HONDA INTEGRA 1998 4.G Workshop Manual

Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 1131 of 1681

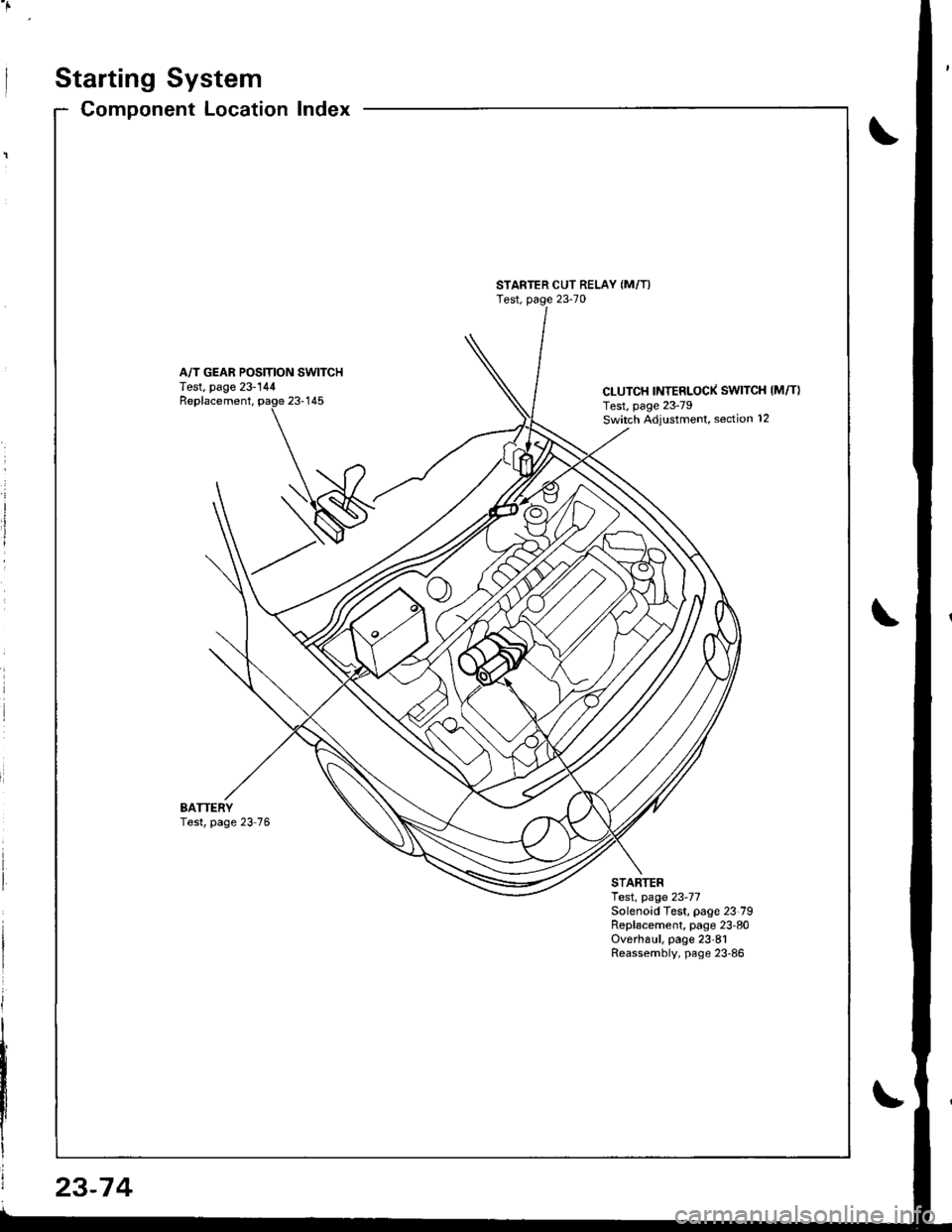

Starting System

Component LocationIndex

STARTER CUT RELAY (M/T)

Test, page 23-70

A/T GEAR POSITION SWITCHTest, page 23-144CLUTCH INTERLOCK SWITCH IM/T}Test, page 23-79Switch ,Adiustment, section 12

Replacement,

BATTERYTest, page 23 76

STARTERlest, page 23-77Solenoid Test, page 23 79Replacement, page 23'80Overha!1, page 23'81Reassembly, page 23'86

23-74

Page 1132 of 1681

![HONDA INTEGRA 1998 4.G Workshop Manual Circuit Diagram (M/Tl

tJ

STARTEBCUT RELAY

)/

ll-G2o1G401

rAa rtFz5- r3

) -rr

CLUTCHINTERLOCKSW]TCH

IGNITIONX SWITCH

!_*",.^-*-G-l

"T"

BTKWHT BLKWHT

llr - tr |

BLKFED 8LU/BLK

- BLK,BE I__-lrror.oo*

I HONDA INTEGRA 1998 4.G Workshop Manual Circuit Diagram (M/Tl

tJ

STARTEBCUT RELAY

)/

ll-G2o1G401

rAa rtFz5- r3

) -rr

CLUTCHINTERLOCKSW]TCH

IGNITIONX SWITCH

!_*",.^-*-G-l

"T"

BTKWHT BLKWHT

llr - tr |

BLKFED 8LU/BLK

- BLK,BE I__-lrror.oo*

I](/img/13/6069/w960_6069-1131.png)

Circuit Diagram (M/Tl

tJ

STARTEBCUT RELAY

)/

ll-G2o1G401

rAa rtFz5- r3

) -rr

CLUTCHINTERLOCKSW]TCH

IGNITIONX SWITCH

!_*",.^-*-G-l

"T"

BTKWHT BLKWHT

llr - tr |

BLKFED 8LU/BLK

- BLK,BE' I__-lrror.oo*

I I

+Yffii'"'Tf'o' | |

u"T-l

i,t^il'r** | |

=-T--. I

twt t

l$*Tl r

IA II

BLK

tY--lt I-|ffim-

|

rl

UNDEB HOOD FUSE/BELAY BOX

No 41 (100A) N0.42 (404)

Page 1133 of 1681

Starting System

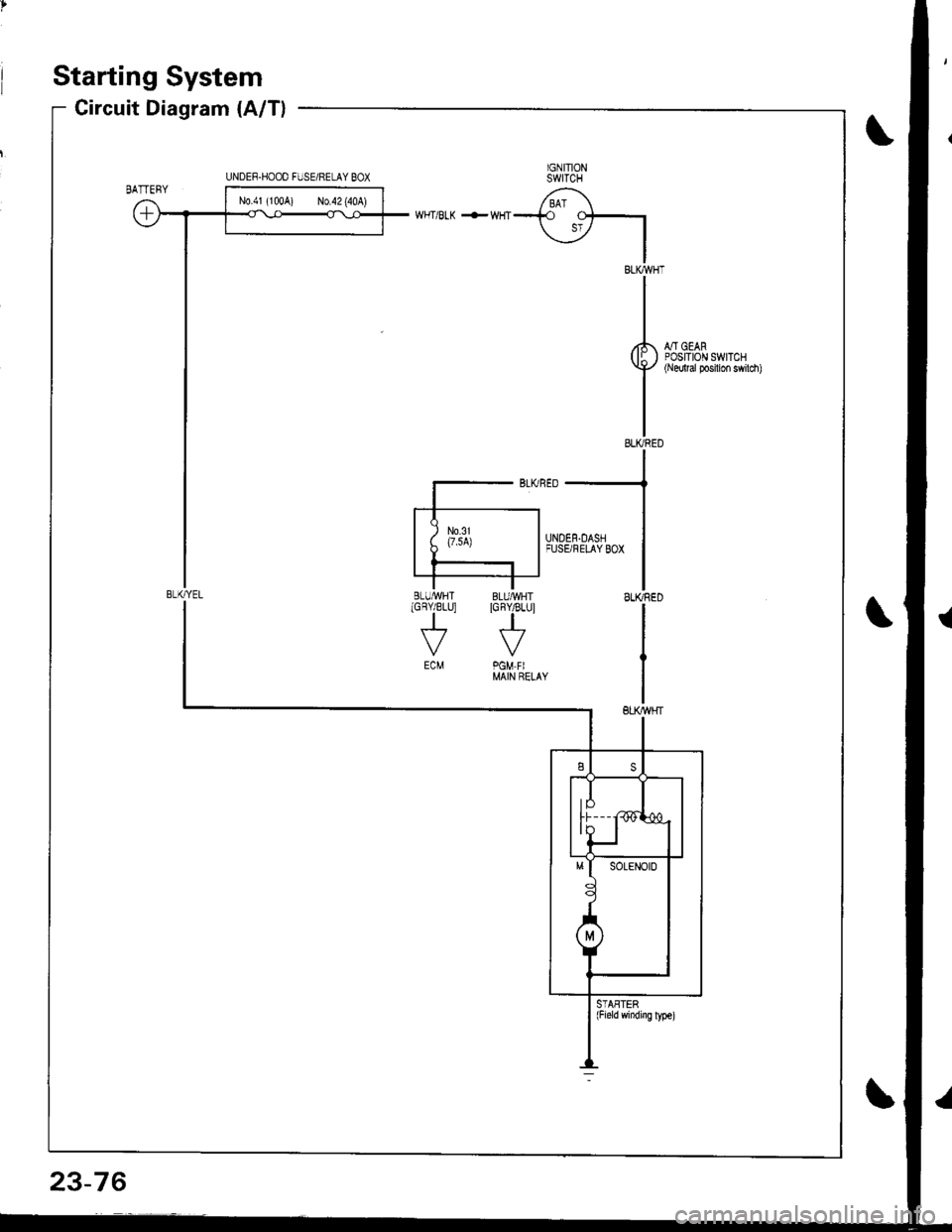

Circuit Diagram (A/T)

IGNITIONSWITCH

/ BAT \--i.o

\jz IIBLKWHT

II

I

rl., - oro,( lI ) POStlOr\l swrTcHY+'/ {Nedtal Posilion swilch)

II

IELIVRED

WHT/BLK +WHT

::--JFUSBFELAYBox

ISLIffiED

I

IGBY/BLU]

J

ECM

STASTER(Field windiig ly!€)

UNDEF.HOOO FIJSE/RELAY BOX

BLI(YEL

N0.41 (100A) No.42 (40A)

23-76

Page 1134 of 1681

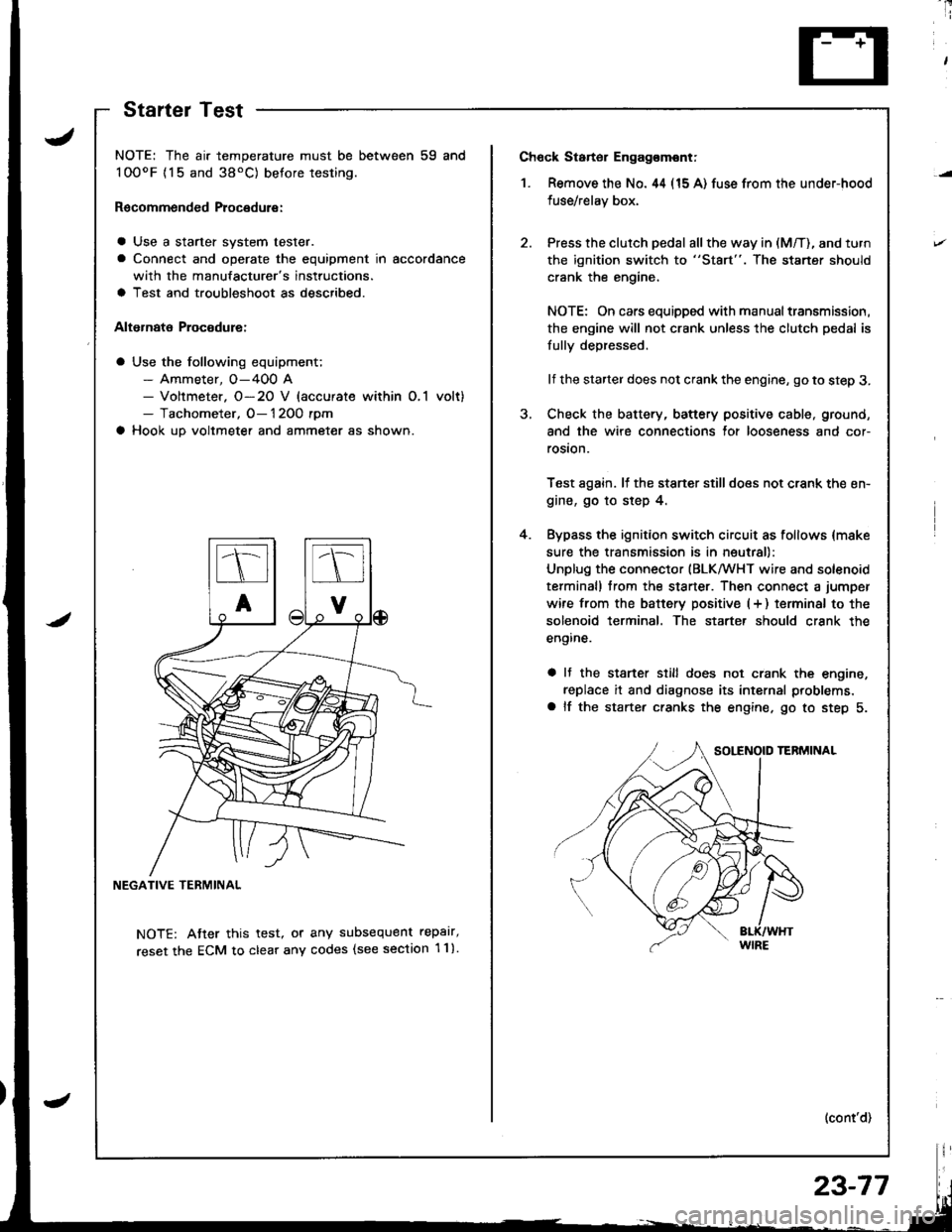

Ch6ck Starter Engag€mont;

1. Remove the No. 44 (15 A) fuse from the under-hood

fuse/relay box,

Press the clutch pedal all the way in (M/T), and turn

the ignition switch to "St8rt". The staner should

crank the engine,

NOTE: On cars equipped with manual transmission,

the engine will not crank unless the clutch pedal is

fully depressed.

lf the starter does not crank the engine, go to step 3.

Check the battery, battery positive cable, ground,

and the wire connections for looseness and cor-

rosion.

Test again. lf the stsner stilldoes not crank the en-

gine, go to step 4.

Bypass the ignition switch circuit as follows {make

sure the transmission is in neutral)

Unplug the connector (BLKMHT wire and solenoid

terminal) trom the staner. Then connect a jumper

wire from the batterv positive (+ ) terminal to the

solenoid terminal. The starter should crank the

engine.

a It the stsrter still does not crank the engine,

replace it and diagnose its internal problems,

a lf the starter cranks the engine. go to step 5.

(cont'd)

4.

NOTE: The air temperature must be between 59 and

100oF {15 and 38'C) betore testing.

Recommended Procedure:

a Use a starter system tester.

a Connect and operate the equipment in accordance

with the manufacturer's instructions.

a Test and troubleshoot as described.

Alternate Procodure:

a Use the following equipment;- Ammeter, O-400 A- Voltmeter. O-20 V (accurate within O,1 volt)- Tachometer, O- 1 2OO rpm

a Hook up voltmeter and ammeter as shown.

NEGATIVE TERMINAL

NOTE: Atter this test, or any subsequent repalr,

reset the ECM to clear any codes (see section 1 1).

StartelTest

23-77

Page 1135 of 1681

Starting System

Starter Test (cont'dl

Check Cranking rpmr

Engine speed during cranking should be above 1OO rpm.

lJ speed is too low, check for:

a Loose batlery or starter terminals

a Excessively worn starter brushes

a Open circuit in commutator segments

a Dirty or damaged helical spline or drive gear

a Defective drive gear overrunning clutch

Check Starter Disengagement:

Press the clutch pedal all the way in (M/T), turn rhe igni

tion switch to "lll" and release to "11".

The starter drive gear should disengage from the flywheel

or torque converter ring gear when you release the key.

It the drive gear hangs up on the flywheel or torque con-

verter ring gear, check for:

a Solenoid plunger and switch mallunction

a Dirty drive gear assembly or damaged overrunning

clutch

5. Check for an open in the BLK/WHT wire circuit be

tween the starter and ignition switch, and con-

necrors,

6. Check the ignition switch (see page 23-71).

7. On cars with automatic transmission, check the A/Tgear position switch (neutral position switch) and

connector. On cars with manualtransmission, check

the starter cut relay, clutch interlock switch, and

connectors.

NOTE: Check the No. 42 (40 A) fuse in the under,hoodfuse/relay box for the starter cut relay.

Check Jor Wear and Damage:

The starter should crank the engine smoothly and stead,ily. lf the starter engages, but cranks the engine errati

cally, remove it. Inspect the starter, drive gear, andllywheel or torque converter ring gear lor damage.

a Check the drive gear overrunning clutch for binding

or slipping when the armature is rotated with the drivegear held. Replace the gears i{ damaged.

Check CJanking Voltage and Current Draw:

Cranking voltage should be no less than 8.O volts.

Current draw should be no more than * amperes.* 1.2 kW: 27O A

1 .4 kW: 360 A

It cranking voltage is too low, or current draw too high,check for:

a Dead or low charged batterya Open circuit in starter armature commutator segmentsa Starter armalure dragging

a Shorted armature windinga Excessive drag in engine

Page 1136 of 1681

![HONDA INTEGRA 1998 4.G Workshop Manual 1.Remove the dashboard lower cover and knee bolster(see page 23-71],, then disconnect the 2P connector

from the switch.

Check for continuity between the terminals accord-

ing to the table.

2.

3.ll nec HONDA INTEGRA 1998 4.G Workshop Manual 1.Remove the dashboard lower cover and knee bolster(see page 23-71],, then disconnect the 2P connector

from the switch.

Check for continuity between the terminals accord-

ing to the table.

2.

3.ll nec](/img/13/6069/w960_6069-1135.png)

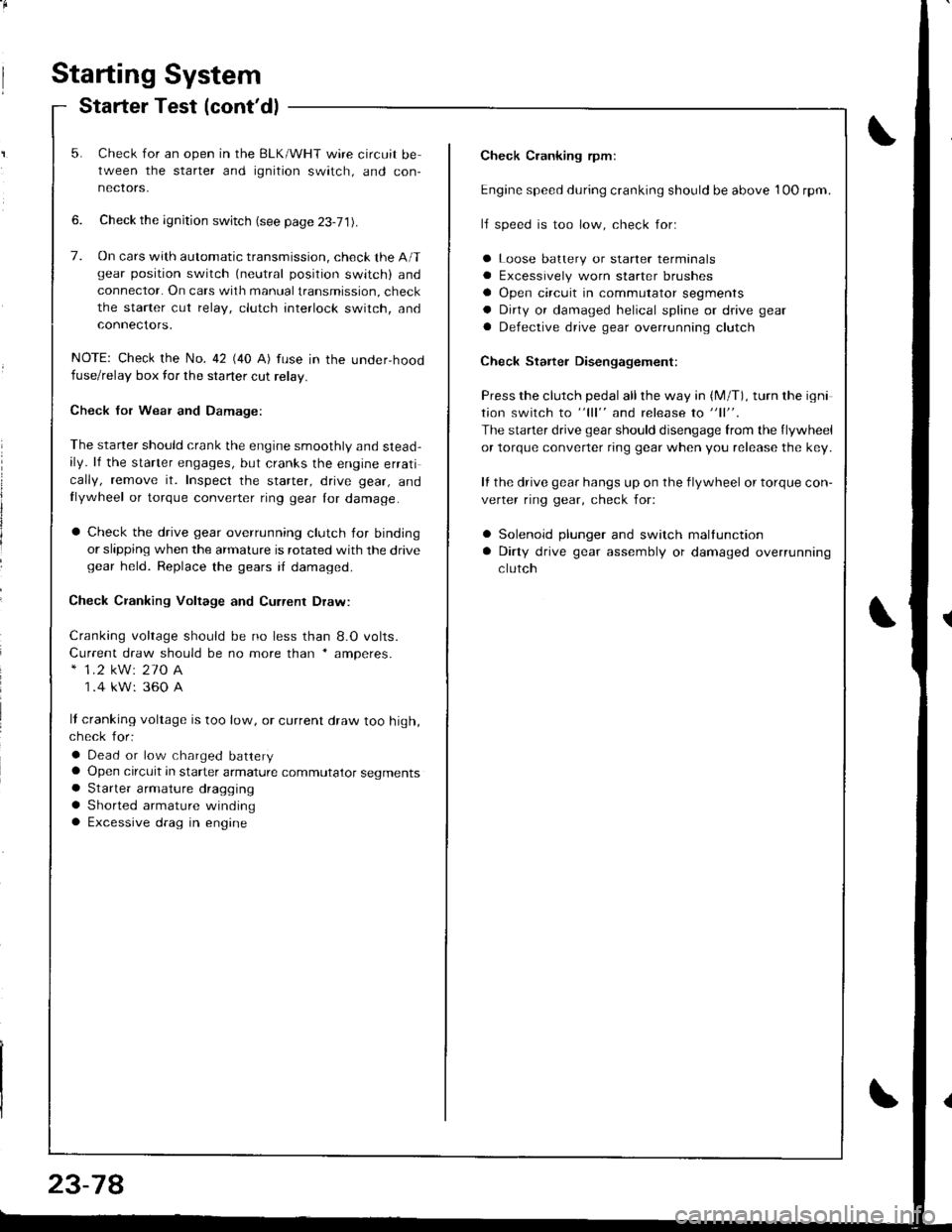

1.Remove the dashboard lower cover and knee bolster(see page 23-71],, then disconnect the 2P connector

from the switch.

Check for continuity between the terminals accord-

ing to the table.

2.

3.ll necessary, replace the switch or adiustthe switch

position (see section 12).

Terminal

cr,t"hP;i

-_\B

RELEASED

PUSHEDoo

Clutch lnterlock Switch TestStarter Solenoid Test

1. Check for continuity between the terminals accord-

ing to the table.

HOLD_ IN COIL

23-79

I

/

-

I

-a

Coil

Teminalt\4sHousing

HOLD INO-o

PULL-INo-o

PULL_ IN COIL

Page 1137 of 1681

Starting System

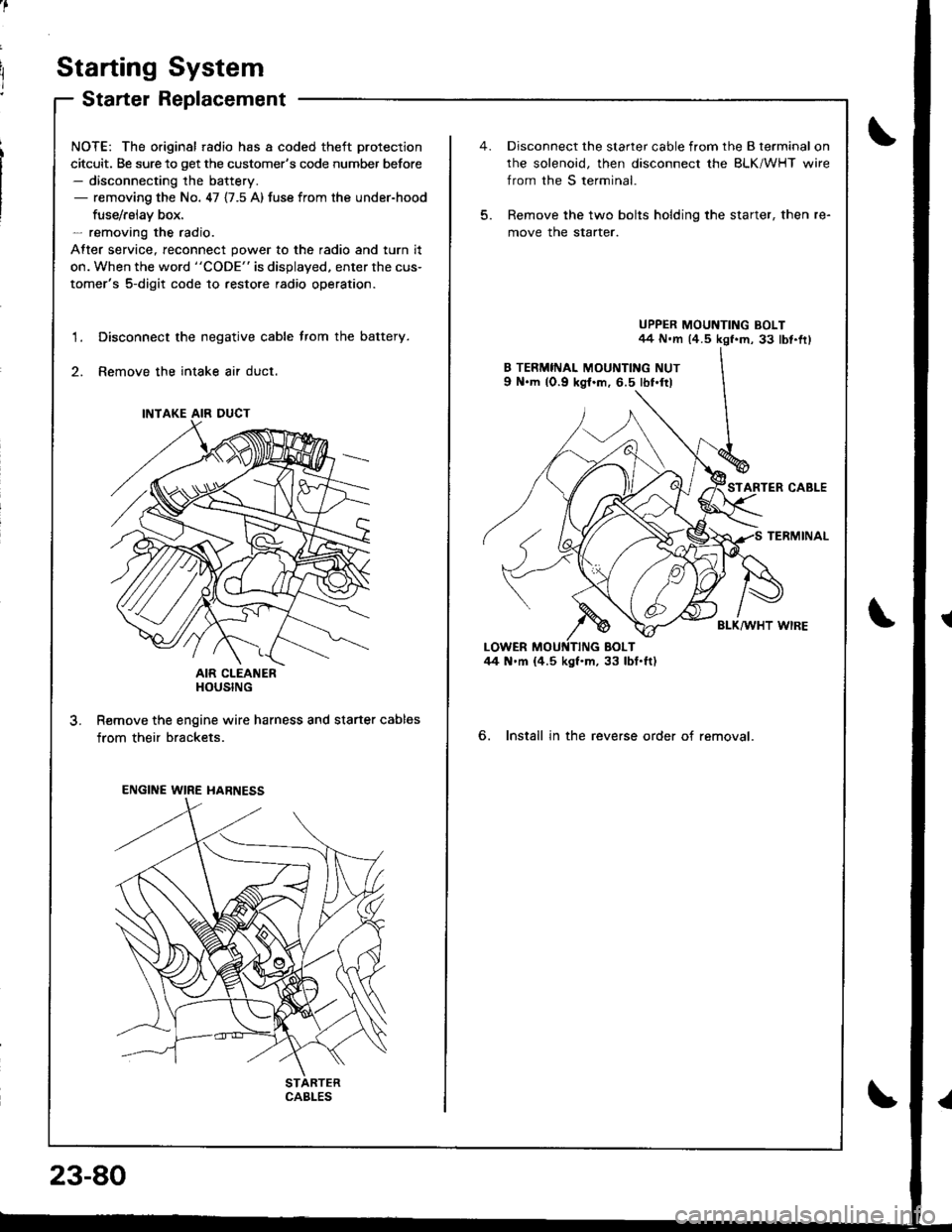

Starter Replacement

NOTE: The original radio has a coded theft protection

citcuit. Be sure to get the customer's code number before- disconnecting the battery.- removing the No. 47 {7.5 A) fuse from the under-hood

fuse/rslav box.- removing the radio.

After service, reconnect power to the radio and turn it

on. When the word "CODE" is displayed. enter the cus-

tomer's 5-digit code to restore radio operation.

Disconnect the negative cable trom the battery.

Remove the intake air duct.

AIR CLEANERHOUSING

R€move the engine wire harness and starter cables

from their brackets.

1.

3.

INTAKE AIR DUCT

ENGINE WIRE HARNESS

CABLES

23-80

5.

Disconnect the starter cable from the B terminal on

rhe solenoid, then disconnect the BLK/WHT wire

from the S terminal.

Remove the two bolts holding the starter, then re-

move the starter.

UPPER MOUNTING BOLT44 N.m (4.5 kgf.m, 33 lbt.fr)

STARTER CABLE

TERMINAL

BLK/WHT WIRE

6. Install in the reverse order of removal.

Page 1138 of 1681

I

,.

u

J

/

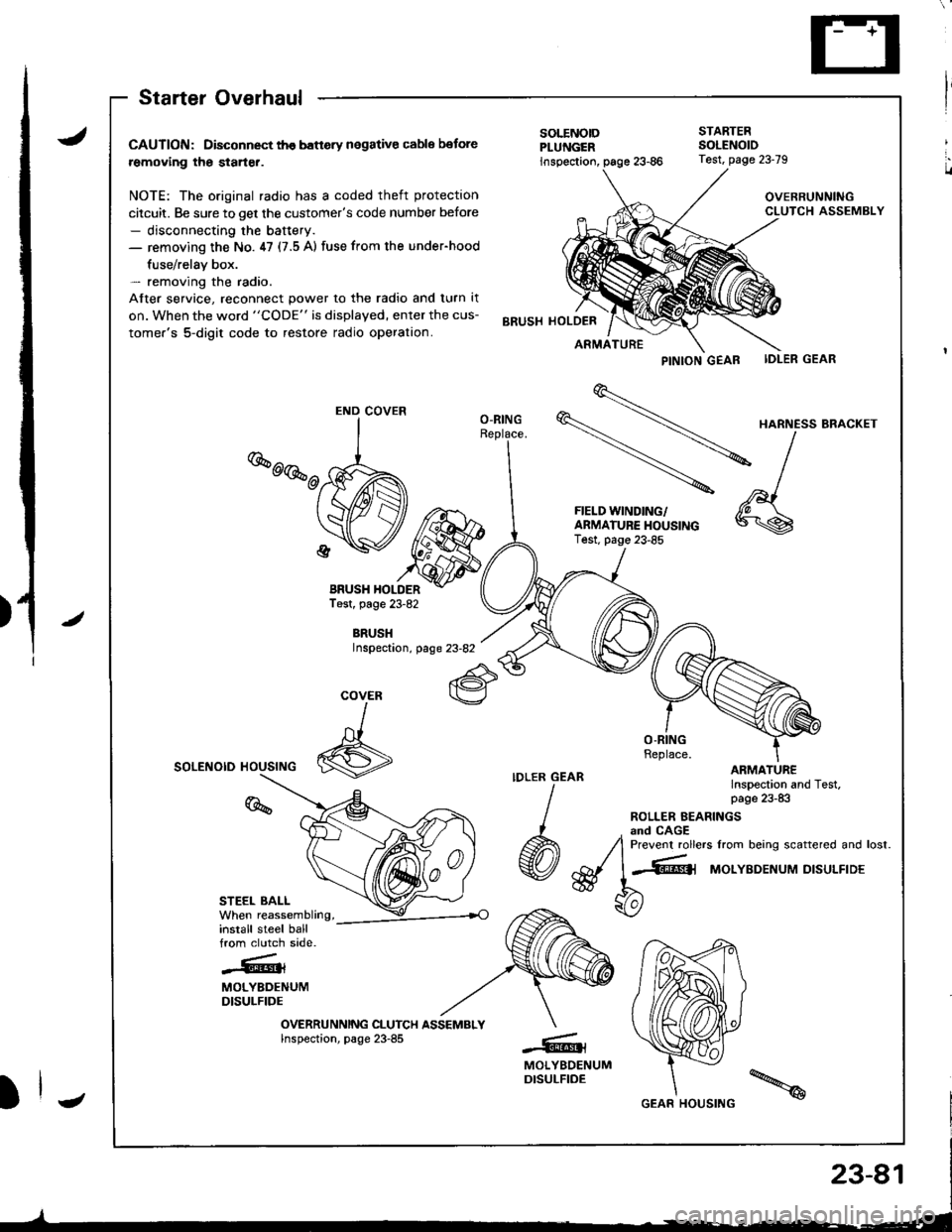

Starter Overhaul

CAUTION: Disconnect th€ banery negative cable botore

removing the starter.

NOTE: The original radio has a coded theft protection

citcuit. Be sure to get the customer's code number before- disconnecting the baftery.- removing the No. ,17 (7.5 A) fuse from the under-hood

fuse/relav box.- removing the radio.

After service, reconnect power to the radio and turn it

on. When the word "CODE" is displayed, enter the cus-

tomer's 5-digit code to restore radio operation.

BRUSH HOLDERTest, page 23-82

BRUSHInspectaon, page 23-82

SOLENOID HOUSING

STEEL BALL

install steel ballfrom clutch side.

-.''.!k.��rt{l{

MOLYBDENUMDISULFIDE

OVERRUNNING CLUTCH ASSEMBLYInspection, page 23-85

PINTON GEAB IDLER GEAR

\

HARNE'SBRA.KET

-\l

-

^,1FIELD WINDING/ 'A \

f:$i:y5J*"""

*\s

SOLENOIDPLUNGER

STARTEBSOLENOID

inspection,

BRUSH HOLDER

Test, page 23-79

OVERRUNNINGCLUTCH ASSEMBLY

ARMATURE

O-RING

COVER

I

6

%

-@t

MOLYBDENUMDISULFIDE

END COVER

GEAR HOUSING

Page 1139 of 1681

Staning System

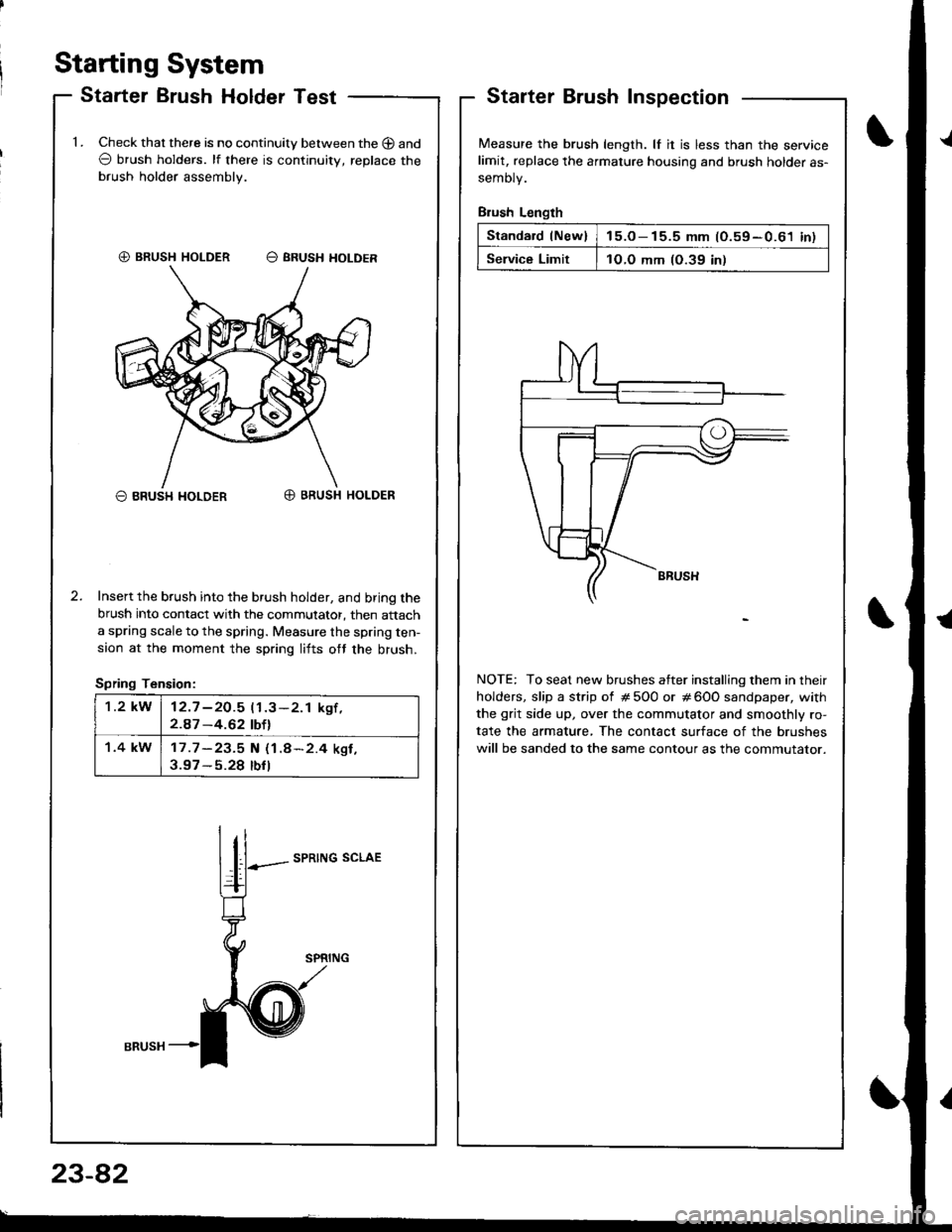

Starter Brush Holder TestStarterInspection

Measure the brush length. lf it is less than the servicelimit, replace the armature housing and brush holder as-

semoty.

Brush Length

Standard lNew)15.o- 15.5 mm (O.59-0.61 inl

Service Limit1O.O mm (O.39 in)

NOTE: To seat new brushes atter installing them in their

holders, slip a strip of # 5O0 or # 600 sandpaper, with

the grit side up, over the commutator and smoothly ro-

tate the armature, The contact surface of the brushes

will be sanded to the same contour as the commutator.

1.Check that there is no continuity between the O and

O brush holders. lf there is continuitv, replace the

brush holder assembly.

O BRUSH I{OLDERO BRUSH HOLDER

Insert the brush into the brush holder, and bring the

brush into contact with the commutator, then attach

a spring scale to the spring. Measure the spring ten-

saon at the moment the spring lifts ott the brush.

Spring Tension:

SPRING SCLAE

€) BRUSH HOLDER O SRUSH HOLDER

1.2 kW12.7 -2O.5 11.3-2.1 kgf ,2.A7 -4.62 tbtl

1.4 kW17 .7 -23.5 N (1.8*2.4 ksf ,3.97 - 5.28 tbfl

I

23-82

Page 1140 of 1681

J

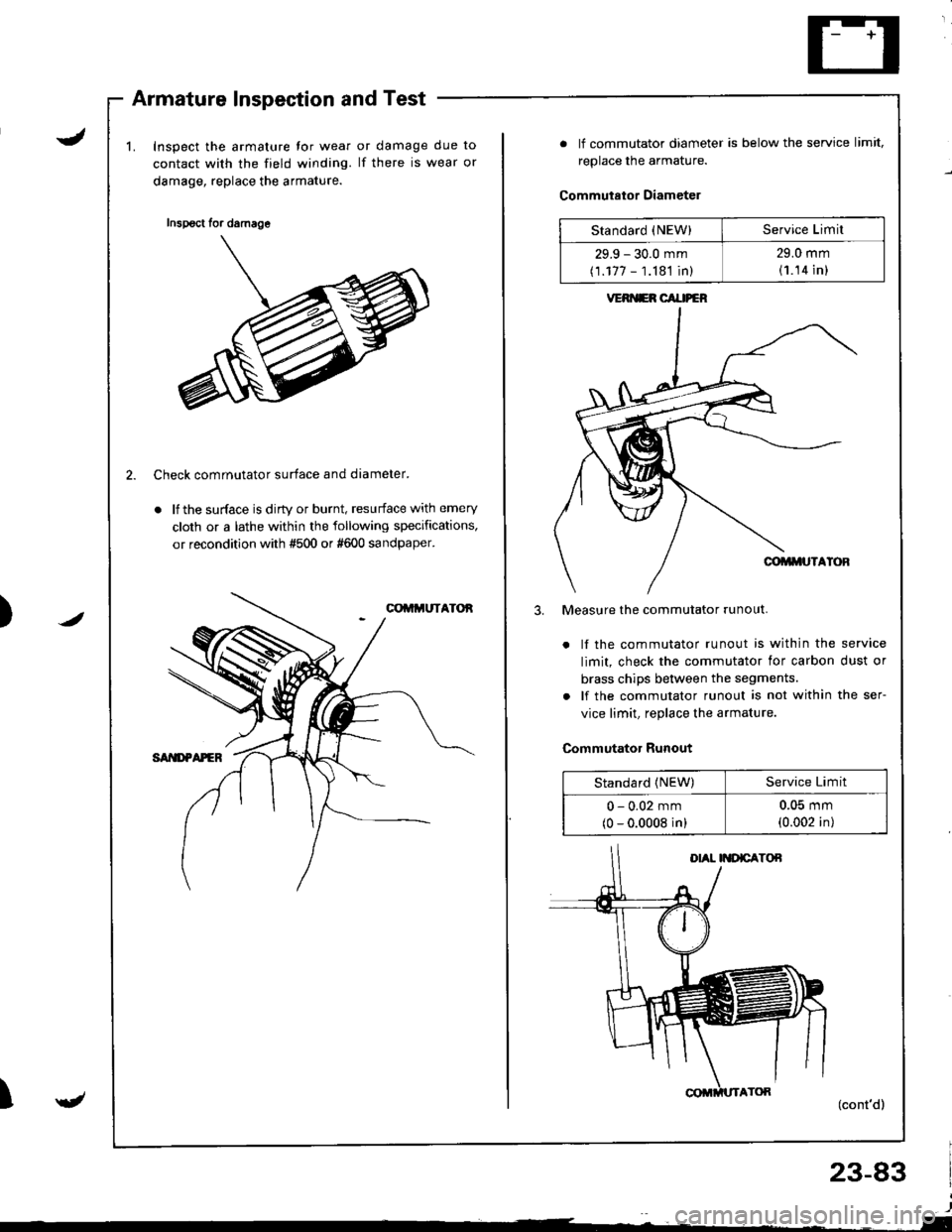

Armature Inspection and Test

Inspect the armature tor wear

contact with the field winding.

damage, replace the armature.

or damage due to

lf there is wear or

/)

2. Check comrnutator surface and diameter.

. lf the surface is dirty or burnt, resurface with emery

cloth or a lathe within the following specifications,

or recondition with #500 or #600 sandpaper.

gt

Inspsct for damage

. lf commutator diameter is below the service limit,

replace the armature.

Commutator Diameter

Measure the commutator runout.

. lf the commutator runout is within the service

limit, check the commutator lor carbon dust or

brass chips between the segments.

. lf the commutator runout is not within the ser-

vice limit, replace the armature.

Commutator Runout

(cont'd)

23-83

Standard (NEW)Service Limil

29.9 - 30.0 mm

(1.177 - 1.181 in)

29.0 mm

(1.14 in l

VERI{ER CAI|PEN

Standard (NEW)Service Limit

0 - 0.02 mm

(0 - 0.0008 in)

u-(J5 mm

(0.002 in)