HONDA INTEGRA 1994 4.G Workshop Manual

INTEGRA 1994 4.G

HONDA

HONDA

https://www.carmanualsonline.info/img/13/6067/w960_6067-0.png

HONDA INTEGRA 1994 4.G Workshop Manual

Trending: Ignition coil, center console, fuse box diagram, crank shaft sensor, boot lid, hose, under hood fuse

Page 571 of 1413

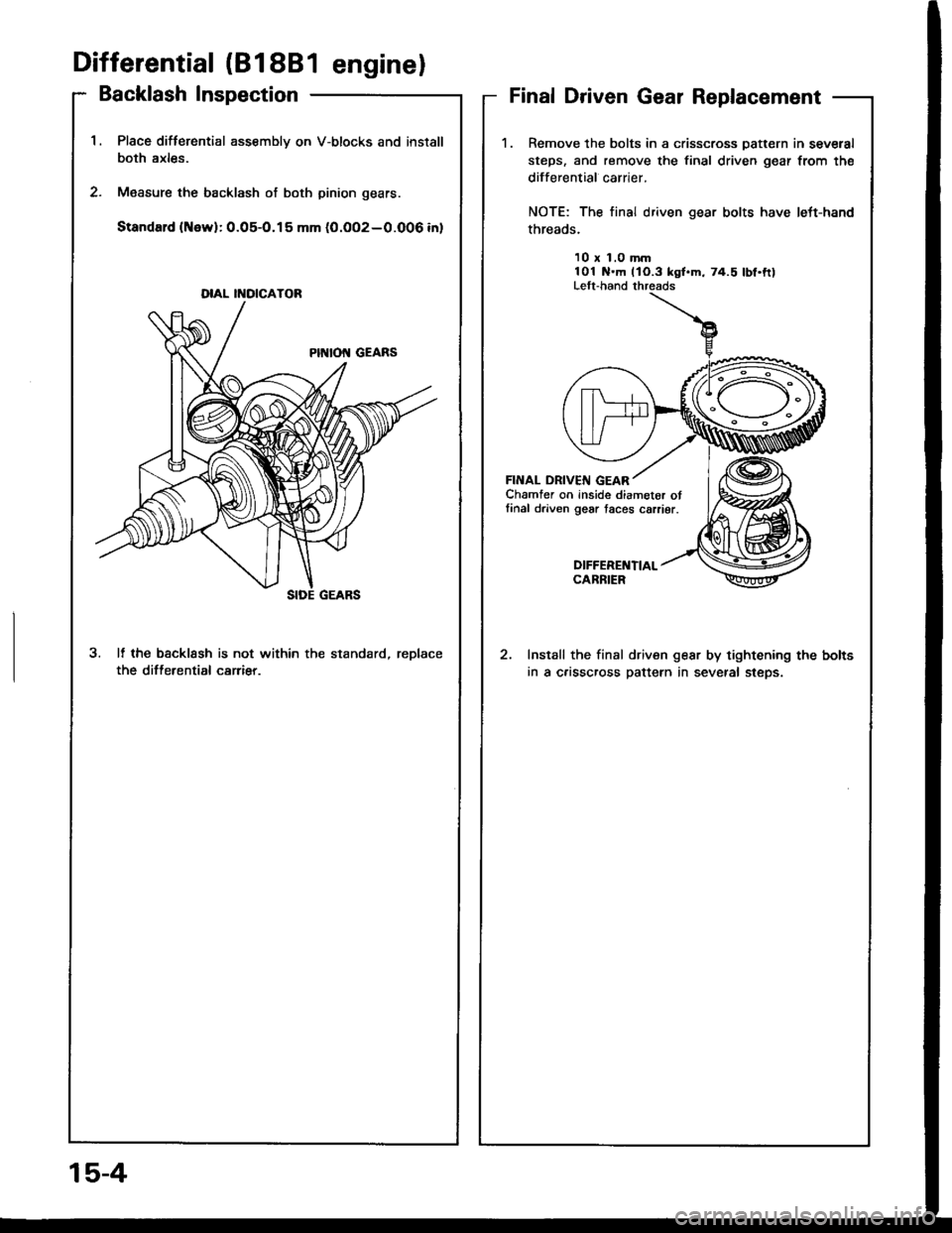

'1.Place difterential assembly on V-blocks and install

both axles.

M€asure the backlash of both pinion gears.

Standard (New):0.05-O.15 mm (0.OO2-0.006 inl

3. It the bscklssh is not within the standard, reDlace

the differential carrier.

DIAL II{OICATOR

Differential (818B1 enginel

Backlash InspectionFinal Driven Gear Replacement

1.Remove the bolts in a crisscross Datt€rn in several

steps, and remove the final driven gear from the

differential carrier.

NOTE: The final driven gear bolts have left-hand

threads.

10 x 1.0 mm101 N.m llO.3 kgl.m, 74.5 lbf.ftlLelt-hand threads

FINAL DRIVEIII GEARChamfer on inside diameter otlinal driven gear taces carrier.

DIFFEREI{TIALCARBIER

Install the final driven gear by tightening the bolts

in a c.isscross pattern in several steps.

15-4

Page 572 of 1413

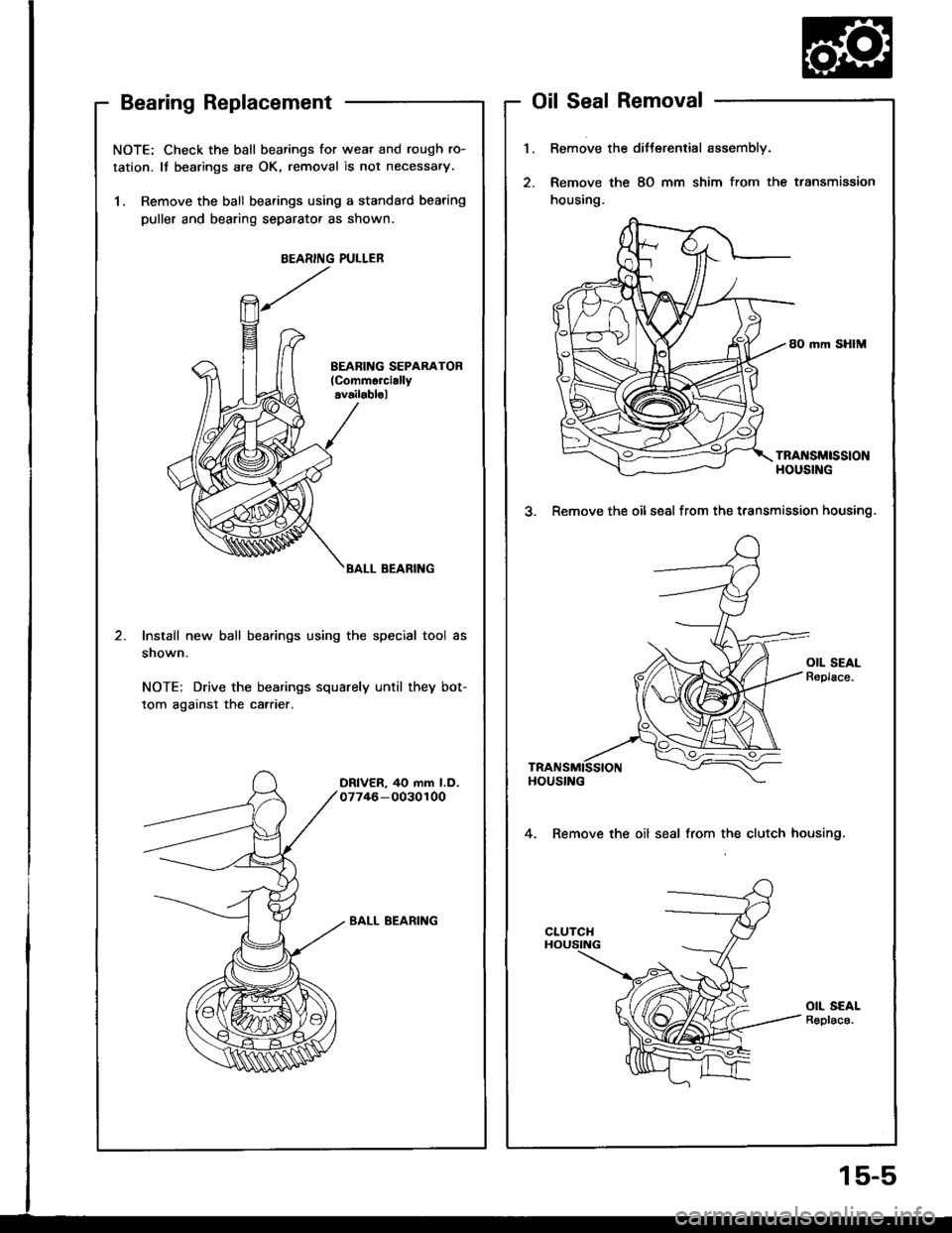

NOTE: Check the ball bearings for wear and rough ro-

tation. It bearings are OK, removal is not necessary.

1. Remove the ball bearings using a standatd bearing

puller and bearing separator as shown.

BEARING PULLEB

BALL BEARING

Install new ball bearings using the special tool as

snown.

NOTE: Drive the bearings squarely until they bot-

tom against the carrier.

DRIVER, 40 mm l.D.07746-0030100

BALL BEARING

Bearing ReplacementOil Seal Removal

1.Remove the ditterential assembly.

Remove the 8O mm shim from the transmission

housing.

80 mm SHIM

TRA[{SMtSStONHOUSING

3. Remove the oilseal from the t.ansmission housing.

4. Remove the oil seal from the clutch housing,

OIL SEALR€plac6.

15-5

Page 573 of 1413

Differential (81 881 engine)

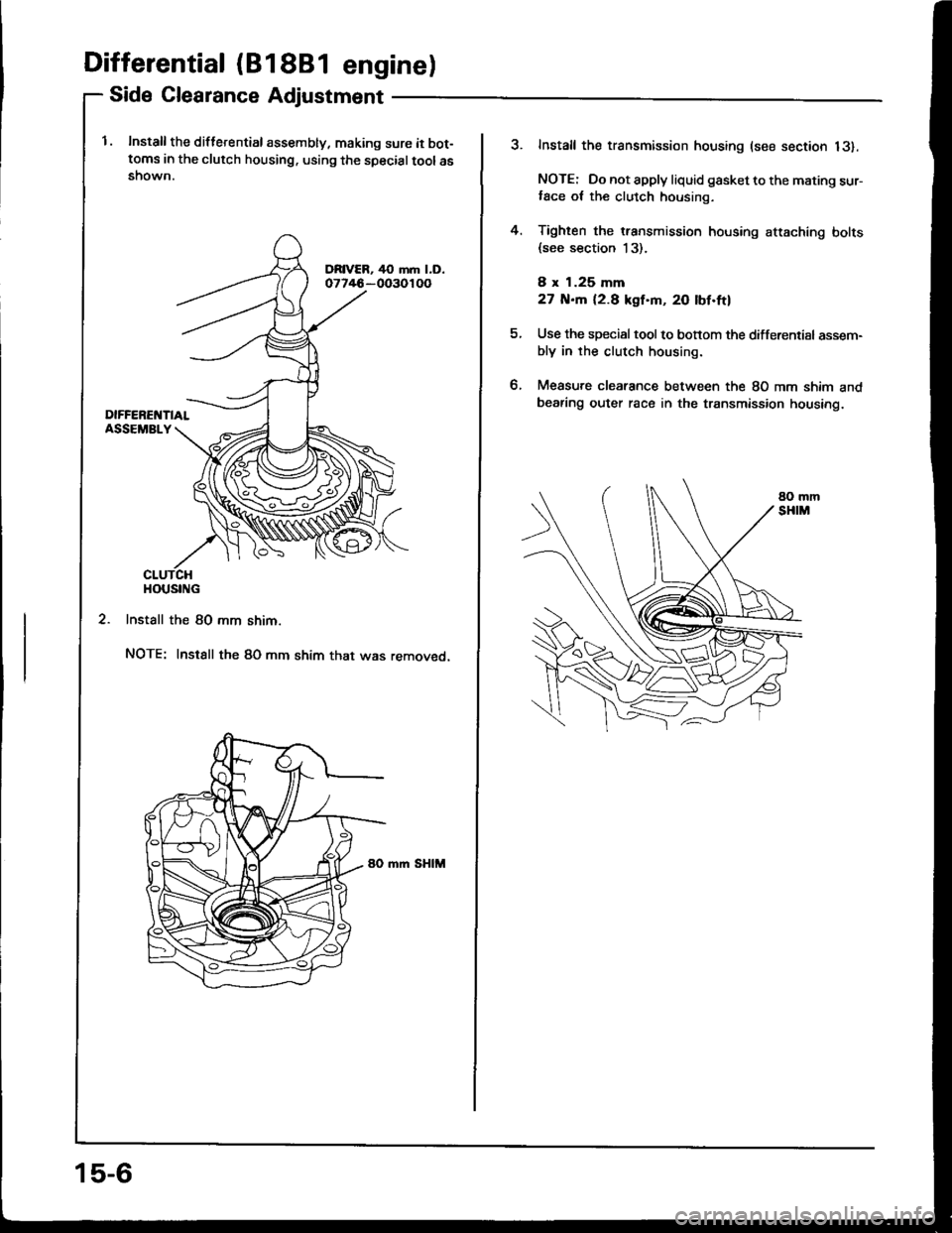

Side Clearance Adjustment

l. Install the diflerential assembly, making sure it bot-toms in the clutch housing. using the specialtoolasshown.

2. Install the 80 mm shim.

NOTE: Instsll the 80 mm shim that was removed.

mm SHIM

HOUSING

15-6

?Install the transmission housing (see section 13).

NOTE: Do not apply liquid gasket to the mating sur-,ace ot the clutch housing.

Tighten the transmission housing attaching bolts(see section 13).

8 x 1.25 mm

27 N.m 12.8 kgf'm, 20 lbf.ftl

Use the special tool to bonom the differential assem-bly in rhe clutch housing.

Measure clearance between the 80 mm shim andbearing outer race in the transmission housing.

4.

tt.

Page 574 of 1413

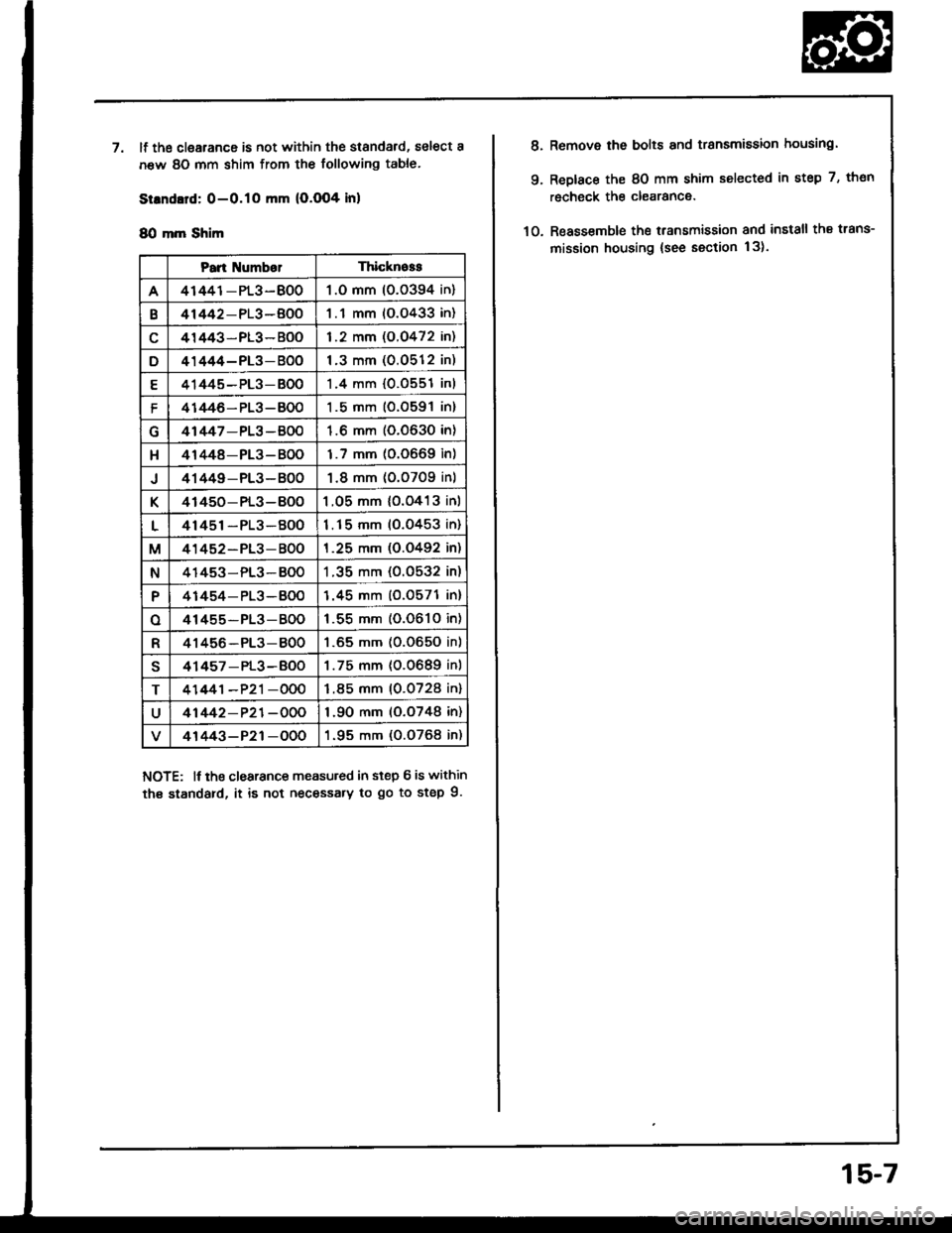

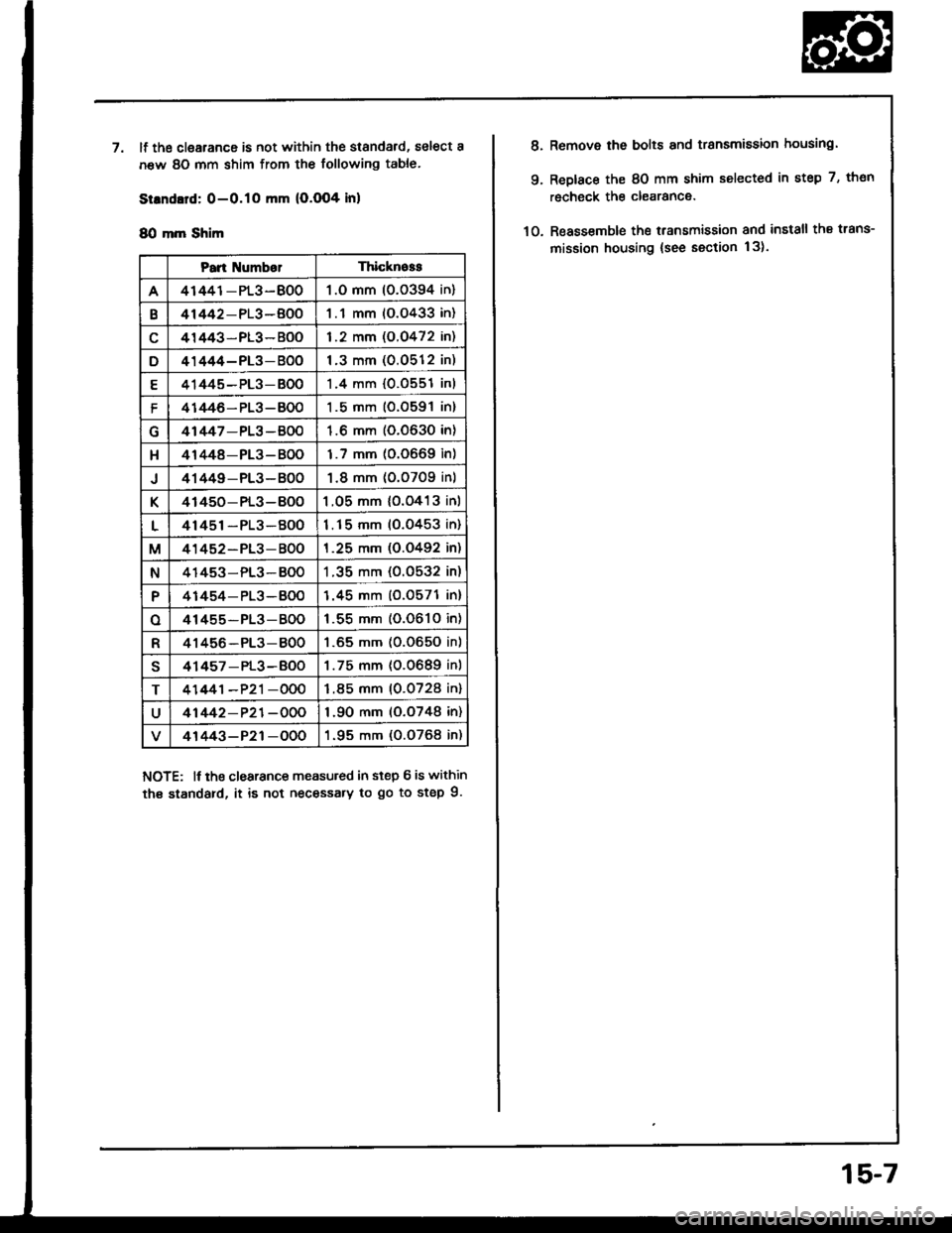

'llf the clearance is not within the standard, select a

new 80 mm shim from the following table.

Strndard: 0-O.1O mm (O.O04 inl

8O mm Shim

NOTE: lf tho clearance measuled in step 6 is within

th€ standard, it is not necessary to go to step 9.

Pan NumberThicknoss

A41441-PL3-BO01.O mm 10.0394 in)

B41442-PL3-BOO1.1 mm (O.O433 in)

41443-PL3- BOO1.2 mm (O.O472 in)

D41444-PL3-BOO1.3 mm (0.0512 in)

E41445-PL3-BO01.4 mm {0.0551 inl

f41446- PL3-BO01.5 mm (O.O591 in)

41447-PL3 -BOO1.6 mm (0.0630 in)

H41448-PL3- B001.7 mm (0.0669 in)

J41449-PL3- BO01.8 mm (0.0709 inl

K41450- PL3-BOO1.05 mm {o.o413 inl

L41451-PL3-BOO1.15 mm (0.0453 in)

M41452-PL3-BOO1.25 mm (O.O492 in)

N41453-PL3-BO01 .35 mm (0.0532 in)

P41454-PL3-BOO1.45 mm (0.0571 in)

o41455-PL3-BOO1 .55 mm (0.061O in)

R41456-PL3-8001.65 mm (0.O650 in)

s41457 - PL3-BOO1.75 mm (0.0689 in)

T41441-P21-OOO1.85 mm (0.0728 in)

U41442-P21-OOO1.90 mm (o.o748 in)

41443-P21-OOO1.95 mm (0.O768 in)

8.

9.

Remove the bolts and transmission housing.

Replace the 8O mm shim selected in step 7, thon

recheck the clearance.

Reassemble the transmission and install the trans-

mission housing {see section 13).10.

15-7

Page 575 of 1413

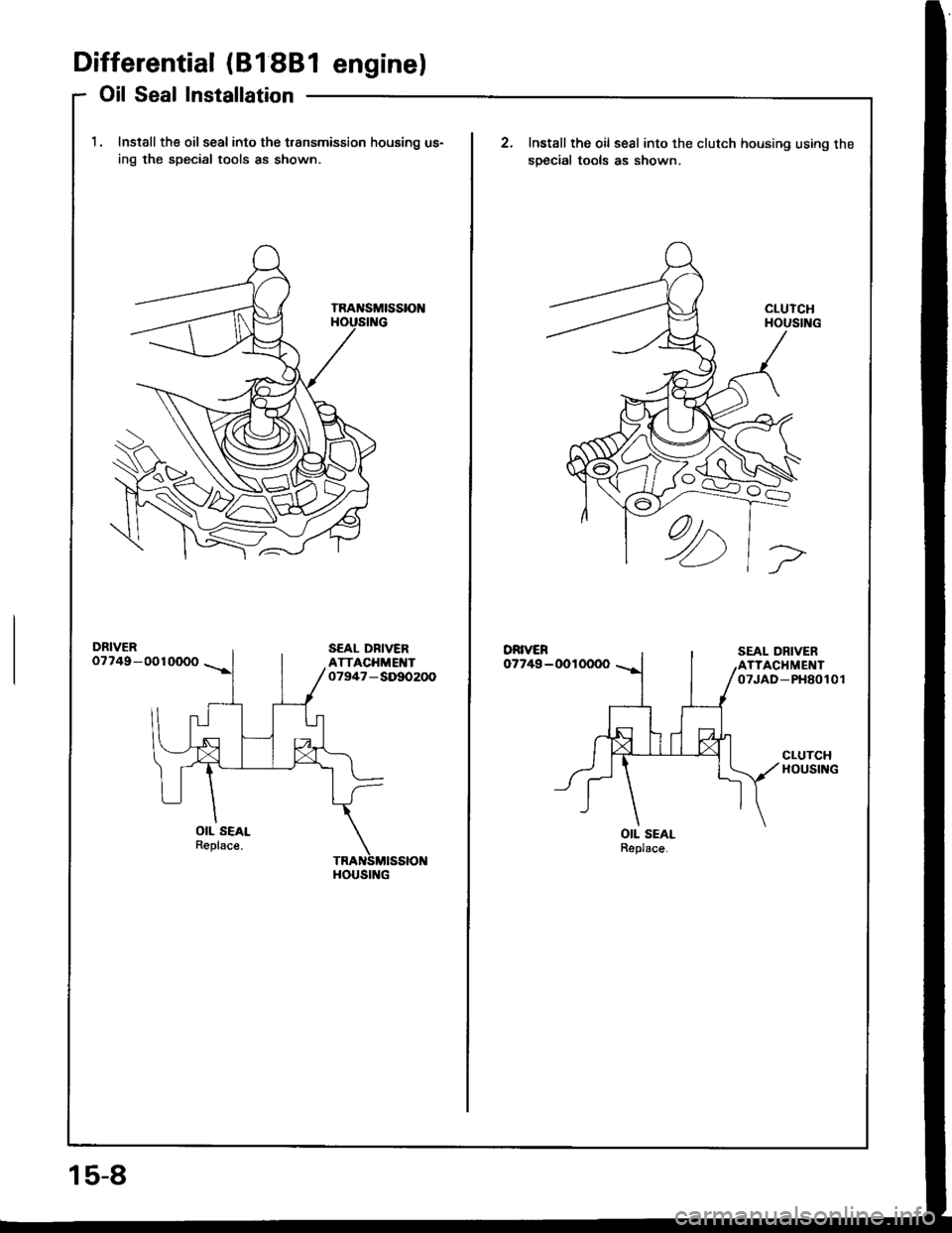

Differential (81 88l enginel

Oil Seal Installation

1. Install the oil seal into the t.ansmission housing us-

ing the special tools as shown

DRIVER07749-0010000

OIL SEALReplsce.

HOUSING

15-8

Install the oil seal into the clutch housing using the

soecial tools as shown.

DRIVER07749-0010000

OIL SEALReplace.

Page 576 of 1413

Differential (818C1 enginel

Special Tools ........

Differential

lllustrated Index .........

Backlash Inspection

Final Driven Gear Replacement ......

Tapered Roller Bearing Replacement.

Oil Seal Removal

Bearing Outer Race Replacement ...

Tapered Roller Bearing Preload

Adjustment

Oil Seal Installation

1 5-10

15-1 1

15-12

15-12

15-13

15-13

15-14

15-15

15-17

Page 577 of 1413

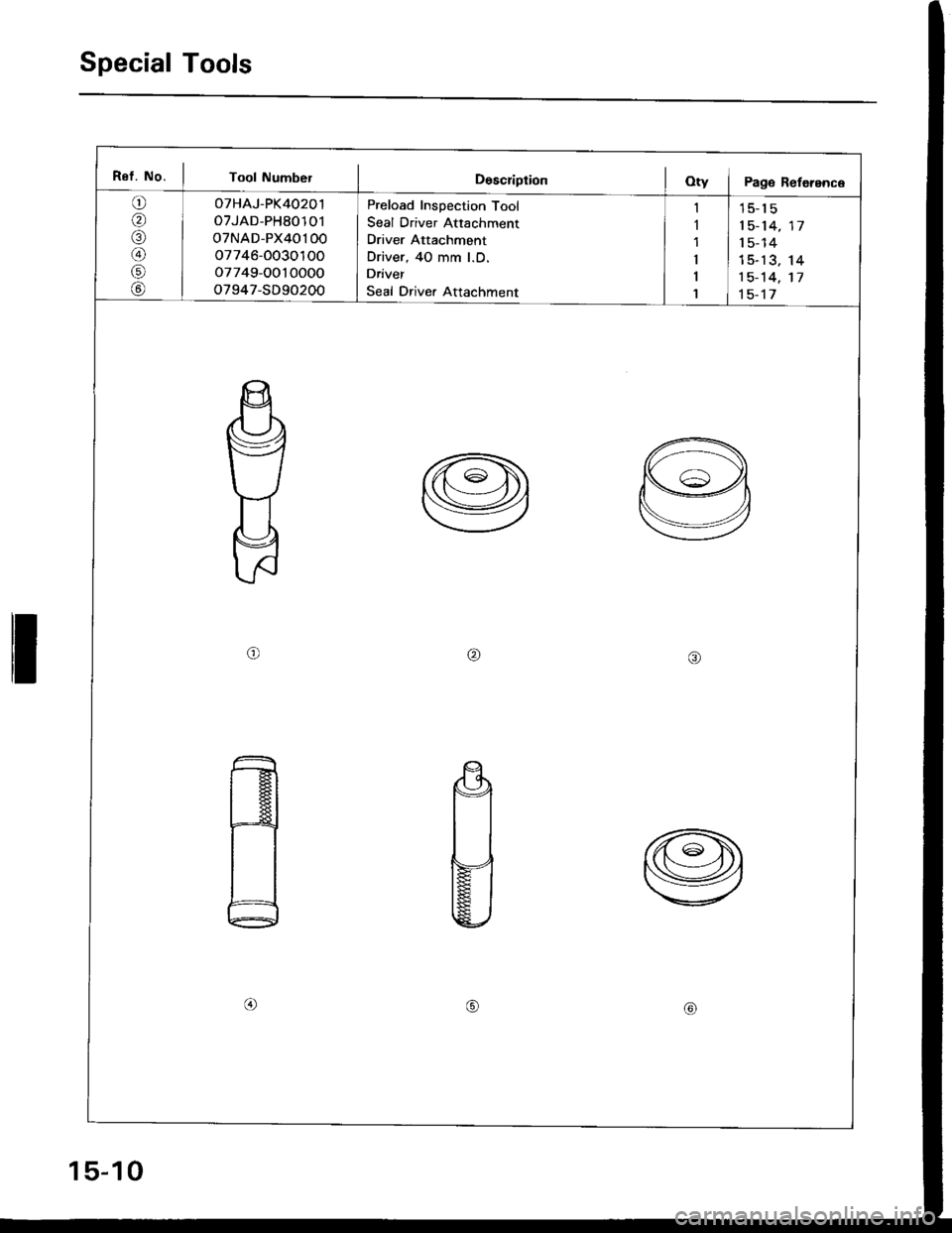

Special Tools

I

Ref. No. I Toot Number I DescriprionOty I Page Reference

o(

,a\

@

r.l

@

oTHAJ-PK40201

oTJAD-PH80101

oTNAD-PX40100

o7746-O030'l OO

o7749-OO10000

o7947-SD90200

Preload Inspection Tool

Seal Driver Attachment

Driver Attachment

Driver, 40 mm l.D.

Driver

Seal Drive. Attachment

I

I

1

15-1 5

1 5- 14

1 5- 14

15-13

1 5- 14

1 5-17

14

17

I

I

1

ort\aa\

@tl

$

s

15-10

Page 578 of 1413

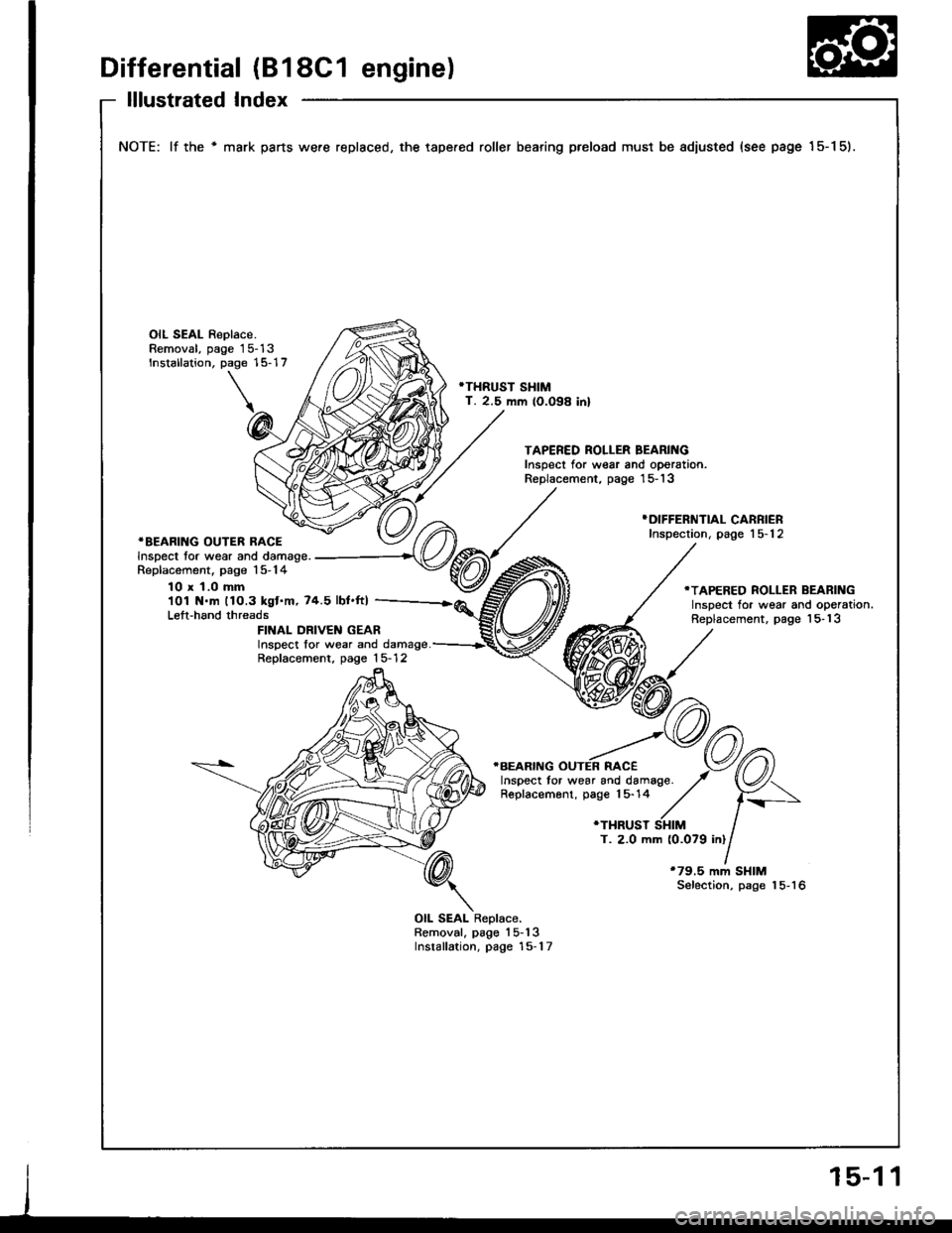

Differential (B18C1 engine)

lllustrated Index

NOTE: lf the ' mark parts were replaced, the tape.ed roller bearing preload must be adiusted (see page 15-1 5).

OIL SEAL Replace.Removal, page 15-13Installation, page 15-17

'THRUST SHIMT. 2.5 mm lO.O98 inl

TAPERED ROLLER BEARINGInspect for wear and oporation.Replacement, page '15- 13

*BEARING OUTER RACEInspect tor wear and damage.Replacement. page 15-14

}DIFFERNTIAL CARRIERInspection, page 15-12

10 x 1.0 mm101 N.m 11O.3 kgt.m,74.5 lbt.ft)Left-hand threads

.TAPERED ROLLER BEARINGInspect for wear and operation.Replacement, page 'l5- 13FINAL DRIVEN GEARInspect lor wear and damage.Replacement, page 15- 12

T. 2.0 mm (0.079 inl

*79.5 mm SHIMSelection, page 15-16

OIL SEAL Replace.Removal, page'l5-13Installation, page 15-1 7

Page 579 of 1413

Differential (818C1 enginel

Backlash Inspection

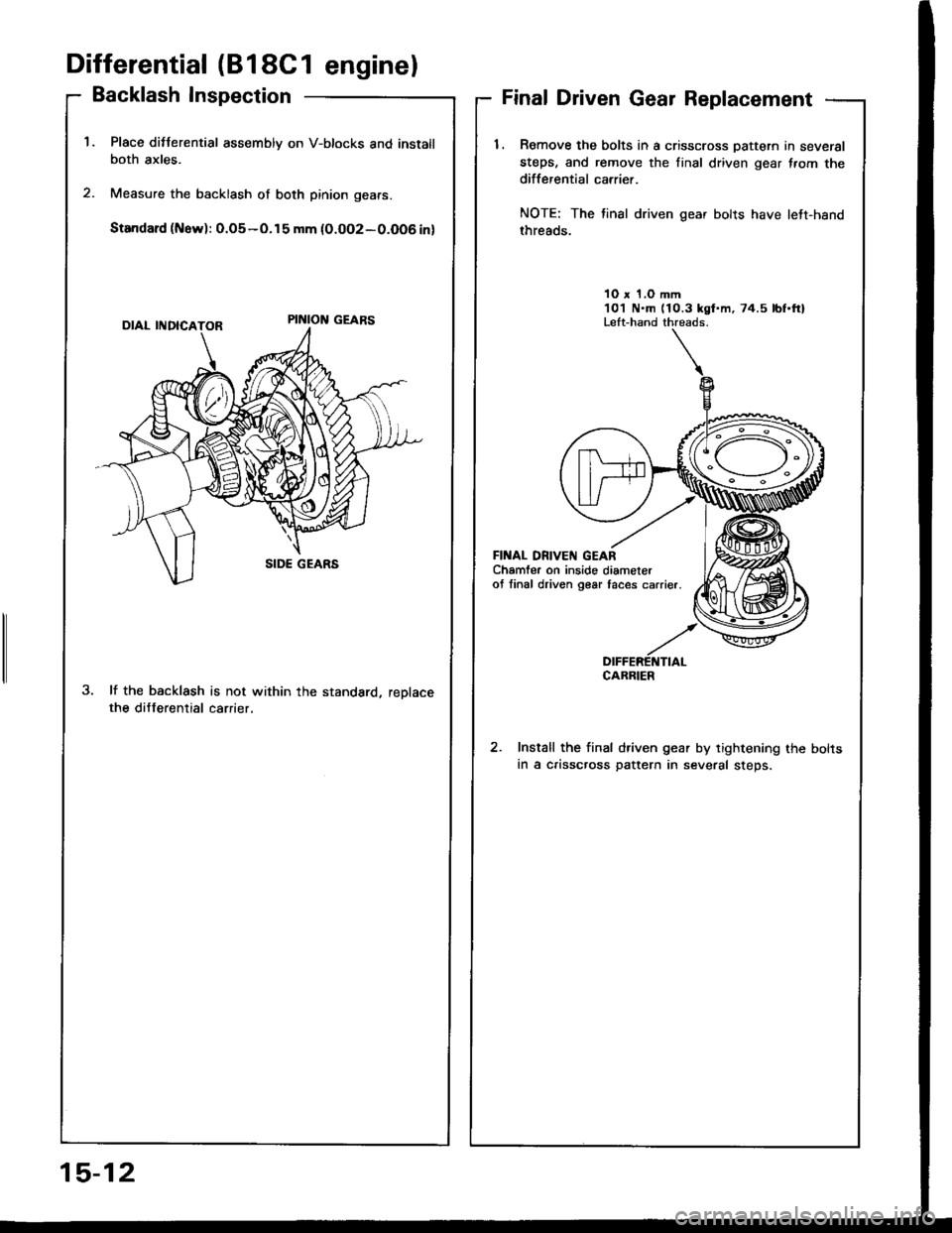

Place ditterential assembly on V-btocks and instatlboth axles.

Measure the backlash of both pinion gears.

Standard (Now): 0.o5-o.15 mm {0.oo2-0.O06 in)

lf the backlash is not within the standard, reDlacethe differential carrier,

Final Driven Gear Replacement

1. Romove the bolts in a crisscross Dattern in several

steps, and remove the tinal driven gear f.om thedifferential carrier.

NOTE: The tinal driven gear bolts have lett-hand

threads.

10 x 1.O mm101 N.m (10.3 kgt.m, 74.5 lbf.ftlLeft-hand threads.

FII{AL DN|VEN GEARChamfer on inside diameterof linal driven g€ar taces carrier.

DIFFERETTTIALCABRIER

Install the final driven gear by tightening the bolts

in a crisscross pattern in several steps.

15-12

Page 580 of 1413

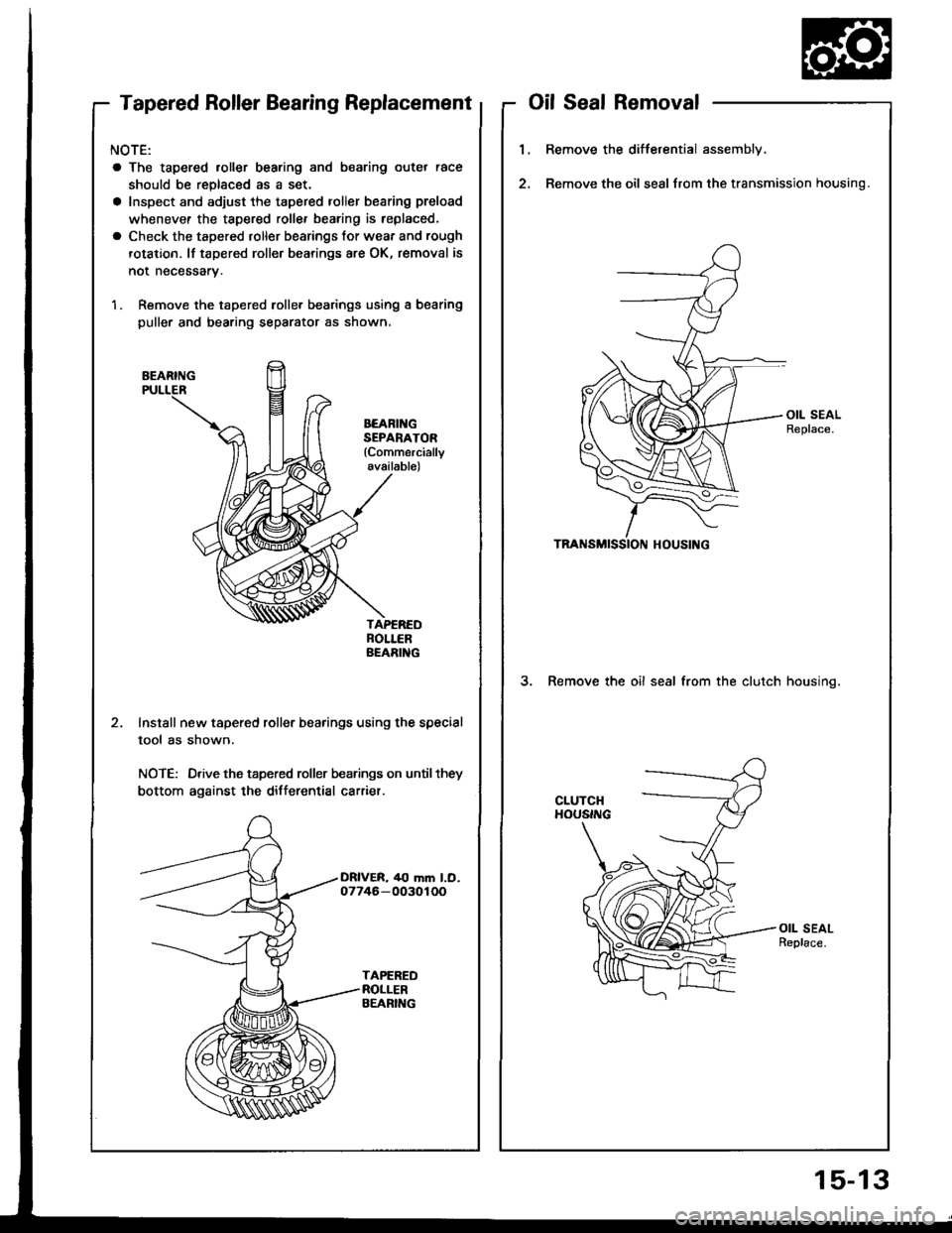

Tapered Roller Bearing Replacement

NOTE:

a The tapered roller bearing and bearing outer race

should be replaced as a set.

a Inspect and adjust the tapered roller bearing preload

whenevef the tapered rollef bearing is replaced.

a Check the tapered roller bearings tor wear and rough

rotation. lf tapered roller bearings are OK, removal is

not necessary.

1. Remove the tapered rolle. bearings using a bearing

puller and bearing separator as shown,

BEARING

BEARII{GSEPANATOR(Commercially

available)

Install new tapered roller bearings using the special

tool as shown.

NOTE: Drive the tapered roller bearings on until they

bottom against the differential carrier.

oilSealRemoval

1.Remove the differential assembly.

Remove the oil seal from the transmission housing.

3. Remove the oil seal from the clutch housino.

15-13

Trending: Dashboard wire harness, service, Remove trans, check engine, Steering wheel, oil level, Hood removal