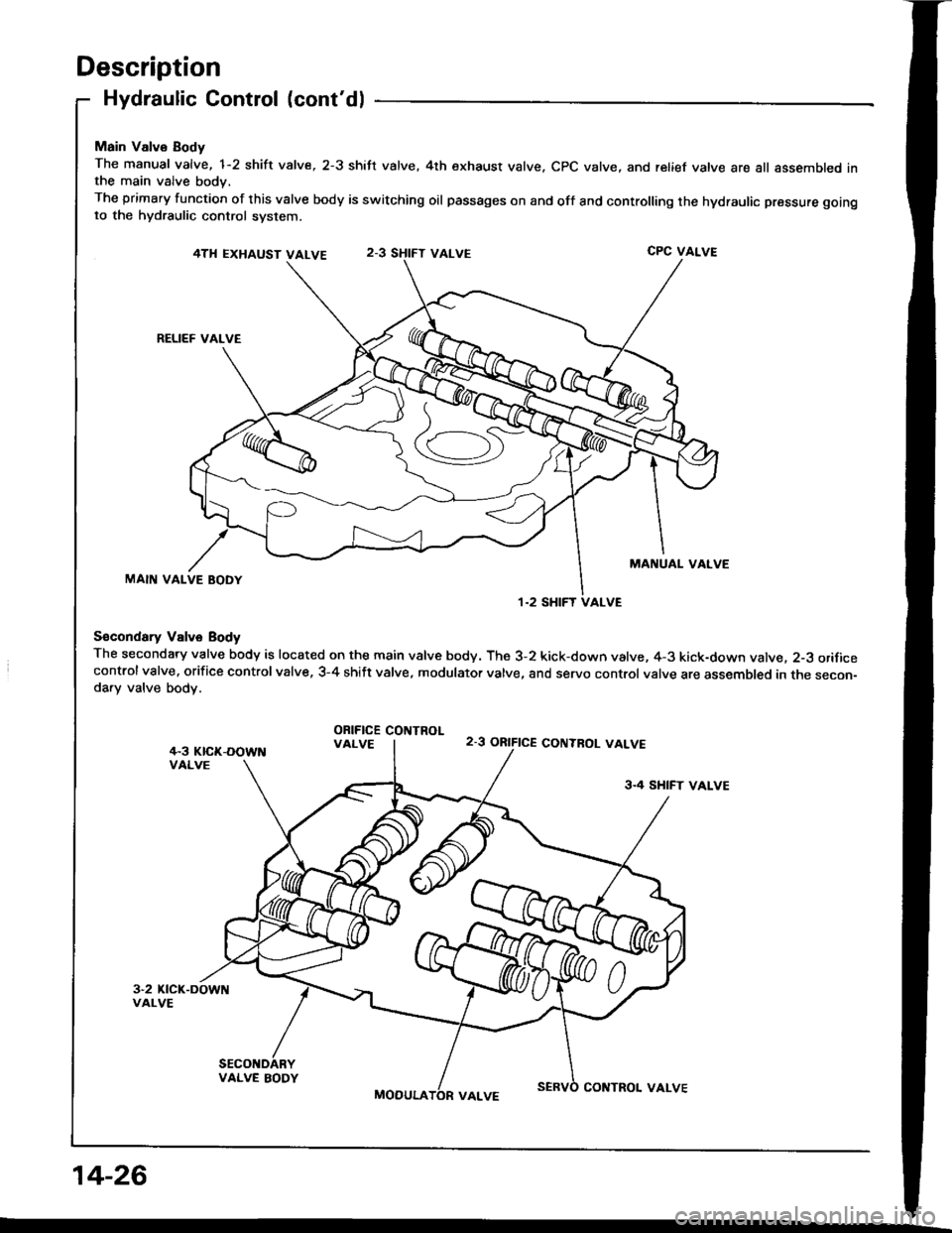

Main Valvo Body

The manual valve, 1-2 shift valve, 2-3 shift valve. 4th exhaust valve. CPC valve, and relief vatve are all assembled inthe main valve body,

The primary function of this valve body is switching oil passages on and off and controlling the hydraulic pressure gotngto the hydraulic control system.

4TH EXHAUST VALVECPC VALVE

RELIEF VALVE

MANUAL VALVEMAIN VALVE BODY

S€condary Vslve Body

The secondary valve body is located on the main valve body. The 3-2 kick-down valve, 4-3 kick-down valve. 2-3 orificecontrolvalve. orifice controlvalve, 3-4 shift valve, modulator valve, and servo control valve are assembled in the secon-da.y valve body.

ORIFICE COIITROLVALVE2-3 ORIFICE CONTBOL VALVE

3.4 SHIFT VALVE

VALVE BODY

MOOULACOITTROL VALVE

1.2 SHIFT VALVE

14-26

Page 419 of 1413

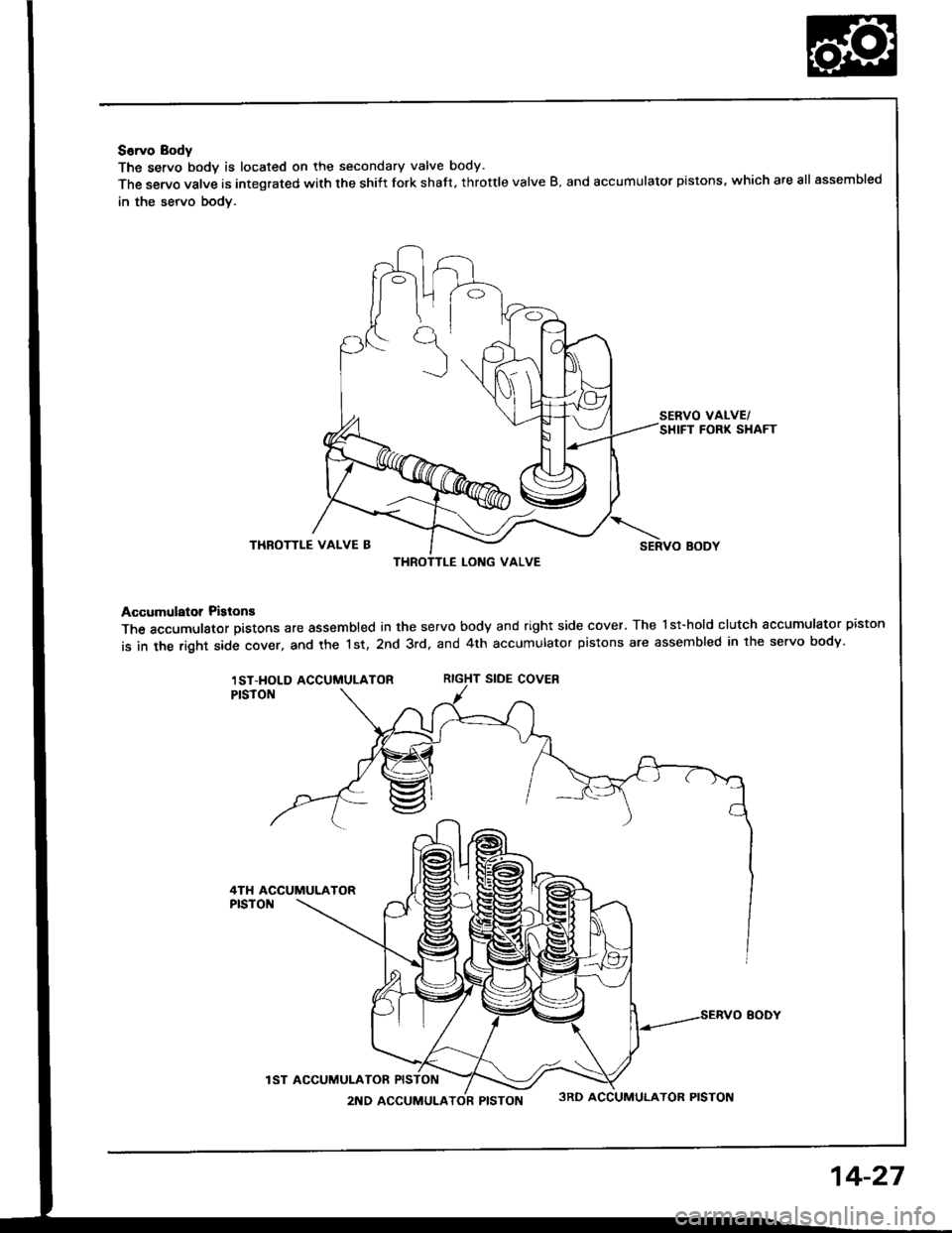

S6rvo Body

The servo bodv is located on the secondary valve body.

The servo valve is integrated with the shiit fork shatt, throttle valve B. and accumulator pistons, which are all assembled

in the servo bodv.

SERVO VALVE/SHIFT FORK SHAFT

THROTTLE VALVE BSERVO BODY

Accumulator Pislons

The accumulator pistons are assembled in the servo body and right side cover. The l st-hold clutch accumulator piston

is in the right side cover, and the 1st, 2nd 3rd, and 4th accumulator pistons are assembled in lhe servo body.

RIGHT SIDE COVER

THROTTLE LONG VALVE

1ST-HOLD ACCUMULATOR

4TH ACCUMULATOR

IST ACCUMUI-ATOR

2ND ACCUMULATOR PISTON3RD ACCUMULATOR PISTON

14-27

Page 420 of 1413

![HONDA INTEGRA 1994 4.G Workshop Manual Description

Genelal Chart ol Hydraulic Pressure

Hydraulic Flow

. Regulator Valve

. Manual Valve

. Modulator Valve

. 1-2 Shilt Valve l. 2-3 Shitt Valve. 3 4 Shift Vlave ]

. Throttle Valve B

Oil Pump - HONDA INTEGRA 1994 4.G Workshop Manual Description

Genelal Chart ol Hydraulic Pressure

Hydraulic Flow

. Regulator Valve

. Manual Valve

. Modulator Valve

. 1-2 Shilt Valve l. 2-3 Shitt Valve. 3 4 Shift Vlave ]

. Throttle Valve B

Oil Pump -](/img/13/6067/w960_6067-419.png)

Description

Genelal Chart ol Hydraulic Pressure

Hydraulic Flow

. Regulator Valve

. Manual Valve

. Modulator Valve

. 1-2 Shilt Valve l. 2-3 Shitt Valve. 3 4 Shift Vlave ]

. Throttle Valve B

Oil Pump - Regulator Valve -

Distribution ot Hydraulic Pressure

Line Pressure

Torque Converter Pressure

Lubrication Pressure

-,.Ltne rressure

] Torque Converter Pressure

L Lubrication Pressure

To Select Line Pressure

Modulator Pressure

Clutch Pressure

Throttle B Pressure

NO.DESCRIPTION OF PRESSURENO.DESCRIPTION OF PRESSURENO.DESCRIPTION OF PRESSURE

ILIN E6CMODULATOR

ITOCK-UP CONTROL SOLENOID VATVE AI55THROTTLE B

2LIN E6DMODULATOR(IOCX.UP CONTROT SOTENOID VALVE B)56THROTTLE B

3LIN E9LIN E57THROTTLE B

3'LINE10l ST CLUTCH58THROTTLE B

3"LINE1ST-HOLD CLUTCH90TOROUE CONVERTER

4LIN EIt)l ST.HOLD CLUTCH91TOROUE CONVERTER

LIN E18LINE92TOROUE CONVERTER

5LIN E202ND CLUTCH93OIL COOLER

5'LIN E212ND CLUTCH94TOROUE CONVERTER

5"LIN E25LIN E95LUBRICATION

6MODULATOR303RD CLUTCH96TOROUE CONVERTER

6'�MODULATOR313RD CLUTCH97TOROUE CONVERTER

6AMODULATOR(SHIFT CONTROL SOTENOID VALVE A404TH CLUTCH99SUCTION

6BMODULATOR(SHIFT CONTROL SOLENOID VALVE B414TH CLUTCHBLEED

14-28